Patents

Literature

1693results about "Containment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

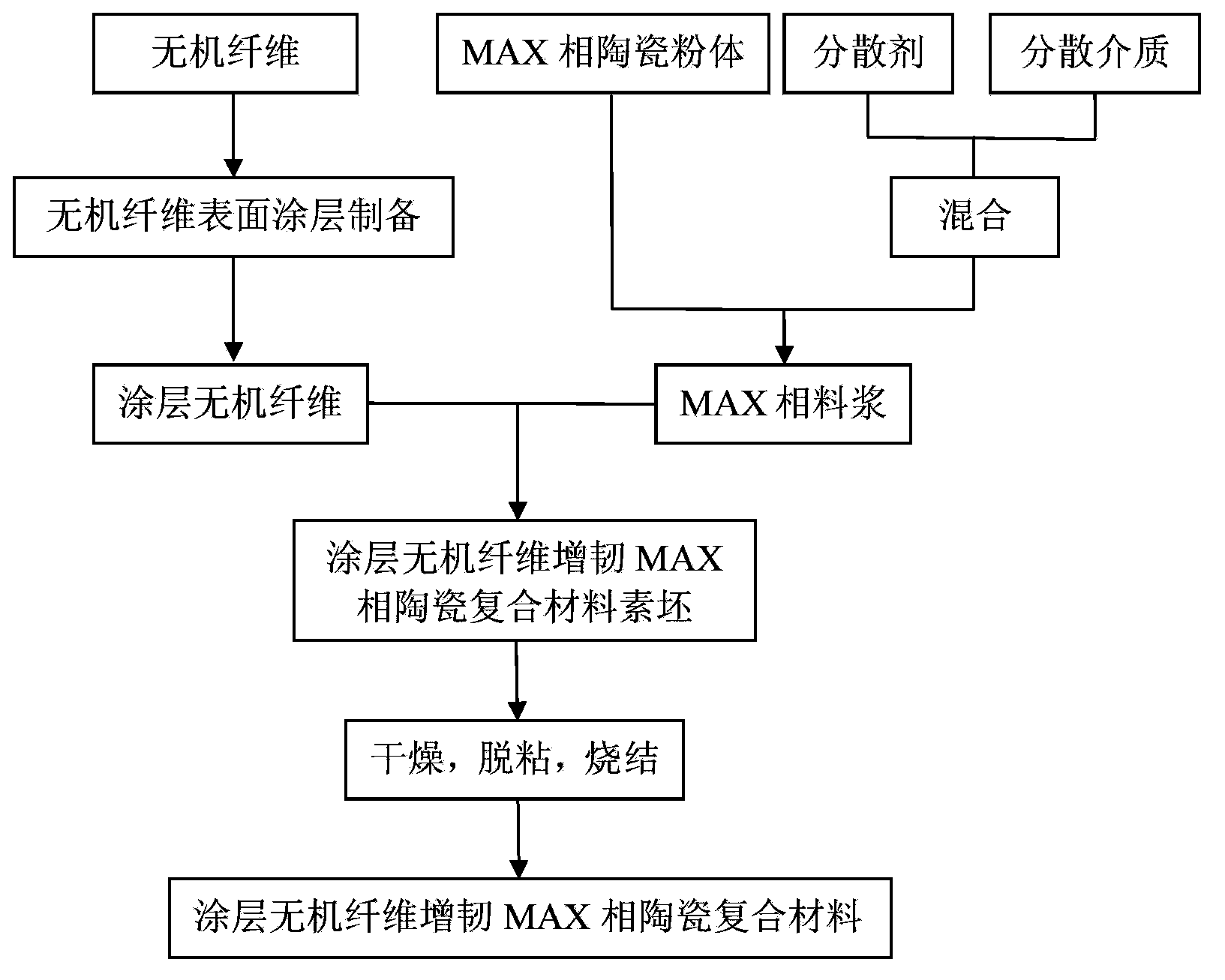

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

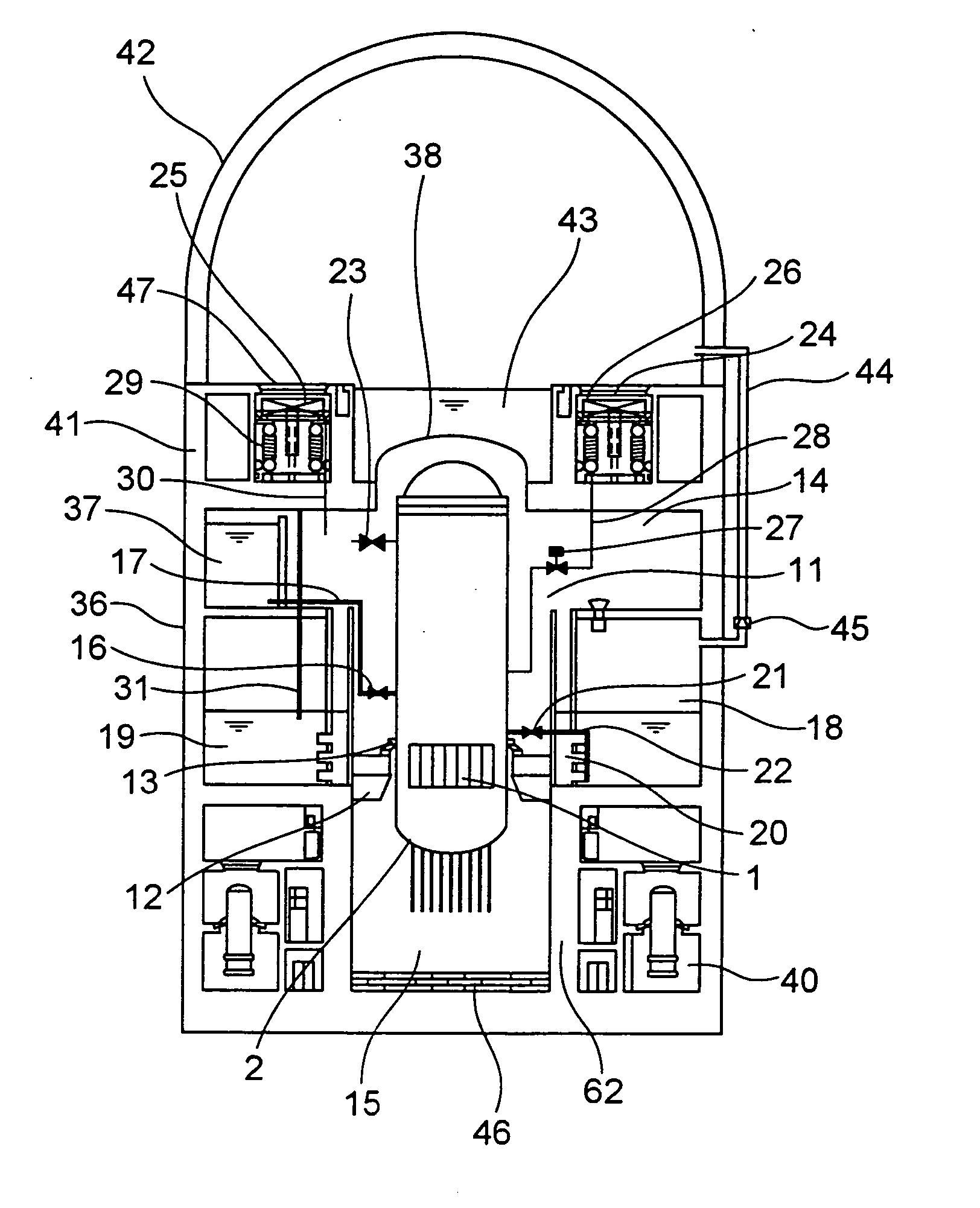

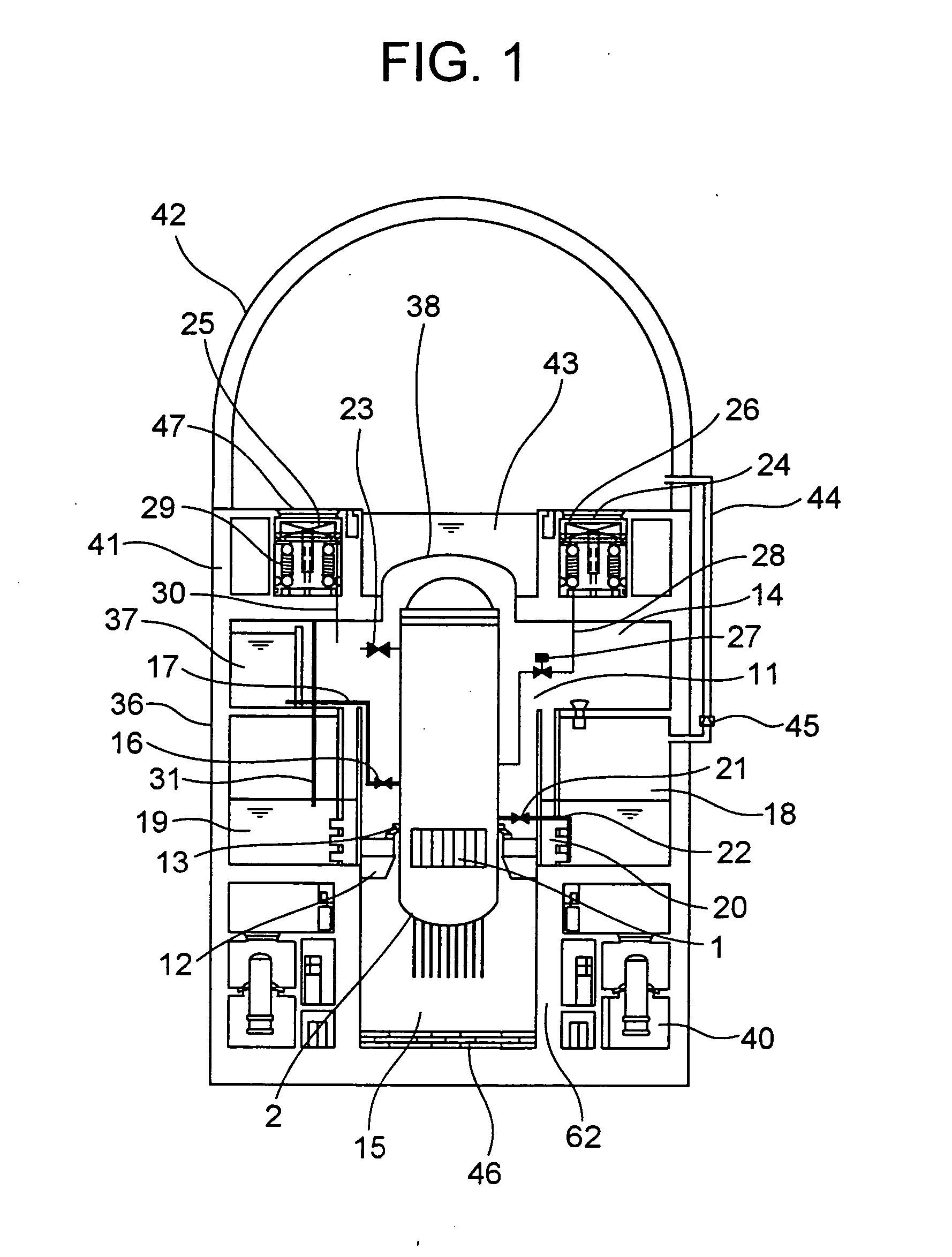

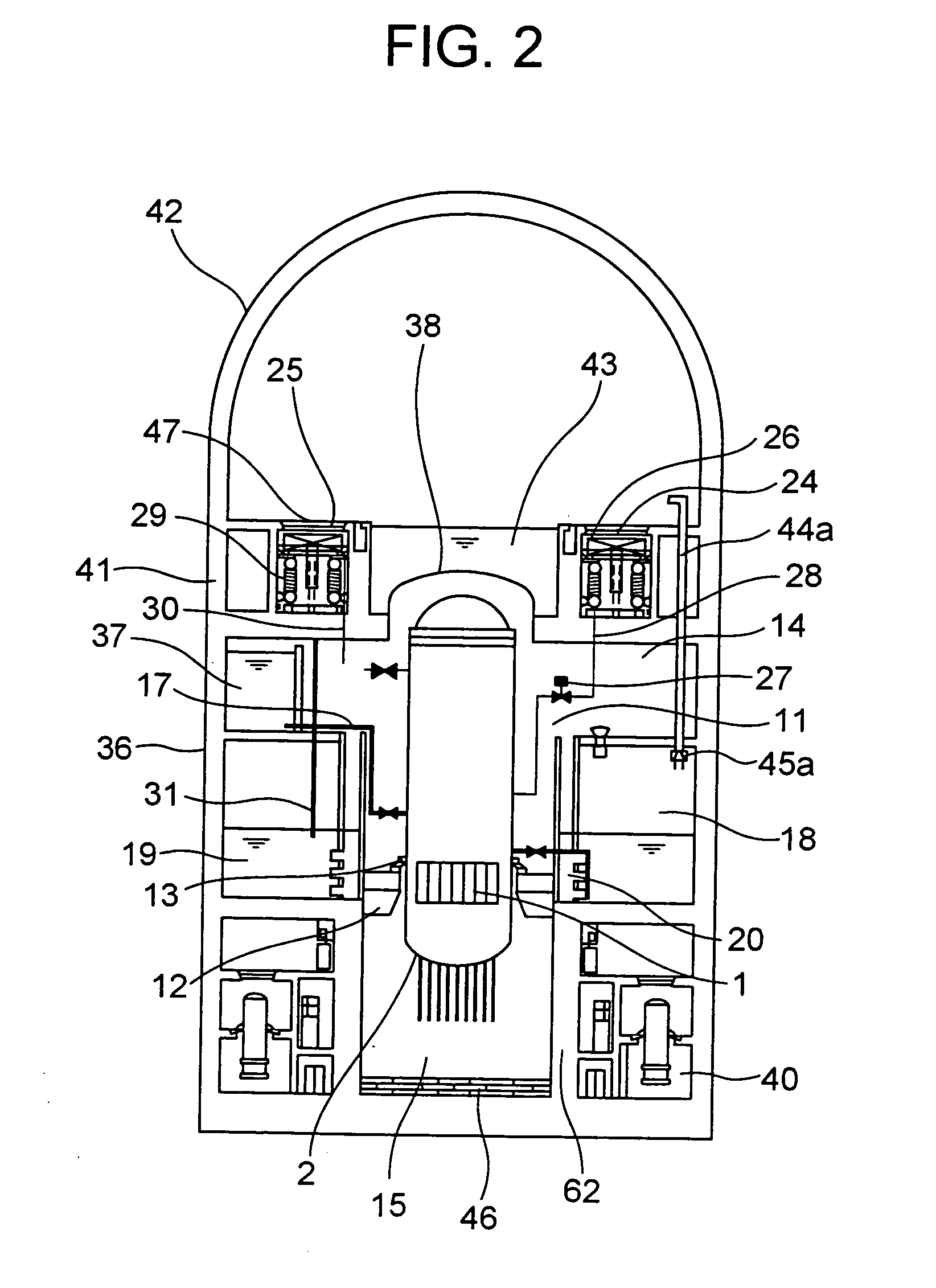

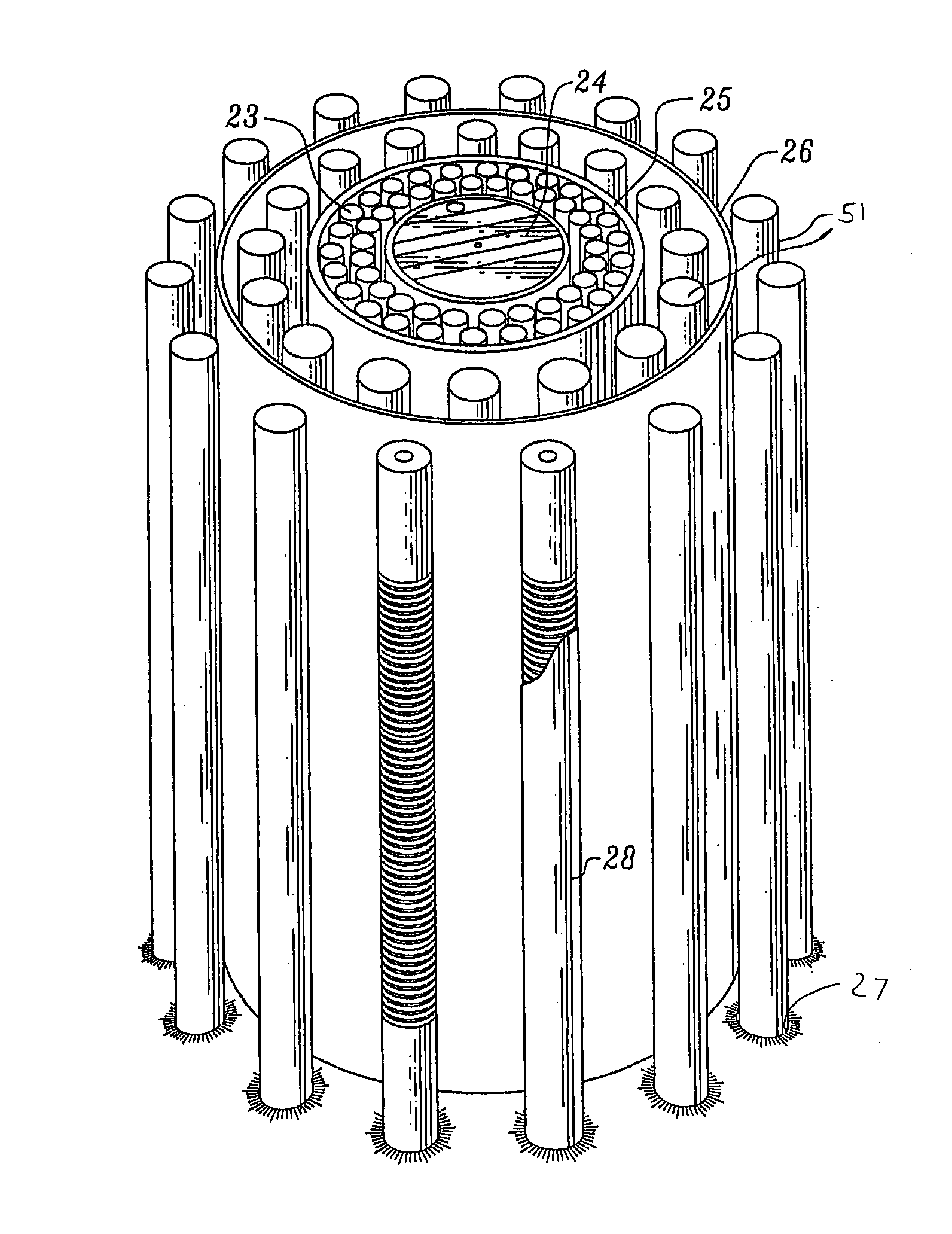

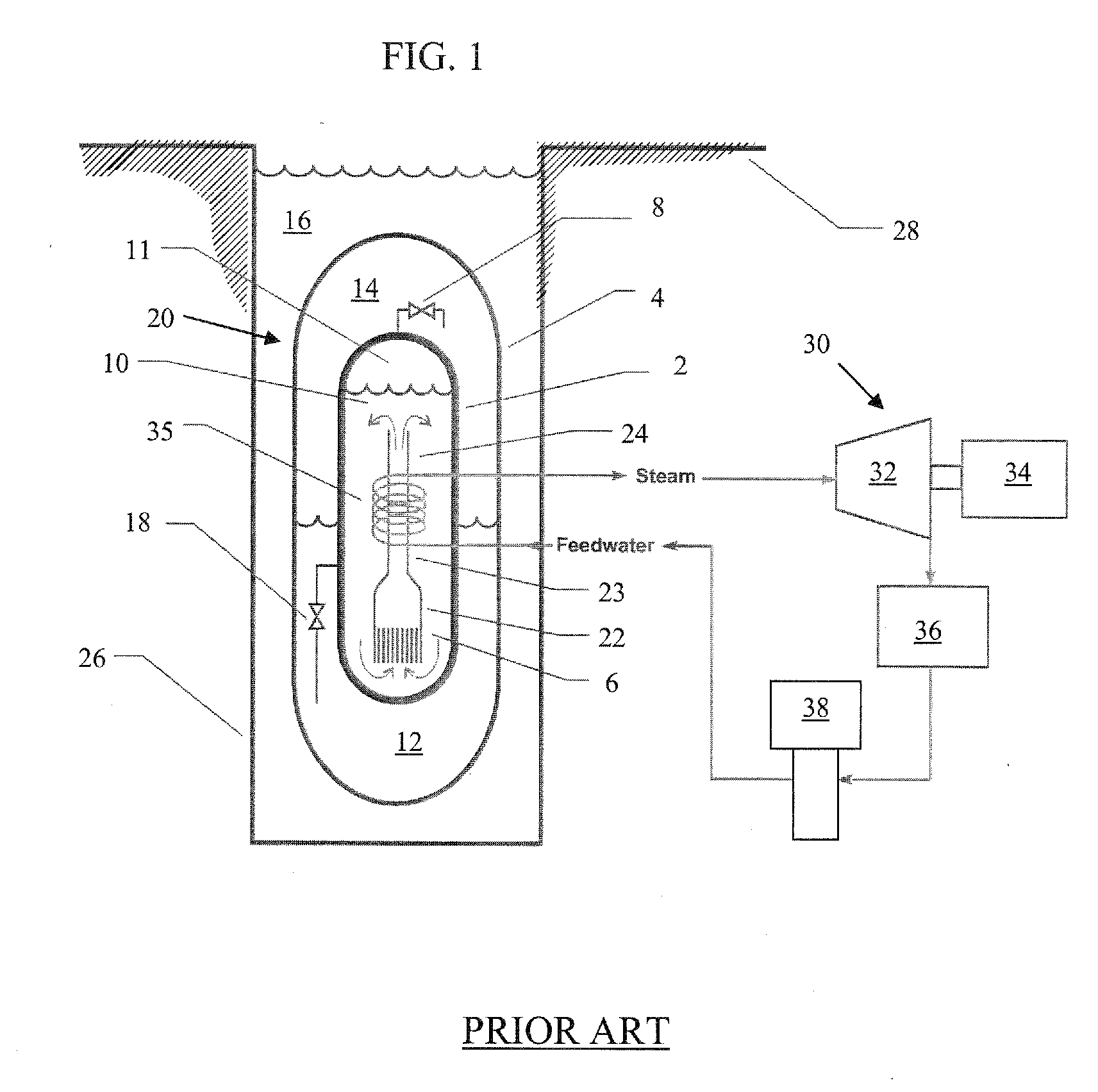

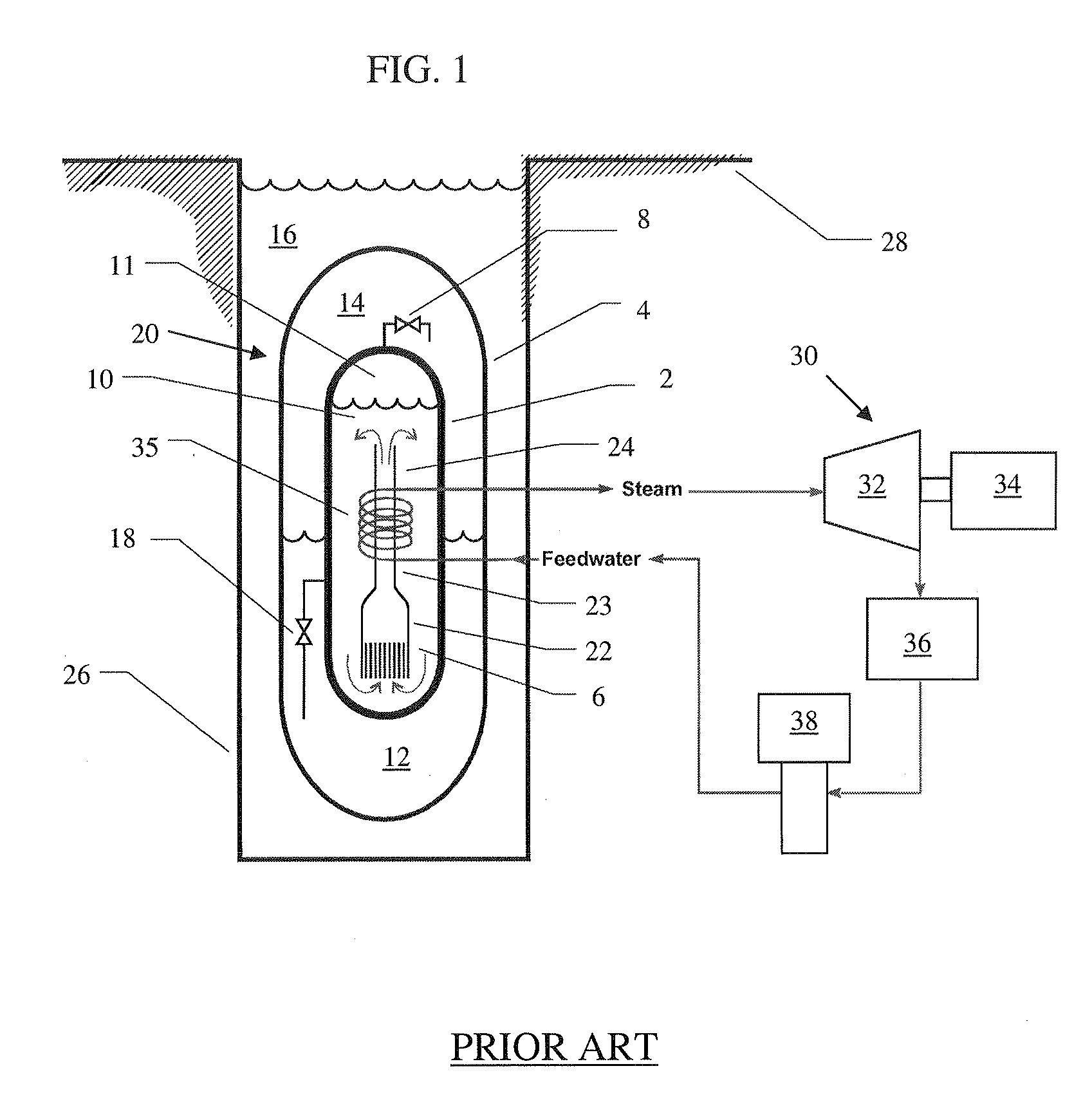

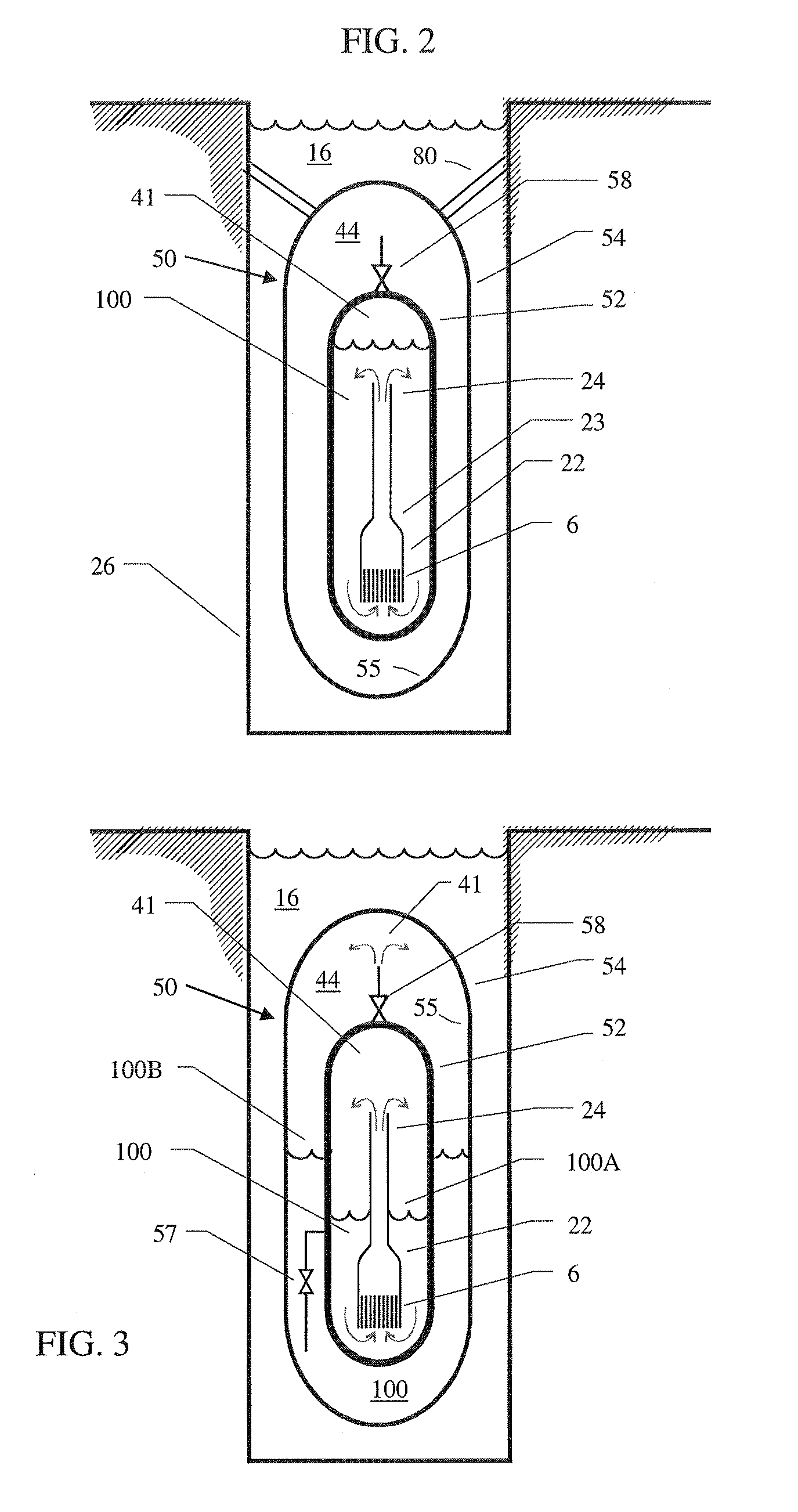

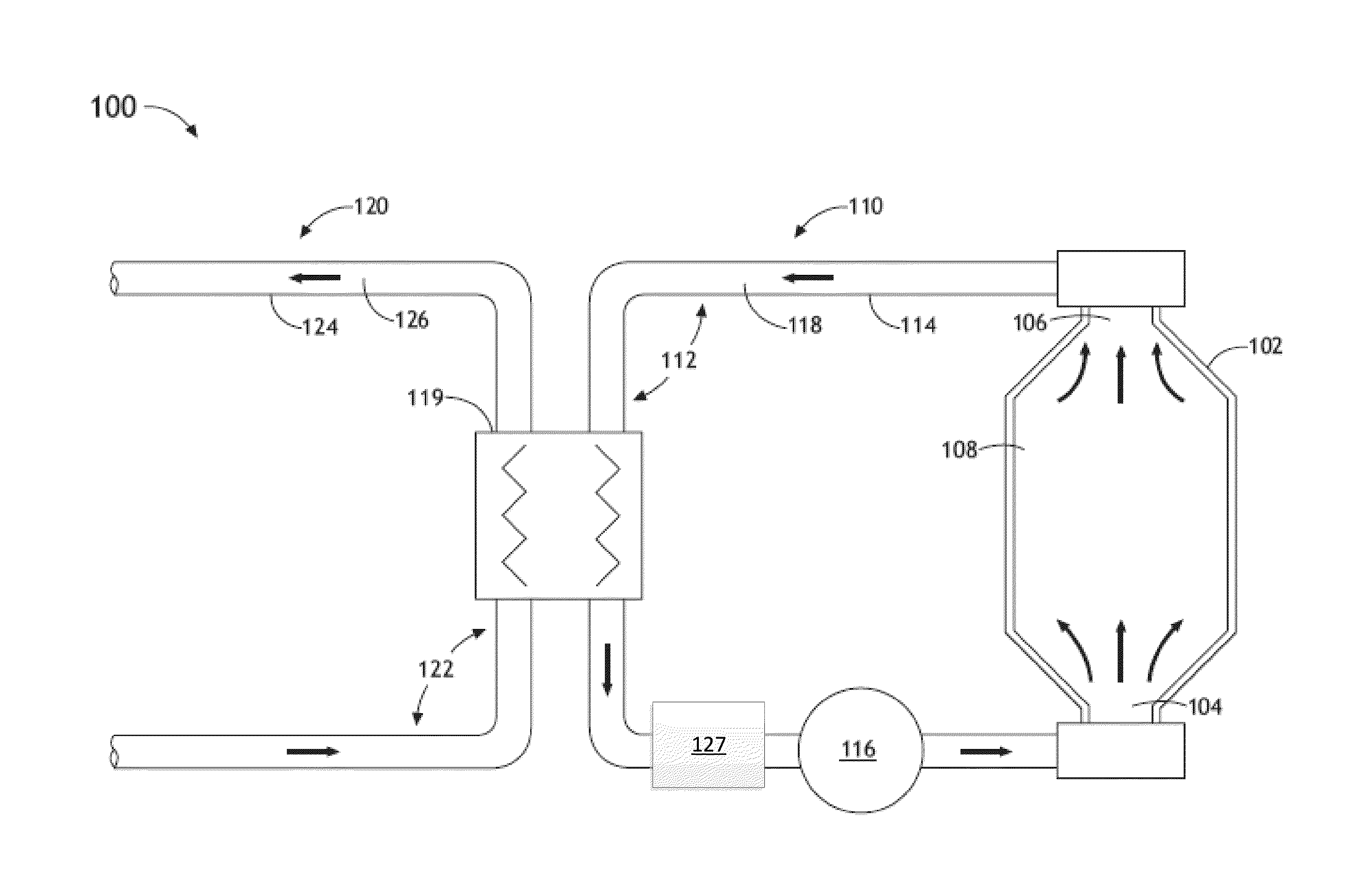

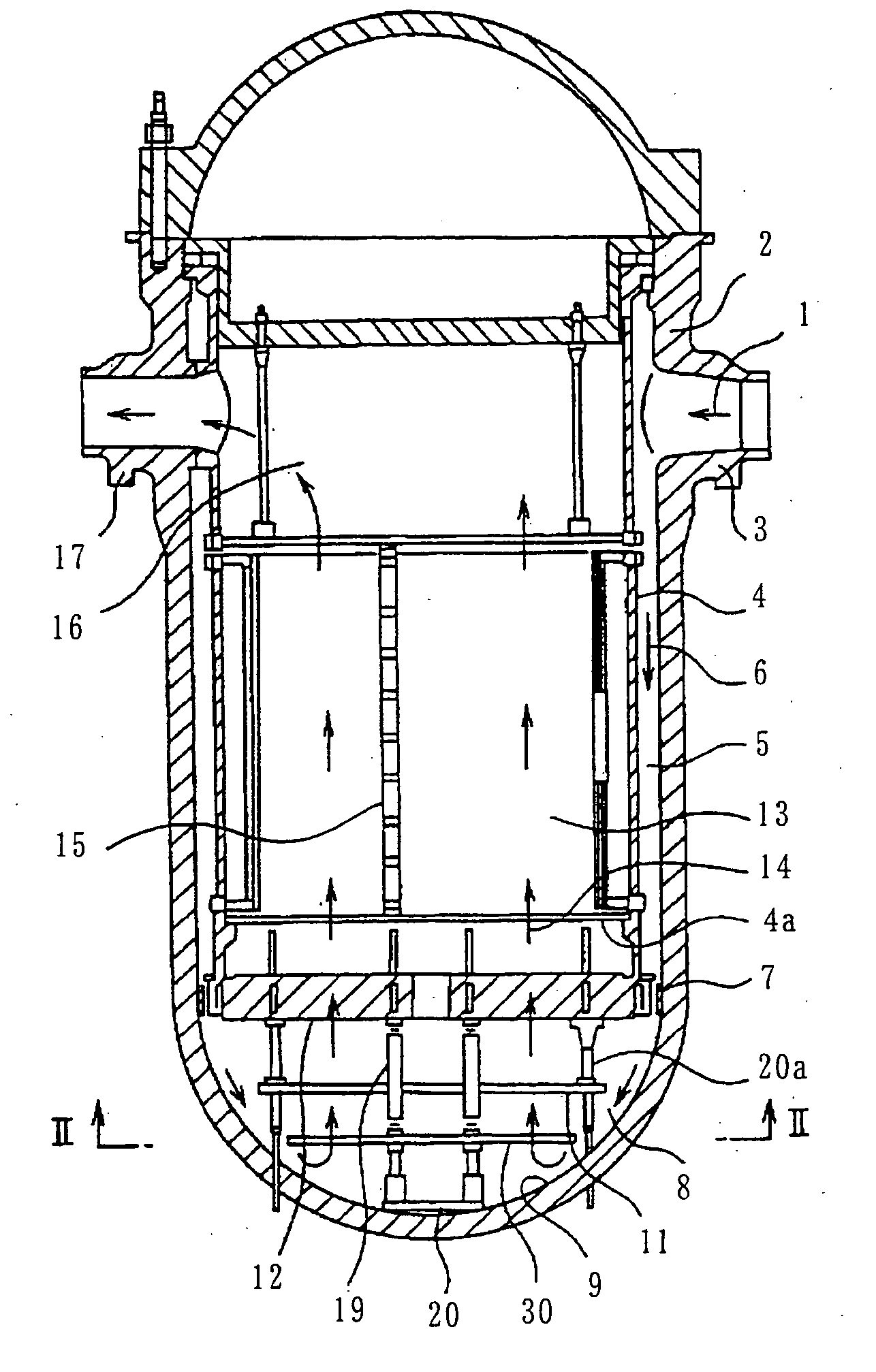

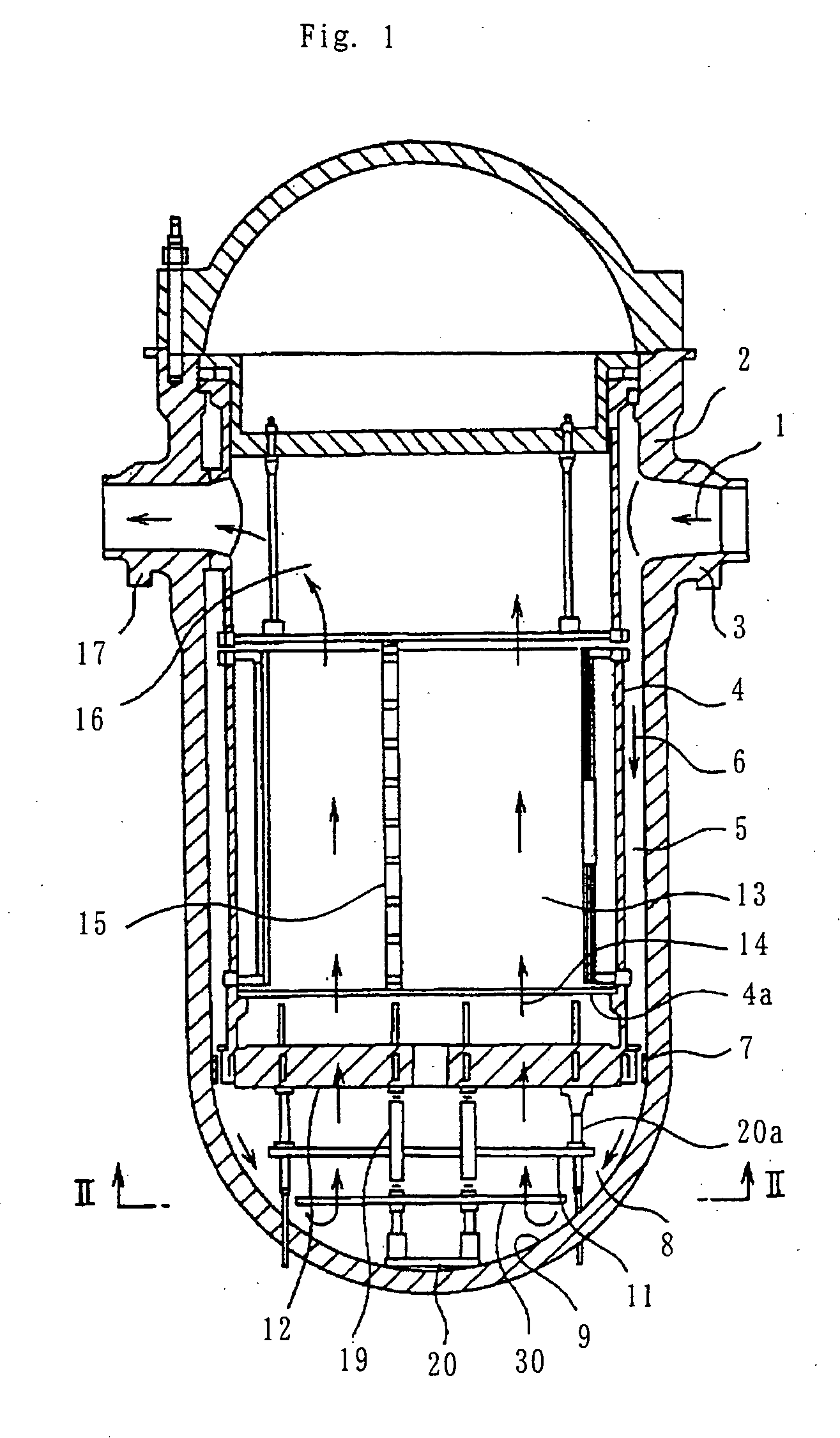

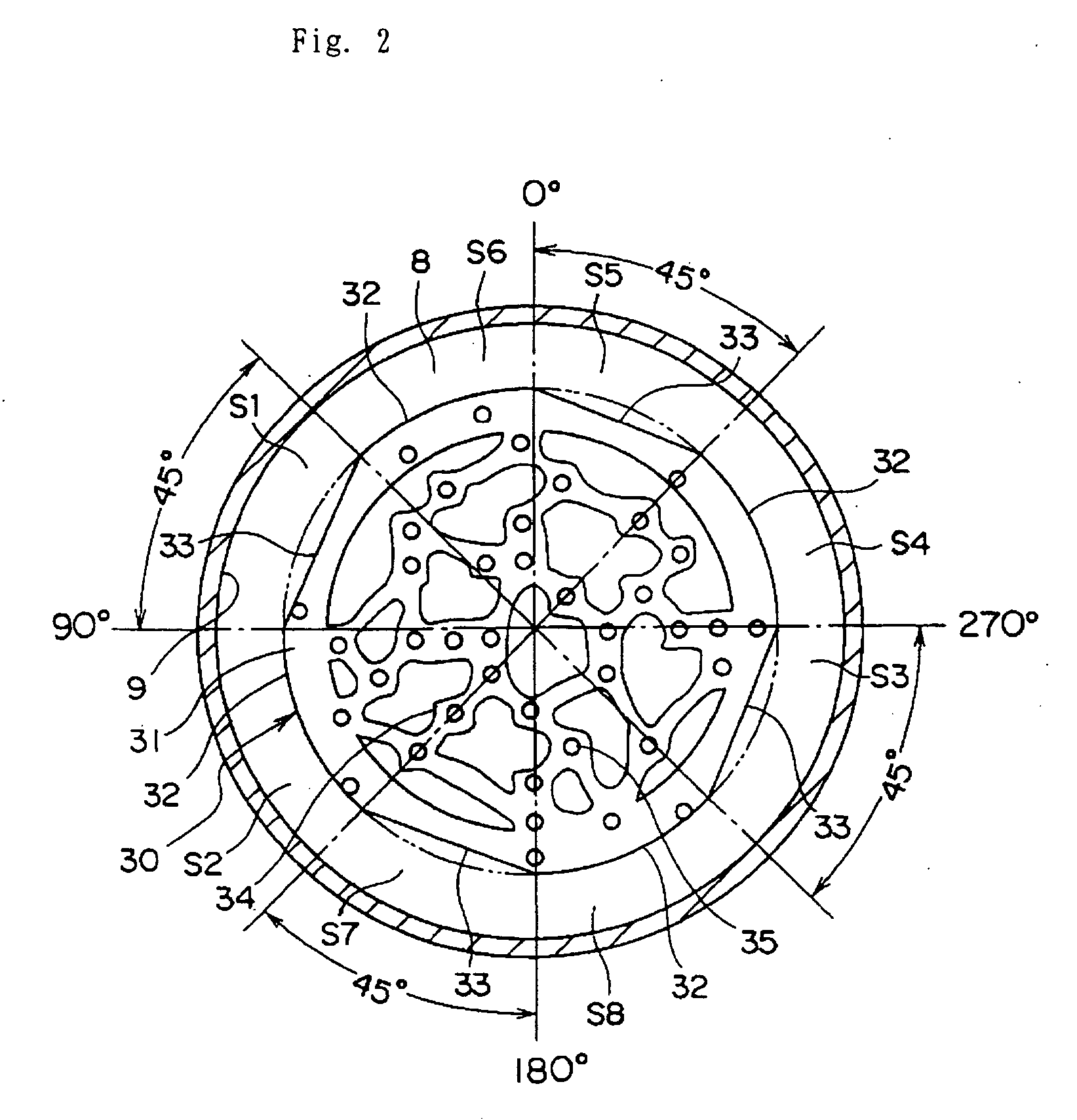

Reactor containment vessel and boiling water reactor power plant

ActiveUS20070092053A1Nuclear energy generationNuclear engineering problemsPower stationReactor pressure vessel

A containment vessel includes a primary containment vessel containing a reactor pressure vessel, an upper secondary containment vessel arranged above the primary containment vessel, and a gas-phase vent pipe linking the primary containment vessel and the upper secondary containment vessel by way of an isolation and connection switching system. The gas-phase vent pipe may be arranged either inside or outside the primary containment vessel and the upper secondary containment vessel. Alternatively, it may be embedded in the wall. An igniter may be arranged in the upper secondary containment vessel. The air in the upper secondary containment vessel may be replaced by nitrogen. A gravity-driven flooding system pool may be arranged in the upper secondary containment vessel and cooling water may be led from the inside of the pool to the inside of the primary containment vessel.

