Patents

Literature

46results about How to "Improve natural circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

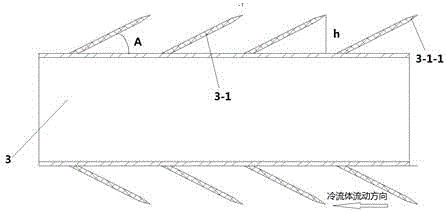

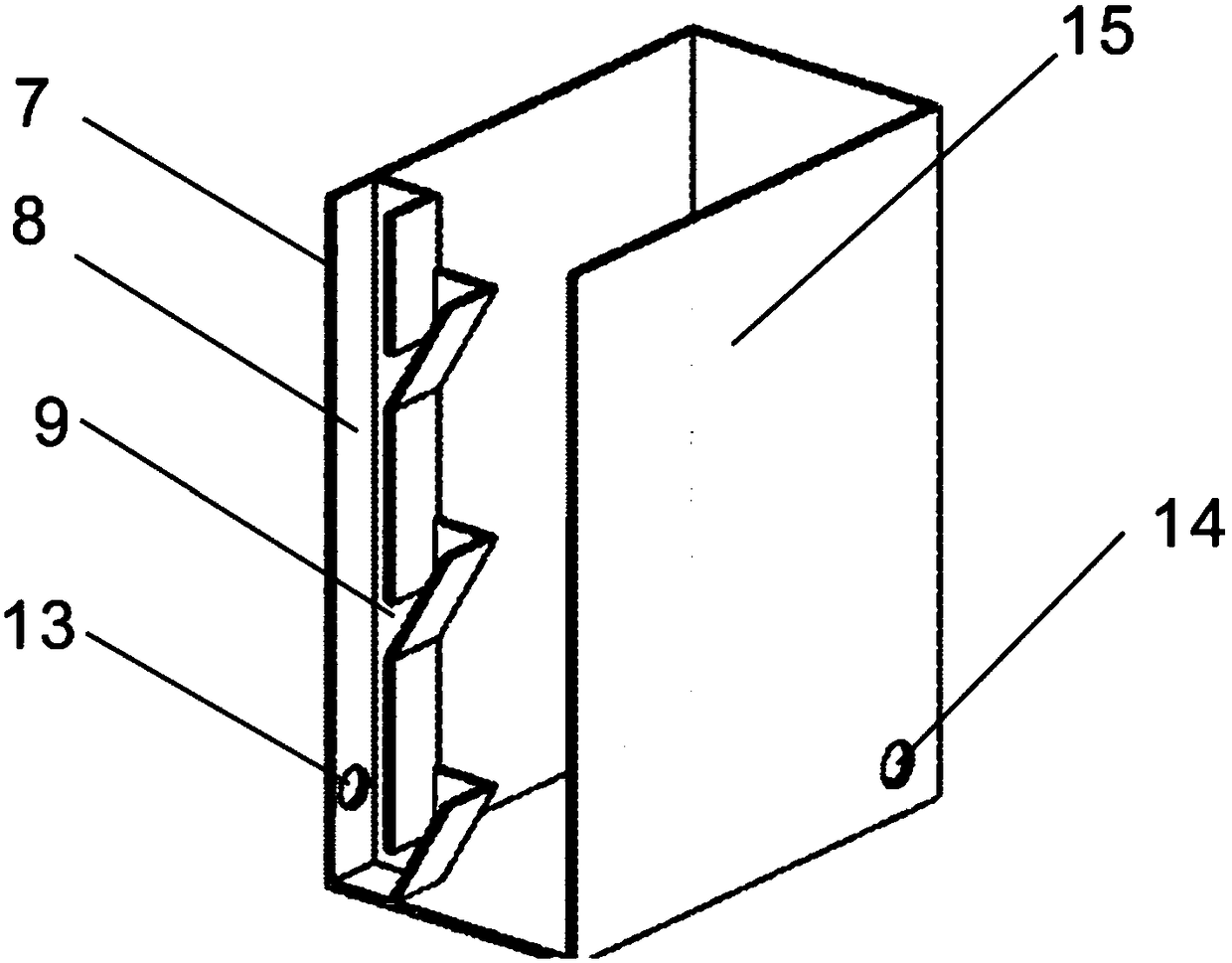

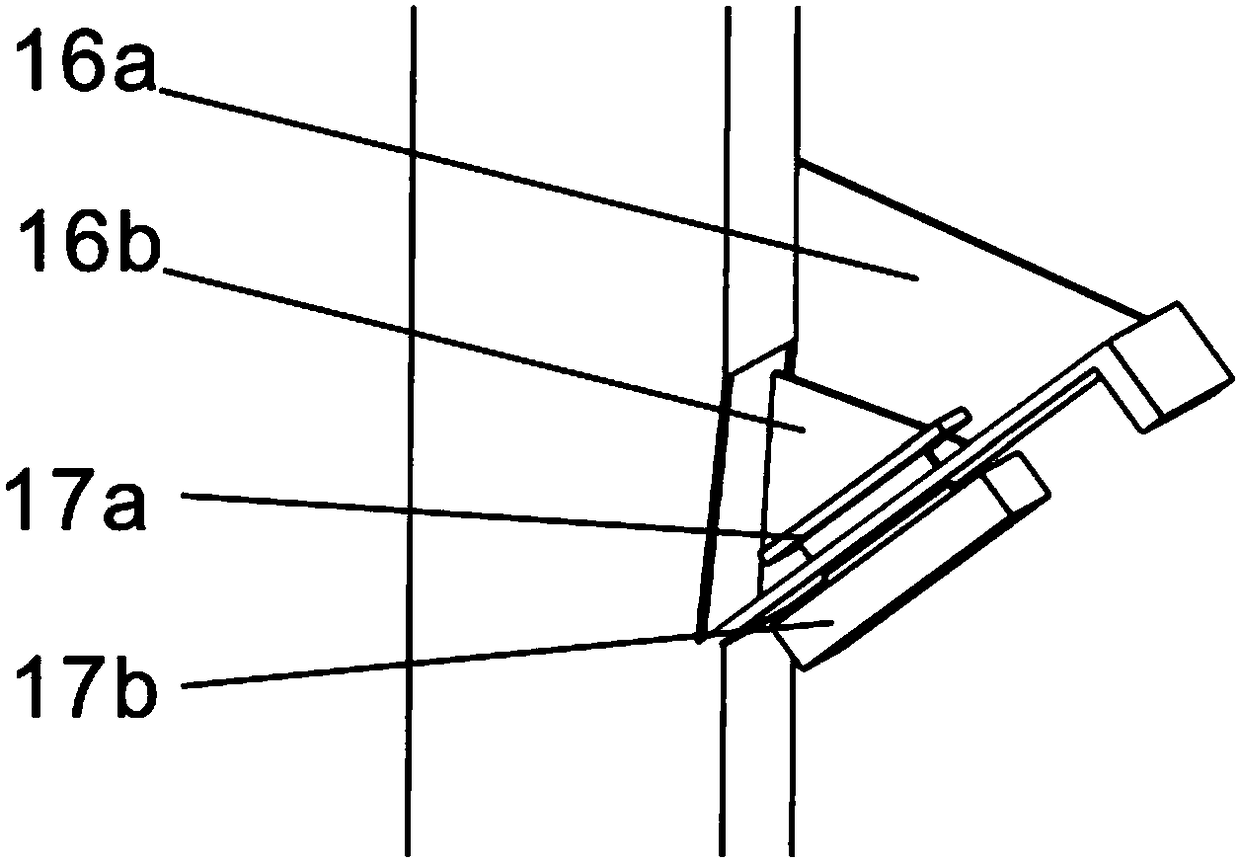

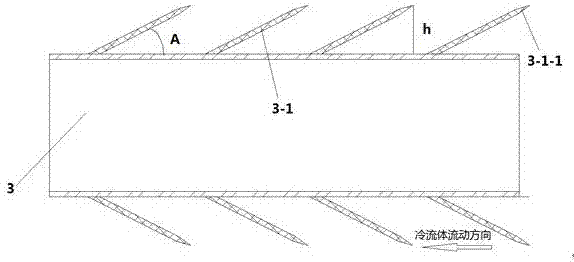

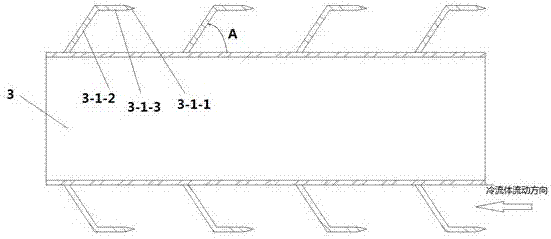

Heat exchange provided with sharp structure out of pipe

ActiveCN106767007ADoes not increase flow resistanceIncrease heat transfer areaStationary conduit assembliesHeat exchanger casingsInlet channelGas phase

The invention provides a heat exchanger. The heat exchanger comprises a pipe pass side and a shell pass side; the pipe pass side includes an inlet pipe, an inlet cavity, a heat transfer pipe bundle, an outlet cavity and an outlet pipe; a hot fluid enters the inlet cavity from the inlet pipe to pass through the heat transfer pipe bundle, the outlet cavity and the outlet pipe in sequence; the shell pass side includes an inlet channel, an inner shell, an outer shell and an outlet cavity; a cold fluid passes through space limited by the inlet channel, the inner shell and the outer shell and the outlet cavity in sequence; the inlet cavity, the heat transfer pipe bundle and the outlet cavity are arranged in space limited by the inner shell and the outer shell; a metal rod outwards extends from the outer wall of the heat transfer pipe bundle; the end part of the metal rod is a sharp structure; and the direction from the outer wall of the heat transfer pipe bundle to the end part of the metal rod is opposite to the flowing direction of the cold fluid. The rod with the sharp end part is arranged at the external of the heat exchange pipe; in flowing of a gas-liquid two-phase flow, on the one hand, the laminar flow bottom layer can be broken, and the heat transfer area is increased for forced heat transfer; because of the rod, the flowing resistance is low, and the shell pass flowing resistance cannot be increased; and as the sharp end part is provided, bubbles can be punctured to realize increment of a gas-liquid interface and a gas-phase boundary layer and reinforcement of the disturbance.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

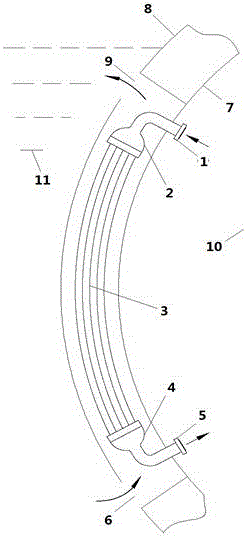

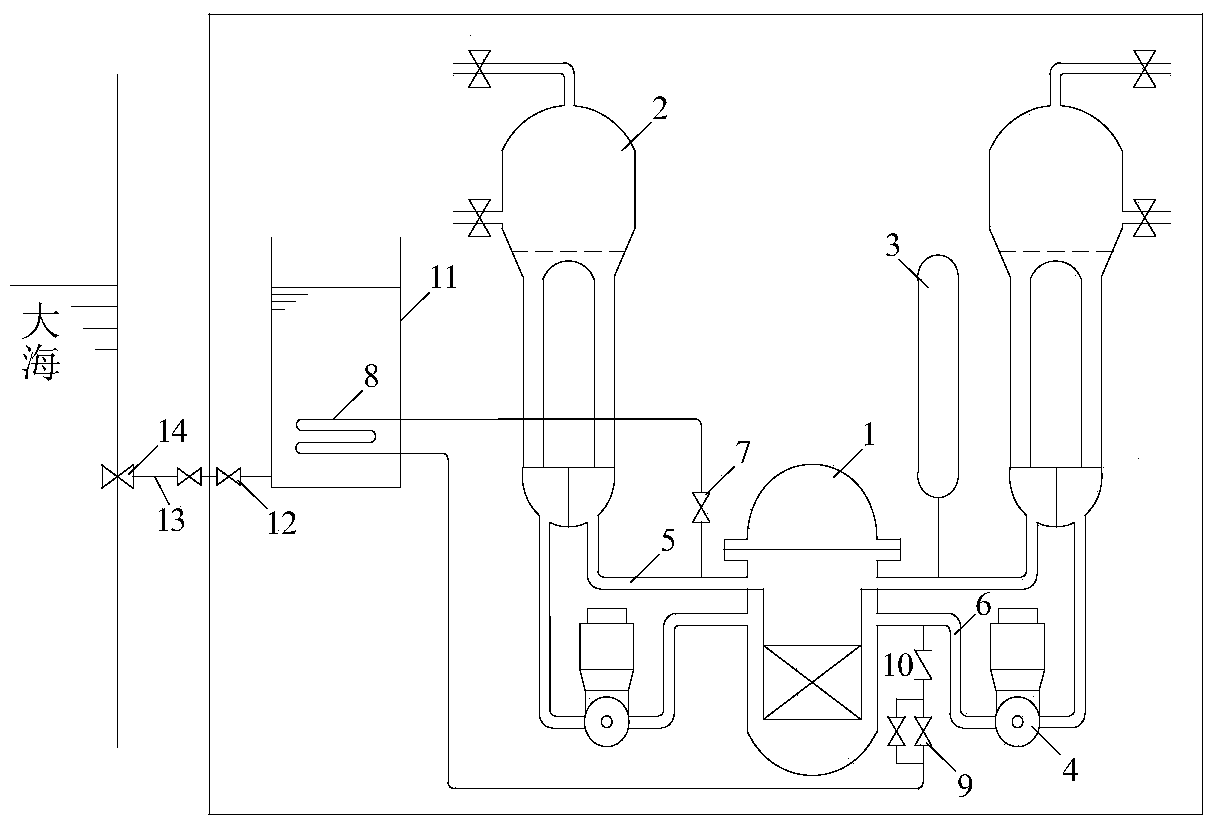

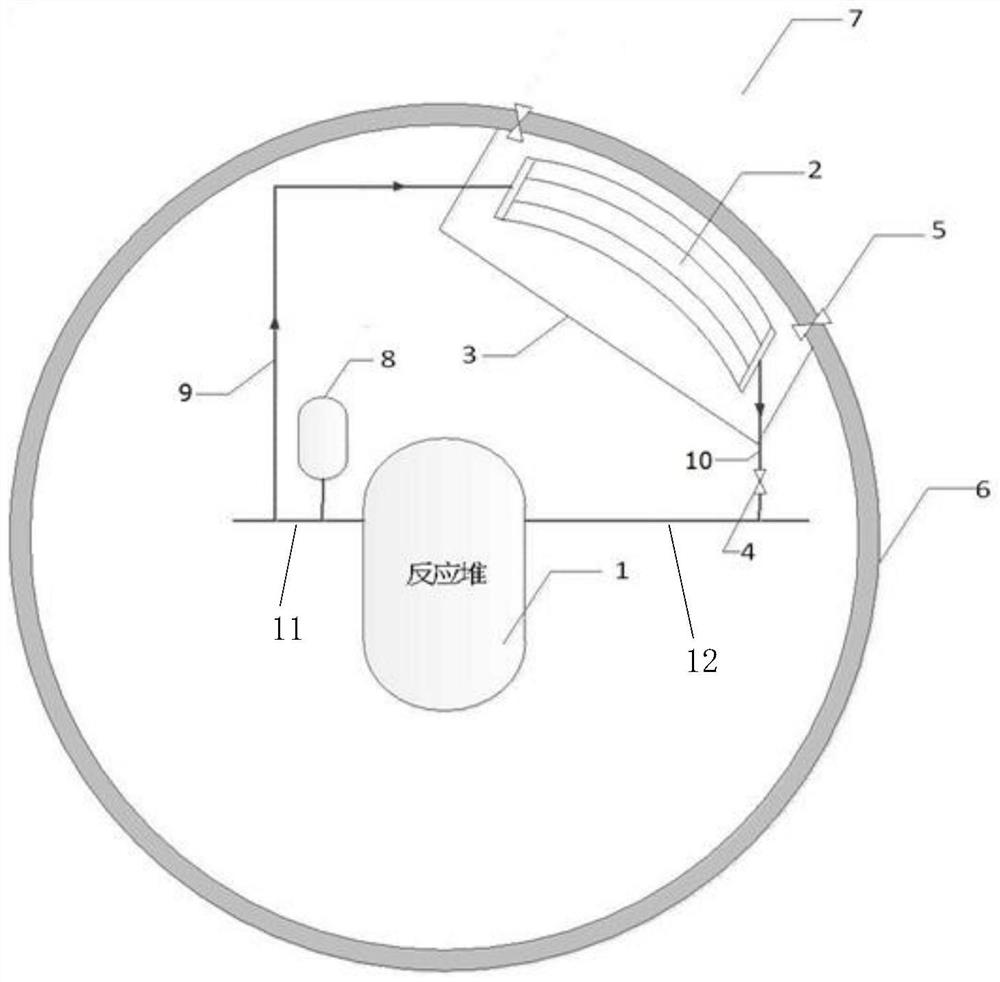

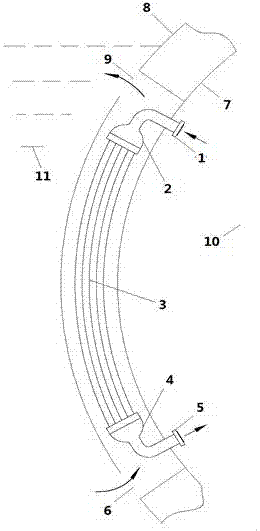

Passive waste heat removal system for floating nuclear power plant

ActiveCN103903659ALow flow resistanceReduce trafficNuclear energy generationCooling arrangementReactor pressure vesselNuclear power

The invention relates to a passive waste heat removal system for a floating nuclear power plant. The system consists of a reactor pressure vessel 1, a passive waste heat removal heat exchanger 8 and a passive emergency cooling water tank 11, wherein the passive waste heat removal heat exchanger 8 is arranged in the emergency cooling water tank 11; an inlet / outlet of the heat exchanger is connected with a loop main coolant pipeline; the emergency cooling water tank 11 is arranged in the pressure vessel; the bottom of the water tank is connected with an ocean through a seawater pipeline; a water level in the water tank is kept consistent with the sea level, and the passive waste heat removal heat exchanger 8 is completely submerged. The passive waste heat removal system is operated under accident conditions, and heat in a loop is finally taken into an atmospheric environment by means of evaporation of water in the water tank. When the water level in the water tank is reduced, seawater automatically enters the water tank through a seawater pipeline, the water level in the water tank is kept, and the reactor is cooled for a long time.

