Major loop circulation device used for nuclear energy system

A technology of circulation device and main circuit, applied in nuclear power generation, cooling device, nuclear engineering and other directions, can solve the problems of low economic efficiency, chemical control and corrosion of structural materials, uneven distribution of oxygen concentration in liquid heavy metal coolant, etc. Economical, enhanced natural circulation ability, and effect of suppressing thermal stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

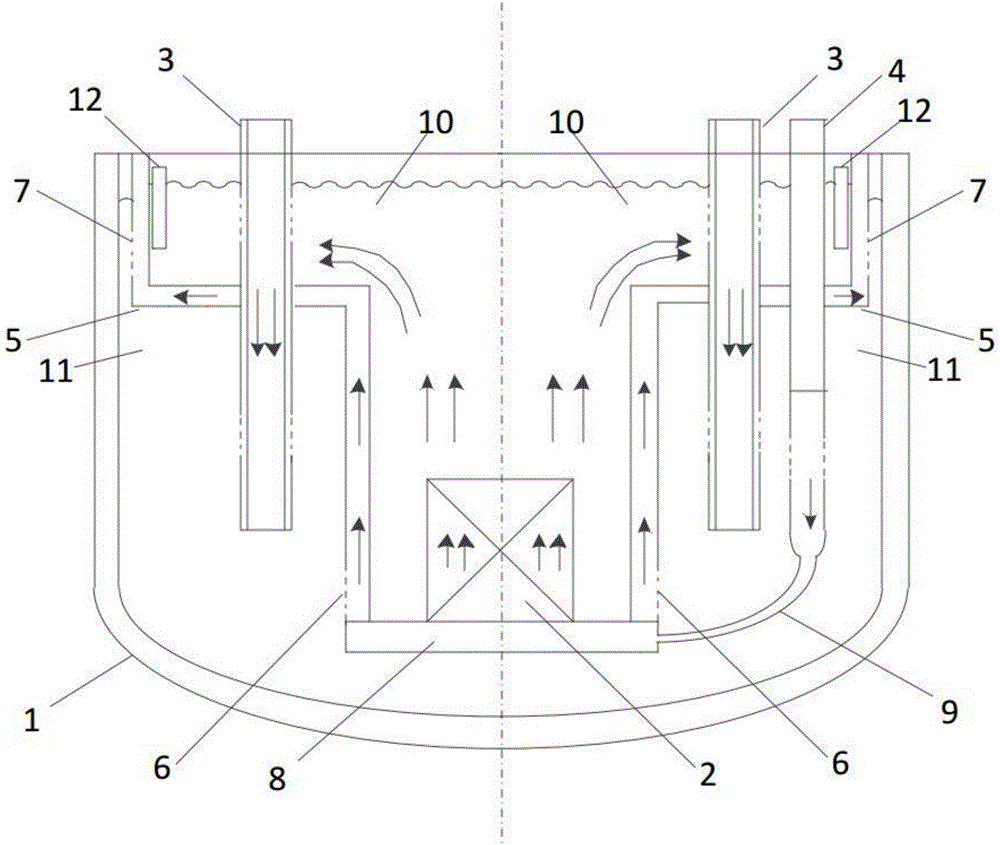

[0022] Such as figure 1 As shown, the present invention is a main circuit circulation device for a nuclear energy system, including a container 1, a core 2, a heat exchanger 3, a main pump 4, a thermal partition 5, a grid header 8, a pipeline 9, and a heat pipe 12 ;

[0023] The thermal partition 5 divides the inner cavity of the container 1 into two parts, the internal hot pool 10 and the external cold pool 11, the thermal partition 5 is a hollow structure, and the thermal partition 5 is provided with a thermal partition inlet end 6 and the outlet port 7 of the thermal partition, the inlet port 6 of the thermal partition is arranged on the side of the cold pool 11 at the lower part of the thermal partition 5, and the outlet port 7 of the thermal partition is arranged at the cold pool 11 at the upper part of the thermal partition 5 side;

[0024] The grid header 8 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com