U-10Zr alloy smelting technology

A u-10wt.%zr alloy technology, applied in the field of U-10Zr alloy smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

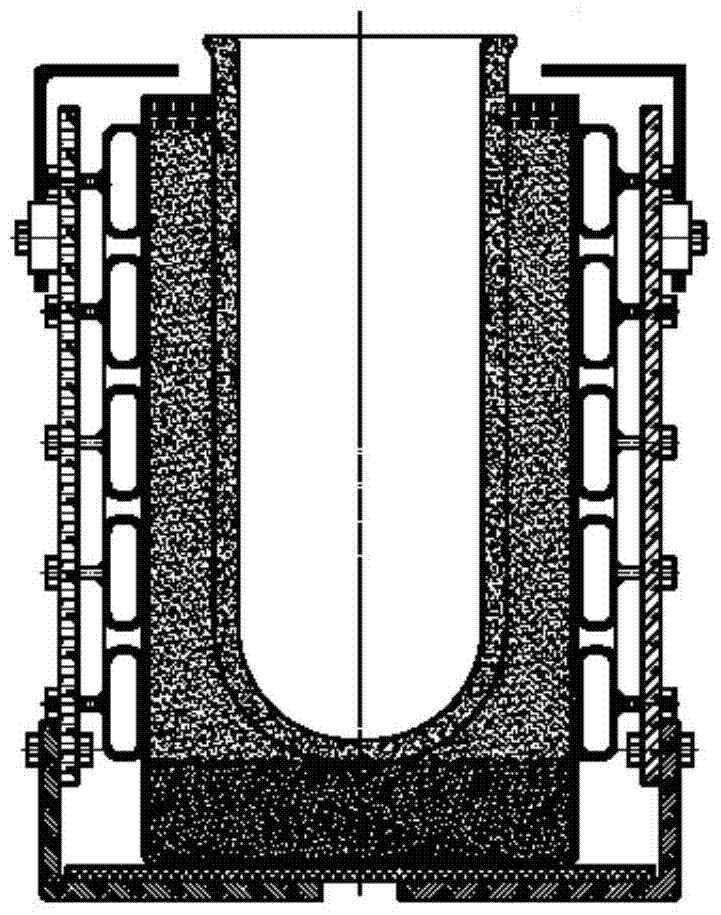

[0026] A kind of U-10Zr alloy smelting process of the present invention comprises the following steps:

[0027] (1) Preparation of master alloy.

[0028] Prepare U and Zr in an equal weight ratio, and repeatedly smelt the alloy for 5 to 8 times in a non-consumable electric arc furnace to prepare a U-50wt.% Zr master alloy with Zr as the matrix and uranium solid-dissolved in the matrix;

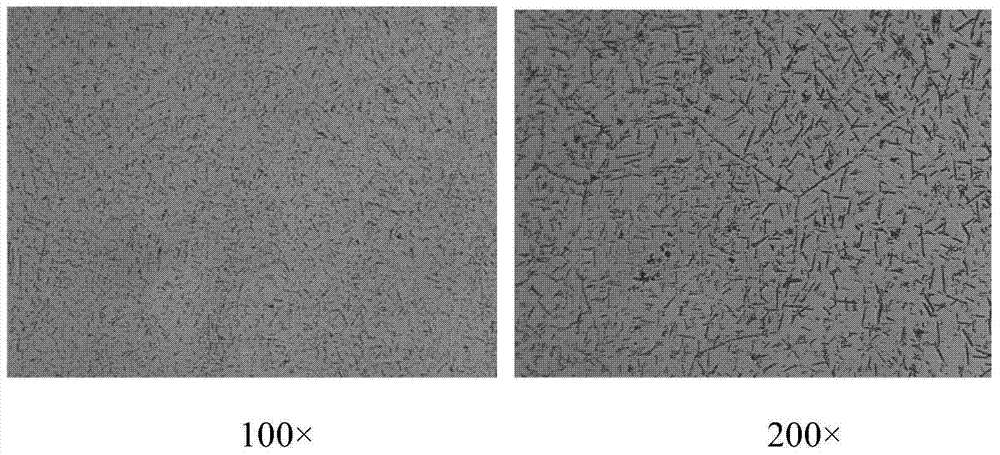

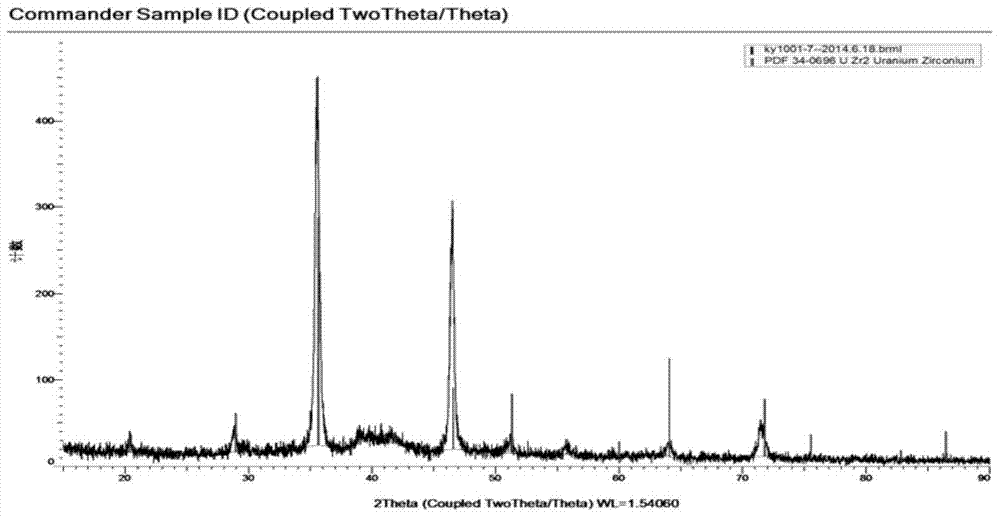

[0029] figure 2 The metallographic phase of the U-50wt.% Zr master alloy smelted 8 times, the sample was polished, and there was no undissolved matter in the sample. The black needle-like structure in the figure is the second phase, and the distribution is uniform. image 3 It is the XRD pattern of the sample U-50wt.%Zr, which is analyzed as the second phase UZr 2 .

[0030] In this example, the main technical indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com