Owner:HARBIN ENG UNIV

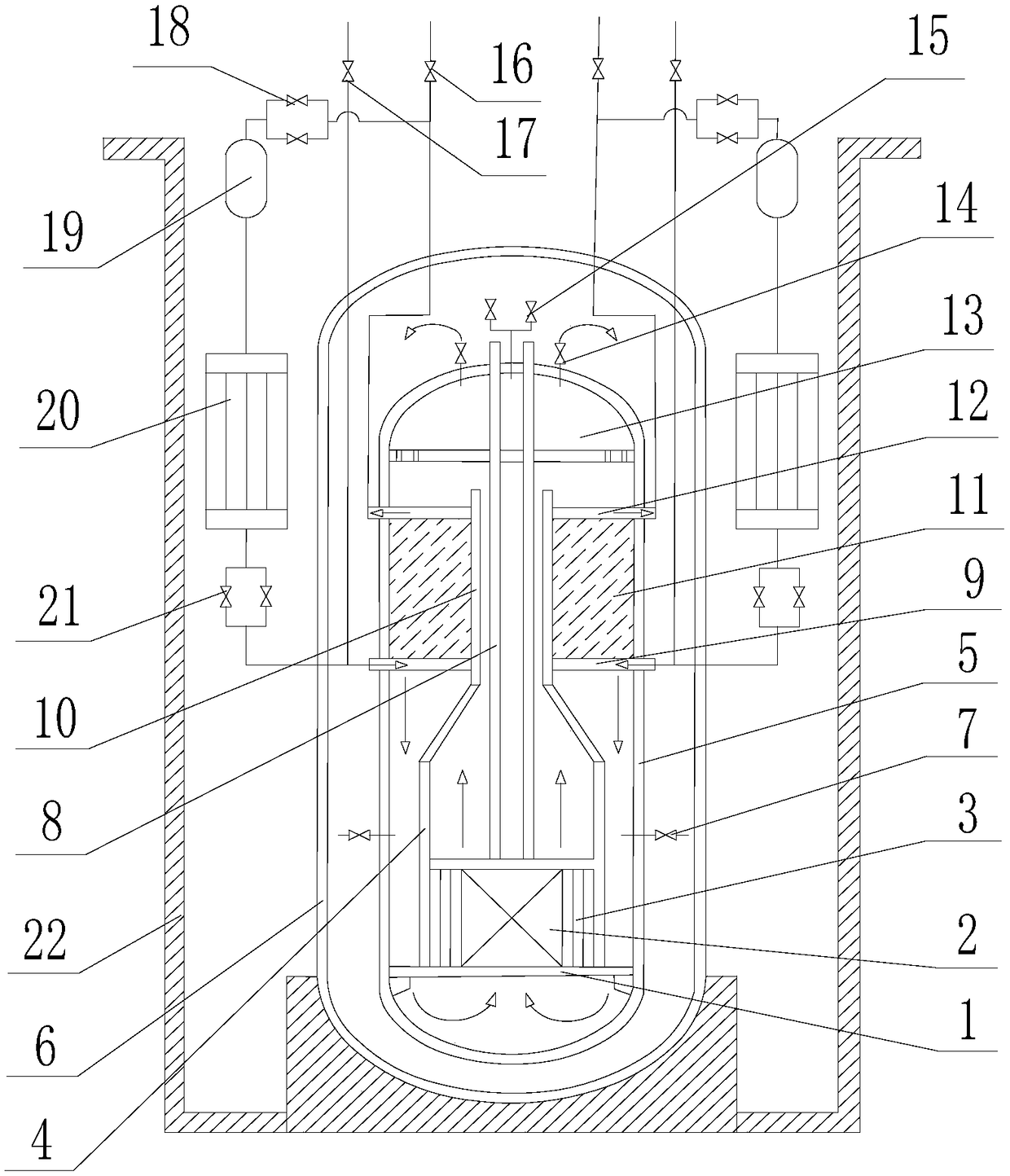

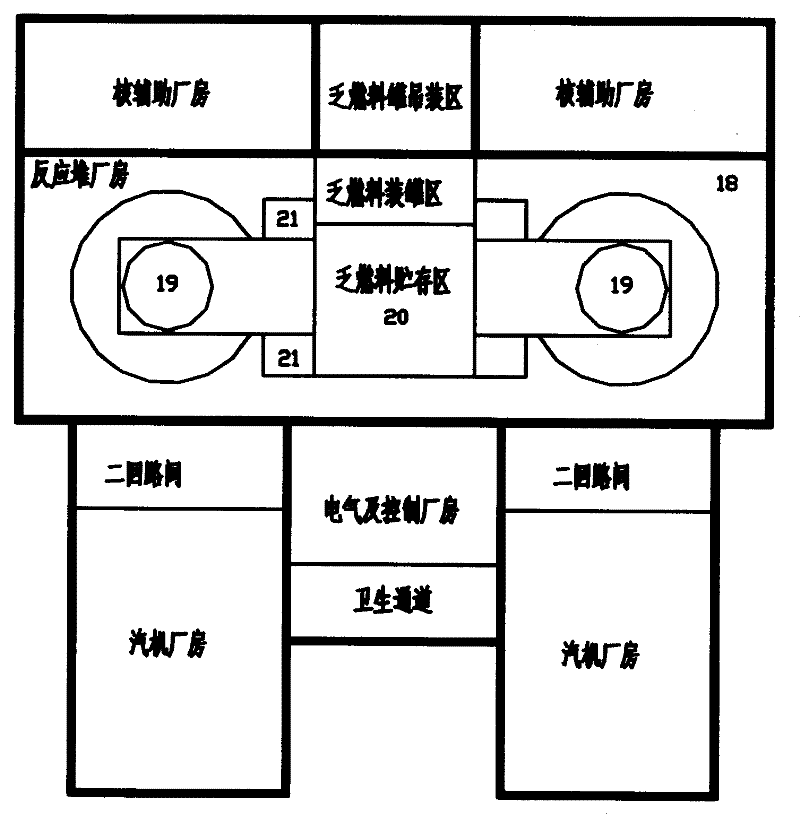

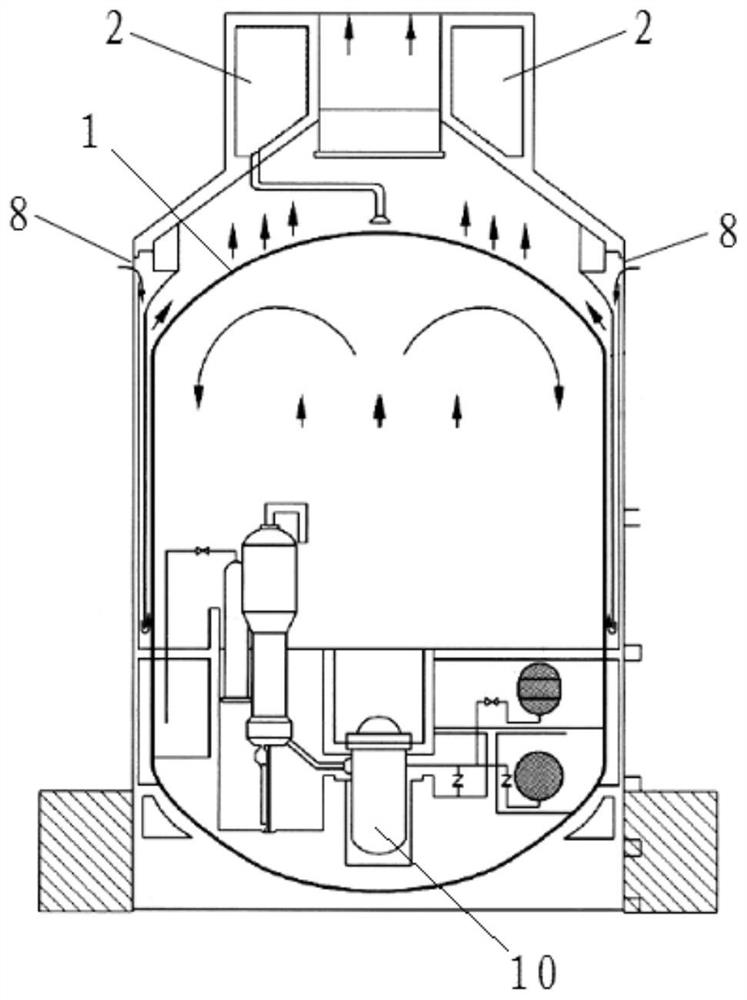

All natural circulation-type modular small reactor

ActiveCN108648837AReduce resistanceImprove natural circulationNuclear energy generationCooling arrangementPotential differenceHeat transmission

The invention discloses an all natural circulation-type modular small reactor. The all natural circulation-type modular small reactor comprises a reactor main body, a safe shell, a water tank and a passive safety system. The reactor main body comprises a pressure vessel. A reactor core, a direct current steam generator and a voltage stabilizer are orderly arranged in the pressure vessel from bottom to top. One end of a control rod driving mechanism matched with the reactor core is arranged at a top cover of the pressure vessel. The pressure vessel is arranged in the safe shell. The safe shellis immersed in the water tank. The passive safety system comprises a passive residual heat removal system and a passive safe shell heat transmission system. The reactor is free of forced circulation of a path of a cooling agent driven by a main pump, and utilizes density contrast of cooling agents between the direct current steam generator and the reactor core and cold and hot core potential difference to drive the cooling agents to all naturally circulate in the pressure vessel so that the reactor safety is improved. The passive safety system realizes a lasting submerged state of the reactorcore and carries out the residual heat of the reactor core to prevent core damage.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

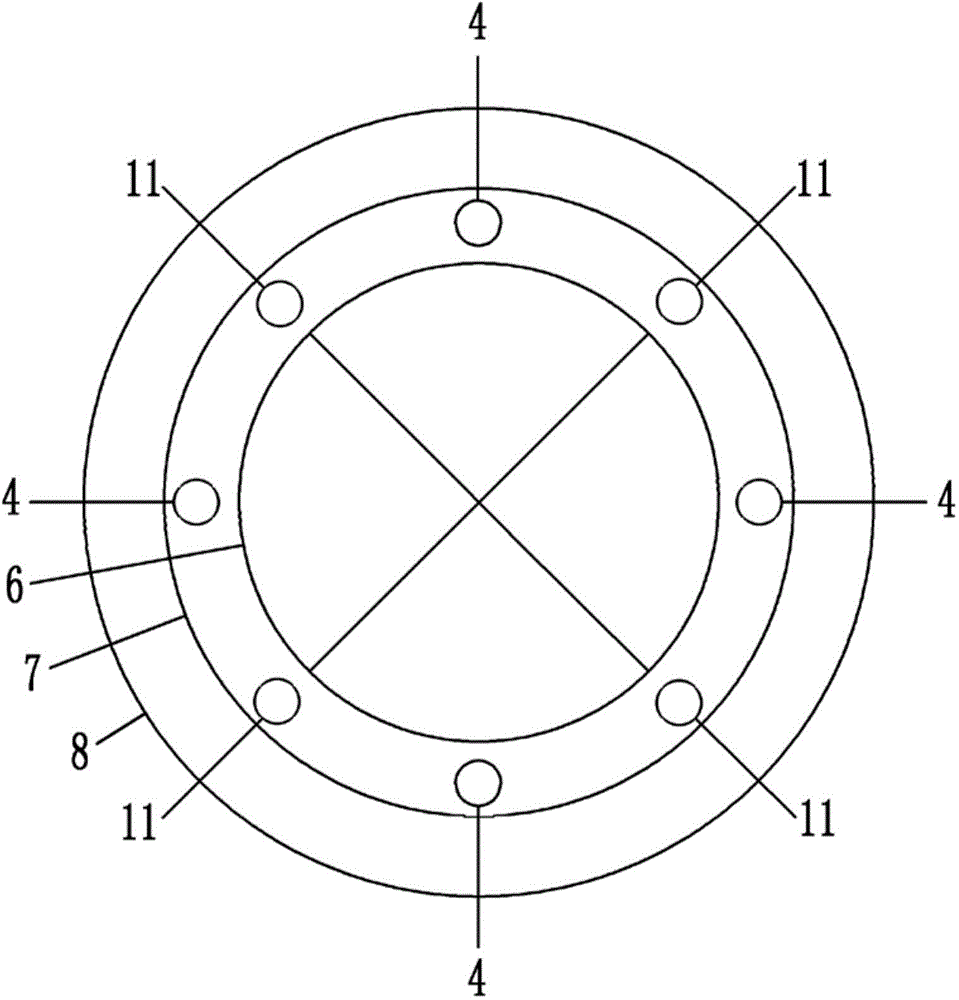

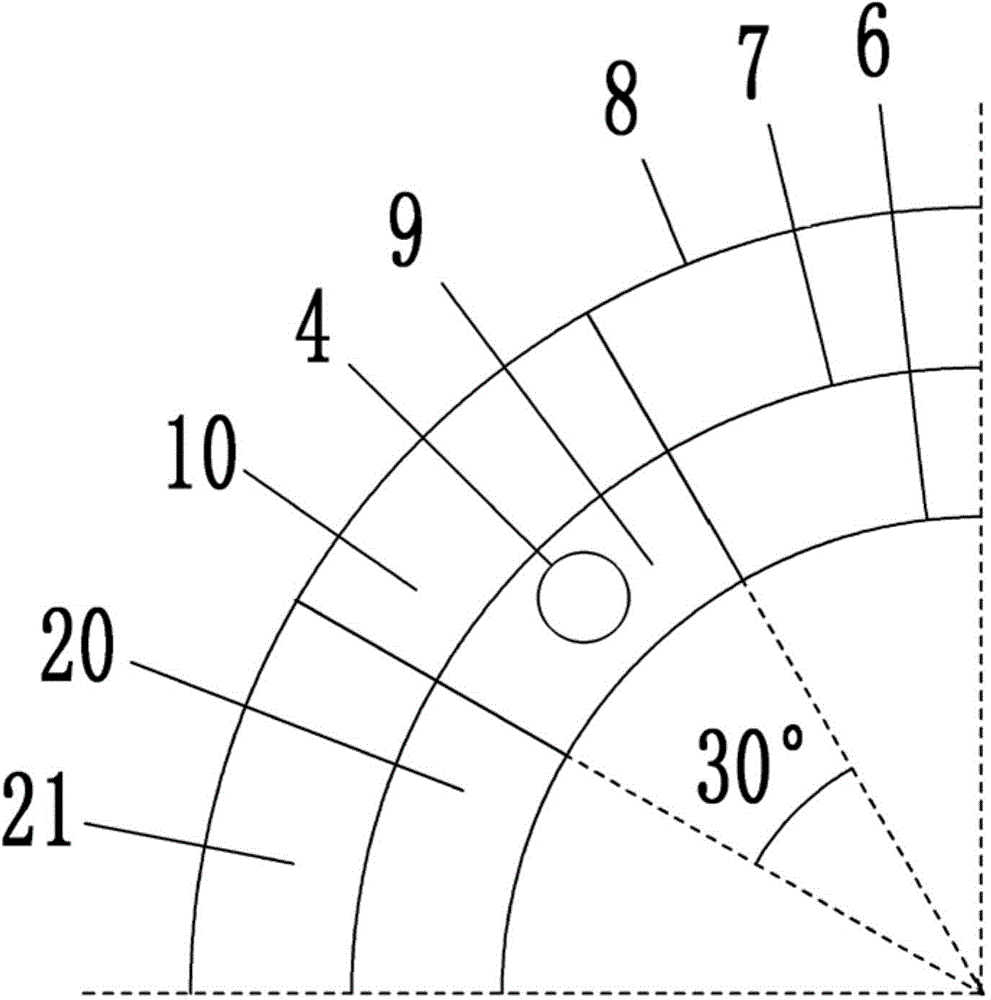

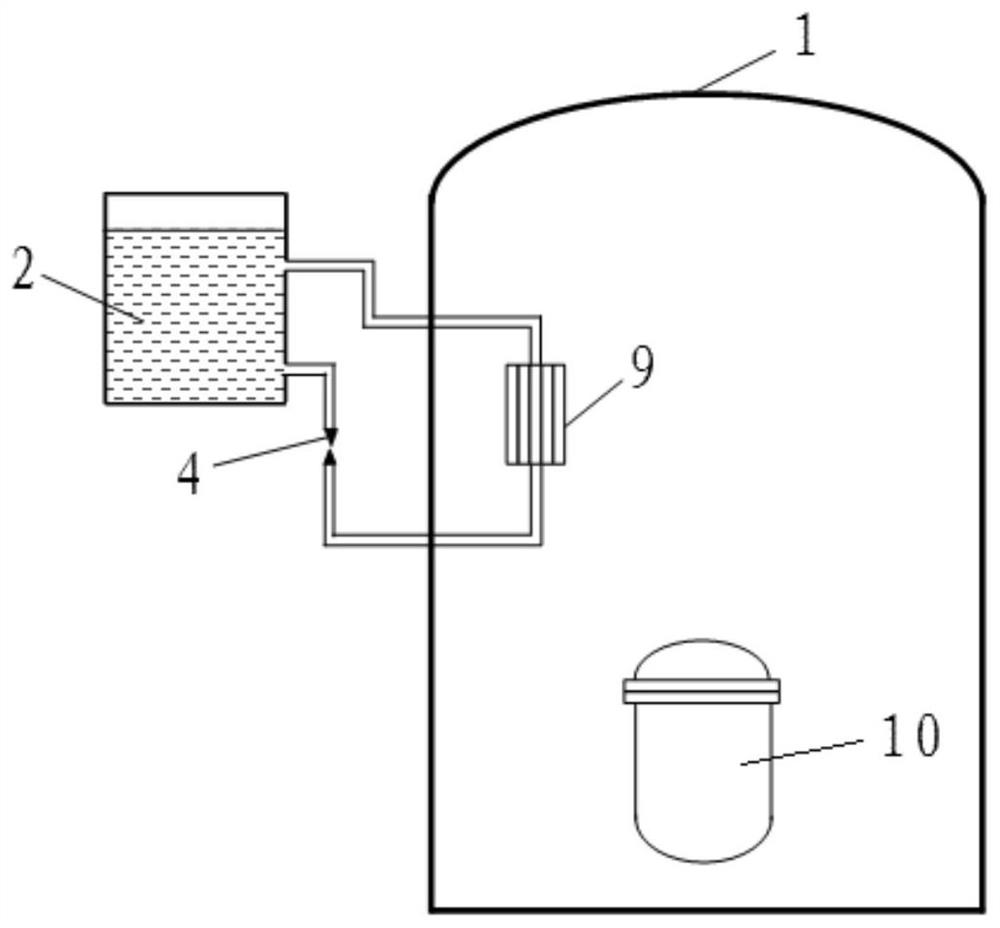

Cooling water tank for passive containment cooling system

ActiveCN108122622AImprove natural circulationIncrease powerNuclear energy generationNuclear monitoringHeat managementWater source

The invention discloses a cooling water tank for a passive containment cooling system. The cooling water tank comprises a state monitoring and water supplementing system and a closed box body arrangedon the outer side of a reactor containment wall body capable of realizing automatic heat management, wherein the state monitoring and water supplementing system is used for monitoring the state of cooling water in the closed box body and supplementing water according to the state; the closed box body is connected to a heat exchanger arranged on the inner side of the reactor containment wall bodythrough a circular pipeline; the closed box body is divided into at least two water body units through a water body partition plate, and the water body units are connected to an overflow outlet and anincoming flow inlet; and the effluent circular pipeline of the closed box body and the return circular pipeline of the closed box body are separately connected to the two different water body units.The cooling water tank provided by the invention has the beneficial effects that cooling return water is layered for heat management through the water body units, and a low-temperature cooling water source can be provided to the system put into operation all the way, so that the system can obtain a relatively high natural circulating ability and heat exhaust power.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Accelerator driven lead bismuth cooling subcritical traveling wave reactor

ActiveCN104464842AEliminate the Possibility of Nuclear Criticality AccidentsImprove securityNuclear energy generationCooling arrangementPower reactorNeutron source

The invention discloses an accelerator driven lead bismuth cooling subcritical traveling wave reactor. The accelerator driven lead bismuth cooling subcritical traveling wave reactor comprises a mobile neutron source target, a reactor core fuel, a reactor inner component, main heat exchangers, a reactor top cover, a reactor container and a main pump. An external source neutron is provided via the mobile neutron source target; the reactor is started and ignited; the traveling wave type reactor is driven to run under the subcritical state, and a combustion wave and a proliferation wave are continued; meanwhile, the heat of the reactor core is taken out by a lead bismuth cooling agent with good chemical inertness so as to guarantee the safety of the reactor, so that the requirement for high-enrichment-degree fissile nuclear fuels for realizing critical start by the critical traveling wave reactor is prevented, the requirements for reactor core materials and high fuel consumption by the traveling of the proliferation wave are lowered, and the practical feasibility, reliability and safety of the traveling wave reactor are improved effectively.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

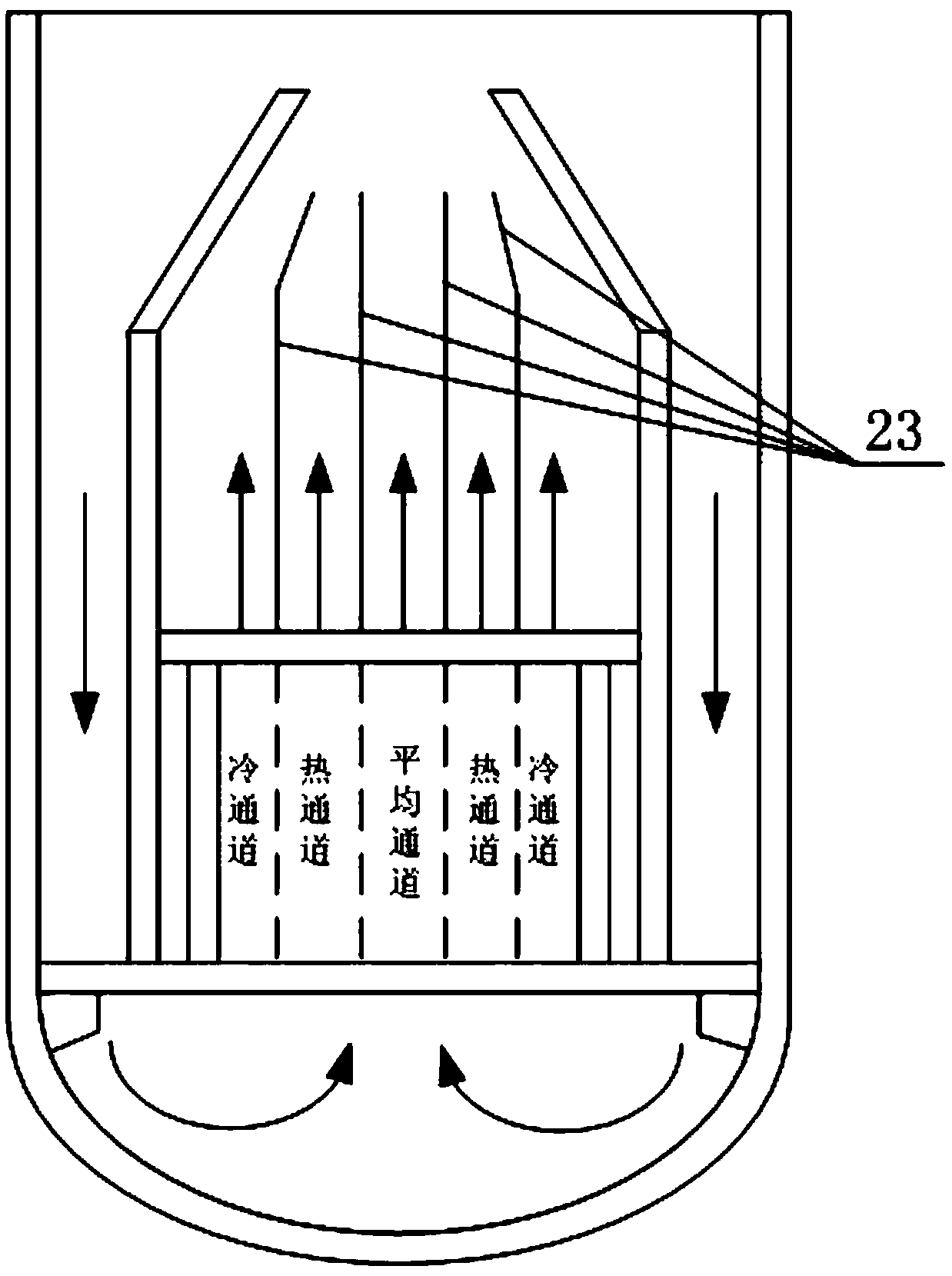

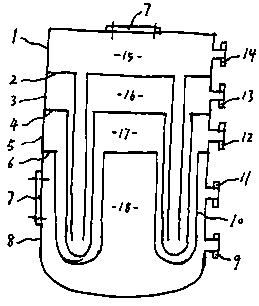

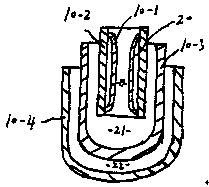

In-pile heat separation system of liquid heavy metal cooling natural circulating pool type reactor

InactiveCN103714868AImprove reliabilityImprove securityNuclear energy generationCooling arrangementNuclear engineeringLiquid state

The invention discloses an in-pile heat separation system of a liquid heavy metal cooling natural circulating pool type reactor. The system consists of an inner layer coolant inlet, an outer layer coolant inlet, a coolant inlet baffle, an inner layer heat partition plate, a middle layer heat partition plate, an outer layer heat partition plate, an inner layer coolant outlet, an outer layer coolant outlet, an inner layer coolant outlet baffle and an outer layer coolant outlet baffle. Gaps between the heat partition plates of the system are filled with liquid heavy metal and are communicated with a cold pool; coolants in the gaps between the heat partition plates are used for cooling the heat partition plates from bottom to top under the action of natural circulating driving force and are gathered into a hot pool through the coolant outlets above the heat partition plates. The in-pile heat separation system realizes a function of separating the cold pool from the hot pool in the liquid heavy metal cooling natural circulating pool type reactor; with the adoption of the complete passive design, the system is simple in structure; during running, an in-pile structural member does not need to be added or started; the heat efficiency of the liquid heavy metal cooling natural circulating pool type reactor can be effectively improved, the circulating stability of the coolants of the reactor can be guaranteed, and the economical property and the safety of the reactor can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

Method for simulating natural circulation flow characteristics of nuclear reactor fluid

InactiveCN107527664ASimulation is accurateSolving the simulation puzzle of natural cyclesNuclear energy generationNuclear monitoringReactor systemNuclear reactor

The invention discloses a method for simulating the natural circulation flow characteristics of nuclear reactor fluid, aiming at solving the problems that a simple way of reducing the power scale and reducing the system size is adopted, so that fluid flow and heat transfer characteristics in a reactor core and a steam generator are greatly different from the actual characteristics, and the natural cycle characteristics can not be the accurately simulated. The method comprises the steps of acquiring a simulation ratio of the main parameters of an experimental device and a prototype reactor system according to the criteria number of simulating single-phase natural circulation and on the basis of a limiting condition of the criteria number of the experimental device being the same as that of the prototype reactor system; setting the experimental device according to the simulation ratio so as to obtain the natural circulation characteristics which are the same as the natural circulation characteristics of the prototype reactor system. The method can be used for accurately simulating the natural circulation capability of the reactor core in real time after the accident of a nuclear reactor happens as well as the variation rule of the parameters which are closely related with the safety of the reactor based on a small-scale experimental size proportion.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

