Anti-corrosion and anti-scale titanium-copper alloy material

A titanium-copper alloy, anti-corrosion technology, applied in the field of anti-corrosion and anti-scaling materials, to achieve the effect of slowing down corrosion, excellent corrosion resistance and anti-scaling performance, and reducing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

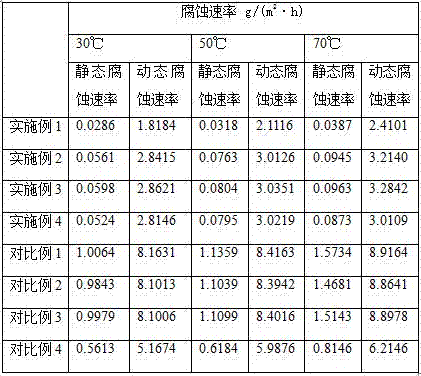

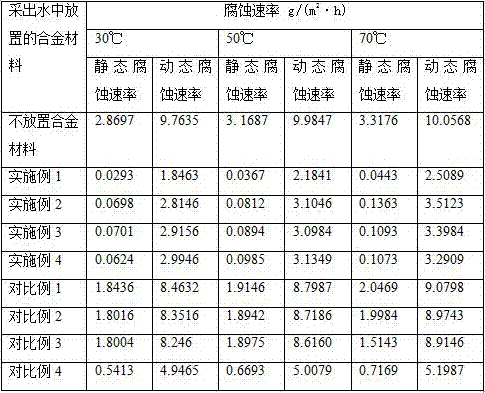

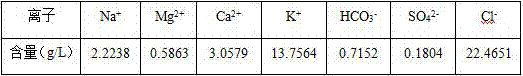

Examples

Embodiment 1

[0023] 1. An anti-corrosion and anti-scaling titanium-copper alloy material, comprising the following components in mass percentage: 34.12% titanium, 27.28% copper, 20.16% zinc, 11.05% nickel, 2.20% tin, 1.25% tellurium, and 0.76% aluminum , 0.5% indium, 0.43% niobium, 0.20% silicon, 0.15% scandium, 0.75% depleted uranium, 1.09% mixture of NaF and NaCl, 0.06% unavoidable impurities, among which, the weight ratio of NaF and NaCl is 2:3.

[0024] 2. The preparation method of the anti-corrosion and anti-scaling titanium-copper alloy material is as follows:

[0025] The preparation method of the above-mentioned anti-corrosion and anti-scaling titanium-copper alloy material: the vacuum arc melting method is adopted, and the arc melting is carried out on a water-cooled copper crystallizer using graphite as an electrode. Vacuumize the melting furnace before melting, fill it with high-purity inert gas, burn the arc in easily ionized argon, then transfer the arc to the charge in the cr...

Embodiment 2

[0027] An anti-corrosion and anti-scaling titanium-copper alloy material, comprising the following components in mass percentage: titanium: 26.26%, copper: 29.68%, zinc: 15.46%, nickel: 14.21%, tin: 4.67%, tellurium: 4.85% , aluminum: 2.23%, indium: 0.2%, niobium: 0.30%, silicon: 0.05%, scandium: 0.4%, depleted uranium: 0.1%, mixture of NaF and NaCl: 1.5%, unavoidable impurities 0.09%, among them, NaF The weight ratio with NaCl is 2:2.5.

[0028] Its preparation method is with embodiment 1.

Embodiment 3

[0030] An anti-corrosion and anti-scaling titanium-copper alloy material, comprising the following components in mass percentage: titanium: 27.64%, copper: 24.21%, zinc: 23.56%, nickel: 13.83%, tin: 2.06%, tellurium: 3.04% , aluminum: 2.89%, indium: 0.78%, niobium: 0.49%, silicon: 0.01%, scandium: 0.01%, a mixture of NaF and NaCl: 0.5%, depleted uranium: 1%, unavoidable impurities 0.01%, of which, NaF The weight ratio with NaCl is 2:5.

[0031] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com