Patents

Literature

140results about How to "Good antifouling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium-Containing Silica Sol and Process for Producing the Same, Antifouling Film and Base Material with Ink-Receptive Layer, and Method for Reproducing Recording Base Material

InactiveUS20070249736A1Good antifoulingWell formedMaterial nanotechnologyPigmenting treatmentDispersed mediaTitanium

It is an object of the present invention to provide a material which is applied to substrates by an easy and simple process, is applicable to substrates of a wide range and is capable of forming an antifouling film exhibiting excellent antifouling performance, and a substrate with an ink-receiving layer having excellent decoloring property. The titanium-containing silica sol of the invention includes (a) the following fine particles (a1) or the following fine particles (a2) and (b) a dispersion medium: (a1) titania fine particles having a mean particle diameter of 2 to 50 nm and porous silica fine particles having a mean particle diameter of 5 to 100 nm and a specific surface area, as determined by BET method, of not less than 300 m2 / g, or (a2) porous silica fine particles obtained by surface-modifying surfaces of porous silica fine particles having a mean particle diameter of 5 to 100 nm and a specific surface area, as determined by BET method, of not less than 300 m2 / g with a titanate compound.

Owner:JGC CATALYSTS & CHEM LTD

Composite antiscale agent

InactiveCN101993685AAdsorption - large amount of precipitationModerate release rateDrilling compositionBarium sulfateSURFACTANT BLEND

The invention relates to a composite antiscale agent. The composite antiscale agent comprises the following components in percentage by weight: (a) 10.0 to 20 percent of organic phosphonate, (b) 10.0 to 20 percent of polycarboxylic acid and (c) 2.0 to 10 percent of surfactant. The composite antiscale agent is used for performing antiscale construction or / and cooperating with pressing crack and acidization on a scaling oil well, wherein the common using amount of the composite antiscale agent for a single well is 2 to 5 tons; and the using concentration is 2 to 6 percent. Due to the adsorption of the composite antiscale agent on the surface of formation sandstone, the precipitation capacity is high; the release rate is moderate; the antiscale property is high; when the concentration of the composite antiscale agent is 20 mg / L, the antiscale efficiency on calcium carbonate (CaCO3) and barium sulfate (BaSO4) reaches 90 percent; when the concentration of the composite antiscale agent is 0.1 percent, the interfacial tension of the composite antiscale agent and crude oil reaches 32.7 mN / m; the antiscale useful life exceeds 2 years; and the total effective rate is 93.9 percent.

