Patents

Literature

80 results about "Depleted uranium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Depleted uranium (DU; also referred to in the past as Q-metal, depletalloy or D-38) is uranium with a lower content of the fissile isotope U-235 than natural uranium. Natural uranium contains about 0.72% U-235, while the DU used by the U.S. Department of Defense contains 0.3% U-235 or less. Uses of DU take advantage of its very high density of 19.1 g/cm³ (68.4% denser than lead). The less radioactive and non-fissile uranium-238 constitutes the main component of depleted uranium.

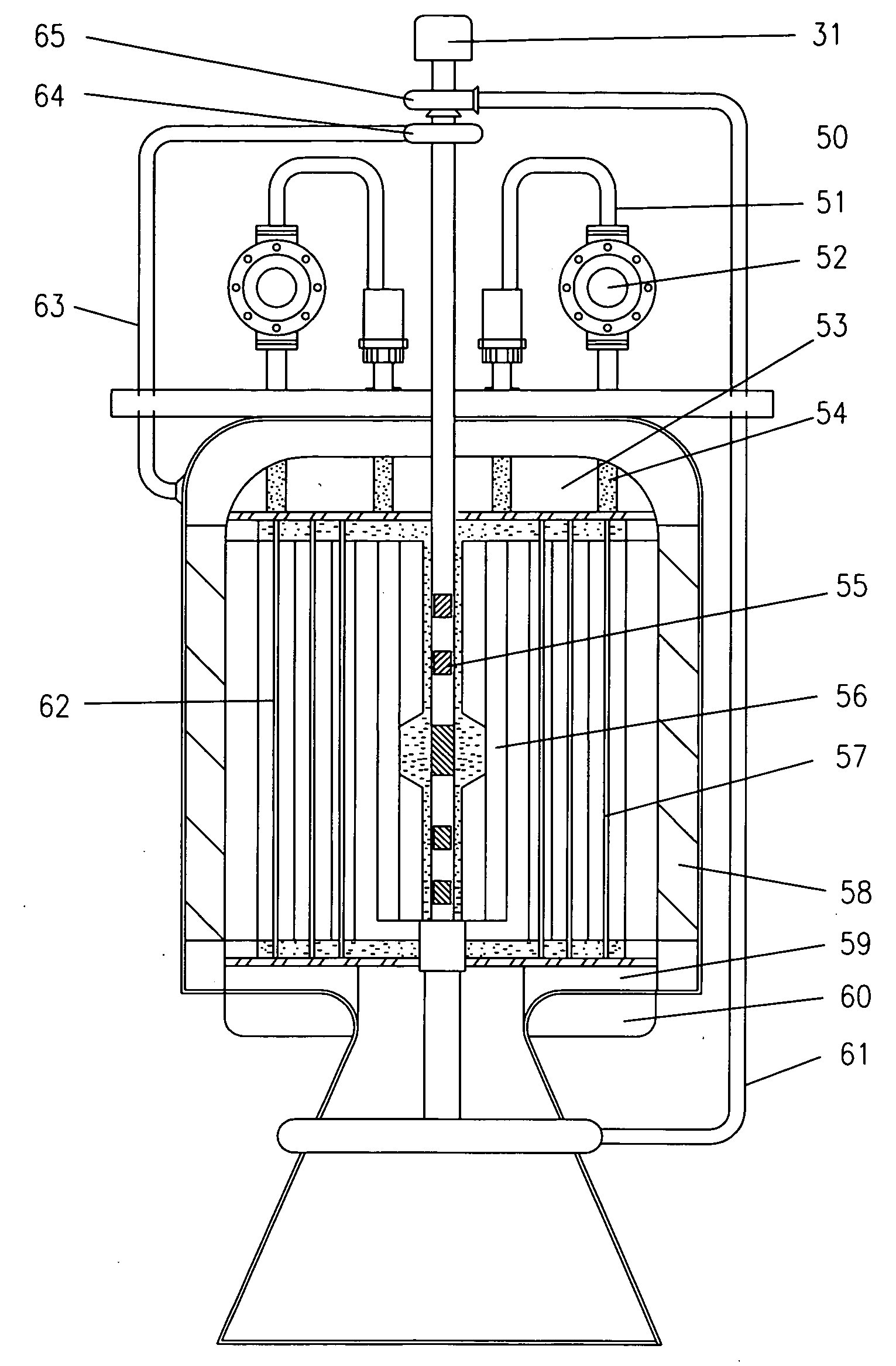

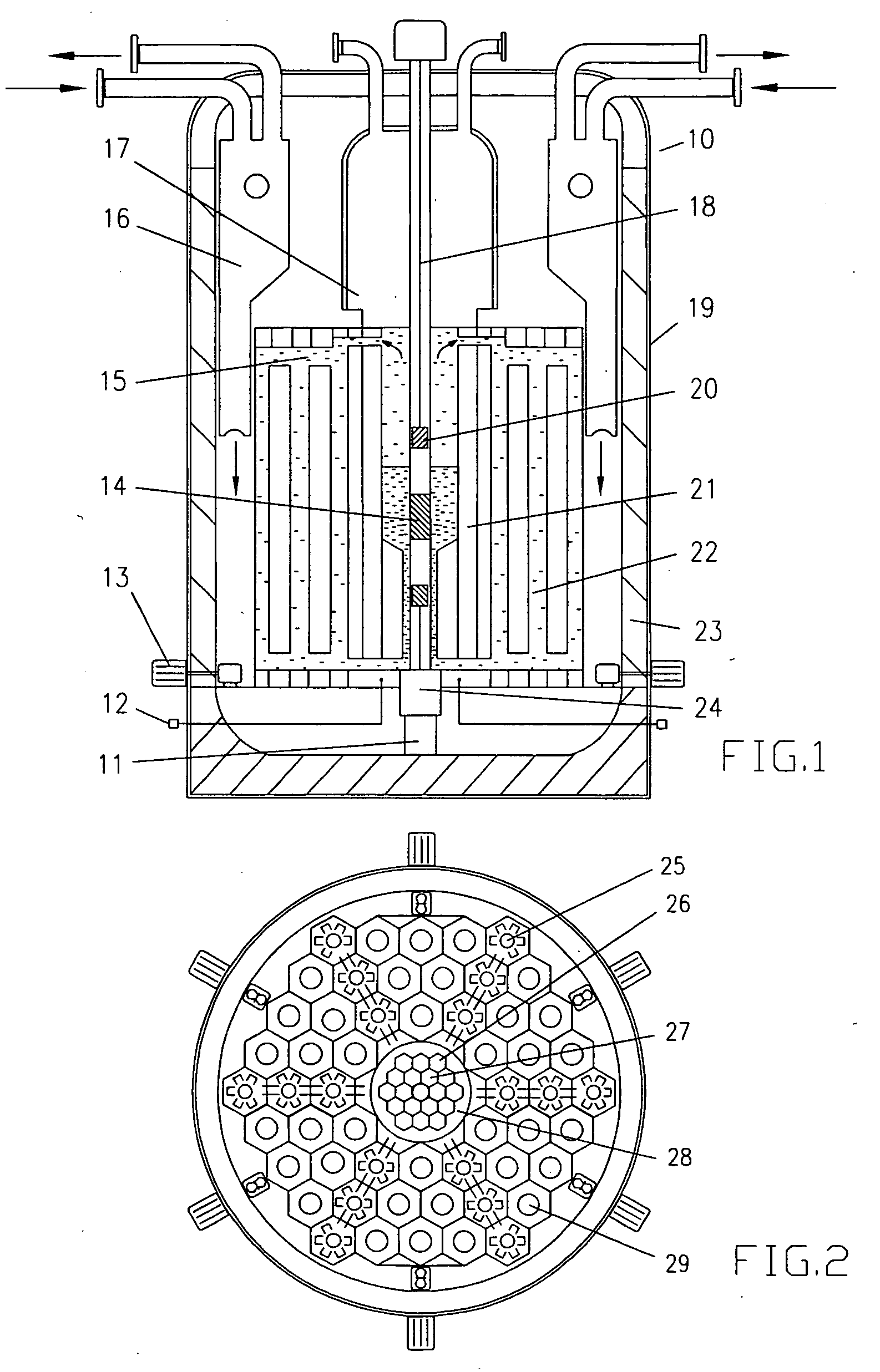

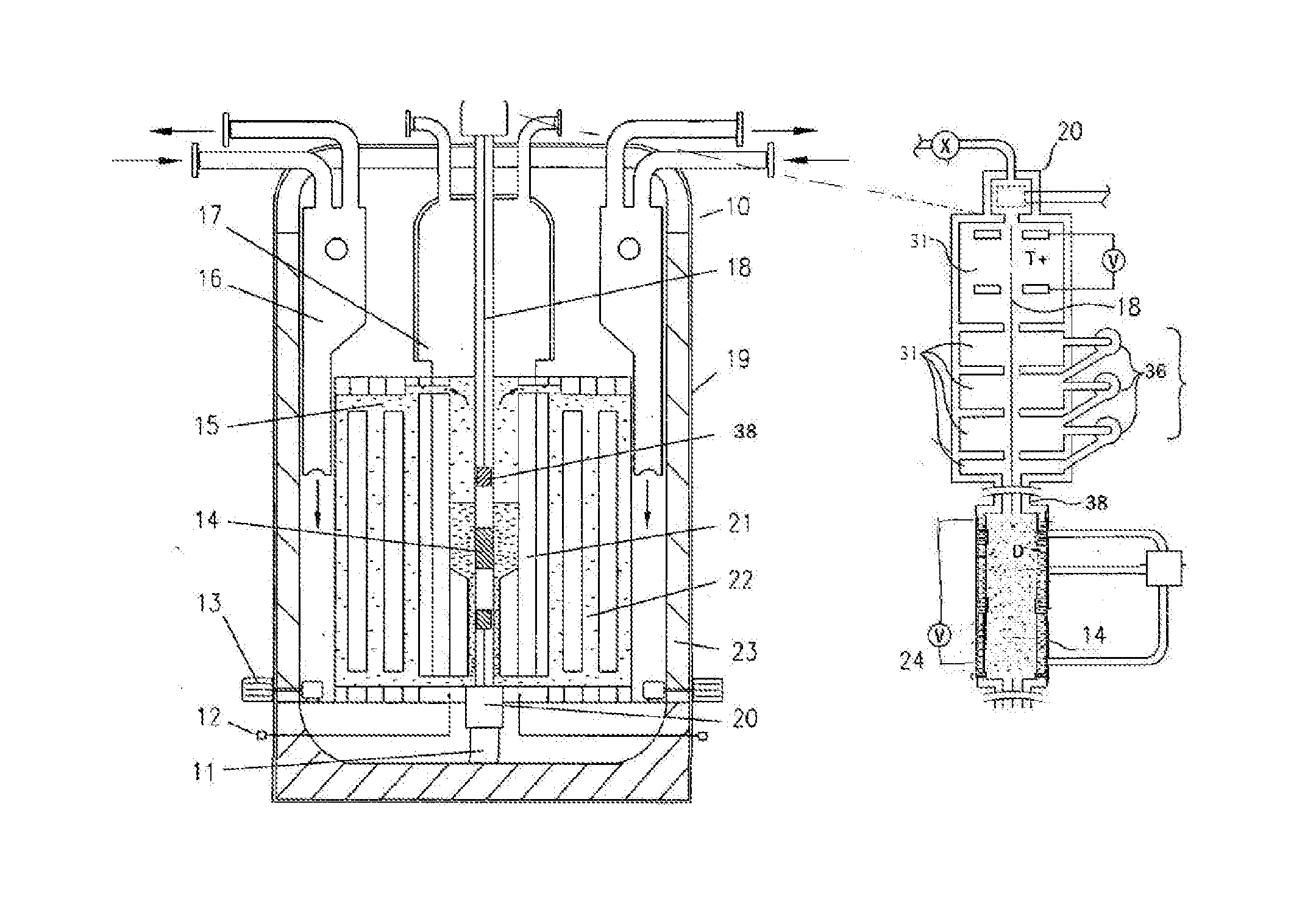

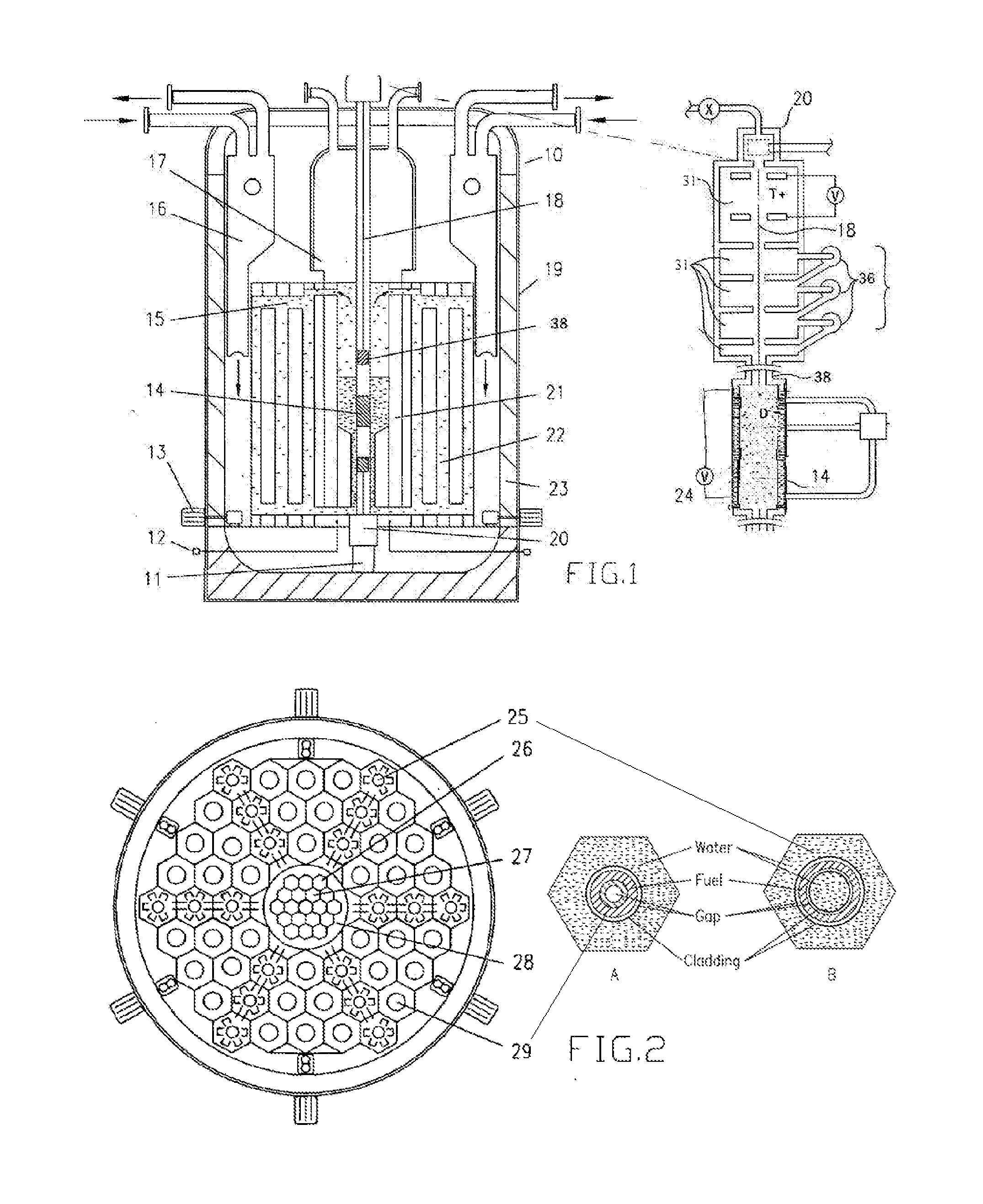

High flux sub-critical reactor for nuclear waste transmulation

InactiveUS20080232533A1Improve distributionImprove economyConversion outside reactor/acceleratorsNuclear energy generationHigh fluxPu element

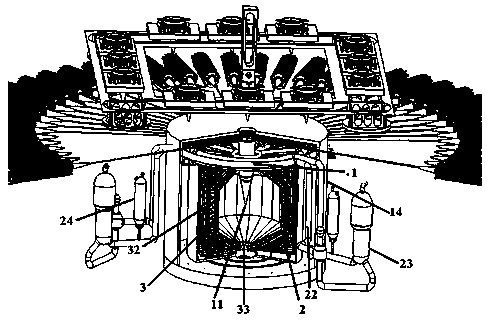

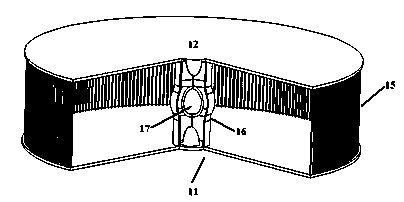

A process to safely convert about 95% of the nuclear waste into a usable fuel source is disclosed. The process, involving a sub-critical power reactor and a proliferation-resistant fuel cycle, consumes depleted uranium or thorium fuel with fissionable fuel, including reactor or weapons-grade plutonium. The reactor is comprised of coaxial neutron and energy-amplifying regions separated by moderating and thermal neutron absorbing layers. Control of the water or gas-cooled reactor is provided by plutonium-helium loops with a variable volume flow rate and an external source of neutrons that quickly reacts to any fluctuations of the reactor parameters. A second embodiment of the invention is a compact sub-critical propulsion reactor utilizing fission electric cell and thermo-acoustic technology for electrical power generation.

Owner:BLANOVSKY ANATOLY

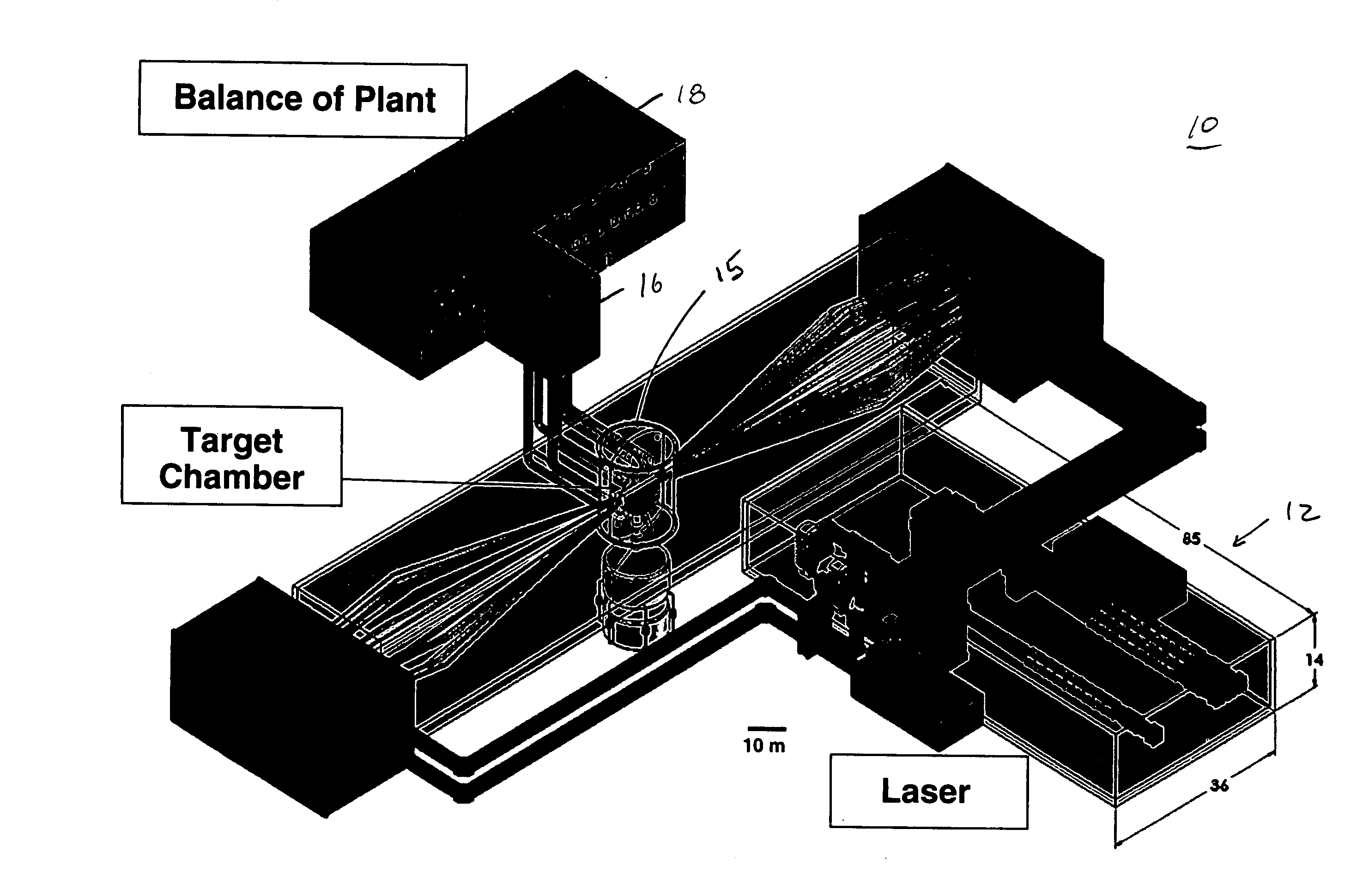

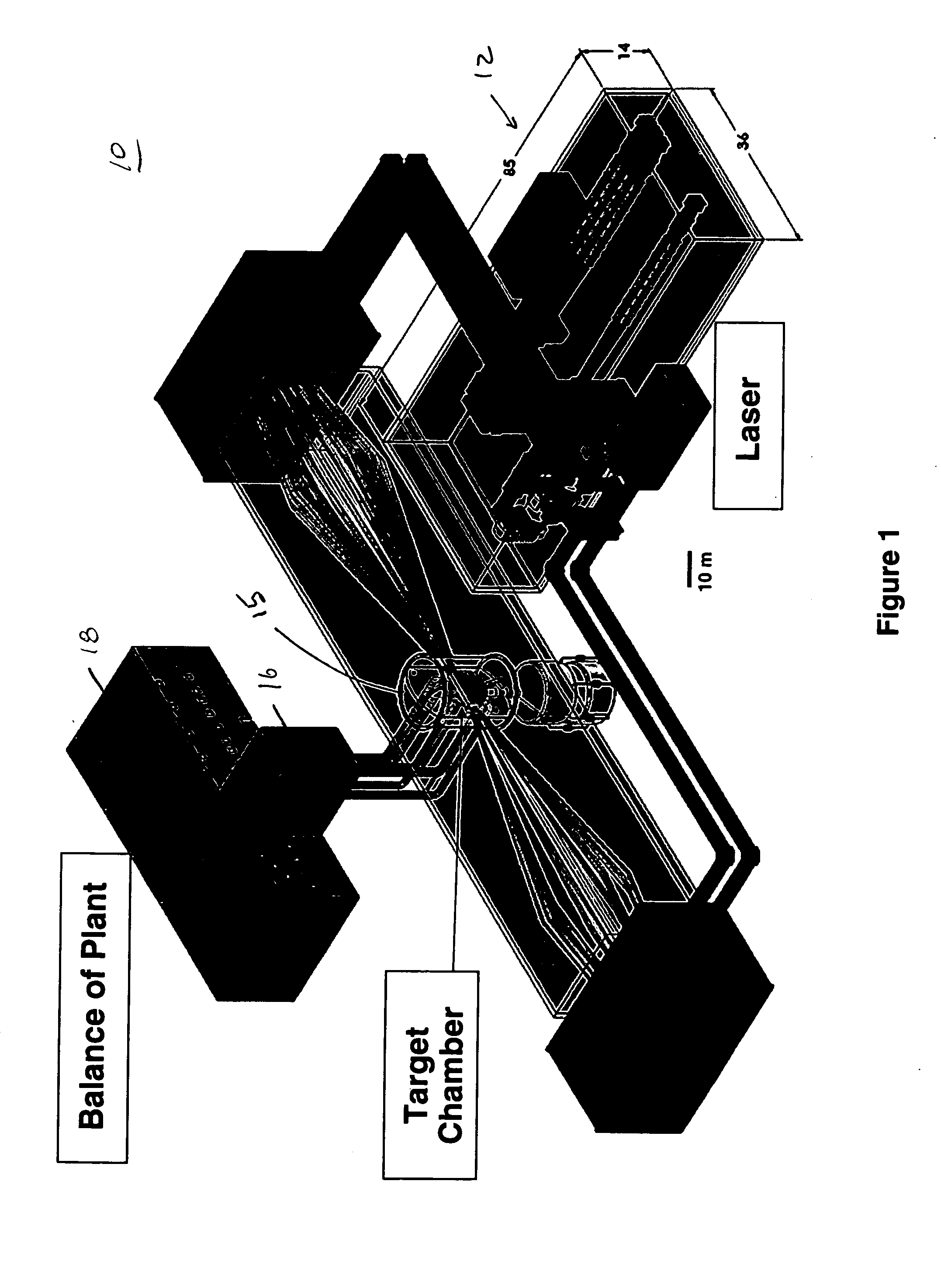

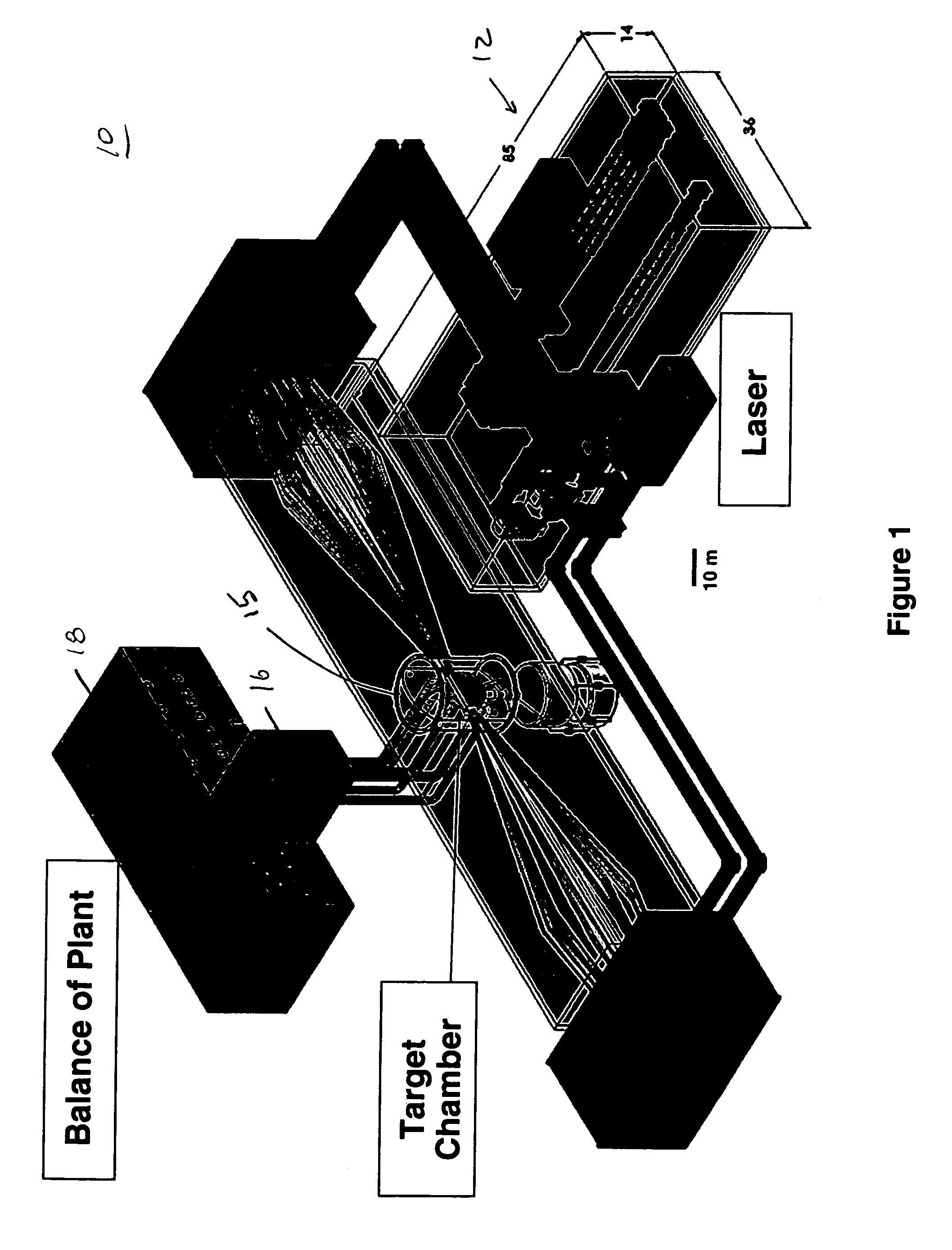

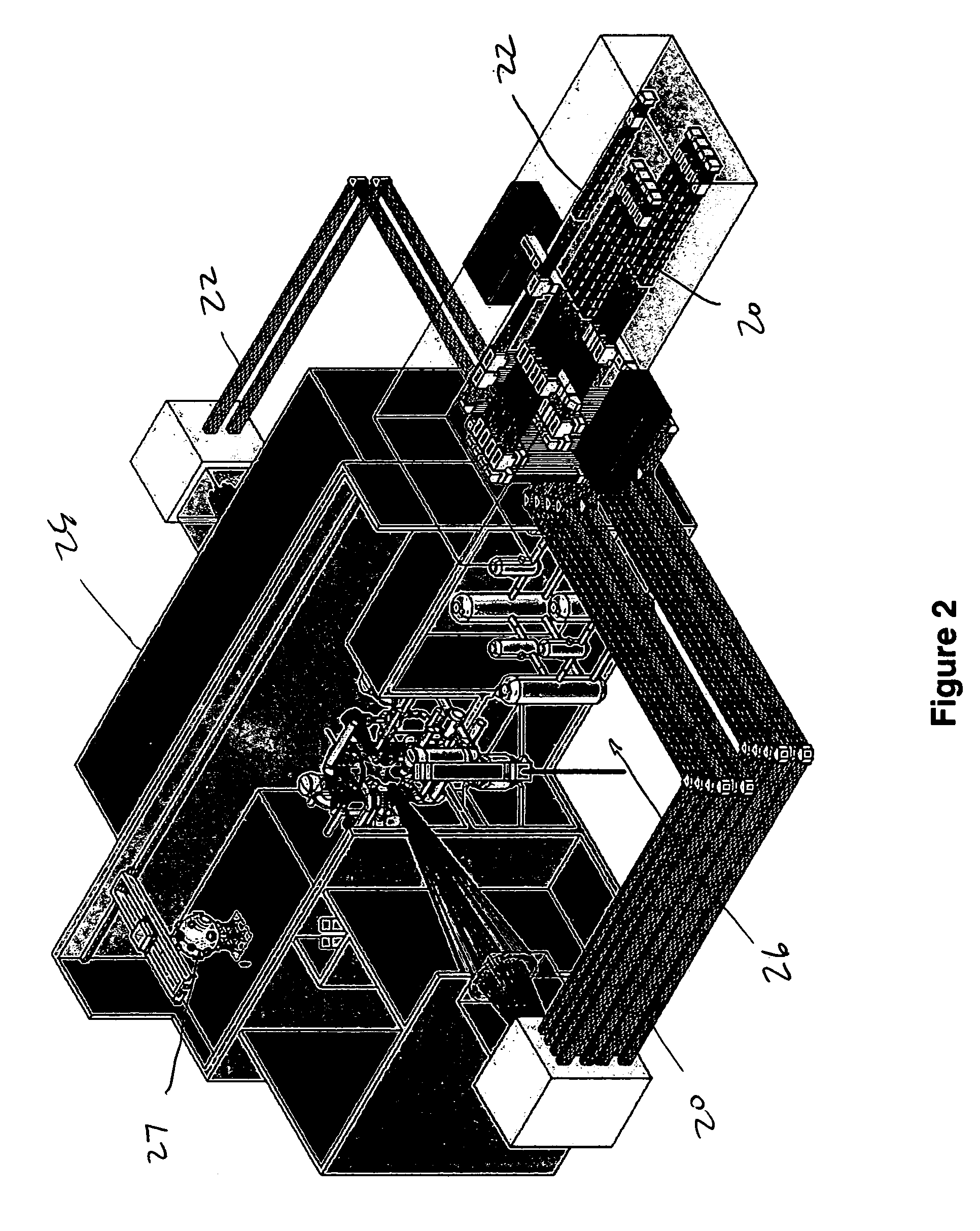

Control of a Laser Inertial Confinement Fusion-Fission Power Plant

ActiveUS20110286563A1Extended service lifeReduce spreadNuclear energy generationWaste based fuelFusion fissionEngineering