Owner:KK TOSHIBA

Reactor tray vertical geometry with vitrified waste control

InactiveUS20060171498A1Reduce the amount of wasteNegative environmental impactConversion outside reactor/acceleratorsNuclear energy generationThermal energyVitrification

A nuclear-powered plant for systems of up to about 100 MWs with a confinement section where the reaction takes place in a core having a reactive thorium / uranium-233 composition, and where an external neutron source is used as a modulated neutron multiplier for the reactor core output. The core is housed in a containment structure that radiates thermal energy captured in a multiple-paths heat exchanger. The exchanger heat energy output is put to use in a conventional gas-to-water heat exchanger to produce commercial quality steam.

Owner:D B I CENTURY FUELS & AEROSPACE SERVICES

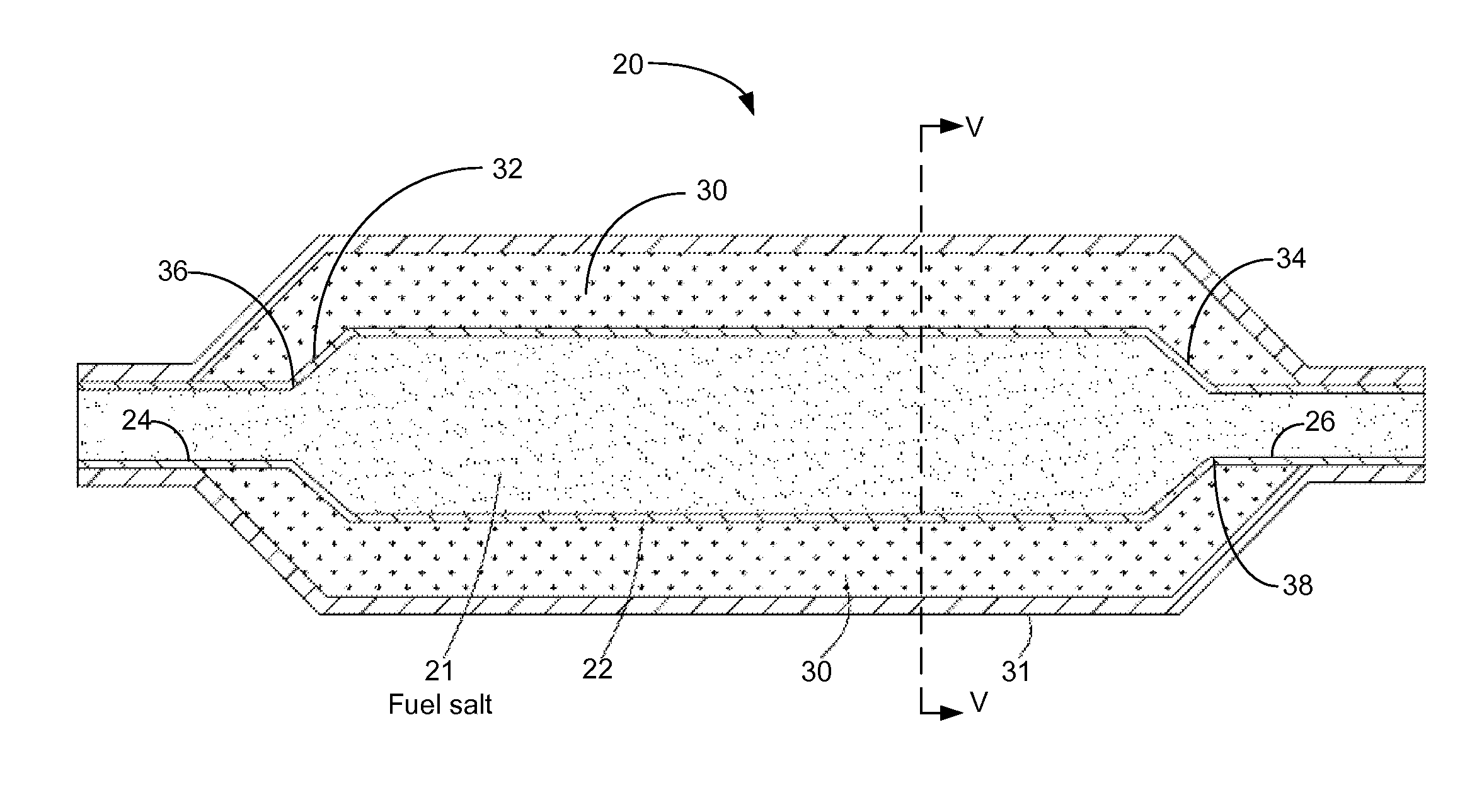

Molten salt nuclear reactor

InactiveUS20090279658A1Maximize probabilityFuel elementsNuclear energy generationBreeder reactorNuclear reactor

A molten salt breeder reactor that has fuel conduit surrounded by a fertile blanket. The fuel salt conduit has an elongated core section that allows for the generation of electrical power on a scale comparable to commercially available nuclear reactors. The geometry of the fuel conduit is such that sub-critical conditions exist near the input and output of the fuel salt conduit and the fertile blanket surrounds the input and output of the fuel salt conduit, thereby minimizing neutron losses.

Owner:OTTAWA VALLEY RES ASSOCS

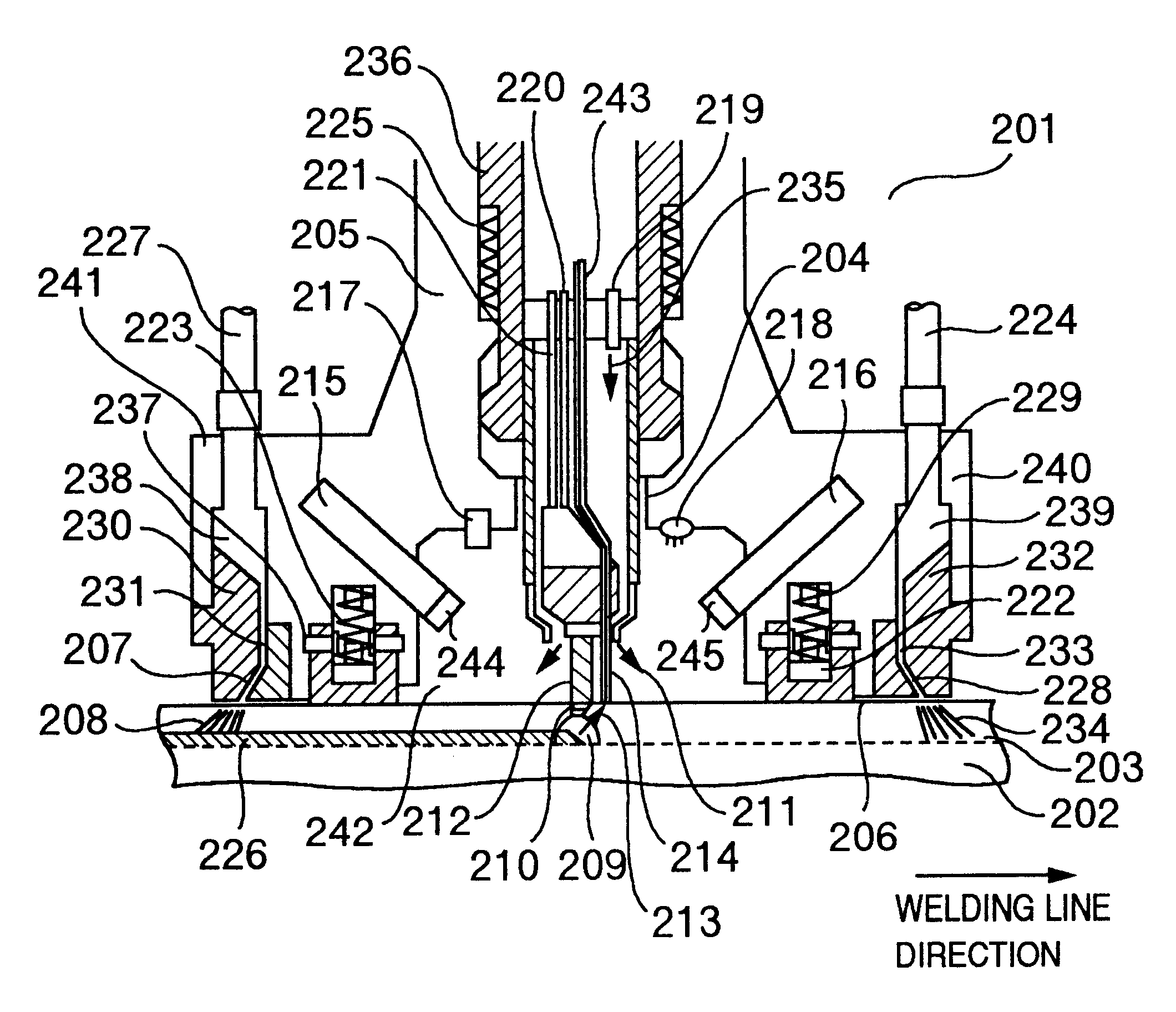

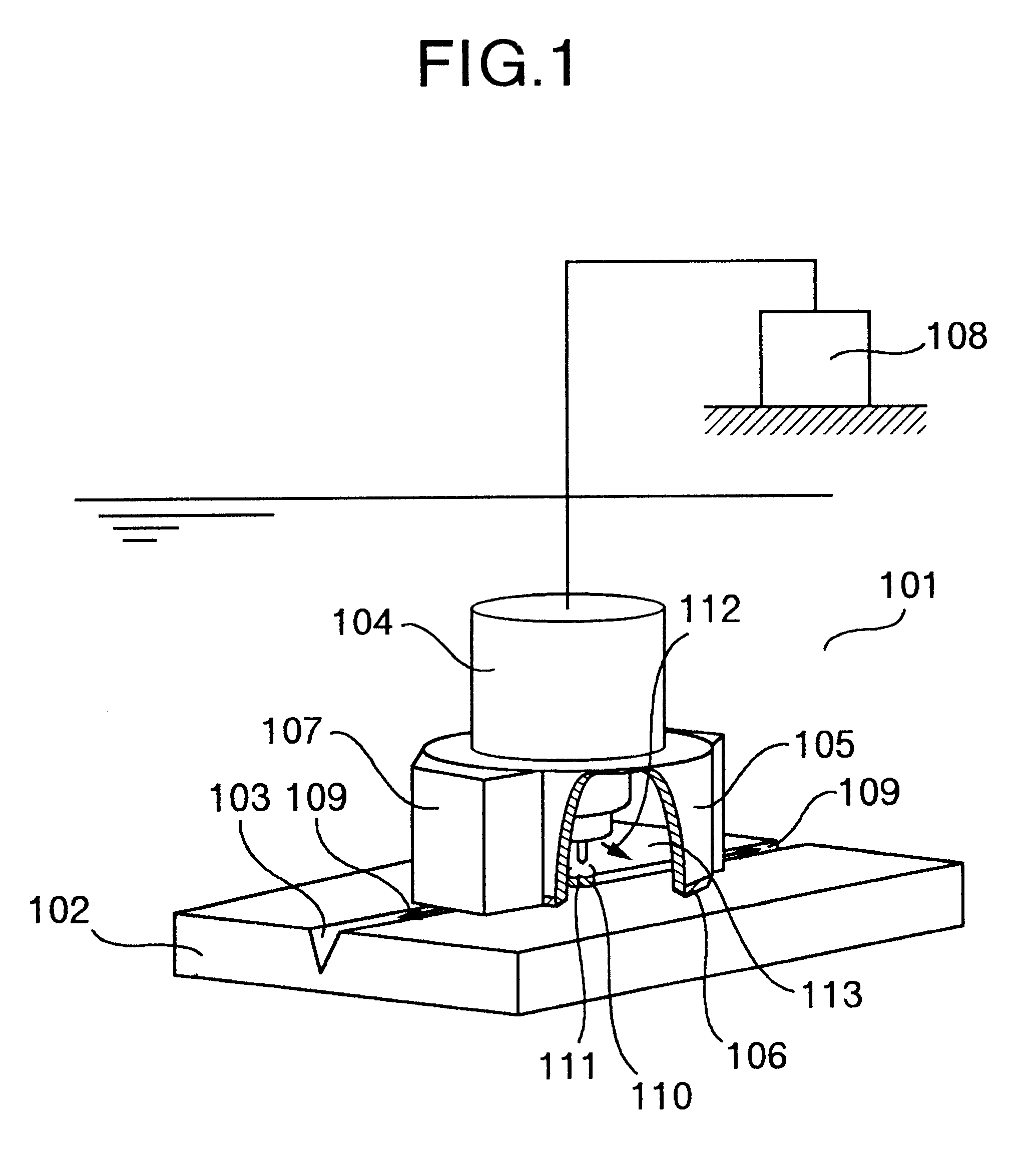

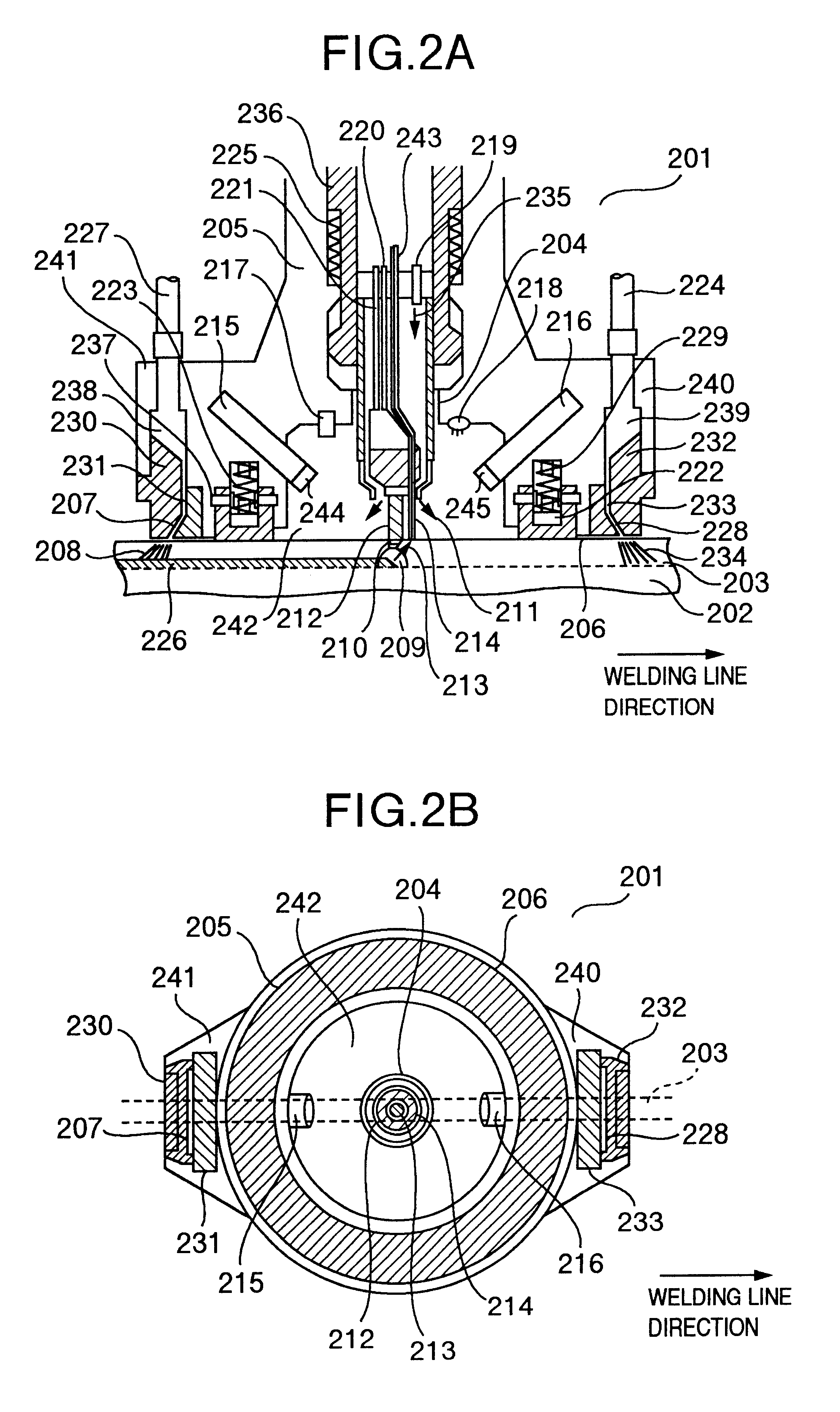

Underwater processing device and underwater processing method

InactiveUS6555779B1Reduce supplyReduce variationSupport devices with shieldingNuclear energy generationNuclear reactorEngineering

Provided are an underwater processing apparatus which can effectively prevent water from entering a shield for a workpiece having a surface ruggedness, and in which variation in a gas flow for a processing part is reduced, a processing method and an application thereof to a nuclear reactor, and the under water processing device is composed of a shield means which locally cover the processing part with the gas in order to prevent water from entering the shield member, the shield means having a solid wall formed of a member which is slidable in a part where it make contact with the workpiece, and adapted to make contact with the workpiece and to be moved up and down by a pressing force, and a water jetting means for forming a water curtain around the outer periphery of the solid wall.