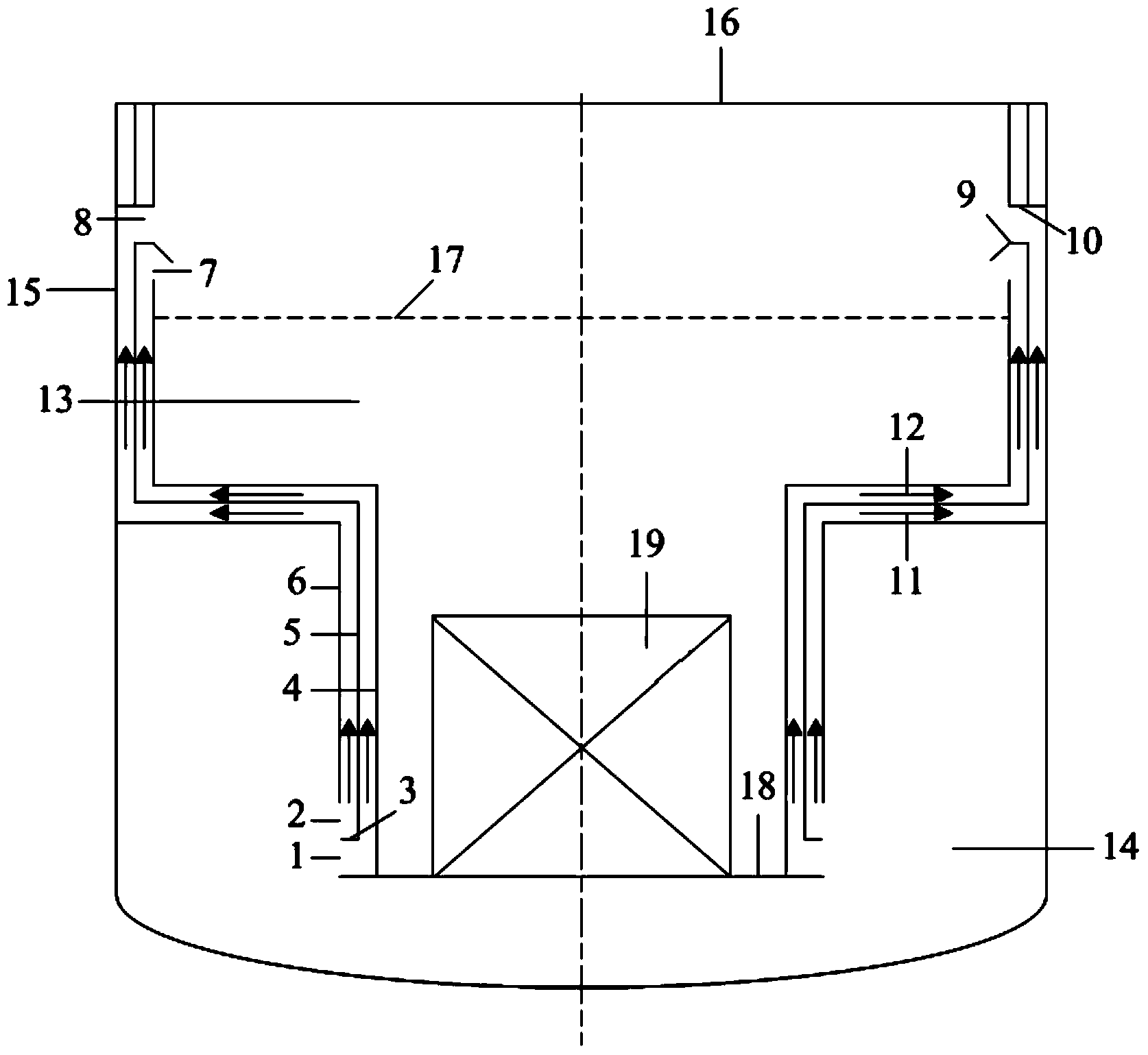

Major loop circulation device used for nuclear energy system

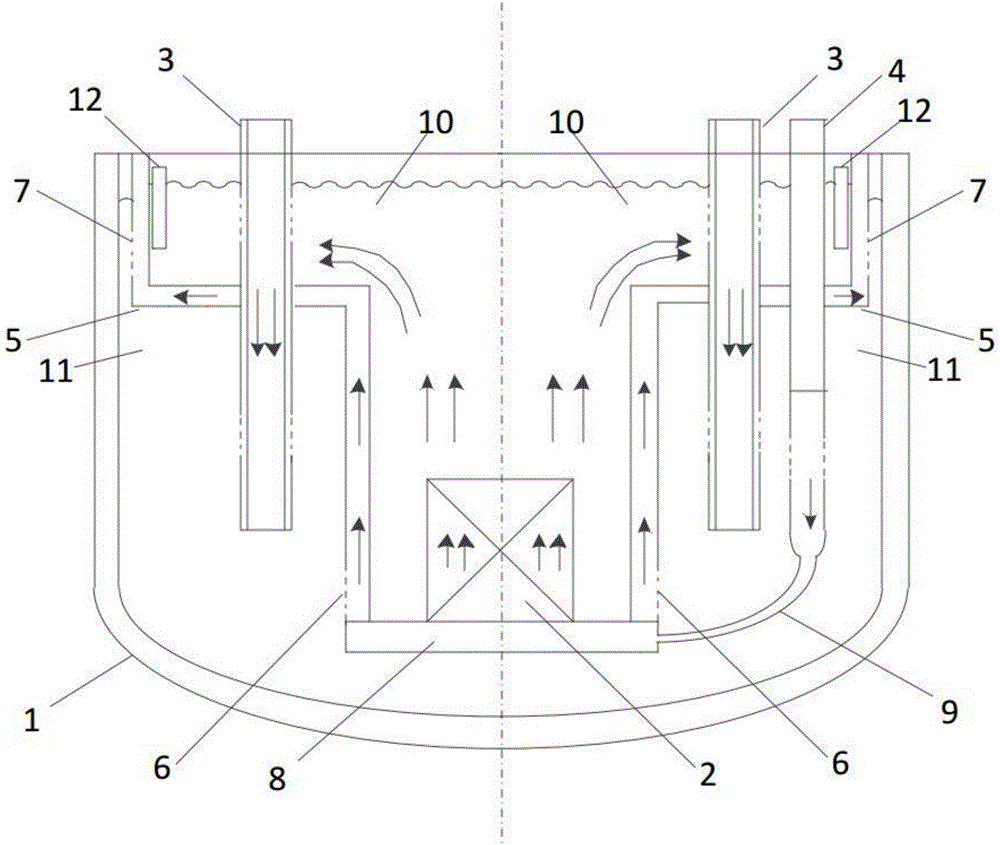

ActiveCN106710645ASpeed up the flowImprove natural circulationNuclear energy generationCooling arrangementEngineeringEnergy system

The invention discloses a major loop circulation device used for a nuclear energy system. The device comprises a container, a core, heat exchangers, a main pump, heat separator plates, a grid plate collecting box and a pipeline; the heat separator plate divide the inner chamber of the container into an external heat tank and an external cold tank, every heat separator plate is a hollow structure, every heat separator plate is provided with a heat separator plate inlet end and a heat separator plate outlet end, the heat separator plate inlet ends are arranged at the cold tank side of the lower portions of the heat separator plates, and the heat separator plate outlet ends are arranged at the cold tank side of the upper portions of the heat separator plates. The device enhances the flow of a coolant in the cold tank, and provides a cold tank and heat tank separation function under normal running and accidental conditions of a reactor; and the device inhibits heat layering in the heat tank under a shutdown condition of the reactor, enhances the natural circulation ability of the reactor, and effectively improves the economy, the reliability and the safety of the reactor.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Full natural-circulating air cooling tower

InactiveCN1815121AReduce deliveryImprove natural circulationTrickle coolersCooling towerAtmospheric air

Present invention relates to a heat exchanging apparatus, especially an all natural circulation atmospheric cooling tower used for normal pressure nuclear heat supply pile. Said all natural circulation atmospheric cooling tower includes tower body, heat transfer pipe, chimney, normal pressure pile secondary loop heat tube, rising pipe, expansion box, water tank, thermal insulation blanket and fins. Said structure characteristics effectively enlarge waterside natural circulation ability and air side reasonable natural circulation ability for ensuring transferring heat quantity to atmosphere for long time.

Owner:北京北大青鸟新能源科技有限公司

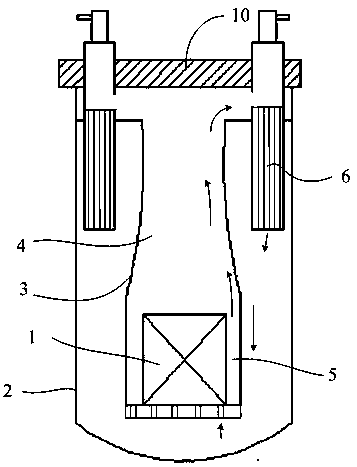

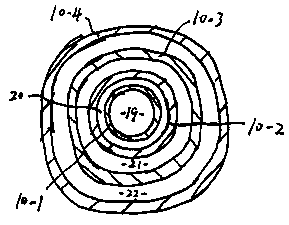

Liquid metal cooling pool type reactor multifunctional in-reactor heat separation system

InactiveCN104916335AImprove natural circulationImprove auxiliary heating efficiencyNuclear energy generationCooling arrangementExhaust valveReactor system

The invention discloses a liquid metal cooling pool type reactor multifunctional in-reactor heat separation system including a gas storage tank, a gas filter, a gas heater, a gas input pipe, a gas inlet valve, an inner heat clapboard, a middle heat clapboard, an outer heat clapboard, an inner heat clapboard fixed steel plate, an outer heat clapboard fixed steel plate, a gas outlet pipe, an exhaust valve, a gas extractor and pipes and valves for connection of devices. Hot and cold pool spacing and auxiliary heating function of a liquid metal in a main container can be realized in a liquid metal cooling pool type reactor, the system is simple in structure, and easy to start, the spacing and auxiliary heating function can be realized in one system, the utilization rate of the reactor system is improved, the complexity of the reactor system is reduced, and the economy and security of the reactor can be effectively improved.

Owner:刘紫静

Reactor with passive reactor core waste heat emission function

ActiveCN106409357AReduced risk of overpressurePrevent evaporationOptical rangefindersNuclear energy generationNuclear engineeringStorage tank

The invention provides a reactor with a passive reactor core waste heat emission function. The reactor comprises a fully-enclosed safety shell. A reactor container, at least one storage tank and a heat insulating layer are arranged inside the safety shell. The storage tanks are used for storing solid heat conduction media. The heat insulating layer is of a fully-enclosed structure, is filled with inert gases and is provided with at least one first outer sidewall connected with the inner wall of the safety shell, at least one second outer sidewall connected with the outer wall of the reactor container and at least one third outer sidewall with one or a plurality of communication valves. A conduction tube extends from each storage tank and is connected with the corresponding communication valve on the heat insulating layer, and each storage tank is communicated with the heat insulating layer after the corresponding communication valve is turned on when a certain temperature is reached or a signal is received. A cooling cycling system for cooling the outer wall of the safety shell is arranged outside the safety shell. The reactor with the passive reactor core waste heat emission function has the advantages that the solid cooling media are adopted to avoid overpressure risks in the safety shell, the system mounting space is saved, and construction cost is reduced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Auxiliary heating system in liquid state heavy metal cooling natural circulating pool type reactor

InactiveCN103730172AImprove natural circulationImprove heating efficiencyNuclear energy generationCooling arrangementNuclear engineeringHeavy metals

The invention discloses an auxiliary heating system in a liquid state heavy metal cooling natural circulating pool type reactor. The system comprises a gas storing tank, a filter, a gas heater, a fan, a gas input tube, an inner-layer thermal insulation plate, an outer-layer thermal insulation plate, a bottom heating ring, a gas output tube, a reactor core coolant entrance baffle, a pipeline fixing steel plate, and pipelines and valves connected between the devices. The system realizes the function of assisting in heating liquid state metal in a main vessel of the liquid state metal cooling pool type reactor, has a simple structure, is convenient to start, can build large-space natural circulation of the liquid state heavy metal in the main vessel even if the reactor is at low power or in shutdown condition after being put into operation, guarantees the temperature of the liquid state heavy metal to be above the melting point, and effectively improves the reliability and safety of the reactor.

Owner:UNIV OF SCI & TECH OF CHINA

Long-term cooling system for loss-of-coolant accident during isolation failure of modular small reactor containment

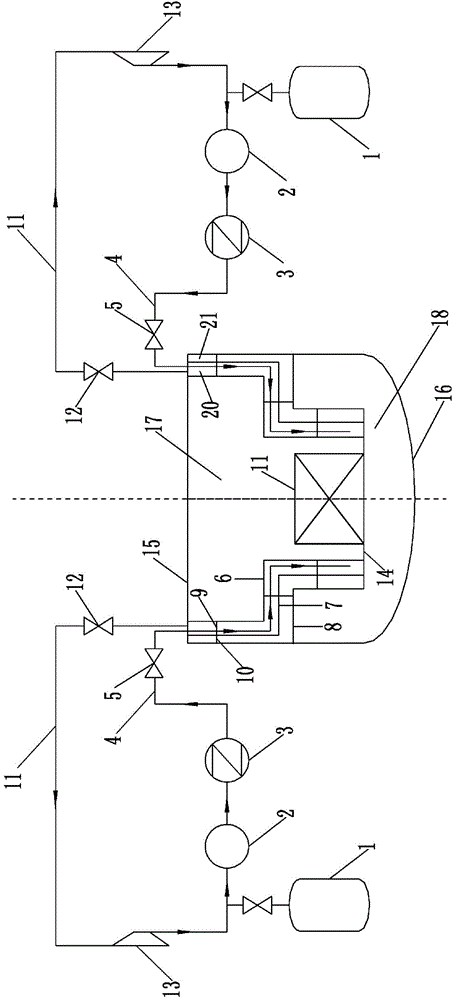

InactiveCN109887624ARelieve stressAvoid interruptionNuclear energy generationEmergency protection arrangementsWater storage tankNuclear engineering

The invention discloses a long-term cooling system for a loss-of-coolant accident during the isolation failure of a modular small reactor containment. The cooling system comprises a primary cooling loop, a secondary cooling loop and a tertiary cooling loop, the primary cooling loop is a loop formed between a reactor core water supply tank and a pressure container, boron-containing water in the reactor core water supply tank enters the pressure container through a pressure container direct-injection pipeline and is supplied to the reactor core, the boron-containing water in the pressure container returns into the reactor core water supply tank through a pipeline, the secondary cooling loop is a loop formed between a built-in refueling water storage tank and the pressure container, the boron-containing water in the built-in refueling water storage tank enters the pressure container through the pressure container direct-injection pipeline, and is supplied to the reactor core, steam generated by the reactor core returns into the built-in refueling water storage tank through an automatic pressure relief system, and the tertiary cooling loop is a natural circulation loop formed between aground pit and the reactor core. The problem that existing cooling systems cannot achieve long-term cooling of the reactor core after the loss-of-coolant accident during isolation failure of the containment is solved in the invention.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