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

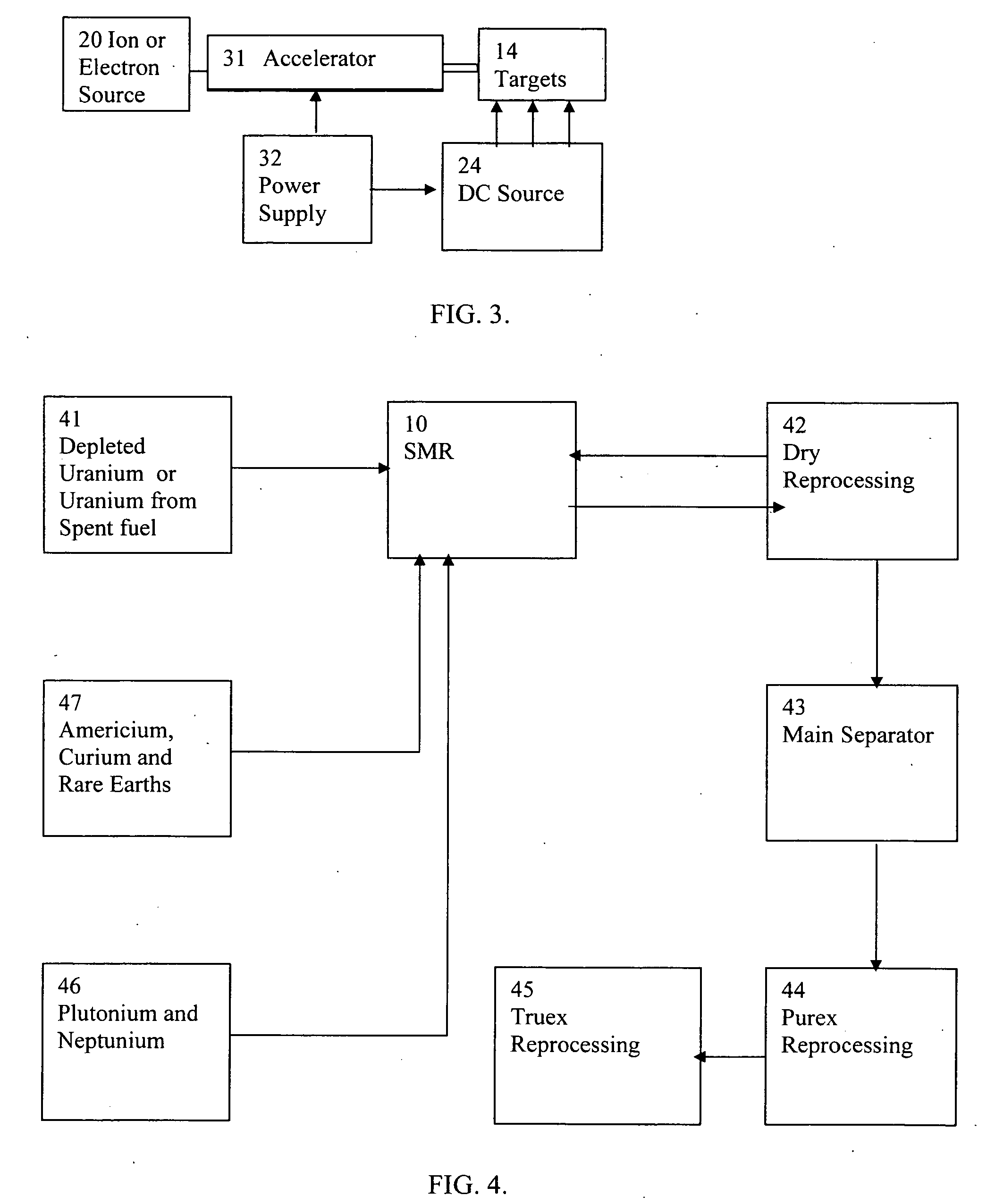

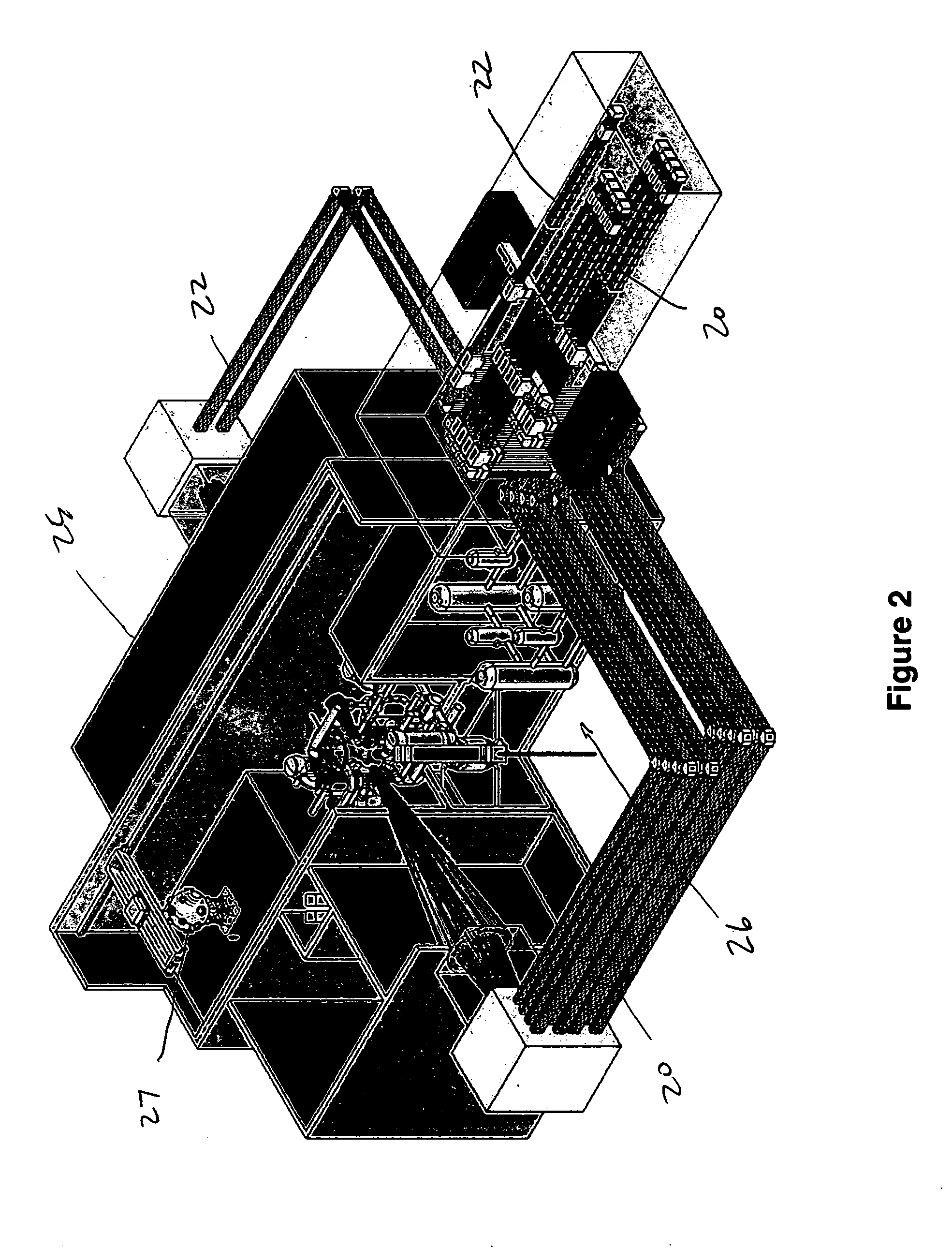

Sustainable Modular Transmutation Reactor

InactiveUS20150098544A1Improve distributionImprove economyIntegral reactorsConversion outside reactor/acceleratorsFission fusionDelayed neutron

A light water reactor to safely convert depleted uranium into a fuel source that could be used as a sustainable source of energy for centuries. The reactor is a type of breed-burn reactor uniquely combined with a proliferation-resistant fuel cycle with no uranium enrichment and no plutonium isolation. It is comprised of a compact factory-produced fast region and a thermal region that produces about 95% of the core power and contains the passageways for transports of delayed-neutron emitters to the fast region, where they can provide additional neutrons (source-based mode) or all the necessary excitation without an external neutron source (self-regulating mode). A second embodiment of the invention is a small unit driven by a neutron source with beam recycling for propulsion, electrical power or radioisotope production. It could also serve as a demonstration facility for the transmutation reactor with fission-fusion fuel.

Owner:BLANOVSKY ANATOLY

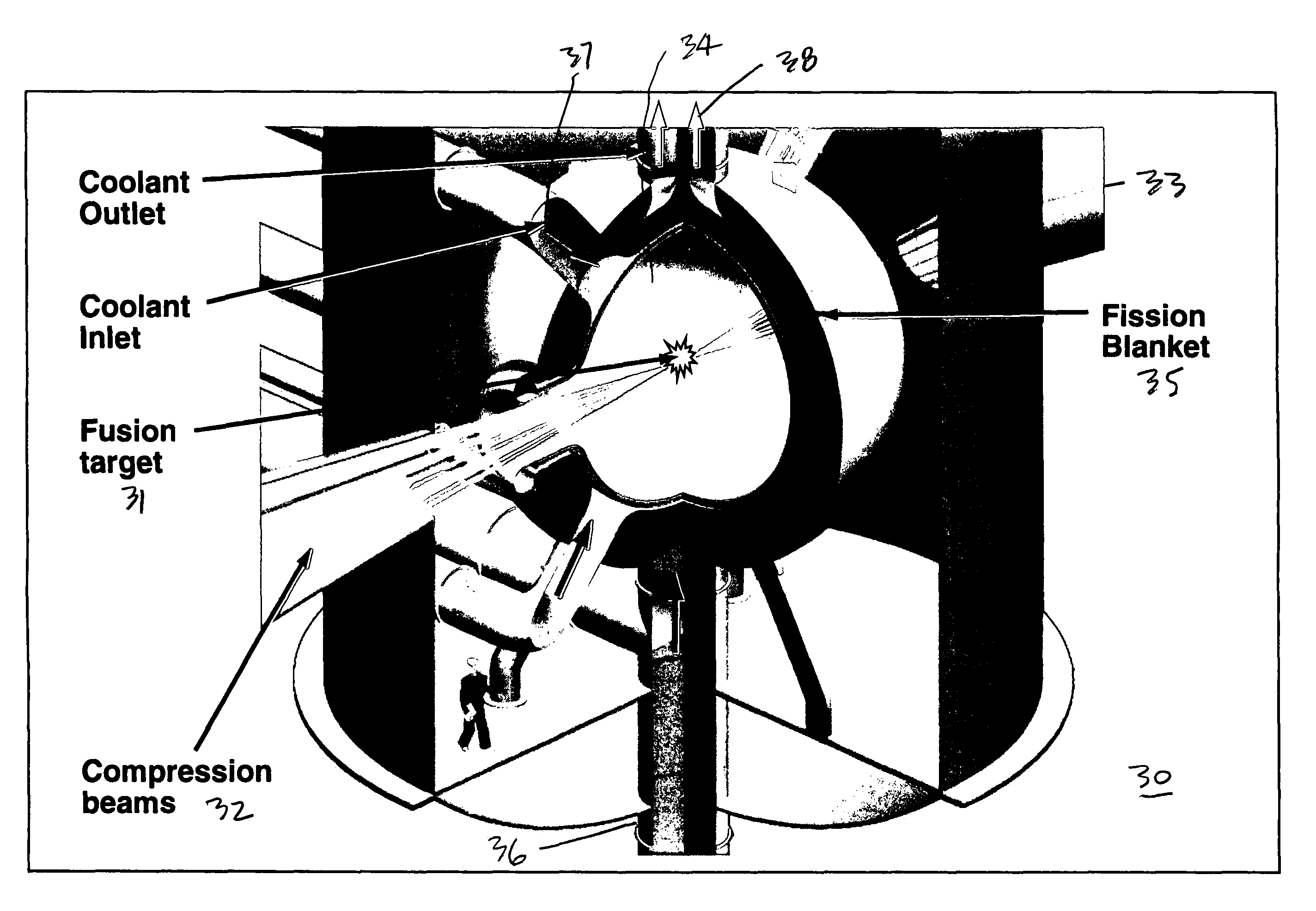

Control of a laser inertial confinement fusion-fission power plant

ActiveUS9171646B2Extended service lifeNuclear energy generationWaste based fuelFusion fissionEngineering

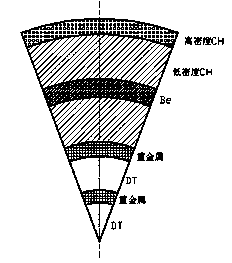

A laser inertial-confinement fusion-fission energy power plant is described. The fusion-fission hybrid system uses inertial confinement fusion to produce neutrons from a fusion reaction of deuterium and tritium. The fusion neutrons drive a sub-critical blanket of fissile or fertile fuel. A coolant circulated through the fuel extracts heat from the fuel that is used to generate electricity. The inertial confinement fusion reaction can be implemented using central hot spot or fast ignition fusion, and direct or indirect drive. The fusion neutrons result in ultra-deep burn-up of the fuel in the fission blanket, thus enabling the burning of nuclear waste. Fuels include depleted uranium, natural uranium, enriched uranium, spent nuclear fuel, thorium, and weapons grade plutonium. LIFE engines can meet worldwide electricity needs in a safe and sustainable manner, while drastically shrinking the highly undesirable stockpiles of depleted uranium, spent nuclear fuel and excess weapons materials.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

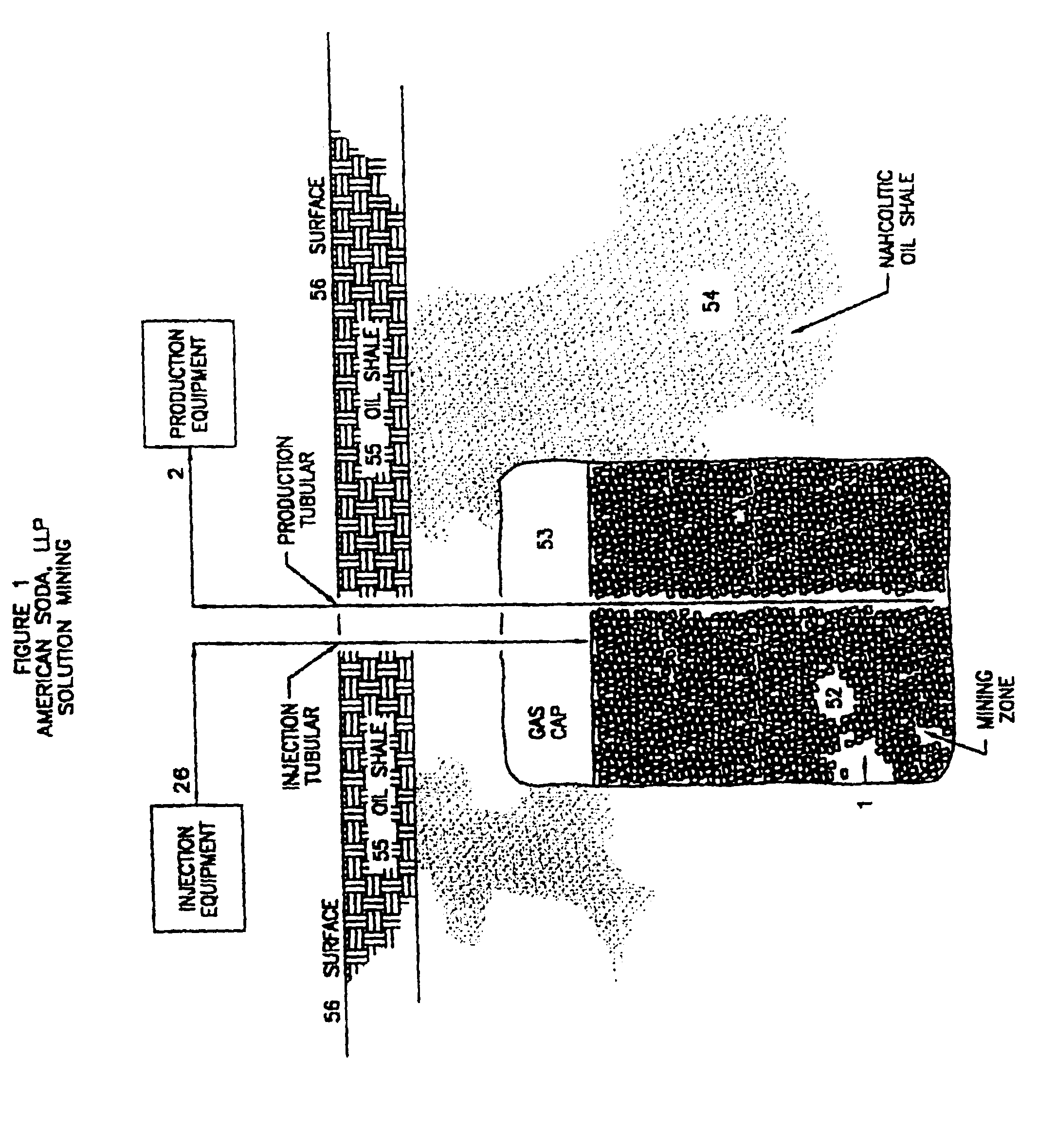

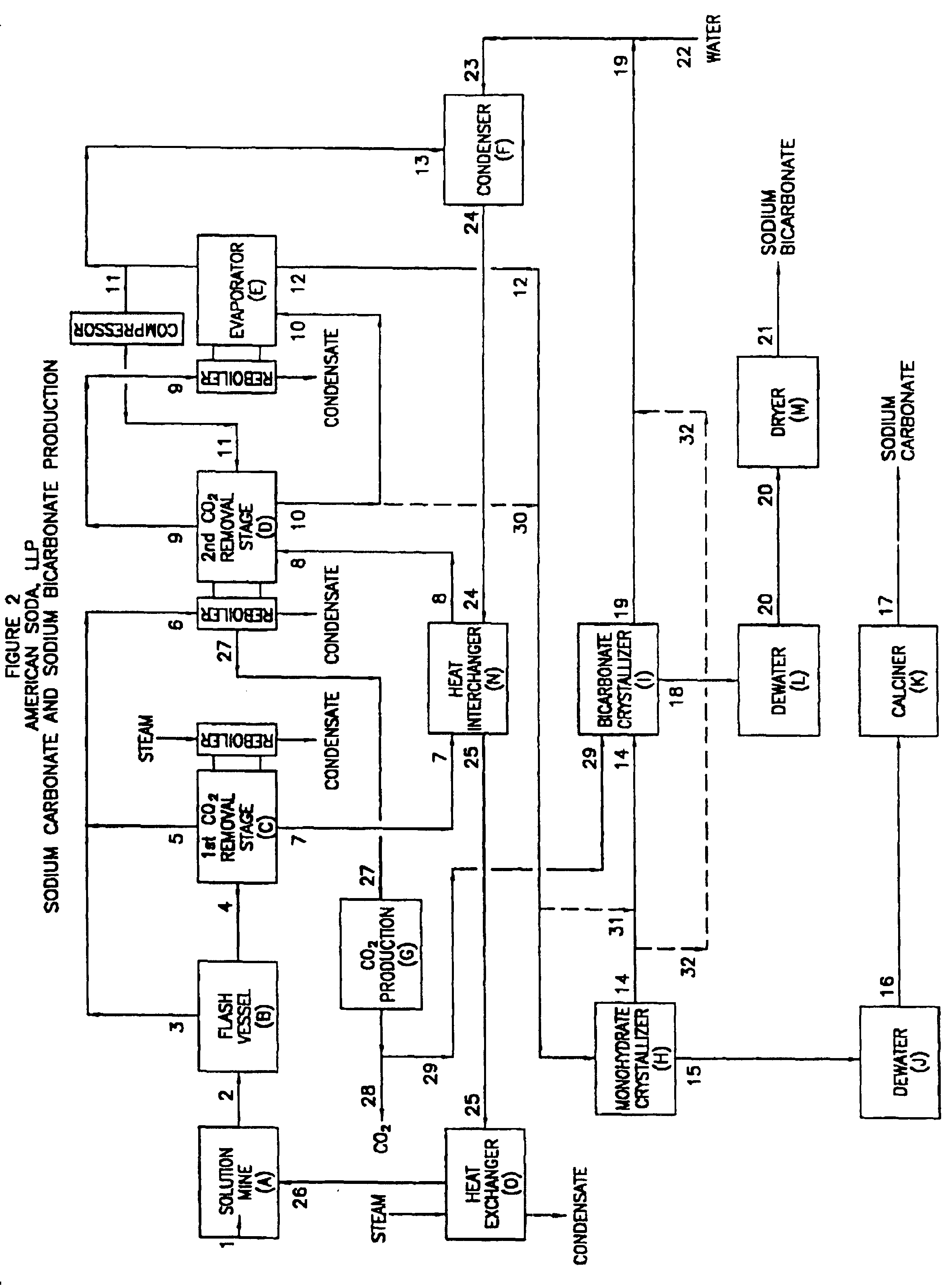

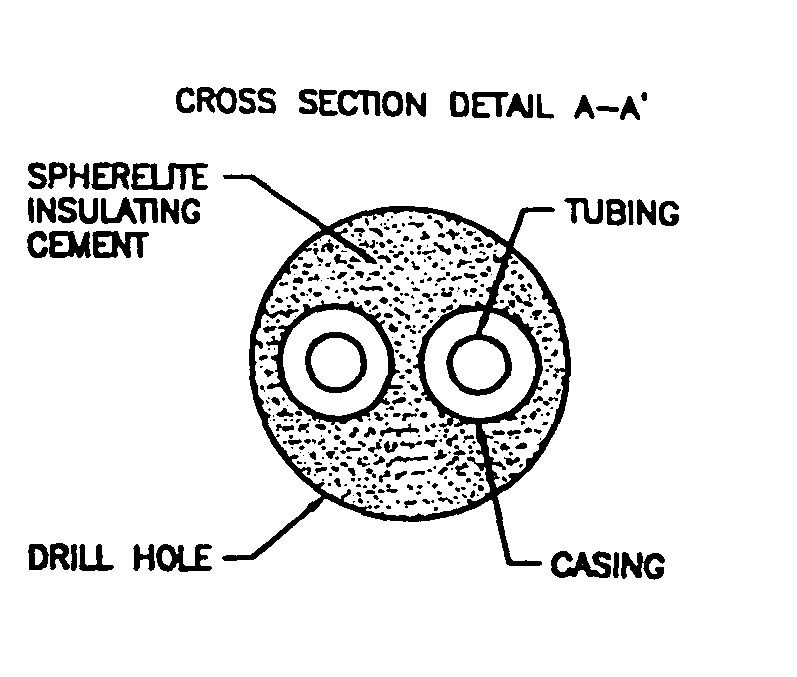

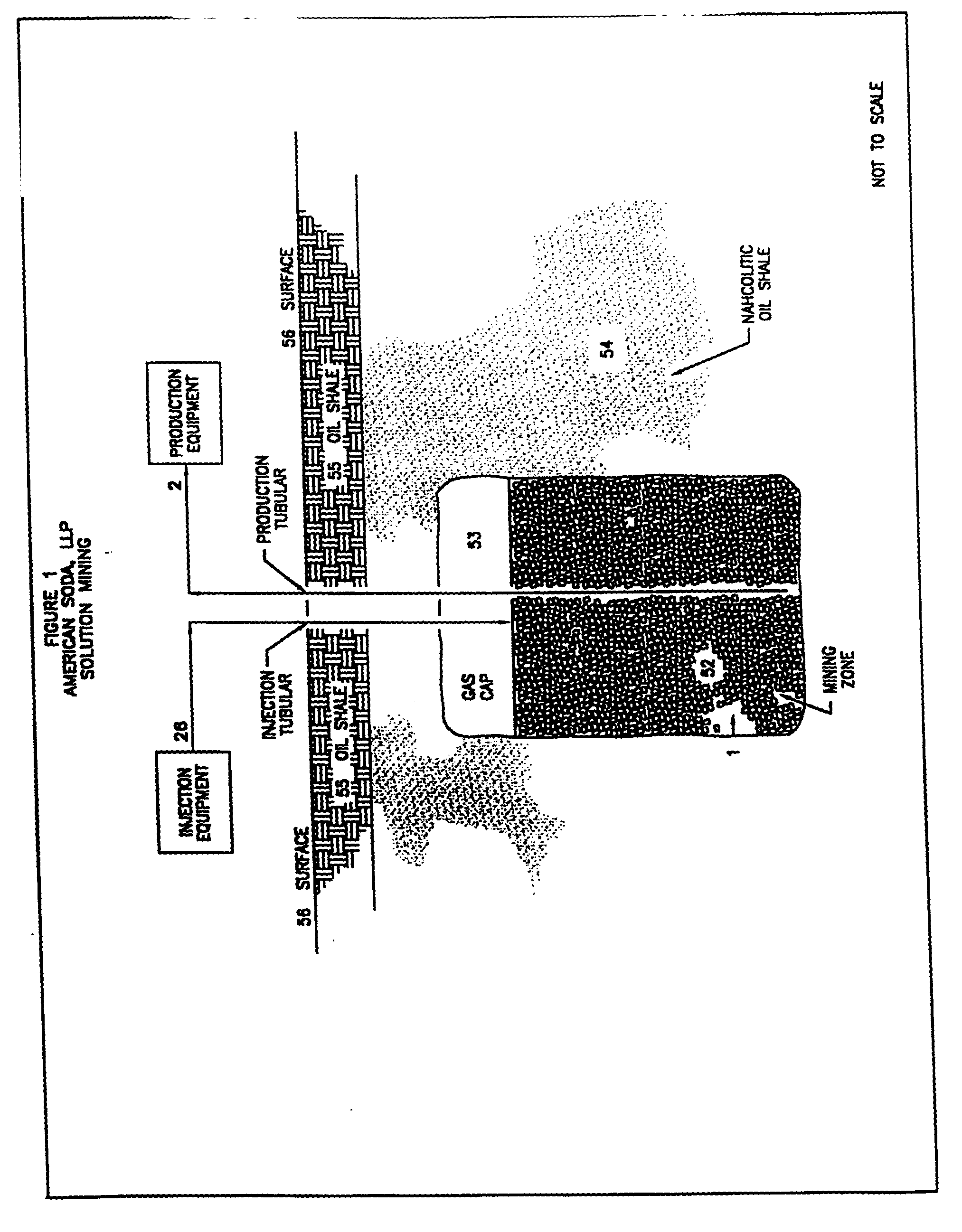

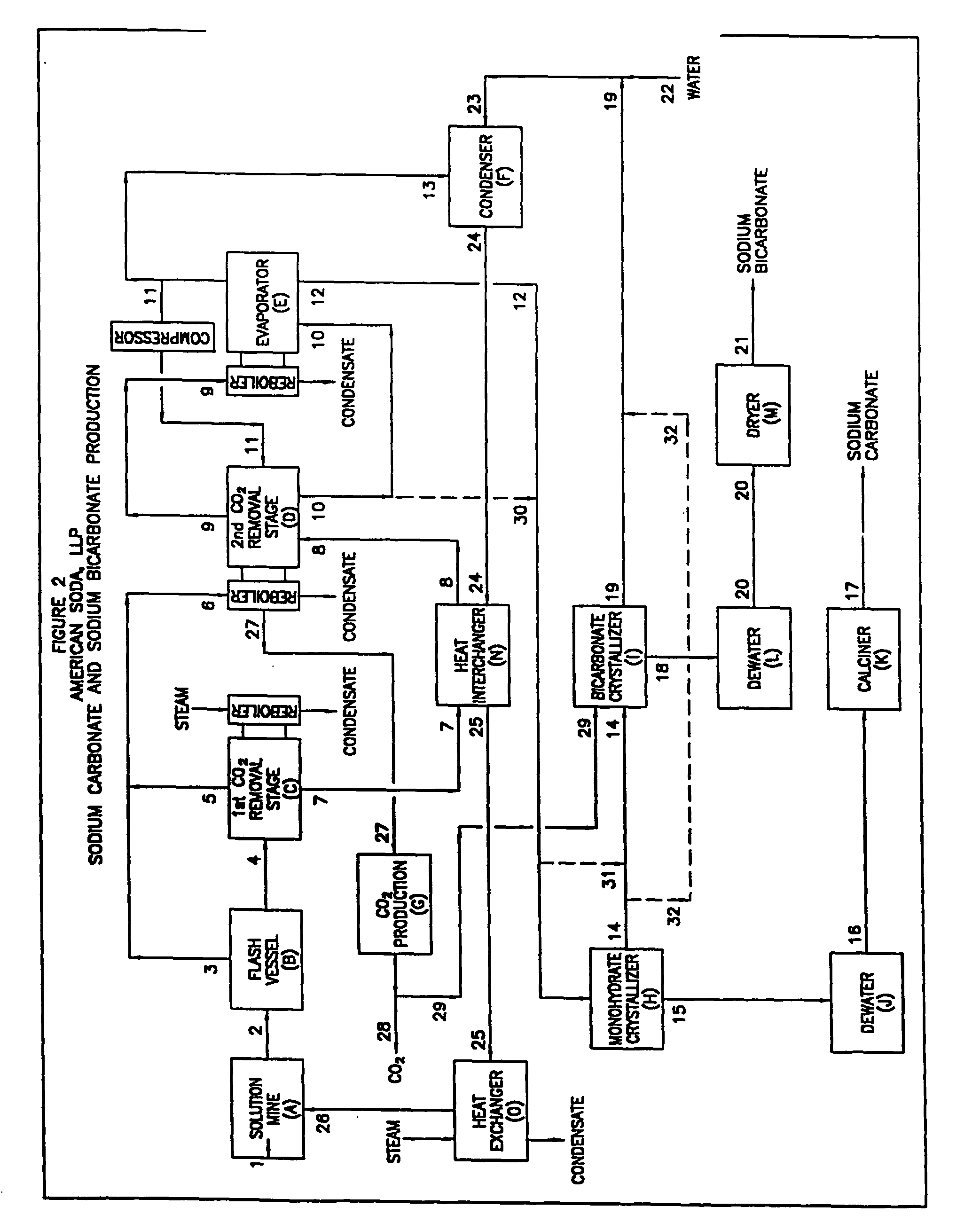

Sodium carbonate and sodium bicarbonate production from nahcolitic oil shale

InactiveUS6854809B1Solve the blockageEfficient executionVarying alkali metal carbonate water contentUnderground miningSodium bicarbonateNahcolite