Owner:HITACHI LTD

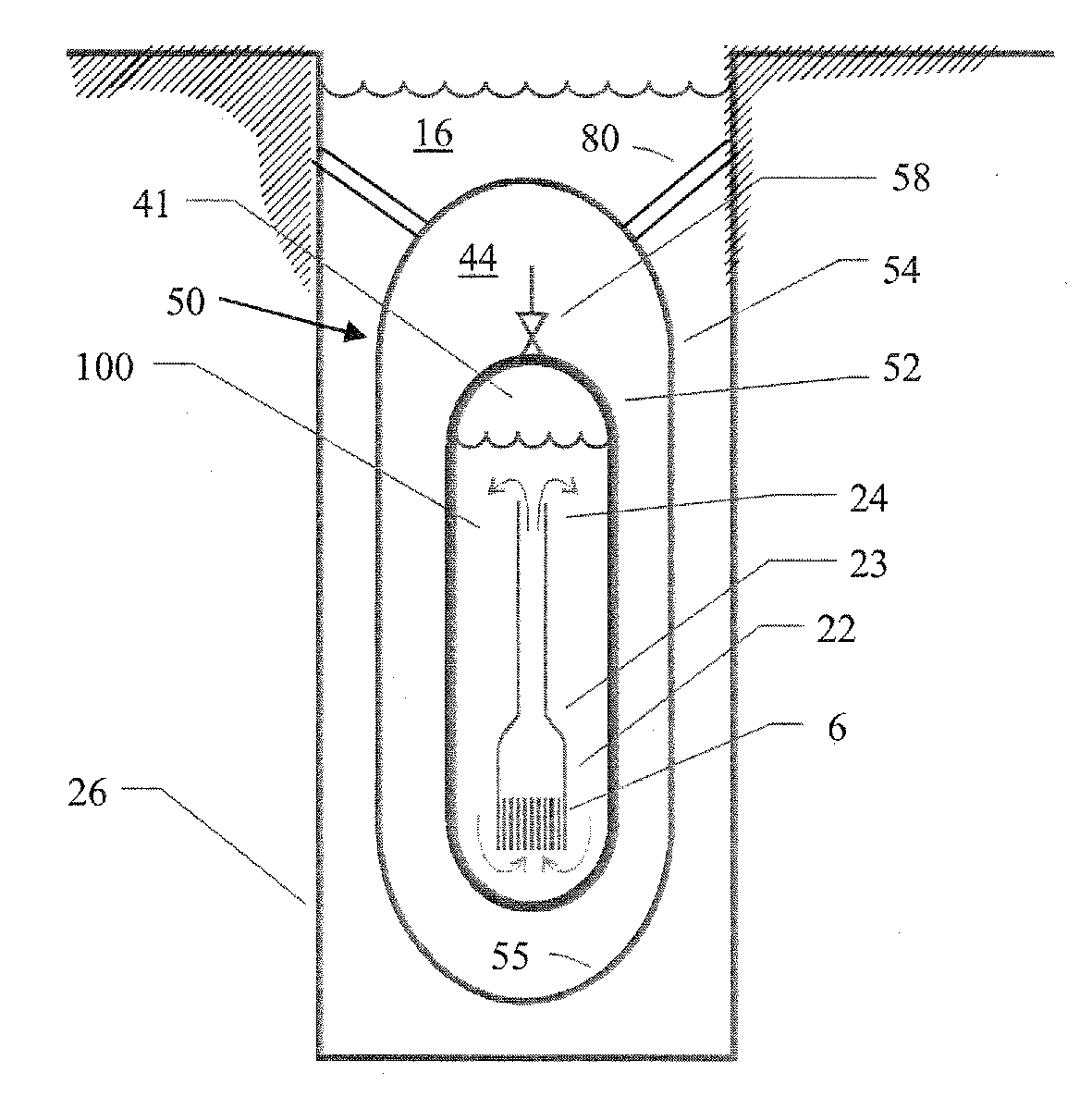

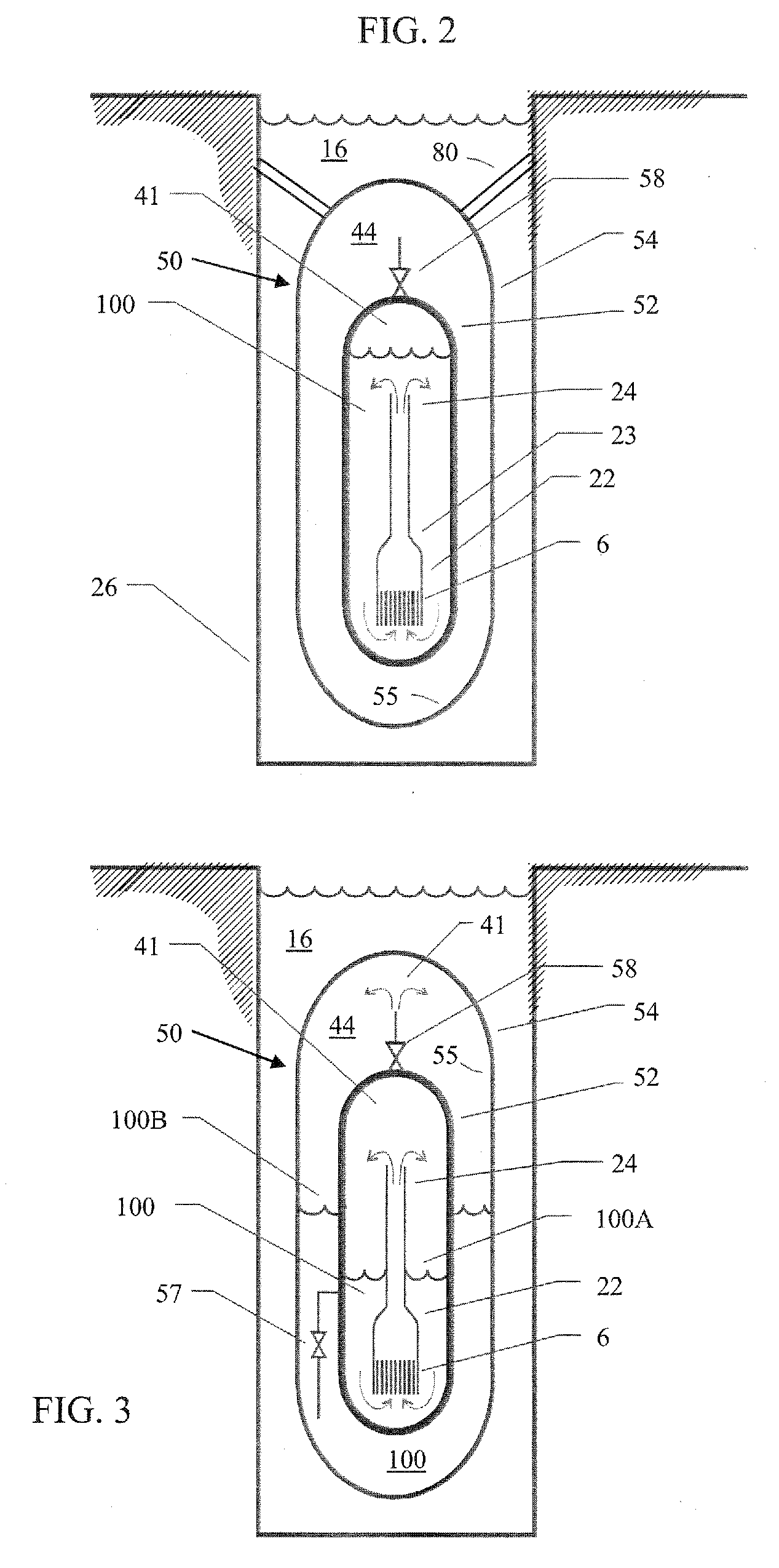

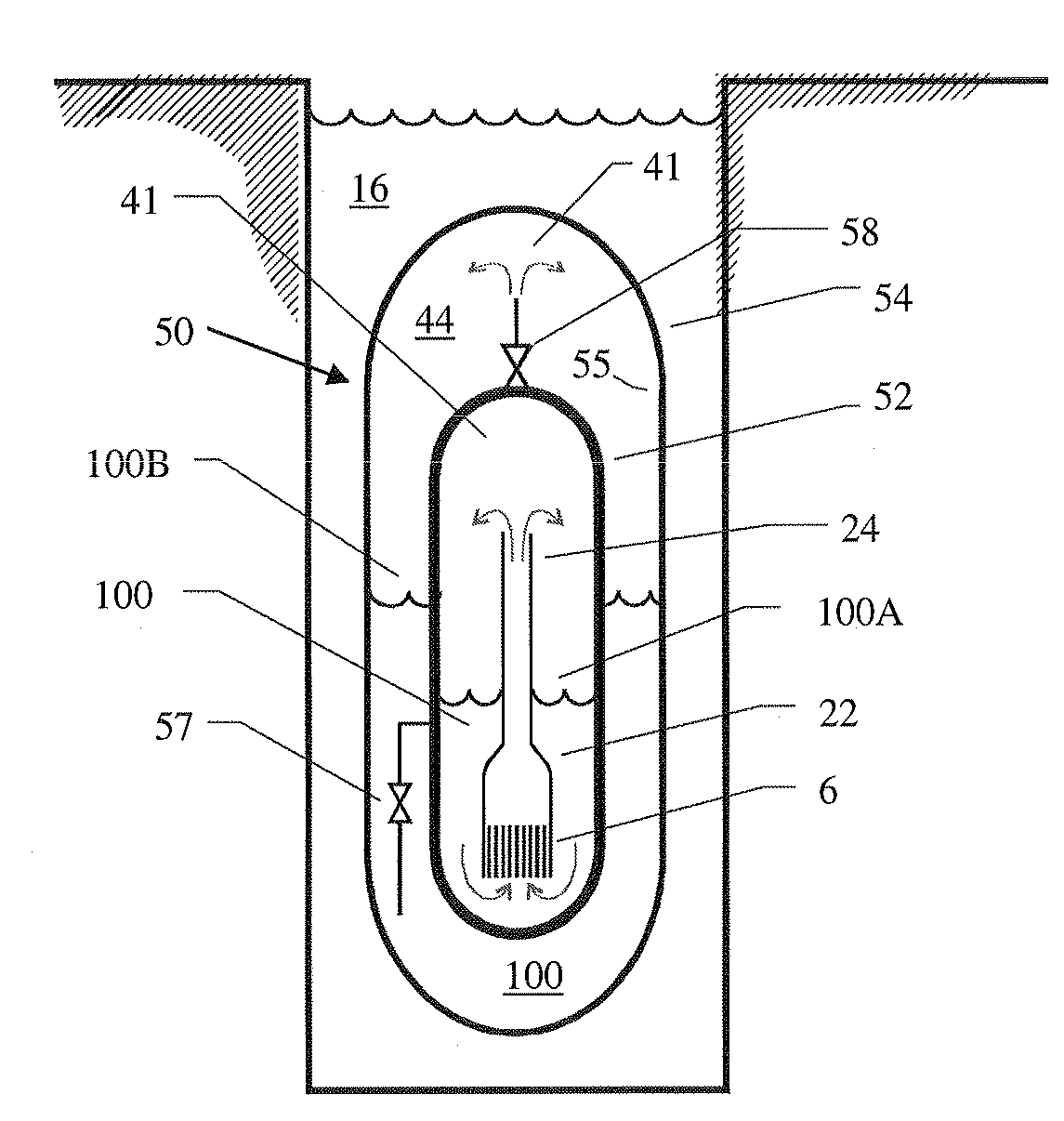

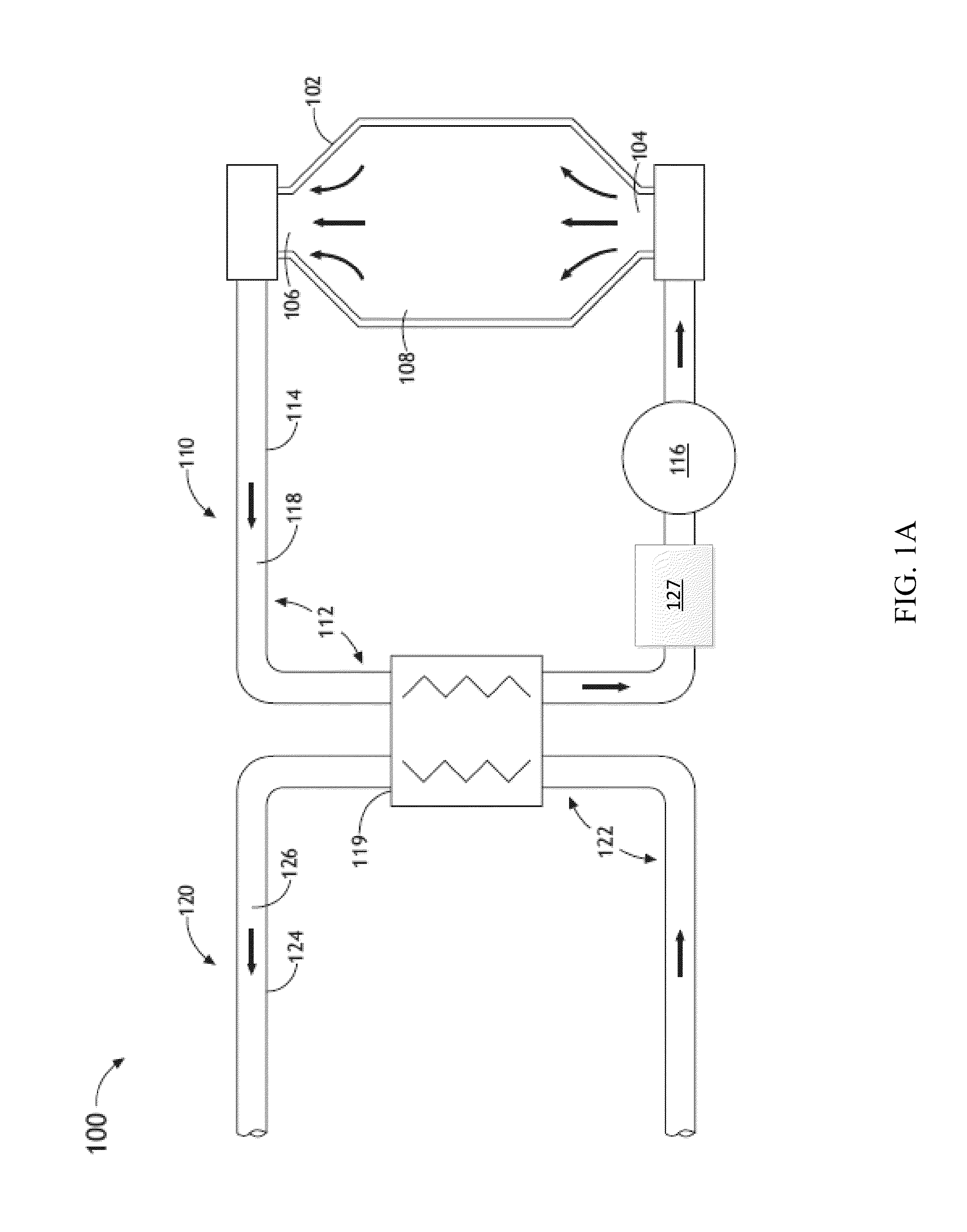

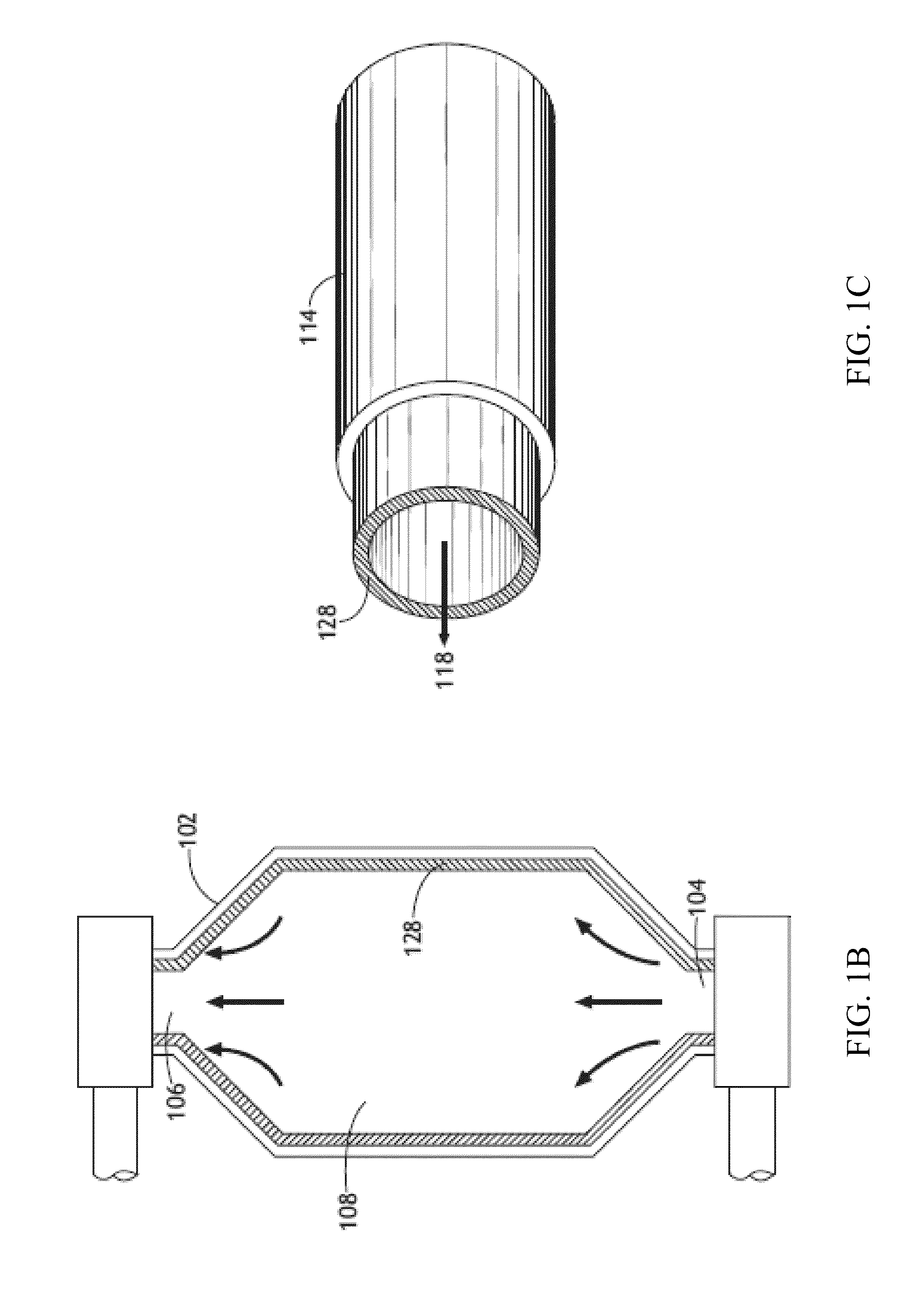

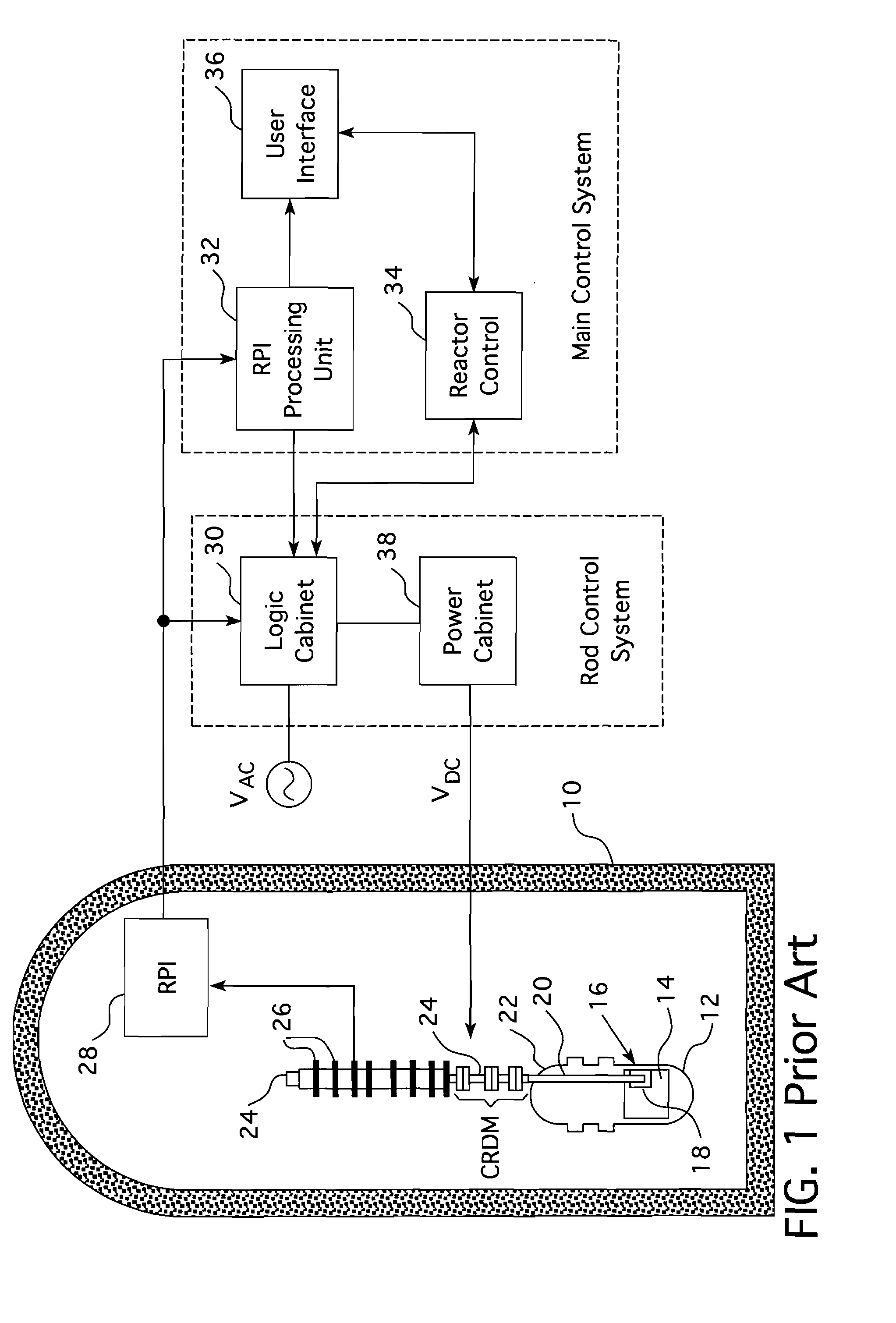

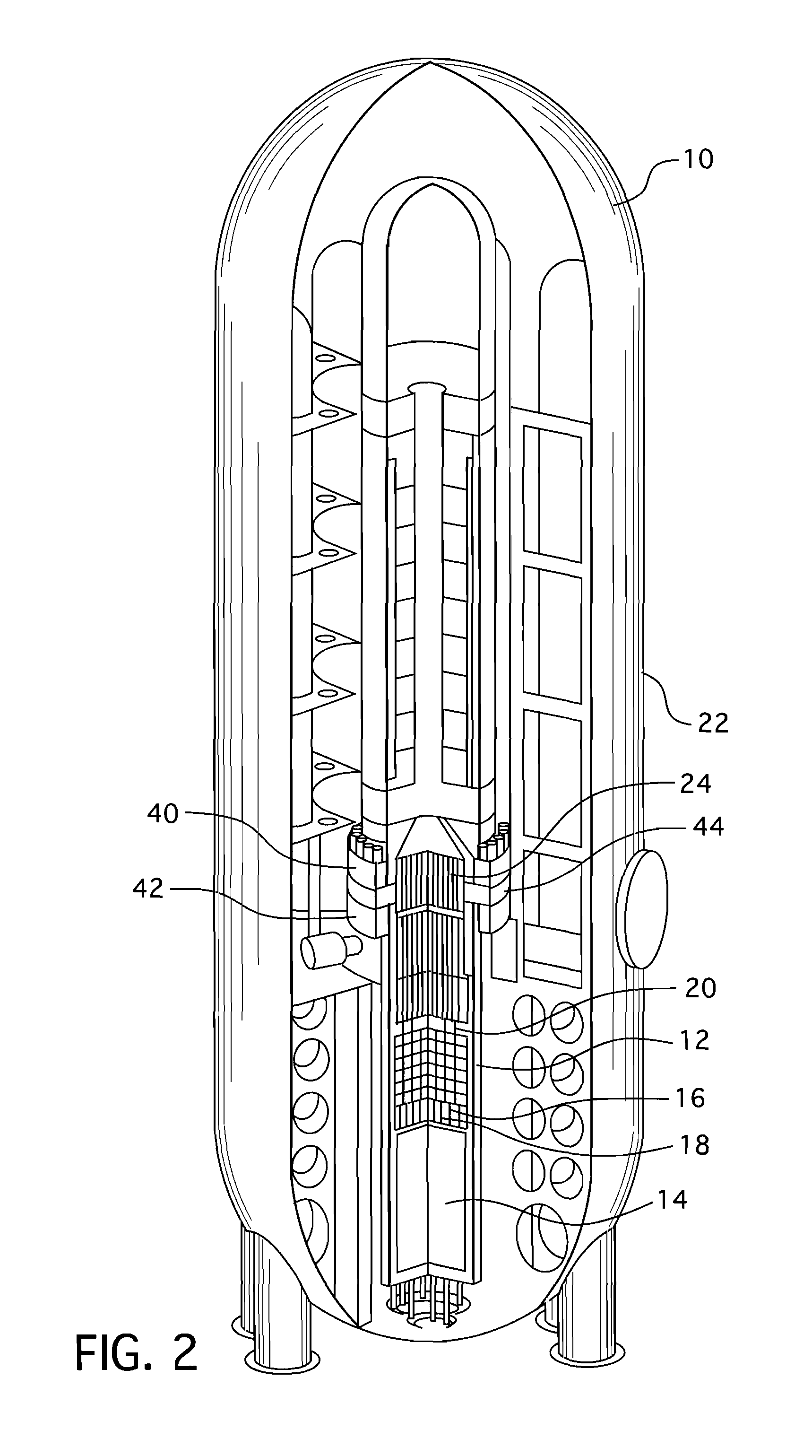

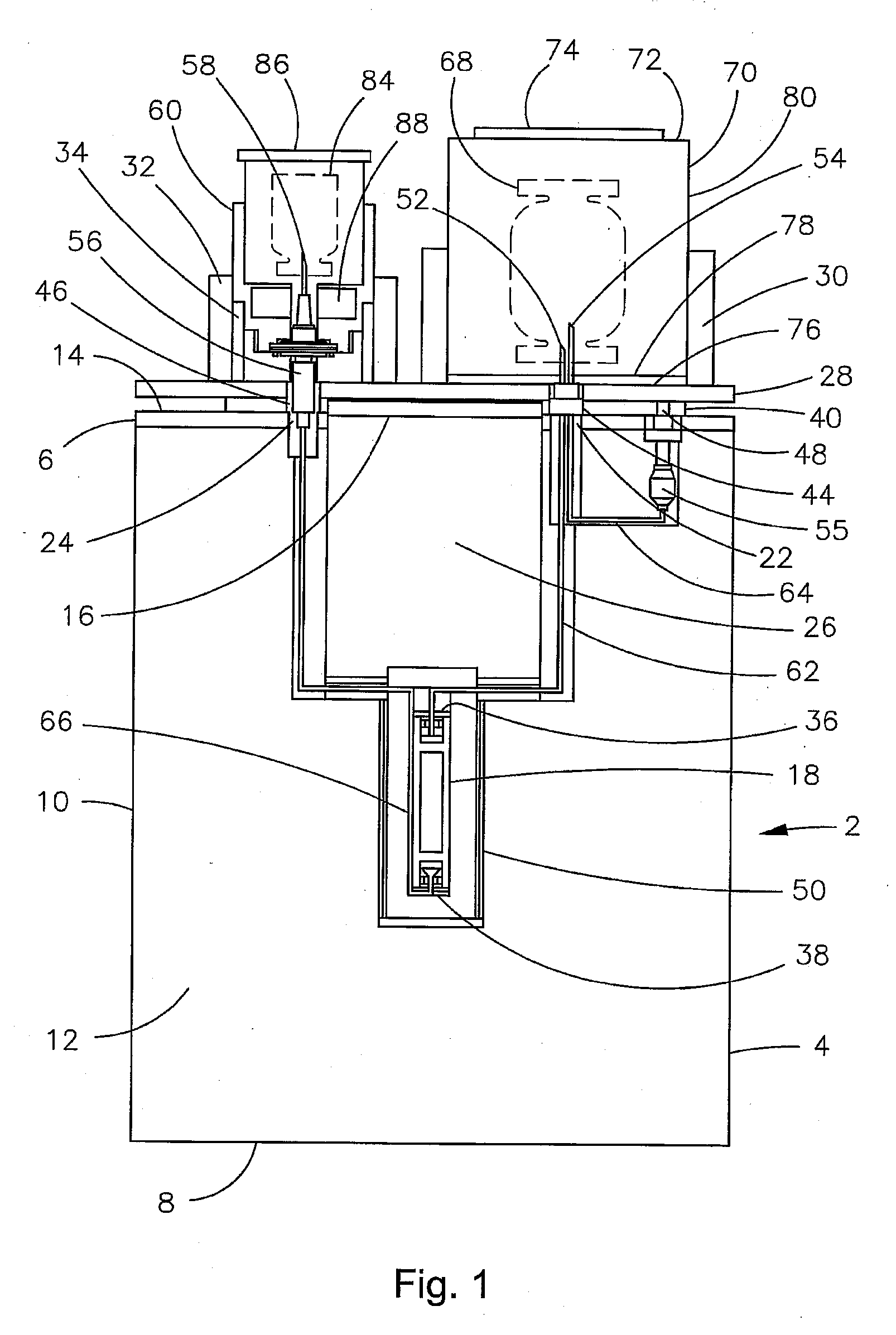

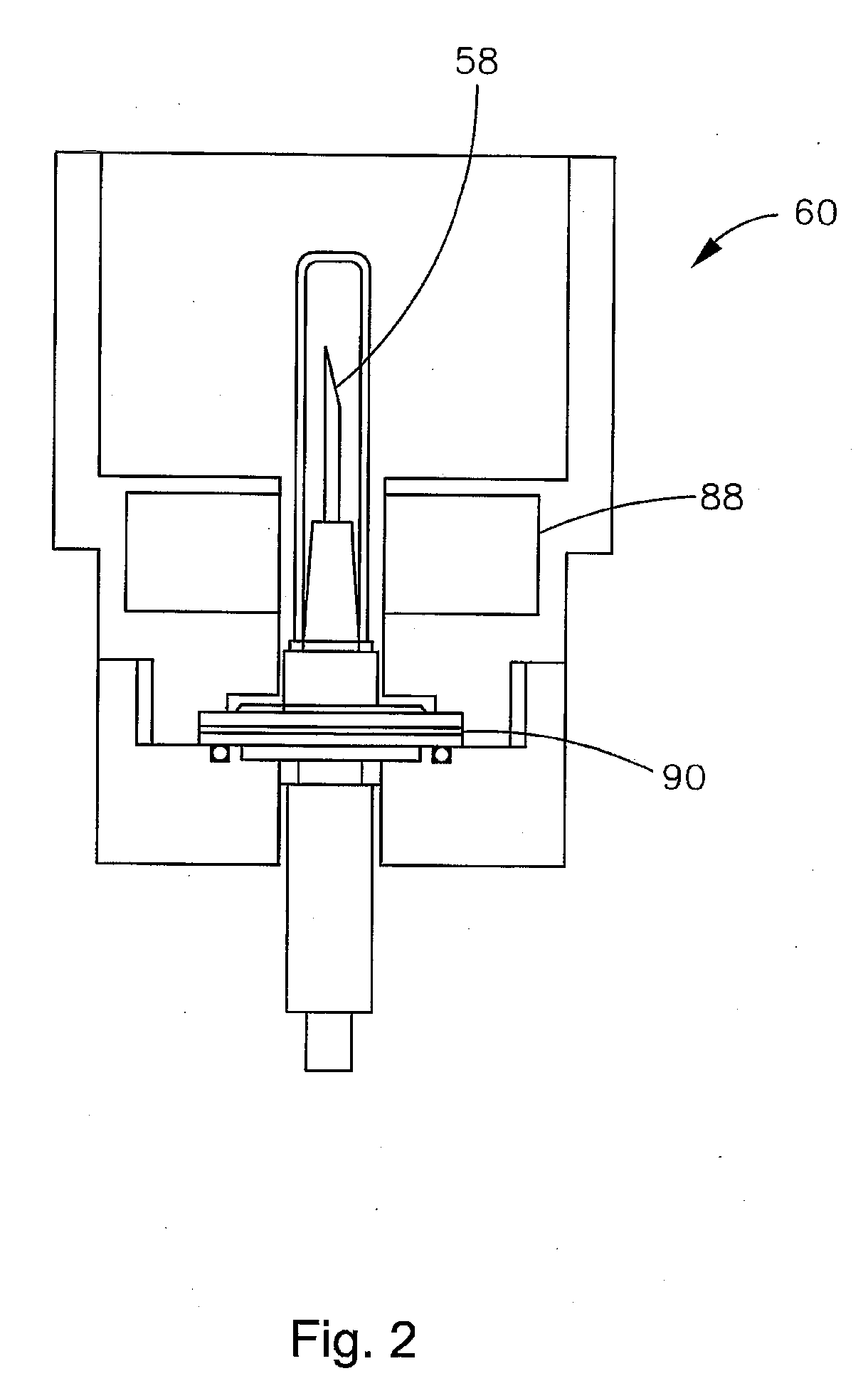

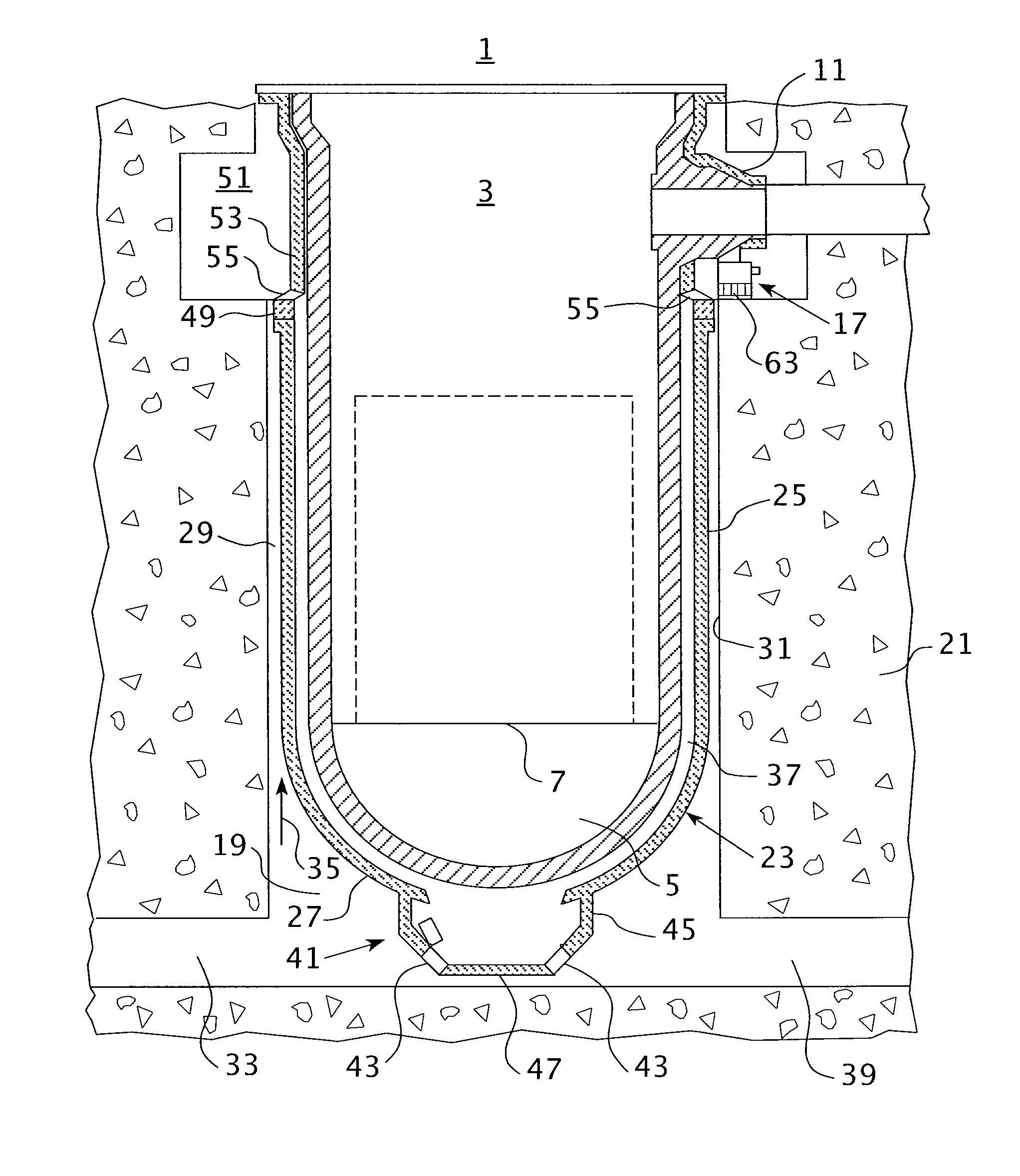

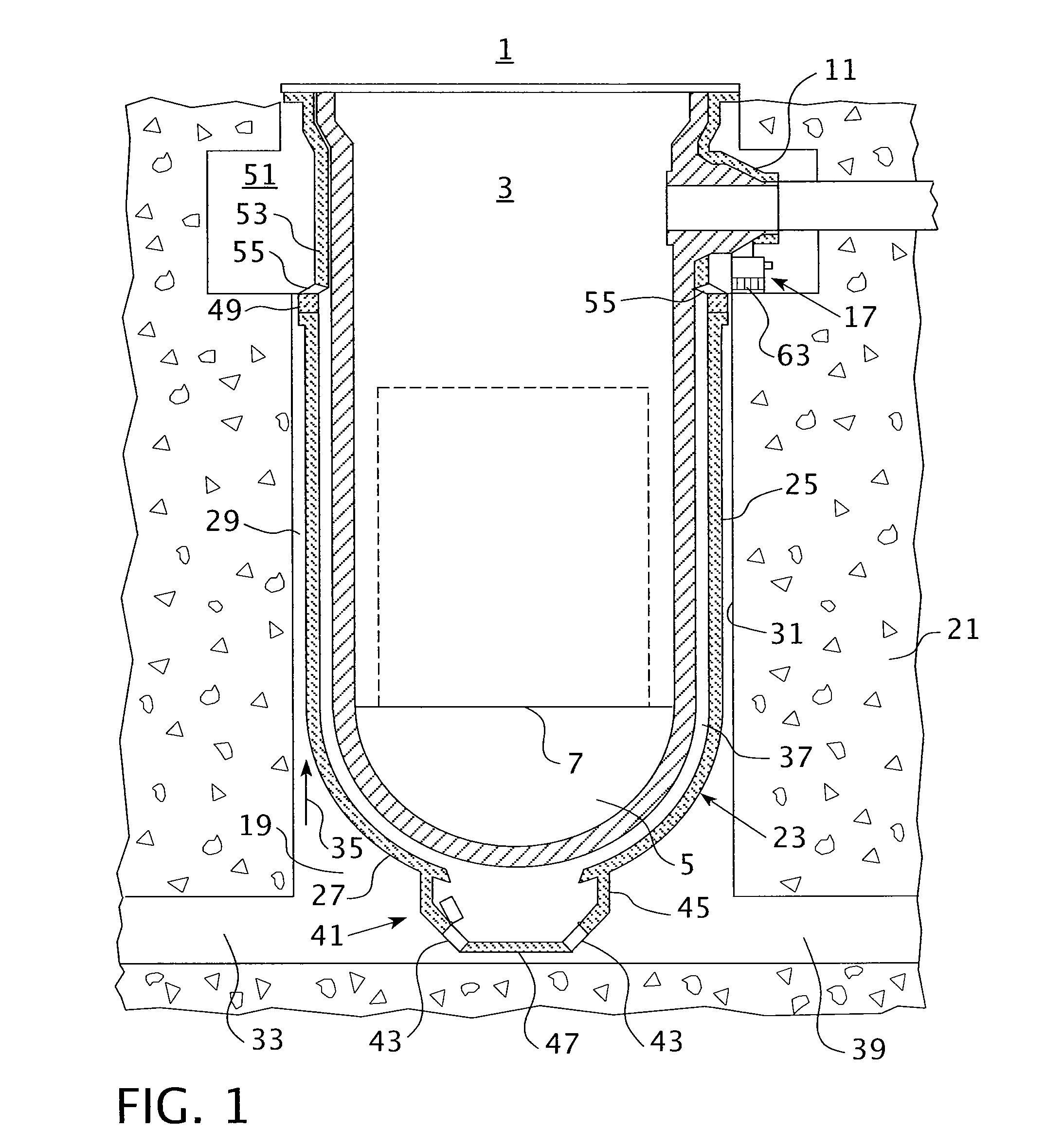

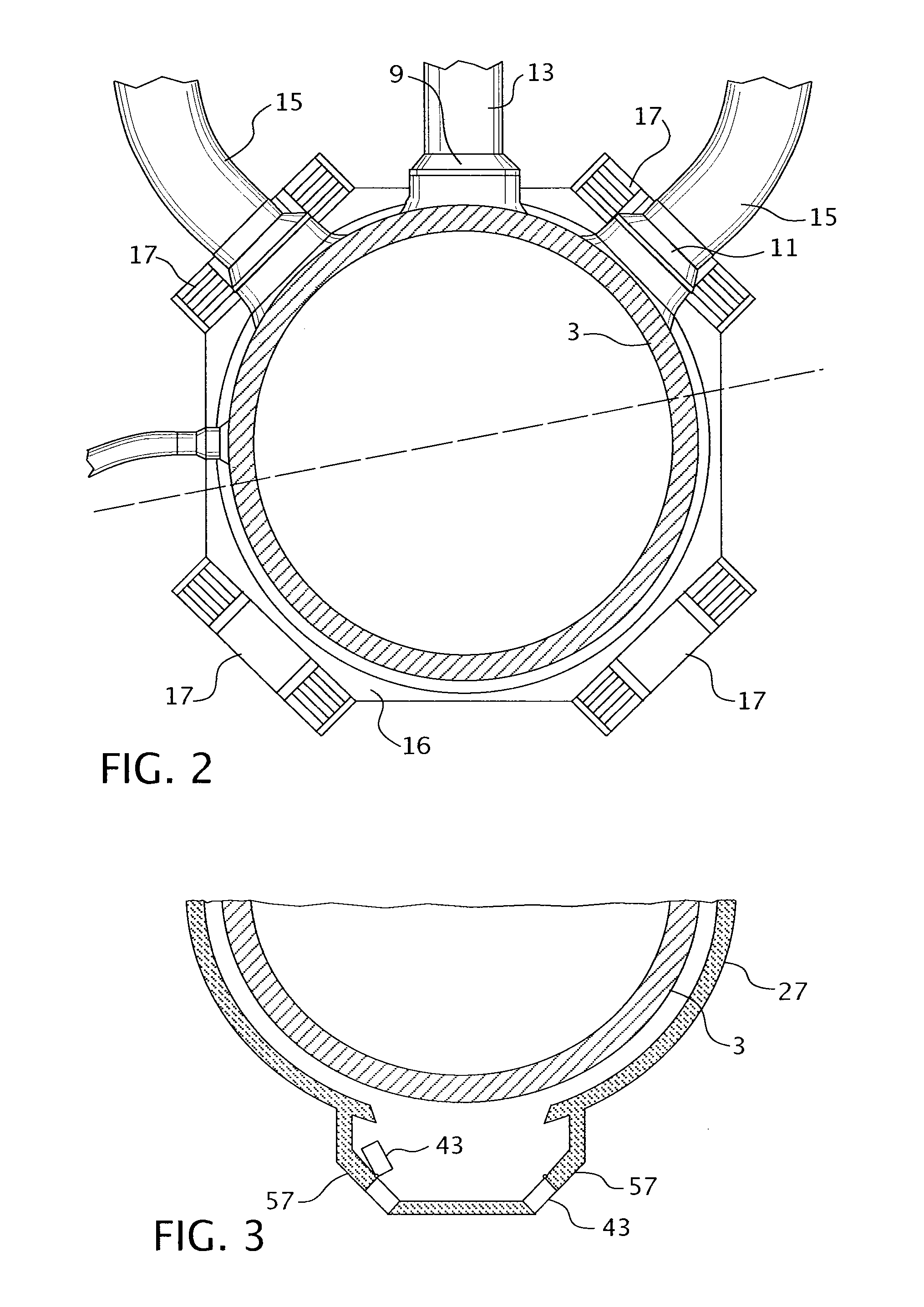

Submerged containment vessel for a nuclear reactor

A power module assembly includes a reactor core immersed in a coolant and a reactor vessel housing the coolant and the reactor core. An internal dry containment vessel submerged in liquid substantially surrounds the reactor vessel in a gaseous environment. During an over-pressurization event the reactor vessel is configured to release the coolant into the containment vessel and remove a decay heat of the reactor core through condensation of the coolant on an inner surface of the containment vessel.