Owner:PETROCHINA CO LTD

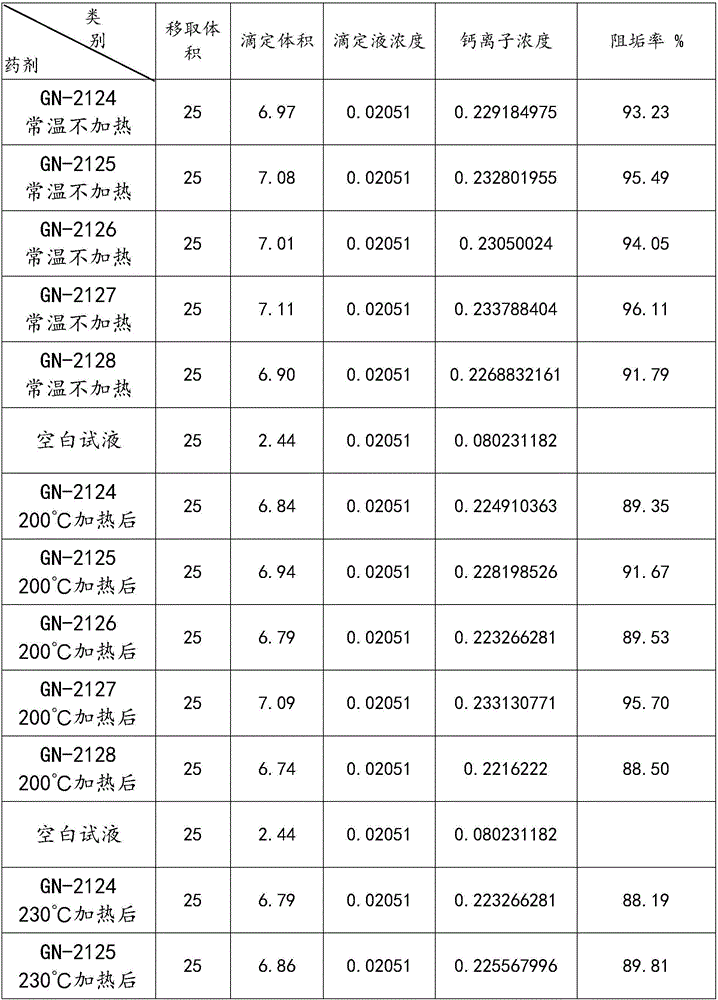

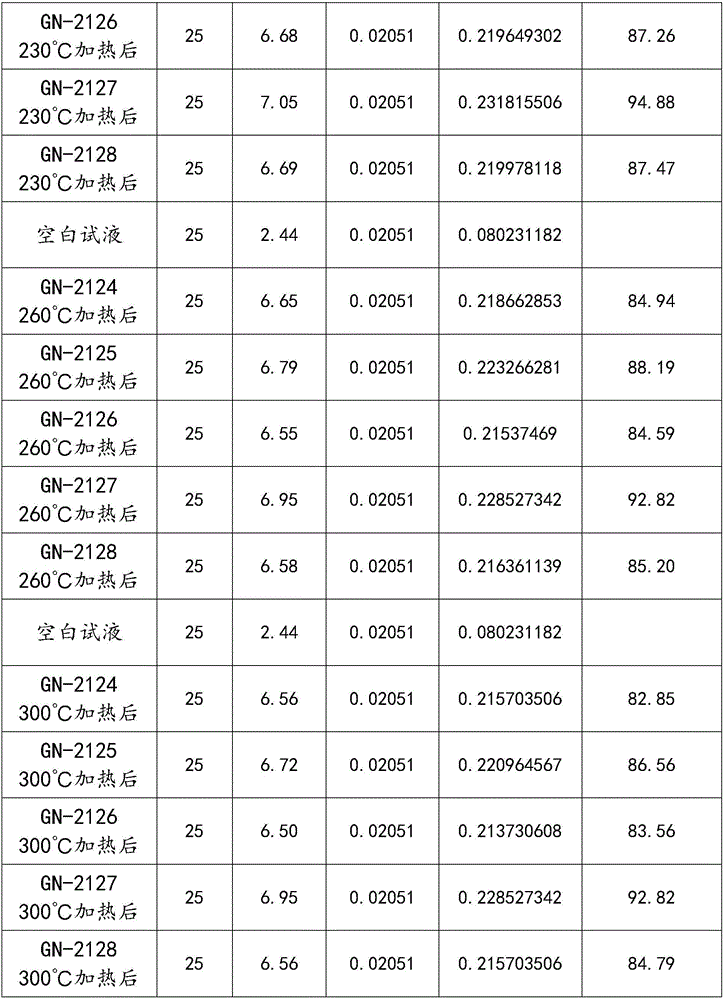

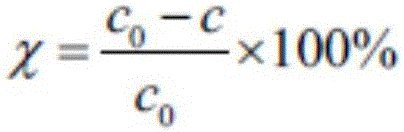

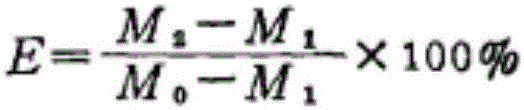

Ash water scale inhibitor as well as preparation and screening test methods thereof

ActiveCN106830378AGood dispersionImprove stabilityChemical analysis using titrationSpecific water treatment objectivesWater qualityTricarboxylic acid

The invention discloses an ash water scale inhibitor as well as preparation and screening test methods thereof. the ash water scale inhibitor is prepared from raw materials in percentage by weight as follows: 2%-10% of HEDP, 10%-15% of 2-phosphonobutane-1,2,4-tricarboxylic acid, 20%-30% of a maleic acid-acrylic copolymer, 10%-20% of hydrolytic polymaleic anhydride, 5%-10% of an acrylic acid-hydroxypropyl acrylate copolymer, 5%-15% of a phosphono-carboxylic acid copolymer, 5%-10% of an acrylic acid-2-acrylamide-2-methyl propane sulfonic acid copolymer and the balance of purified water. The prepared ash water scale inhibitor has calcium resistance, pH resistance and high-temperature resistance, has good corrosion and scale inhabitation performance, has good scale inhibition and prevention effects and is applicable to ash water with water quality characteristics of high temperature, high alkali and high pH, particularly to a power plant ash removal system. The ash water scale inhibitor screened with the ash water scale inhibitor screening test method reaches the expected corrosion and scale inhabitation effects, and the hydraulic ash removal efficiency is improved.