A method for solution mining nahcolite, capable of extracting nahcolite from geological formations lean in nahcolite comprising injecting high pressure water (which may include recycled aqueous solution of bicarb and sodium carbonate) at a temperature of at least 250° F. into the formation, dissolving nahcolite in the hot water to form a production solution and recovering the production solution. The invention also includes the processing of the production solution to provide sodium carbonate and, optionally, sodium bicarbonate, comprising: decomposing the sodium bicarbonate portion of the hot aqueous production solution to form a hot aqueous solution of sodium carbonate; evaporating water from the hot aqueous solution comprising sodium carbonate to form a concentrated solution of sodium carbonate; producing sodium carbonate monohydrate from the concentrated solution of sodium carbonate by crystallization; and dewatering and calcining the sodium carbonate monohydrate to produce anhydrous sodium carbonate.

Owner:AMERICAN SODA

Z-pinch driven fusion-fission hybrid energy reactor

InactiveCN104240772AReasonable designGuarantee continuous and stable operationNuclear energy generationThermonuclear fusion reactorFusion fissionNuclear engineering

The invention discloses a Z-pinch driven fusion-fission hybrid energy reactor. The Z-pinch driven fusion-fission hybrid energy reactor comprises a Z-pinch inertial confinement fusion reactor core, a subcritical fission cladding and energy output system, and a tritium production cladding and deuterium-tritium circulation system. The fusion reactor core comprises a fusion load, fusion targets, a fusion driver and a fusion target chamber supporting continuous operation of fusion. The subcritical fission cladding and energy output system comprises a subcritical cladding, a cooling loop, a steam generator and a voltage stabilizer. The tritium production cladding and deuterium-tritium circulation system comprises a tritium production cladding, a reactor core residual tritium recovery system and an out-of-reactor tritium factory. According to the Z-pinch driven fusion-fission hybrid energy reactor, the inertial confinement fusion reactor core scheme based on the integrated ignition technology is high in realizability and reliable in performance, depleted uranium and thorium can be fully utilized, and therefore the fission resource utilization efficiency is improved; the whole fusion-fission hybrid energy reactor is reasonable and balanced in design, the subcritical cladding is driven through the Z-pinch fusion reactor core, and long-term sufficient clean electrical energy can be provided.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

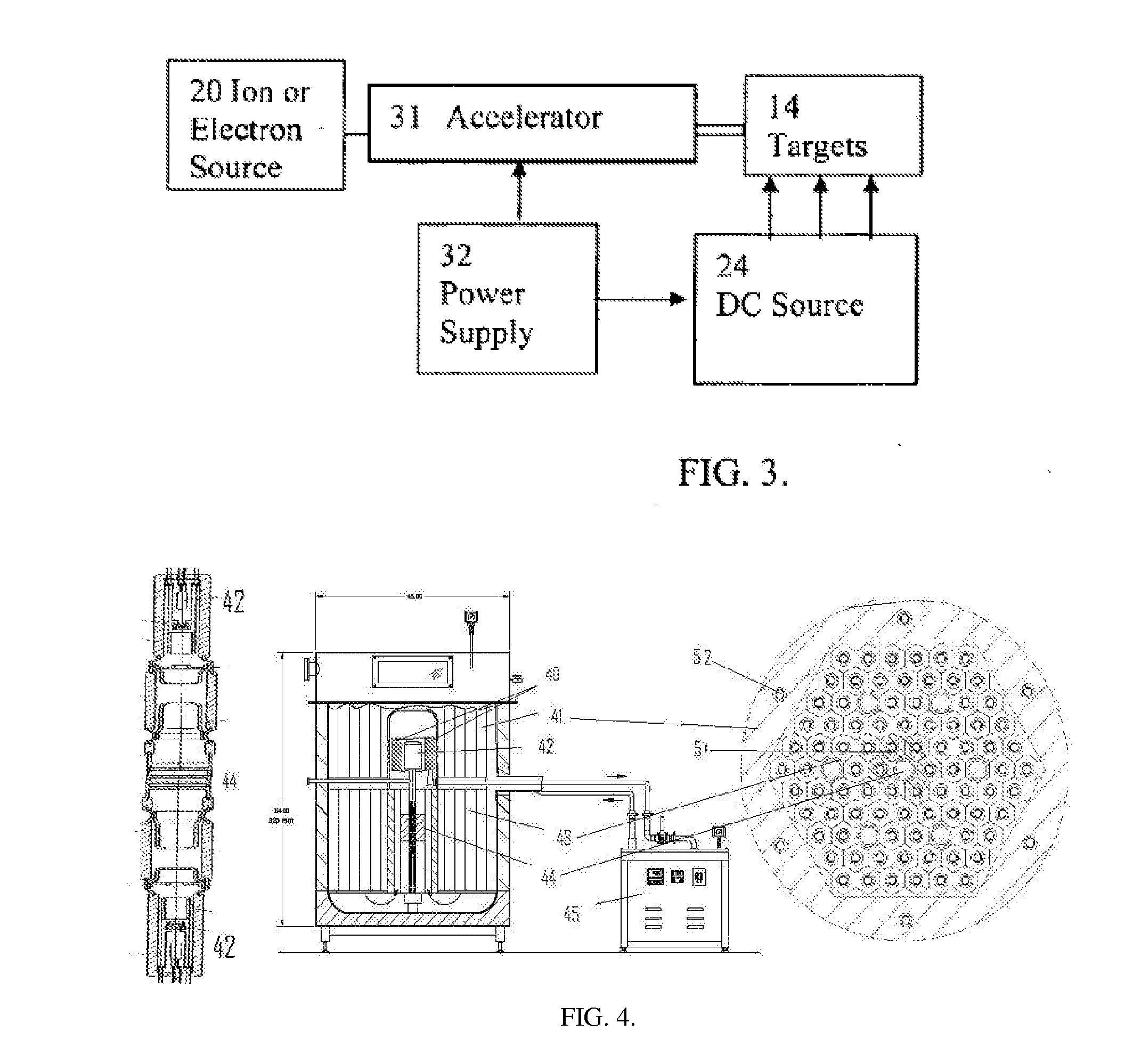

Method and system for subcritical nuclear rubbish treatment and nuclear fuel production based on fissioner neutron breeding

InactiveCN1591700AIncrease productivityImprove processing efficiencyConversion outside reactor/acceleratorsRadioactive decontaminationNatural uraniumBoron carbide

The present invention discloses a method for making subcritical nuclear waste material treatment and nuclear fuel production based on fissionable material neutron proliferation and its system. The exterior of external neutron source generation zone is enclosed successively with actinide elements treating zone, fissionable fuel proliferation zone, fission product treating zone and reflecting and shielding zone, all the zones are separated by means of structure material. The actinide elements treating zone includes actinide elements, fissionable fuel mixture and covering structure material; the fissionable fuel proliferation zone includes natural uranium or thorium or lean uranium and covering structure material; the fission product treating zone includes high radioactive fission product and covering structure material and neutron slowing agent, and the reflecting and shielding zone is formed from graphite, boron carbide, stainless steel and lead, etc.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Polymer compositions and methods for shielding radioactivity

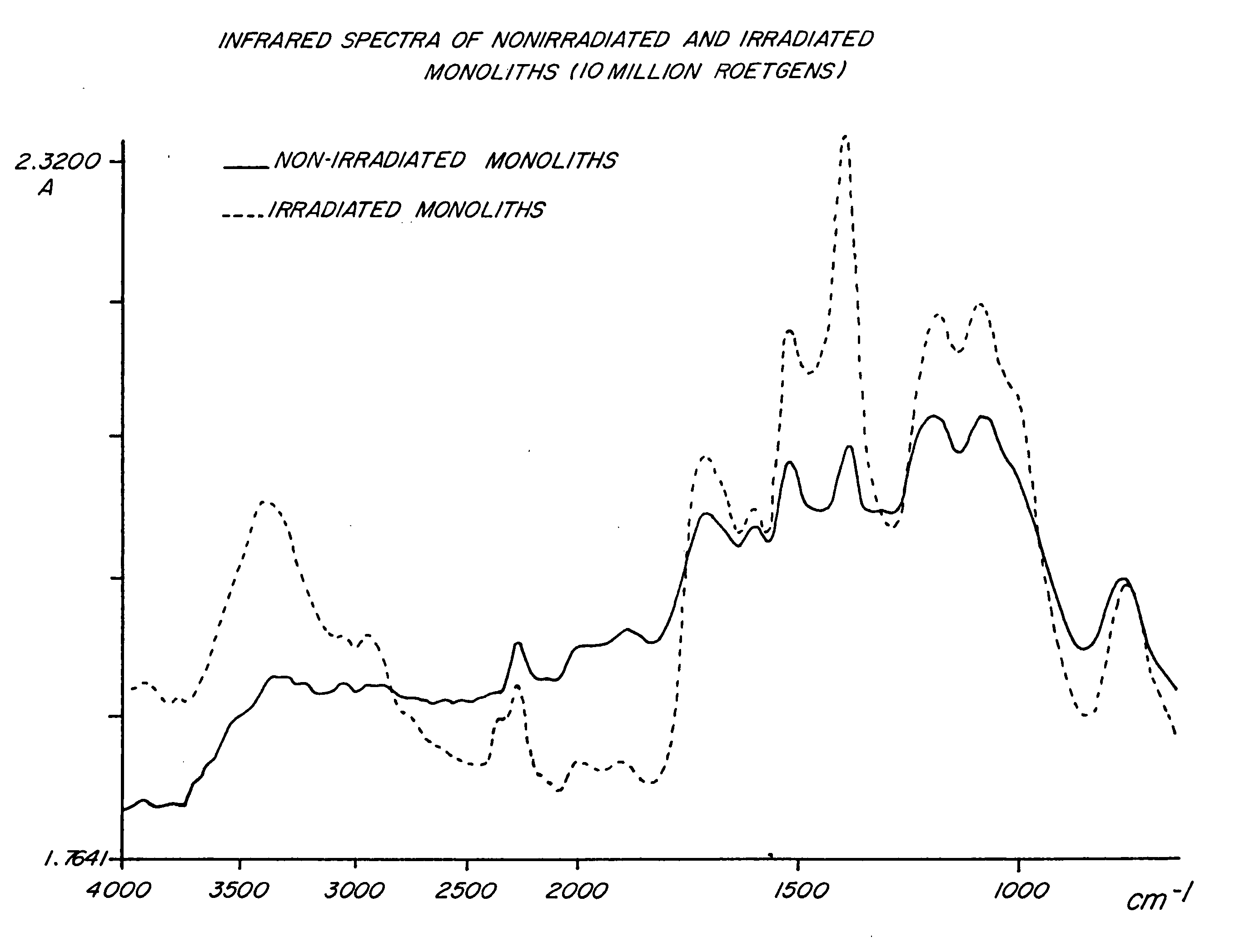

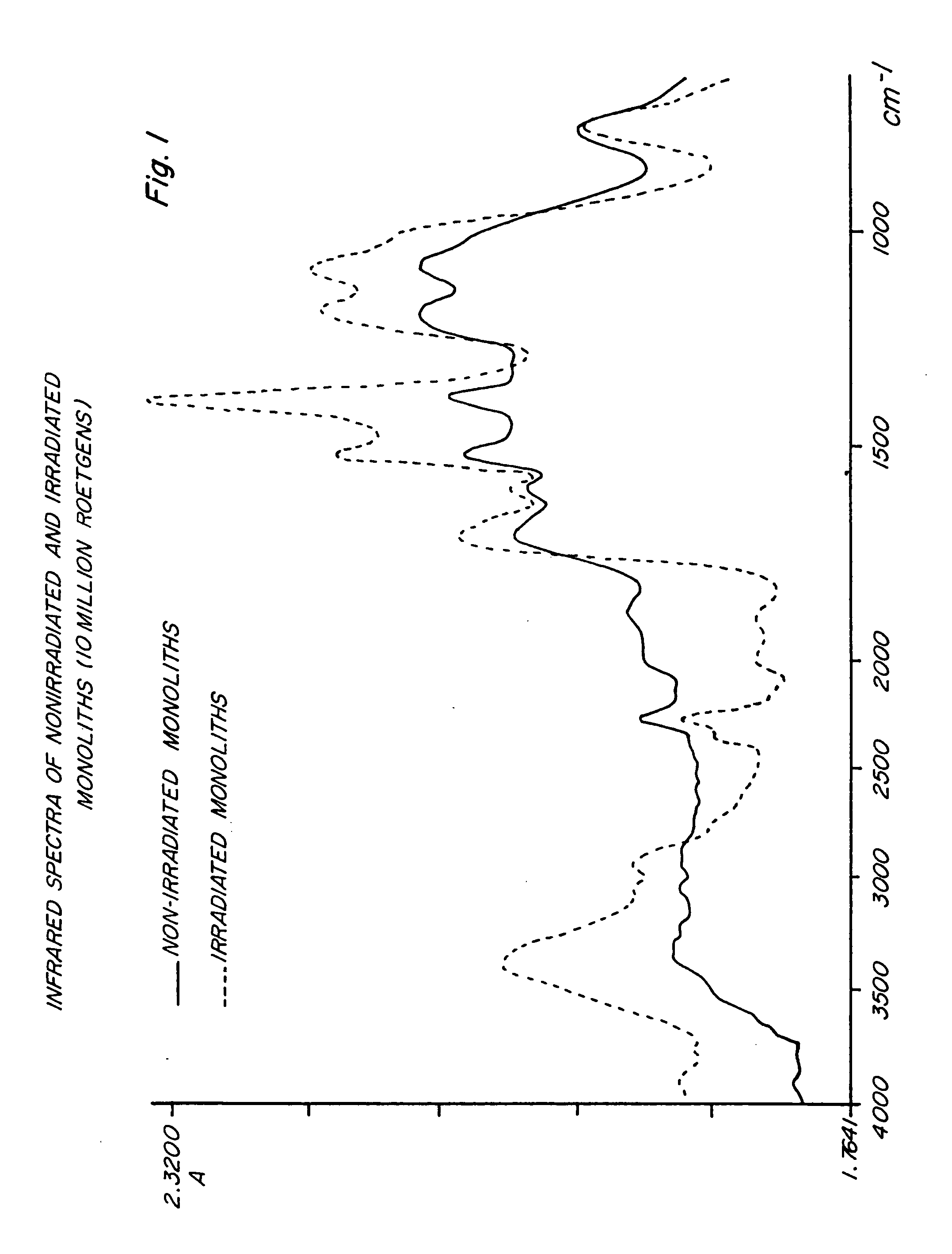

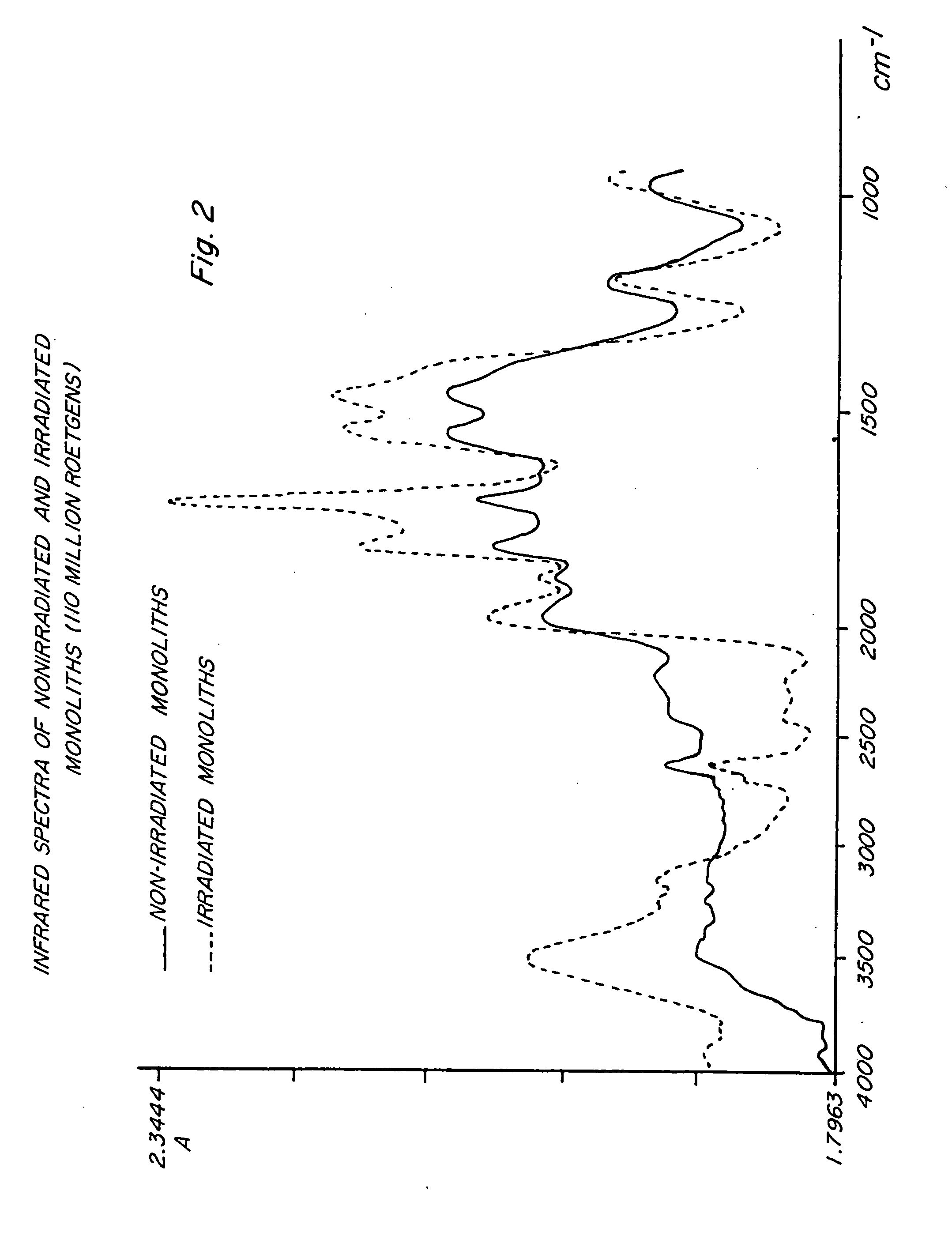

InactiveUS20050203229A1Prevent leakageSafety of tradementPolyurea/polyurethane coatingsShieldingDepleted uraniumScrap

A urethane based polymer composition is provided that exhibits superior shielding properties during and after exposure to high level radiation. The composite is formed by mixing a liquid isocyanate monomer, preferably 4,4′-diisocyanate monomer with a liquid phenolic resin, preferably phenol formaldehyde resin, and a phosphate ester flame retardant. An optional pyridine catalyst may be added to shorten the cure time. The resulting composition cures at room temperature and can be utilized in several manners, including spraying or pouring the composition prior to curing over radioactive material to prevent leakage of radiation. The uncured composite can be sprayed on the walls of a room or container to prevent leakage of radiation and can also be used to contain radiation prior to demolition. The uncured composite can also be molded into bricks or panels for use in construction. In a preferred embodiment, the polymer composition further incorporates radioactive waste, namely depleted uranium oxide, and can be used in conjunction with specially designed containers for storing radioactive material. The resulting polymer / waste composition cures at room temperature and does not deteriorate or suffer structural damage when exposed to higher levels of gamma radiation, nor do the mechanical or chemical properties undergo any detectable change. The composition is resistant to biodegradation and combustion, and does not creep or shrink during thermal cycling.

Owner:SOUNDARARAJAN RENGARAJAN

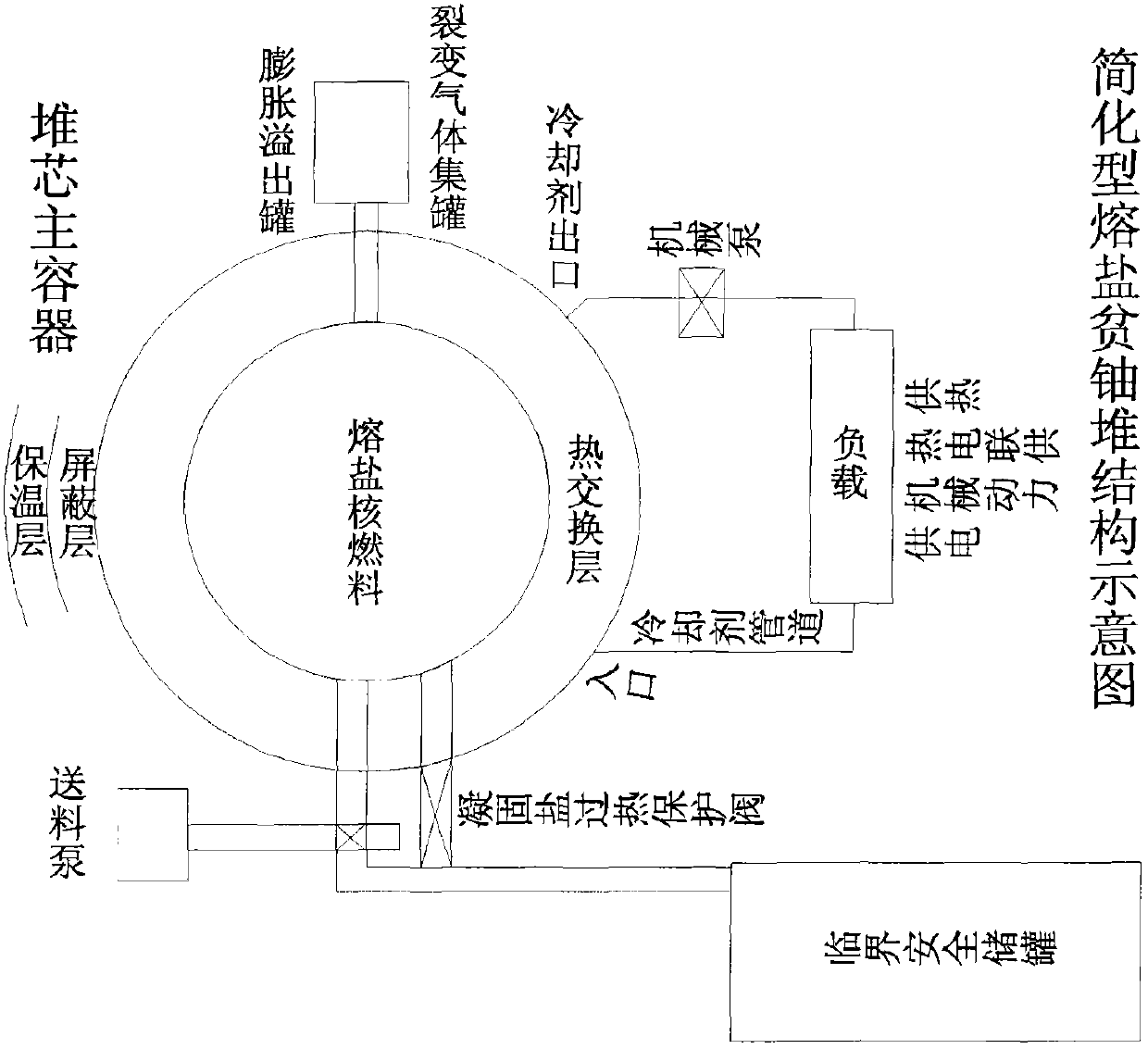

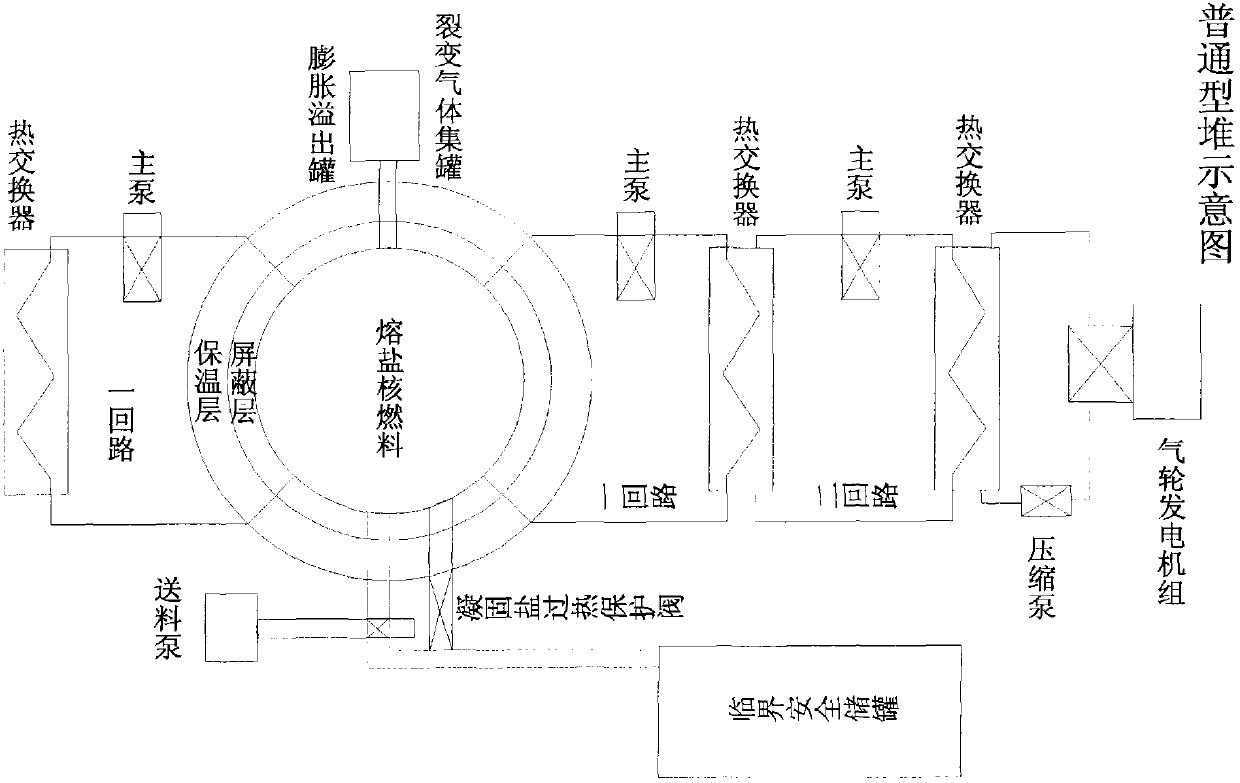

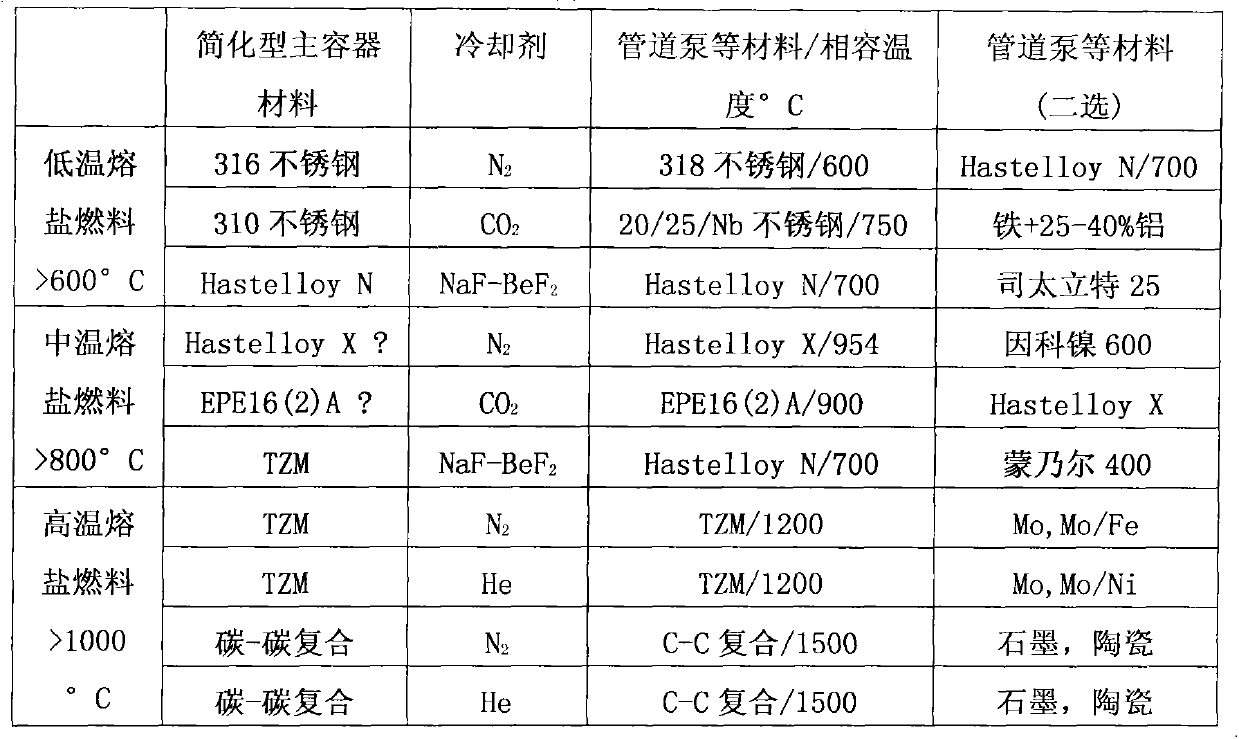

Molten salt depleted uranium reactor

PendingCN104183277AIncrease fuel consumptionSimple structureNuclear energy generationSubcritical reactorsNitrogen gasSteel pipeline