Owner:NUSCALE

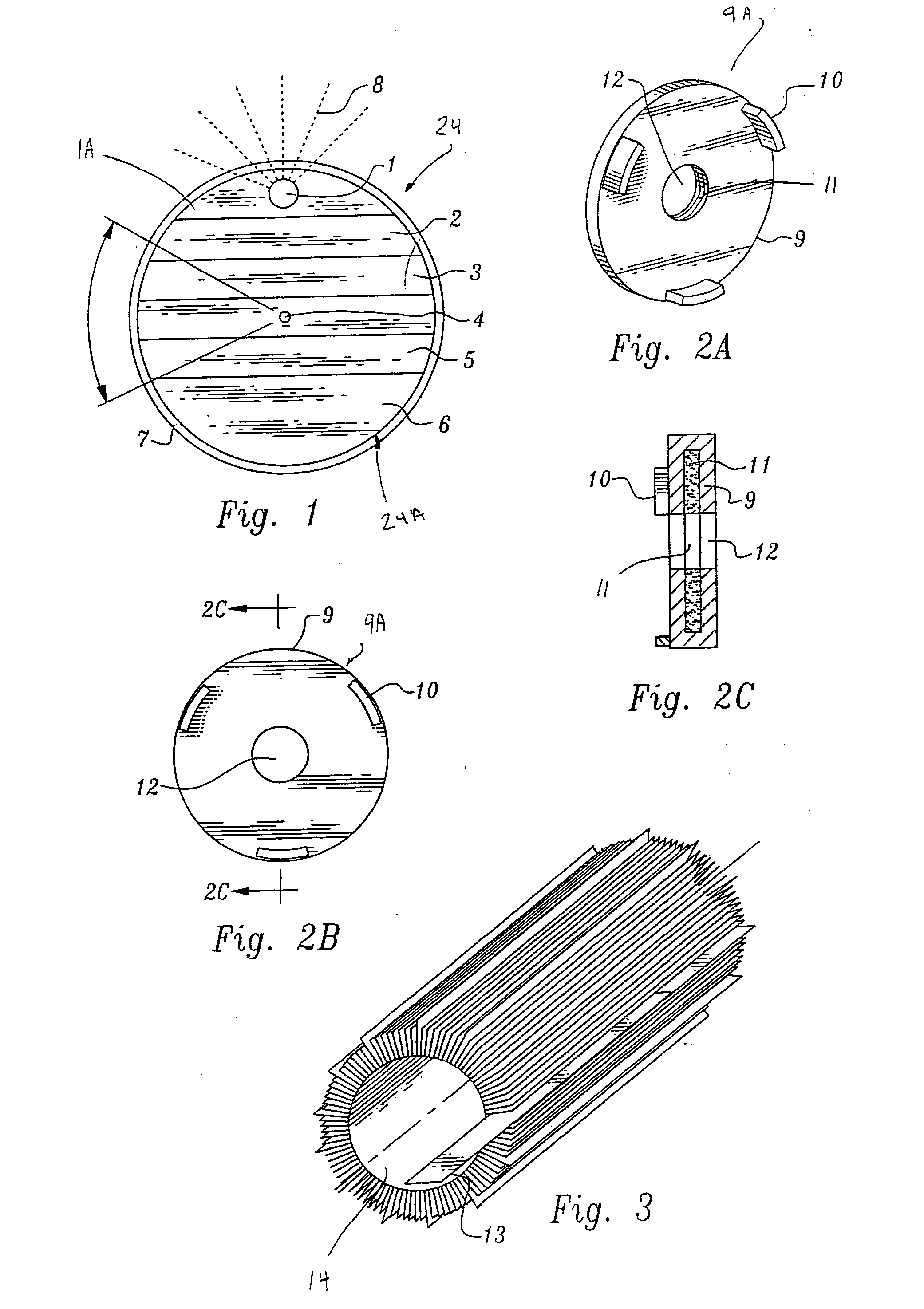

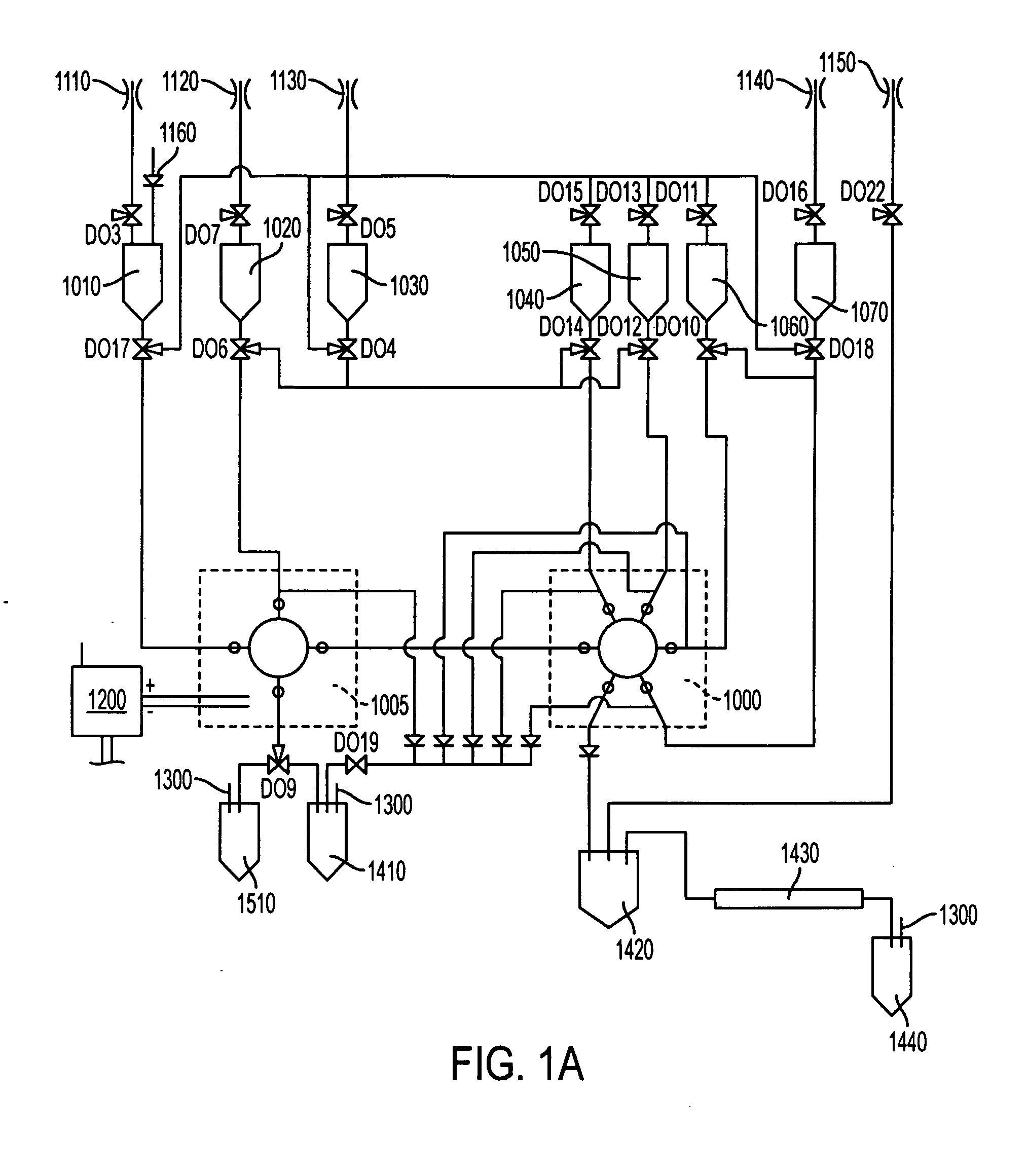

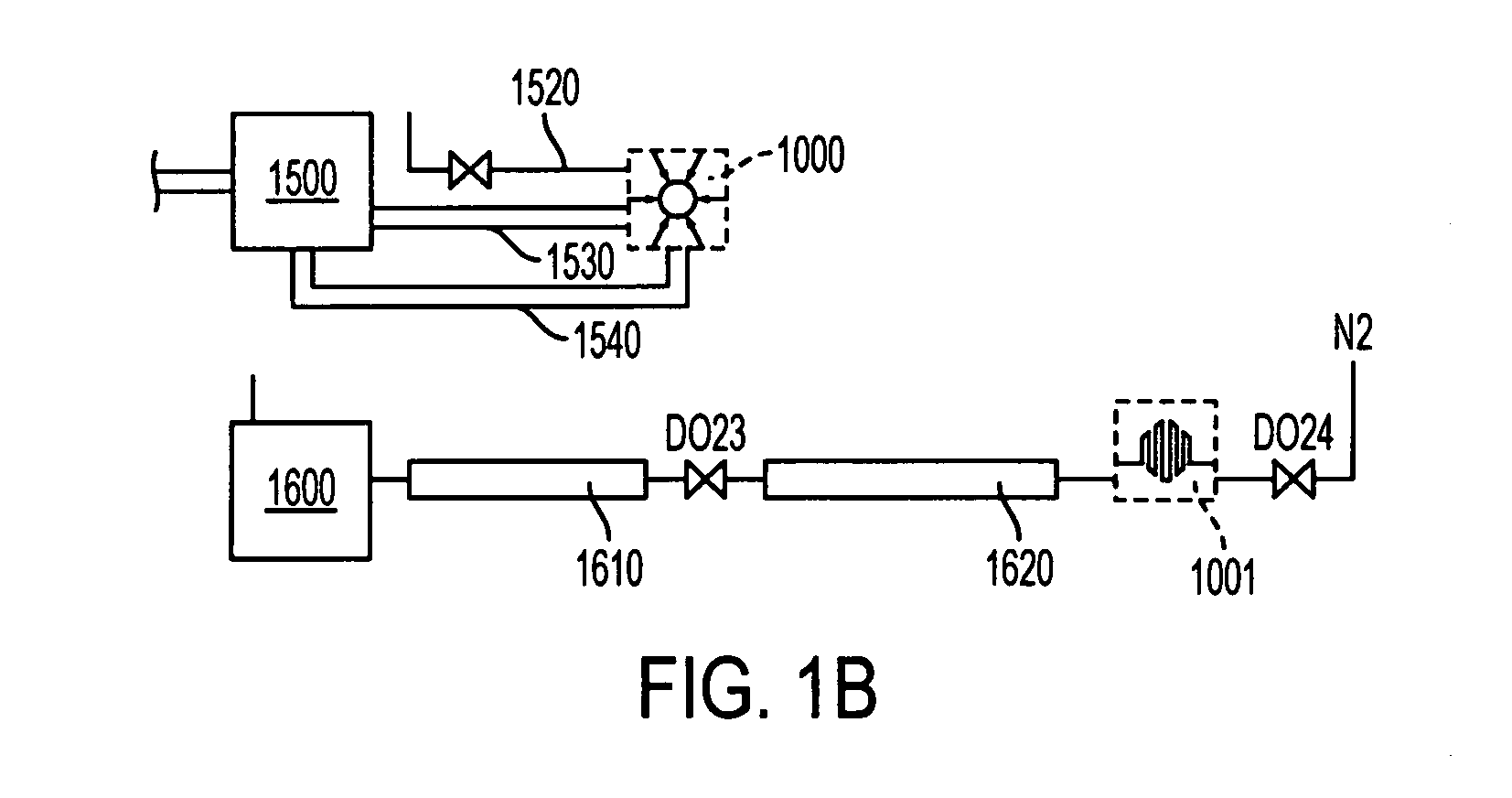

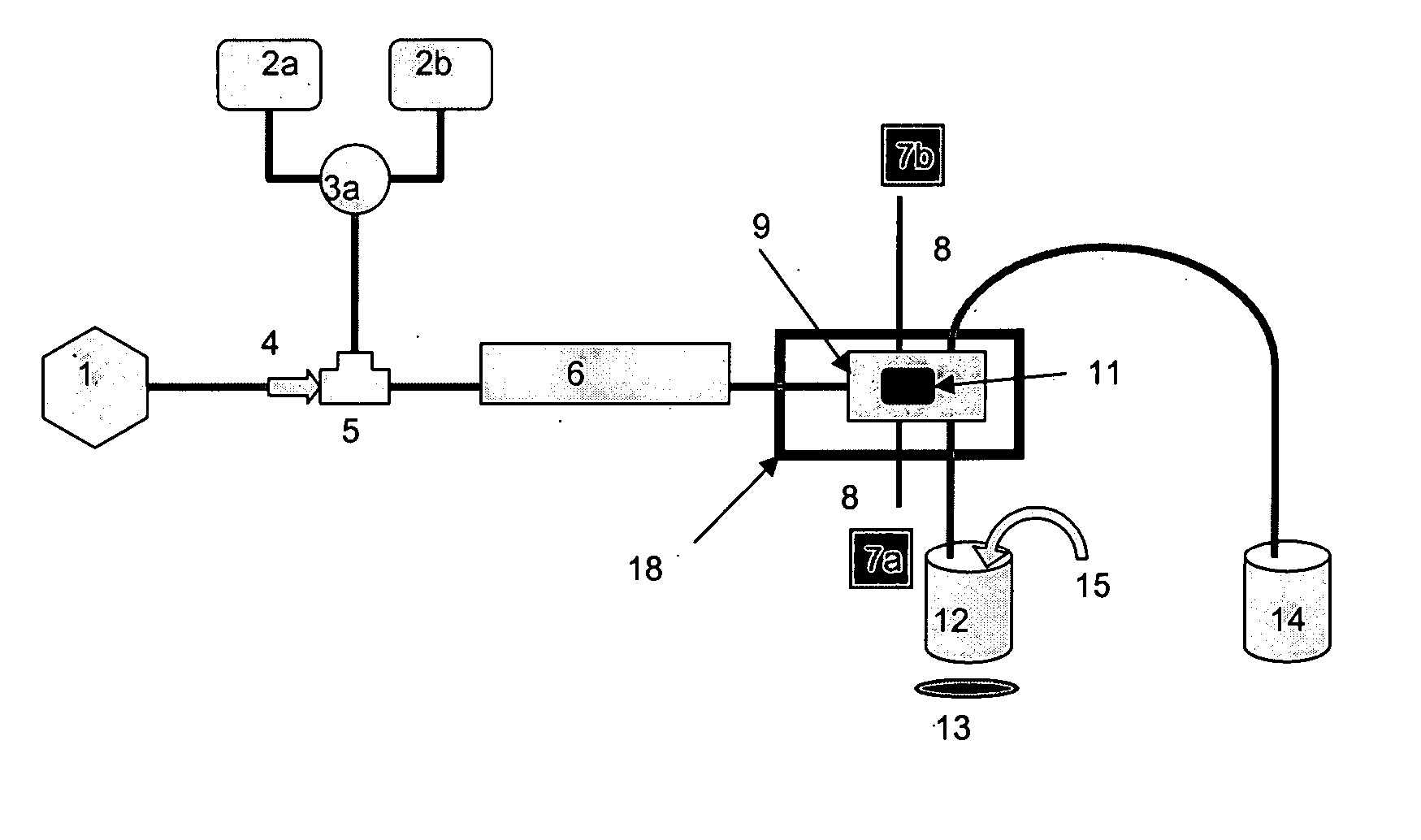

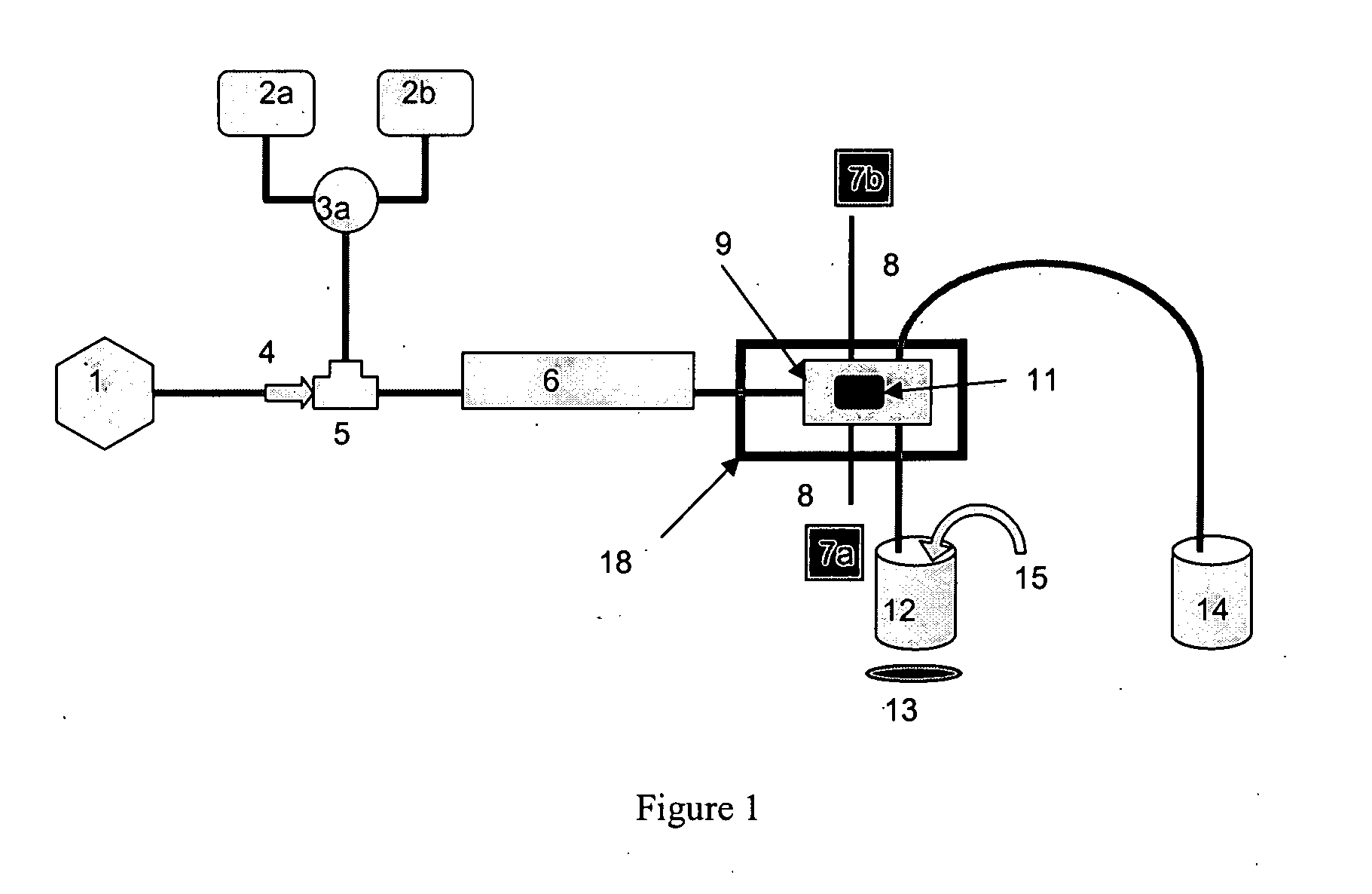

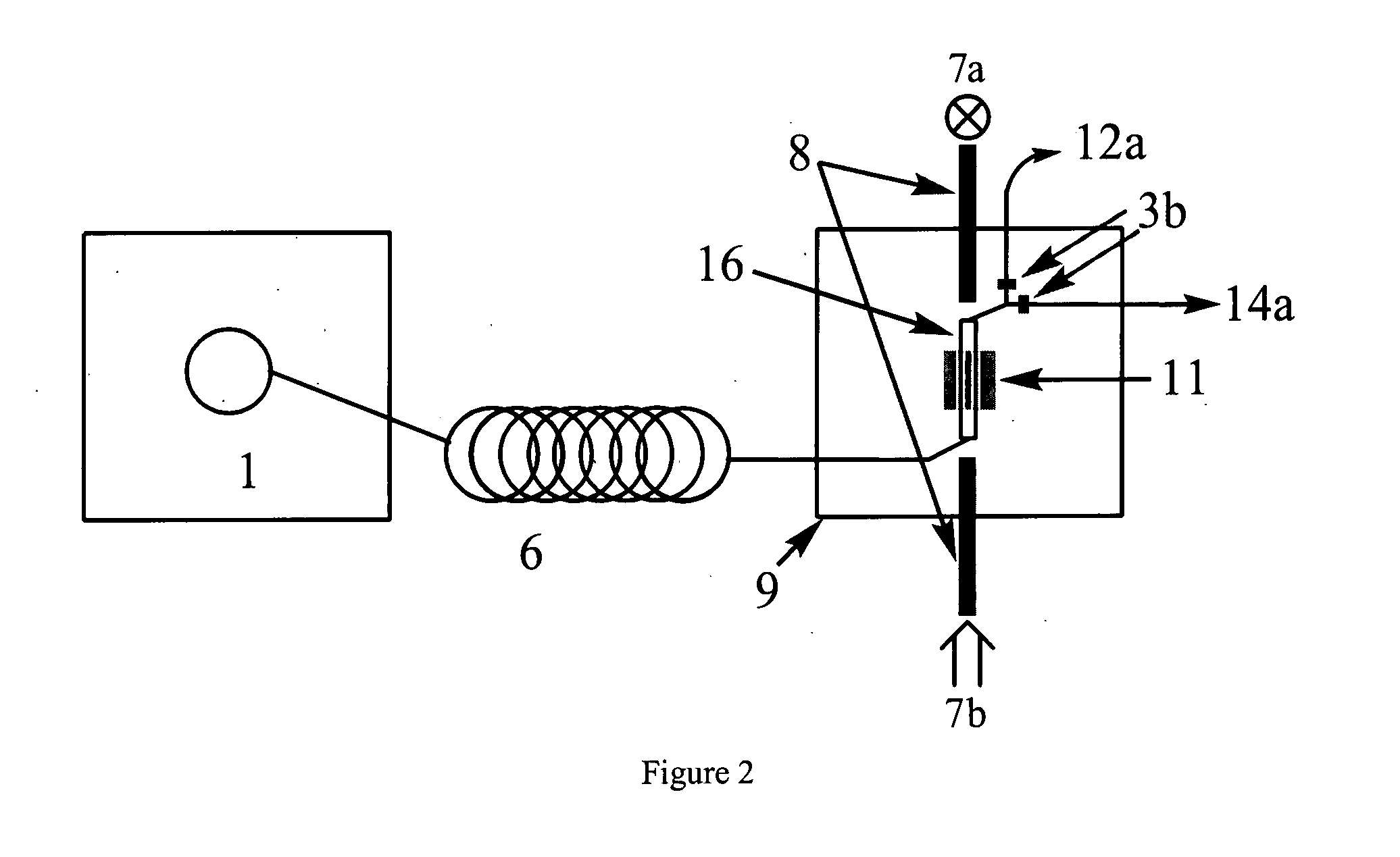

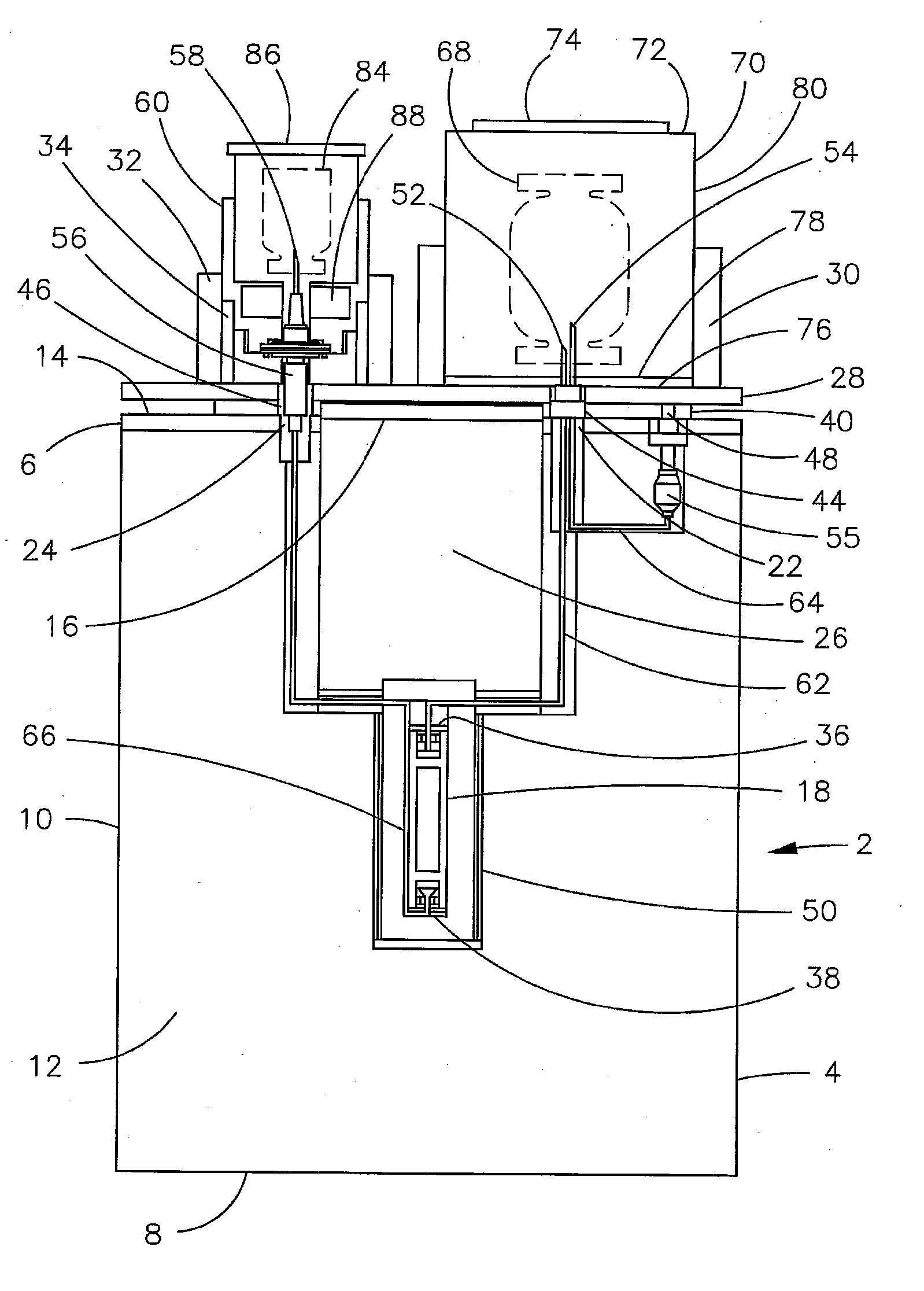

Fully-automated microfluidic system for the synthesis of radiolabeled biomarkers for positron emission tomography

InactiveUS20080233018A1Isotope introduction to sugar derivativesSugar derivativesChemical synthesisConfocal

The present application relates to microfluidic devices and related technologies, and to chemical processes using such devices. More specifically, the application discloses a fully automated synthesis of radioactive compounds for imaging, such as by positron emission tomography (PET), in a fast, efficient and compact manner. In particular, this application describe an automated, stand-alone, microfluidic instrument for the multi-step chemical synthesis of radiopharmaceuticals, such as probes for PET and a method of using such instruments.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

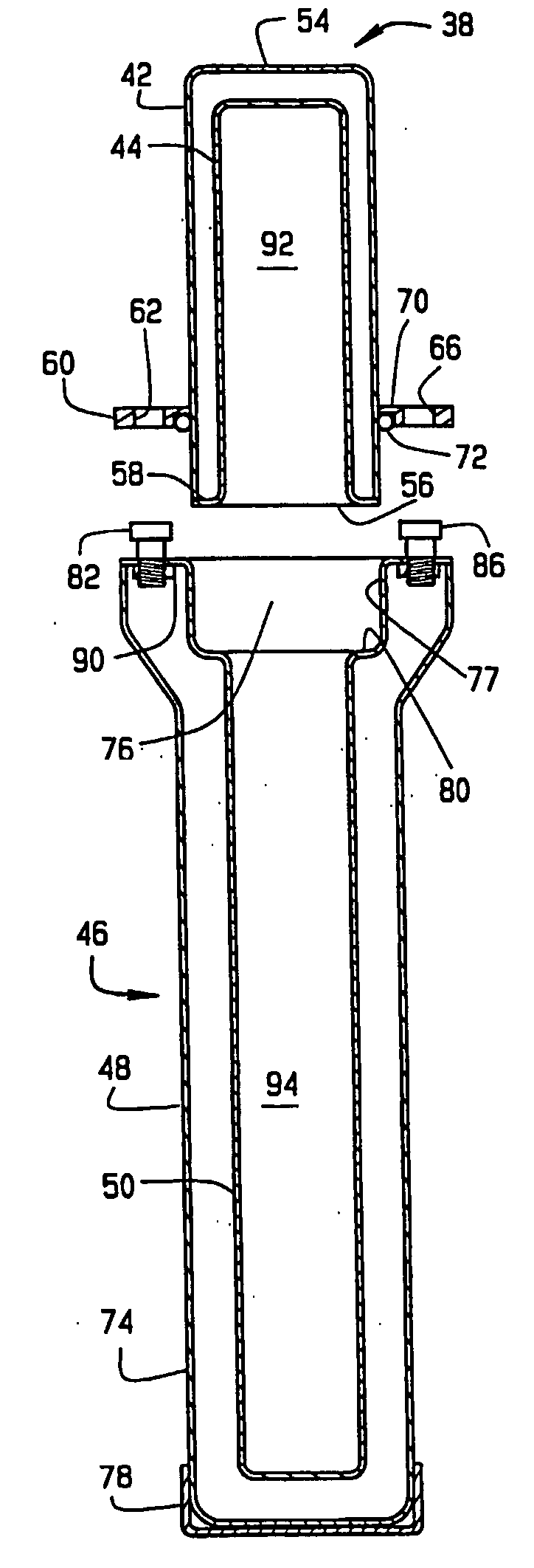

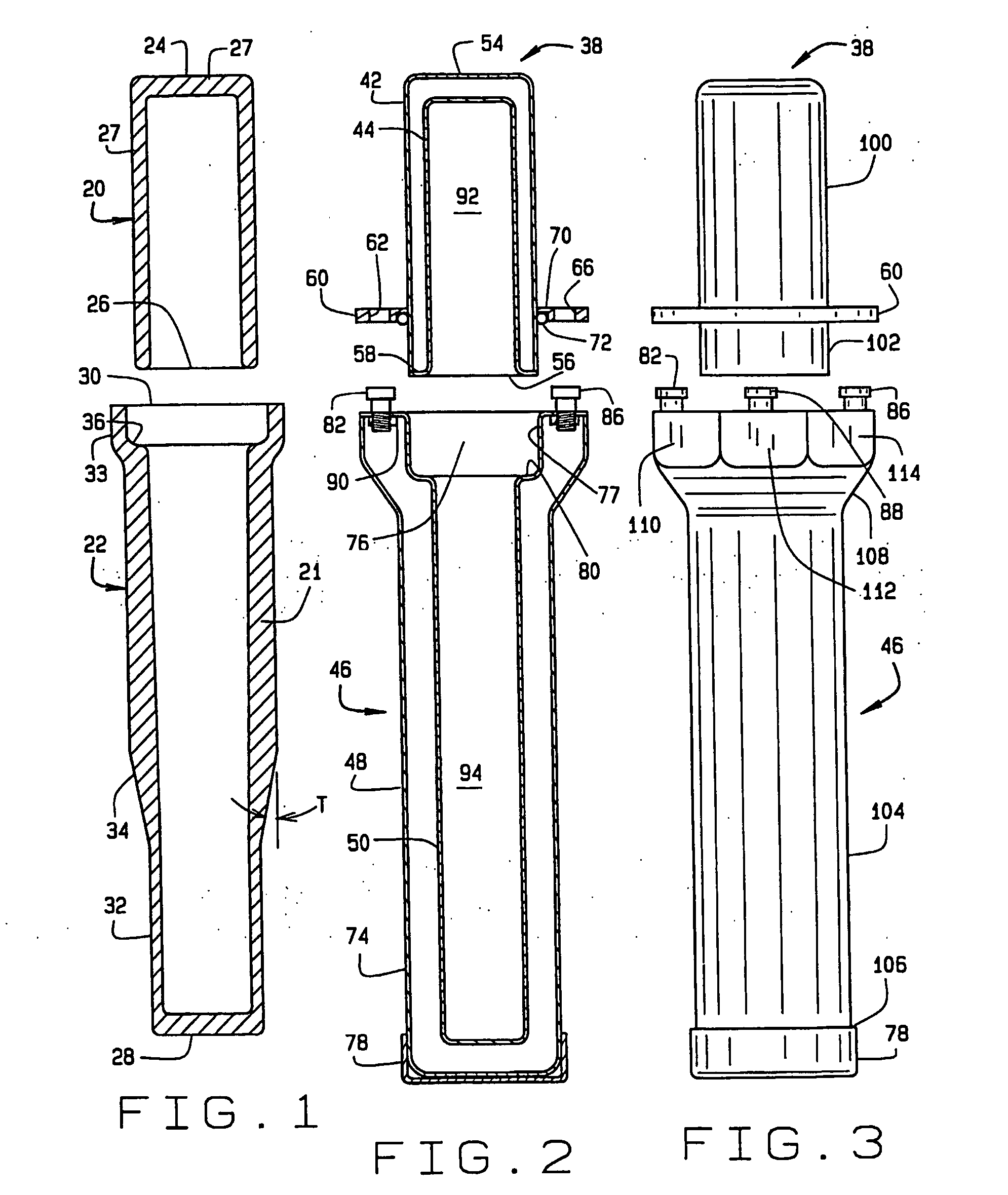

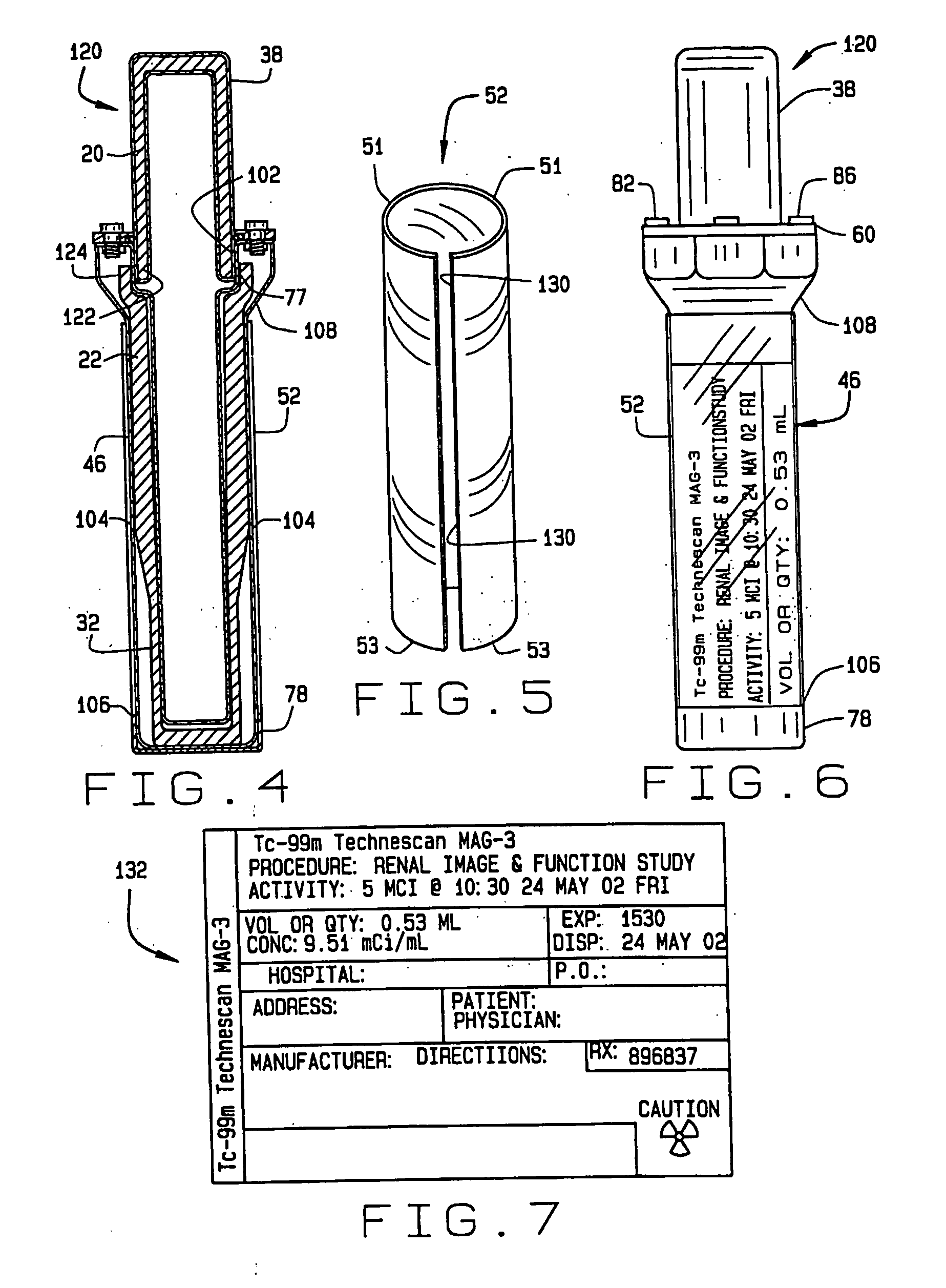

Pharmaceutical pig and method of use

InactiveUS20050234424A1Reduce weightReduce Radiation LeakageInfusion syringesMedical devicesEngineeringDrug treatment

A pharmaceutical pig is used to transport a syringe containing a liquid radiopharmaceutical from a radiopharmacy to a medical facility for administration to a patient. The used syringe is sent back in the pig to the radiopharmacy for disposal. The pig includes a cap that is removably attached to a base. Shielding elements, typically formed from lead, are enclosed in the cap and the base. The pig can be used to transport a conventional syringe or a safety syringe. The pig can be used with or without an inner liner in the base. There is never an inner liner in the cap.

Owner:MALLINCKRODT INC

System for purification and analysis of radiochemical products yielded by microfluidic synthesis devices

InactiveUS20080064110A1Minimizes sample lossReduce pollutionOrganic compounds purification/separation/stabilisationMaterial analysis using wave/particle radiationRadiochemistryMicrofluidics

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

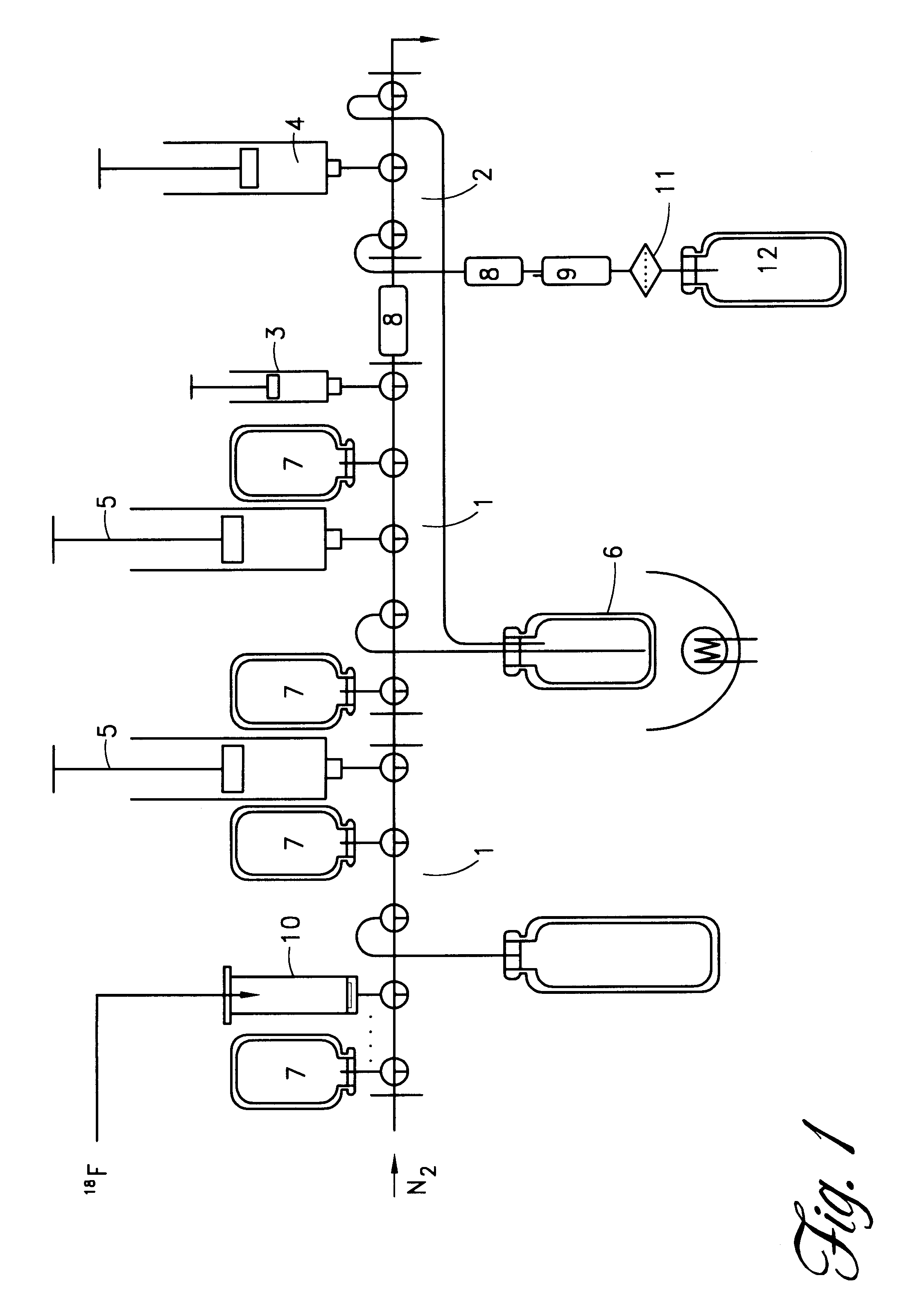

Method for synthesizing labelled compounds

InactiveUS6172207B1Reduce duration and complexityShorten the timeIsotope introduction to sugar derivativesIn-vivo radioactive preparationsCompound aRoom temperature

A process and a device for synthesizing labeled compounds. The process involves preparing a labeling agent, labeling a precursor with the labeling agent, where the precursor is a protected substrate, and deprotecting the labeled precursor to convert the labeled precursor to a labeled compound by passing the labeled precursor through a solid support in a column or a cartridge. The process may be used to convert labeled tetraacetylfluoroglucose (TAFg) to labeled fluoro-deoxy-glucose (FDG) for use in nuclear medical imaging. The process is more rapid than conventional methods and is performed at room temperature rather than high temperature for conventional technology.

Owner:UNIV LIBRE DE BRUXELIES +2

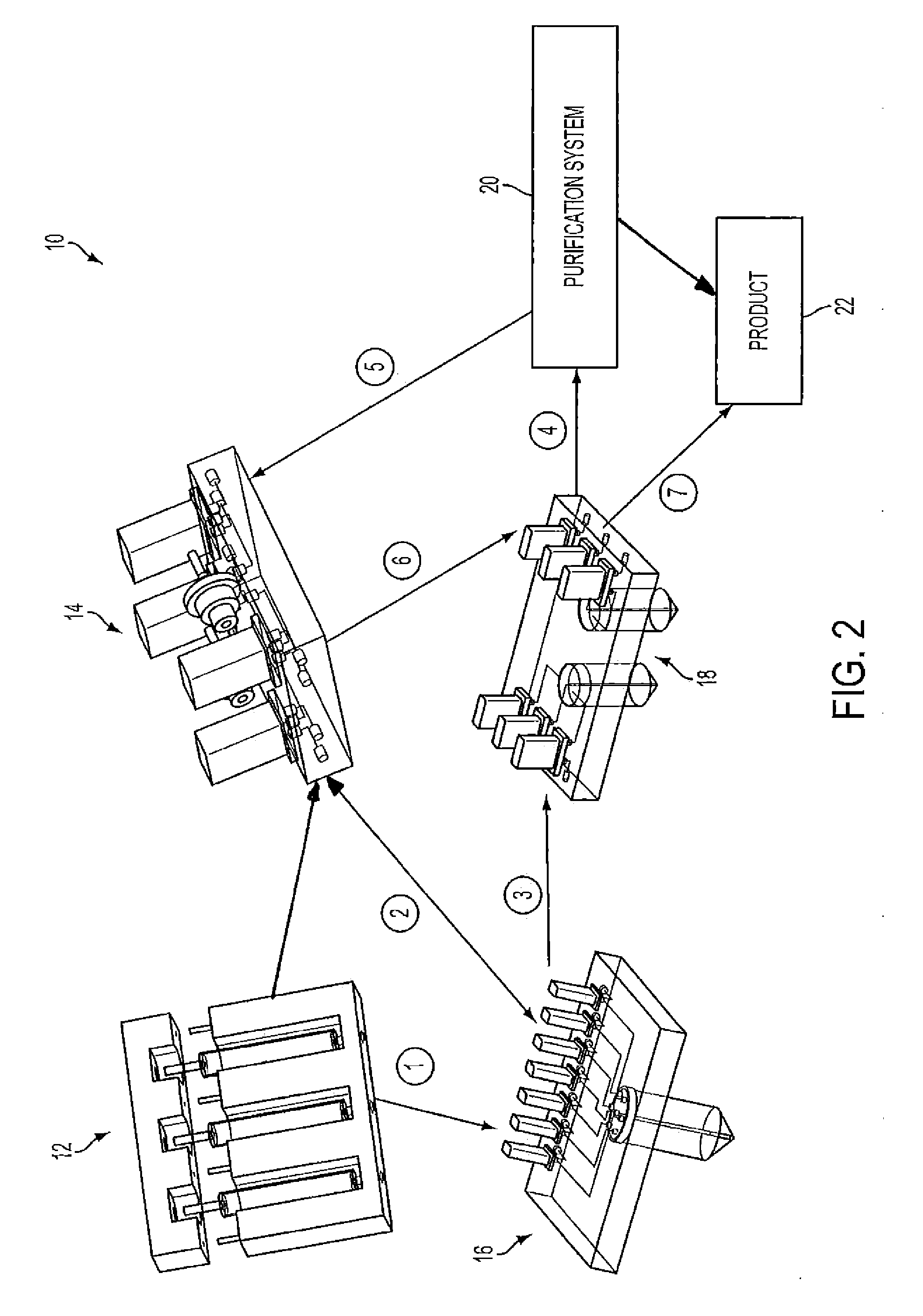

Modular System for Radiosynthesis with Multi-Run Capabilities and Reduced Risk of Radiation Exposure

InactiveUS20110150714A1Fast and efficient and compact and safe to operatorMinimize exposureIon-exchange process apparatusIon-exchanger regenerationRadiosynthesisRadiation exposure