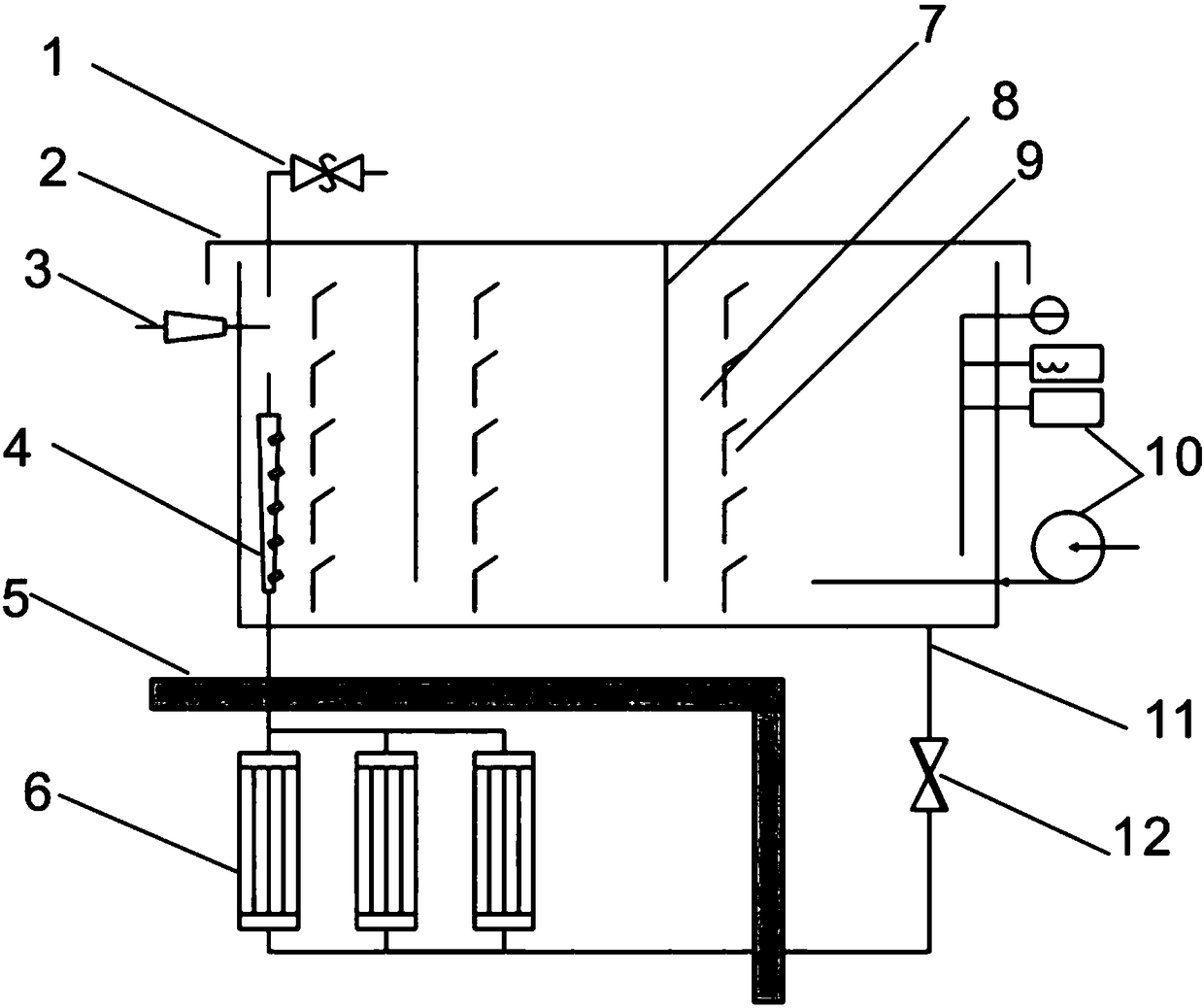

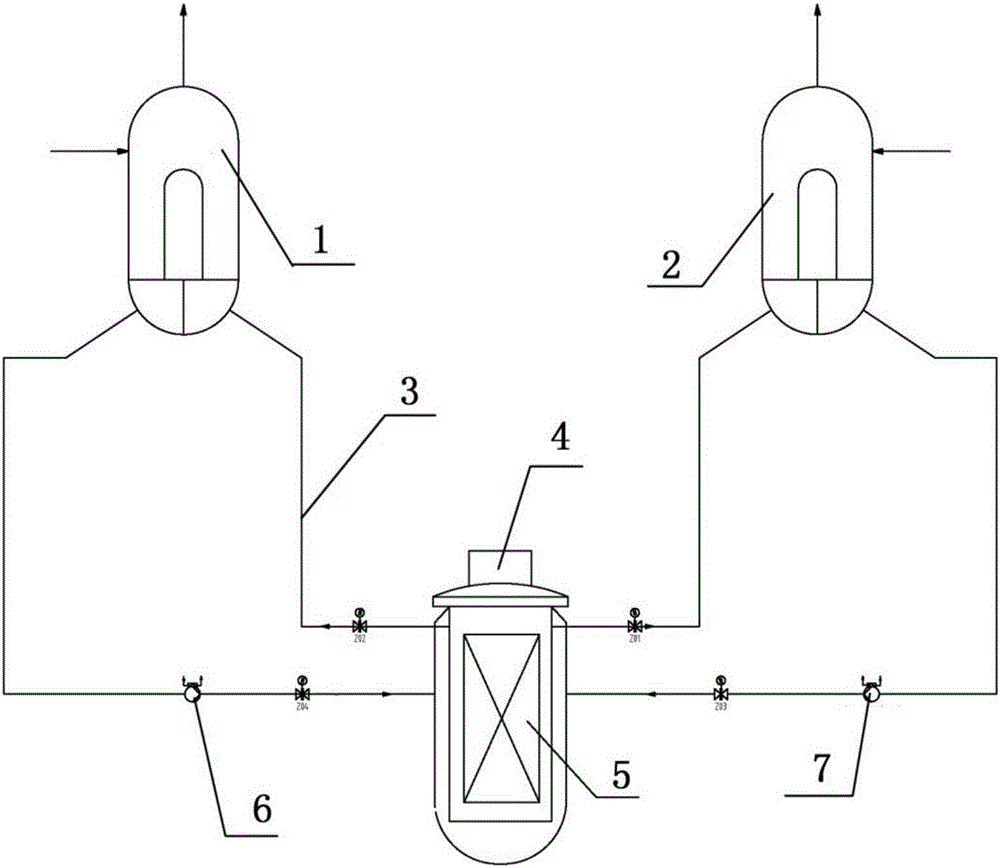

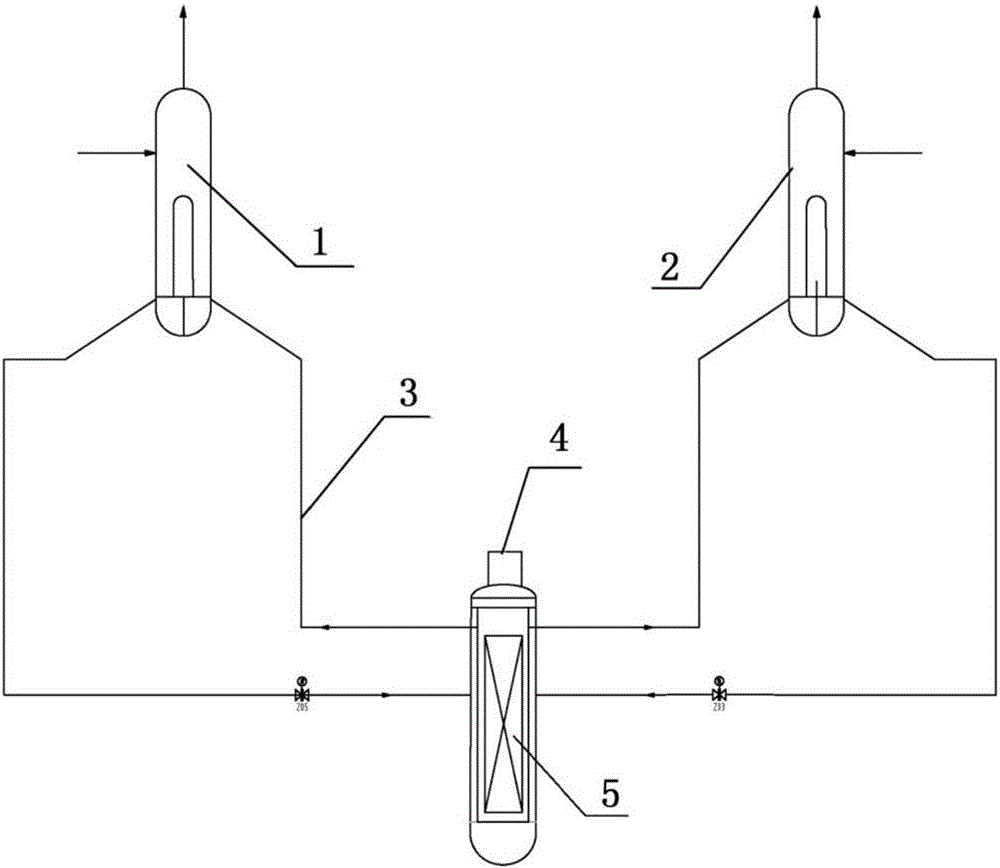

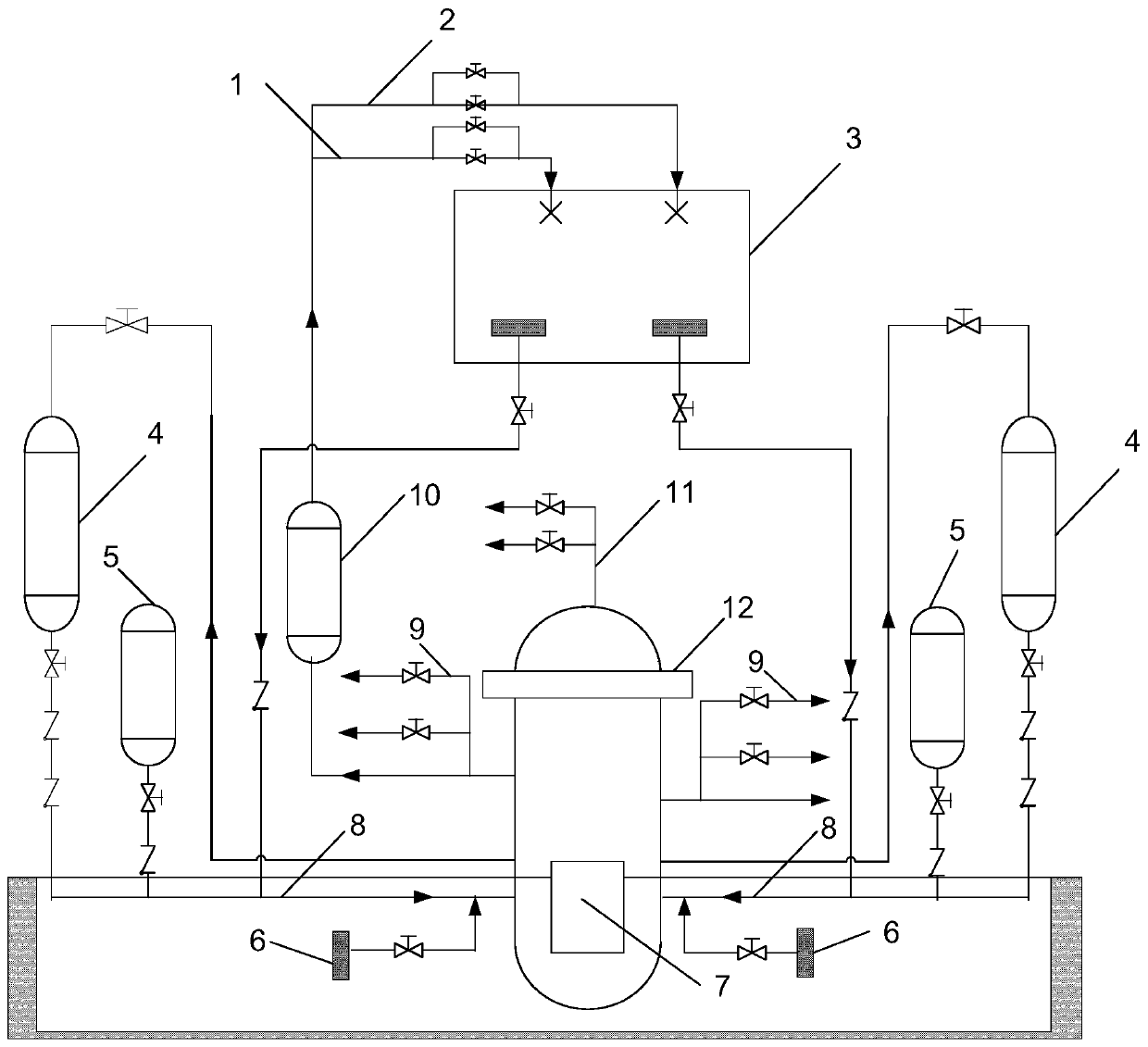

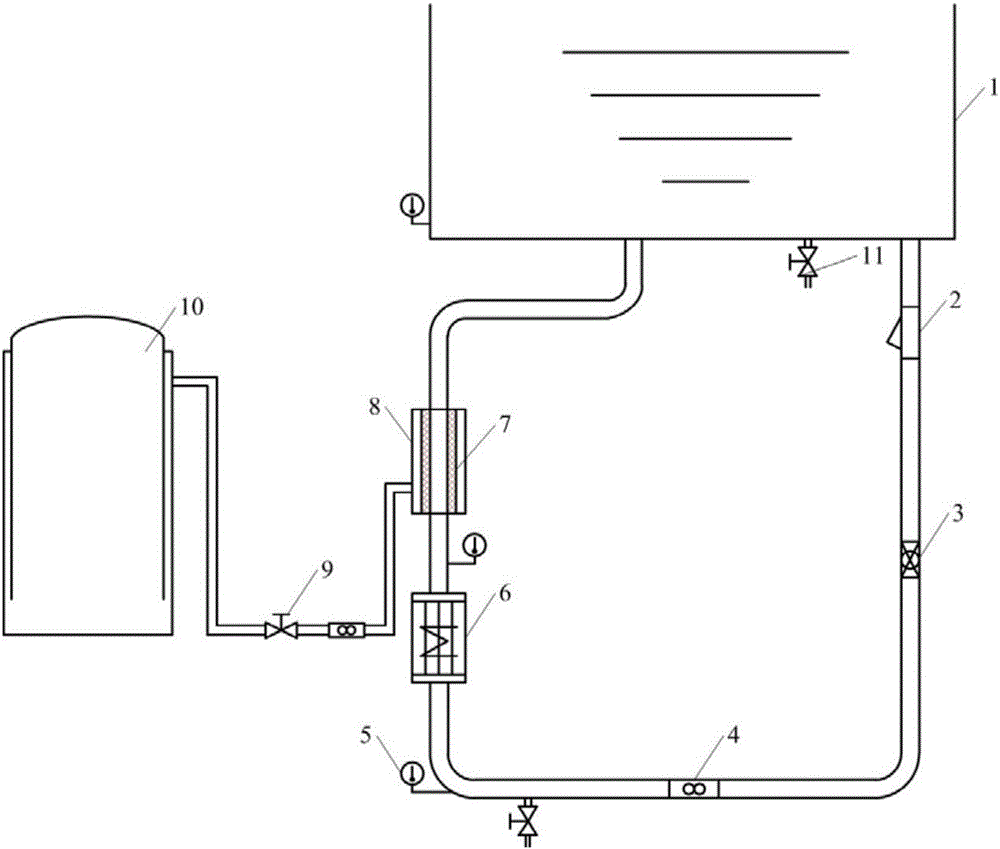

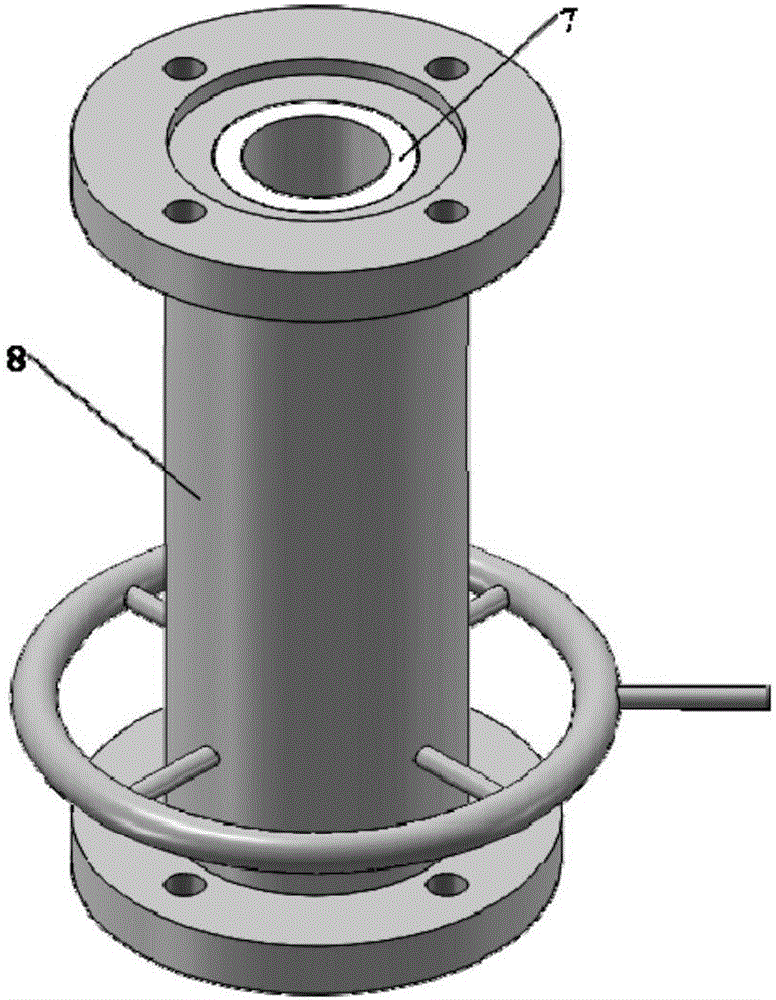

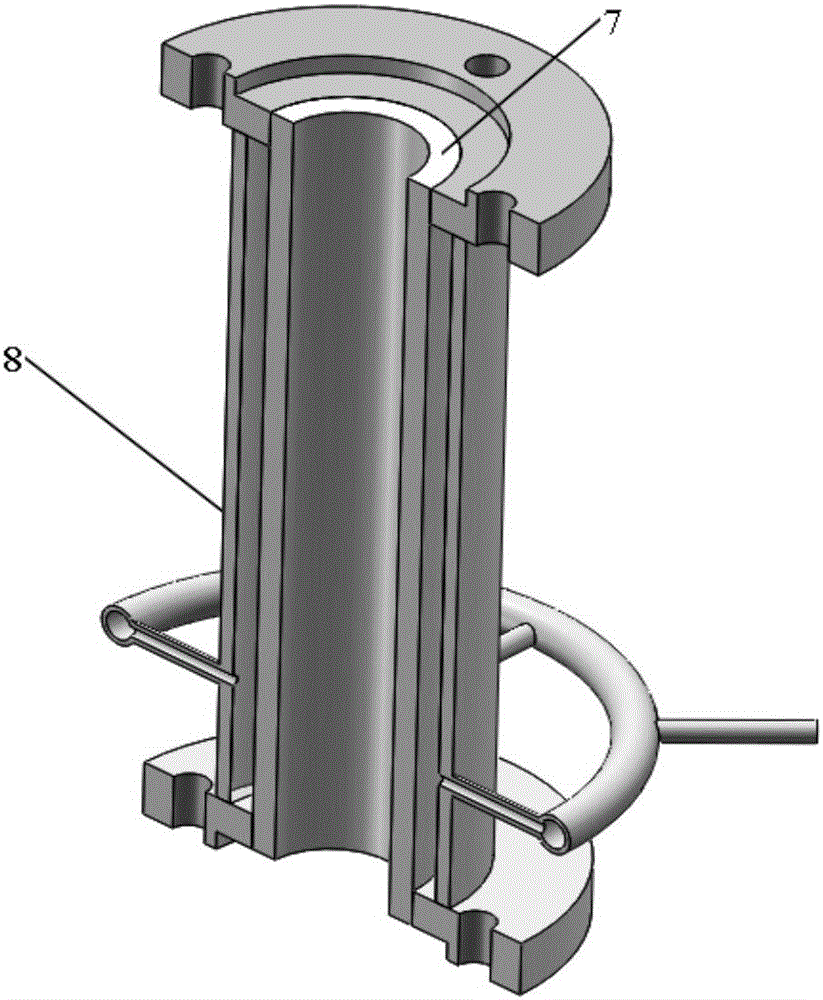

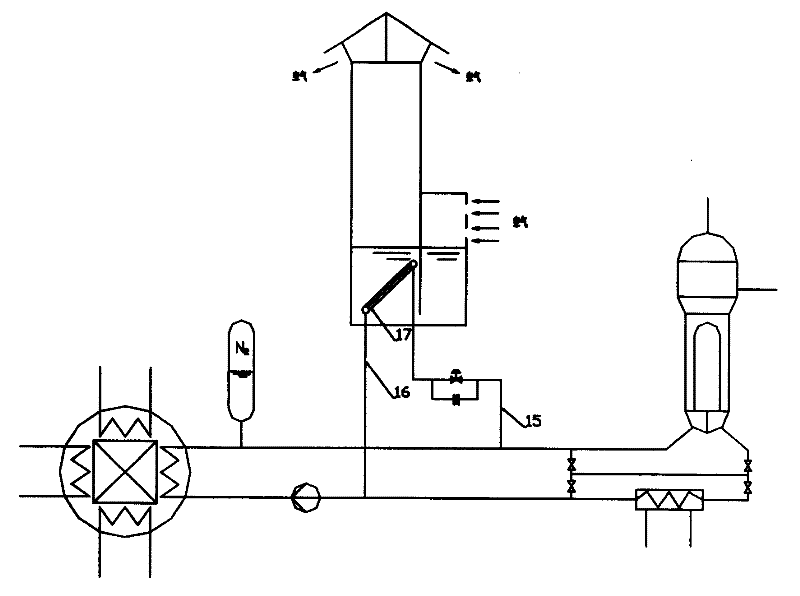

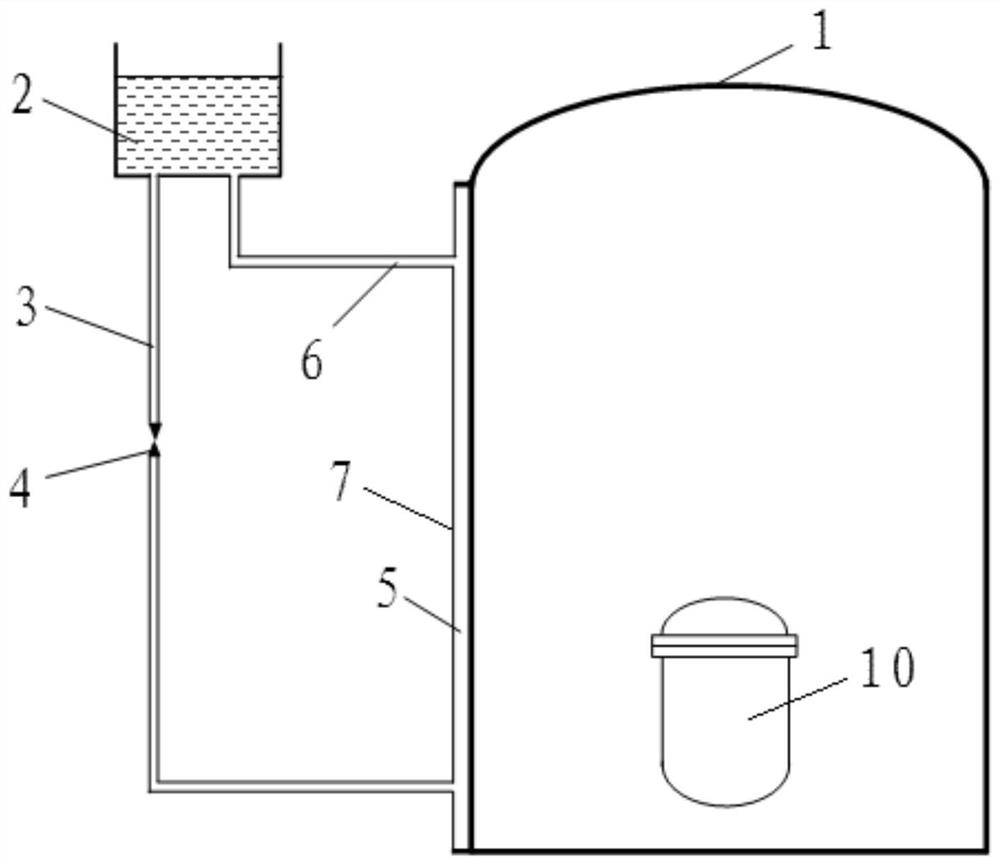

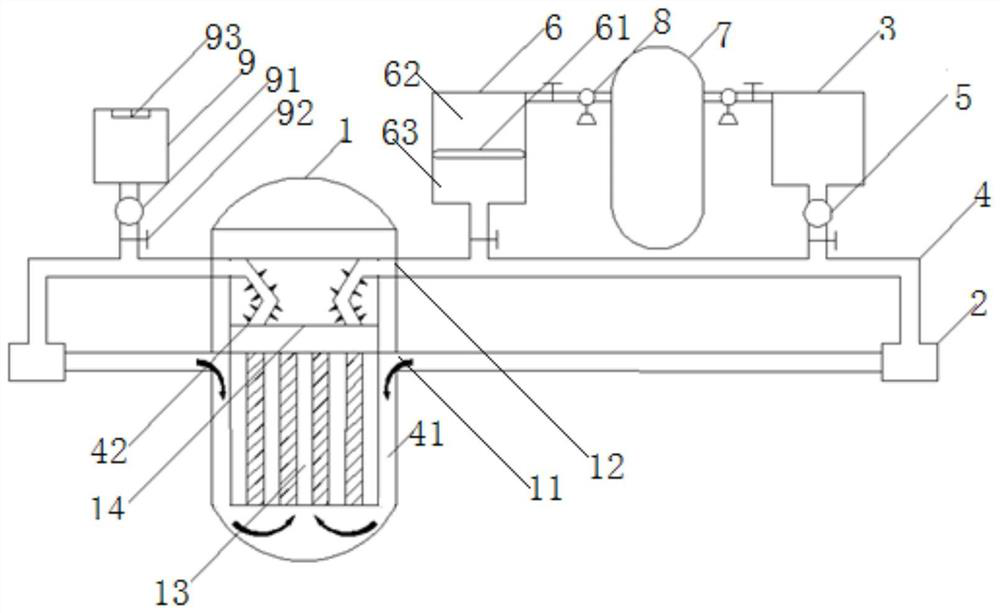

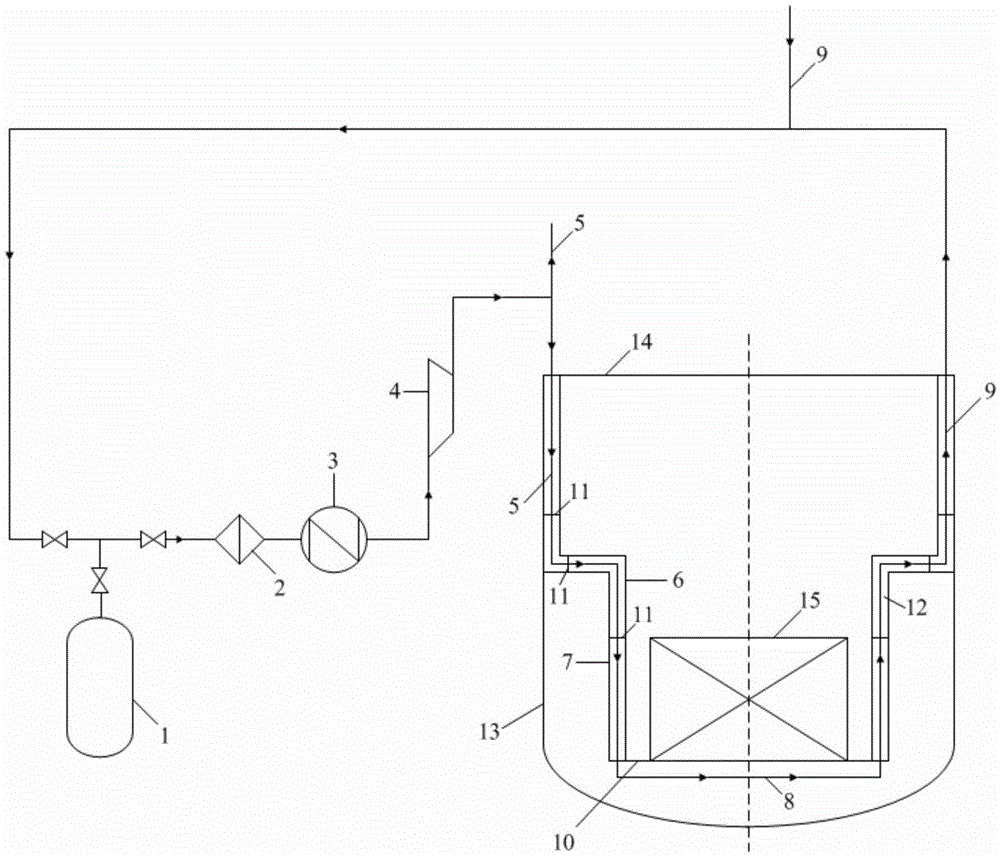

Open passive heat extraction system suitable for long-term operation condition

ActiveCN106409354AImprove natural circulationAdditional resistance is smallNuclear energy generationCooling arrangementInstabilityProcess engineering

The invention provides an open passive heat extraction system suitable for long-term operation condition, comprising: a heat exchange water tank, a filter device, a mass flowmeter, a heat exchanger, a bubble generator, a gas storage tank, a temperature sensor and other corresponding valve pipes. Compared with traditional passive heat extraction systems, the system is provided with the additional bubble generator, and heat changing capacity of the system is improved by means of adjusting gas injection according to system operation condition; by using peripheral gas injection, it is possible to effectively reduce additional resistance intervening a circulating loop; equipment is simple, easy to operate and capable of uniform bubbling, stable bubble flows can be generated, natural circulating capacity of the passive heat extraction system can be enhanced, the problem that reduced system heat exchanging capacity and instable flashing flow occur in long-term operation condition is solved, the passive characteristic of the system can be retained, and the passive heat extraction system is safer and more reliable.

Owner:HARBIN ENG UNIV

Passive residual heat removal system for high-temperature heat pipe reactor

ActiveCN110767332AImprove natural circulationAchieve compactNuclear energy generationCooling arrangementNuclear powerProcess engineering

The invention relates to a passive residual heat removal system for a high-temperature heat pipe reactor, and belongs to the technical field of nuclear power station safety systems. The system comprises a passive residual heat removal heat exchanger, high-temperature heat pipes, a transverse partition plate and ascending channels, wherein the passive residual heat removal heat exchanger is a cylindrical heat exchanger, is arranged inside a pressure vessel and at the upper part of a reactor core, and can be arranged at the upper part or the lower part of a main heat exchanger, the plurality ofhigh-temperature heat pipes are arranged inside the passive residual heat removal heat exchanger, the transverse partition plate divides the inside of the passive residual heat removal heat exchangerinto an upper layer and a lower layer, and the ascending channels are connected with the top of the passive residual heat removal heat exchanger. The system realizes passive residual heat removal of the high-temperature heat pipe reactor, the high-temperature heat pipes are used as heat transfer pipes of the passive residual heat removal heat exchanger, the reactor core decay heat is brought intothe environment by means of two-phase natural circulation in the high-temperature heat pipes and natural circulation of a working medium in the passive residual heat removal heat exchanger under the accident condition, and thereby the long-term cooling of a reactor is realized.