The invention discloses a molten salt depleted uranium reactor, belonging to the technical field of molten salt reactors; fast neutron spectrum, chloride molten salt, uranium plutonium cycle and depleted uranium are used; after start, only by use of a nuclear fuel of self proliferation, long-term stable and safe operation can be achieved, and a supercritical accident may not happen; negative feedback can keep in the critical state; the entire uranium plutonium cycle can be completed in the reactor; normal operation only requires the use of the depleted uranium, the reactor itself does not need uranium enrichment and purification; and high burnup of the depleted uranium can be realized. The reactor has the advantages of simple structure and easy operation, is very suitable for large-scale popularization and application. The reactor is applicable to various types of molten salt formulas and structure materials. The technology, complete set of system technology, engineering and industrialization are feasible. The preferred system is as follows: simplified low temperature IV type + 316 stainless steel main container + nitrogen coolant + 318 stainless steel pipeline pump heat exchanger and the like. Fission nuclear energy can be used to fully meet the national long-term energy needs, at the same time, the problems of the shortage of uranium resources, nuclear criticality safety and low carbon development can be solved, and the reactor is mainly used for heat, electricity or mechanical power supply.

Owner:董保国 +2

Sodium carbonate and sodium bicarbonate production from nahcolitic oil shale

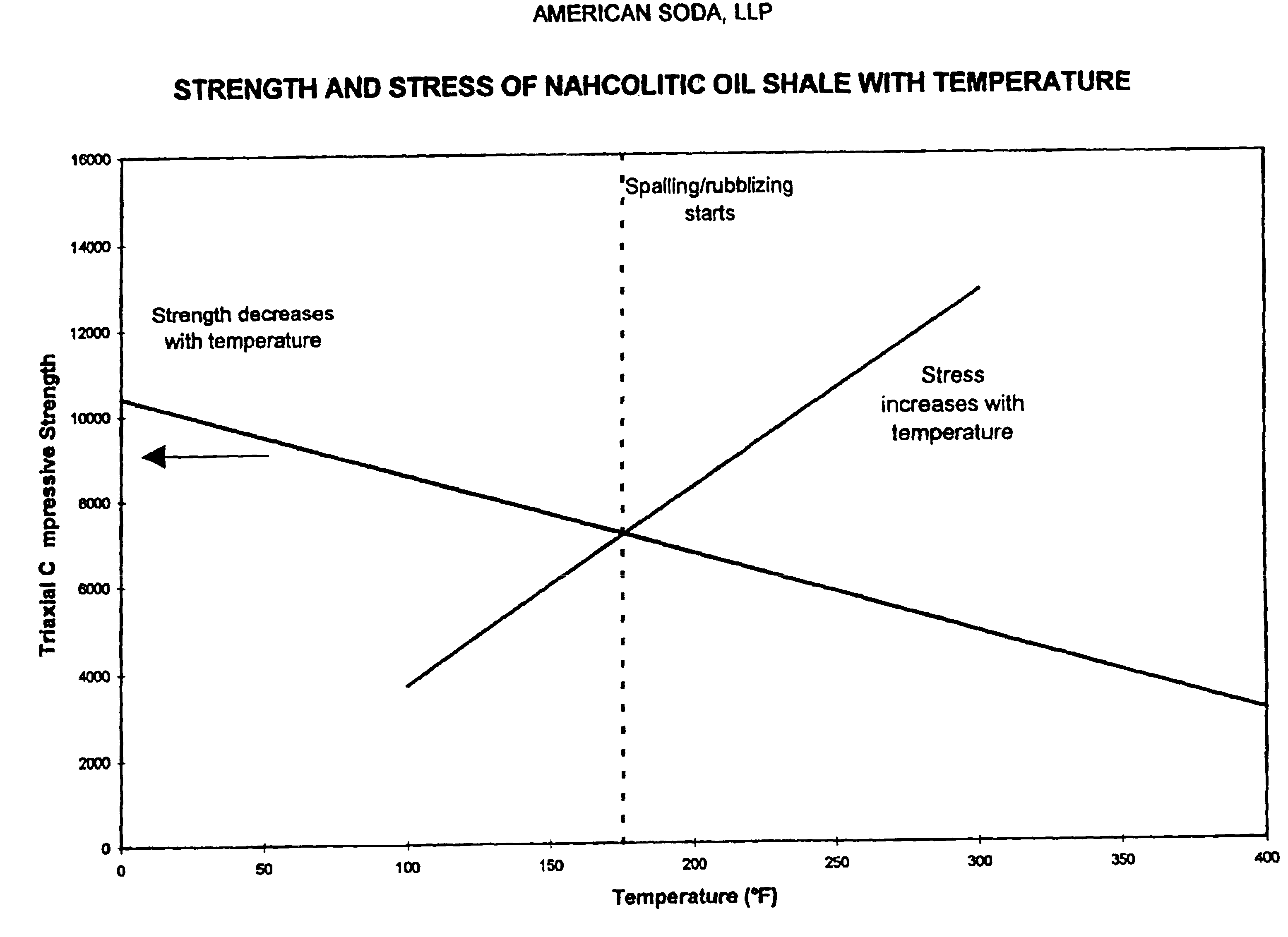

InactiveUS20040026982A1Reduced compressive strengthIncrease pressureVarying alkali metal carbonate water contentConstructionsSodium bicarbonateNahcolite

A method for solution mining nahcolite, capable of extracting nahcolite from geological formations lean in nahcolite comprising injecting high pressure water (which may include recycled aqueous solution of bicarb and sodium carbonate) at a temperature of at least 250° F. into the formation, dissolving nahcolite in the hot water to form a production solution and recovering the production solution. The invention also includes the processing of the production solution to provide sodium carbonate and, optionally, sodium bicarbonate, comprising: decomposing the sodium bicarbonate portion of the hot aqueous production solution to form a hot aqueous solution of sodium carbonate; evaporating water from the hot aqueous solution comprising sodium carbonate to form a concentrated solution of sodium carbonate; producing sodium carbonate monohydrate from the concentrated solution of sodium carbonate by crystallization; and dewatering and calcining the sodium carbonate monohydrate to produce anhydrous sodium carbonate.

Owner:SOLVAY CHEM INC

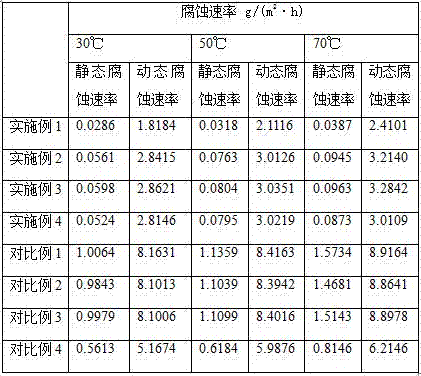

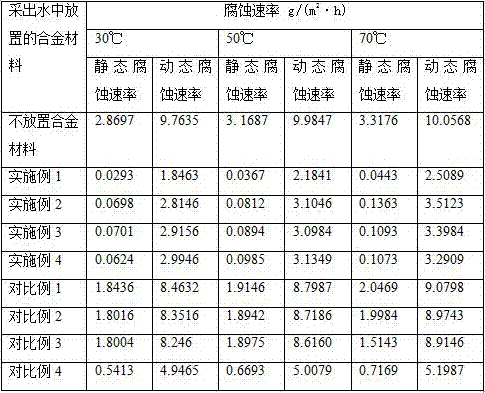

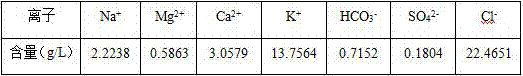

Anti-corrosion and anti-scale titanium-copper alloy material

The invention provides an anti-corrosion and anti-scale titanium-copper alloy material. The anti-corrosion and anti-scale titanium-copper alloy material comprises the following components with contents in percentage by mass: 25-40% of titanium, 20-30% of copper, 10-25% of zinc, 10-15% of nickel, 2-5% of tin, 1-5% of tellurium, 0.01-3% of aluminium, 0.01-0.8% of indium, 0.3-0.5% of niobium, 0.01-0.3% of silicon, 0.01-0.5% of scandium, 0.1-1% of depleted uranium, 0.5-1.5% of the mixture of NaF and NaCl, and less than 0.1% of inevitable impurities. The material is excellent in anti-corrosion and anti-scale performance, capable of slowing down the corrosion of water in the case of being placed in produced water, and capable of reducing the corrosion of solution in the last period of oil and gas development, and reducing the scaling of the solution to equipment.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

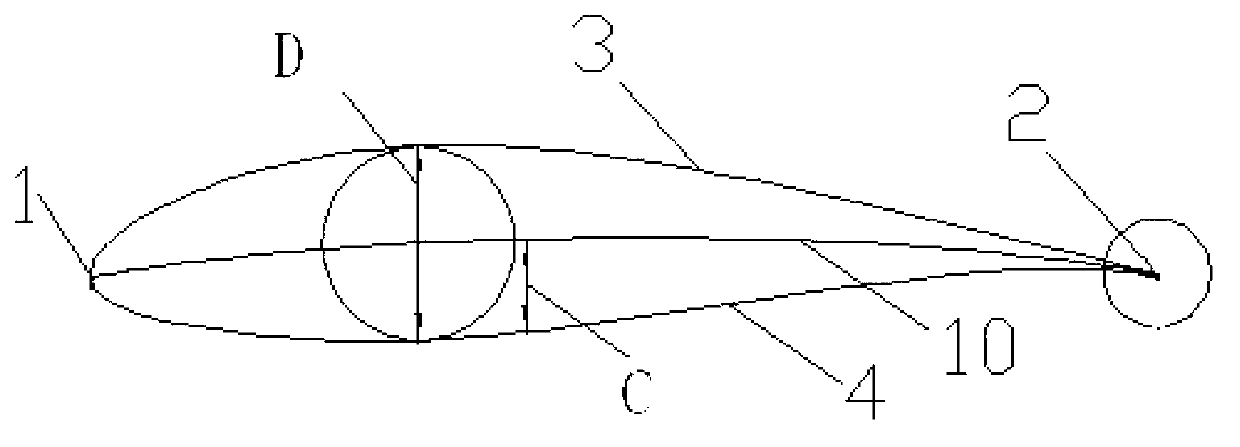

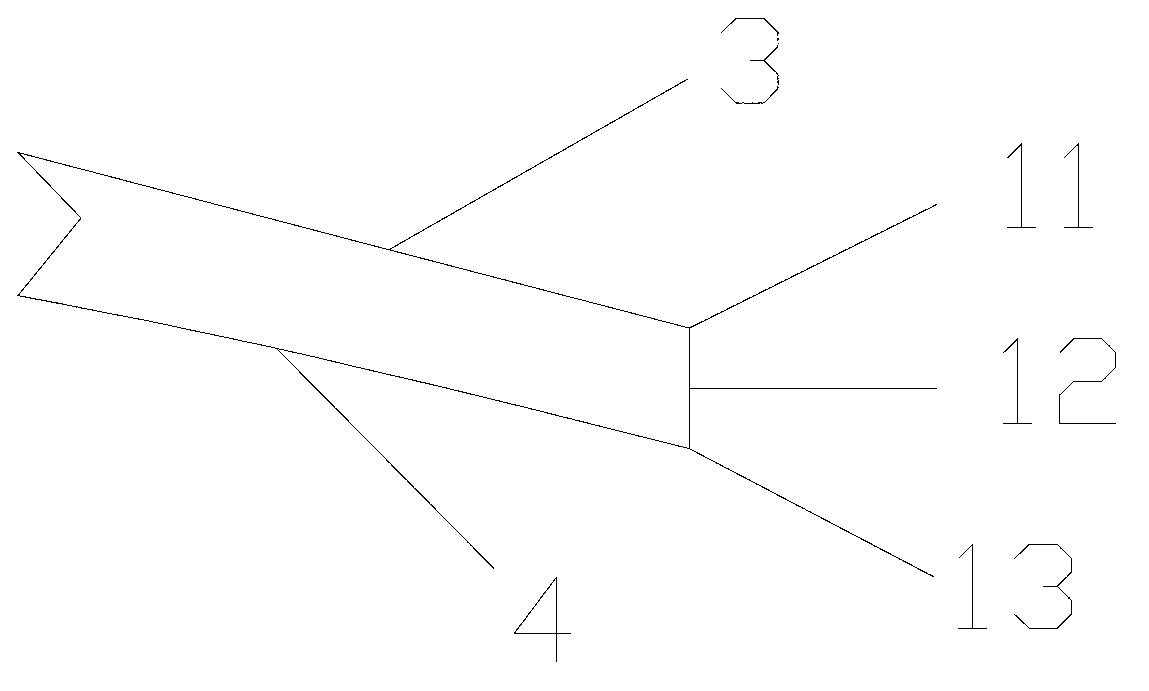

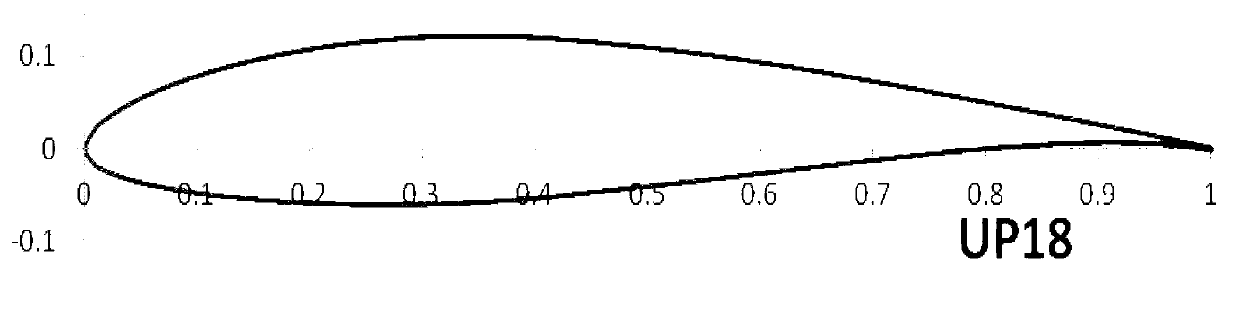

Thin airfoil type blade of large-scale fan

InactiveCN103133272AImprove performanceImprove utilization efficiencyFinal product manufactureWind energy generationTO-18Leading edge

The invention relates to a thin airfoil type blade of a large-scale fan. An outer contour of a cross-section of a blade tip part of the thin airfoil type blade of the large-scale fan comprises a leading edge, a trailing edge, a suction surface profile and a pressure profile, wherein the distance between the leading edge and the trailing edge is chord length, the thickness of an end surface of the trailing edge is 0% to 5% of the chord length, and the radius of the leading edge is 2.5% to 3.5% of the chord length. The maximum thickness of the section-cross is 17.5% to 18.5% of the chord length, the distance of a thickest portion of the cross-section and the leading edge is 25% to 35% of the chord length, the maximum bending degree of the cross-section is 3.0% to 4.0% of the chord length, and the distance of a portion with the maximum bending degree and the leading edge is 40% to 60% of the chord length. The comprehensive performance of the thin airfoil is better than the comprehensive performance of a traditional depleted uranium (DU), national advisory committee for aeronautics (NACA) airfoil with the same relative thickness, not only is the wind energy utilization rate improved, but also the structural weight is reduced and the fatigue loading is reduced. The thin airfoil type blade of the large-scale fan becomes an important technical basis for developing large-scale low-cost wind turbines.

Owner:GUODIAN UNITED POWER TECH

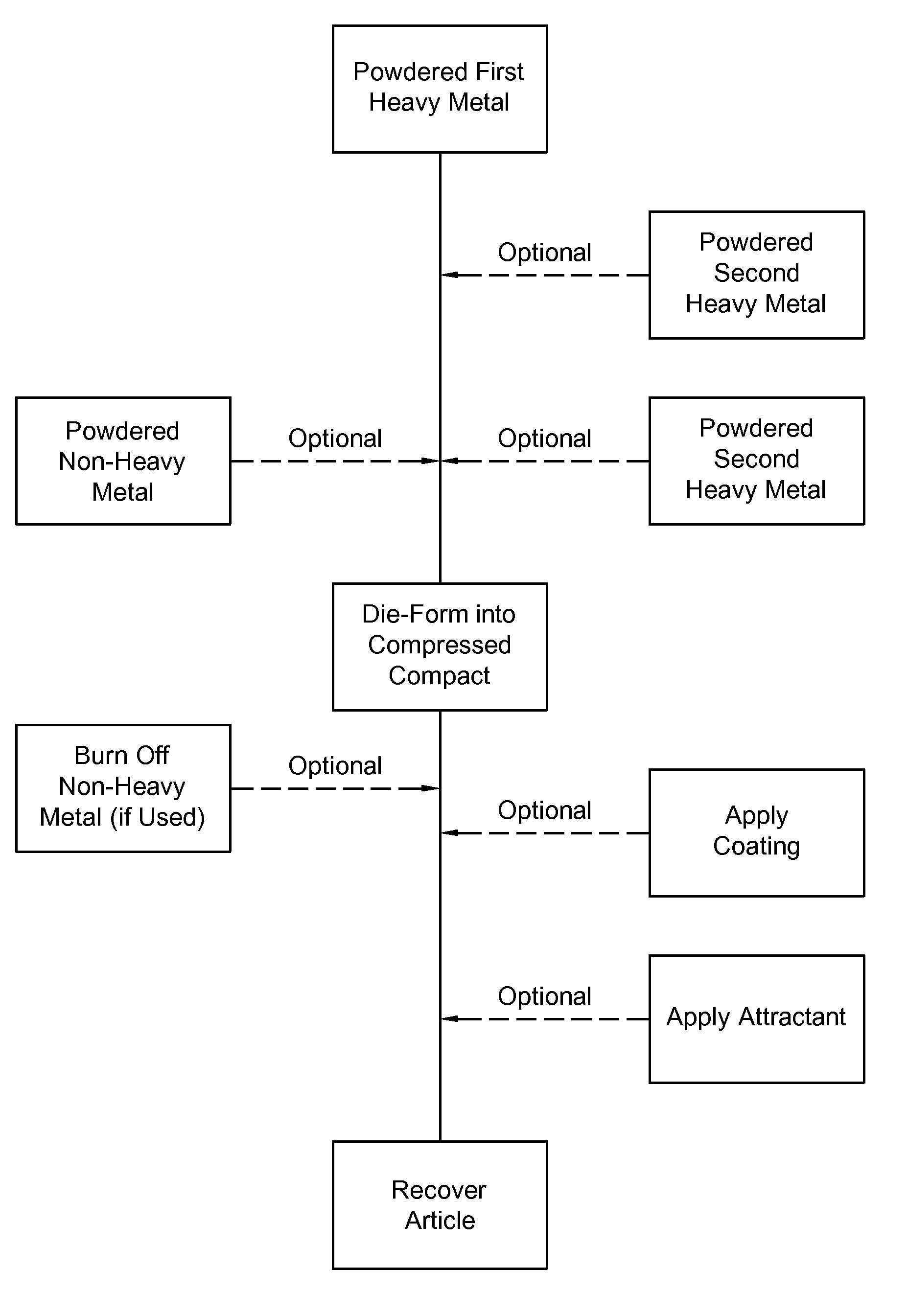

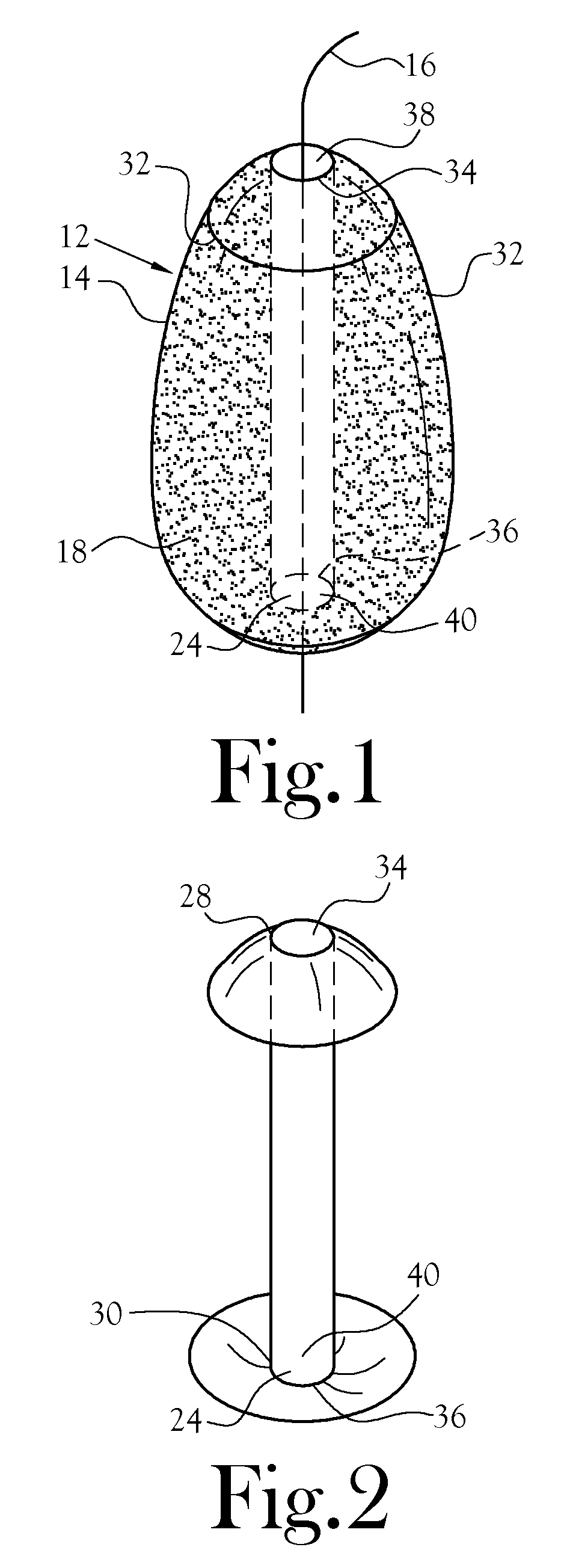

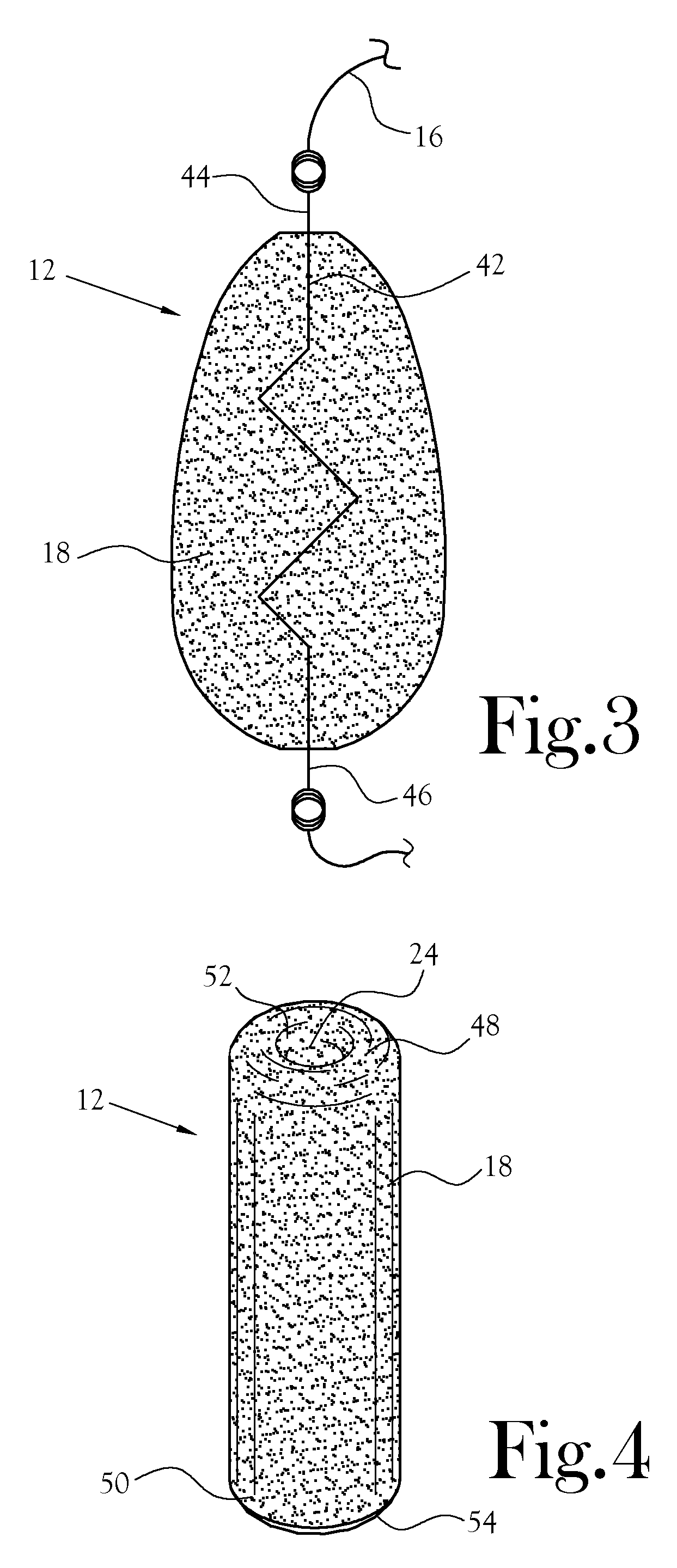

Article of Fishing Tackle and Method of Making Same

An article of fishing tackle which exhibits one or more of the physical properties of a heavy metal such as tungsten, tantalum, depleted uranium etc., their carbides, alloys thereof, and / or mixtures thereof. The article of the present invention comprises a quantity of a powdered heavy metal, either alone or in combination with a further powdered metal, of like or disparate physical properties, compressed, as by die forming, at room temperature and without sintering to produce a self-supporting compact. The article may comprise a sinker, a lure or combination thereof.