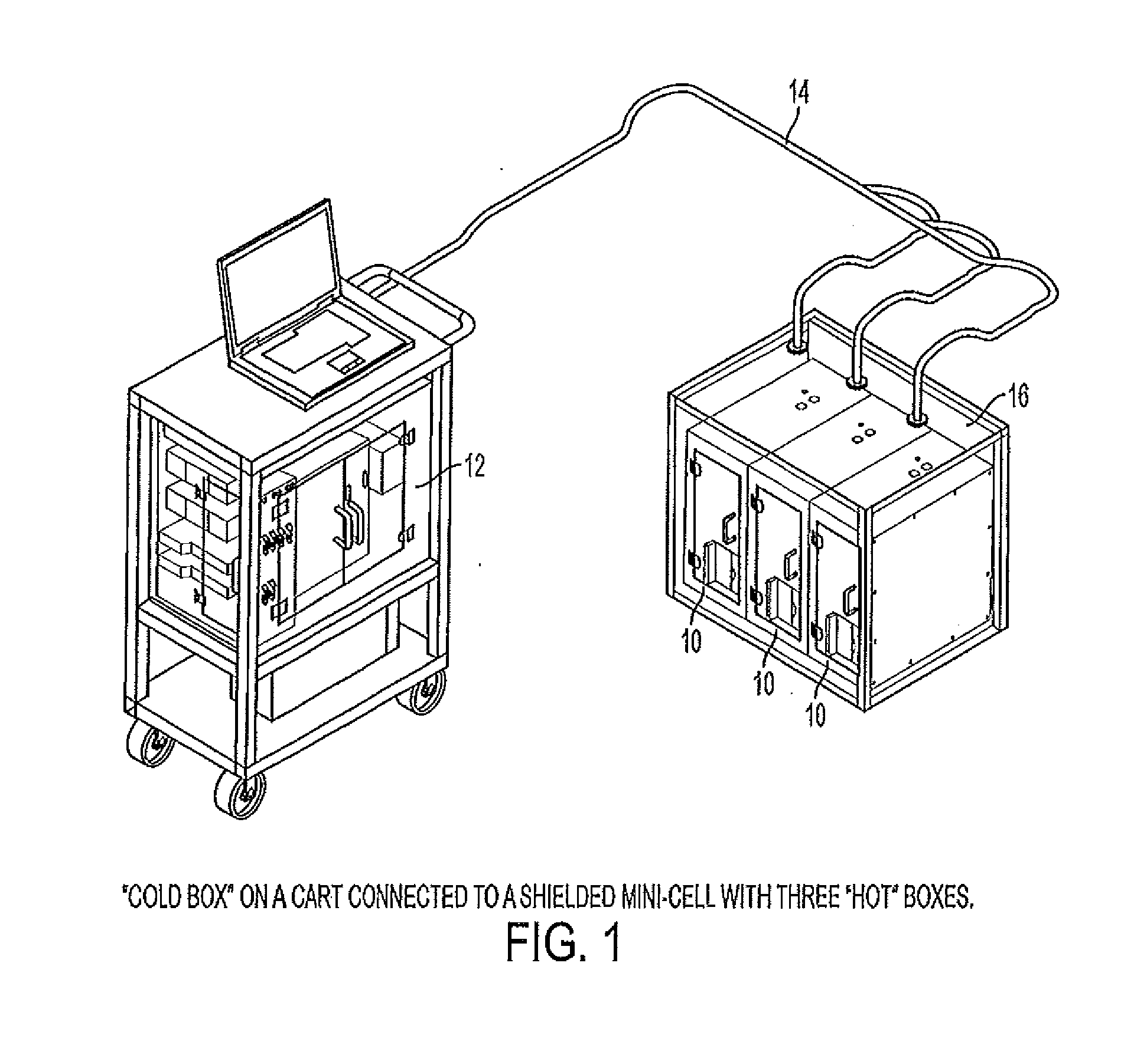

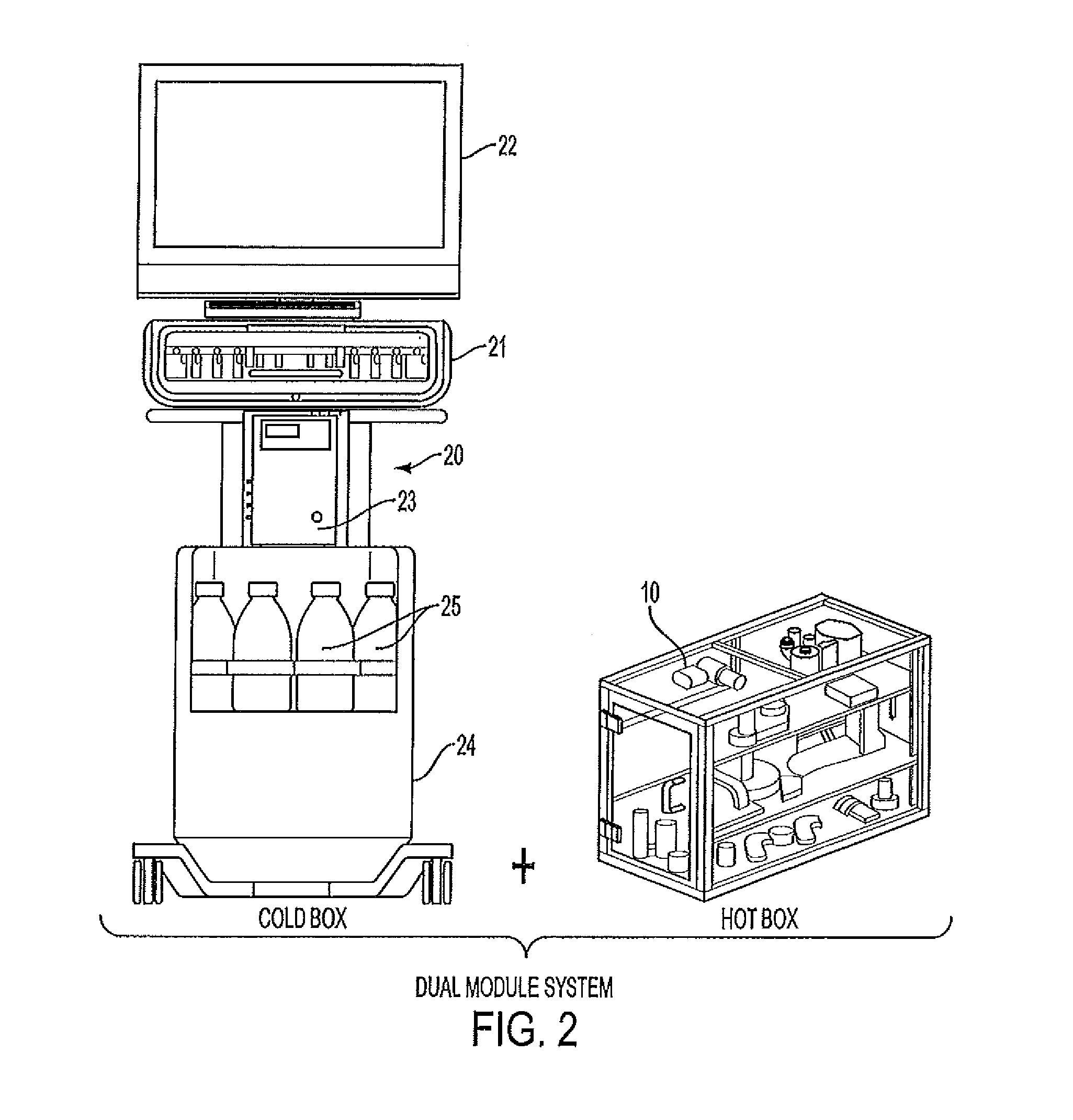

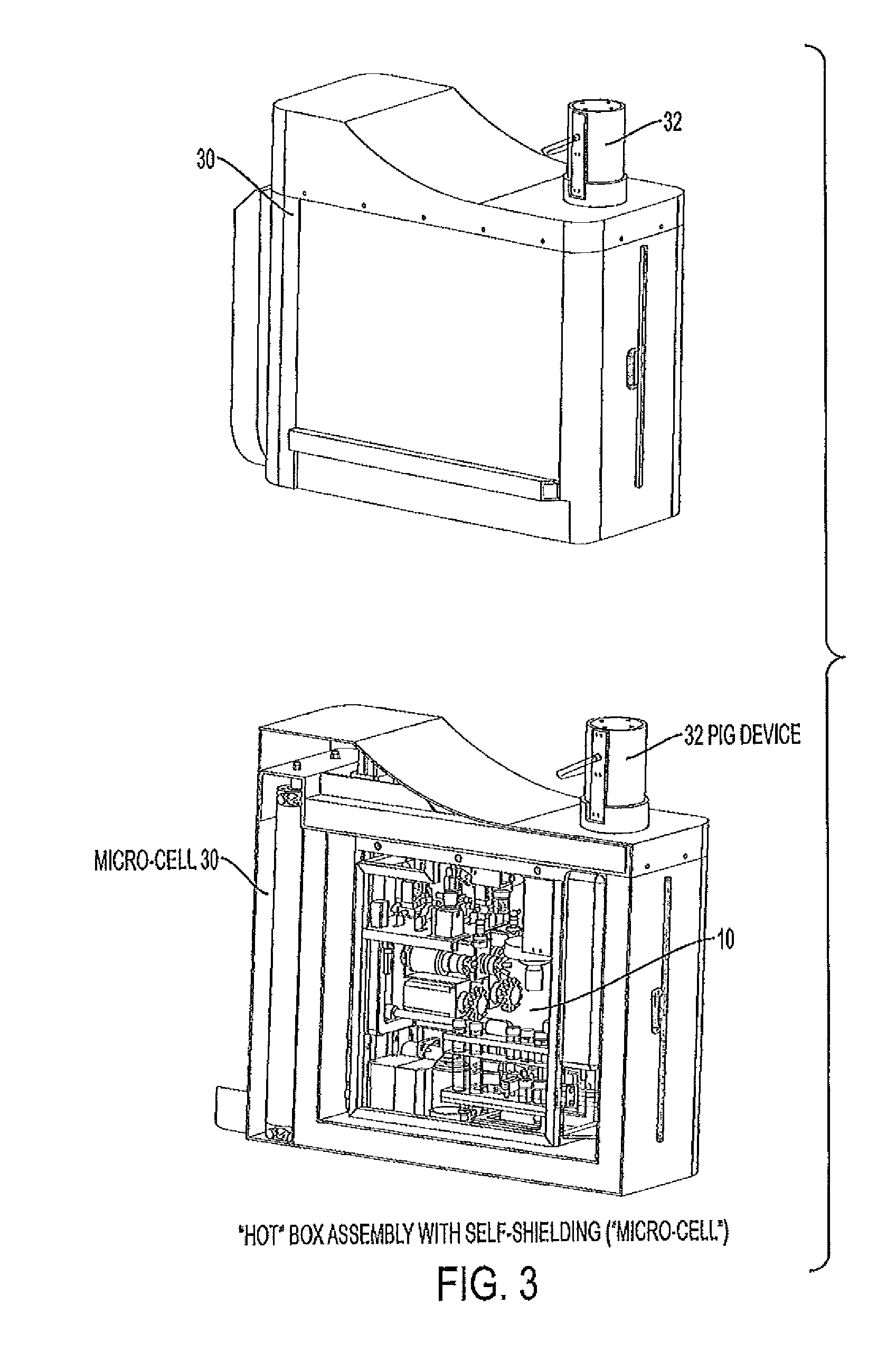

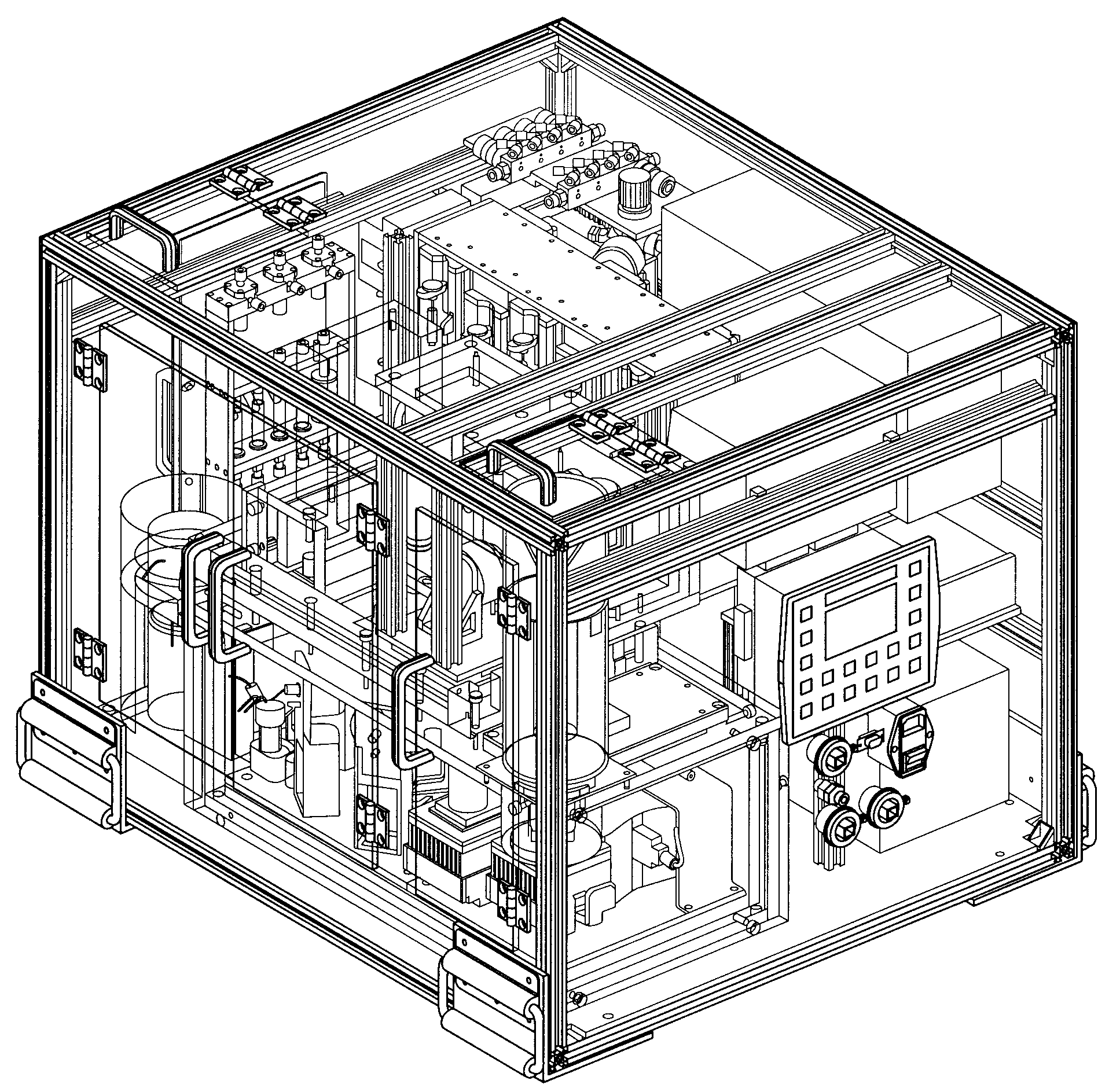

Macro- and microfluidic devices and related technologies, and chemical processes using such devices. More specifically, the devices may be used for a fully automated synthesis of radioactive compounds for imaging, such as by positron emission tomography (PET), in an efficient, compact and safe to the operator manner. In particular, embodiments of the present invention relate to an automated, multi-run, microfluidic instrument for the multi-step synthesis of radiopharmaceuticals, such as PET probes, comprising a remote shielded mini-cell containing radiation-handing components.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Microfluidic radiosynthesis system for positron emission tomography biomarkers

InactiveUS20090036668A1Fast and efficient and compact mannerSmall amountGaseous chemical processesSugar derivativesHands freeEngineering

Methods and devices for a fully automated synthesis of radioactive compounds for imaging, such as by positron emission tomography (PET), in a fast, efficient and compact manner are disclosed. In particular, the various embodiments of the present invention provide an automated, stand-alone, hands-free operation of the entire radiosynthesis cycle on a microfluidic device with unrestricted gas flow through the reactor, starting with target water and yielding purified PET radiotracer within a period of time shorter than conventional chemistry systems. Accordingly, one aspect of the present invention is related to a microfluidic chip for radiosynthesis of a radiolabeled compound, comprising a reaction chamber, one or more flow channels connected to the reaction chamber, one or more vents connected to said reaction chamber, and one or more integrated valves to effect flow control in and out of said reaction chamber.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Evacuated containment vessel for a nuclear reactor

ActiveUS20090161812A1Nuclear energy generationNuclear engineering problemsNuclear reactorEngineering

A system includes a containment vessel configured to prohibit a release of a coolant, and a reactor vessel mounted inside the containment vessel. An outer surface of the reactor vessel is exposed to below atmospheric pressure, wherein substantially all gases are evacuated from within the containment vessel.

Owner:NUSCALE

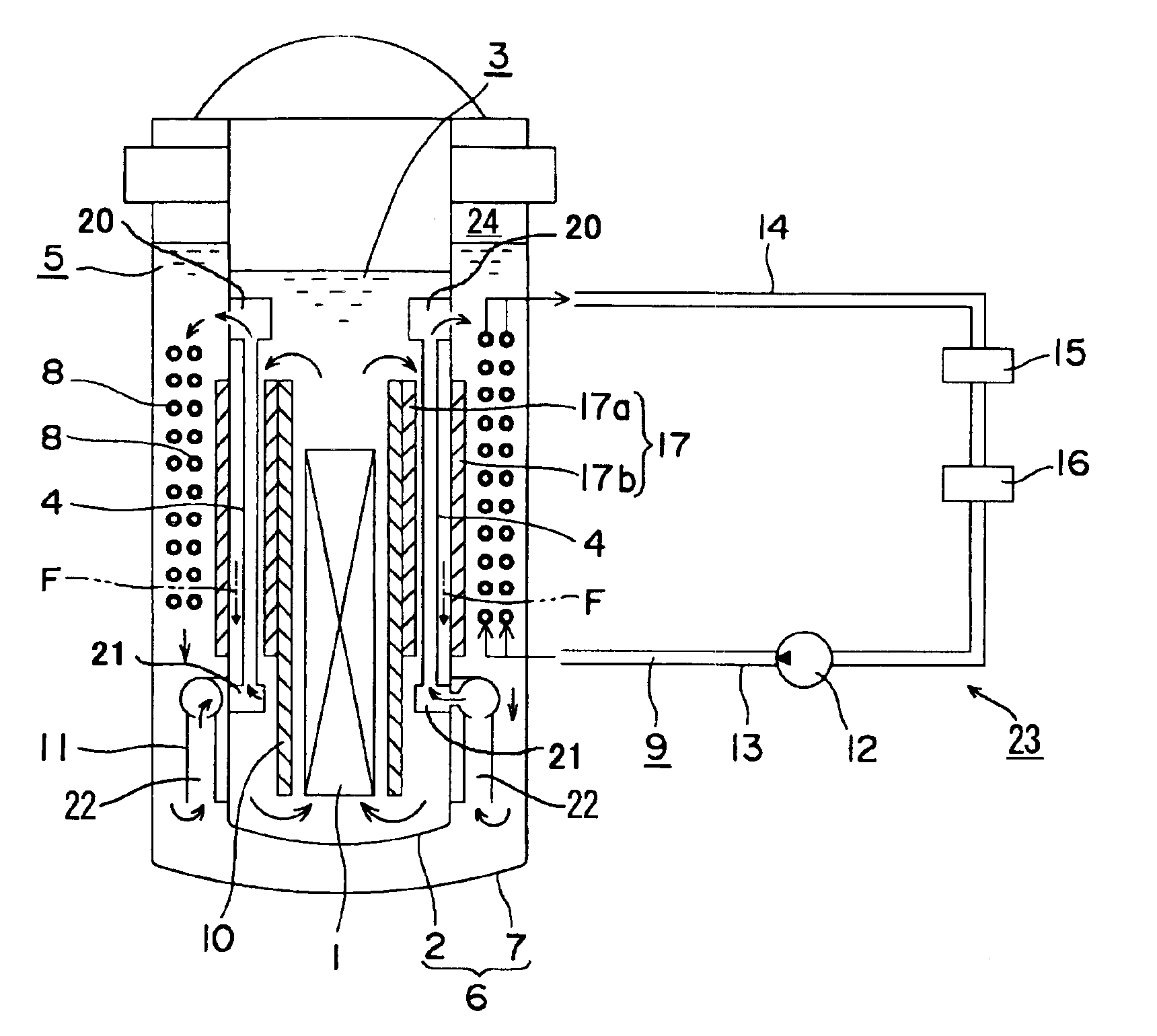

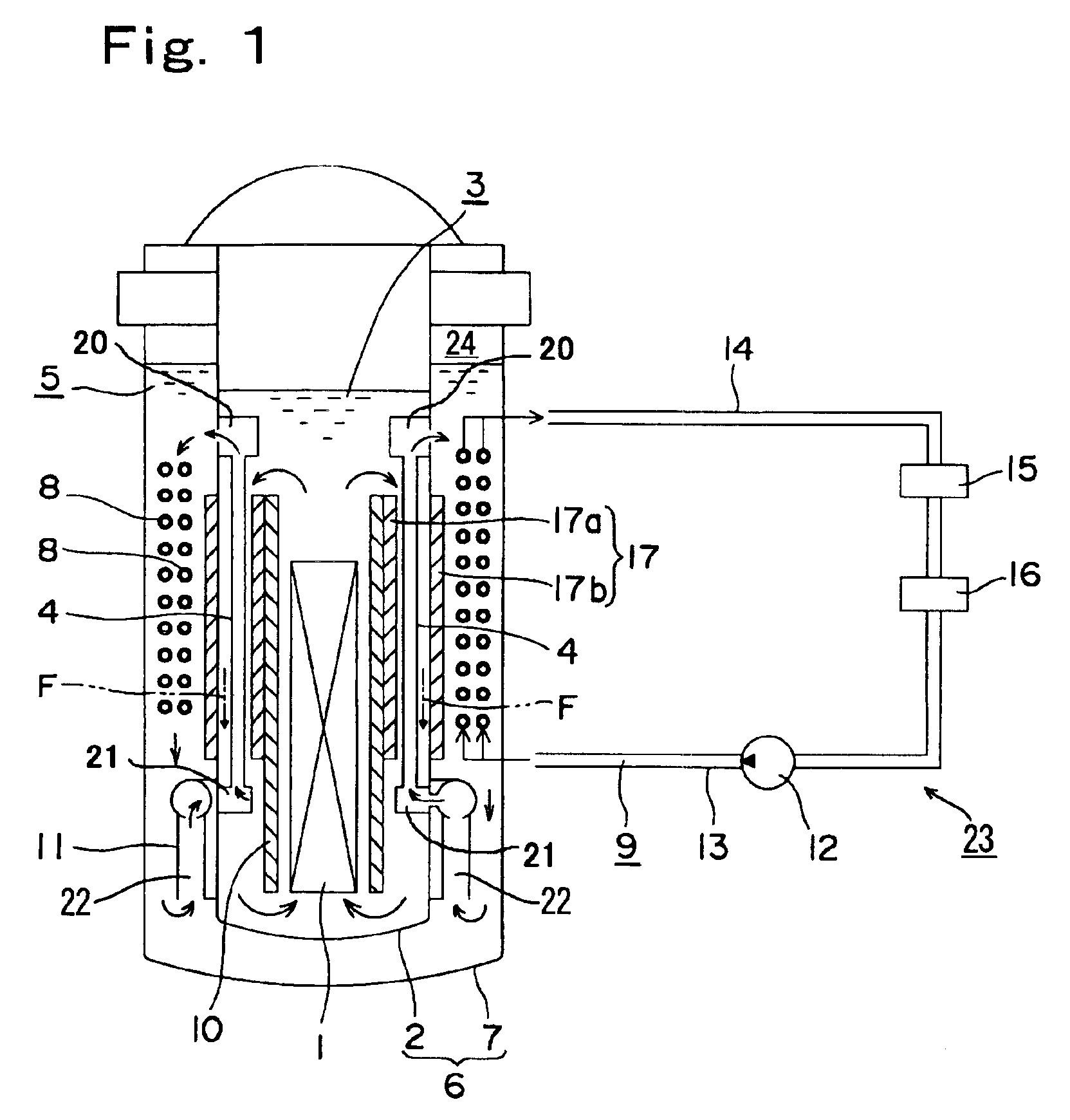

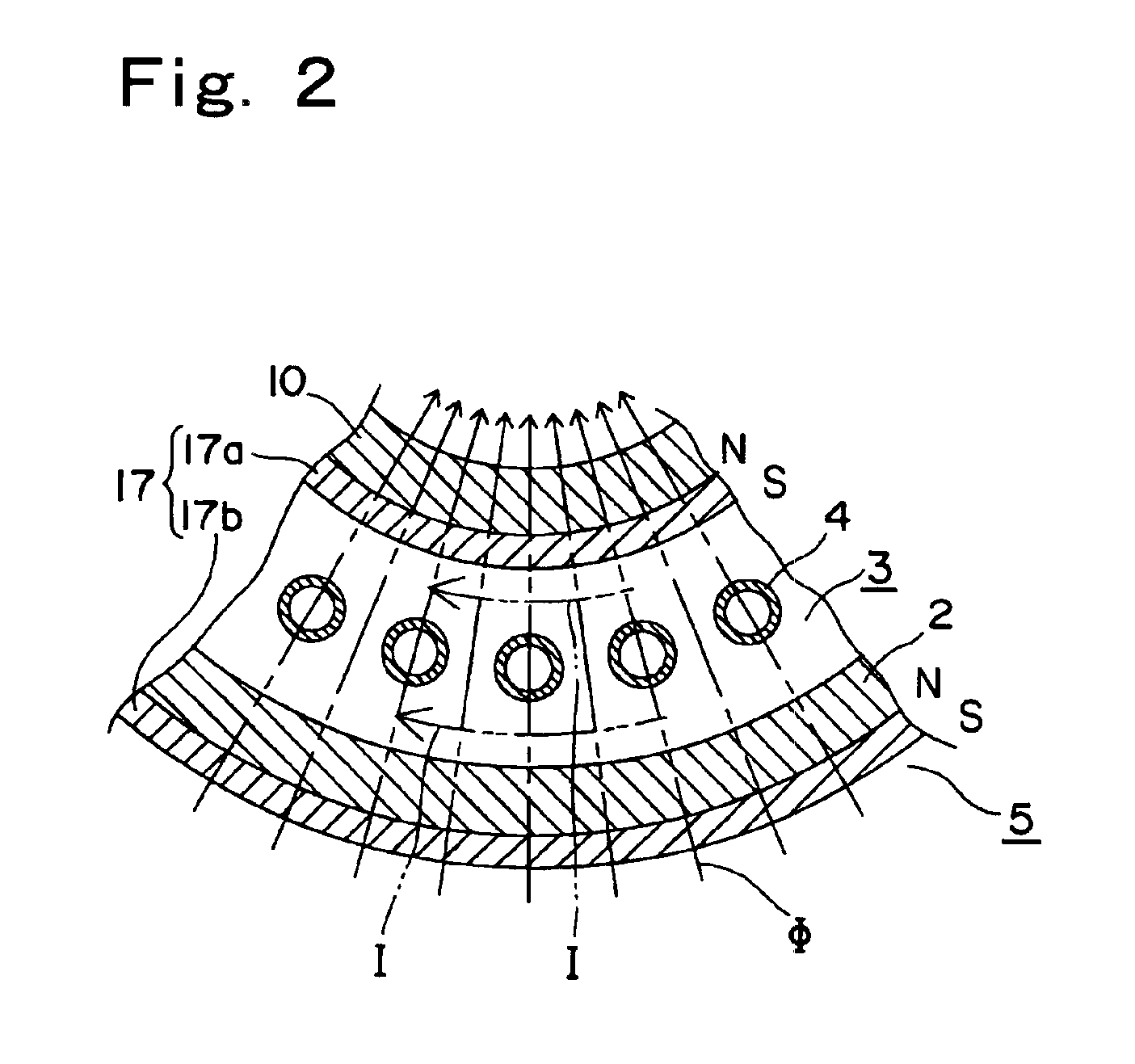

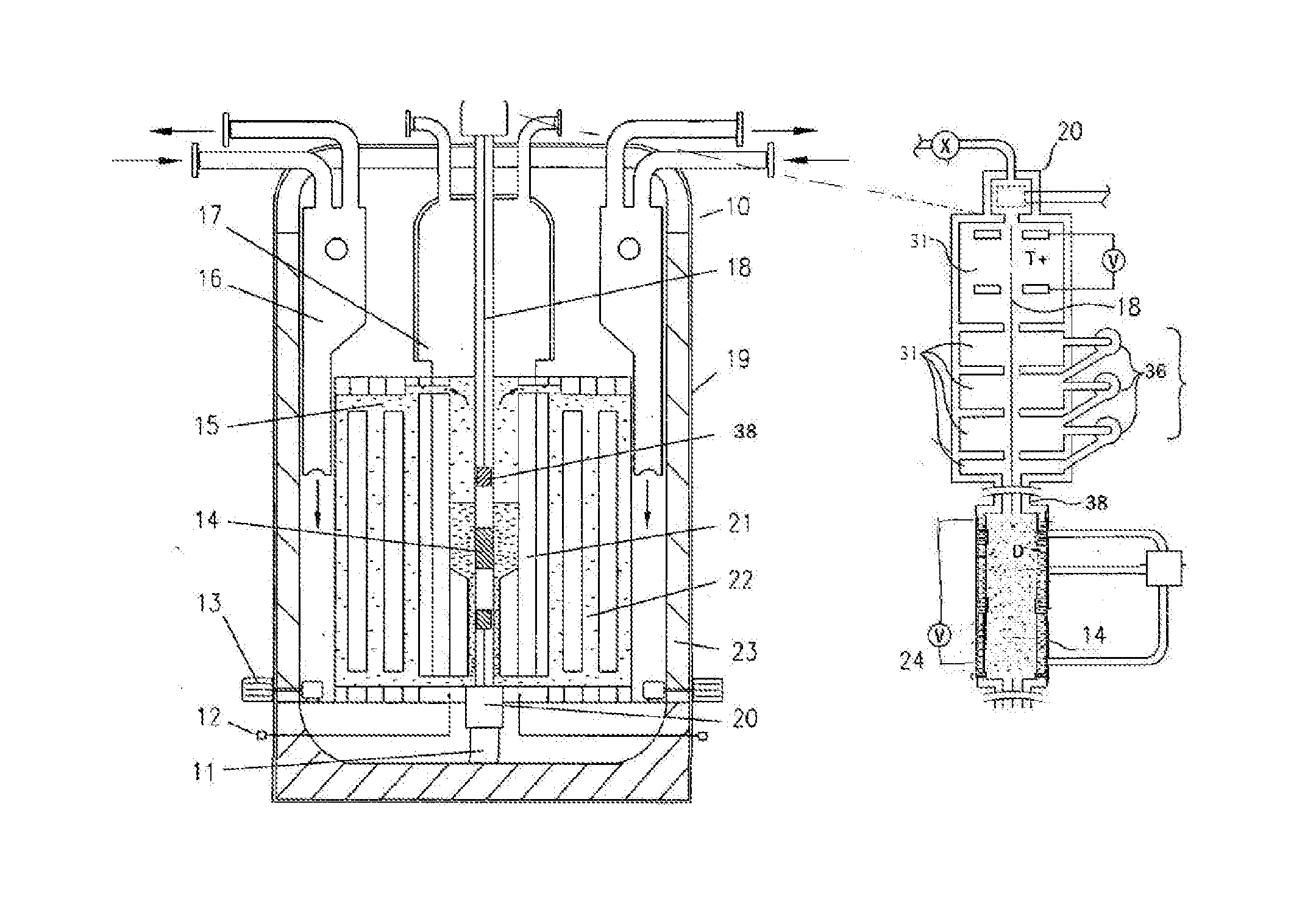

Nuclear reactor

InactiveUS6944255B2Small sizeReduce manufacturing costIntegral reactorsNuclear energy generationNuclear reactorHeat transfer tube

A nuclear reactor in which a secondary or tertiary coolant system of a nuclear steam supply system is simplified, comprising: a reactor vessel (2) which integrates a reactor core (1); a first coolant (3) which is stored in the reactor vessel (2) and heated by the reactor core (1) to convect; a first heat transfer tube (4) which is arranged in the reactor vessel (2) and comes into contact with the first coolant (3); and a second coolant (5) which is supplied from the outside of the reactor vessel (2) to the first heat transfer tube (4), cools the first coolant (3) and led to the outside of the reactor vessel (2).

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

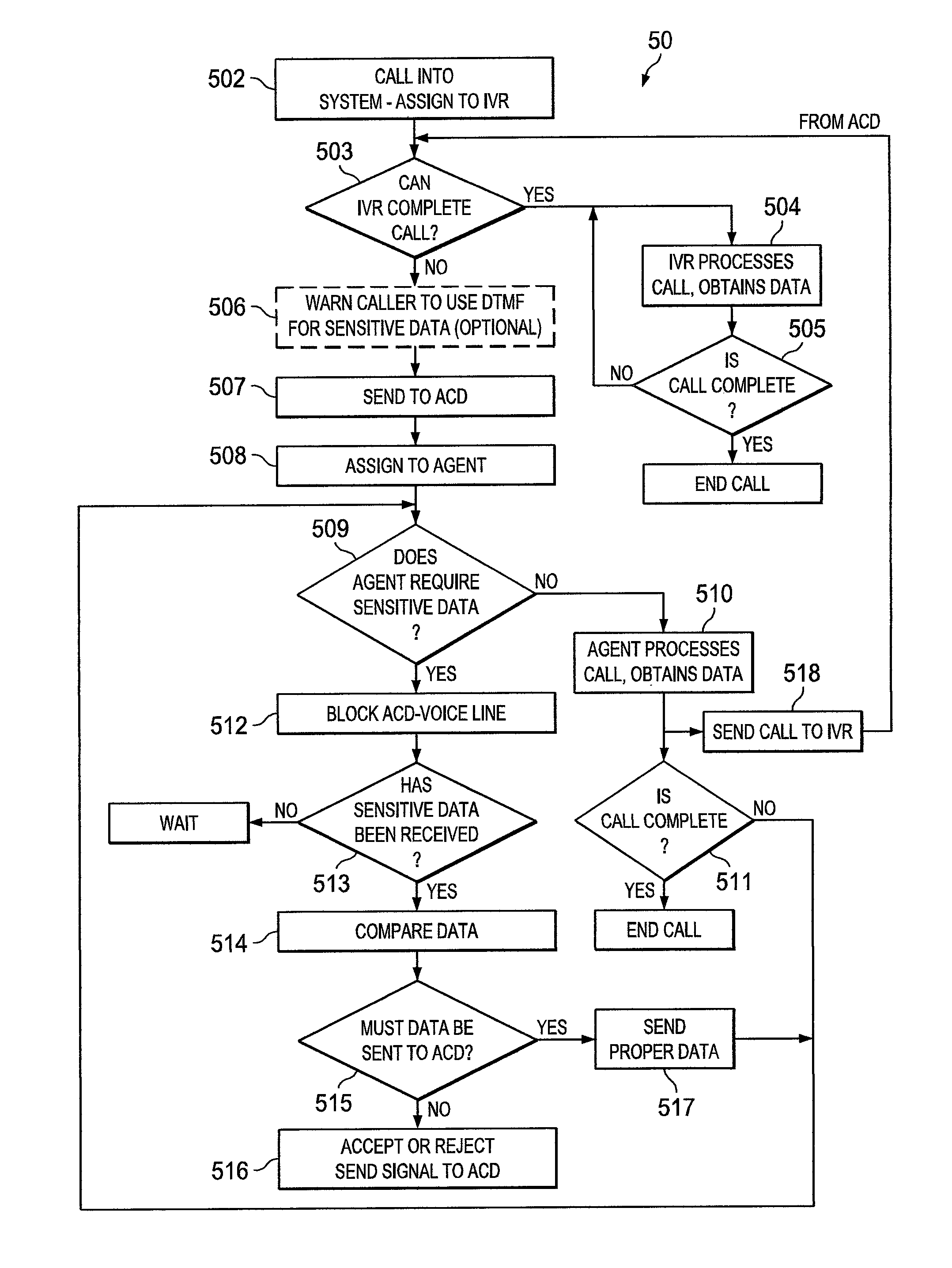

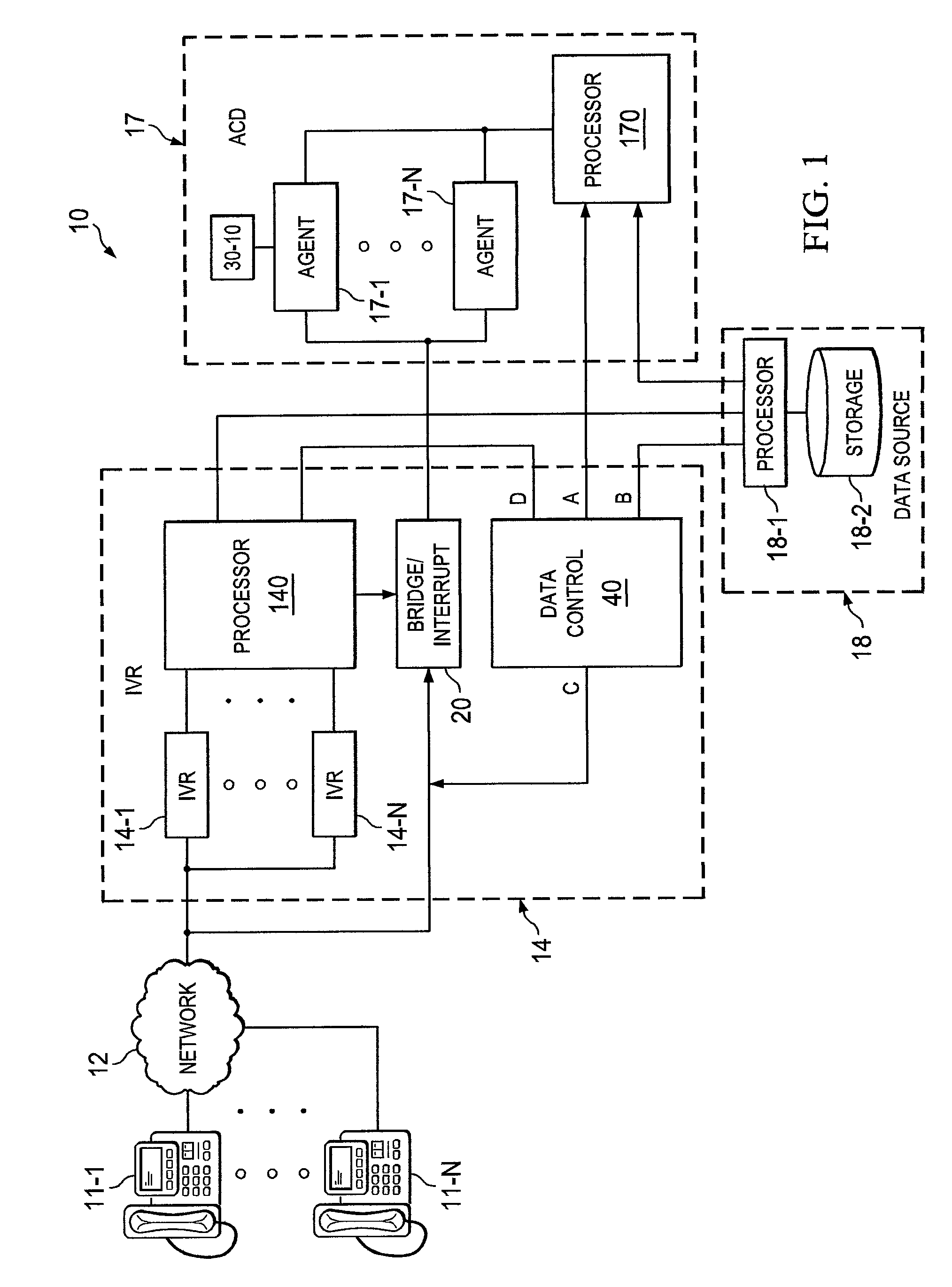

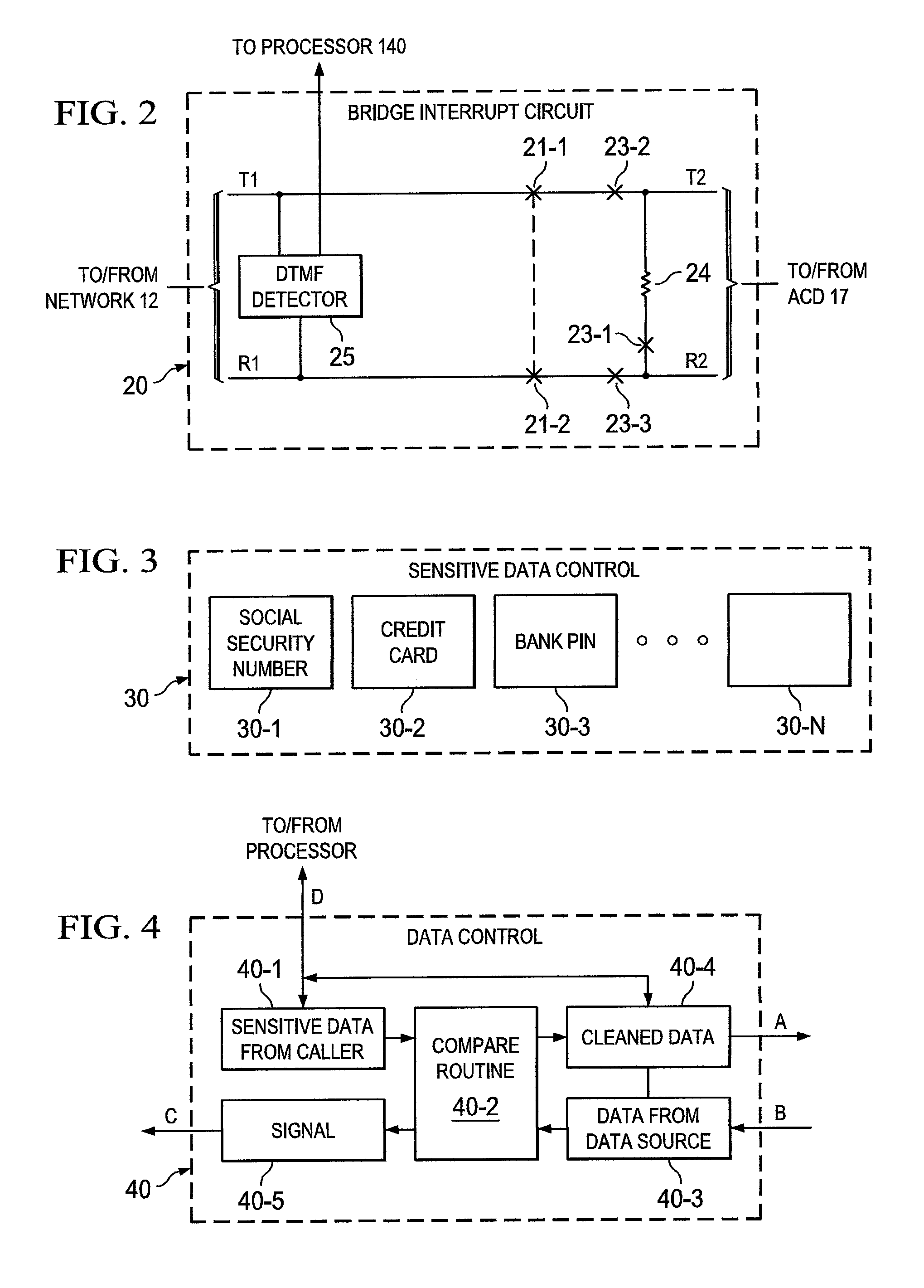

Systems and methods for preventing sensitive information from being communicated into a non-secure environment

ActiveUS8204180B1Interconnection arrangementsUnauthorised/fraudulent call preventionBidirectional communicationOnline chat

A telecommunication system is arranged between a trusted automated interactive system and a non-secure agent. The trusted automated interactive portion is operable for bidirectional communications with a caller. The agent portion is arranged to be bridged onto a communication connection between the caller (or network chat user) and the trusted interactive system under certain conditions. Sensitive data transmitted between the system and a calling user may be blocked from being communicated to the agent even while the agent is bridged onto the connection. In one embodiment, information (such as a verification of authenticity of the caller) pertaining to the sensitive data (but not the sensitive data itself) is communicated to the agent.

Owner:INTERVOICE PARTNERSHIP

Molten nuclear fuel salts and related systems and methods

InactiveUS20160189813A1Improve power densityImprove the level ofFuel elementsNuclear energy generationPresent methodChloride

This disclosure describes nuclear fuel salts usable in certain molten salt reactor designs and related systems and methods. Binary, ternary and quaternary chloride fuel salts of uranium, as well as other fissionable elements, are described. In addition, fuel salts of UClxFy are disclosed as well as bromide fuel salts. This disclosure also presents methods and systems for manufacturing such fuel salts, for creating salts that reduce corrosion of the reactor components and for creating fuel salts that are not suitable for weapons applications.