Owner:HARBIN ENG UNIV

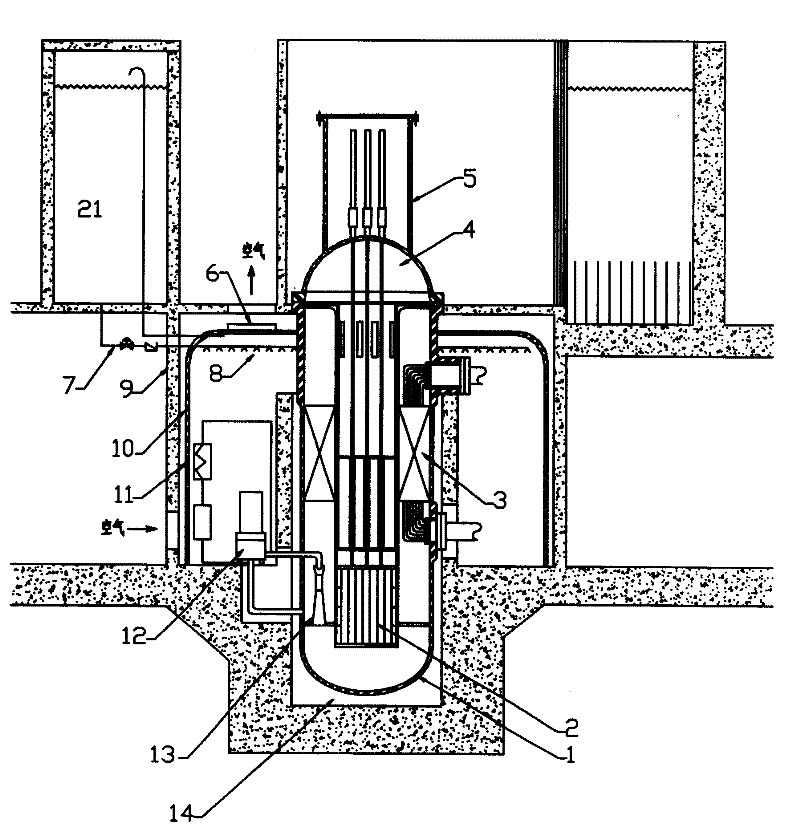

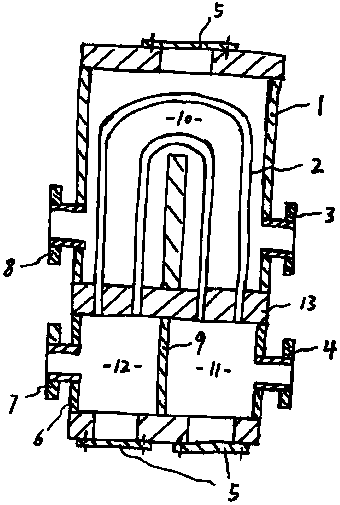

Integrated low-temperature nuclear heat supplying pile

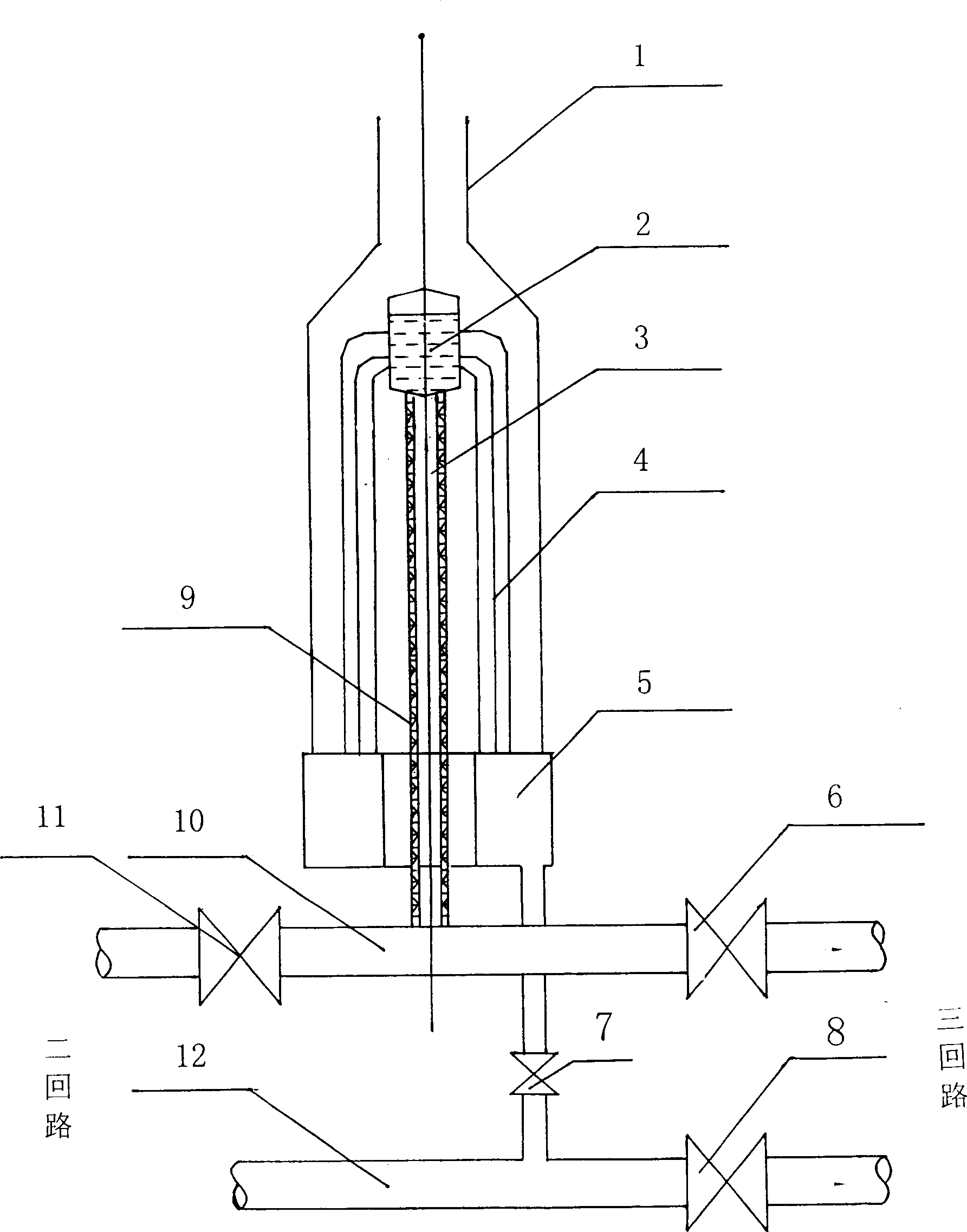

ActiveCN101154472BSmall sizeCompact layoutIntegral reactorsNuclear energy generationReactor pressure vesselPressurized water reactor

The invention discloses an integral low-temperature nuclear heat reactor with the circuit equipment adopting integral arrangement and belonging to the low- and medium-parameter pressurized-water reactor, wherein, a reactor core adopts the mature nuclear power plant fuel component and control rod component; a main heat exchanger is of integral coil type; a voltage stabilizer is a built-in nitrogenpartial pressure control voltage stabilizer; coolant circulation is completed by a built-in jet apparatus and the equipment of an external drive circuit; the drive circuit and the equipment and a main circuit auxiliary system are arranged at the circumference of a reactor pressure vessel; a containment vessel consists of a reactor body containment vessel and a reactor top containment vessel; the reactor body containment vessel which is a structure combined by a reactor vault of reinforced concrete structure and a casing of steel structure is connected with a sealed refueling water storage pool through a pipe and a valve. The thermal power of the reactor can be selected between 50MW and 500MW at will and the outlet temperature of the reactor can be selected between 100 DEG C to 200 DEG C according to application, requirement and power.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

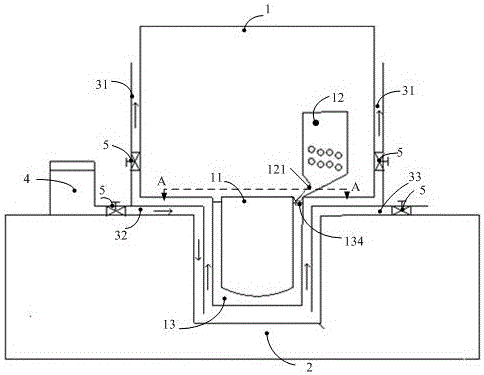

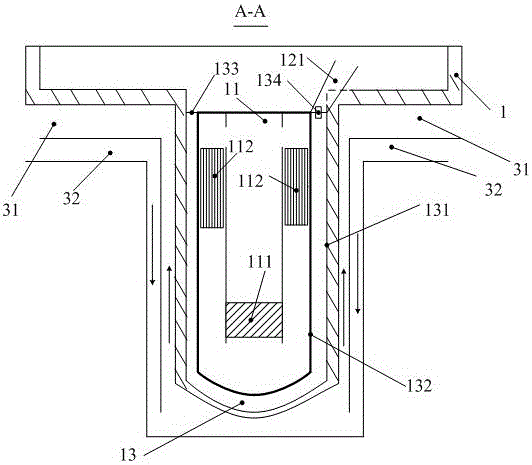

Primary side passive residual heat removal system for nuclear reactor

PendingCN114038591AAchieve heat removalGuaranteed uptimeNuclear energy generationCooling arrangementNuclear reactorIsolation valve

The invention discloses a primary side passive residual heat removal system for a nuclear reactor. The primary side passive residual heat removal system comprises the reactor, a cooling water tank, an inlet pipeline, an outlet pipeline, a heat exchanger and a control unit; the heat exchanger is located in the cooling water tank;one end of the inlet pipeline is connected with the reactor, and the other end of the inlet pipeline penetrates through the cooling water tank to be connected with an inlet of the heat exchanger; one end of the outlet pipeline is connected with an outlet of the heat exchanger and penetrates through the cooling water tank to be connected with the reactor; the inlet and outlet of the heat exchanger are higher than the outlet and outlet connected with the inlet pipeline and the outlet pipeline of the reactor; an isolating valve A is arranged at the part of the outlet pipeline positioned between the cooling water tank and the reactor; the control unit is connected with the isolating valve A; a pressure stabilizer is also provided and used for monitoring a reactor pressure value and transmitting the reactor pressure value to the control unit; and when the reactor is shut down and the pressure value of the reactor is reduced to a set value, the isolating valve A is opened to form a first heat exchange circulation loop. Heat removal can be achieved in a passive mode, external force is not needed, and the system can still be used under the condition that a power source is lost.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