Owner:DORIS NEBEL BEAL INTER VIVOS PATENT TRUST PAWLEYS ISLAND

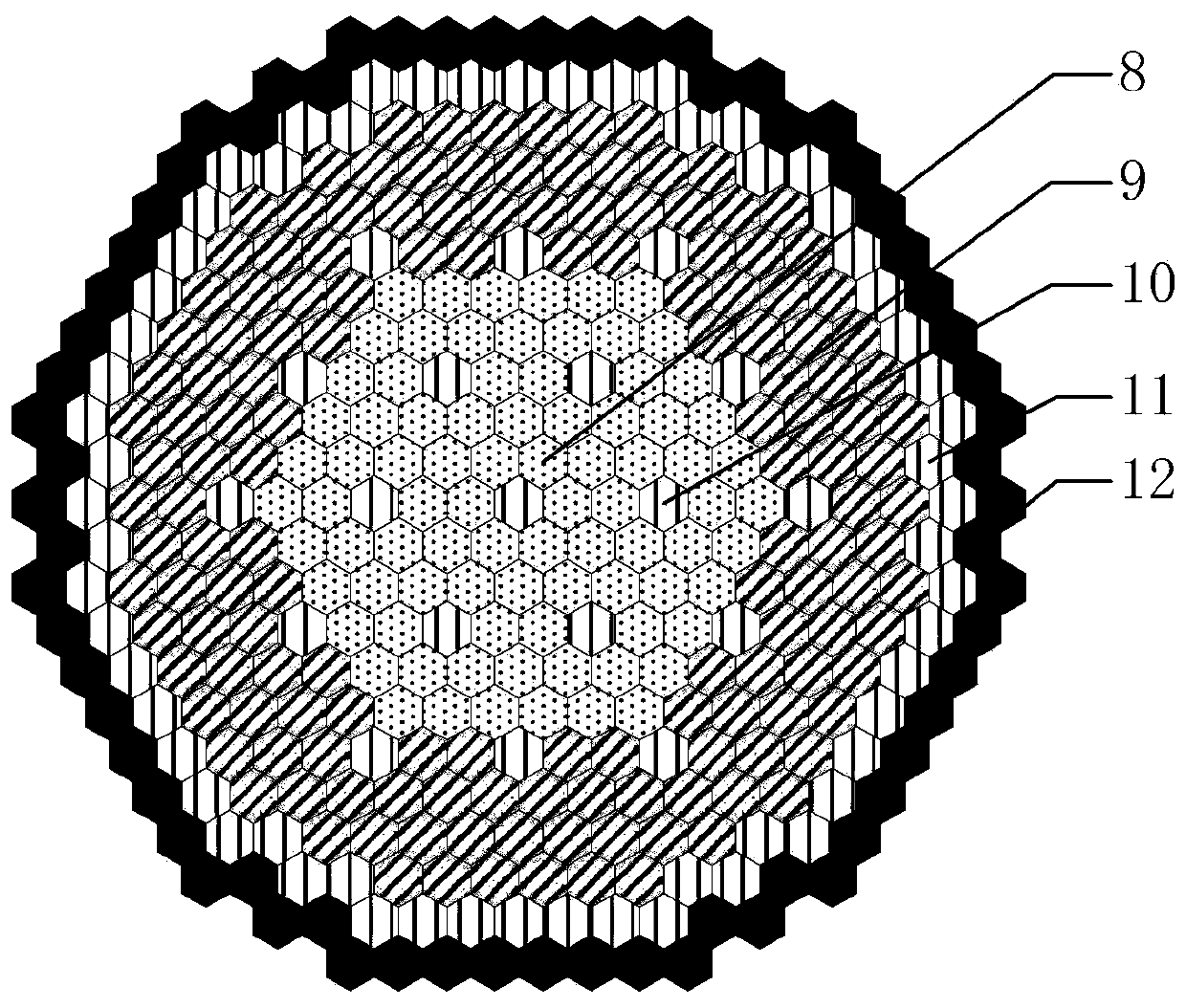

Fuel assembly structure and reactor core structure for enhancing temperature negative feedback of air-cooled fast reactor

InactiveCN110853777AEnhanced Doppler effectLower average neutron energyNuclear energy generationReactor fuel elementsNuclear engineeringCoolant flow

The invention relates to a fuel assembly structure and a reactor core structure for enhancing temperature negative feedback of an air-cooled fast reactor, wherein the fuel assembly is radially dividedinto three areas of an active area, a slowing-down area and an assembly box from inside to outside, the reactor core is radially arranged and divided into an inner fuel area and an outer fuel area according to different arrangement assemblies, coolant flow channels and special radial reflection layers are specifically arranged outside the fuel areas, the fuel area is axially provided with a lowerreflecting layer, a fuel layer, an air cavity and an upper reflecting layer from bottom to top, the fuel layer of the inner fuel area is axially subdivided into three layers, fuel is arranged at thetwo ends, a section of depleted uranium is arranged in the middle, coolant circulation uses double-flow-path design, and a coolant at an inlet inflows downwards from the fuel area and then outflows upwards from a specially-arranged out-of-reactor coolant flow channel. According to the invention, the structures can effectively enhance the temperature negative feedback of air-cooled fast reactors and improve the inherent safety of air-cooled reactors.

Owner:XI AN JIAOTONG UNIV

Smelting preparation method of high-Mo-content U base alloy

ActiveCN106636703AUniform preparationComposition segregation is lightIncreasing energy efficiencySelf consumptionChemical composition

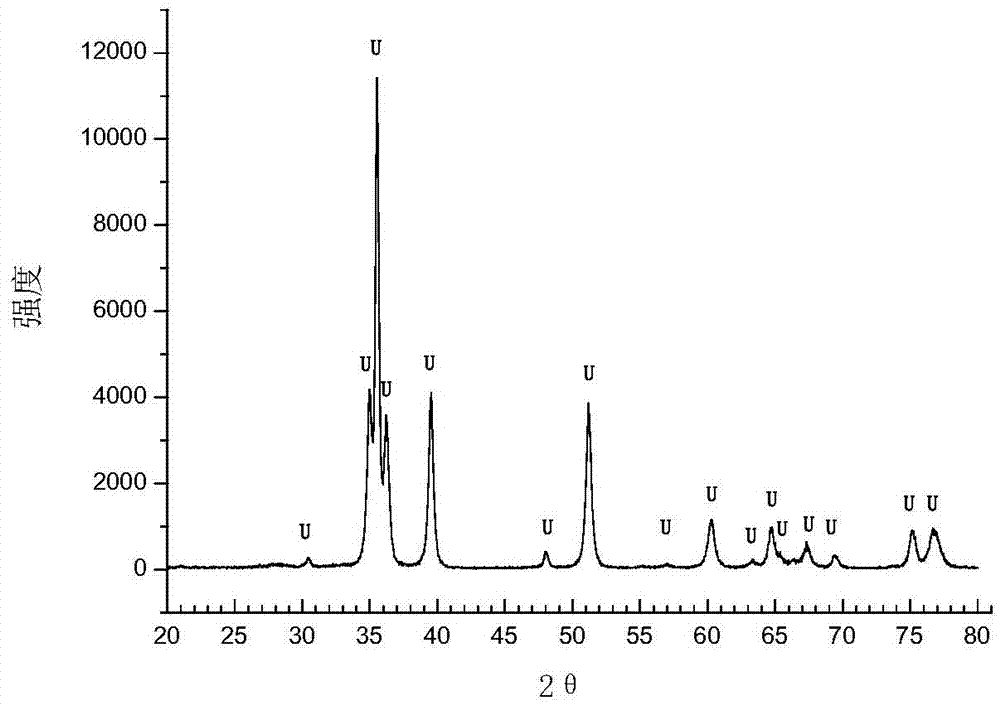

The invention provides a smelting preparation method of high-Mo-content U base alloy. The method firstly uses a non-self-consumption vacuum arc smelting furnace for preparing a U-Mo intermediate alloy, and then, smelts added U blocks in a vacuum induction furnace to dilute the U-Mo intermediate alloy to prepare a U-(16-20)wt% Mo alloy; the U-Mo intermediate alloy comprises the alloy components of: 40-60 wt% of U and 40-60 wt% of Mo; and the U-(16-20)wt% Mo alloy comprises the alloy components of: 80-84 wt% of U, and 16-20 wt% of Mo. The U-Mo intermediate alloy is designed through the components; and high-melting-point Mo is fully fused in depleted uranium base by using non-self-consumption vacuum smelting to obtain an alloy more-sufficient U-Mo intermediate alloy button-shaped sample. The U-Mo intermediate alloy prepared by the method is uniform in chemical components, and is lighter in component segregation phenomenon; and the XRD detects and analyzes the room temperature as stable gamma phase.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

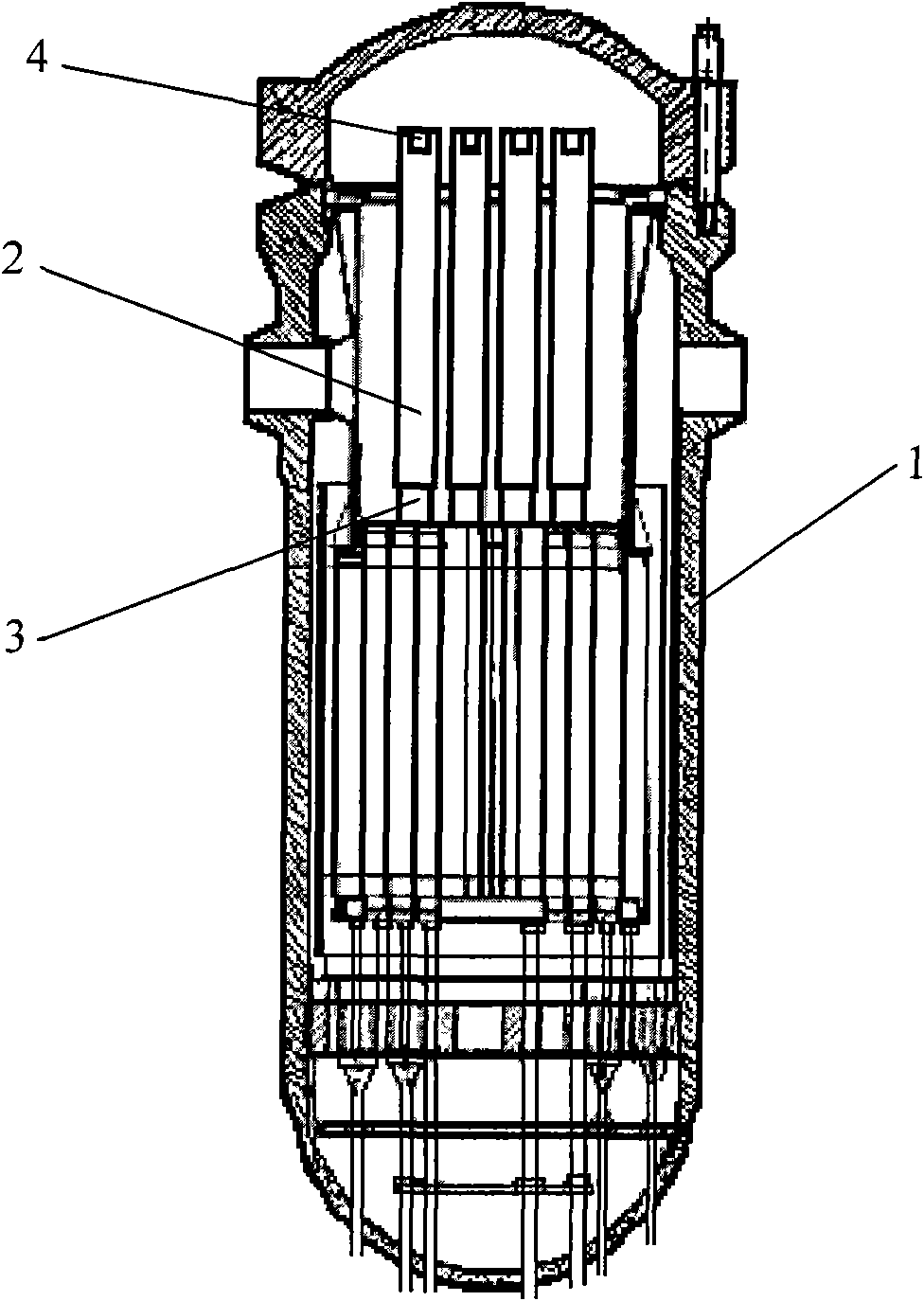

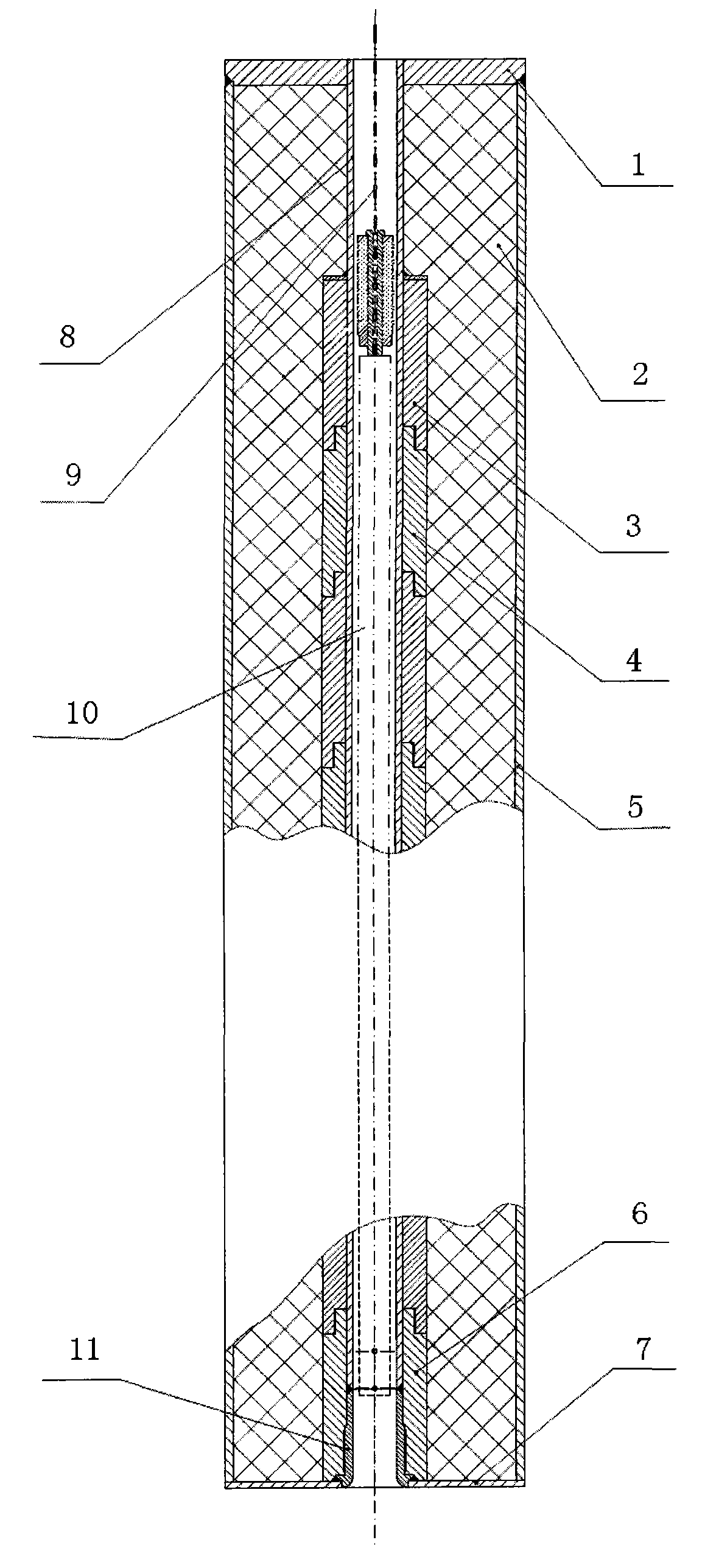

Follower component driven by driving mechanism in pressure shell and water reactor adopting same

InactiveCN101656112APrevent penetrationReduce cycle costsNuclear energy generationContainmentFuel reprocessingNatural uranium

The invention belongs to the field of nuclear reactor engineering, in particular to a follower component driven by a driving mechanism in a pressure shell and a water reactor adopting the same. The invention realizes the spectral shift control of a reactor and compansates the decrease of reactivity in a burn-up process by a depleted uranium (or thorium) compound follower, and adopts a dense weir and residential uranium compound fuel postprocessed by partially utilizing natural uranium and spent fuel, thereby greatly saving nuclear fuel and decreasing fuel cycle cost. A driving mechanisms driving a great amount of follower components are arranged in the pressure shell, so as to prevent the joint sections of the driving mechanism from penetrating through the upper sealing head of the pressure shell, carry out the spectral shift control under the condition without influencing the reliability of the pressure shell, lower the boron concentration of the water reactor in water in an operation process, avoid the occurrence of the problem of serious corrosion of the joint sections and the upper sealing head of the driving mechanism due to the penetration of boric acid through the upper sealing head of the pressure shell, reduce the possibility of elastic rod accidents and improve the safety.

Owner:张育曼 +2

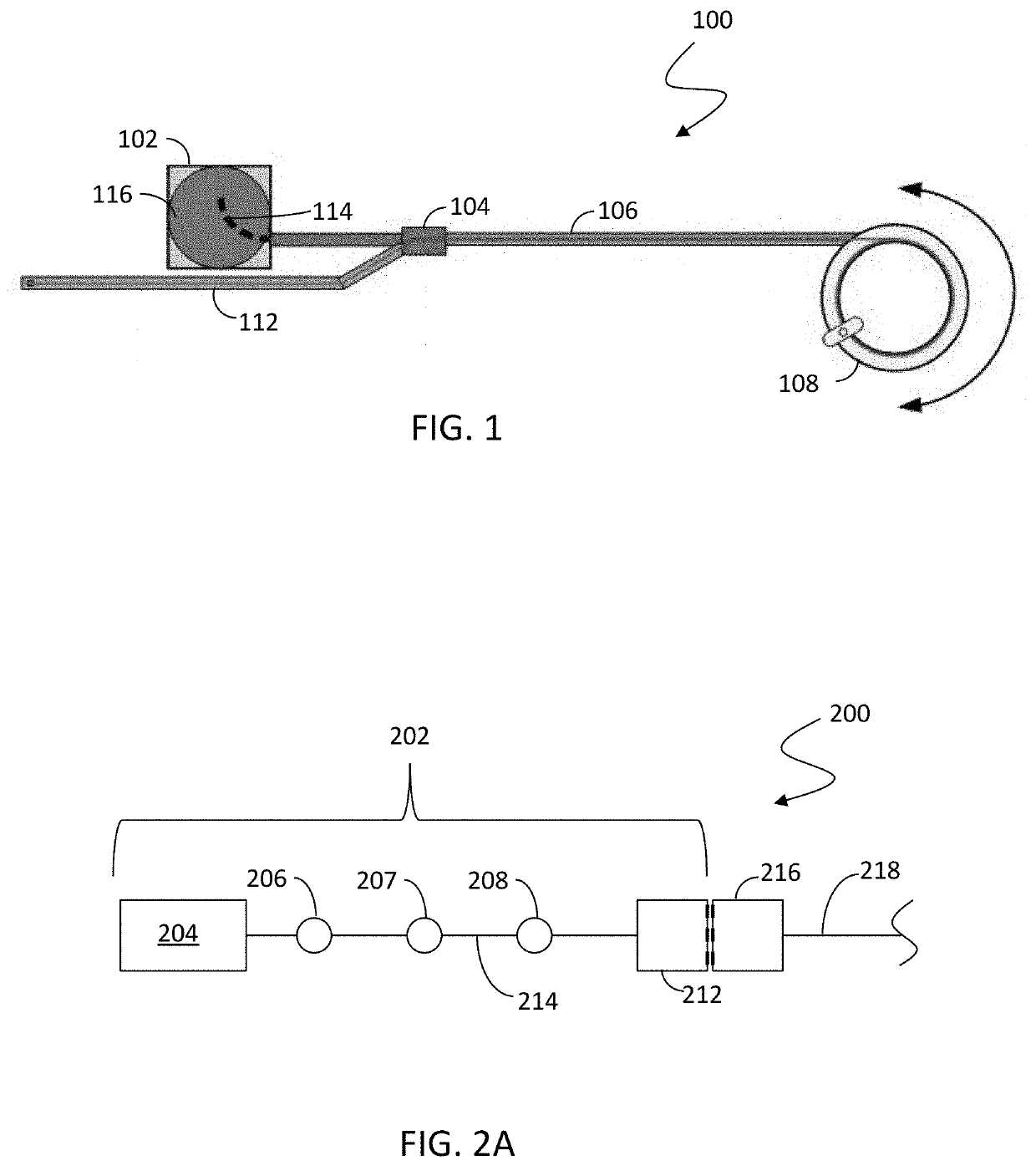

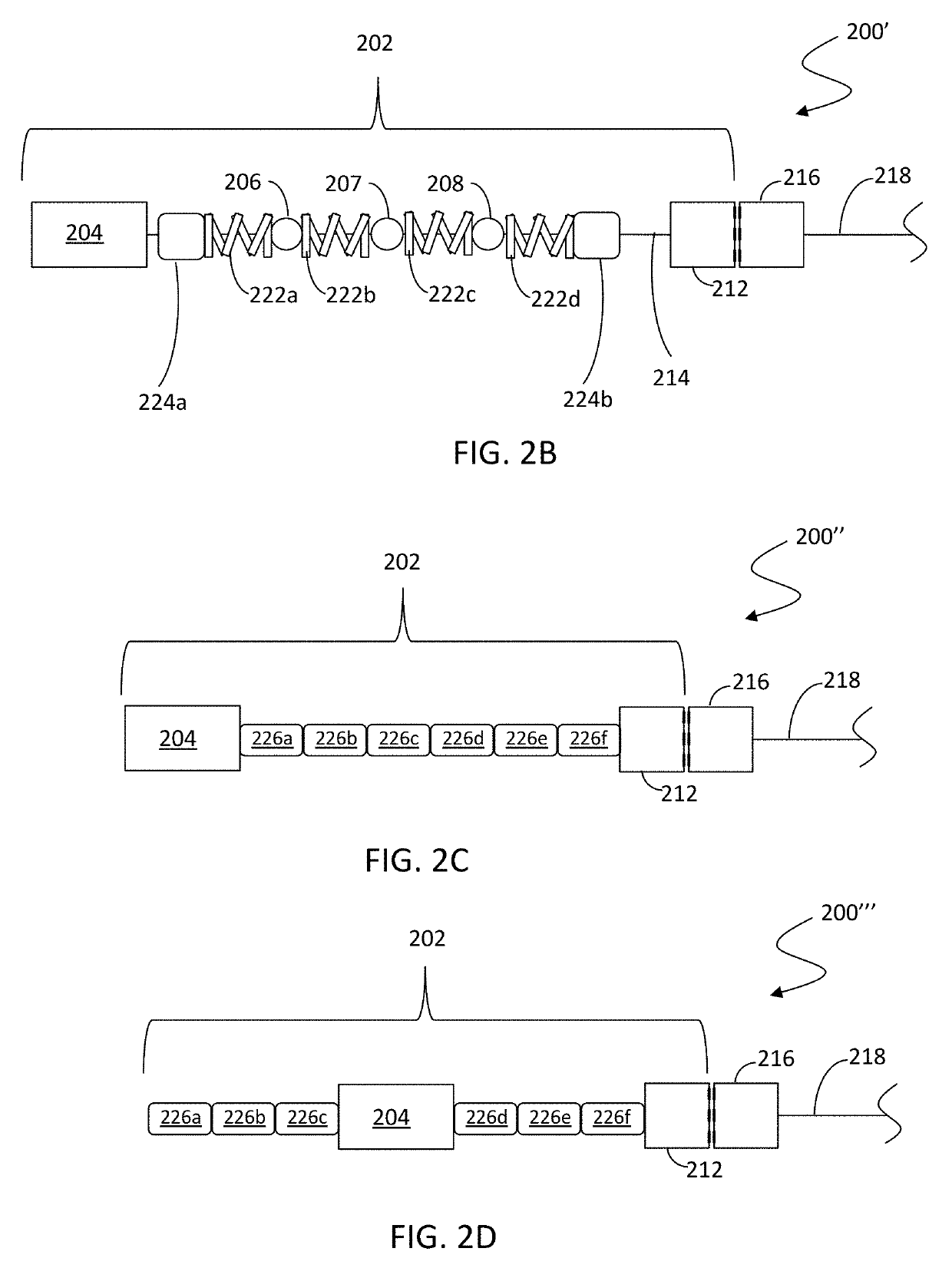

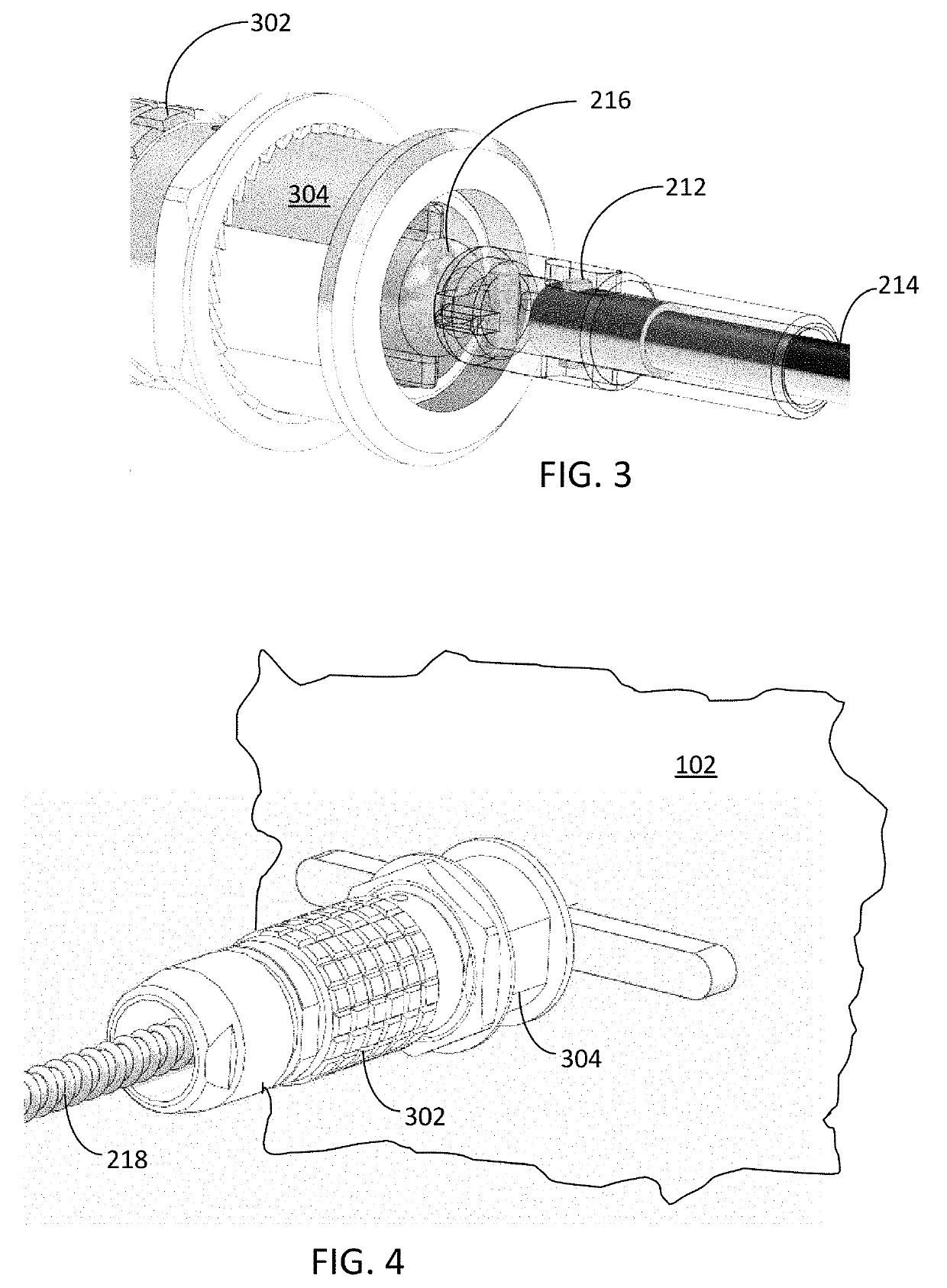

Delivering radiation

A radiography camera system includes an exposure container made from radiation shielding material and having a curved channel therein that terminates inside the exposure container, a first conduit portion having a first end coupled to the exposure container, a switch coupled to a second end the first conduit portion, a second conduit portion having a first end coupled to the switch, a guide tube coupled to the switch, a crank coupled to a second end of the second conduit portion, and a cable disposed in the crank and having a connector for a source assembly on an end thereof, the cable actuating the switch to cause the cable to feed through one of: the first conduit portion or the guide tube when the crank unwinds the cable. The exposure container may be made from depleted uranium, tungsten, and / or lead. The curved channel may be J-shaped.