Owner:TERRAPOWER

Installing method for main pipeline of coolant system of nuclear power station

ActiveCN102169736ASimple structureReduce elbowNuclear energy generationReactors manufactureNumerical controlPressurized water reactor

The invention relates to an installing method for a main pipeline of a coolant system of a nuclear power station, which is characterized in that the main pipeline of the coolant system of a reactor of the pressurized water reactor nuclear power station comprises a cool section (41) and a hot section (42), and a steam generator is directly connected with a main pump. According to the invention, the problem that the main pipeline is installed and welded by only a pressure container or steam generator in place by adopting the installing method of the main pipeline without a transition section issolved, and technical limit that the main pipeline is installed after the pressure container is in place and the steam generator or main pump is in place in the traditional main pipeline constructiontechnology is eliminated. A main pipeline groove is processed by adopting a site numerical control machining technology, the main pipeline and equipment connected with the main pipeline are subjectedto measurement, modeling and process monitoring by adopting a laser tracking measuring and 3D modeling technology, the main pipeline is regulated to meet the assembly welding requirement and is installed by using a narrow TIG (argon tungsten-arc welding) automatic welding technology, thus a feasible method is provided for shortening the construction period of the nuclear power station.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

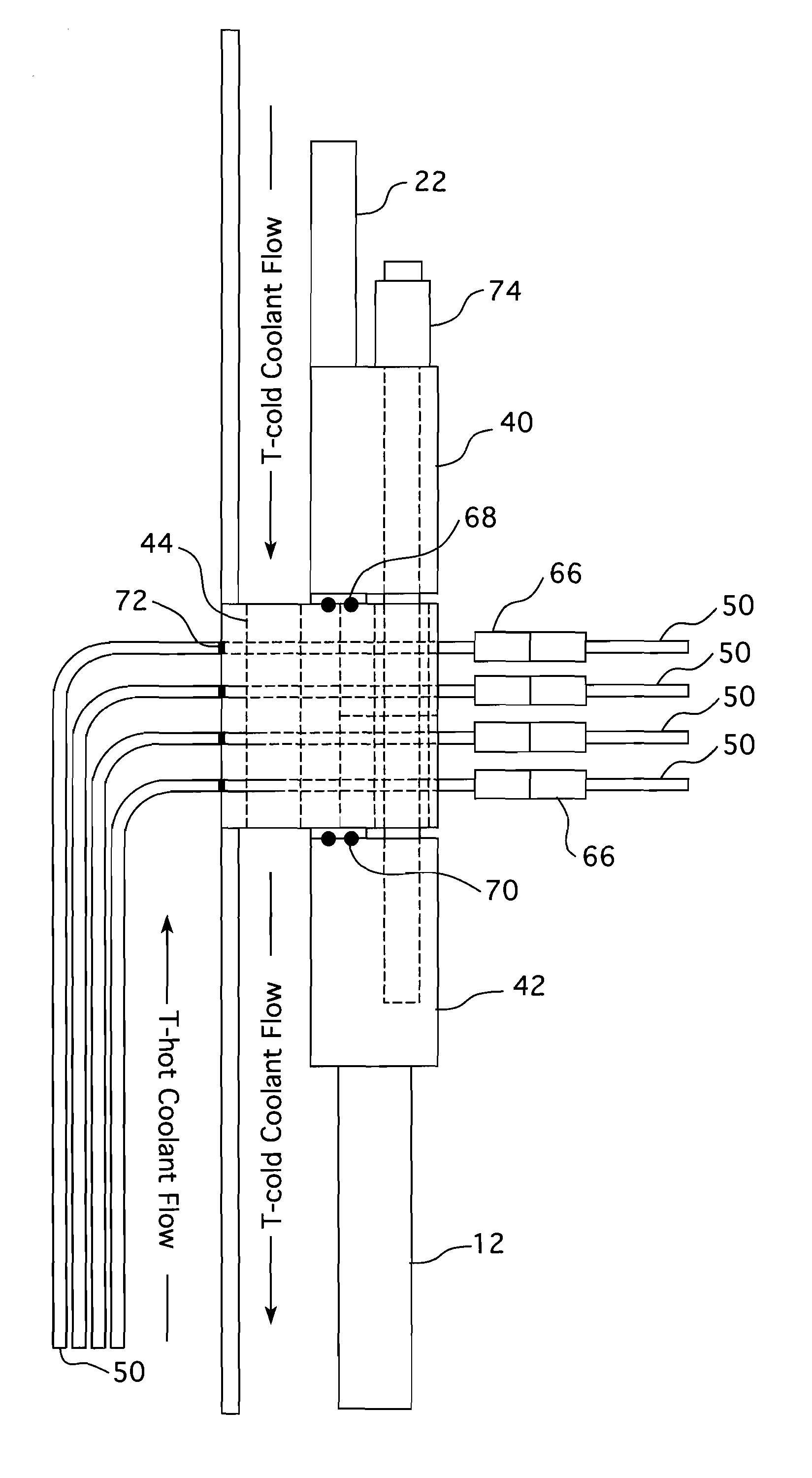

Instrumentation and control penetration flange for pressurized water reactor

A nuclear reactor having a penetration seal ring interposed between the reactor vessel flange and a mating flange on the reactor vessel head. Radial ports through the flange provide passage into the interior of the reactor vessel for utility conduits that can be used to convey signal cables, power cables or hydraulic lines to the components within the interior of the pressure vessel. A double o-ring seal is provided on both sides of the penetration flange and partial J-welds on the inside diameter of the flange between the flange and the utility conduits secure the pressure boundary.

Owner:WESTINGHOUSE ELECTRIC CORP

Nuclear reactor internal structure

ActiveUS20070133732A1Separating vortexReduce flow rateNuclear energy generationNuclear engineering problemsNuclear reactorEngineering

Owner:MITSUBISHI HEAVY IND LTD

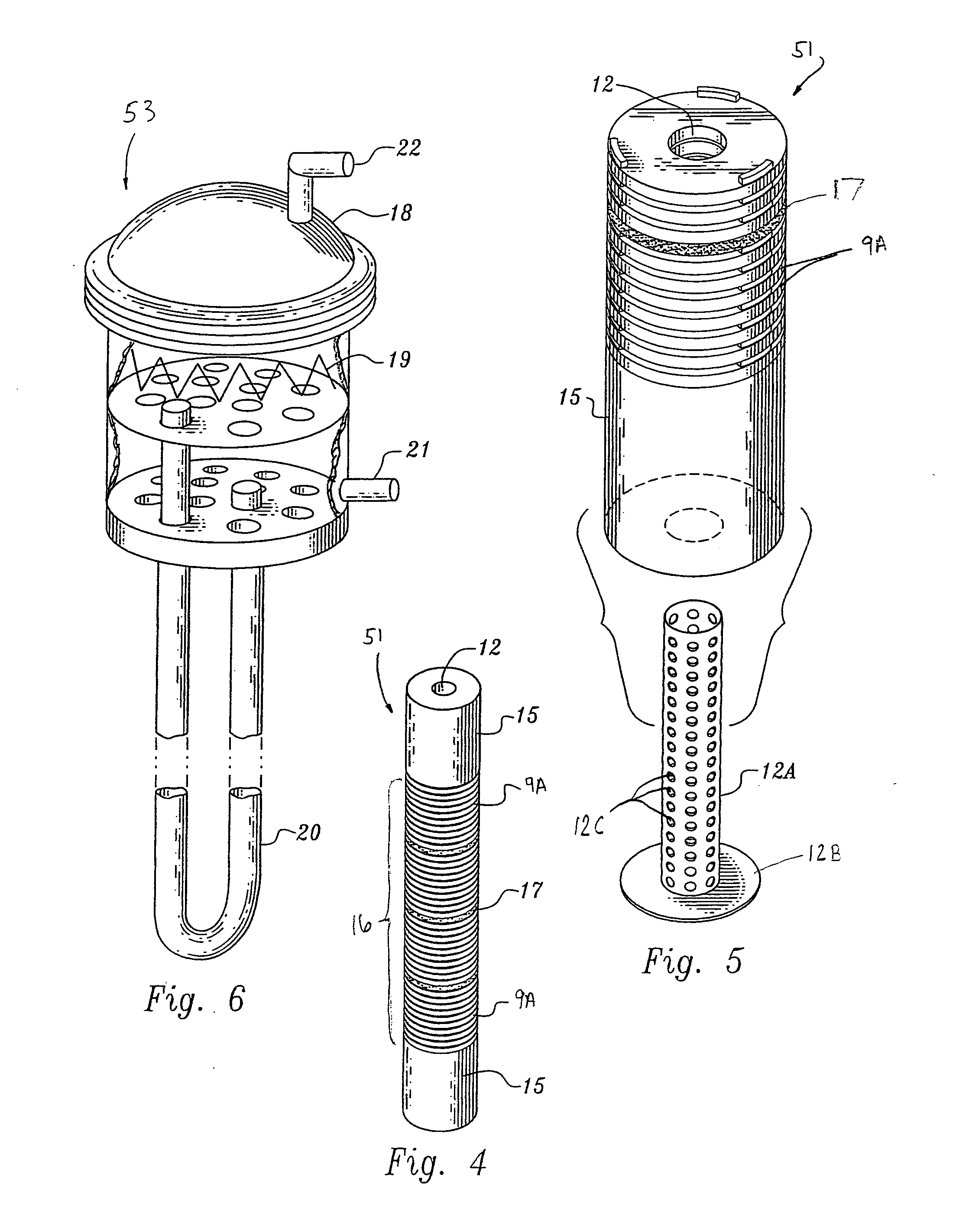

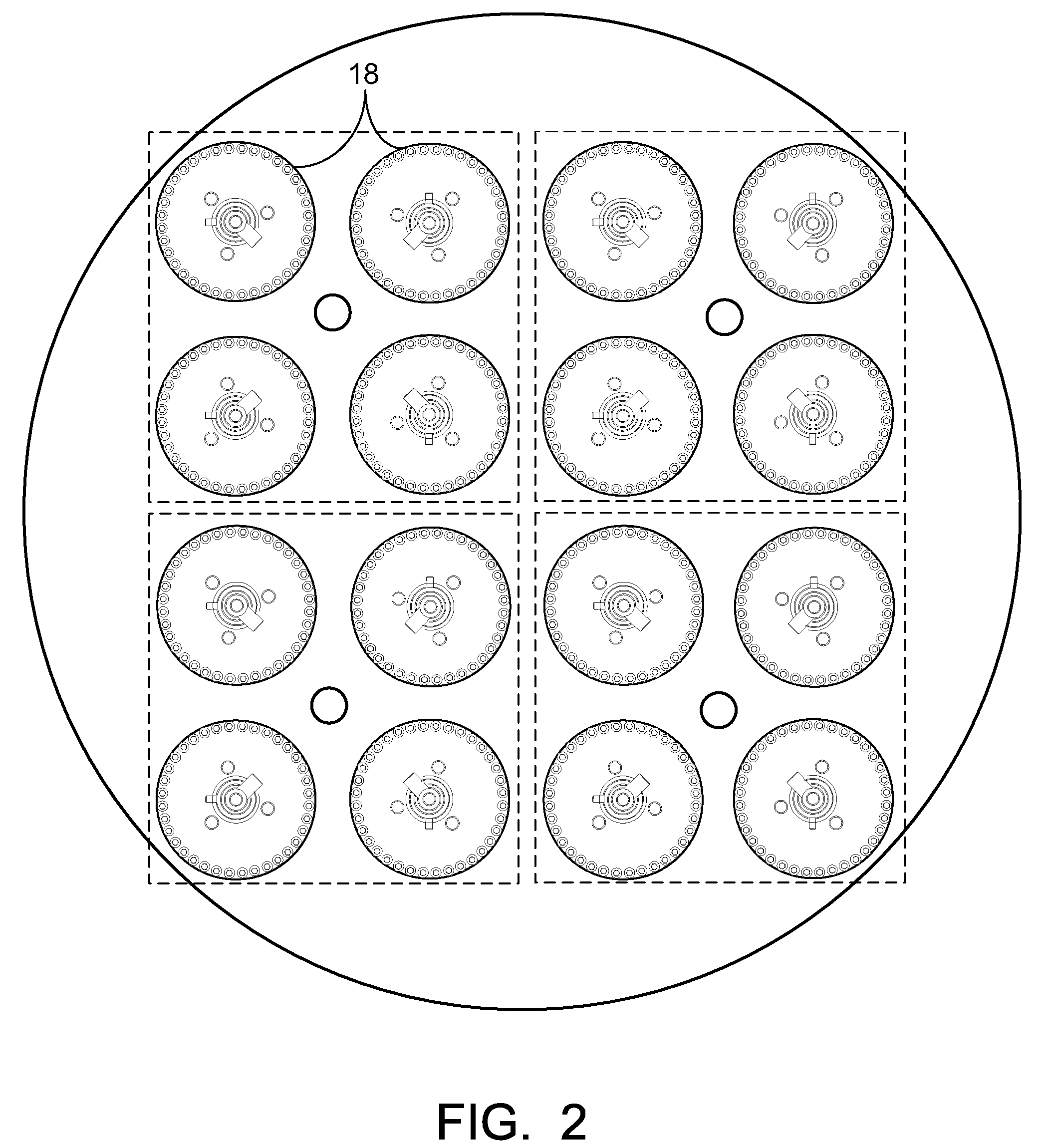

Systems and Methods for Radioisotope Generation

ActiveUS20080093564A1Isotope delivery systemsTransuranic element compoundsEngineeringChromatographic column

Systems and methods are disclosed for producing customized, predictable and reproducible supplies of radioisotopes using, for example, a reactor housing that is fabricated from a radioactive shielding material and has both an internal volume and a surface that comprises an entry port and an exit port, a chromatographic column that is positioned within said internal volume such that a first end of said column is in fluid communication with said entry port and a second end of said column is in fluid communication with said exit port, and a changeable filter module that is disposed external to said reactor housing and in fluid communication with said exit port.

Owner:JUBILANT DRAXIMAGE

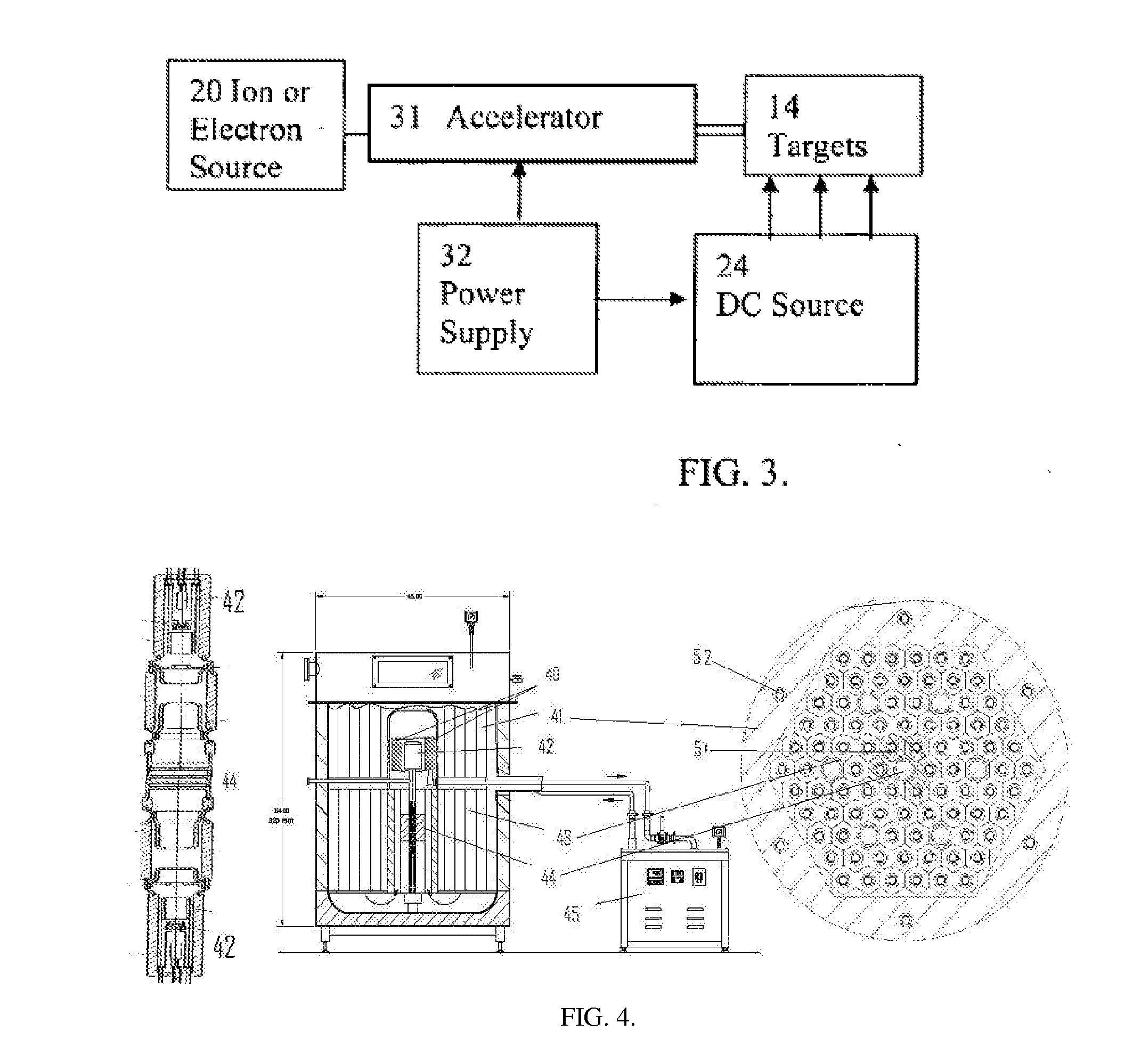

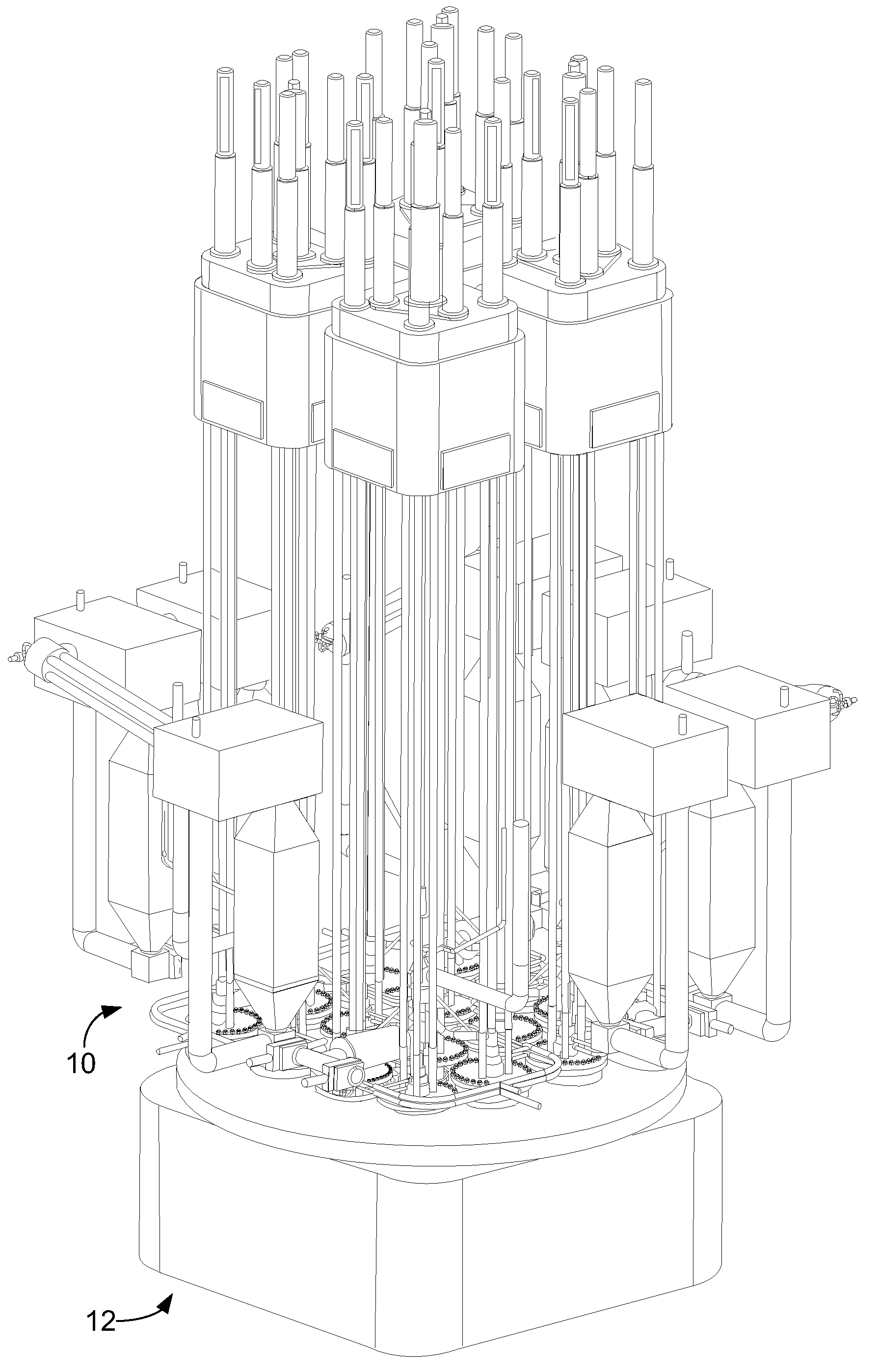

Sustainable Modular Transmutation Reactor

InactiveUS20150098544A1Improve distributionImprove economyIntegral reactorsConversion outside reactor/acceleratorsFission fusionDelayed neutron

A light water reactor to safely convert depleted uranium into a fuel source that could be used as a sustainable source of energy for centuries. The reactor is a type of breed-burn reactor uniquely combined with a proliferation-resistant fuel cycle with no uranium enrichment and no plutonium isolation. It is comprised of a compact factory-produced fast region and a thermal region that produces about 95% of the core power and contains the passageways for transports of delayed-neutron emitters to the fast region, where they can provide additional neutrons (source-based mode) or all the necessary excitation without an external neutron source (self-regulating mode). A second embodiment of the invention is a small unit driven by a neutron source with beam recycling for propulsion, electrical power or radioisotope production. It could also serve as a demonstration facility for the transmutation reactor with fission-fusion fuel.

Owner:BLANOVSKY ANATOLY

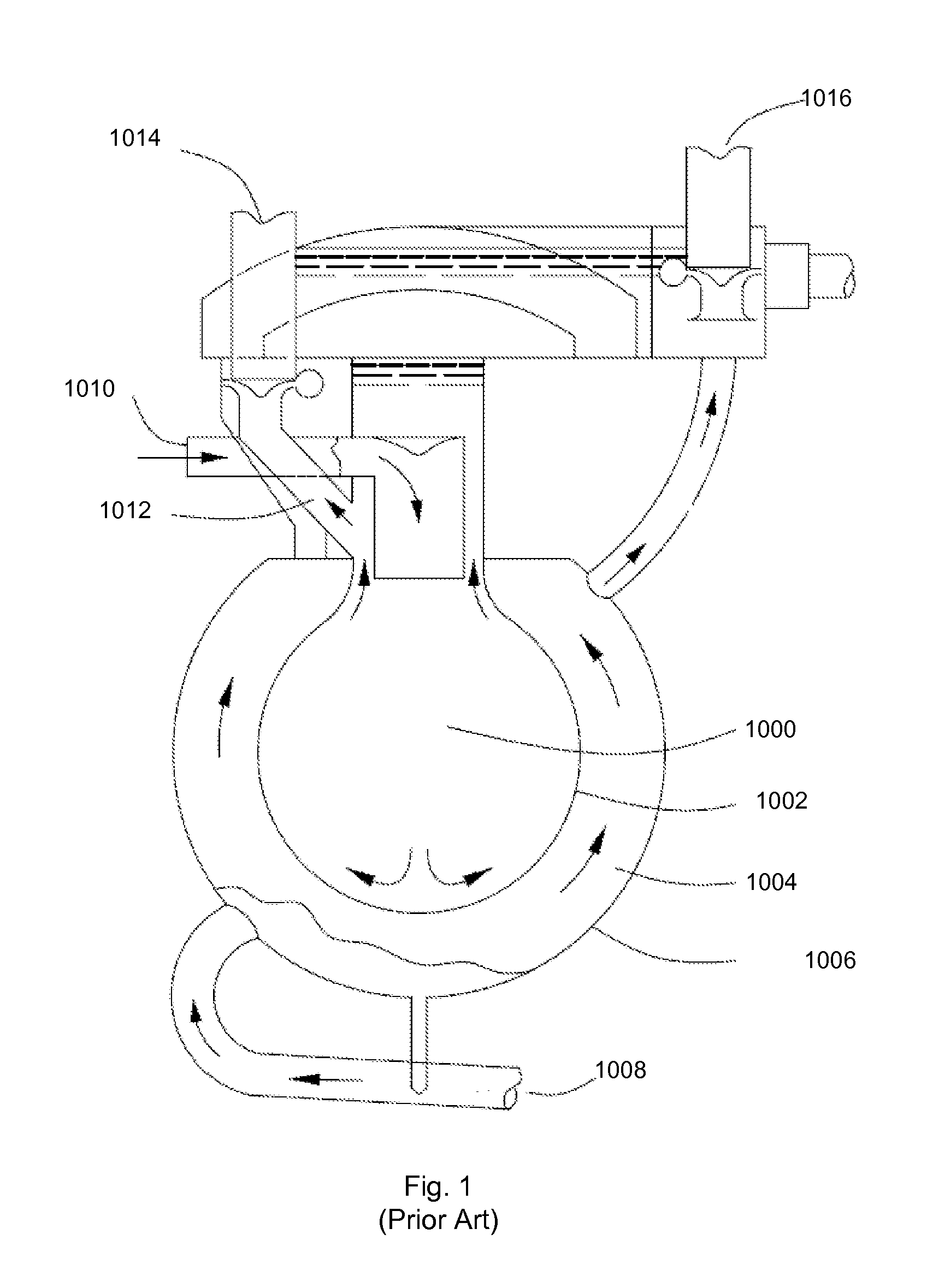

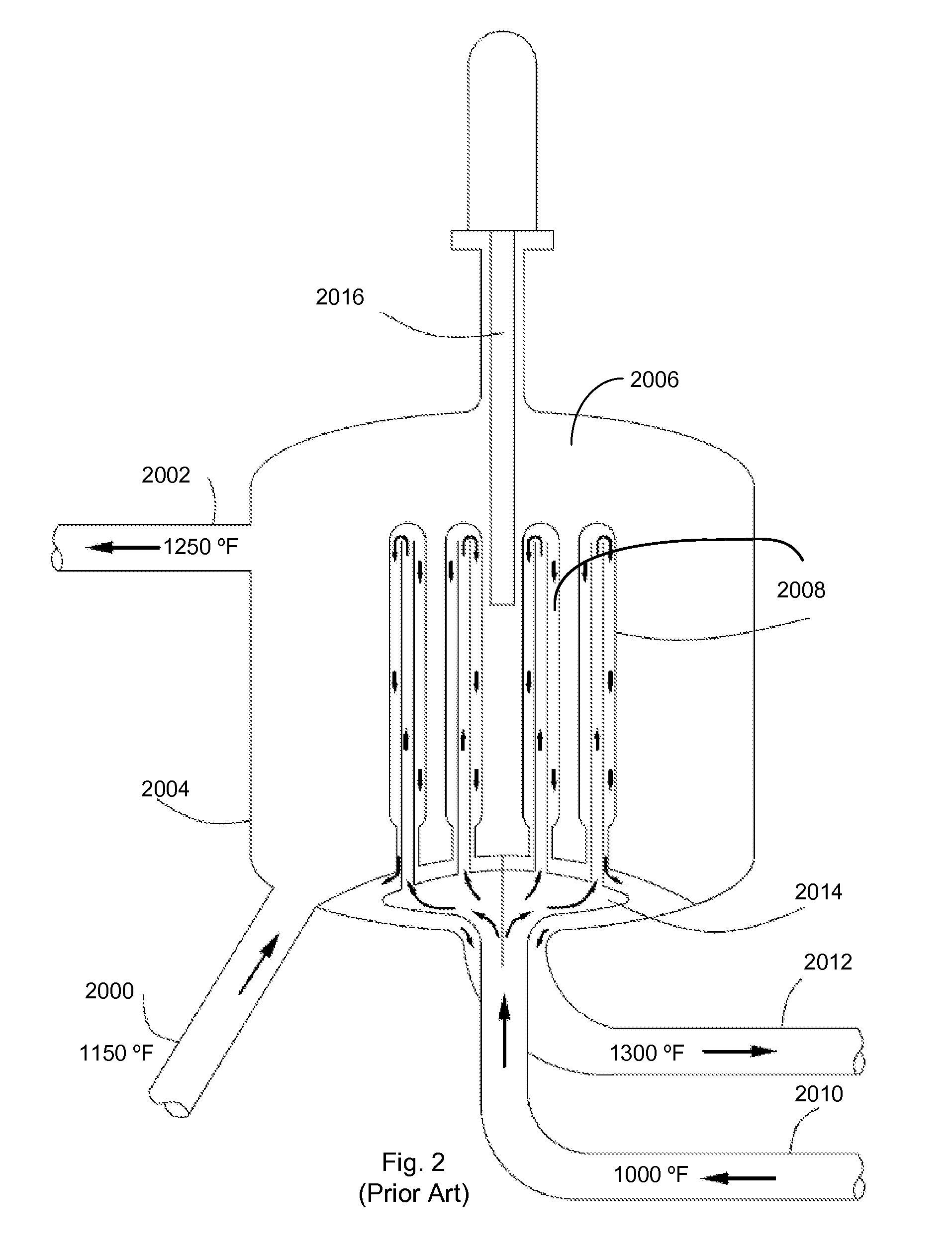

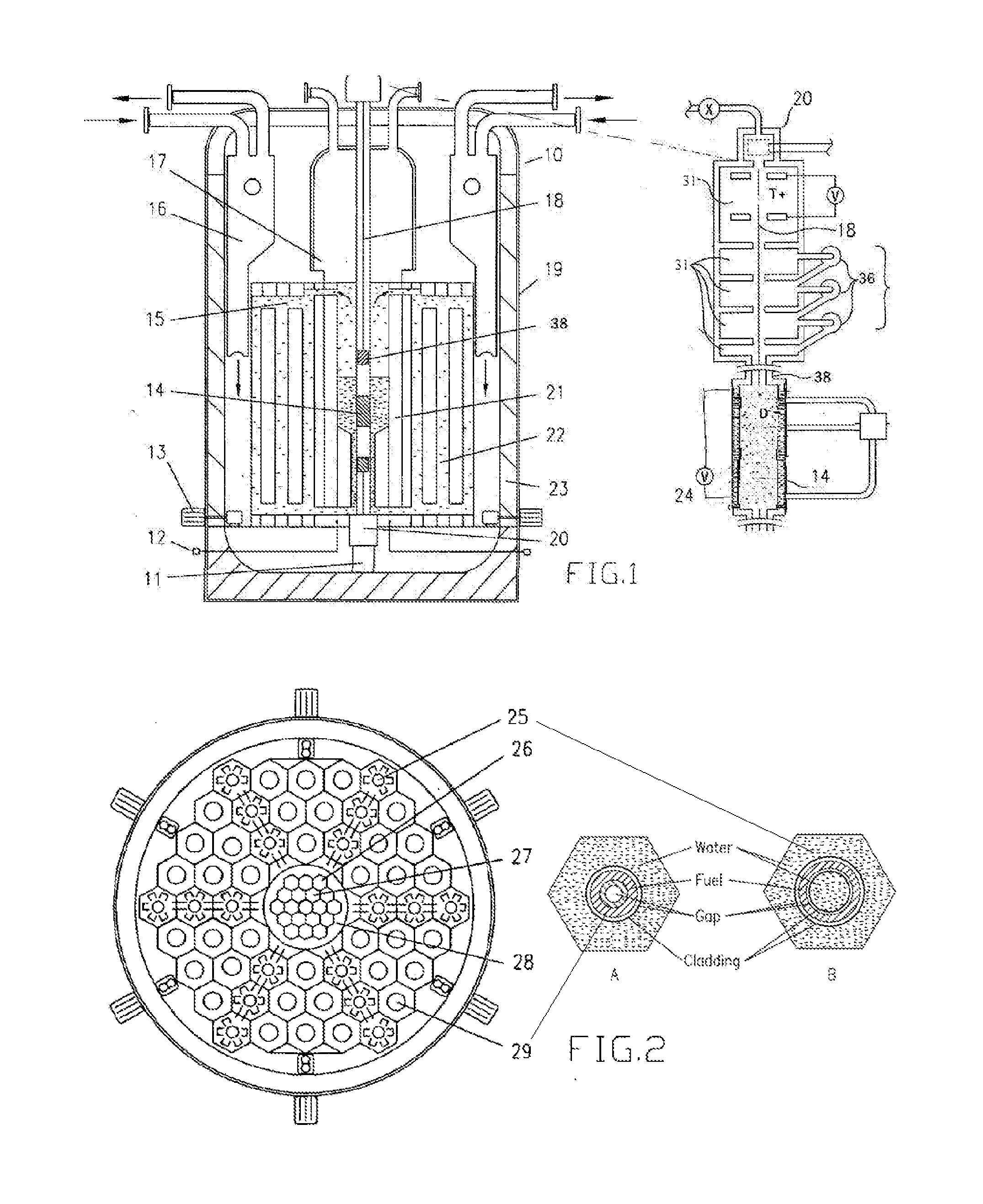

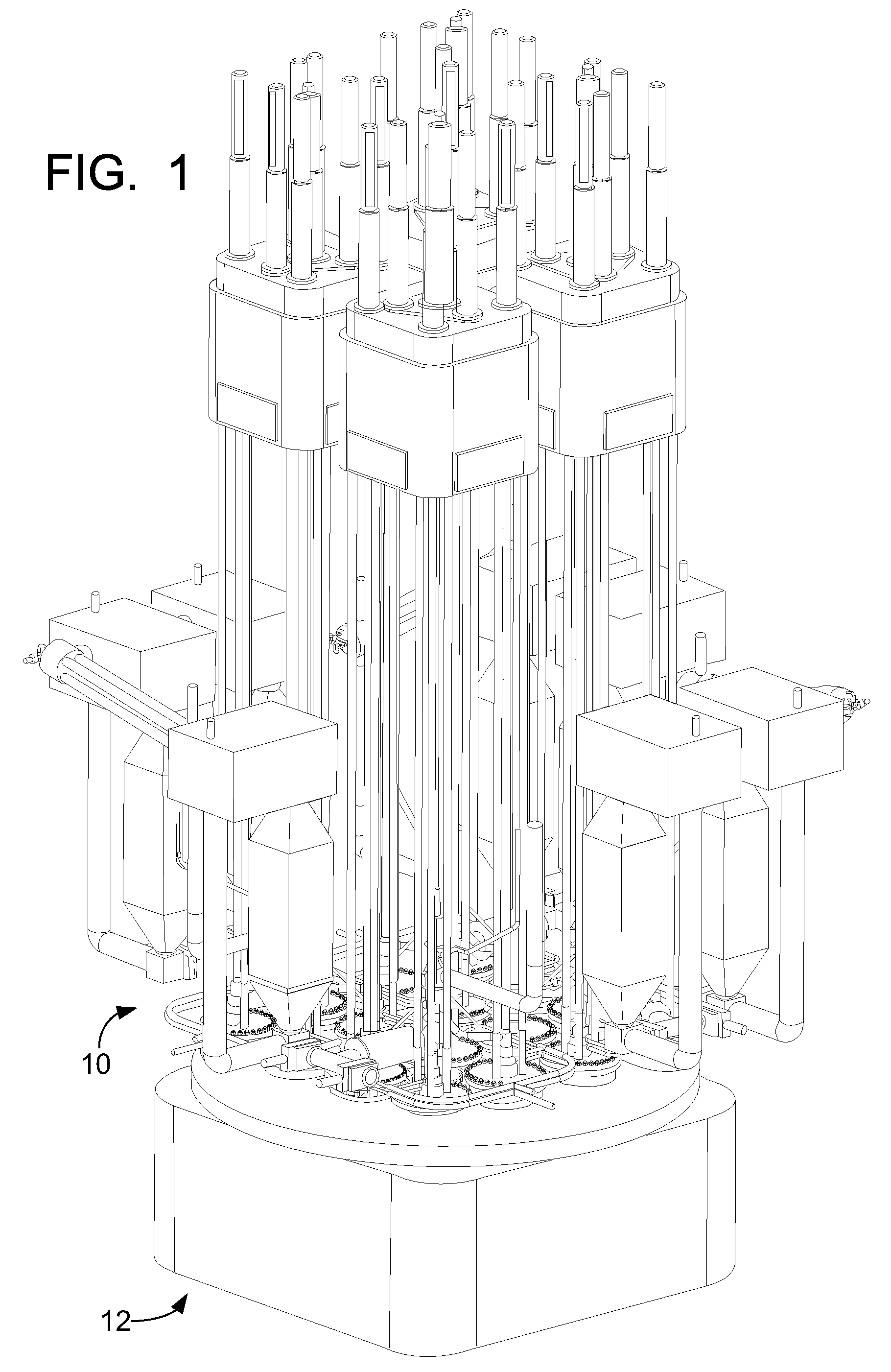

Combinatorial heterogeneous-homogeneous reactor

ActiveUS20090225923A1Reduce power densityIsotope delivery systemsConversion outside reactor/acceleratorsCorrosion resistant alloyNuclear engineering

A combinatorial heterogeneous-homogeneous reactor configuration in which an array or groups of homogeneous fuel assemblies are interlinked together in a heterogeneous lattice. The present invention removes the limitation of a homogeneous reactor by providing a reactor concept that utilizes the inherent advantages of homogeneous fuel elements but in a heterogeneous fuel lattice arrangement that limits the power density of any one homogeneous fuel element and yet forms a reactor arrangement that is capable of producing any product demand of interest. The present invention provides a method for producing medical isotopes by the use of a modular reactor core comprised of homogeneous fuel assemblies arranged in a regular rectangular or triangular pitch lattice. The aqueous fuel solution is contained within individual fuel assemblies that are right circular cylinders clad in corrosion-resistant alloys such as stainless steel, zircalloy, zircalloy alloys, or other metal alloys that are resistant to corrosive fissile environments but preserve neutron economy. The fuel assemblies are supported below by a core plate that is tied directly to the lower reactor support structure. The bottom of each assembly opens into a common plenum area which provides a hydrodynamic communication / coupling path between the individual assemblies in the lattice. The fuel assemblies are supported above by an upper plate that is welded to each assembly tube. The top of each assembly opens to a common upper plenum which provides a means of thermodynamic pressure equalization among the four assemblies in the reactor core lattice.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