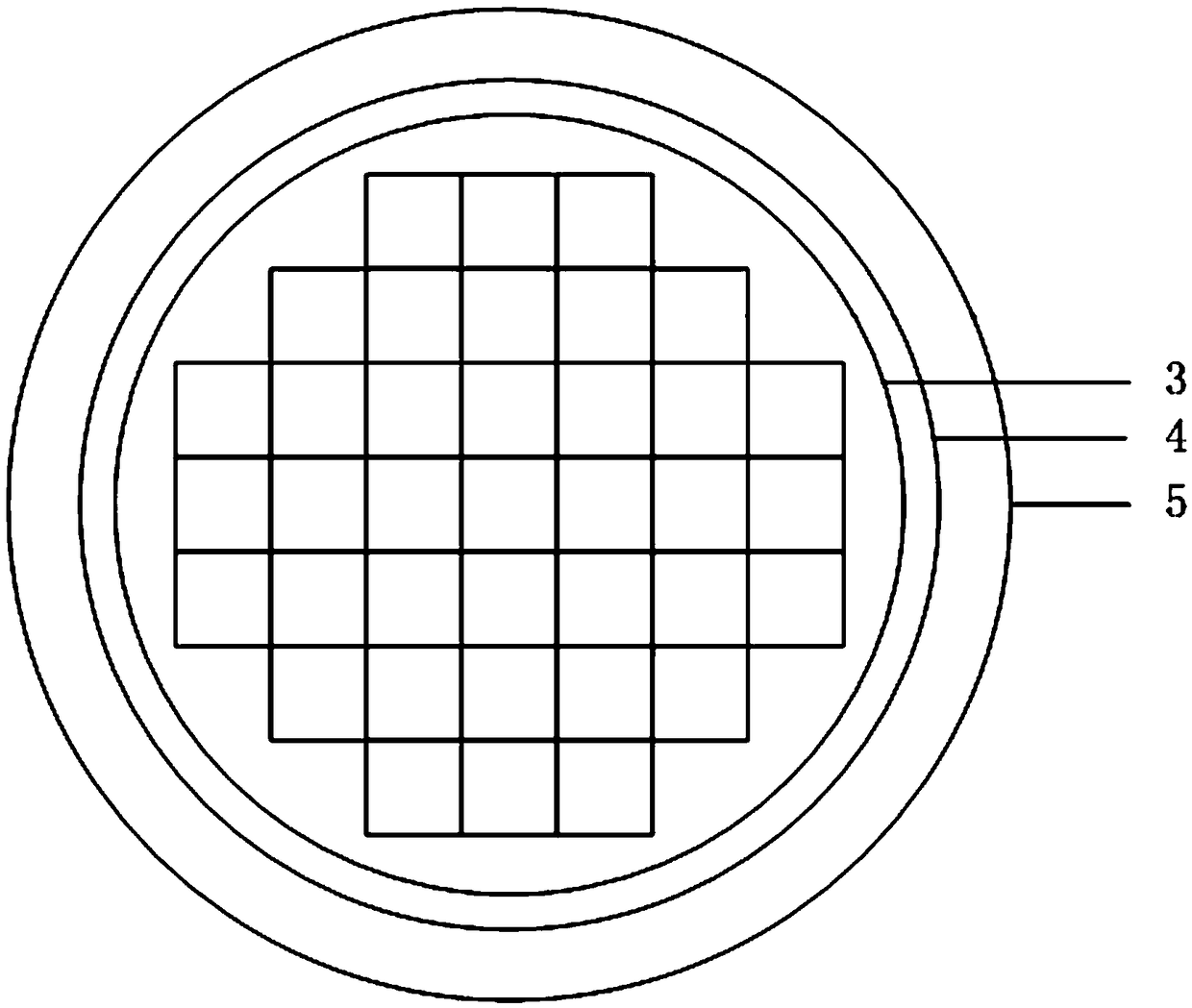

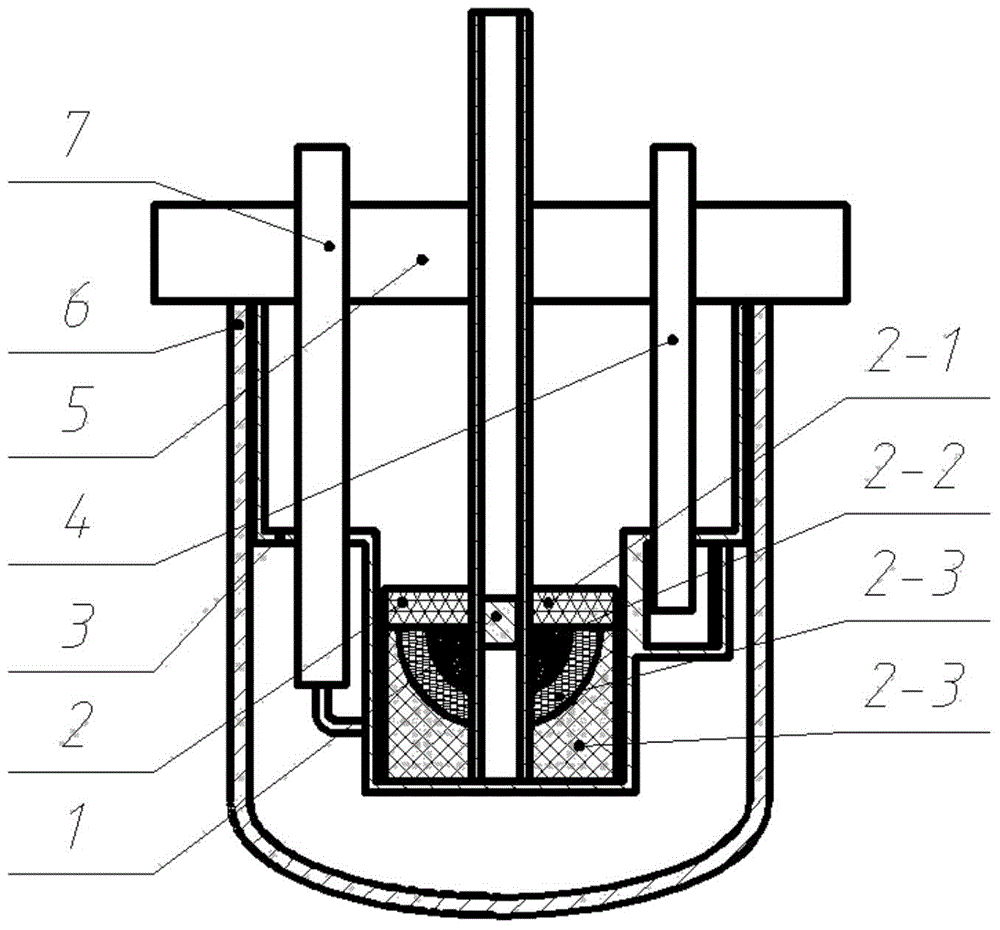

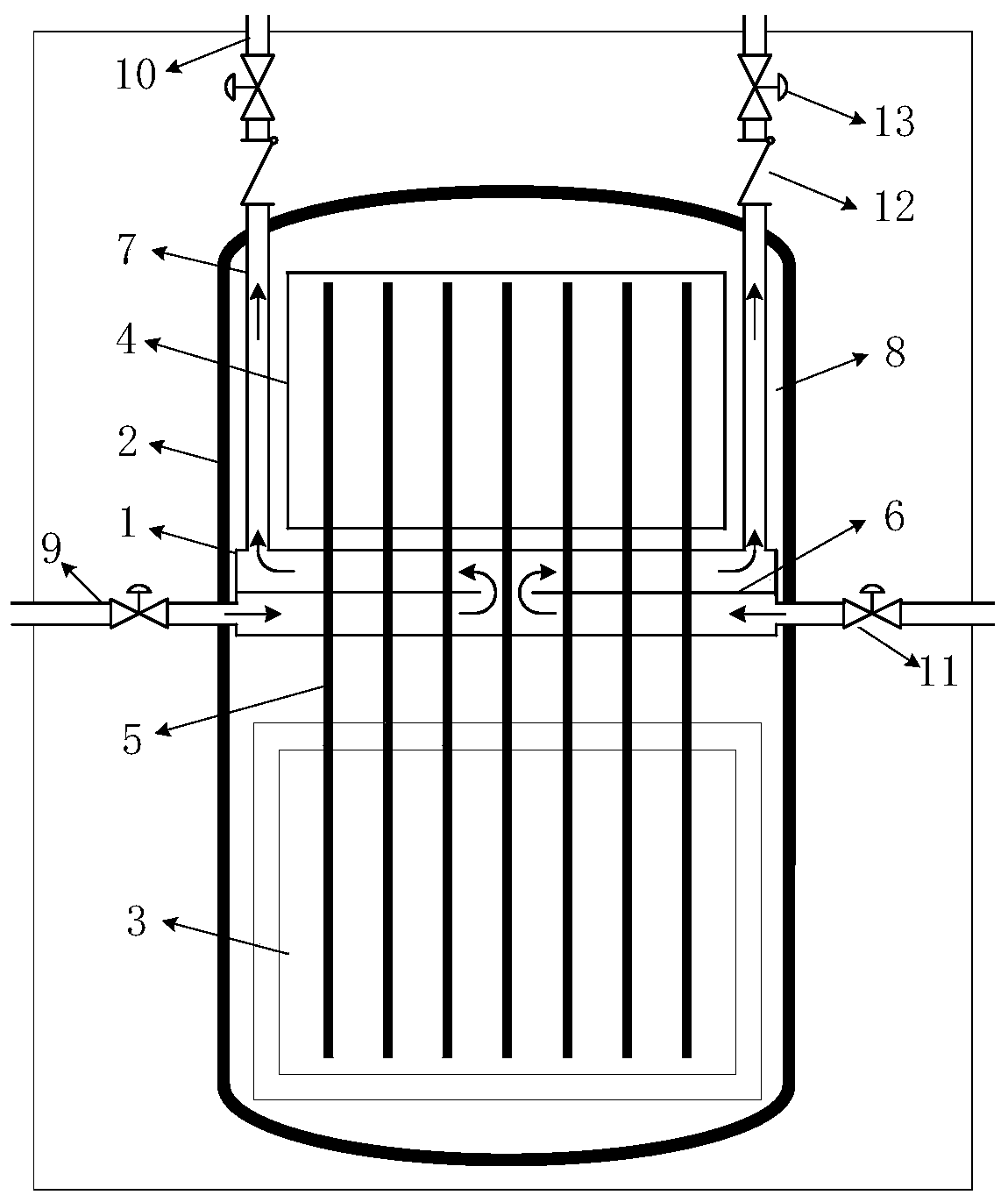

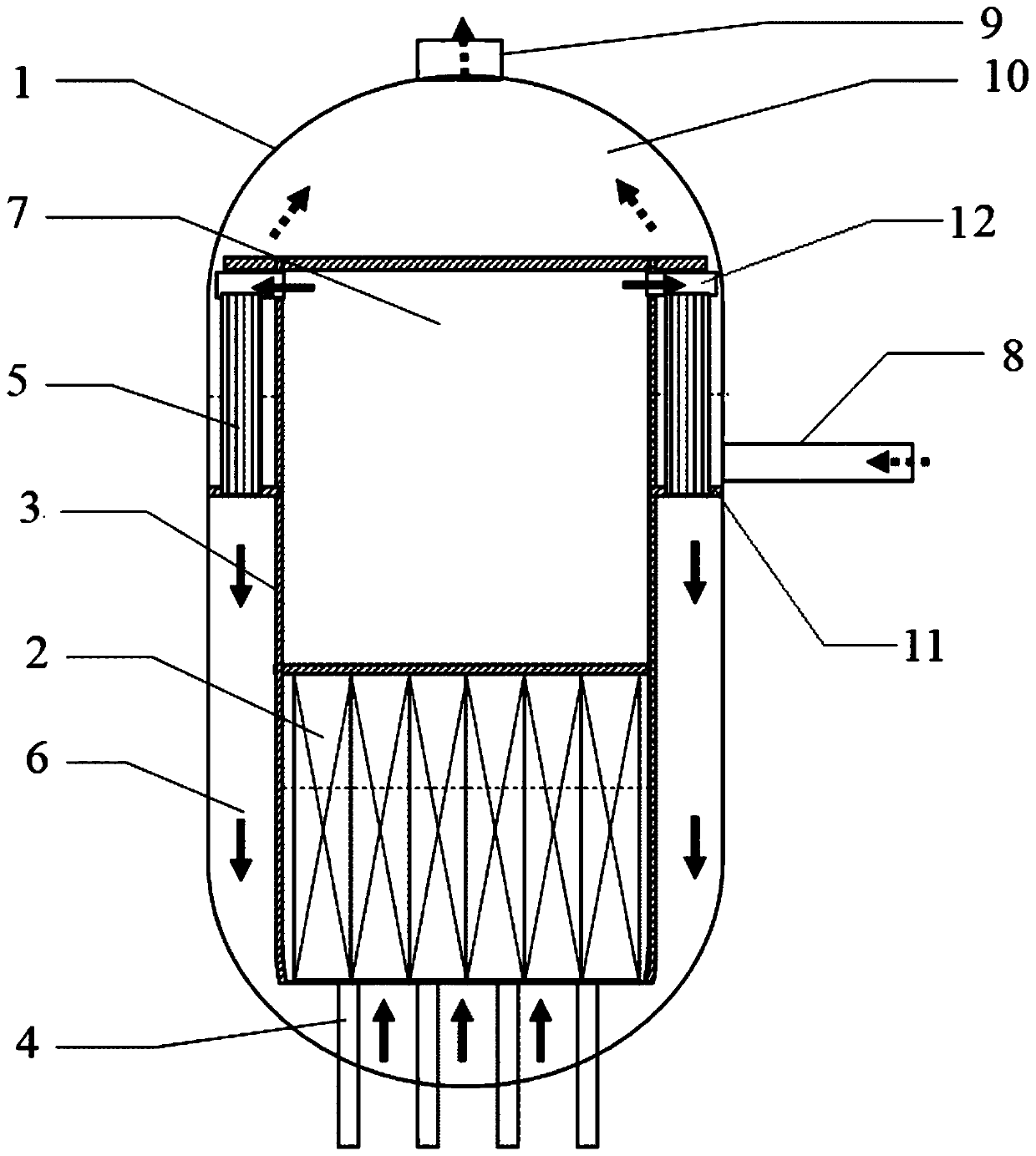

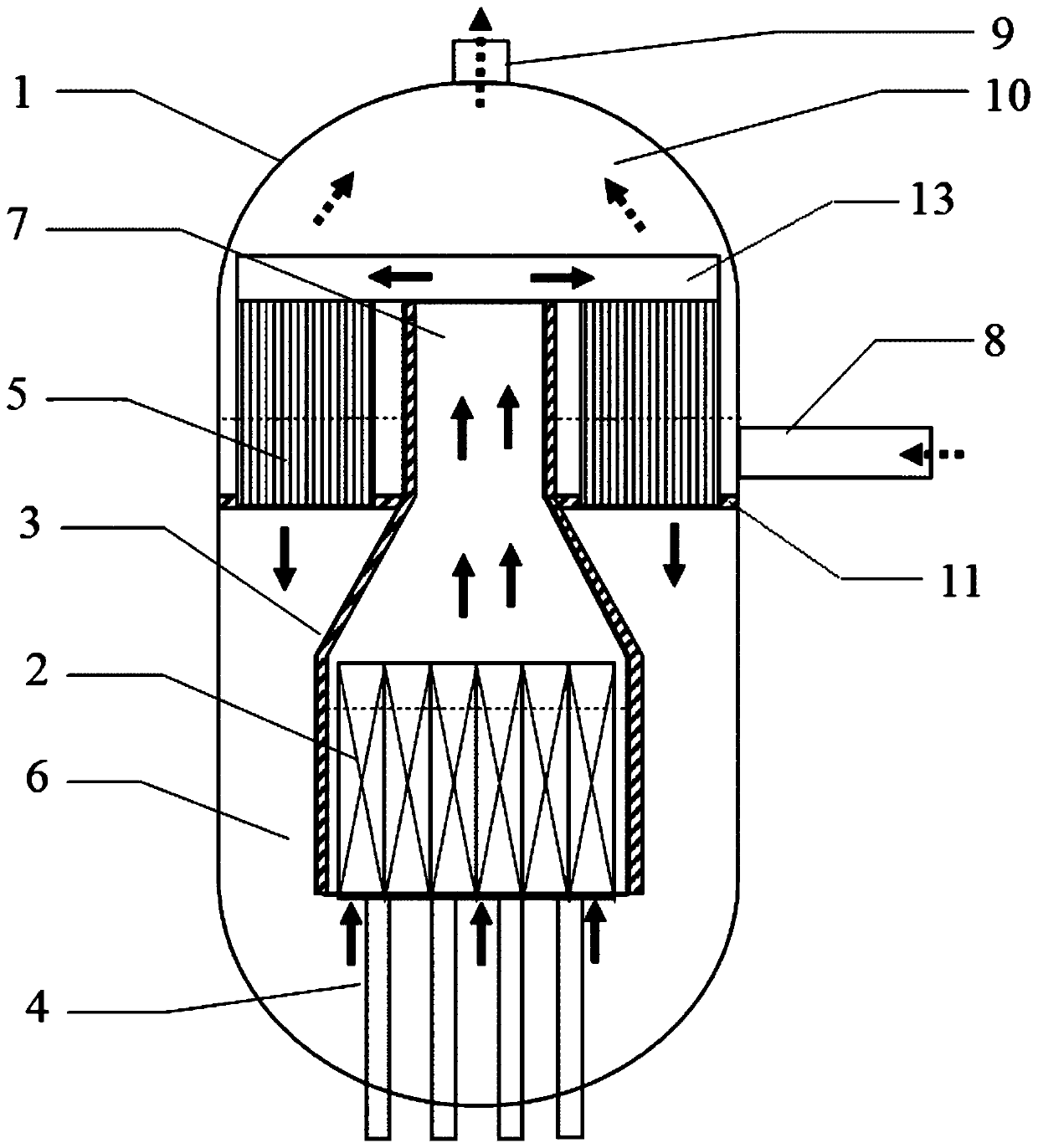

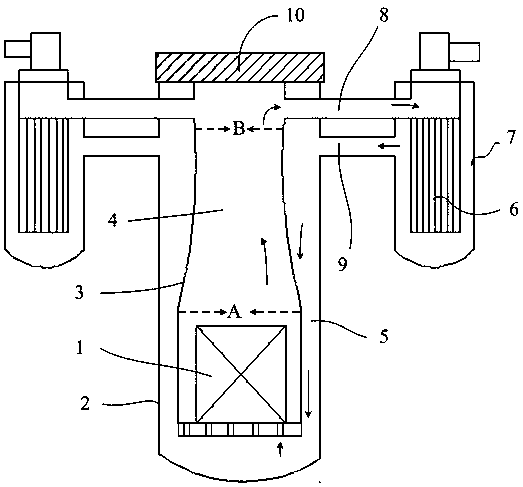

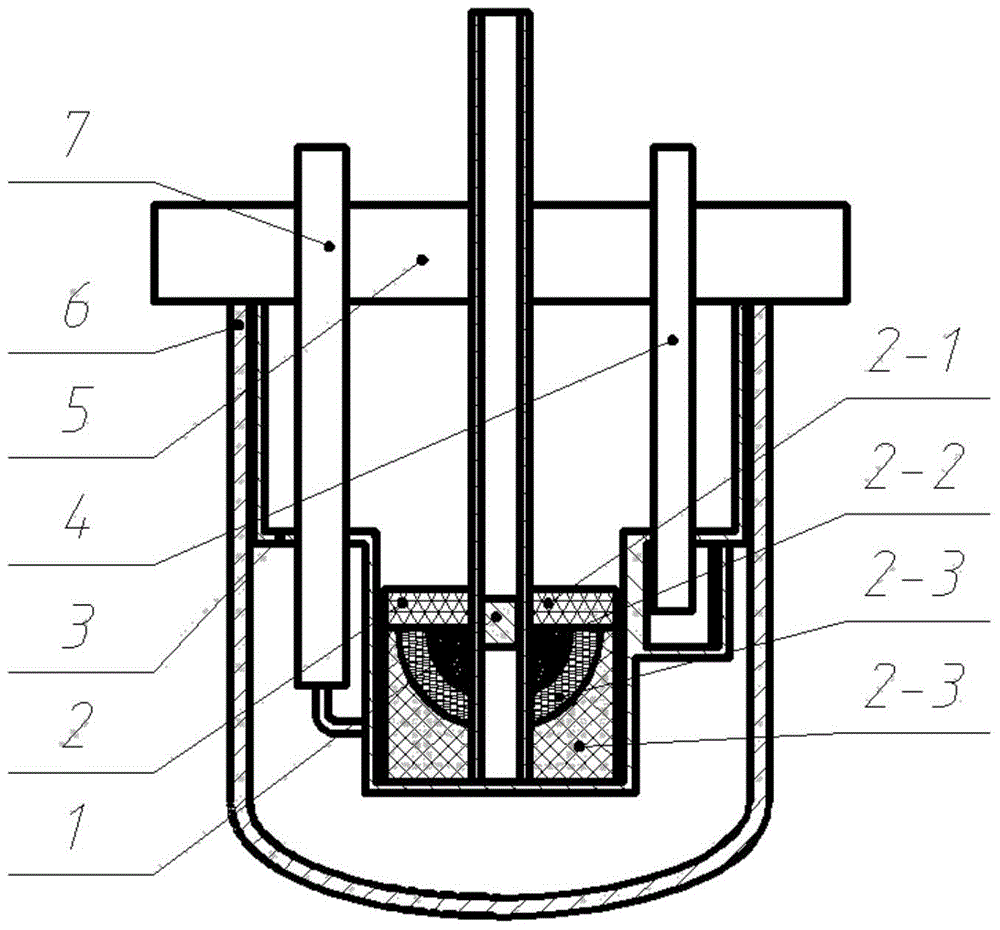

Two-phase natural circulation integrated reactor

PendingCN111599495AReduce failureReduce riskNuclear energy generationCooling arrangementNuclear reactorSecondary loop

The invention belongs to the technical field of nuclear reactors, and particularly relates to a two-phase natural circulation integrated reactor which comprises a pressure vessel (1), a hanging basket(3) in the pressure vessel (1), a reactor core (2) located in the bottom of the hanging basket (3), and a heat exchange area (5) located on the periphery of the top of the hanging basket (3) and communicated with a secondary loop, and the space, located above the reactor core (2), in the hanging basket (3) is a primary loop reactor core outlet chamber (7). First steam generated by the reactor core (2) enters the heat exchange area (5) through the primary loop reactor core outlet cavity (7) to heat cooling water provided by the second loop into second steam, then the second steam is convertedinto condensate water and flows back to the reactor core (2), and the second steam is conveyed to the second loop. The reactor and the steam generator are integrated in the pressure vessel 1, equipment is simplified, the design of a main pump, a primary loop pipeline, a pressure stabilizer and the like is canceled, the risks of active equipment faults and crevasse are reduced, and the influence ofradioactive products on secondary loop equipment is avoided.

Owner:CHINA NUCLEAR POWER ENG CO LTD

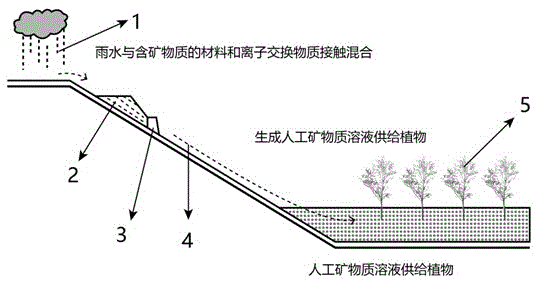

Preparation method of bioavailable mineral ion chelate artificial mineral solution

InactiveCN105523830AImprove natural circulationAccessory food factorsLiquid fertilisersSlagMineral ions

The invention relates to a preparation method of a bioavailable mineral ion chelate artificial mineral solution. On a land or in a water area where minerals which are essential to growth of animals and plants are insufficient, mineral-containing iron steel mineral slag and an ion chelate undergo ion chelation in a water solution so as to form the bioavailable mineral ion chelate artificial mineral solution; and pH value of the bioavailable mineral ion chelate artificial mineral solution is controlled to below 9. The invention has the following beneficial effect: the product is used for improving the natural circulation function on a land or in a water area where minerals which are essential to animals, plants and microbes are insufficient.

Owner:NANJING FORESTRY UNIV

A novel nature cycle cooling lead-based fast reactor

ActiveCN108520786AImprove securityImprove economyNuclear energy generationCooling arrangementInterior spaceNuclear engineering

The invention discloses a novel nature cycle cooling lead-based fast reactor. The novel nature cycle cooling lead-based fast reactor at least includes: a core, a main container, a core shroud, a heatpool, a cool pool, a main heat exchanger and a reactor top cover. The main container is a circular column metal container, the two ends of the main container are sealed; the core shroud is arranged inthe main container, the inner space of the main container is divided into the heat pool and cool pool; at least one part of the core shroud has a circular column metal plate with a taper curved surface, the core is arranged at the bottom of the heat pool of the main container, the height difference is existed between the core and the main heat exchanger, the main heat exchanger is connected withthe heat pool and cool pool, and the nature circulation canal of the cooling agent is formed by the main heat exchanger, cool pool and heat pool. The nature cycle capability of the first loop coolingagent can be enhanced, and the security and economy of the nature cycle cooling lead-based fast reactor are effectively improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

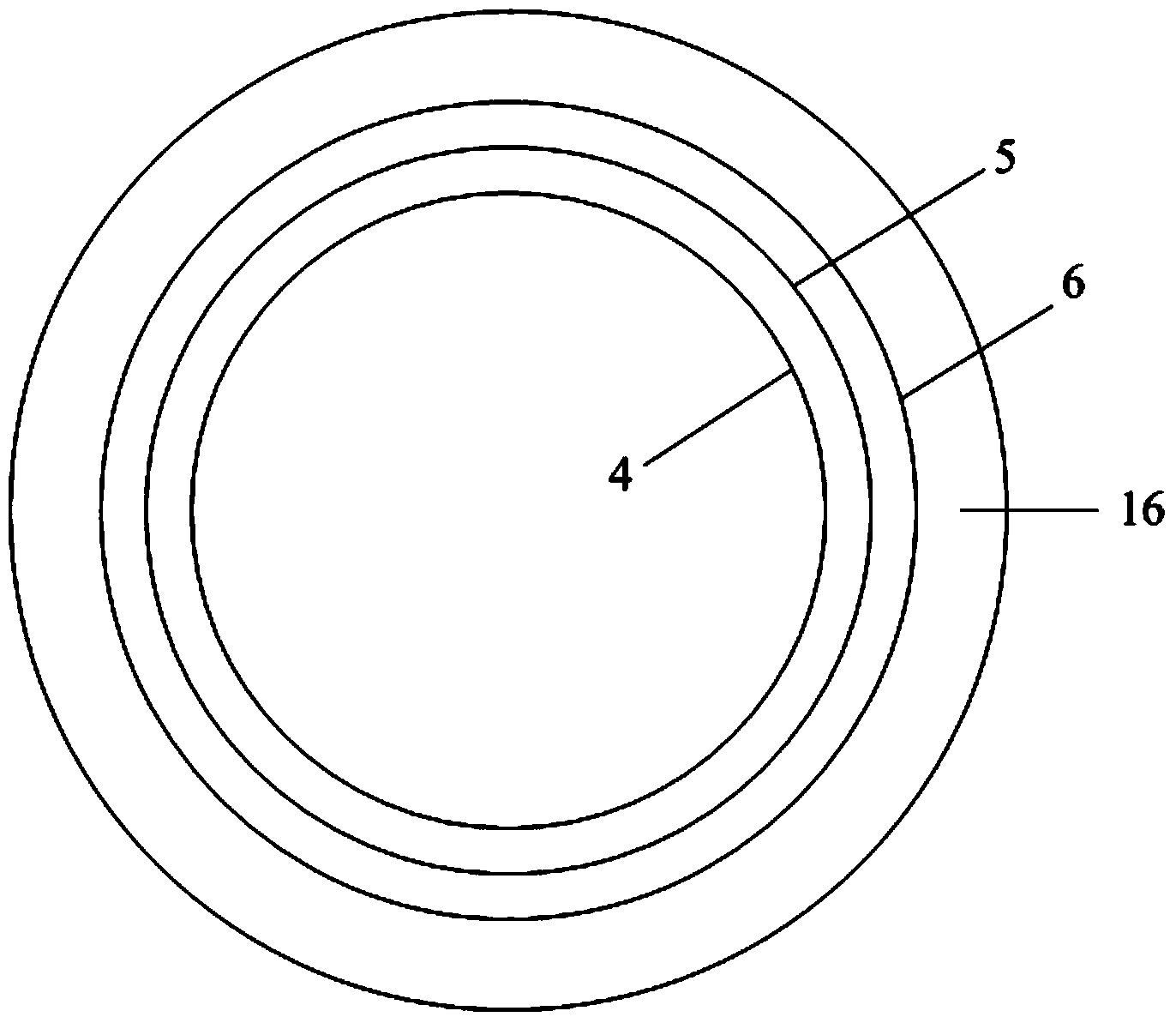

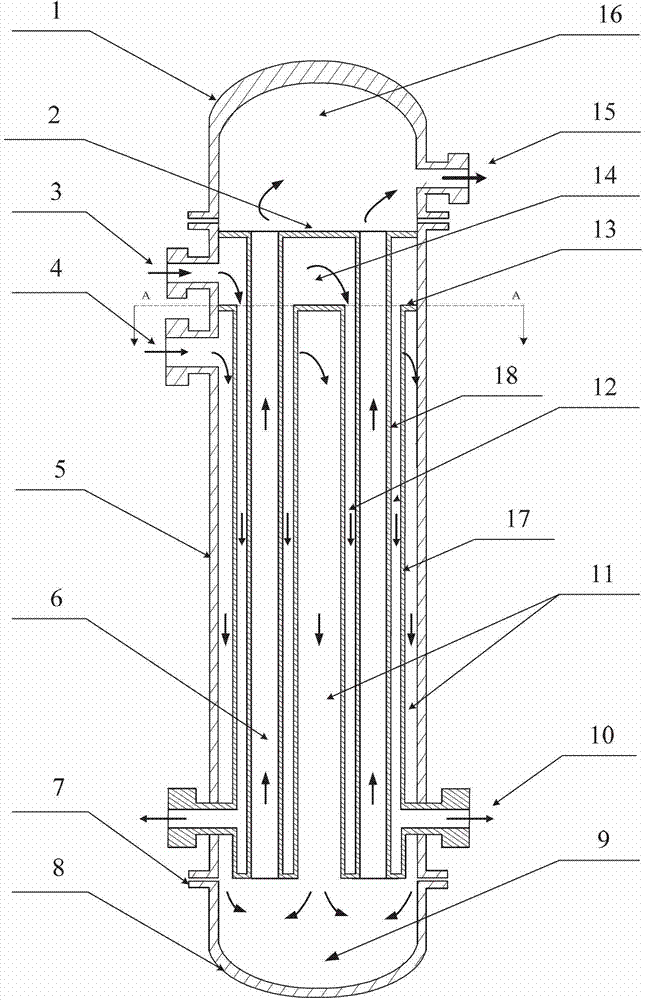

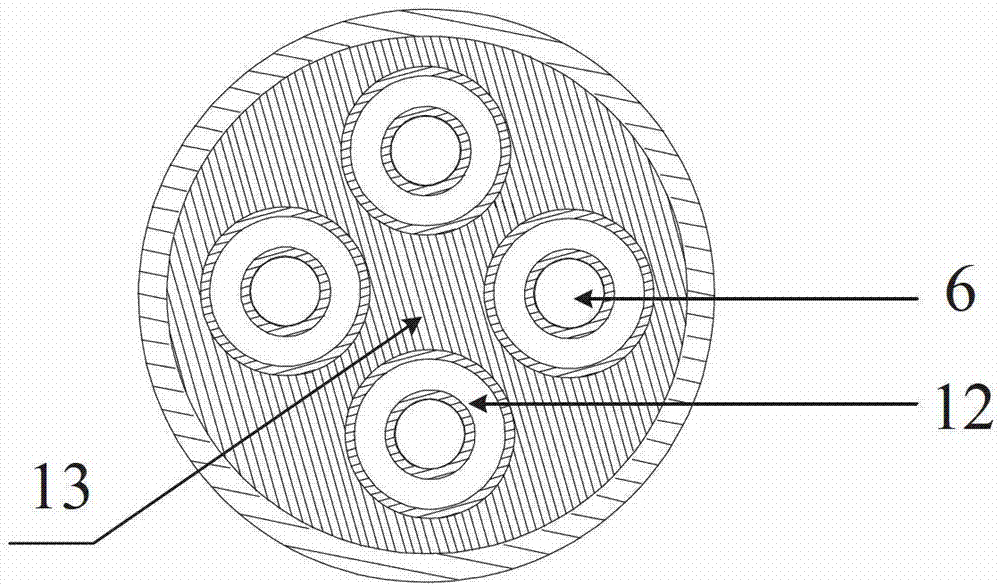

Steam generator for metal fast reactor

InactiveCN108758587ALow flow resistanceSmall pressure dropCorrosion preventionStationary tubular conduit assembliesNuclear engineeringSecondary side

The invention provides a steam generator for metal fast reactor. The steam generator comprises a container body and a heat exchanger arranged in the container body. The container body is provided witha primary side outlet, a primary side inlet, a secondary side outlet and a secondary side inlet from bottom to top, and at least a shell pass and a first pipe pass are formed in the container body. Ahigh-temperature medium enters the shell pass through the primary side inlet, and is exported from the primary side outlet after cooling. A low-temperature medium enters the first pipe pass through the secondary side inlet, and is exported from the secondary side outlet after heating. According to the steam generator for the metal fast reactor, the mode that the high-temperature medium flows through the shell pass and the low-temperature medium flows through the pipe pass is used, the velocity of the shell pass as well as the abrasion degree of the pipe wall of a heat exchange pipe and the container wall are reduced, the circulation ability is improved, and the reliability and safety of the steam generator are improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

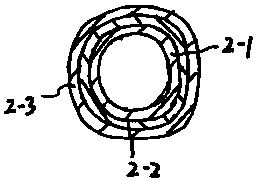

Steam generator for metal fast reactor

InactiveCN108800094ALow flow resistanceReduce manufacturing difficultySteam boilersNuclear engineeringAlloy

The invention provides a steam generator for a metal fast reactor. The steam generator for the metal fast reactor comprises a container body and a U-shaped heat exchange pipe arranged in the containerbody. A shell pass and a pipe pass are formed in the container body. A secondary side outlet and a primary side inlet are arranged from bottom to top on one side of the container body. A secondary side inlet and a primary side outlet are arranged from bottom to top on an opposite side. A high-temperature medium enters the shell pass through the primary side inlet and is exported through the primary side outlet after being cooled. A low-temperature medium enters the pipe pass through the secondary side inlet and is exported from the secondary side outlet after being heated. Furthermore, the pipe wall of the heat exchange pipe is manufactured by adoption of lamination of multiple layers of pipe walls; each pipe wall is made by adoption of stainless steel and nickel base alloy; on the basisthat safety and reliability needed by the steam generator are guaranteed, manufacturing cost and manufacturing difficulty of the steam generator are lowered; and the integral economy of the steam generator is improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Passive steel containment heat export system

PendingCN113593733AEliminate dependenciesImprove securityNuclear energy generationCooling arrangementNuclear plantThermodynamics

The invention belongs to the technical field of nuclear power plant reactor safety systems, and particularly relates to a passive steel containment heat export system, which is characterized in that a cooling cover (7) is arranged on the side wall of a containment (1) of a reactor and forms a closed annular cavity (5) with the containment (1), a cooling water loop is arranged on the cooling cover (7), the cooling water loop can inject cooling water into the annular cavity (5) from the bottom of the cooling cover (7) in a passive mode, the cooling water absorbing heat in the annular cavity (5) can flow back into the cooling water loop from the top of the cooling cover (7) in a passive mode, and the containment (1) is made of stainless steel. According to the invention, dependence of a traditional active safety system on a safety-level power supply is eliminated, high natural circulation capacity and heat removal capacity are achieved, and the capacity of relieving accident consequences for a long time without intervention after an accident is provided.

