Concentric spherical surface separation plate type spherical main container

A main container and baffle type technology is applied in the field of spherical main container of molten salt depleted uranium reactor, which can solve the problems of low utilization rate of uranium resources, high cost, low cost, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] When building a new reactor, it must be designed and built according to the specific index requirements under the actual application conditions of the reactor, such as as a neutron source or a small energy source, and at the same time according to the requirements of the molten salt depleted uranium reactor with a concentric spherical partition type spherical main vessel, in order to meet The proper operation of the heap is a special performance requirement. Provide very cheap neutrons or energy for applications under the conditions of achieving its excellent performance such as no supercritical accidents, using negative feedback to maintain long-term safe and stable operation in a critical state, achieving high fuel consumption, and long life. .

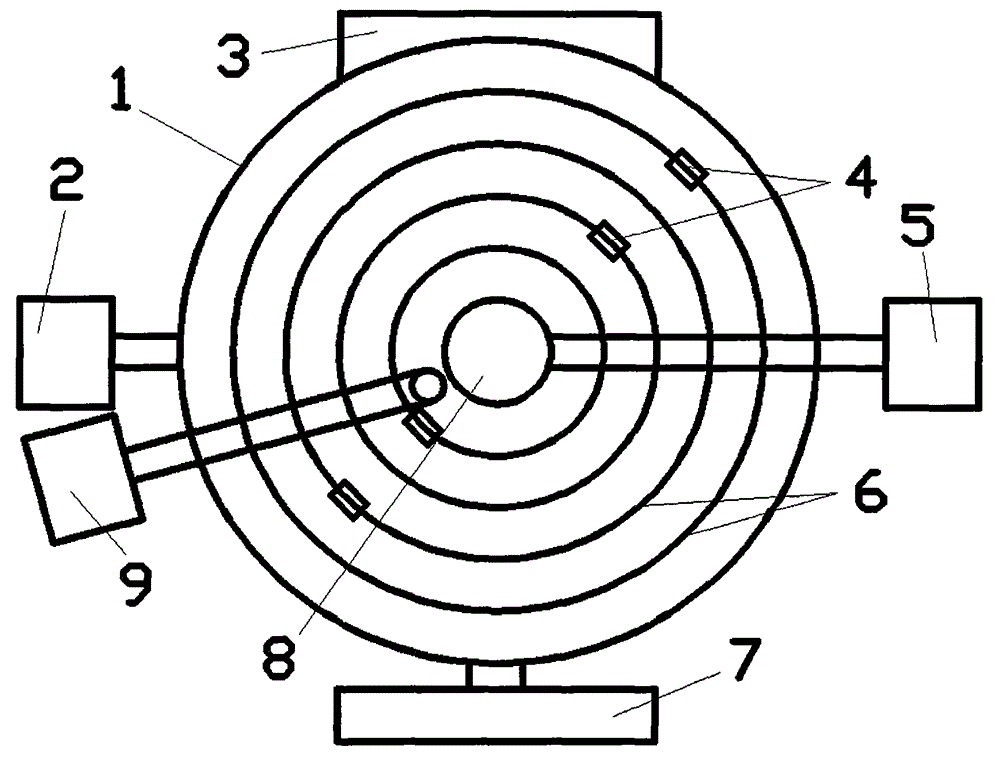

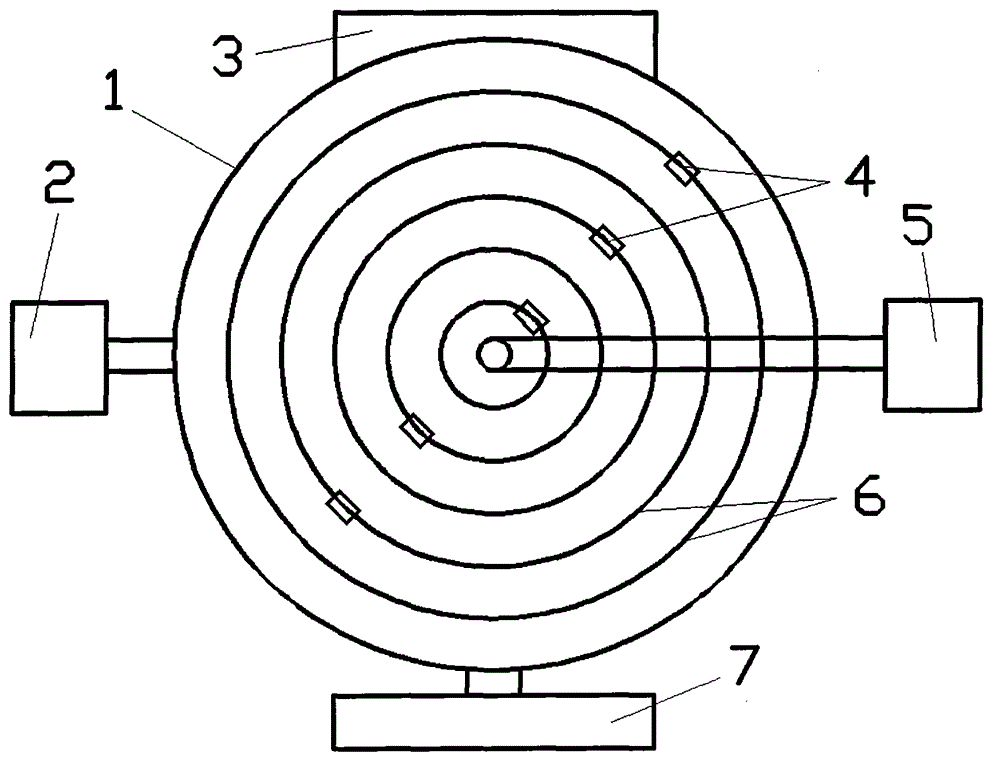

[0033] exist figure 1 Among them, the new material of molten salt enters the outside of the cavity (8) used for the experiment of the center of the sphere through the feeding control storage device and the pipeline (9), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com