Owner:SHANDONG HUAYOU CHEM

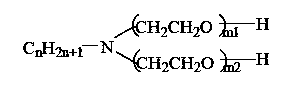

Anti-staining soaping agent for printing of activated dye and preparation method thereof

ActiveCN103642600AImprove stabilitySimple processSurface-active detergent compositionsDetergent compounding agentsFatty amineMonomer

The invention relates to an anti-staining soaping agent for printing of an activated dye and a preparation method thereof. An anti-staining soaping agent for printing of an activated dye, which is high in monomer selectivity and low in preparation cost, and a preparation method thereof are not provided at present. The soaping agent disclosed by the invention is characterized by being prepared from the following raw materials in parts by weight: 20-60 parts of fatty amine polyoxyethylene ether, 1-3 parts of alkylating agent, 0.1-2 parts of stabilizer, 30-70 parts of water and 2-10 parts of polyvinylpyrrolidone. The preparation method disclosed by the invention comprises the following steps of firstly mixing fatty amine polyoxyethylene ether, the alkylating agent, the stabilizer and the water; heating to 80-90 DEG C; distilling in vacuum at 40-50 DEG C for 1-2 hours after stirring for 3-4 hours; cooling to 40-50 DEG C; adding polyvinylpyrrolidone for mixing; heating to 60-70 DEG C, and cooling to 40-50 DEG C after stirring for an hour, so as to prepare a finished product. The anti-staining soaping agent is high in monomer selectivity, low in preparation cost, and simple in preparation technology.

Owner:无锡德冠生物科技有限公司 +1

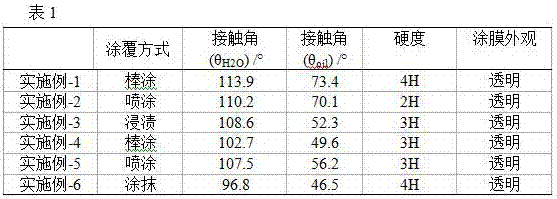

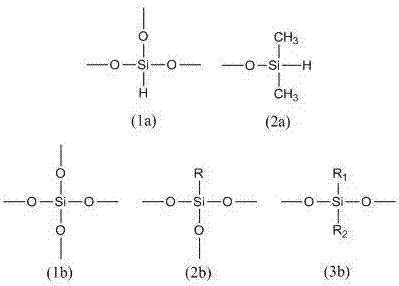

Preparation method and application of solvent-type hydrophobic and oleophobic fluoroalkyl silicone resin

ActiveCN107163254AGood antifouling effectGood antifoulingAntifouling/underwater paintsPaints with biocidesSilicone resinAddition reaction

The invention discloses a preparation method of solvent-type hydrophobic and oleophobic fluoroalkyl silicone resin. The preparation method of the hydrophobic and oleophobic fluoroalkyl silicone resin comprises the following steps: carrying out a hydrosilation addition reaction on hydrogen-containing silicone resin, a fluoroalkyl alkene compound, an alkenyl epoxy compounds and alkenyl silane to synthesize a fluoroalkyl / alkyloxy co-modified silicone resin intermediate FR, and carrying out hydrolysis copolycondensation on the intermediate FR, fluoroalkyl halogenosilane and a multifunctional coupling agent with the functionality being not less than 4 in the solvent in the presence of a non-exogenous catalyst in order to prepare the nanometer rough structure embedded hydrophobic and oleophobic fluoroalkyl silicone resin. The fluoroalkyl silicone resin cooperates with an organic tin catalyst, the obtained mixture is diluted with the solvent, the surface of glass or metal or an another substrate is coated with the diluted mixture, and the coated diluted mixture is cured at a high temperature to form a film, so the substrate is endowed with waterproofing and antifouling effects.