Owner:SOURCE PRODN & EQUIP

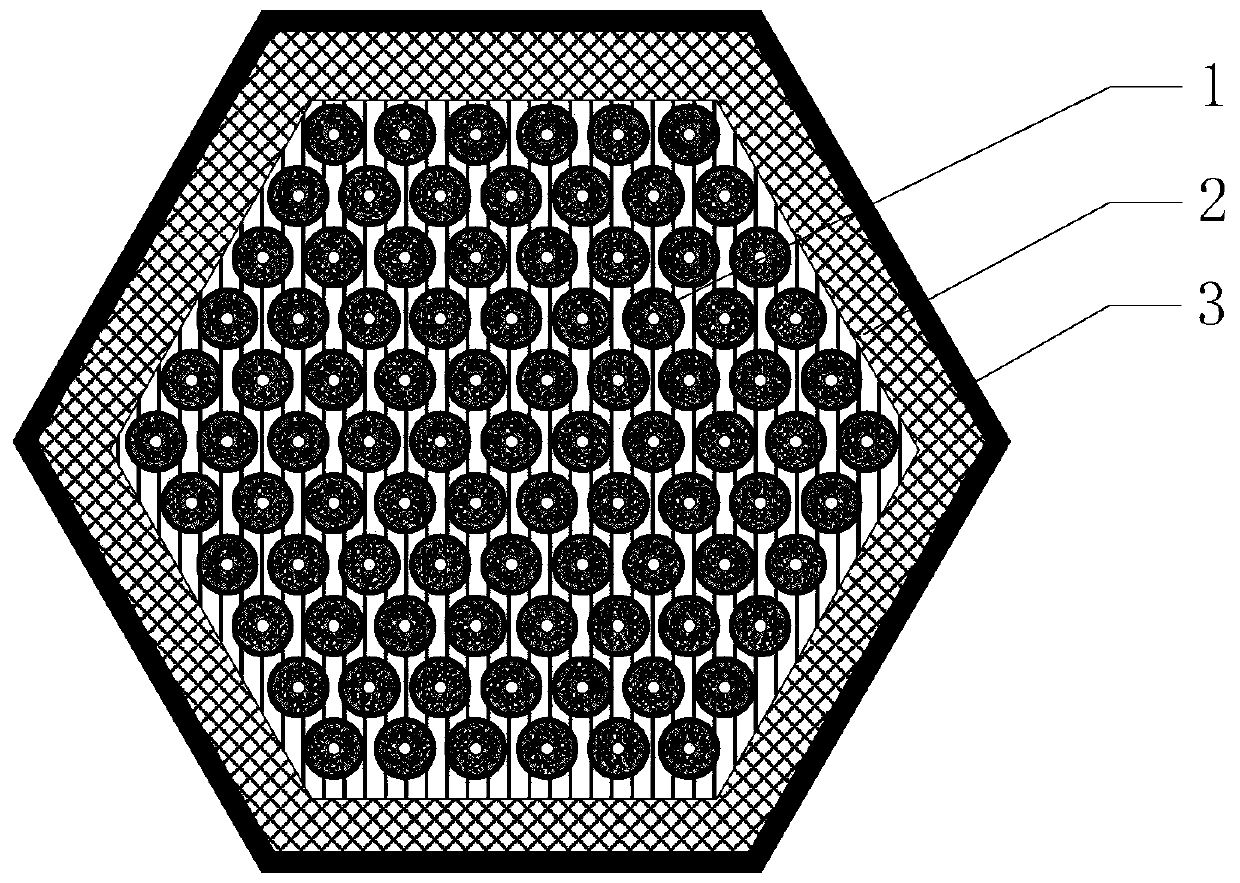

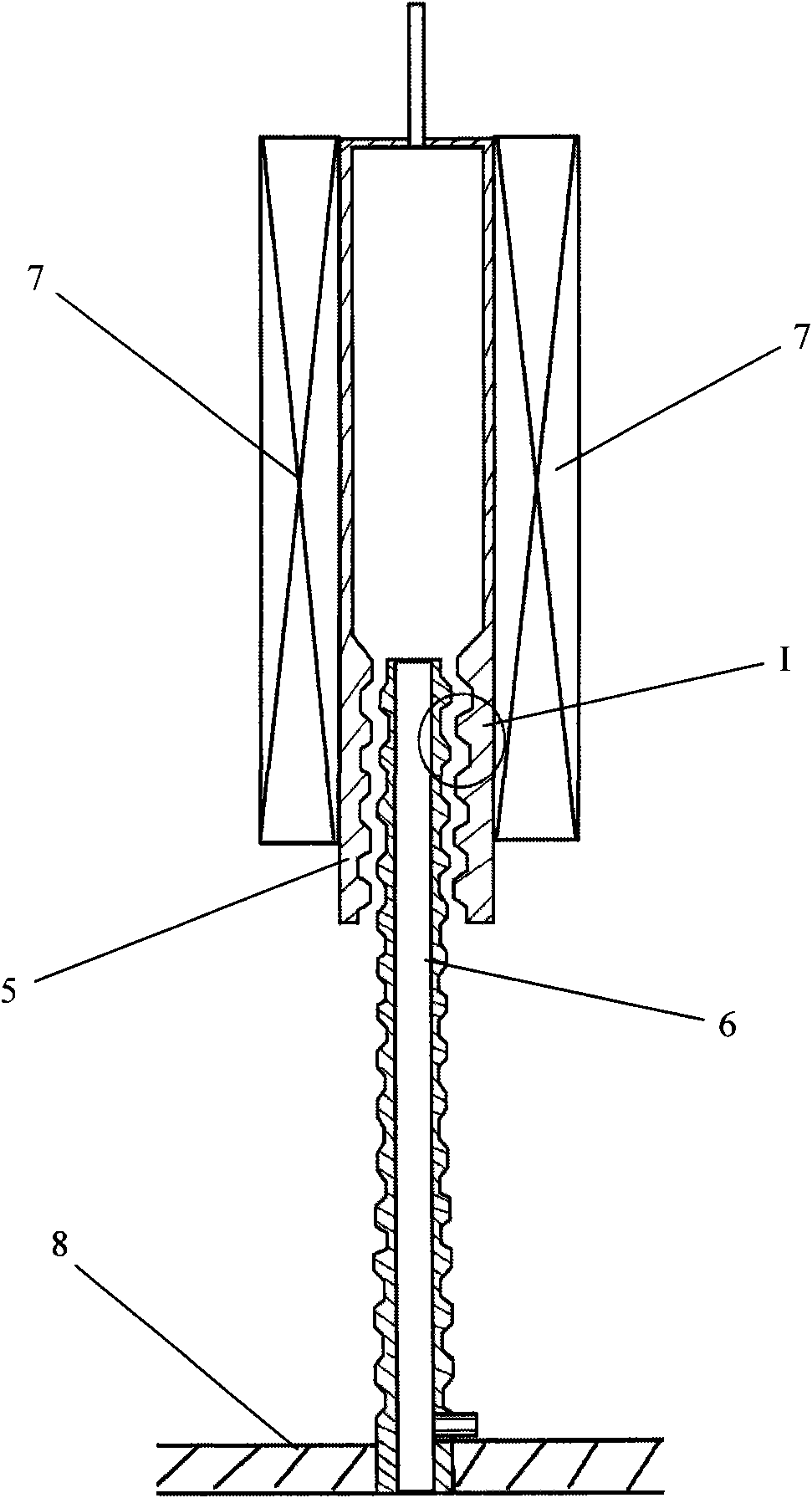

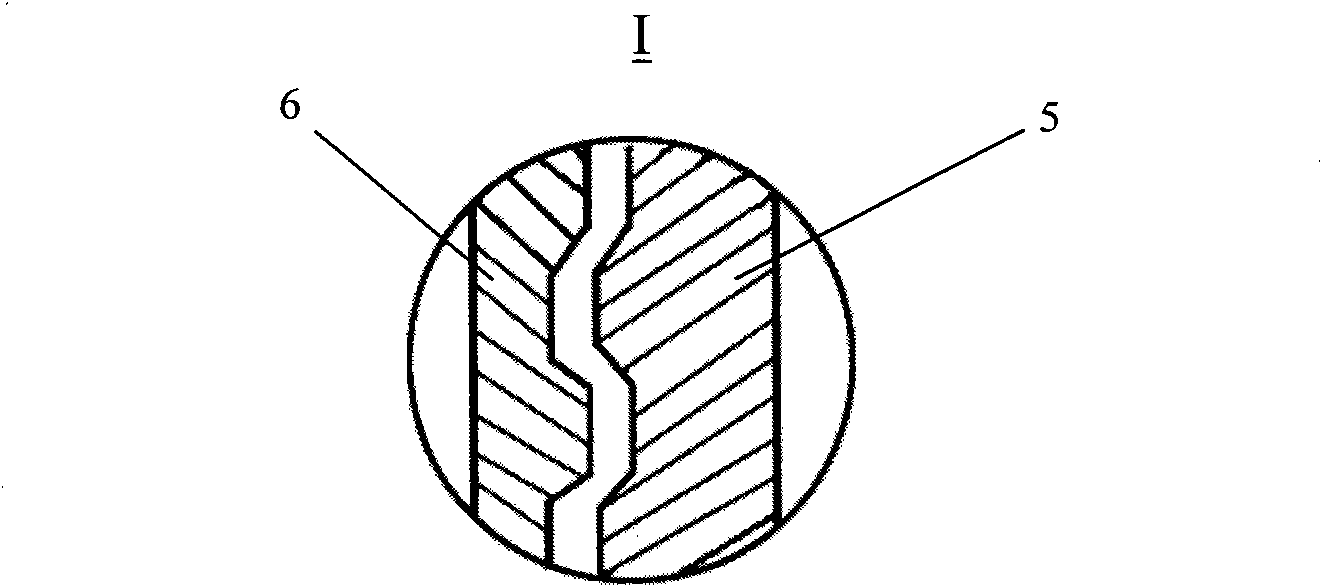

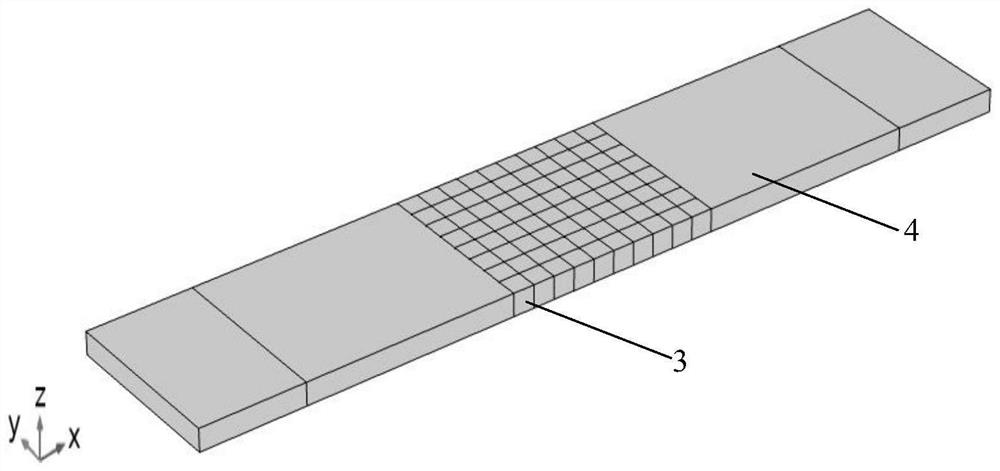

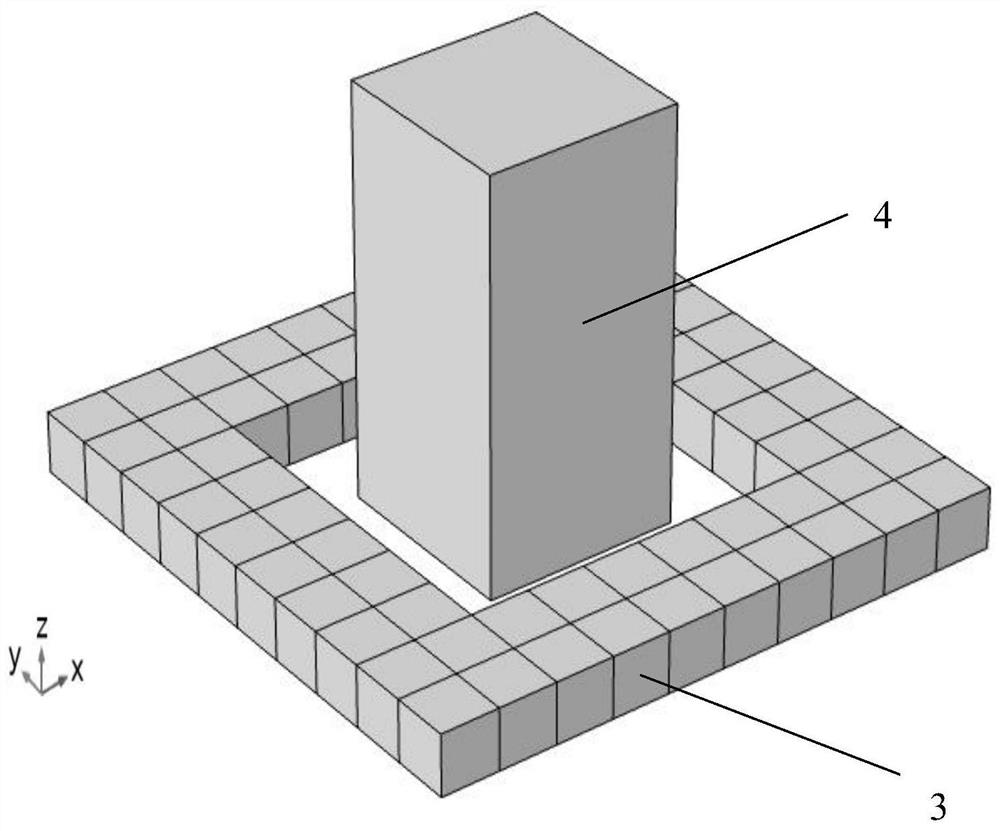

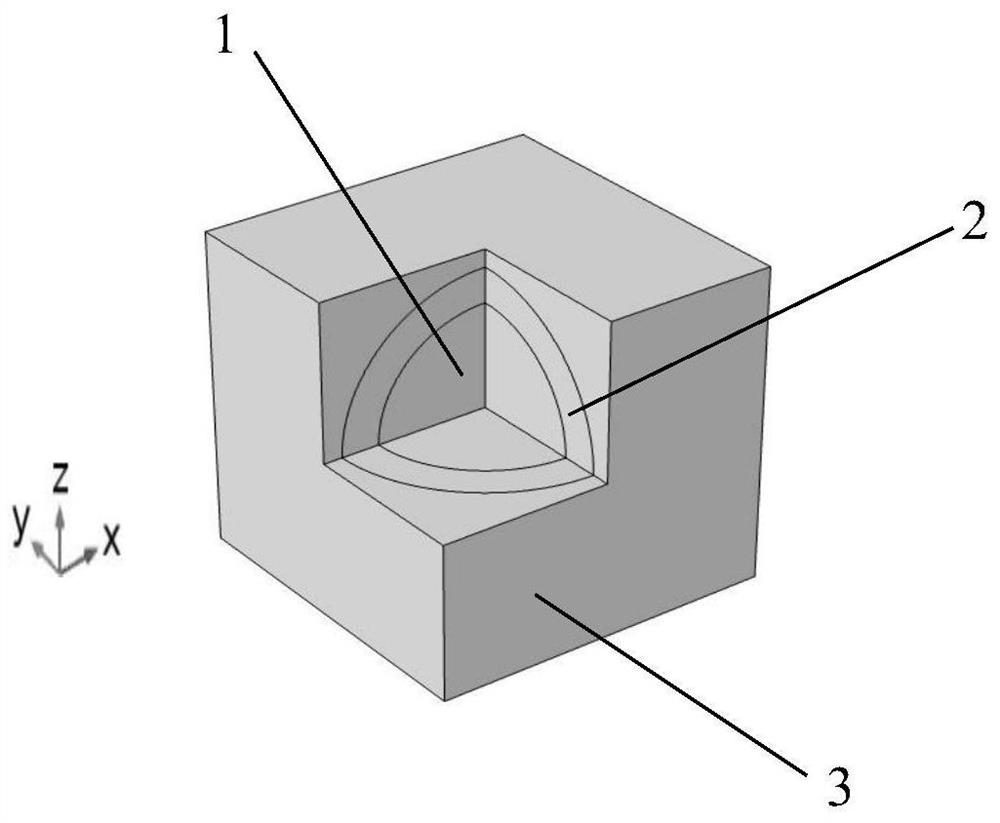

Wave barrier structure with low-frequency ultra-wide attenuation domain and manufacturing method

InactiveCN113389292ASmall sizeEasy to implementArtificial islandsProtective foundationClassical mechanicsYoung's modulus

