Asphalt VOCs waste gas purification device

A technology of asphalt and dust removal device, applied in external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of low purification efficiency, difficult to clean the electrode plate, polluted exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

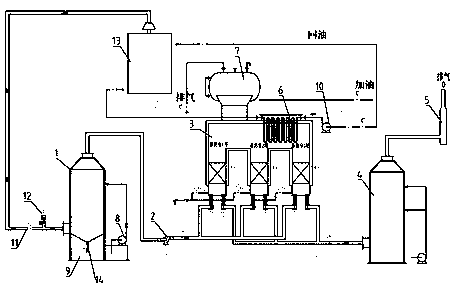

[0011] see figure 1 , connect the air inlet of the 1-high-voltage electrostatic precipitator to the collection cover of the asphalt mixing tank through the SUS304 air pipe, and set a cut-off valve and a fresh air valve on the connecting pipes respectively. When the cut-off valve is cut off, the exhaust gas will not enter the treatment At the same time, the fresh air valve will automatically open, and the fresh air supplied by the fresh air valve can ensure the normal temperature rise or operation of the regenerative combustion and heat transfer oil heat exchange device. Connect the air outlet of 1-high-voltage electrostatic dust removal device and the air inlet of 3-regenerative combustion and heat transfer oil heat exchange device through pipelines, and install induced draft fans on the connecting pipelines. Connect the air outlet of the 3-regenerative combustion and heat transfer oil heat exchange device with the air inlet of the 4-desulfurization tower device through pipes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com