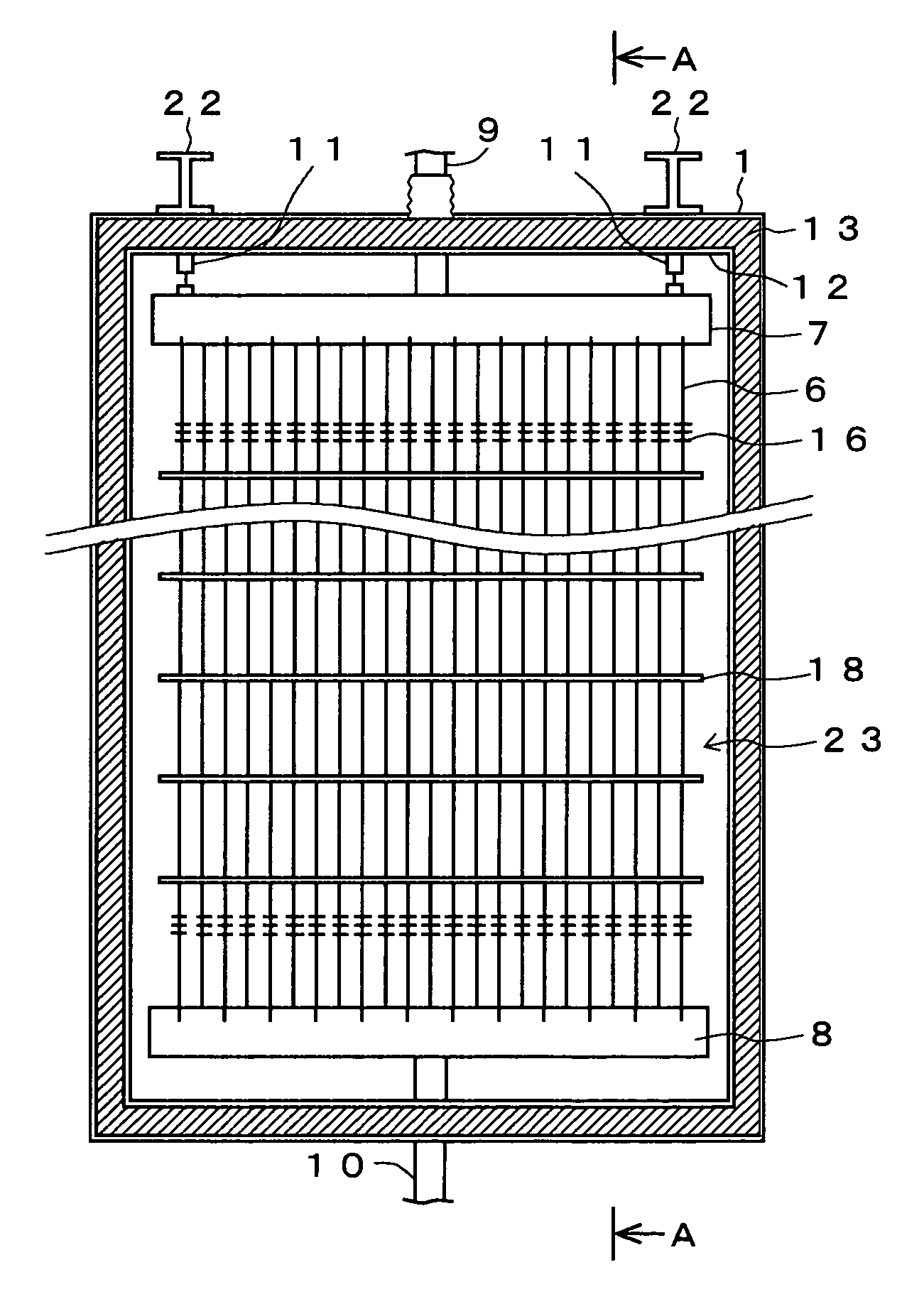

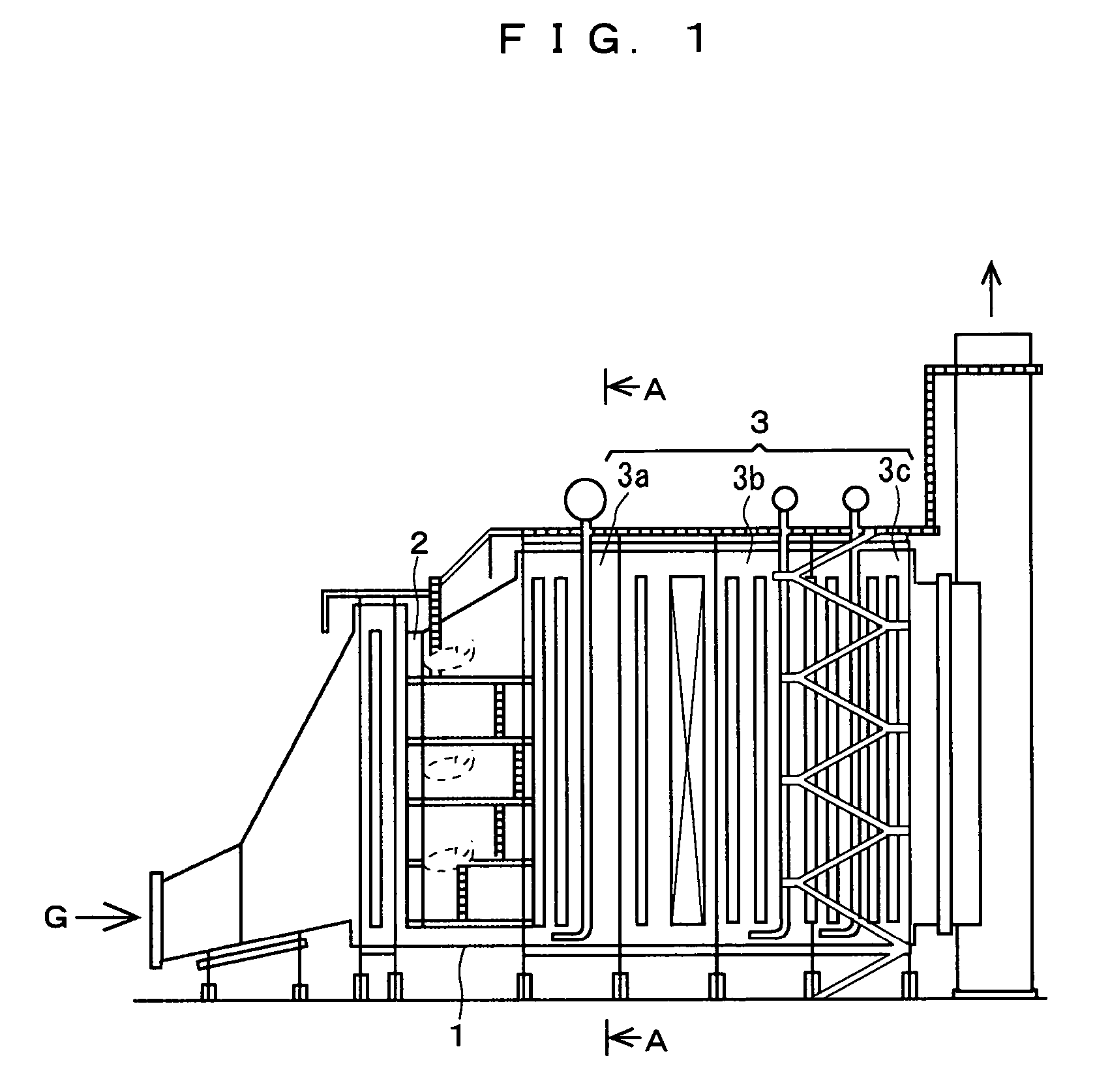

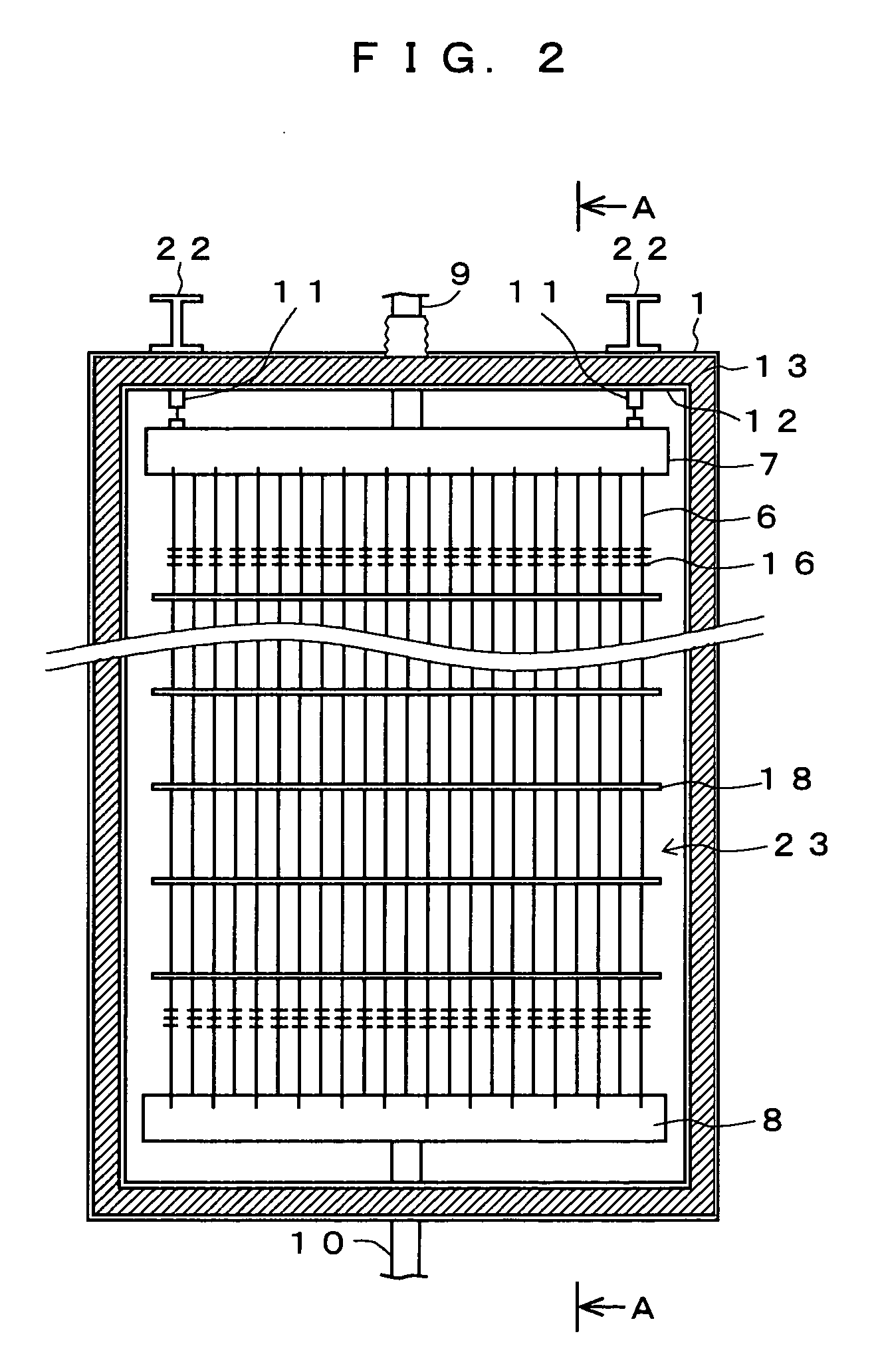

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS20070119388A1Easy to installShort timeBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

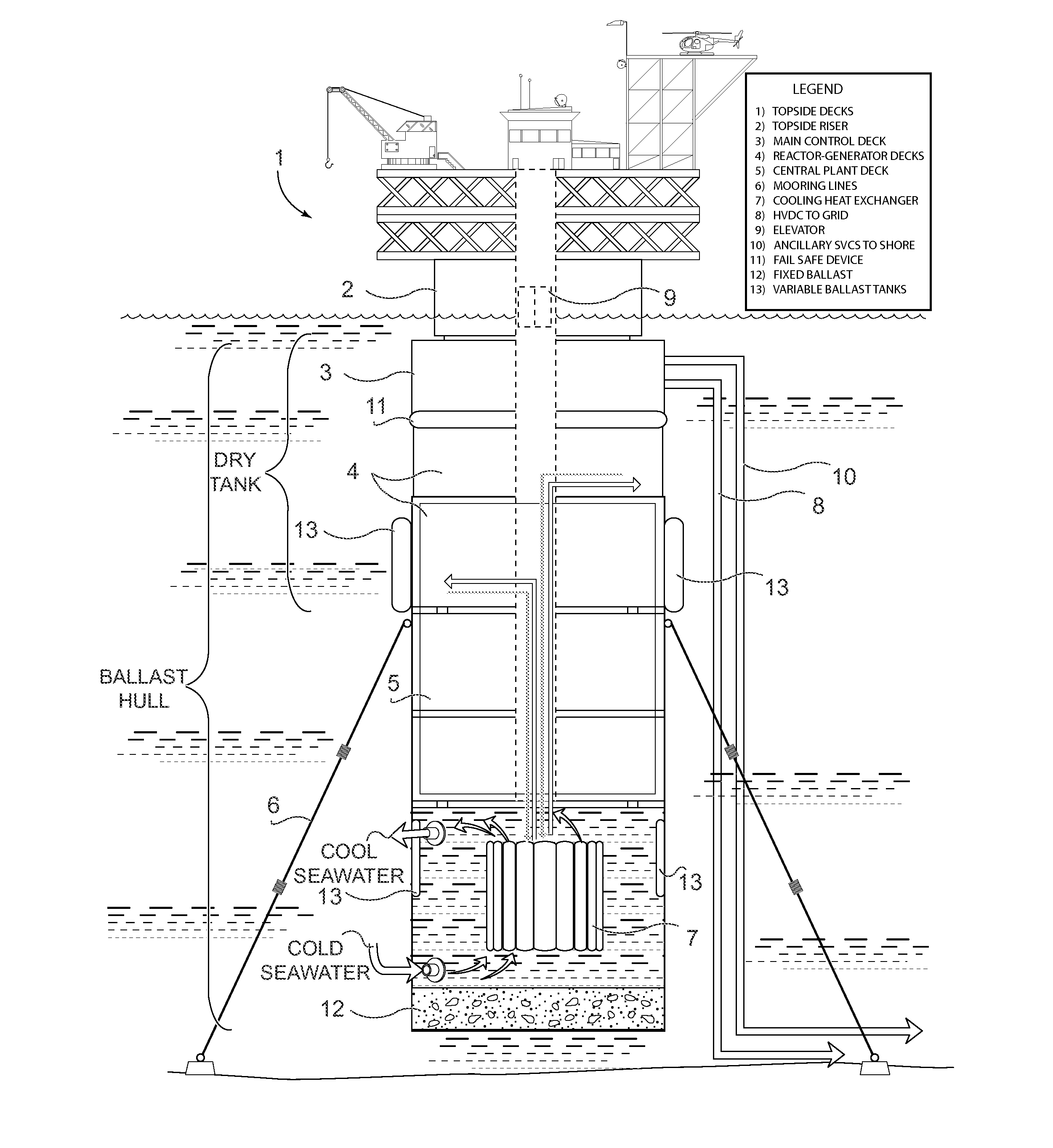

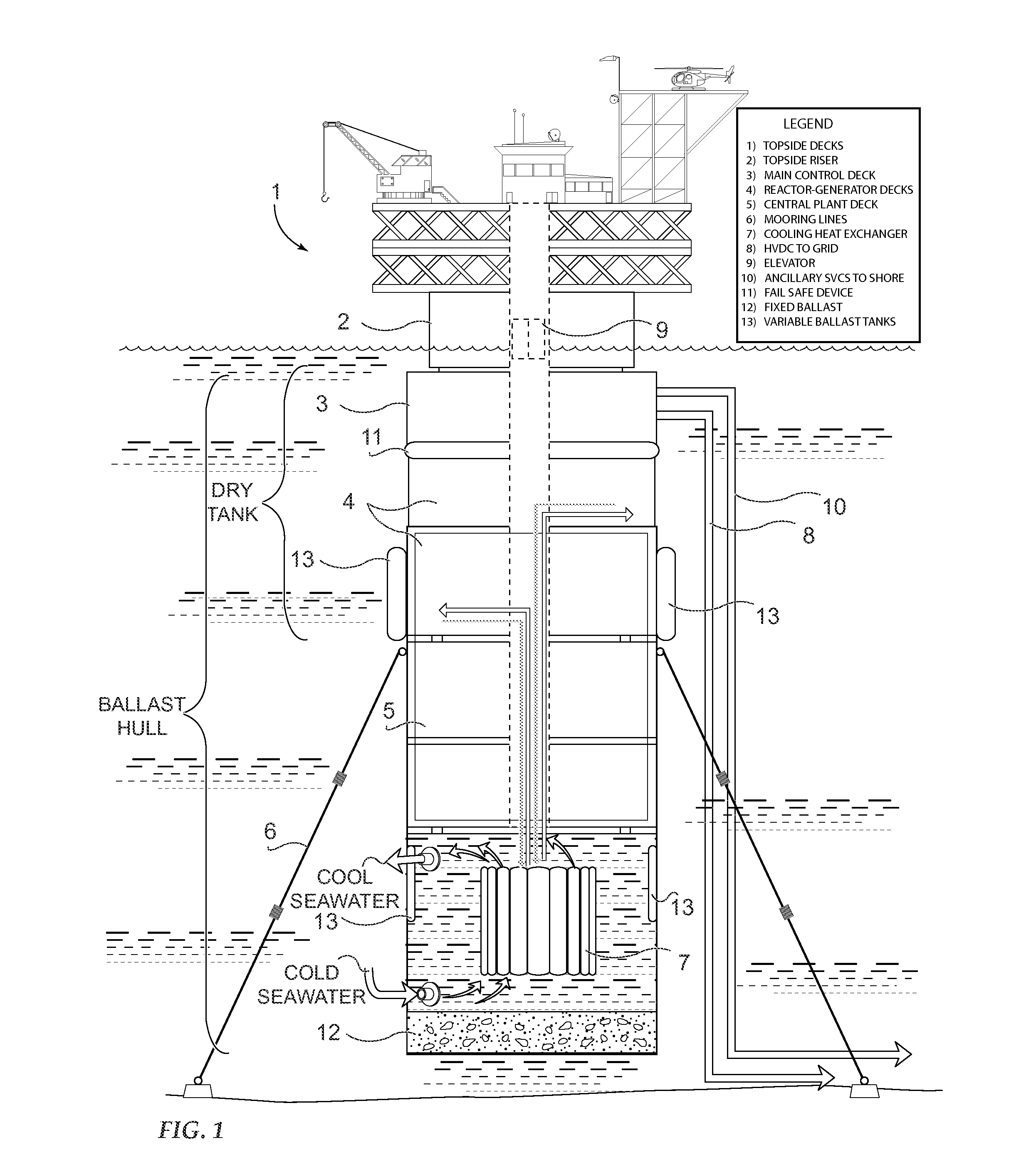

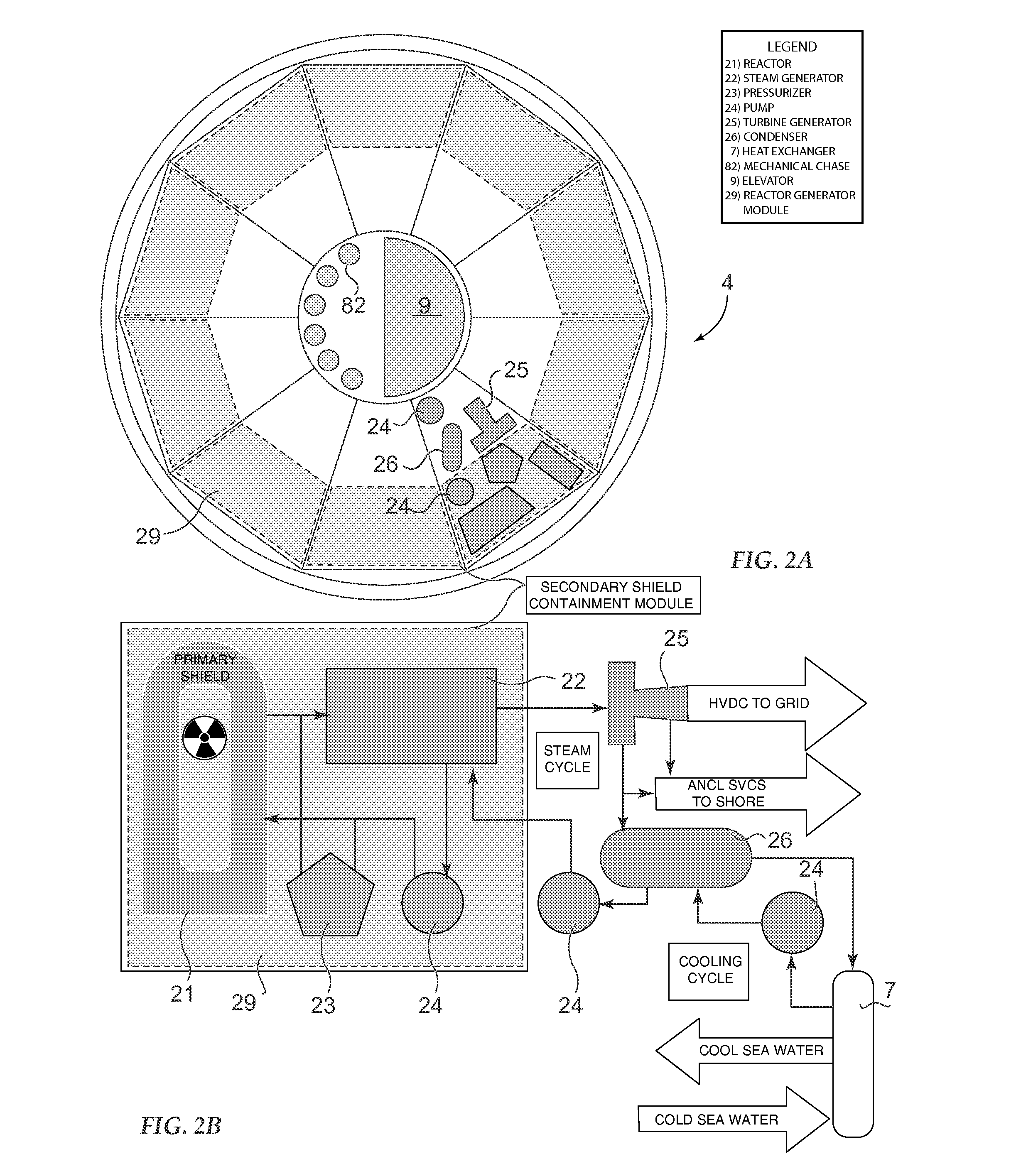

Semi Submersible Nuclear Power Plant and Multi-Purpose Platform

InactiveUS20160203883A1Quality improvementRapid construction timePower plant safety arrangementWaterborne vesselsOcean bottomNuclear power

An offshore, floating, moored, nuclear power generating plant and multi-purpose platform is disclosed herein. In a preferred embodiment, the invention consists of a spar or cell spar platform with multi-purpose, all weather topside decks, attached to a submerged “dry tank” that further includes: reactor generator deck(s), power plant main control deck, and central plant deck, that are all integrated within a watertight ballast hull. The invention design further includes cells that are modular for facilitating factory assembly and ultimate construction in a shipyard environment. Reactor vessels are typical naval nuclear reactor having a time tested outstanding safety record. A plurality of reactor generator modules are interconnected and operate independently and collectively and are transmitted by a plurality of high voltage direct current (HVDC) submarine cables through a transformer to the electrical grid. Multipurpose topside decks house vessel commend, crew, and any ancillary and co-generation equipment. The present invention, constructed in a multi-path manufacturing process, provides exceptional economic, environmental, sustainability, security, safety, and operational advantages over the current art of power generation.