Owner:CHINA NUCLEAR POWER ENG CO LTD

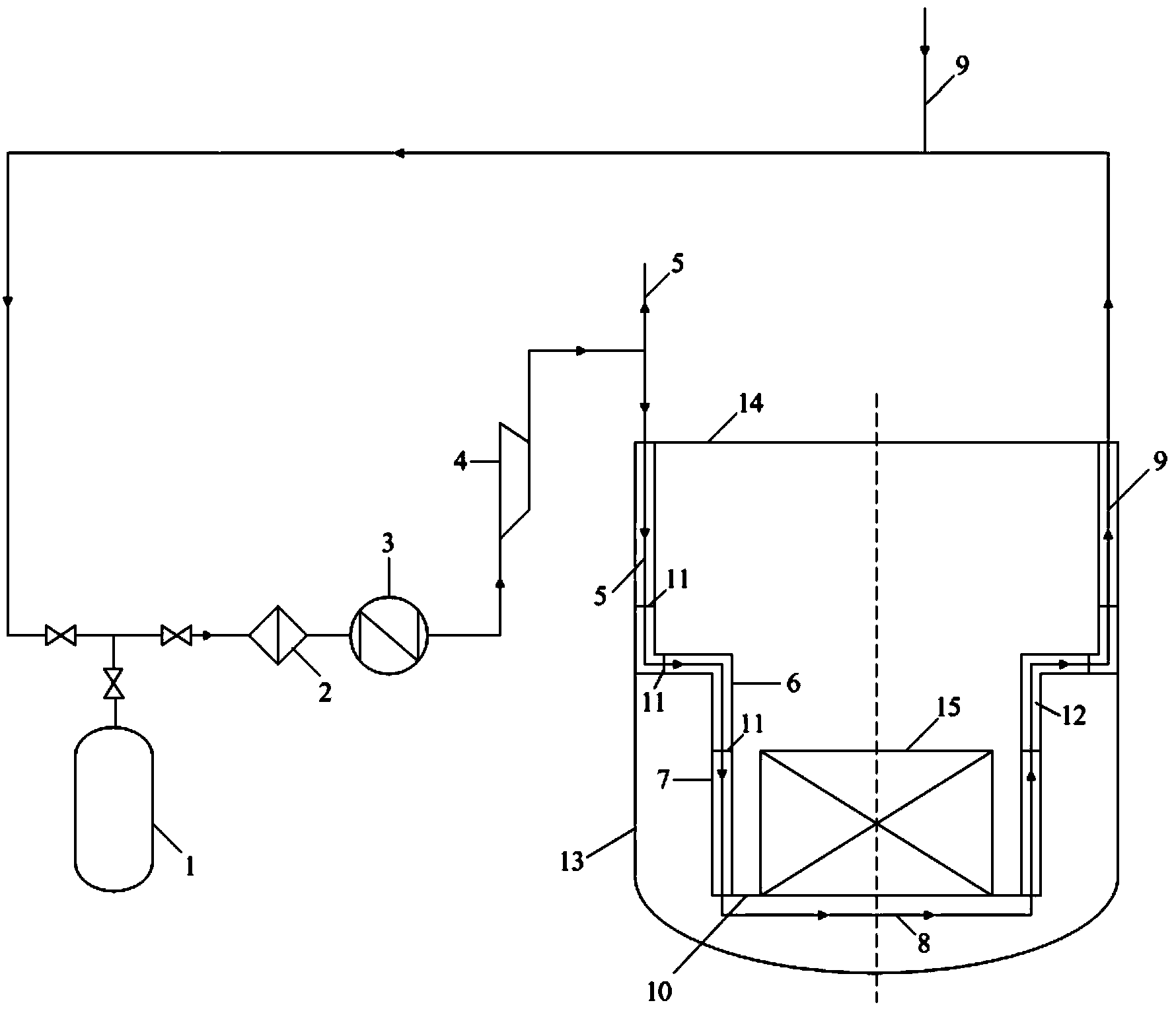

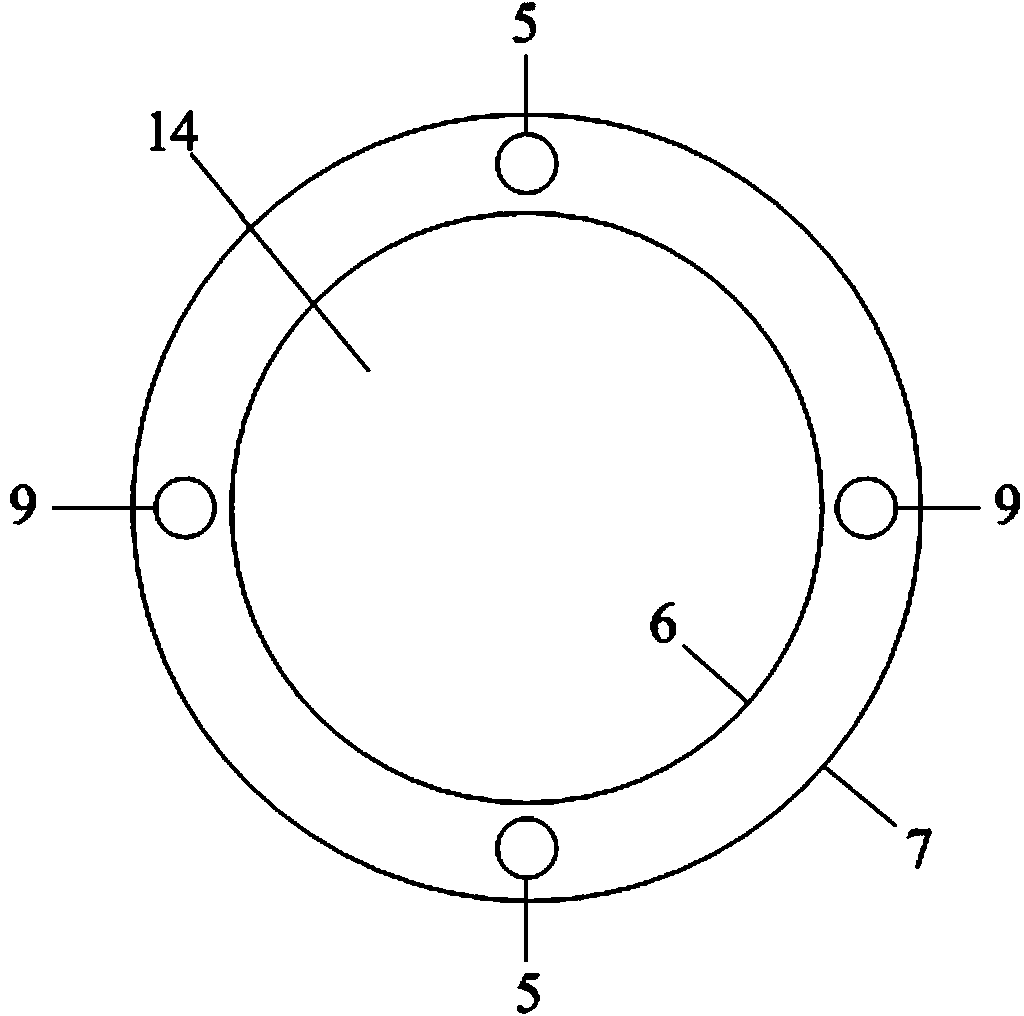

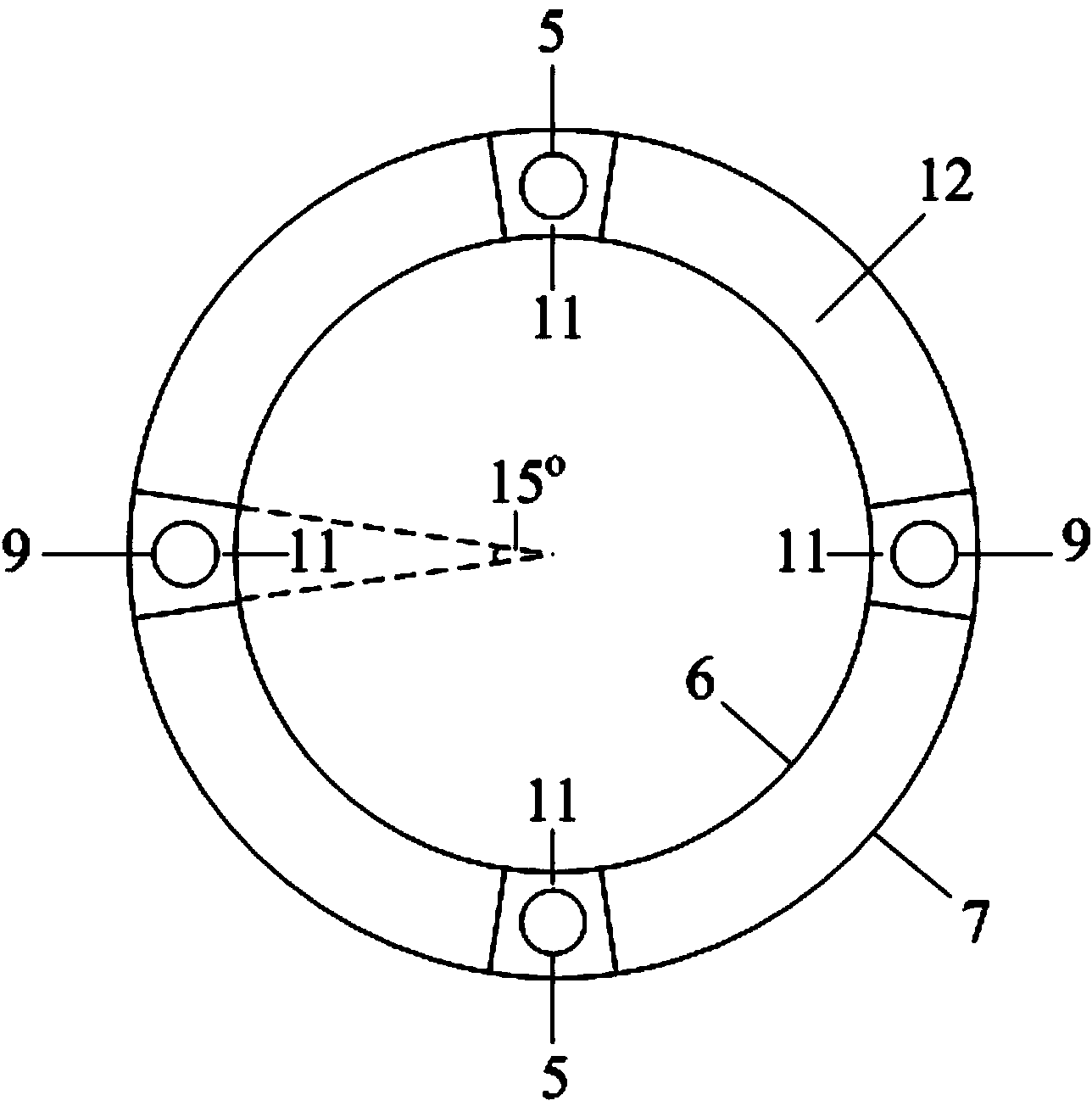

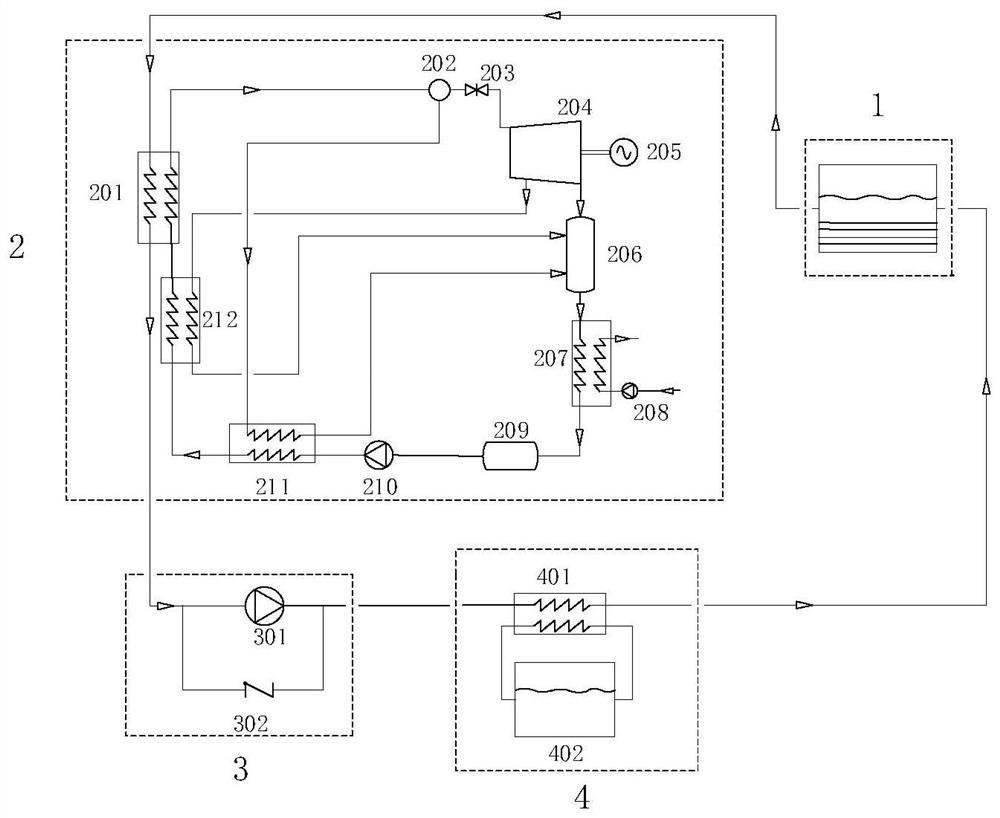

System and method for improving natural circulation capability of nuclear power system by using core waste heat

ActiveCN109322718BImprove natural circulationReduce dependenceSteam engine plantsExternal energyProcess engineering

The invention discloses a system and method for improving natural circulation capability of a nuclear power system by utilizing reactor core waste heat. According to the system, based on a thought that waste heat (reactor core fuel waste heat, spent fuel waste heat and the like) is brought away by utilizing natural circulation in the nuclear power system, on the basis of weak drive force and low power conversion efficiency of an original natural circulation system, an external energy source is not introduced; excess heat of a heat source is recovered by using a designed thermoelectric power generation loop module and electric energy is generated; and then, an electric pump in a loop is driven by the generated electric energy to further drive fluid in the loop to flow, and therefore, the natural circulation capability of the system is greatly enhanced. Operation of the system depends on the own energy of the natural circulation system, and on the premise that the passive characteristicof the natural circulation system is not changed, cooling capability of the natural circulation system is improved.

Owner:XI AN JIAOTONG UNIV

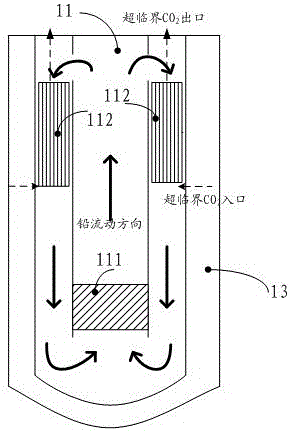

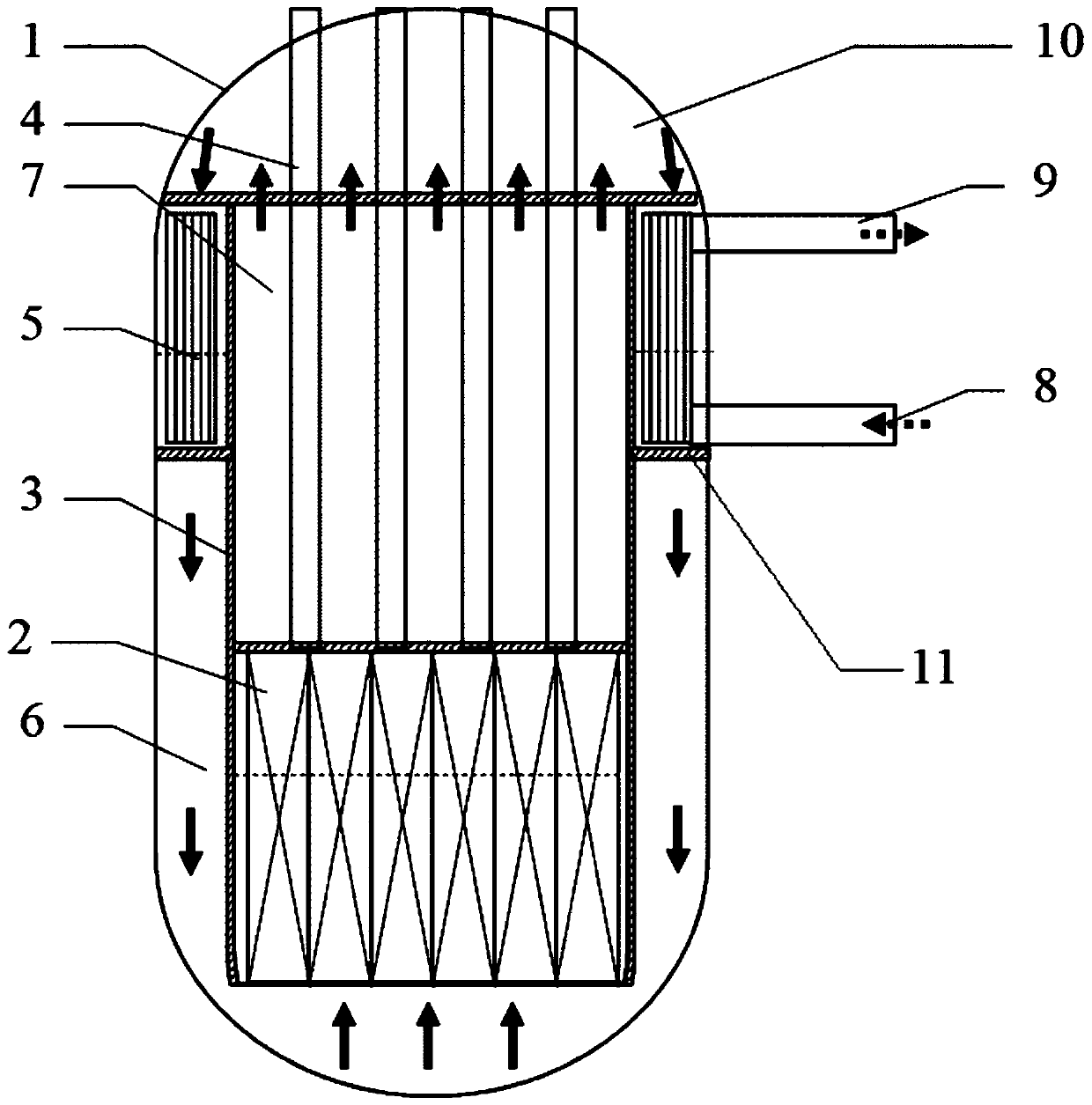

Natural circulation heat exchanger for discharging waste heat of supercritical water reactor

InactiveCN102820067BImprove heat transfer effectReduce resistanceNuclear energy generationCooling arrangementNuclear engineeringWater flow

The invention belongs to the technical field of nuclear power plant safety and especially relates to a natural circulation heat exchanger for discharging waste heat of a supercritical water reactor. Supercritical water flows in a heat fluid supercritical water annular channel, so as to form a first collateral circulation; the heat fluid supercritical water annular channel is a narrow annular pipe; and cold fluid water flows in a cold fluid water descending channel, a lower chamber, a cold fluid water ascending channel and a top chamber, so as to for a secondary collateral circulation. Under the condition of normal tripping or accident emergency tripping of the supercritical water reactor, a supercritical narrow slit natural circulation heat exchanger is used for discharging the waste heat; without any external force, the system failure probability caused by a dynamic part fault and a manual operation error is effectively reduced; and the running safety of the reactor is increased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A small modular reactor coolant system and an experimental method using the same

ActiveCN111951987BImprove natural circulationIncrease disturbanceNuclear energy generationNuclear monitoringTurbulent heat fluxEngineering

The invention discloses a small modular reactor coolant system. In the system, liquid metal gallium is used as a coolant, a certain amount of gas is added to the coolant, and the natural circulation capacity of the liquid gallium metal is increased by the gas, which can also increase its Disturbance to enhance the heat transfer effect; through this system, the liquid gallium metal can be repeatedly increased or decreased, and the doped gas can also be arbitrarily increased or decreased, the air pressure can be adjusted, and the heat transfer capacity and natural circulation of the liquid gallium metal under various conditions can be recorded and analyzed. It provides basic data for building flexible and diverse small modular reactors.