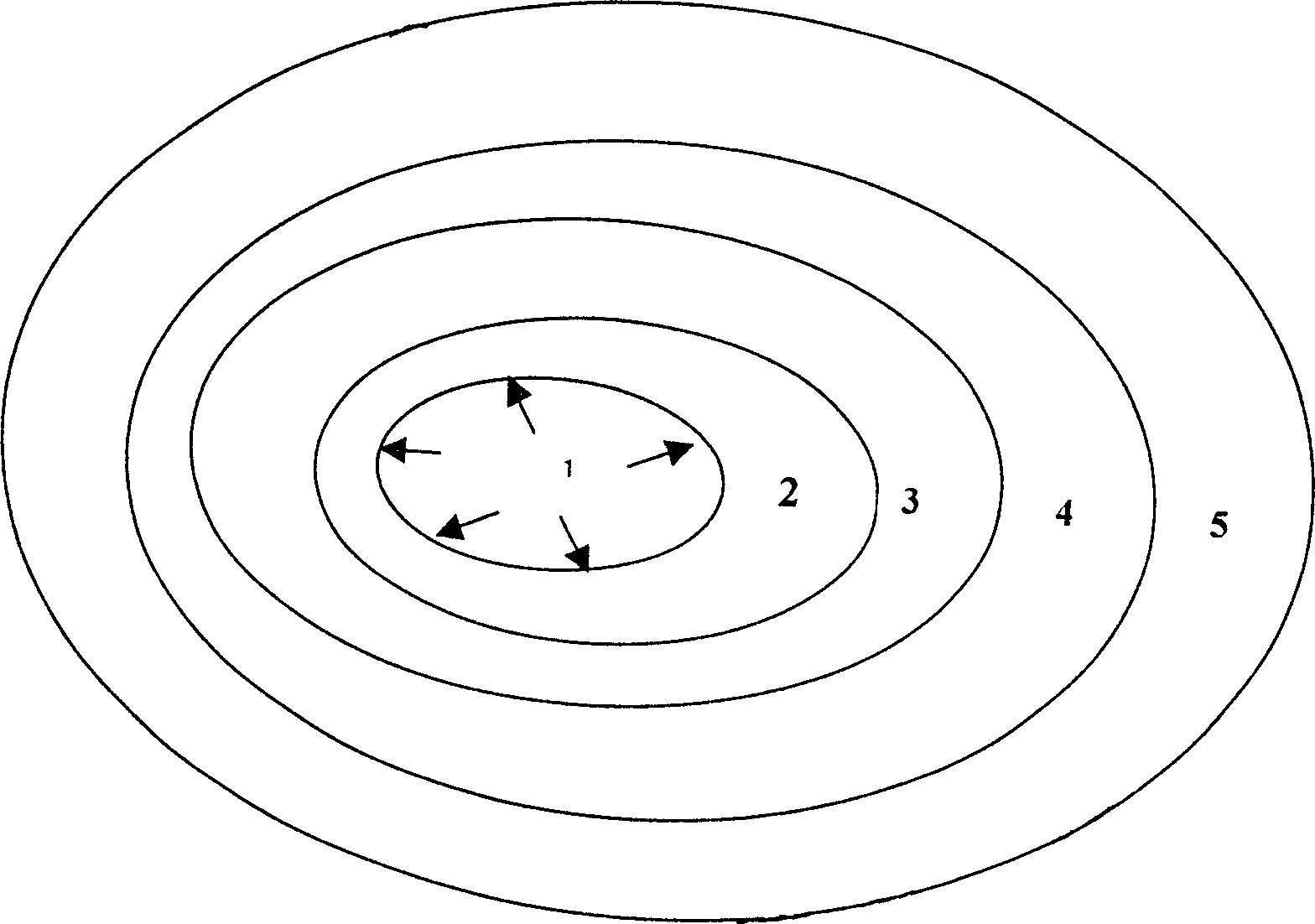

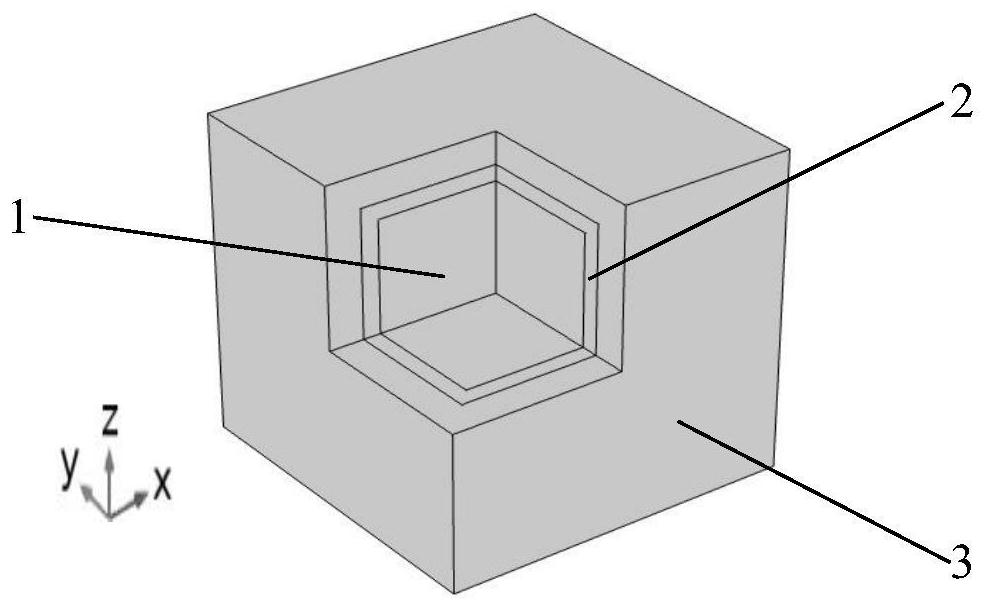

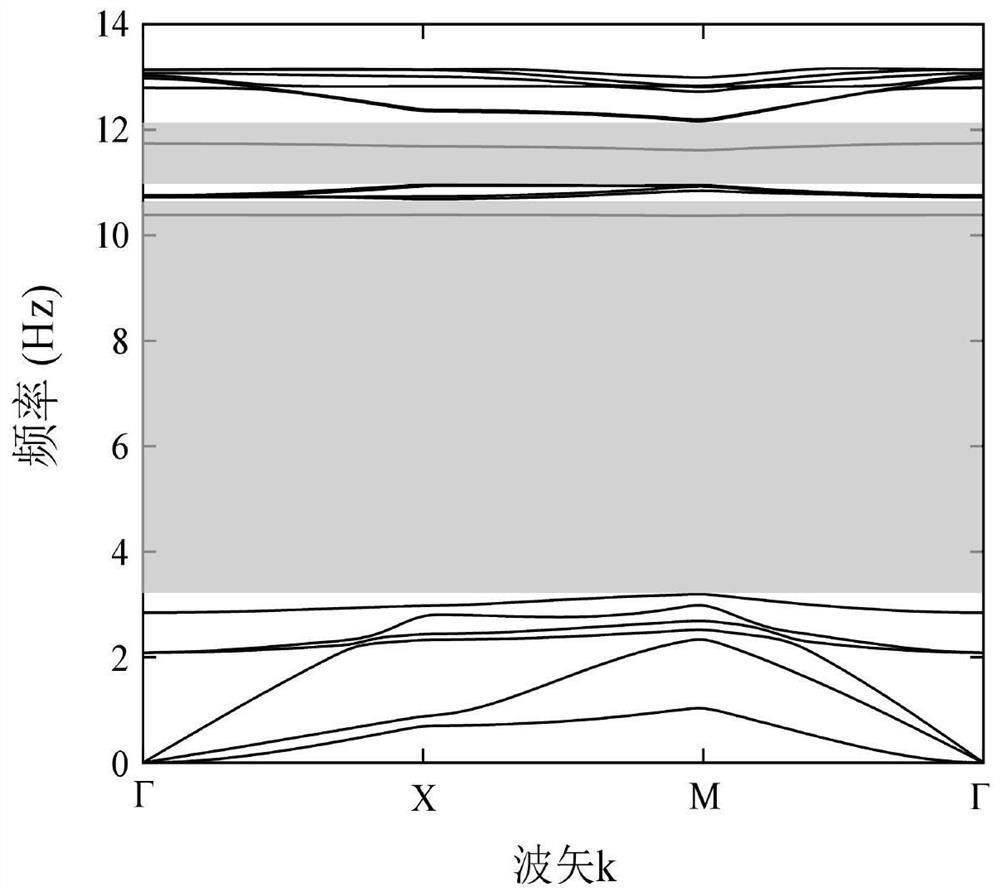

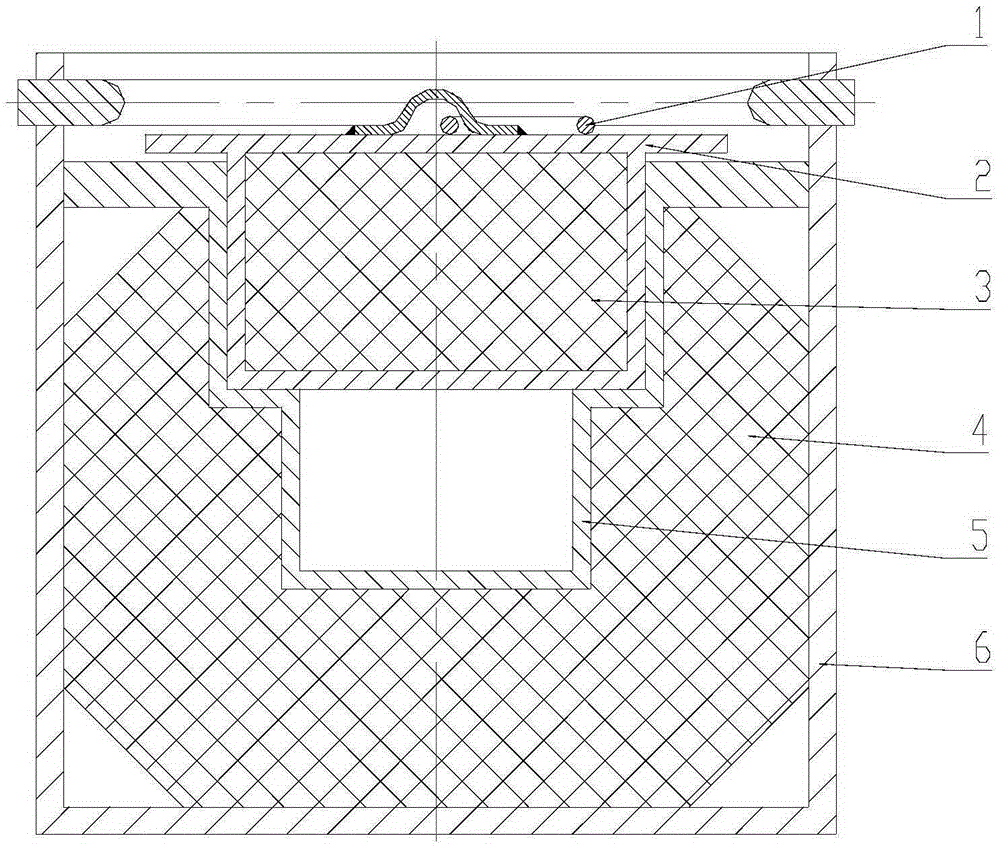

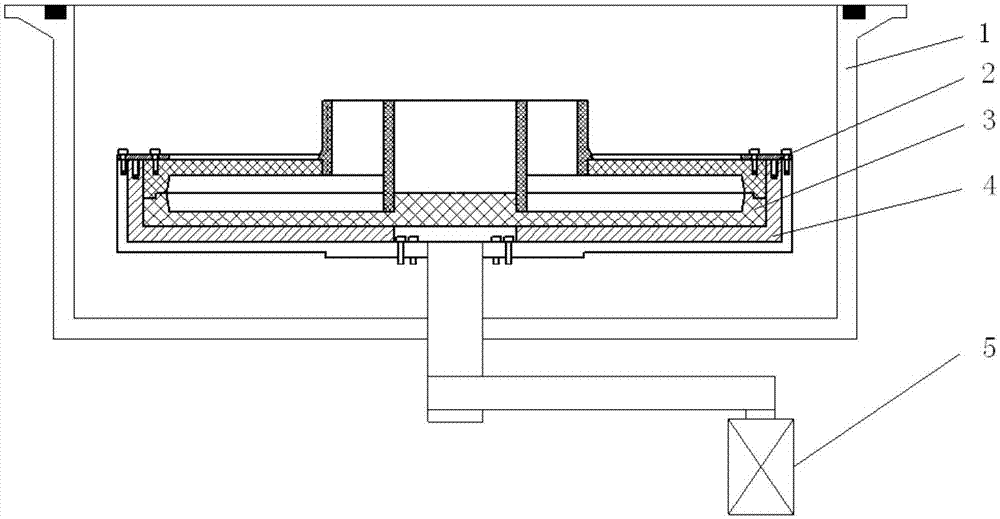

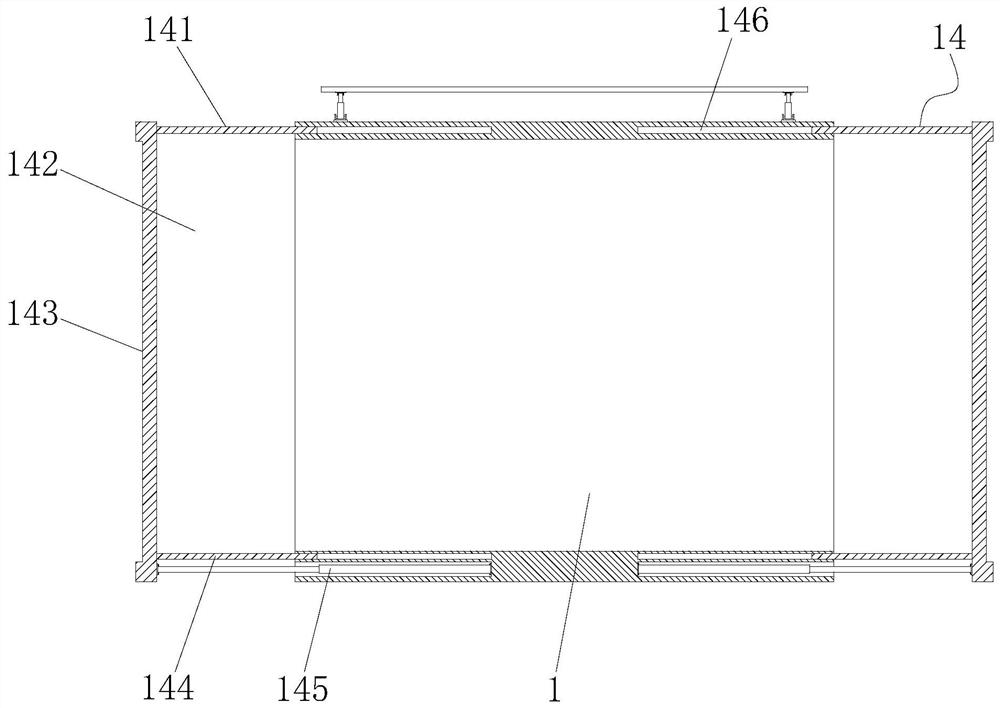

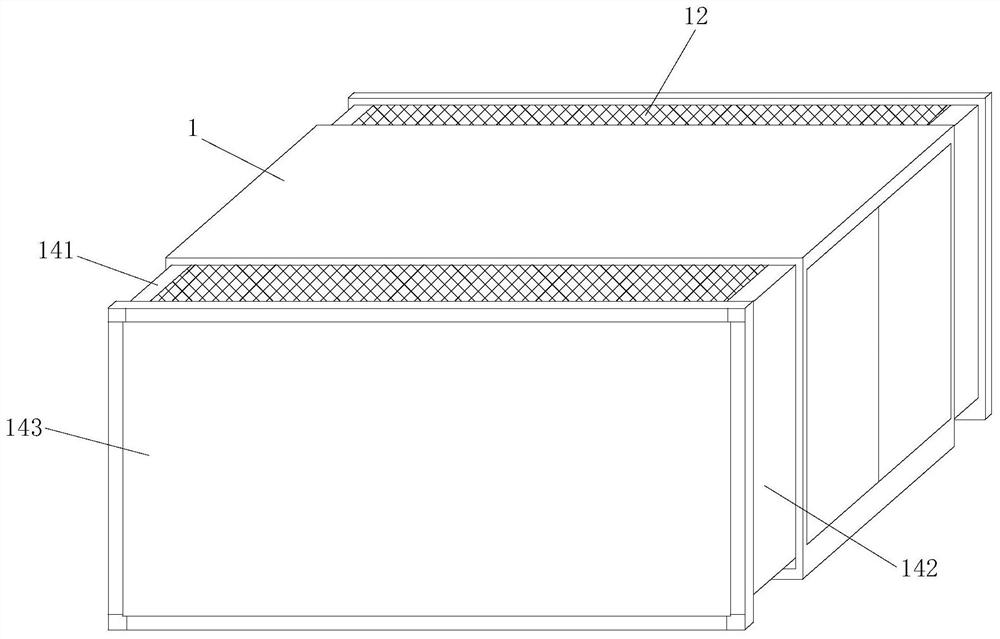

The invention discloses a wave barrier structure with a low-frequency ultra-wide attenuation domain and a manufacturing method. The wave barrier structure is formed by extending structural unit cells in the same horizontal plane in two mutually perpendicular directions and is designed below the ground surface around a building. Each structural unit cell comprises a depleted uranium block (1), a steel pipe layer (2) and a rubber layer (3), wherein the depleted uranium block (1) is a cube, the steel pipe layer (2) wraps the depleted uranium block (1), and the rubber layer (3) wraps the steel pipe layer (2). The seismic ultra-clever plate structure is not only suitable for a certain type of buildings in a certain area, but also can change the side length, thickness and other geometric parameters and density, Young modulus and other material parameters of all components and adjust the band gap width and position according to the site conditions, building environments, occupied area sizes, heights and other factors of different areas through comprehensive consideration, thereby protecting one or more buildings in different areas and at different heights.

Owner:BEIJING UNIV OF TECH

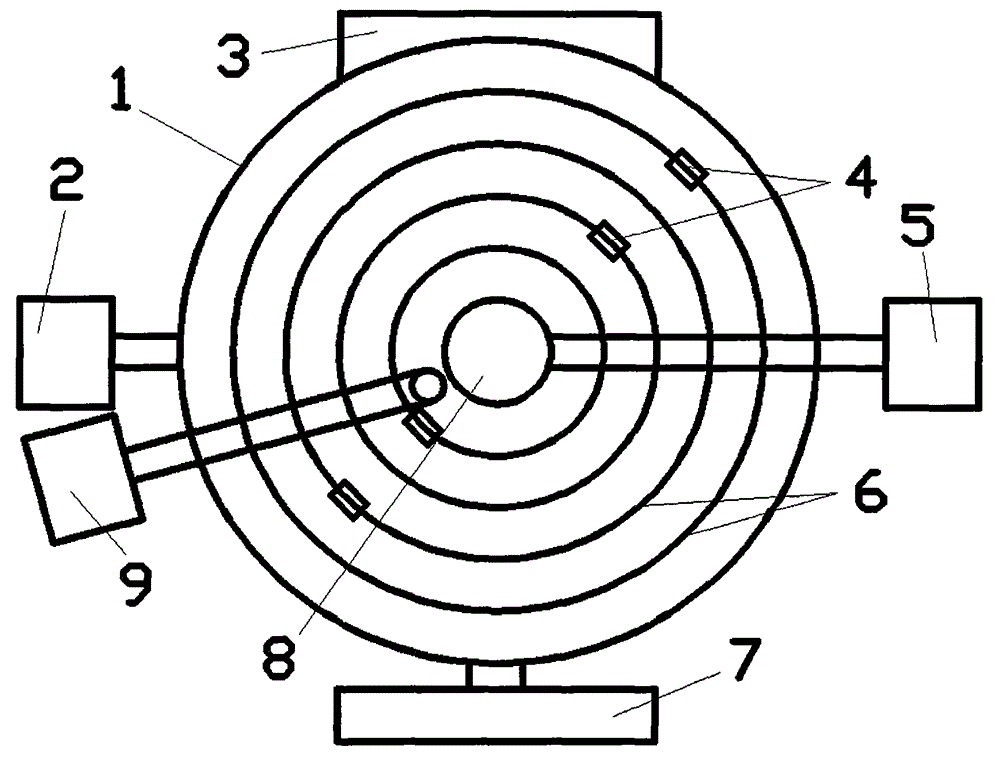

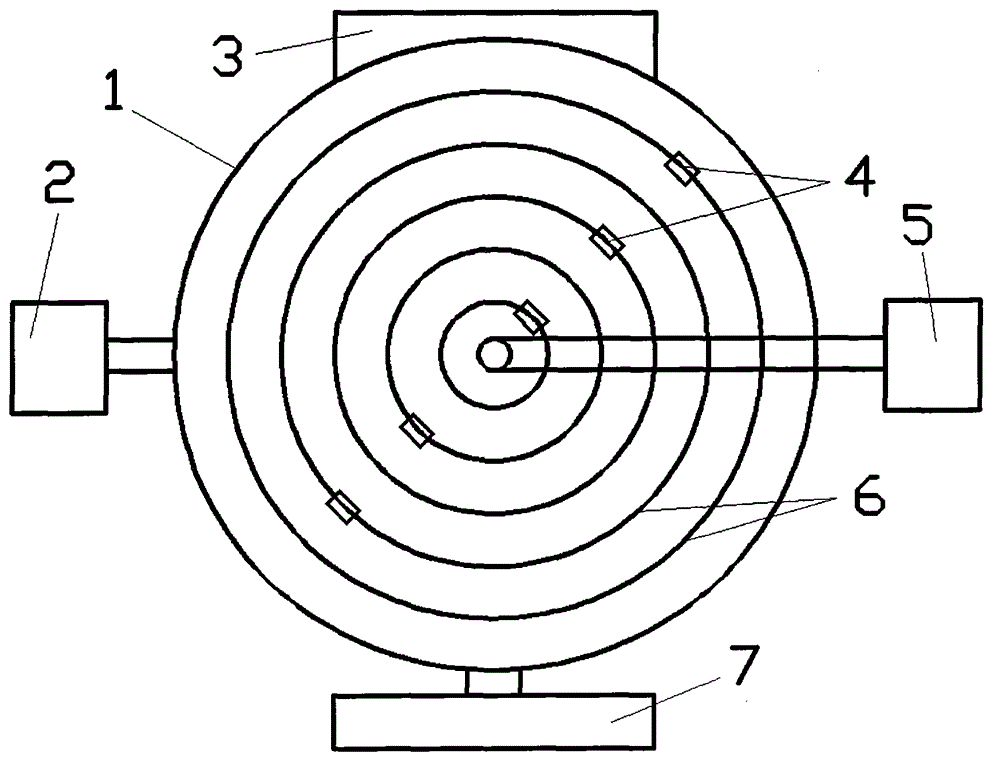

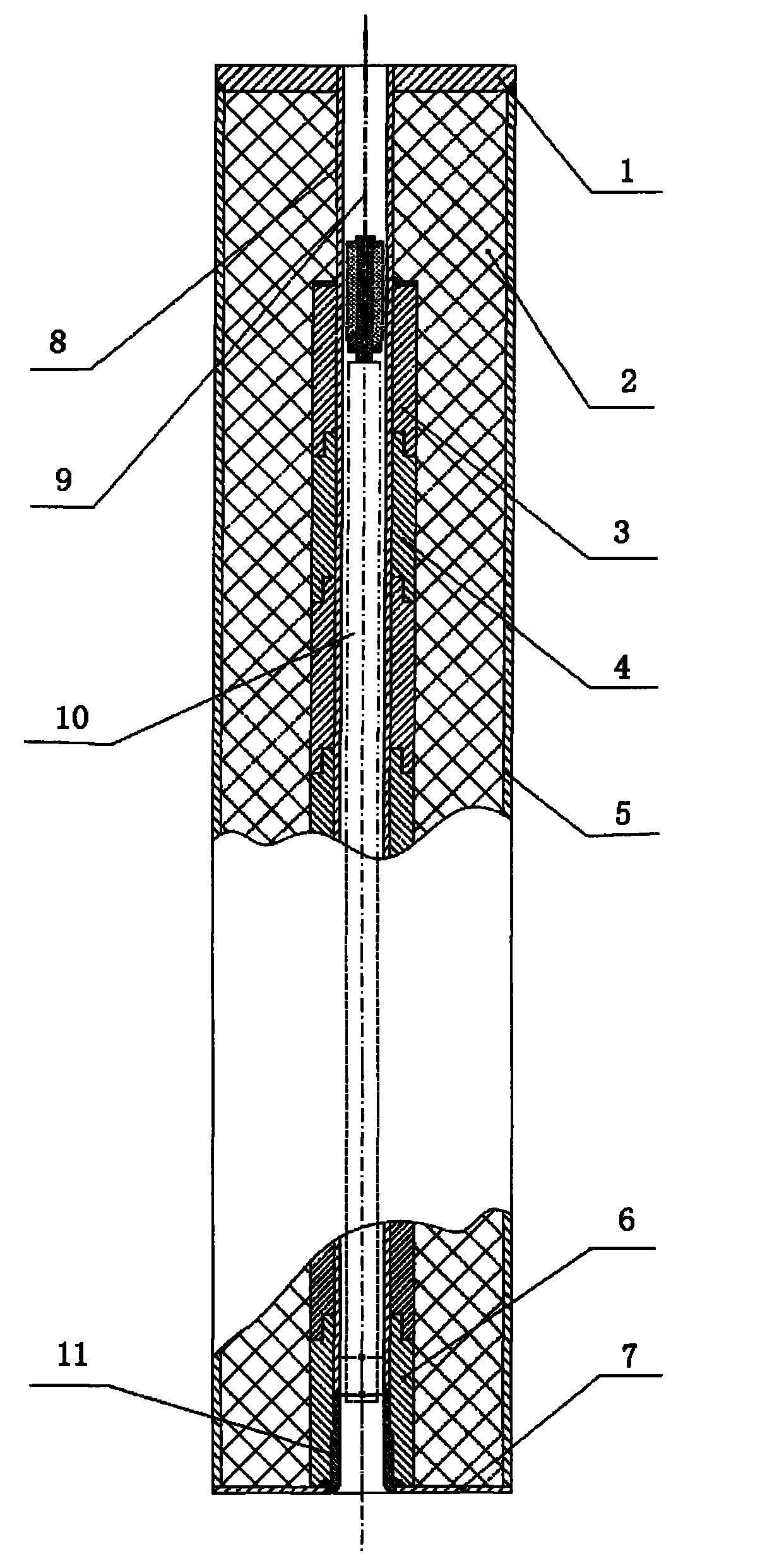

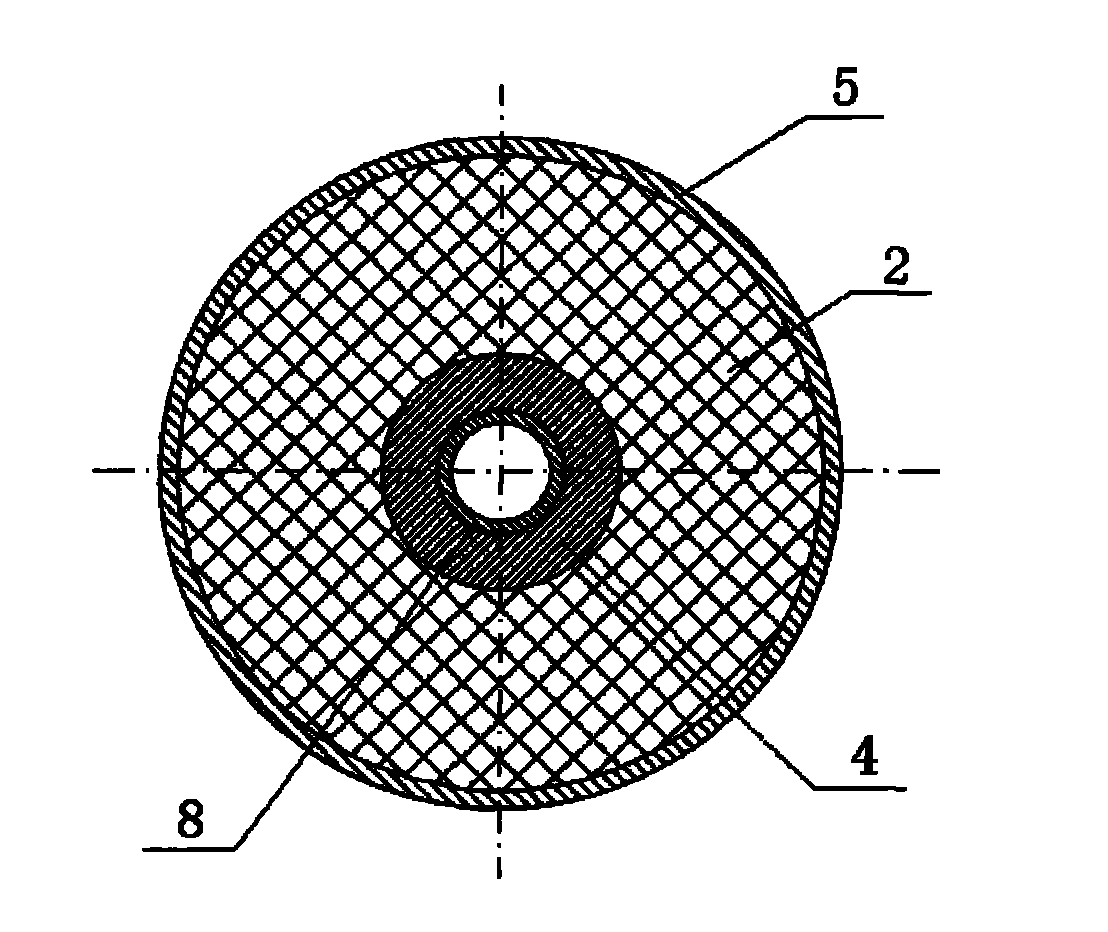

Shielding device for high-reflective material and application of device

ActiveCN108182982AReduce radiation doseReduce penetrationShieldingPortable shielded containersNuclear reactorReflective layer

The invention discloses a shielding device for a high-reflective material and application of the device. The problem that an RPV steel sample obtained after being irradiated with a nuclear reactor hasextremely high harm, and no perfect shielding method or device exists is solved. The high-reflective material is an RPV steel experimental sample obtained after being treated and irradiated with thenuclear reactor for a long time, in other words, the invention provides the shielding device aiming at RPV steel obtained after being irradiated with the nuclear reactor and a processing method and application of the device, and relates to a ray shielding technology and method for the high-reflective material in the long process transportation and processing processes. Accordingly, on the basis ofthe ray shielding theory and the material characteristics of depleted uranium, a novel portable shielding container is designed and made, harmful ray release of the PRV steel in the processes such aslong process turnover and machining can be effectively lowered, the safety in the transportation and machining processes is guaranteed, and the influence of the high-reflective material on the environment is lowered to the maximum extent.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Concentric spherical surface separation plate type spherical main container

ActiveCN106158052ASolve the purification problemSafe and stable operationNuclear energy generationSubcritical reactorsInter layerNuclear engineering

The invention relates to a concentric spherical surface separation plate type spherical main container, and belongs to the technical field of molten salt reactors. With the molten salt depleted uranium reactor formed from the concentric spherical surface separation plate type spherical main container, the difficult problem of the purification of the fission product inside the spherical main container can be solved, the fission product purification system is not required, the burning mode that the direct input of the depleted uranium and the direct output of the spent fuel are performed on the reactor is achieved, the low-cost long-term safe and stable operating is achieved, and all the excellent performances of the molten salt depleted uranium reactor can be maintained. According to the present invention, the space is divided into the thin sheet by using the multi-layer concentric spherical surface thin separation plate having the material inlet and the material outlet, or the space is divided into the tubular channels by additionally using the radial thin separation plate, valves and the like are arranged on the material inlet, the material outlet and the channel to control the molten salt flowing mode, the internal separation plate uses the modes such as module design, non-welded stacking installation of various modules, and whole replacement of the module, the top portion is provided with the openable cover plate system, and the innermost layer, the outermost layer and the required middle layer are provided with the corresponding channels connected to the corresponding control device and other devices outside the reactor core; and the concentric spherical surface separation plate type spherical main container is mainly used as the neutron source and the small energy source.

Owner:董沛 +2

U-10Zr alloy smelting technology

The invention belongs to the technical field of metal mold alloy smelting and forming technologies, and particularly relates to a U-10Zr alloy smelting technology. The U-10Zr alloy smelting technology comprises the following steps: (1) a U-Zr intermediate alloy with the Zr content being 50wt.% is prepared; (2) a U-Zr intermediate alloy with the Zr content being 10wt.% is prepared since by employing a medium-frequency induction furnace, the U-Zr intermediate alloy with the Zr content being 50wt.% and depleted uranium are subjected to induction melting in a CaO ceramic crucible, the vacuum degree of the medium-frequency induction furnace is controlled to be less than 10<-1>Pa, and the smelting temperature is controlled at 1500-1600 DEG C; and (3) the U-Zr intermediate alloy with the Zr content being 10wt.% is cast since the U-Zr alloy obtained in the step (2) is put in the medium-frequency induction furnace and is cast in a graphite crucible uphill casting manner, a casting cup is arranged at the bottom of the graphite crucible, a ceramic foam filter is arranged between the casting cup and a mould, and the U-Zr intermediate alloy with the Zr content being 10wt.% and impurities being removed is obtained through the casting in this step. Through the technical scheme, the preparation quality of the U-Zr intermediate alloy with the Zr content being 10wt.% for a metal mold combustible metal core blank can be ensured, and favorable technology and equipment supports are provided for batch production of metal fuel elements.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Barrel for radioactive substance container

The invention relates to a barrel for a radioactive substance container. The barrel consists of an inner barrel and an outer barrel fixedly connected together, wherein two shielding layers, namely a depleted uranium layer and a lead shielding layer, are respectively arranged between the inner barrel and the outer barrel from the interior to the exterior. The barrel is simple in structure, convenient to machine, good in shielding effect, small in volume, convenient to operate, high in social and economic values and suitable for popularization and application, and can effectively shield rays.

Owner:CHINA NUCLEAR POWER ENG CO LTD +2

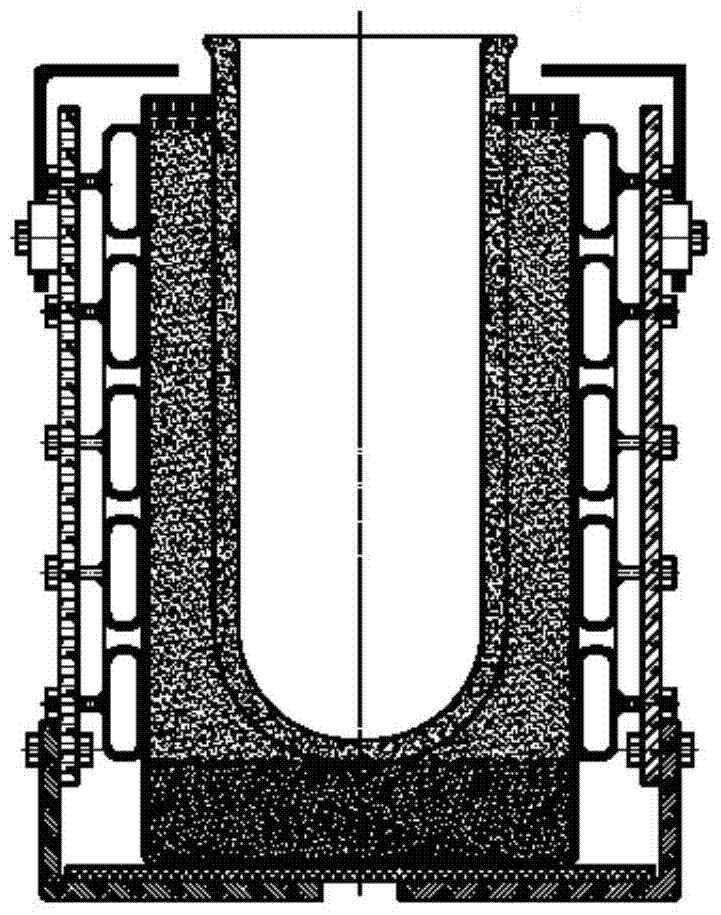

Isotope packaging container

InactiveCN105366223AEffective weak radioactivityEnsure safetyBottlesPackaging poisonsEngineeringGamma ray

The invention belongs to the technical field of isotope transporting and storing and particularly relates to an isotope packaging container. According to the technical scheme, the isotope packaging container is provided with an inner barrel and an outer barrel, the outer barrel is made of a stainless steel material, and the inner barrel is made of a depleted uranium material. A two-stage step-shaped inner cavity is formed in the inner barrel. An upper inner cavity body is used for storing a barrel cover, and a lower inner cavity body is used for containing isotope to be transported and stored. A stainless steel barrel lining is installed on the inner wall of the inner barrel. The shape and the size of the barrel lining are matched with the shape and the size of the inner cavity of the inner barrel, and an edge is arranged at the upper end and fixedly connected with the inner wall of the outer barrel. The barrel cover is made of a depleted uranium material and wrapped with a stainless steel cover lining, and boundary dimension of the barrel cover is matched with that of the upper cavity body of the barrel lining. The isotope packaging container has the advantages that after the barrel cover is covered, the shielding layer thicknesses of the periphery of the lower inner cavity body of the inner barrel are equal, while gamma rays are effectively shielded, the weight can be reduced, materials are saved, and transporting is convenient; the stainless steel barrel lining can effectively isolate the isotope and depleted uranium, and cross contamination is avoided; the stainless steel outer barrel and the barrel cover can effectively shield weak radioactivity of the depleted uranium inner barrel, and safety of personnel and environment is ensured.

Owner:THE 404 CO LTD CHINA NAT NUCLEAR

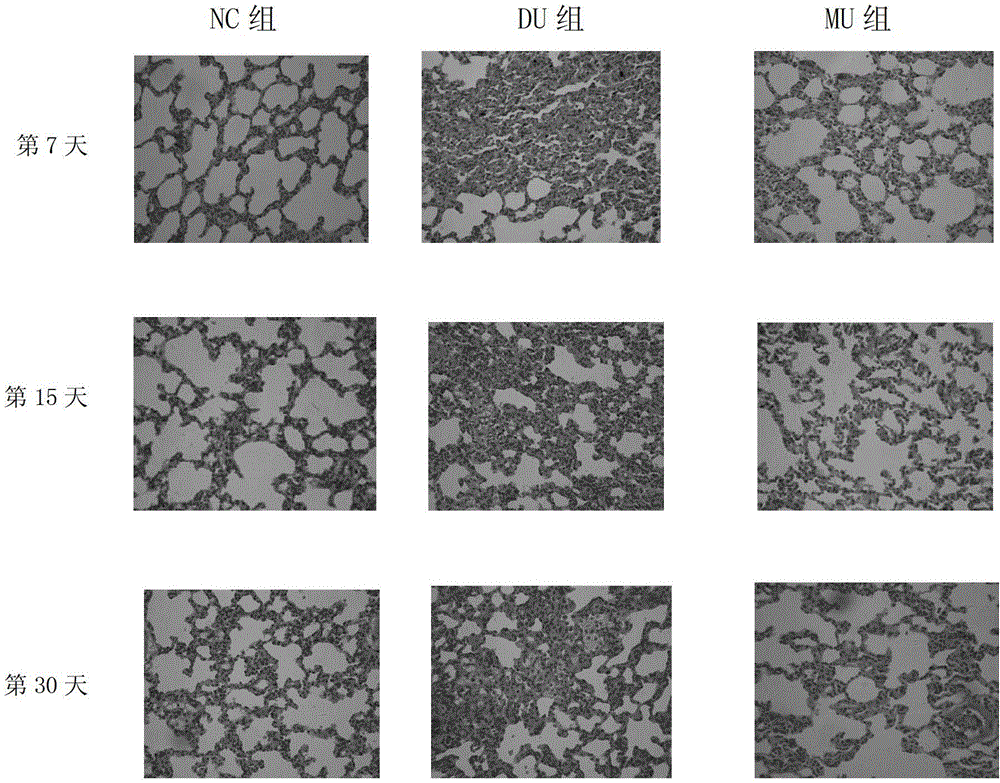

Application of Mucosolvan in preparing product for cleaning depleted uranium particles in lung

The invention discloses an application of Mucosolvan in preparing a product for cleaning depleted uranium particles in lung. According to the invention, a new application of Mucosolvan is discovered, namely an application of Mucosolvan in preparing a product for cleaning depleted uranium particles in lung; a product for cleaning depleted uranium particles in lung is protected, and the active ingredient of the product is Mucosolvan; and Mucosolvan can obviously clean depleted uranium particles in lung so as to reduce damage of the lung tissue and kidney tissue caused by the depleted uranium particles and provide a basis to the prevention of the lung absorbing insoluble DU (depleted uranium) particles.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

Centrifugal casting method for large depleted uranium flywheel

The invention belongs to the technical field of depleted uranium part development and particularly relates to a centrifugal casting method for a large depleted uranium flywheel. A vacuum medium-frequency induction smelting furnace provided with a centrifugal casting device is prepared, a shell is connected with the smelting furnace in a sealed manner, and vacuum is maintained; a disc-shaped die is machined, and a layer of Y2O3 solution coating is brushed to the surface of an inner cavity of the die; a pouring cup is placed at the bottom of a crucible for cooperative use; depleted uranium and a depleted uranium alloy material with the density larger than 18 g / cm<3> are prepared, and the weight is 1000 kg; the crucible is arranged in the vacuum medium-frequency induction smelting furnace, and materials are loaded in to the crucible; the die dried to 100 DEG C is arranged into the centrifugal casting device and is fixed; a sieve tray is assembled over the center of the die; the centrifugal casting device and the smelting furnace are assembled in a sealed manner; vacuum pumping is conducted to be within 10 Pa, point sending heating begins, heating is conducted till the melting state is achieved, and the temperature is increased continuously; materials are heated to 1450 DEG C to 1500 DEG C, and heat preservation is conducted for 30 min; and a motor is started, and casting is conducted at the speed of 12.5 kg / s. the centrifugal casting method is suitable for preparing of hollow disc-shaped structure castings, and the material density can be improved.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Continuous ion exchange process integrated with membrane separation for recovering uranium

InactiveUS20150354027A1Reduce concentrationTransuranic element compoundsHigh concentrationIon exchange

A continuous ion exchange system and method for recovering uranium from a pregnant liquor solution wherein the method includes the steps of: (a) treating the pregnant liquor solution (16) with a membrane (28) to produce: i) a leach permeate solution (30) at least partially depleted of uranium and carbonate and ii) a leach concentrate solution (30′) having a relatively higher concentration of uranium and carbonate and which is at least partially depleted of chloride; (b) passing the leach concentrate stream (30′) through an ion exchange bed to load uranium onto a strong base anion exchange resin and produce an untreated barren (18) solution depleted of uranium, (c) passing an eluant solution (20) comprising bicarbonate through the loaded ion exchange bed to strip uranium from the strong base anion exchange resin and produce an eluate (22) comprising uranium and bicarbonate, (d) precipitating uranium (24) from the eluate (22) to produce a residual eluant solution (26) depleted of uranium, and (e) repeating steps (a)-(d).