Owner:RICHARDSON DAVID W

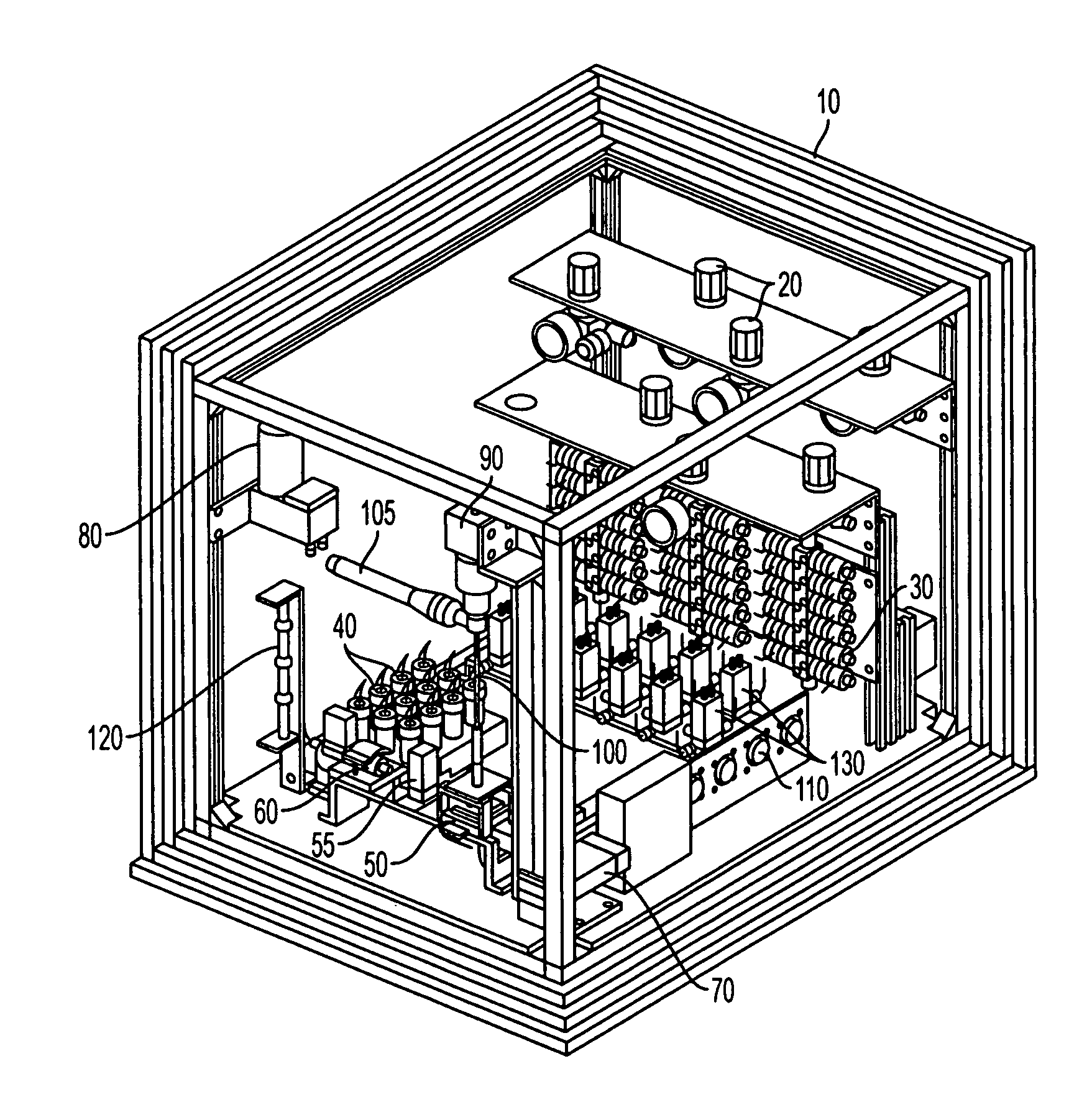

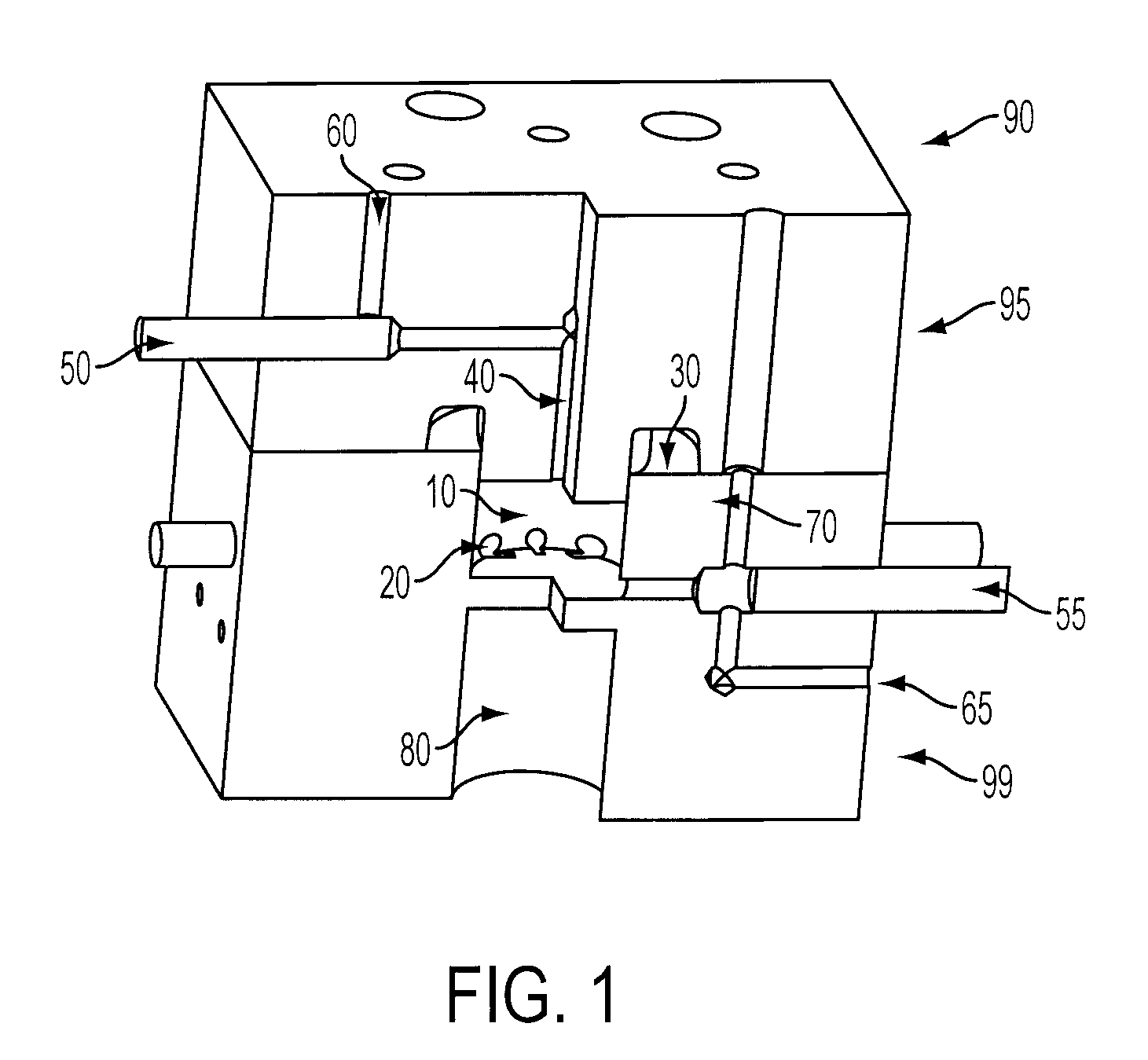

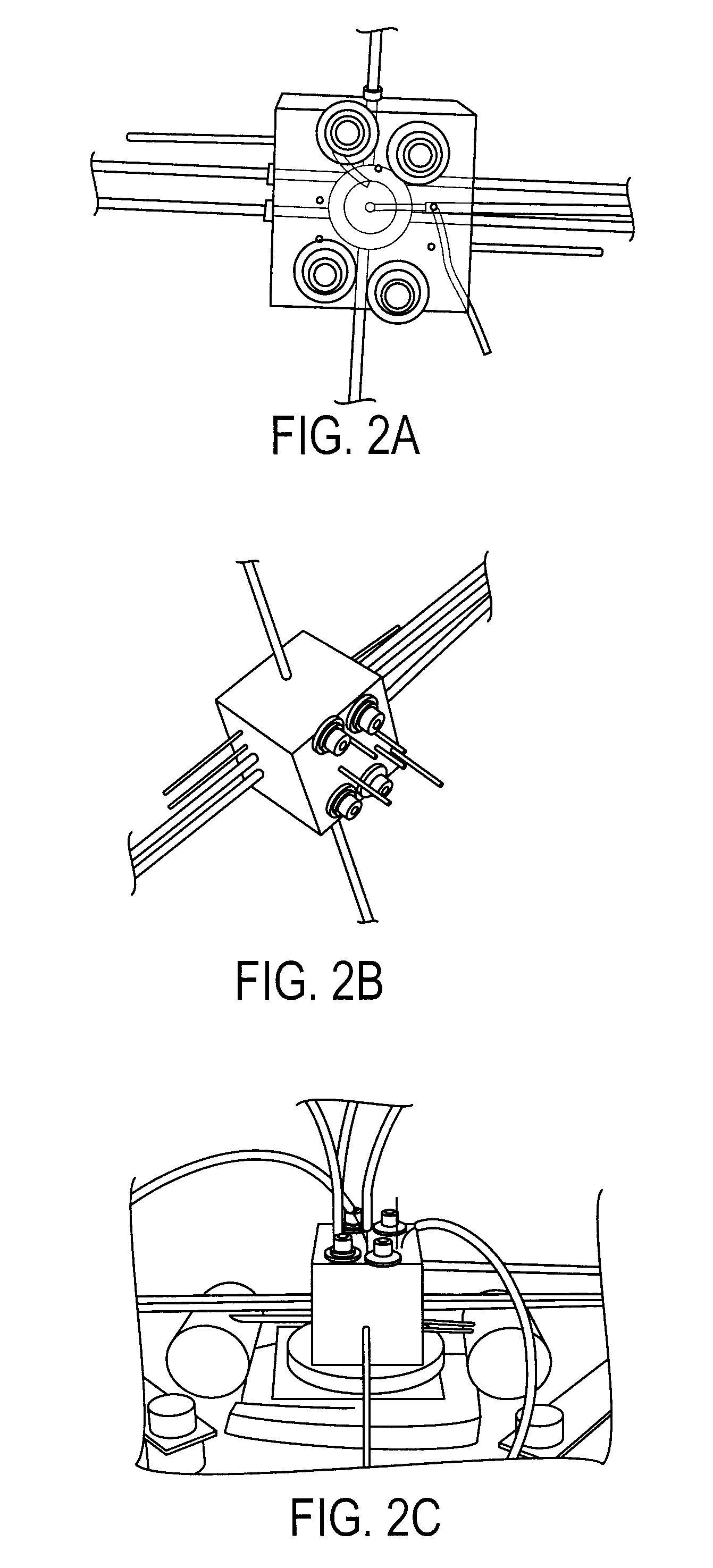

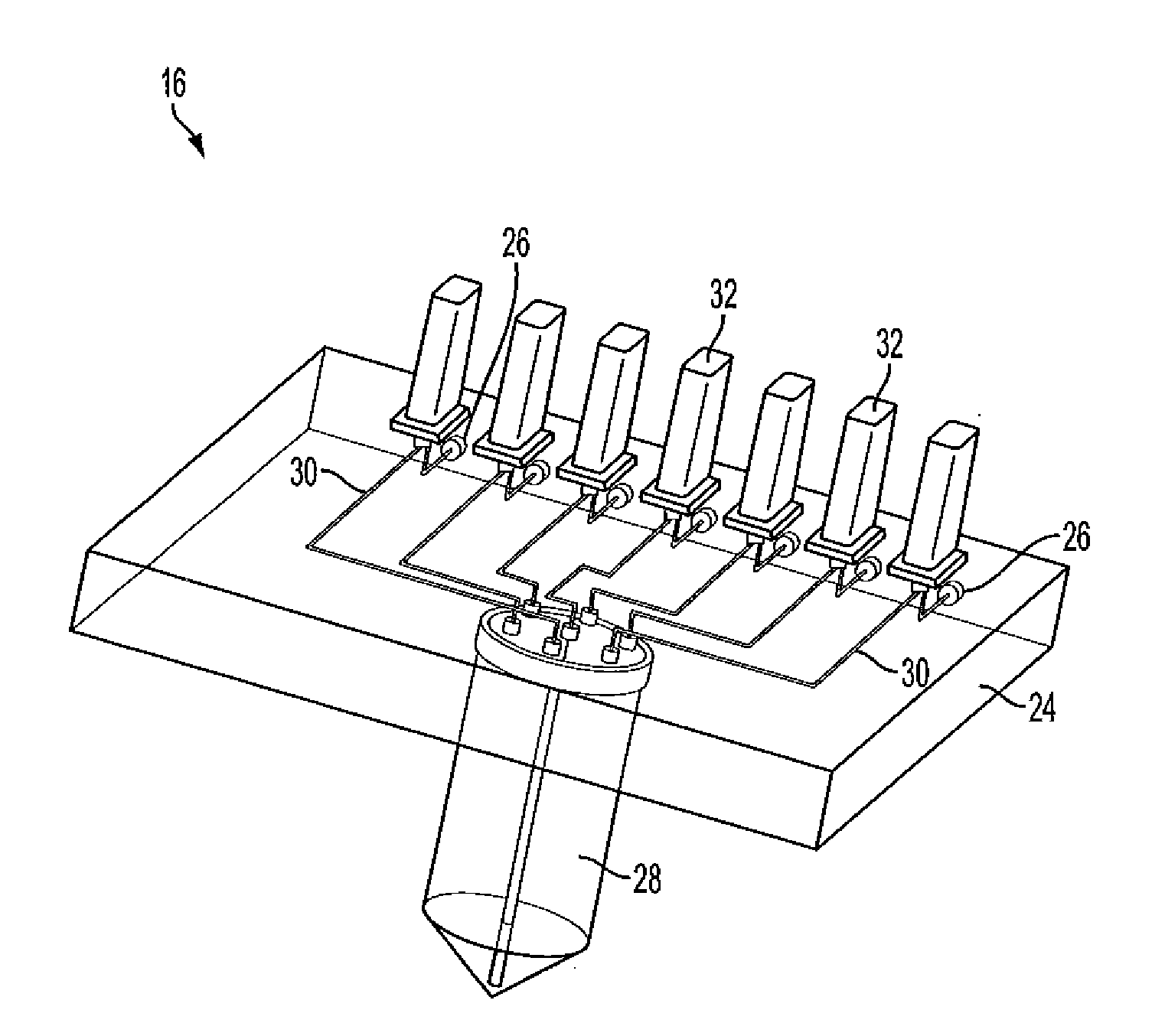

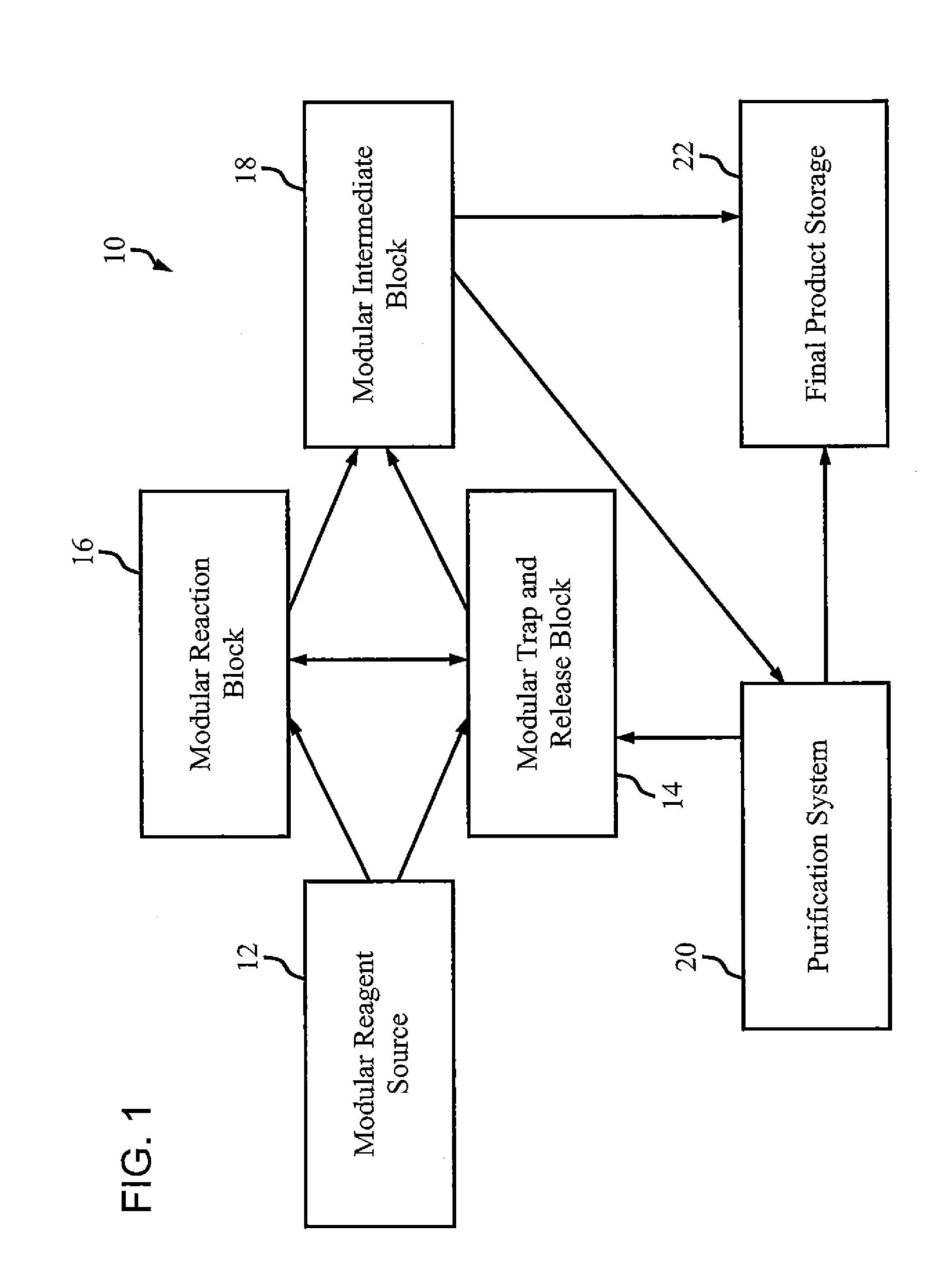

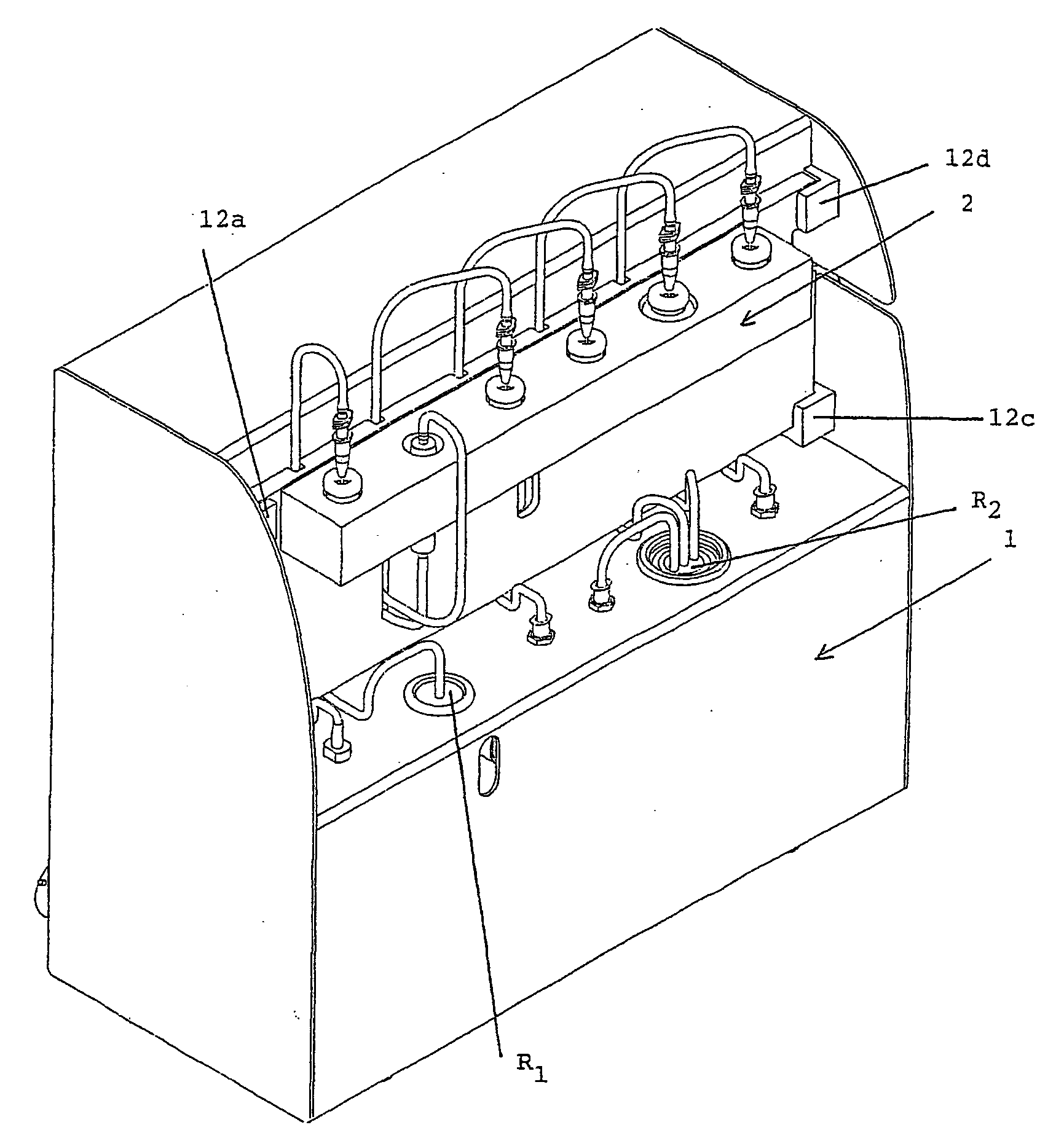

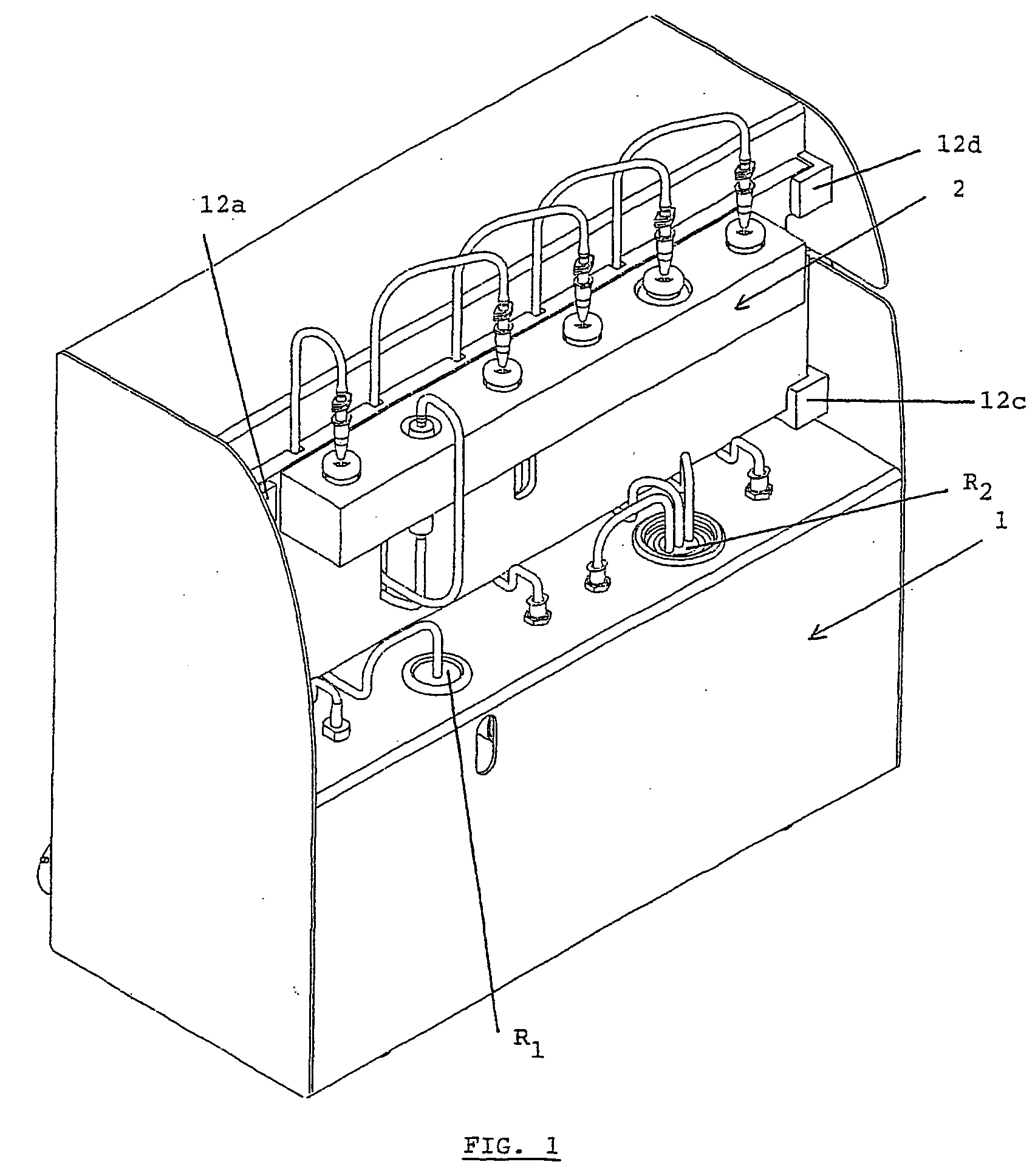

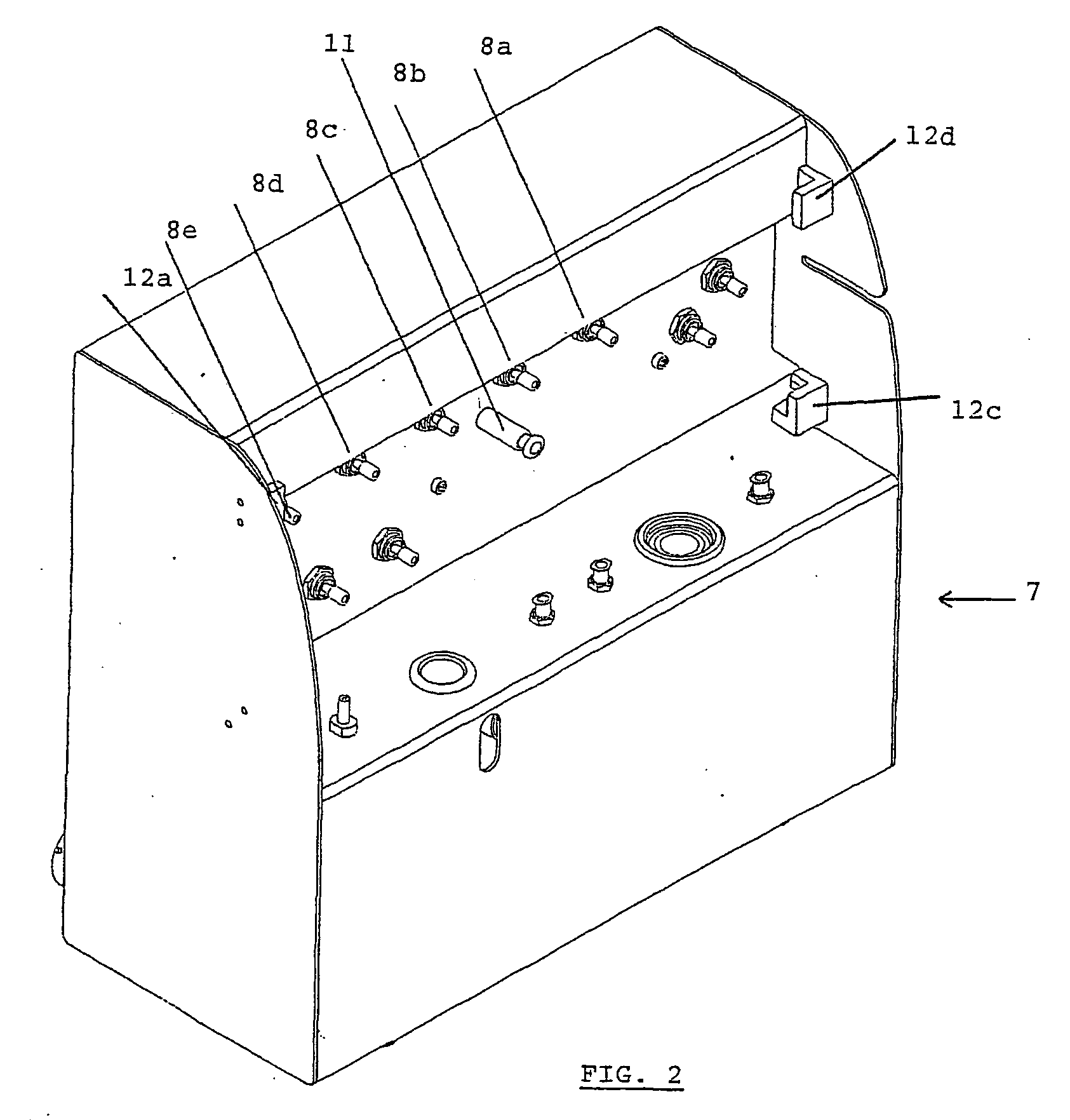

Modular Component Synthesis Unit

InactiveUS20120076692A1Rapid modification and designSimple designChemical/physical/physico-chemical microreactorsContainmentChemical reactionModularity

A kit, for synthesizing a compound or element, which includes a modular reagent source, a modular trap and release apparatus, and a modular reaction unit. The modular reagent source includes a reagent. The modular trap and release apparatus is configured to separate components of the reagent. The modular reaction unit which is in fluid communication with the modular reagent source and the modular trap and release apparatus. In addition, the modular reaction unit includes a reaction vessel configured to facilitate a chemical reaction.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

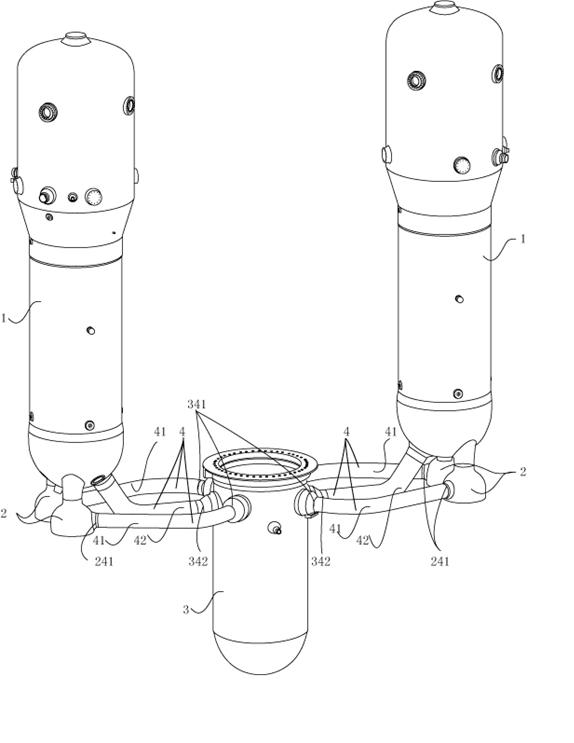

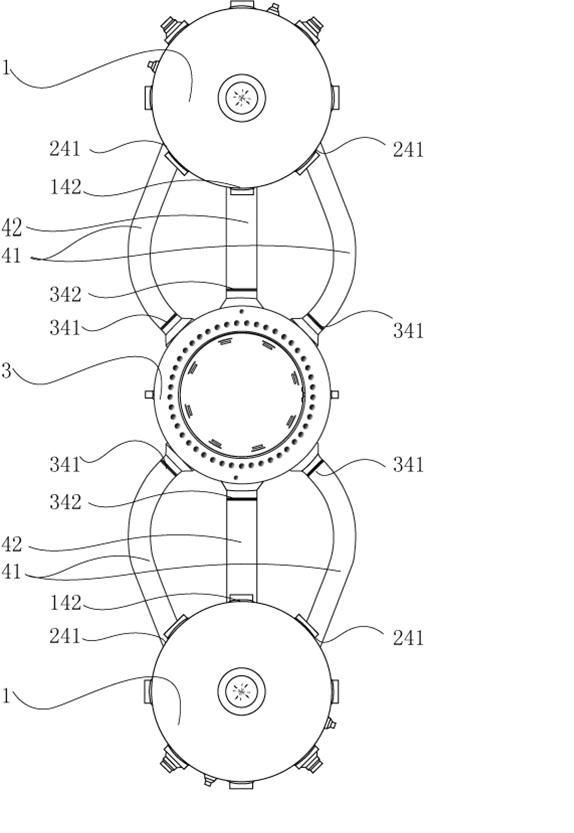

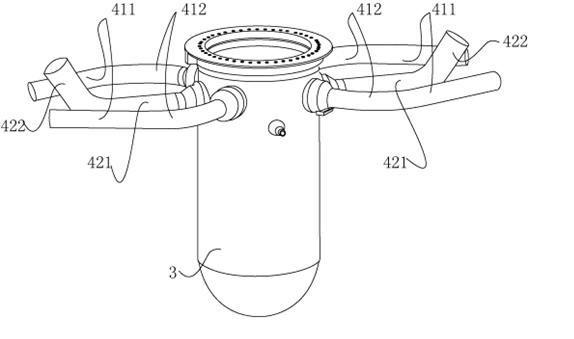

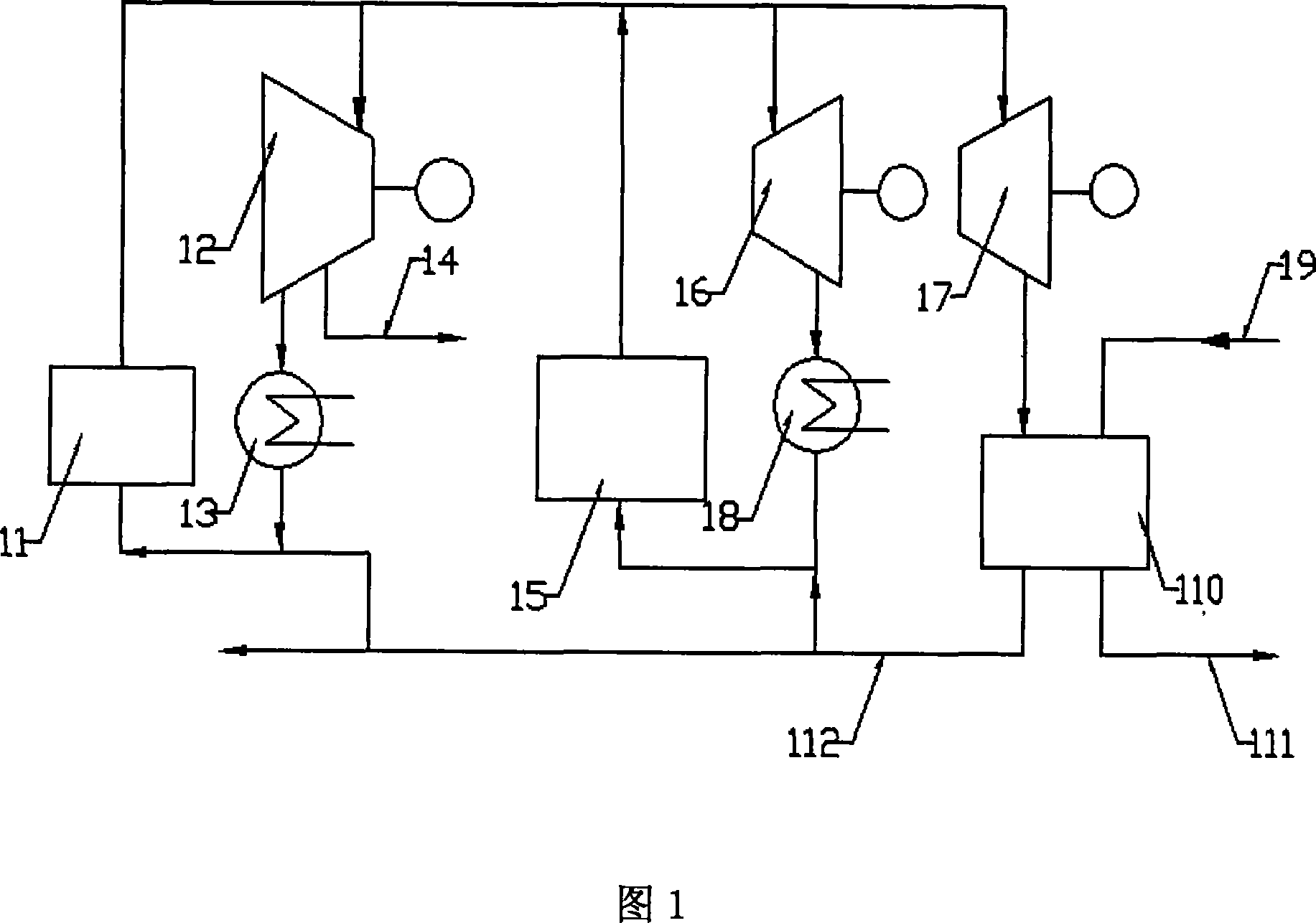

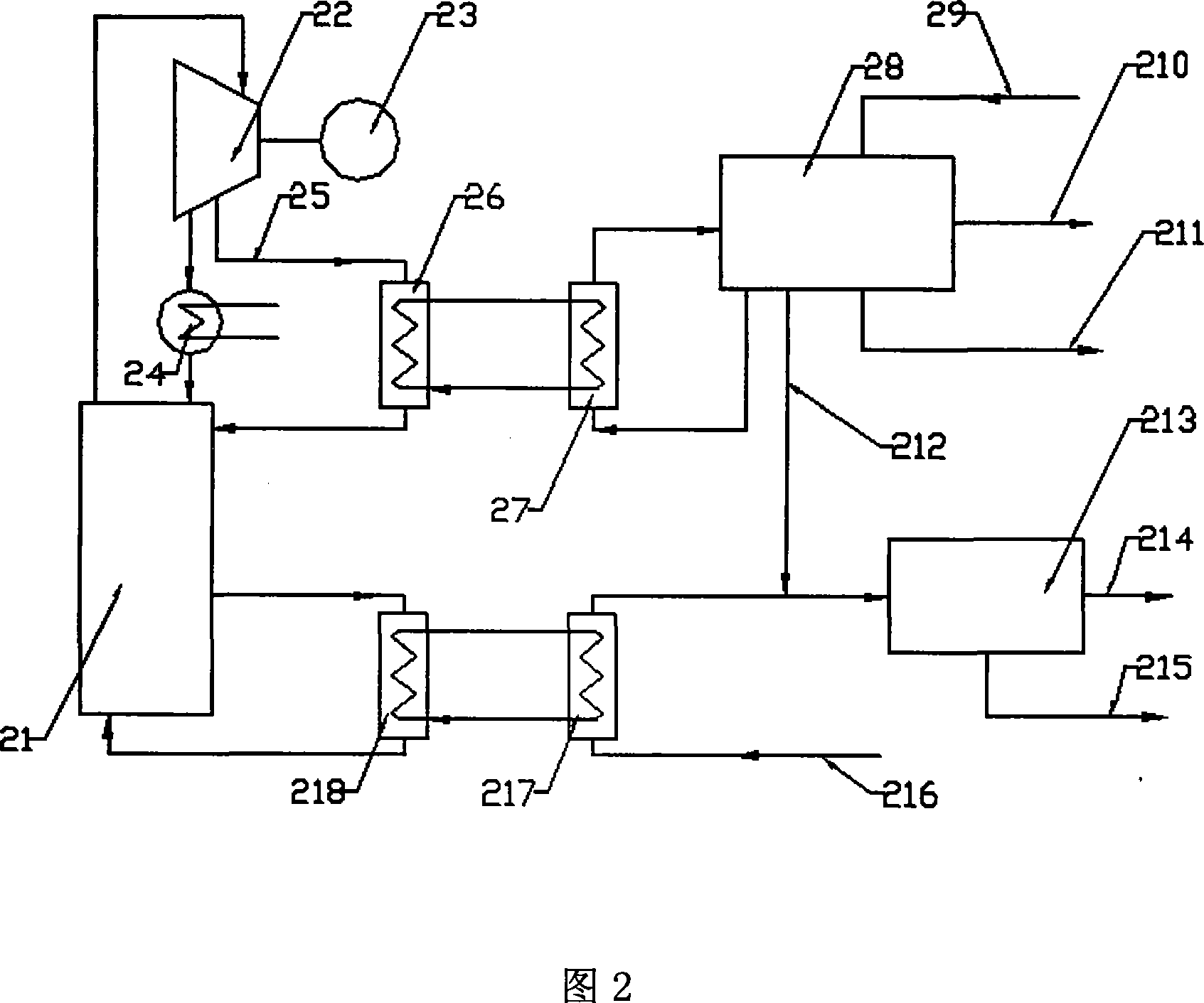

Coupling devices of using nuclear energy for sea water desalination, and method

ActiveCN101049999AEliminate lossesIncrease profitGeneral water supply conservationSeawater treatmentWater desalinationDistillation

This invention relates to coupling apparatus and method for desalting seawater by using nuclear energy. The apparatus comprises: a small-scale nuclear thermal reactor, a reverse osmosis seawater desalting system, a distillation seawater desalting system, and auxiliary apparatus. The method comprises: (1) transferring the heat generated from the small-scale nuclear thermal reactor to the steam generator, and driving the reverse osmosis high-pressure pump with the generated saturated steam in the turbine for seawater desalting; (2) introducing the saturated steam exhausted from the end stage of the turbine to the distillation seawater desalting system for seawater desalting; (3) returning the condensed water to the steam generator; (4) introducing seawater into the distillation seawater desalting system, cooling at the heat discharge section, sending to the reverse osmosis high-pressure pump, pressurizing, sending to the reverse osmosis seawater desalting system, storing the product water in a desalted water tank, and utilizing the condensed seawater or discharging into sea. The method has such advantages as advanced technology, high heat utility, high water productivity and high water quality.

Owner:CHINERGY CO LTD +1

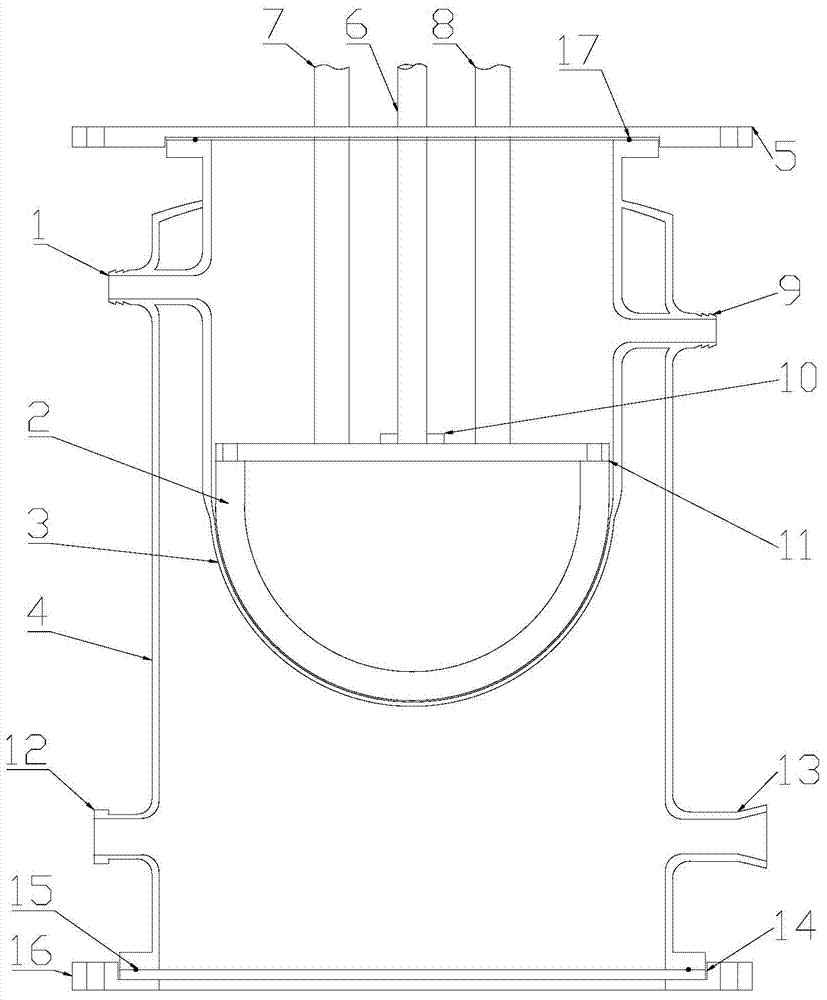

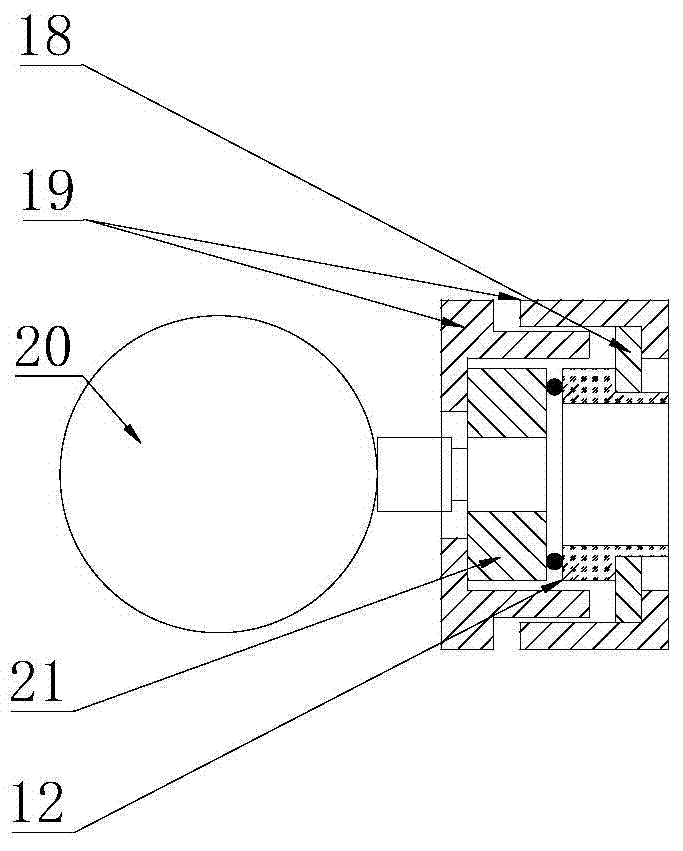

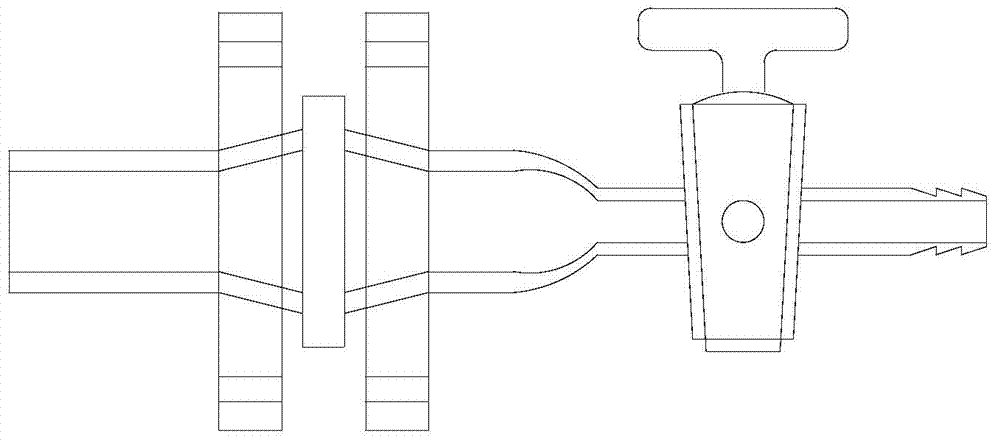

Experiment device for simulating retention of in-pile melts obtained by melting of reactor core of nuclear reactor and experiment method

InactiveCN103594133AReduce heat dissipationReduce uncertaintyNuclear energy generationNuclear monitoringNuclear reactor coreNuclear reactor

The invention discloses an experiment device for simulating retention of in-pile melts obtained by melting of a reactor core of a nuclear reactor and an experiment method. The device consists of a copper heating section, a quartz glass component and a data measurement system. According to the experiment device, a melt hard shell of the reactor core is simulated through a semispherical copper ball shell; decay heat is simulated through a spiral heating wire embedded into the semispherical shell; the inner wall surface of a lower enclosure of a pressure container is simulated through quartz glass, and therefore, a flowing heat exchange phenomenon of a narrow gap between the inner wall surface of the pressure container of the reactor and the melt hard shell can be simulated, and the influence on the retention of the in-pile melts caused by flowing of water in the narrow gap can be researched. The experiment device has the advantages of visible experiment process, high experiment precision, high safety, easiness in operation and the like. A running practice shows that the experiment device runs stably and can thoroughly meet a design requirement.

Owner:XI AN JIAOTONG UNIV

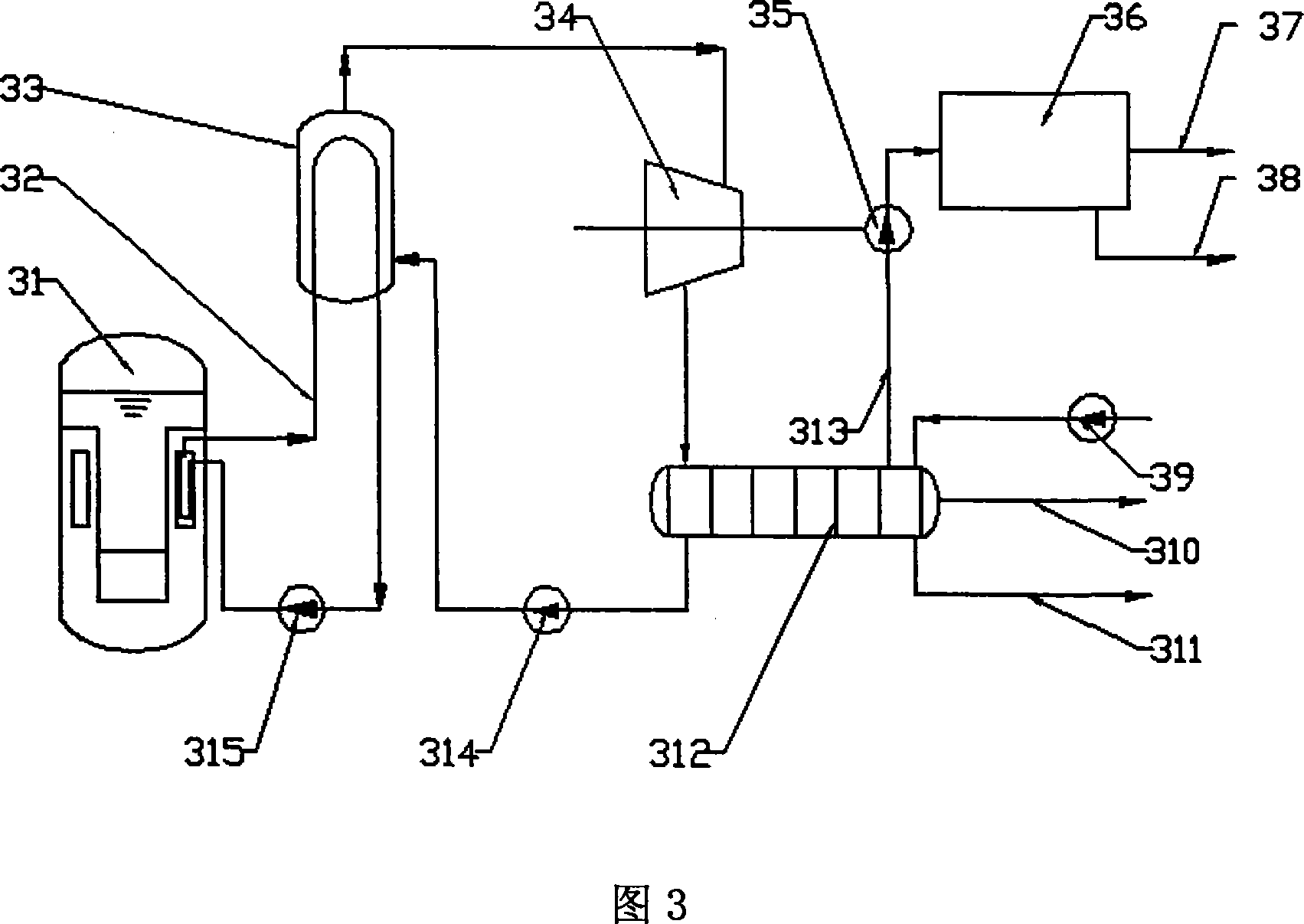

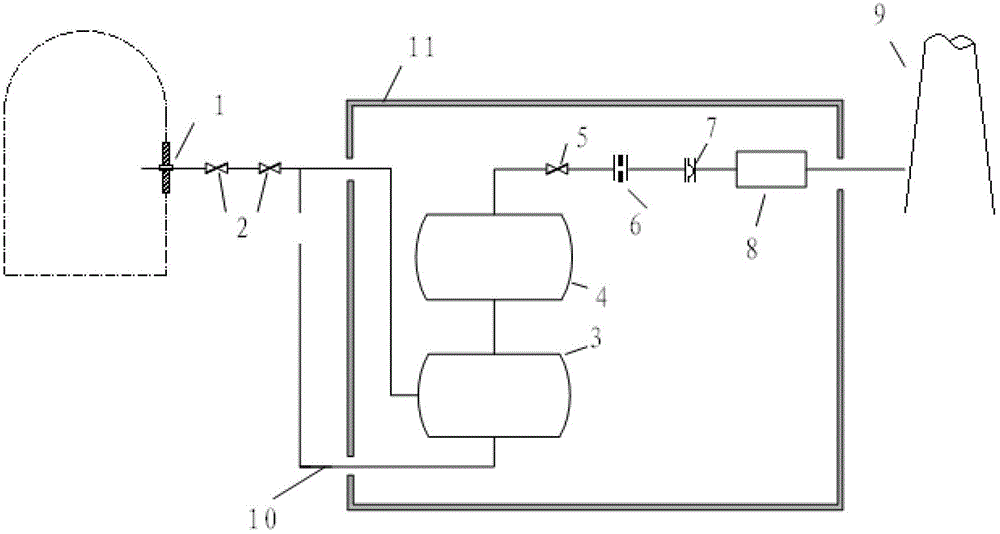

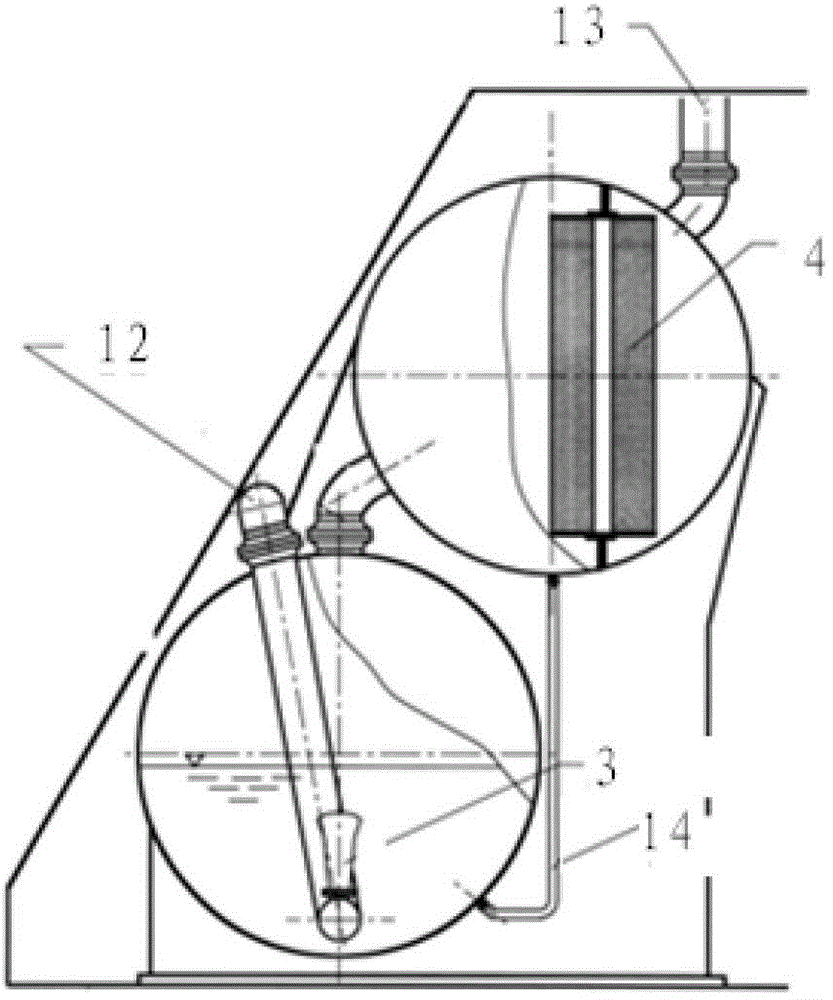

Containment filtering and discharging system

InactiveCN102723114AImprove filtering effectAccumulated radioactivityNuclear energy generationEmergency protection arrangementsLiquid wasteRadioactive agent

The invention relates to a containment filtering and discharging system. As a shielding plant (11) is arranged outside a containment, a discharging and filtering sub system is arranged in the shielding plant (11), a water washing filter (3) and a metal fiber filter (4) connected with each other in sequence are arranged in the discharging and filtering sub system and the water washing filter (3) is provided with a waste liquid returning pipeline (10), gases discharged by the containment are doubly filtered by the water washing filter (3) and the metal fiber filter (4), and the waste liquid accumulated in the water washing filter (3) self-flows into the containment through the waste liquid returning pipeline (10) under the effect of gravity force. Therefore, according to the invention, serious accidents occurred in pressurized-water reactor nuclear power stations are eased, overpressure failure of the containment is prevented, radioactive substances released to the environment are reduced, safeties of the surrounding environment and personnel are protected, and the safety of the nuclear power stations are greatly improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Nuclear reactor vessel fuel thermal insulating barrier

ActiveUS20080198960A1Sufficient weightSmooth transitionNuclear energy generationNuclear engineering problemsNuclear reactorInlet valve

The reactor vessel of a nuclear reactor installation which is suspended from the cold leg nozzles in a reactor cavity is provided with a lower thermal insulating barrier spaced from the reactor vessel that has a hemispherical lower section that increases in volume from the center line of the reactor to the outer extent of the diameter of tiie thermal insulating barrier and smoothly transitions up the side walls of the vessel. The space between the thermal insulating harrier and the reactor vessel forms a chamber which can be flooded with cooling water through passive valving to directly cool the reactor vessel in the event of a severe accident. The passive inlet valve for the cooling water includes a buoyant door that is normally maintained sealed under its own weight and floats open when the cavity is Hooded. Passively opening steam vents are also provided.

Owner:WESTINGHOUSE ELECTRIC CORP

Device for synthesis of radiopharmaceutical products

ActiveUS20040028573A1Short half-lifeEasy to useRadiation measurementPretreated surfacesComputer moduleProduct base

Owner:ION BEAM APPL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com