Owner:SOUTHEAST UNIV +1

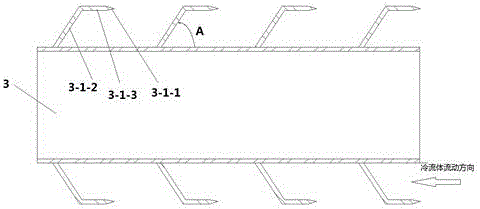

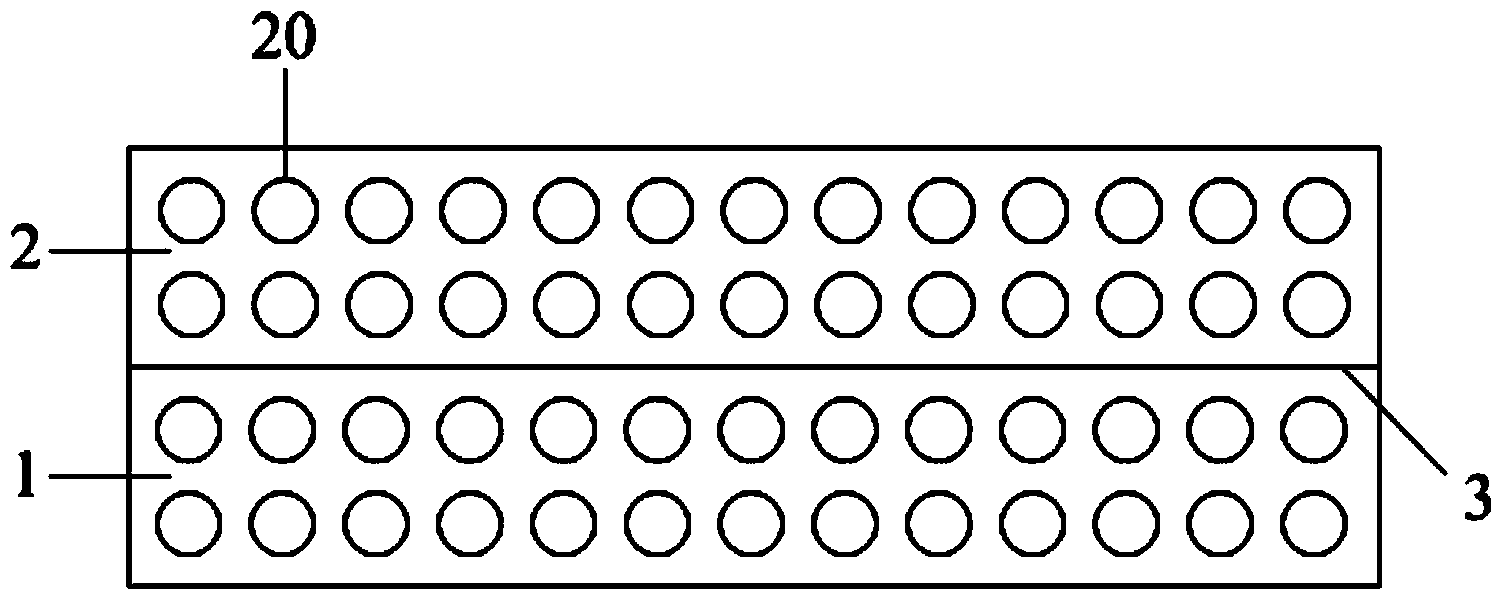

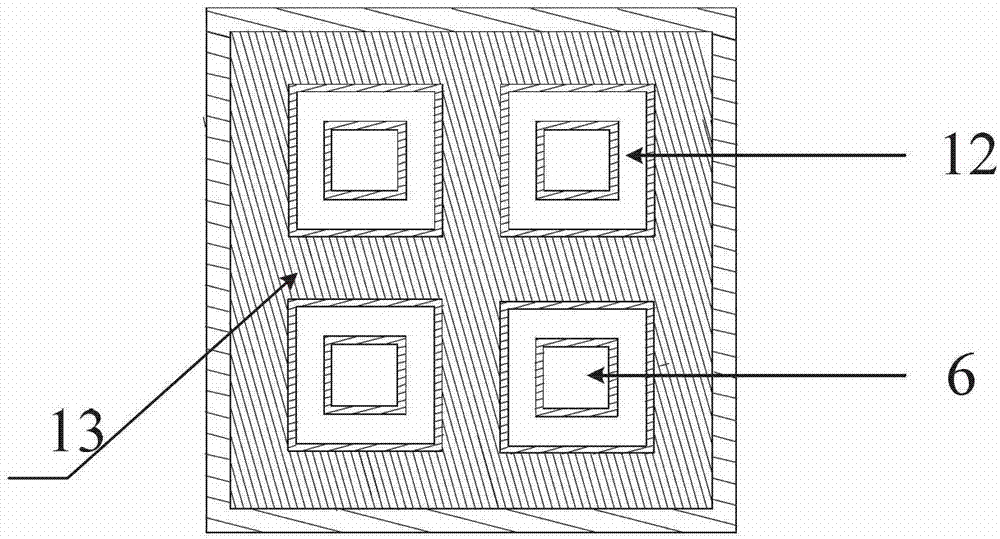

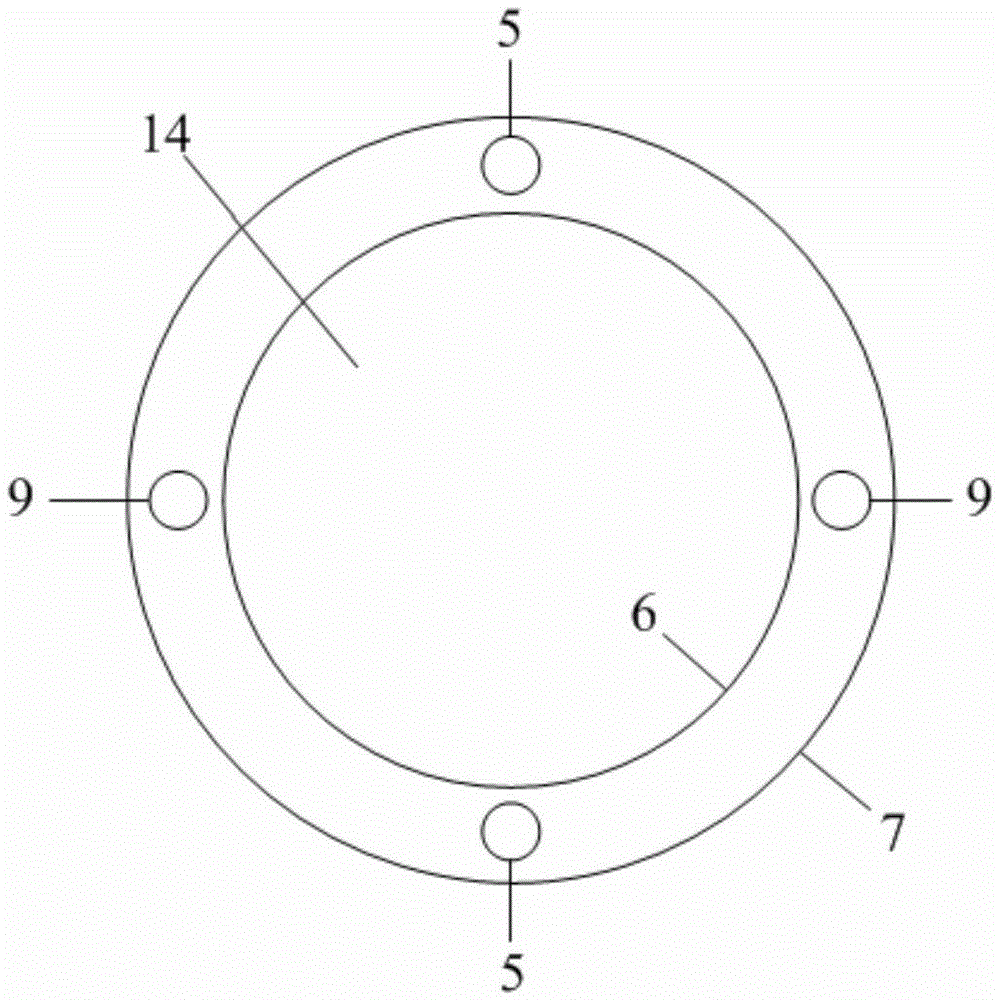

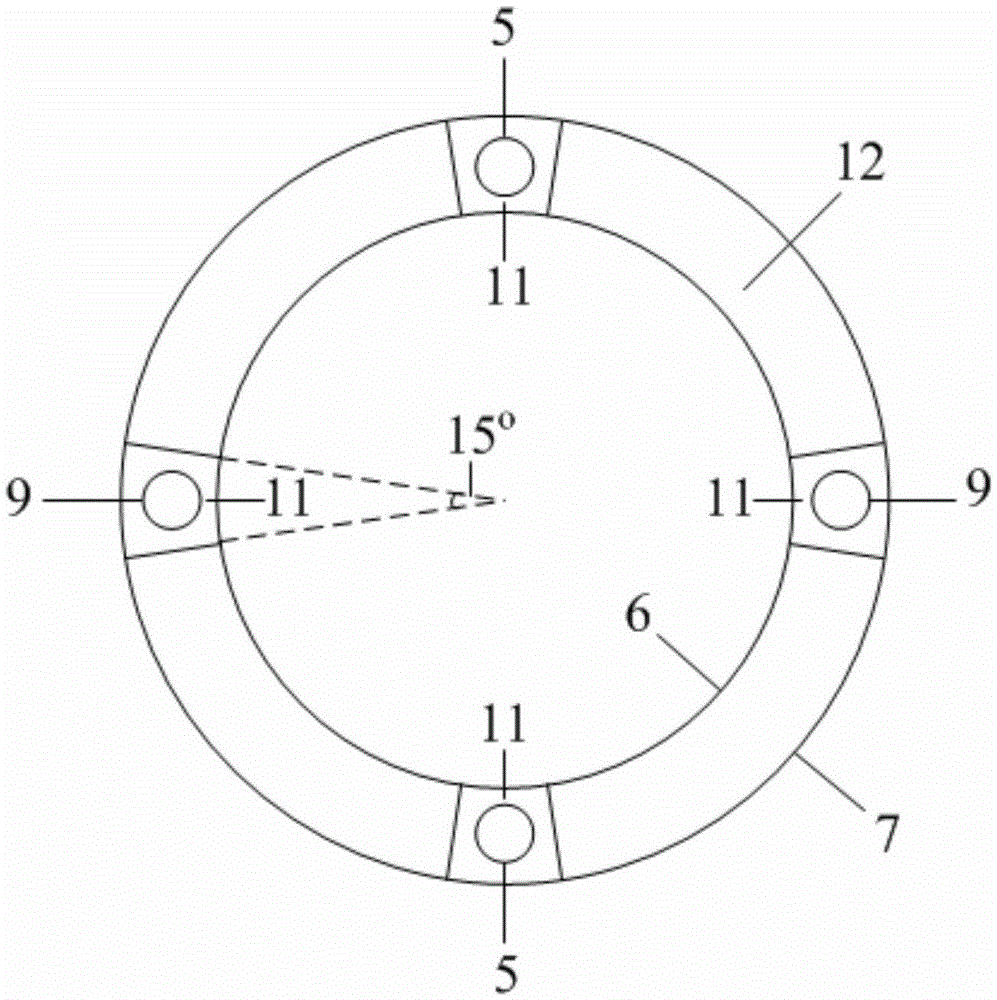

An inner fin heat exchanger

ActiveCN106558350BImprove heat transfer effectUniform internal pressureNuclear energy generationCooling arrangementInternal pressureEngineering

The invention provides a heat exchanger. The heat exchanger comprises a tube side and a shell side, wherein the tube side comprises an inlet tube, an inlet chamber, a heat transfer tube bundle, an outlet chamber and an outlet tube; a hot fluid enters the inlet chamber through the inlet tube and flows through the heat transfer tube bundle, the outlet chamber and the outlet tube in sequence; the shell side comprises an inlet passage, an inner shell, an outer shell and an outlet passage; and a cold fluid flows through the space defined by the inlet passage, the inner shell and the outer shell and the outlet passage in sequence. The heat exchanger is characterized in that inner fins are arranged in each heat transfer tube to divide the heat transfer tube into a plurality of small passages, and communicating holes are formed in the inner fins so that every two adjacent small passages communicate with each other. According to the heat exchanger, the inner fins are arranged in the heat transfer tube bundle to enhance heat exchange and balance internal pressure; and the pressure and heat exchange requirements of the waste heat exchanger are met through optimization of the structures of the inner fins.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Accelerator-driven lead-bismuth cooled subcritical traveling wave reactor

ActiveCN104464842BImprove securityAvoid issues where fuel consumption must be higher than 40%Nuclear energy generationCooling arrangementLead bismuthCombustion

The invention discloses an accelerator driven lead bismuth cooling subcritical traveling wave reactor. The accelerator driven lead bismuth cooling subcritical traveling wave reactor comprises a mobile neutron source target, a reactor core fuel, a reactor inner component, main heat exchangers, a reactor top cover, a reactor container and a main pump. An external source neutron is provided via the mobile neutron source target; the reactor is started and ignited; the traveling wave type reactor is driven to run under the subcritical state, and a combustion wave and a proliferation wave are continued; meanwhile, the heat of the reactor core is taken out by a lead bismuth cooling agent with good chemical inertness so as to guarantee the safety of the reactor, so that the requirement for high-enrichment-degree fissile nuclear fuels for realizing critical start by the critical traveling wave reactor is prevented, the requirements for reactor core materials and high fuel consumption by the traveling of the proliferation wave are lowered, and the practical feasibility, reliability and safety of the traveling wave reactor are improved effectively.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

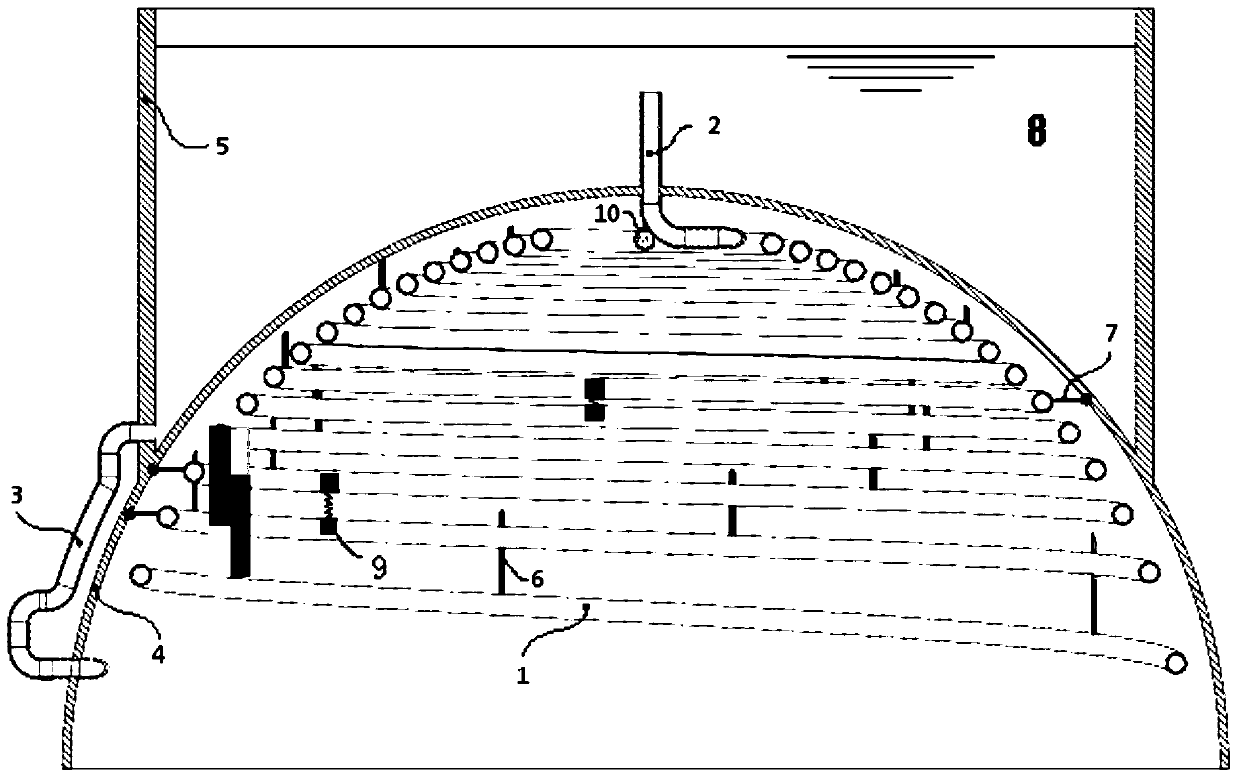

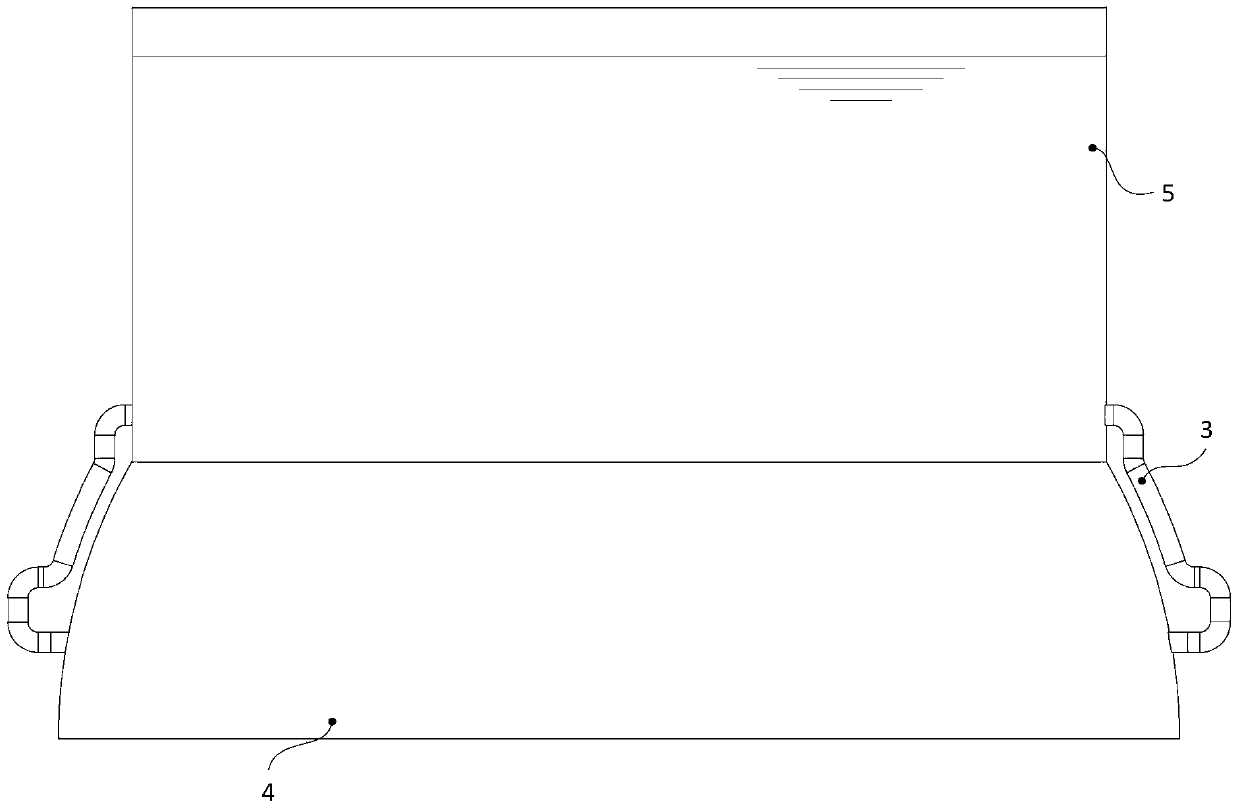

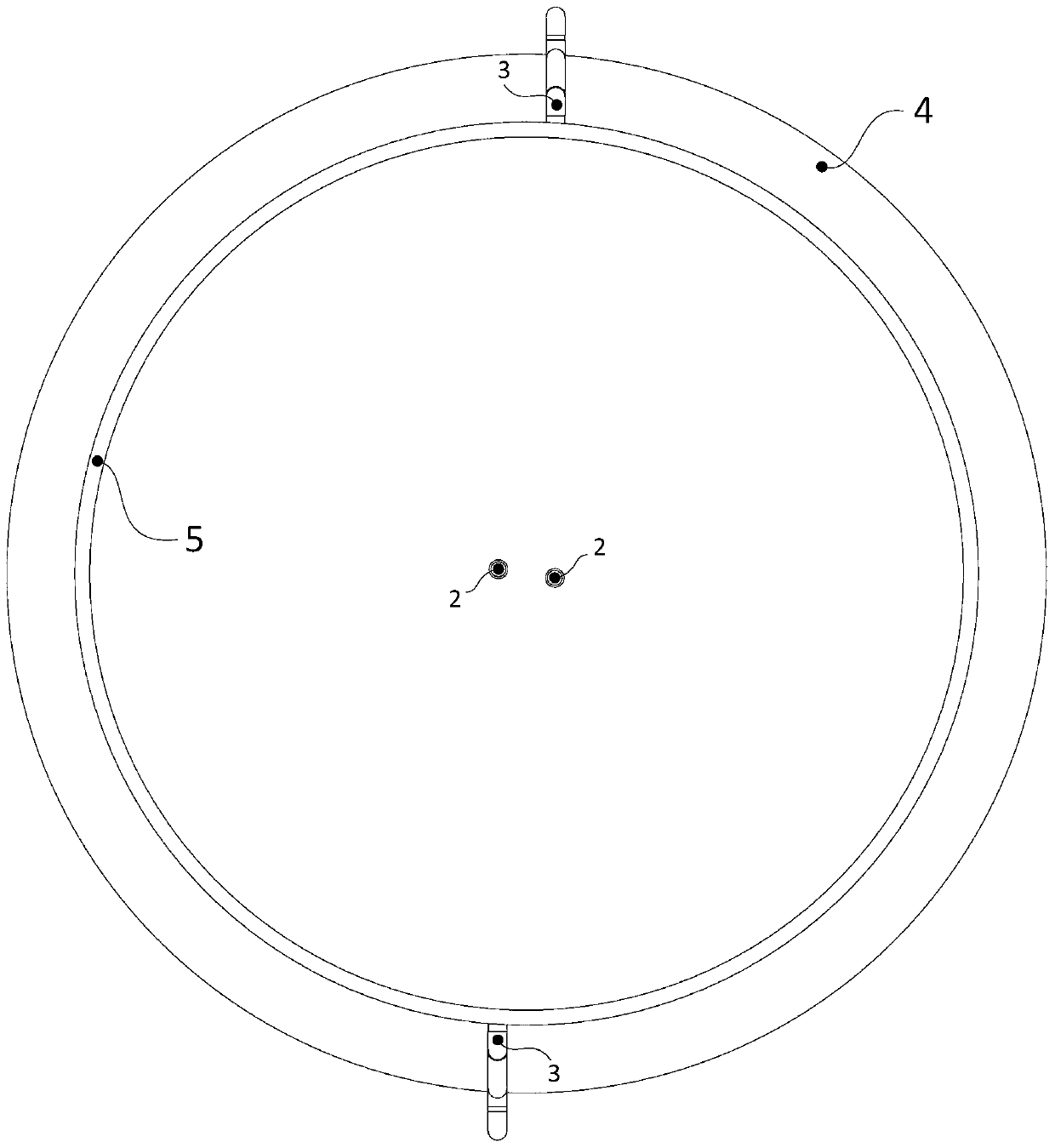

Passive containment cooling system

ActiveCN105355239BIncrease the heat exchange areaTotal heat capacity increaseNuclear energy generationCooling arrangementInherent safetyNuclear reactor core

The invention relates to a passive containment cooling system, which includes a top water tank (5) disposed outside a containment and a spiral coil water cooled wall (1) arranged in the containment, one end of the spiral coil water cooled wall (1) is connected to the top water tank (5) through a natural circulation inlet pipeline (3), the other end of the spiral coil water cooled wall (1) is in connection with the top water tank (5) through a natural circulation outlet pipeline (2), the spiral coil water cooled wall (1) is disposed in a containment dome (4) area and includes one or more spiral coils. The containment cooling system provided by the invention has the advantages of few containment penetration pieces, large heat exchange area, high heat exchange efficiency and good seismic performance, and also has a simple structure, thus providing higher inherent safety for nuclear reactor containments.

Owner:CHINA NUCLEAR POWER ENG CO LTD

A liquid heavy metal cooling natural circulation pool reactor internal auxiliary heating system

InactiveCN103730172BImprove heating efficiencyImprove natural circulationNuclear energy generationCooling arrangementThermal insulationNuclear engineering

The invention discloses an auxiliary heating system in a liquid state heavy metal cooling natural circulating pool type reactor. The system comprises a gas storing tank, a filter, a gas heater, a fan, a gas input tube, an inner-layer thermal insulation plate, an outer-layer thermal insulation plate, a bottom heating ring, a gas output tube, a reactor core coolant entrance baffle, a pipeline fixing steel plate, and pipelines and valves connected between the devices. The system realizes the function of assisting in heating liquid state metal in a main vessel of the liquid state metal cooling pool type reactor, has a simple structure, is convenient to start, can build large-space natural circulation of the liquid state heavy metal in the main vessel even if the reactor is at low power or in shutdown condition after being put into operation, guarantees the temperature of the liquid state heavy metal to be above the melting point, and effectively improves the reliability and safety of the reactor.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com