Owner:DOW GLOBAL TECH LLC +1

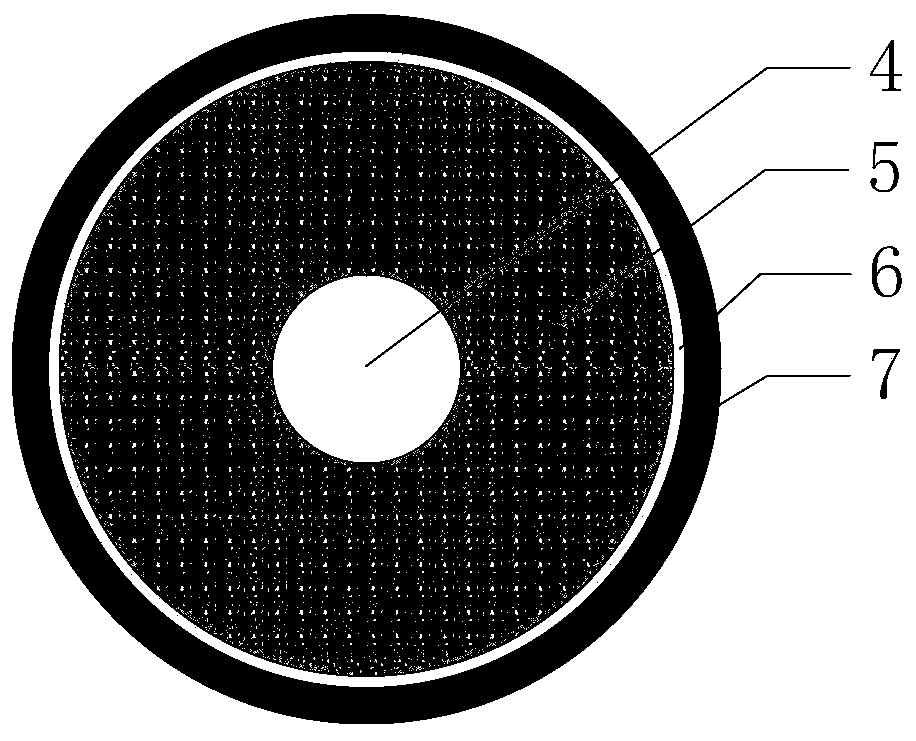

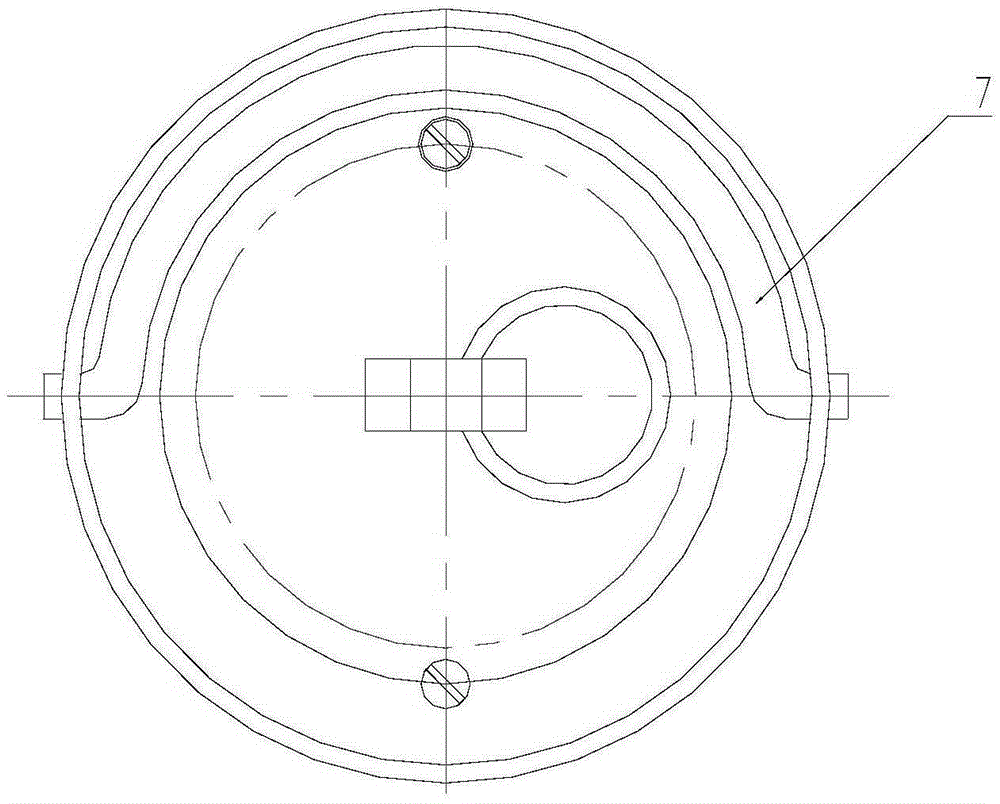

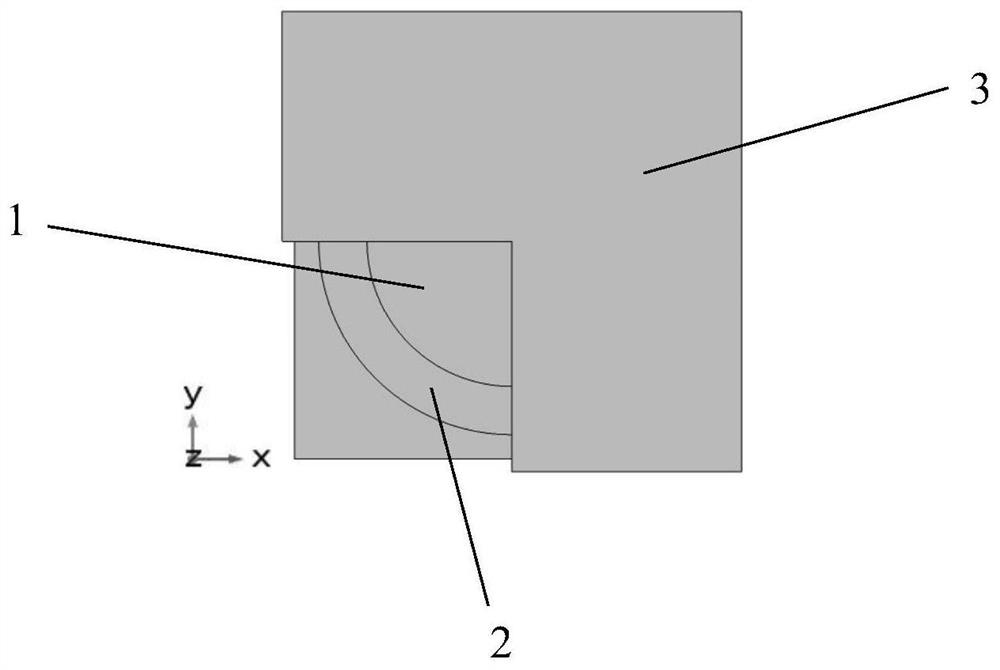

Low-frequency wide-band-gap seismic metasurface structure containing depleted uranium

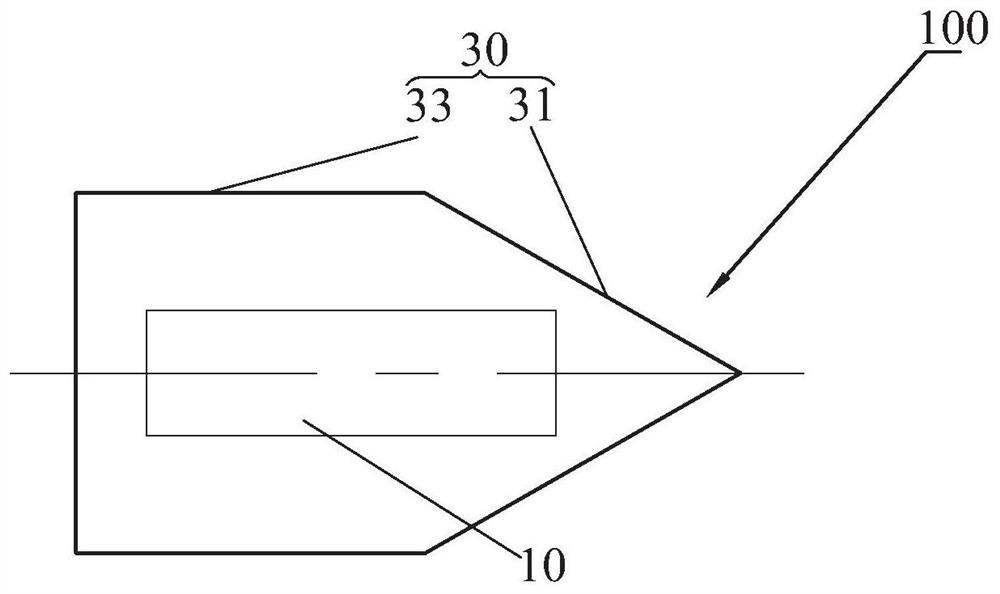

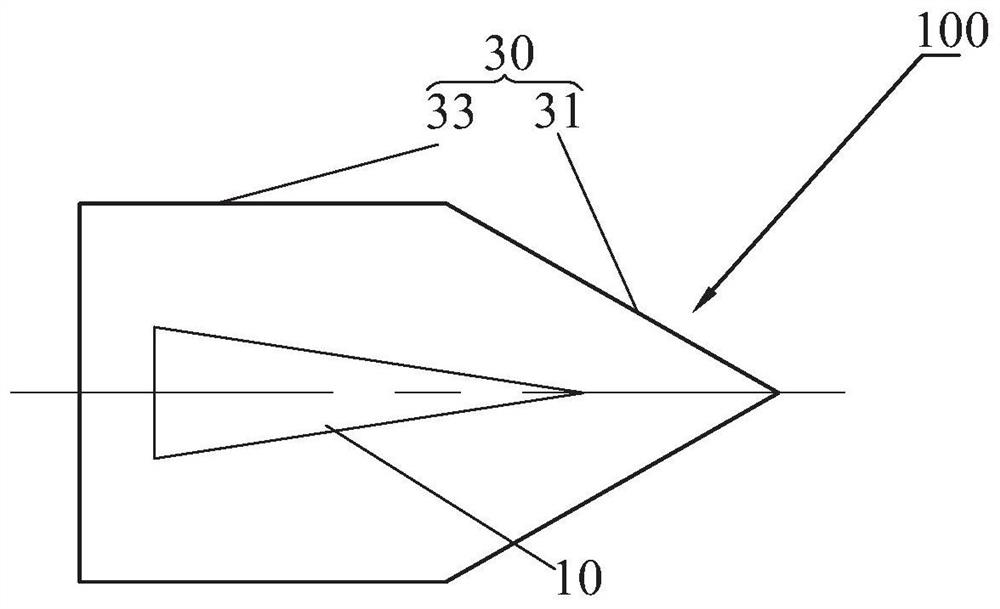

PendingCN113684866ASmall structure sizeOptimize layoutProtective foundationRemote controlEngineering

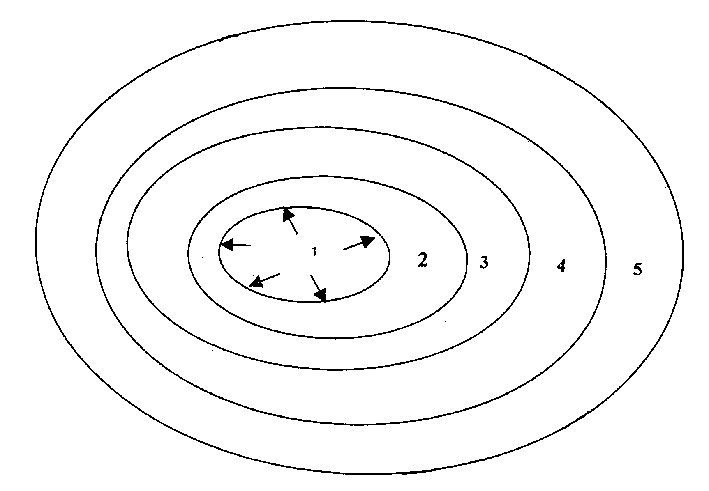

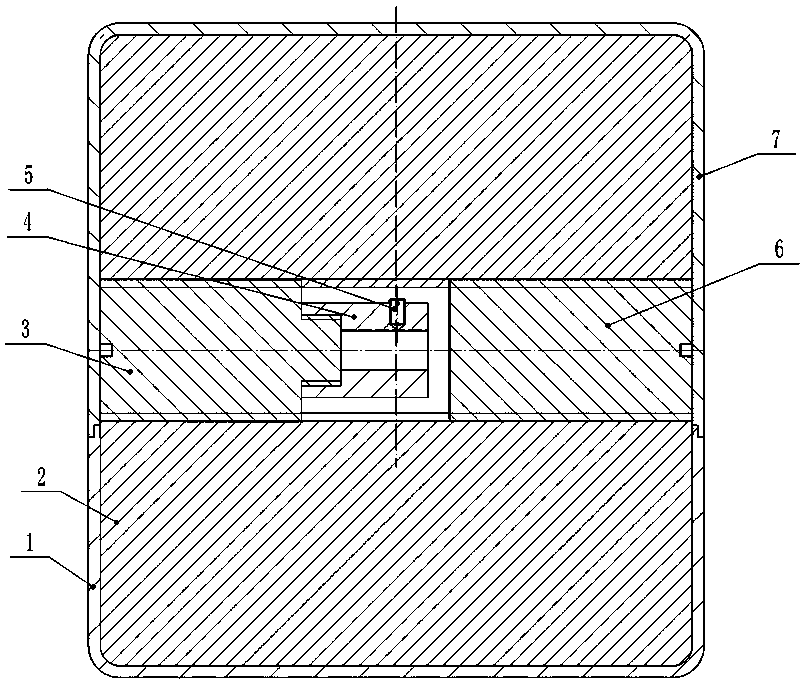

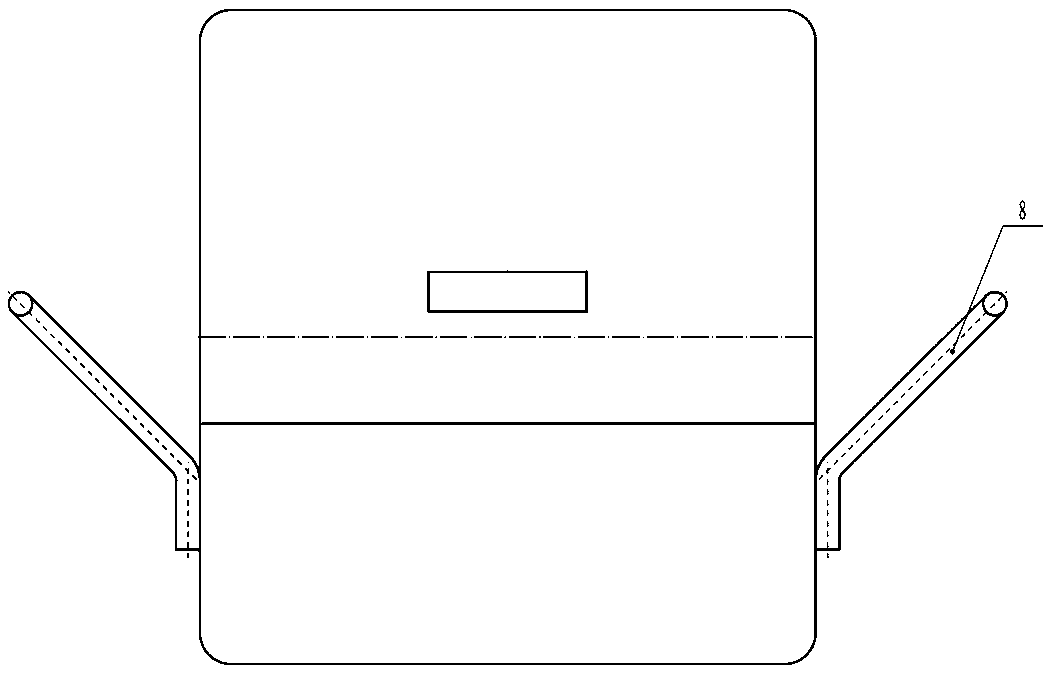

The invention discloses a low-frequency wide-band-gap seismic metasurface structure containing depleted uranium. The seismic metasurface structure is formed by continuation of seismic metasurface structure unit cells in the same horizontal plane along two mutually perpendicular directions and is designed on the periphery of a building foundation, and each seismic metasurface structure unit cell comprises depleted uranium balls (1), a rubber layer (2) and a soil layer (3). A depleted uranium ball (1) is a ball body, the rubber layer (2) is a hollow ball body, and the soil layer (3) is a hollow cube. The low-frequency wide-band-gap seismic metamaterial structure is located between an earthquake source and a protected building, and when an earthquake occurs and seismic waves reach the designed structure, the seismic waves are attenuated. Therefore, the seismic waves are controlled and attenuated in the seismic wave propagation process, and the purpose of remote control is achieved. According to the low-frequency wide-band-gap seismic metamaterial structure containing the depleted uranium, the seismic metasurface structure is mainly obtained by periodically arranging the structural unit cells, and the structural unit cells are mainly obtained by embedding the depleted uranium balls in soil after wrapping the depleted uranium balls with rubber, so that the structural construction is relatively simple.

Owner:BEIJING UNIV OF TECH

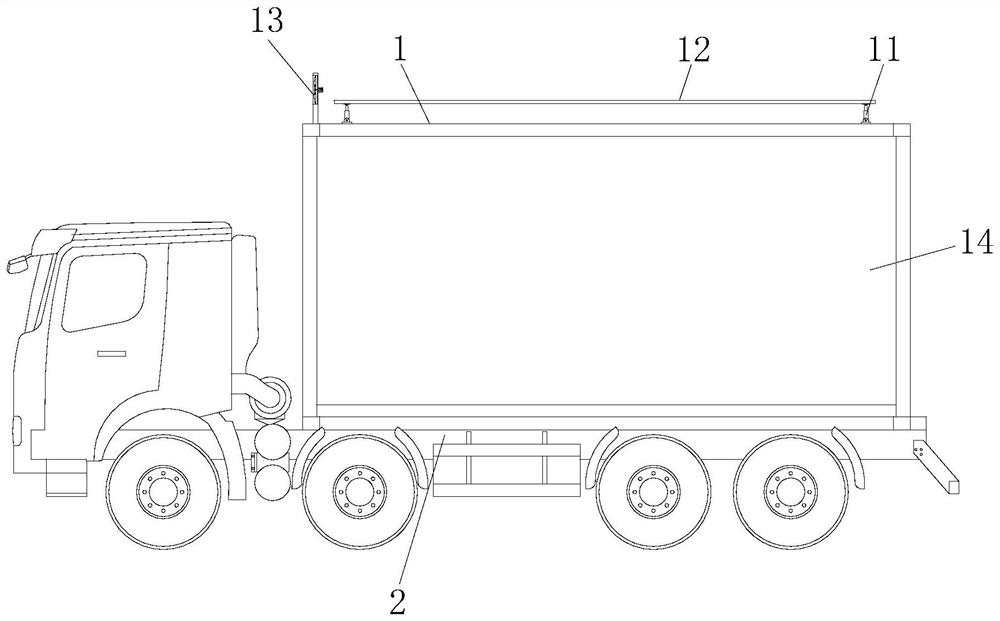

Special material ray sterilization vehicle

PendingCN113456844AQuick emergency responseIncrease dose rateBatteries circuit arrangementsPV power plantsNuclear engineeringEmergency rescue

The invention discloses a special material ray sterilization vehicle, and belongs to the technical field of public health emergency rescue. The vehicle comprises a mounting platform, the upper end of the mounting platform is provided with a square cabin, the middle of the interior of the square cabin is provided with an accelerator main body, and the exterior of the accelerator main body is provided with a shielding cover; an accelerating tube is arranged on the side edge of the accelerator body, and a modulator is arranged on the side edge of the water cooling unit. The square cabin is arranged on the mobile vehicle-mounted mounting platform, and the accelerating tube, the accelerator main body, the shielding cover and the touch screen control chamber are arranged in the square cabin, so the mobile sterilization vehicle is formed, and the blank of domestic special vehicles is filled; ionizing radiation generated by high-energy electron beams generated by the accelerator body destroys protein and DNA / RNA structures of germs, pathogens are inactivated, the disinfection and sterilization functions are achieved, irradiation energy in a square cabin is maximized and the overall size is miniaturized due to the ray shielding function of the depleted uranium special material, the disinfection and sterilization functions are achieved through the electron irradiation technology, and greenness, safety and high efficiency are realized.

Owner:包头北方专用汽车有限责任公司

Armor-piercing head

PendingCN113532204AIncrease aggressivenessIncrease flight speedAmmunition projectilesProjectilesDepleted uraniumStructural engineering

The invention provides an armor-piercing head. The armor-piercing head is composed of a conical or pyramidal tip cone and a platform connected to the lower part of the tip cone in shape, wherein the armor-piercing head comprises a bullet core and a housing integrated with the bullet core; the housing at least wraps part of the bullet core, the tip cone is formed by the housing, the bullet core is made of tungsten or tungsten alloy, and the housing is made of amorphous alloy. The armor-piercing head is formed by integrally compounding the bullet core made of the tungsten or tungsten alloy and the housing made of the amorphous alloy; and the tip cone is made of an amorphous material. The amorphous alloy material has the characteristics of high dynamic fracture toughness and high hardness under the action of a high-speed load, and has good self-sharpening property when penetrating metal, so that the armor-piercing head can greatly improve the attack effect; and meanwhile, the tungsten or tungsten alloy instead of lead, depleted uranium alloy and other materials is adopted, so that terrible aftereffects such as residual radioactivity and the influence on the ecological environment can be avoided. The high flying speed of the armor-piercing head can be achieved through the use of the amorphous material, and the flying stability of the armor-piercing head can be maintained through the use of the high-density material of the tungsten or tungsten alloy.

Owner:东莞梵铃材料科技有限公司

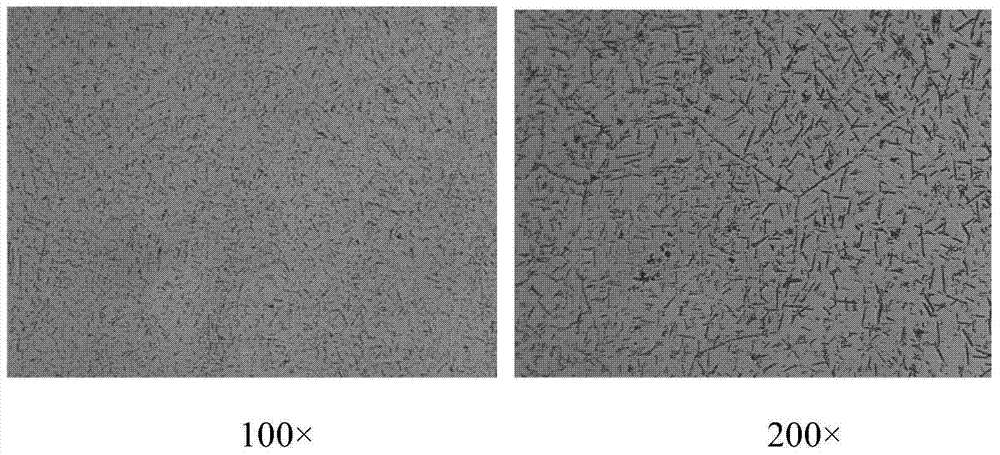

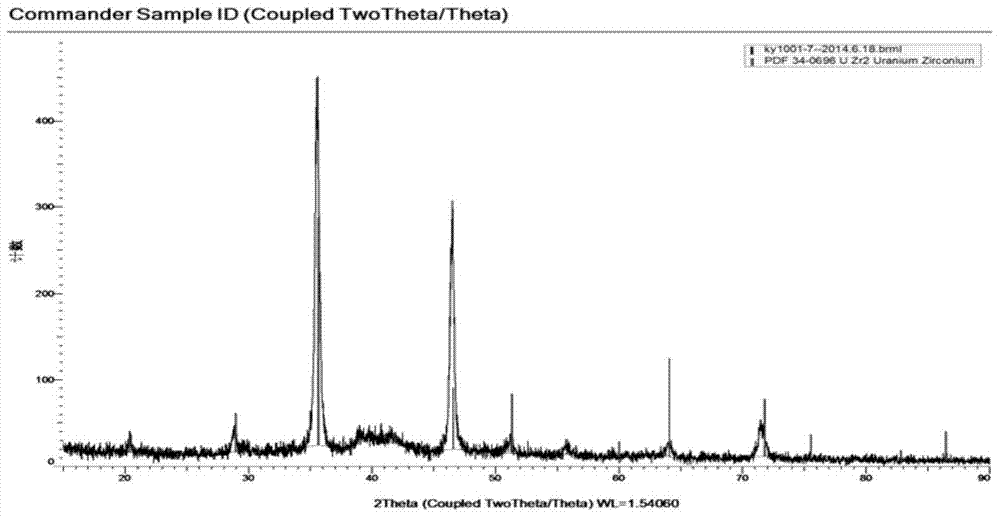

Preparing method of depleted-uranium magnetron sputtering target slices

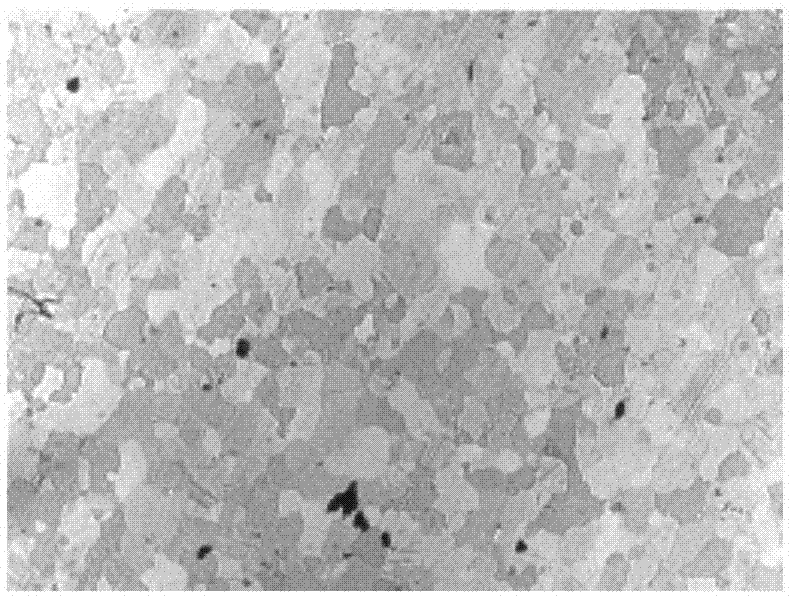

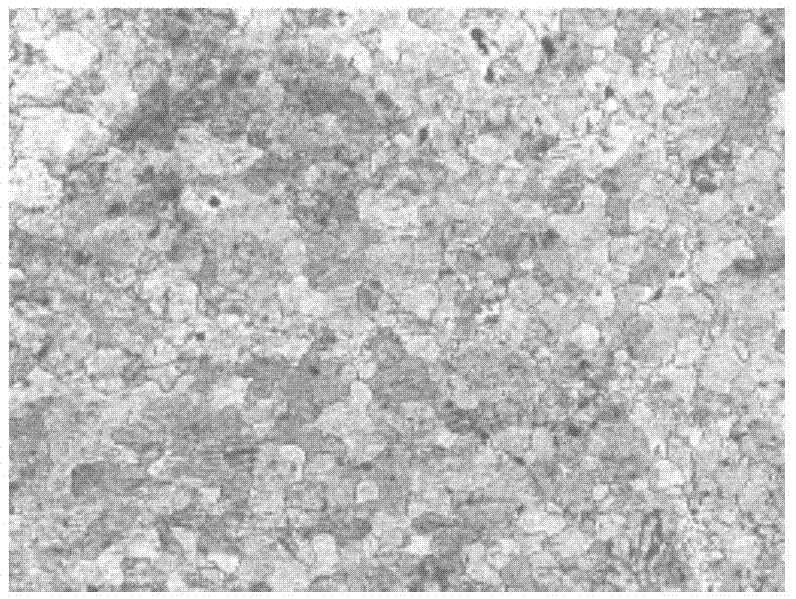

The invention belongs to the technical field of preparation of magnetron sputtering target slices, and particularly relates to a preparing method of depleted-uranium magnetron sputtering target slices. The method comprises following steps: firstly, a uranium ingot obtained through UF4 calcium thermic reduction is subject to vacuum refining, and a purified cylindrical depleted-uranium ingot casting is obtained; secondly, plastic deformation is achieved, wherein the purified cylindrical depleted-uranium ingot casting obtained in the first step is subject to heat extrusion in the height direction, and the cylindrical depleted-uranium ingot casting is subject to upsetting in the height direction; thirdly, the extruded and upset metal uranium piece obtained in the second step is subject to vacuum dehydrogenation heat treatment; fourthly, the metal uranium piece obtained in the third step and subject to vacuum dehydrogenation heat treatment is subject to finish turning, and then accurate grinding is carried out. Projects of the phase, the microstructure, the surface roughness and the like of the depleted-uranium sputtering target slices are subject to detected analysis, and the technical requirement of a magnetron sputtering uranium thin film for the depleted-uranium magnetron sputtering target material can be completely met.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com