Owner:SHAANXI UNIV OF SCI & TECH

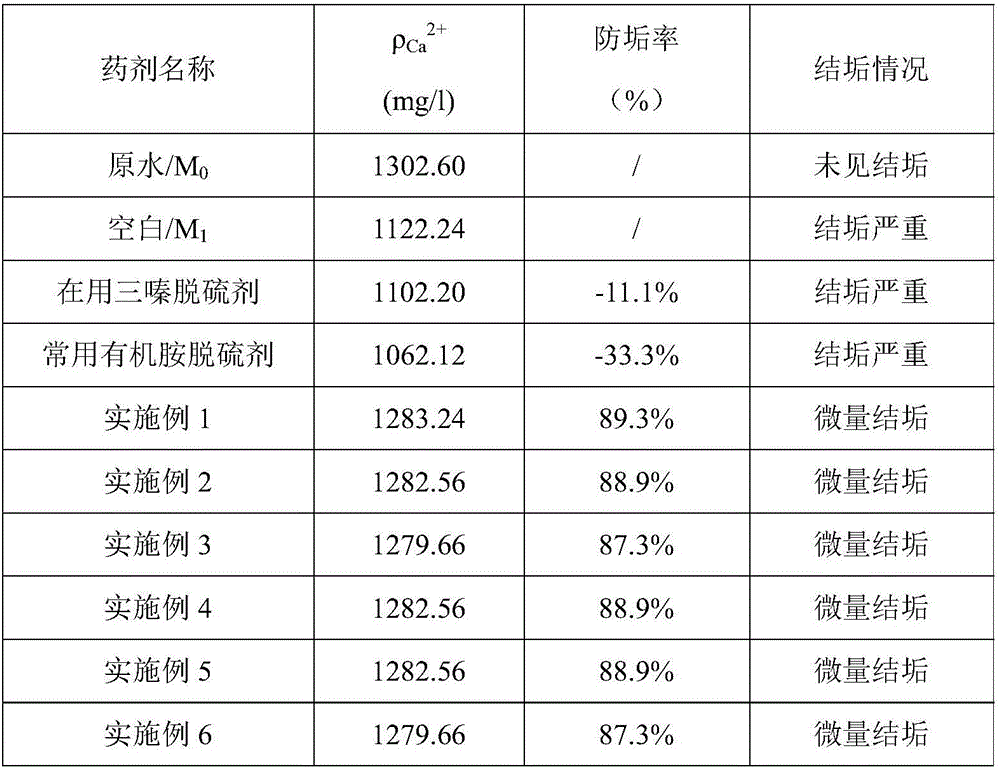

Oil field scale prevention desulfurizing agent and preparing method thereof

ActiveCN106554804AImprove desulfurizationGood antifouling effectHydrocarbon oils refiningTreatment apparatus corrosion/fouling inhibitionTemperature controlPhosphate

The invention relates to the field of chemical desulphuration, and discloses an oil field scale prevention desulfurizing agent and a preparing method thereof. The oil field scale prevention desulfurizing agent is prepared in the manner that a modifying agent, a synergist and a dispersing agent are added in a main agent, and the main agent is obtained in the manner that organic amine and a formaldehyde solution serve as raw materials and are subjected to polymerization, dehydration and refining. The preparing method comprises the steps that the organic amine is stirred under a certain temperature condition, the formaldehyde solution is dripped, the temperature control reaction is conducted after dripping is finished, and the main agent is obtained after decompression dehydration under a certain vacuum degree and temperature condition; then the reaction temperature is controlled, and a modifying agent is dripped in the main agent, and the reaction is conducted; and finally, the synergist and the dispersing agent are sequentially added in a reaction product, and stirring is conducted till uniform mixing. The oil field scale prevention desulfurizing agent has a nitrogen-containing triazine structure, the efficient desulfuration effect can be guaranteed, the phosphate functional group is introduced in molecules, and meanwhile excellent scale prevention performance is achieved. Thus, the oil field scale prevention desulfurizing agent has good desulfuration and scale prevention performance at the same time, and the oil field scale prevention desulfurizing agent is suitable for the desulfuration process of oil field fluid production.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Anti-pollution coating composition and preparation thereof and application to low surface energy antifouling paint

The invention relates to an anti-pollution coating composition and preparation thereof and application to low surface energy antifouling paint. The coating composition comprises an organic polyorganosiloxane polymer. According to a synthetic formula, the anti-pollution coating composition comprises, by weight parts, 100 parts of octamethylcyclotetrasiloxane, 0.05-0.5 part of basic catalyst, 0.5-3 parts of accelerant, 5-100 parts of silane coupling agent, 0.5-3 parts of end capping agent, 0-0.5 part of dehydrating agent and 15-25 parts of butyl acetate, wherein the dosage of organic acid or acid anhydride is 0-200% the molar weight of the silane coupling agent. The anti-pollution coating composition comprises, by weight percentage, 10-70% of organic polyorganosiloxane polymer, 0.5-20% of pigment, 0.5-20% of filler and 5-40% of solvent. The anti-pollution coating composition has the advantages of having low surface energy performance and hydrophilia and can be widely utilized in the ocean anti-pollution coating filed.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Preparation method of marine microorganism antifouling coating

InactiveCN101284956AThe process is simpleReduce manufacturing costAntifouling/underwater paintsHydrolasesRosinAntifouling coating

The invention relates to a method for making a marine microorganism antifouling paint by a marine microorganism fermentation product. The method realizes that bio-material is utilized to prepare the antifouling paint which prevents halobios from being attached; the invention belonging to the biological fouling protection technical field comprises three processing steps of preparing antifouling microorganism, antifouling protease and microorganism antifouling paint; firstly, barnacle and mussel are treated to a homogenate; the homogenate is taken out and put on a liquid substrate agar plate; the antifouling microorganism is obtained by lineation, separation and cultivation; secondly, the microorganism is conducted to a liquid seed substrate by a bevel substrate and cultivated in a fermentation substrate; a target active matter antifouling protease is obtained through the treatments of decompression, refrigeration and drying; finally, rosin is added to an alloprene solution and evenly stirred, then swell soil is added to the mixed solution and evenly stirred by electromotion; the active matter antifouling protease is added and evenly mixed, thereby obtaining the microorganism antifouling paint. The method for making the marine microorganism antifouling paint by the marine microorganism fermentation product has simple process course, low production cost, good antifouling effect and no environmental pollution.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High Quality Calcium Hydroxide Slurries

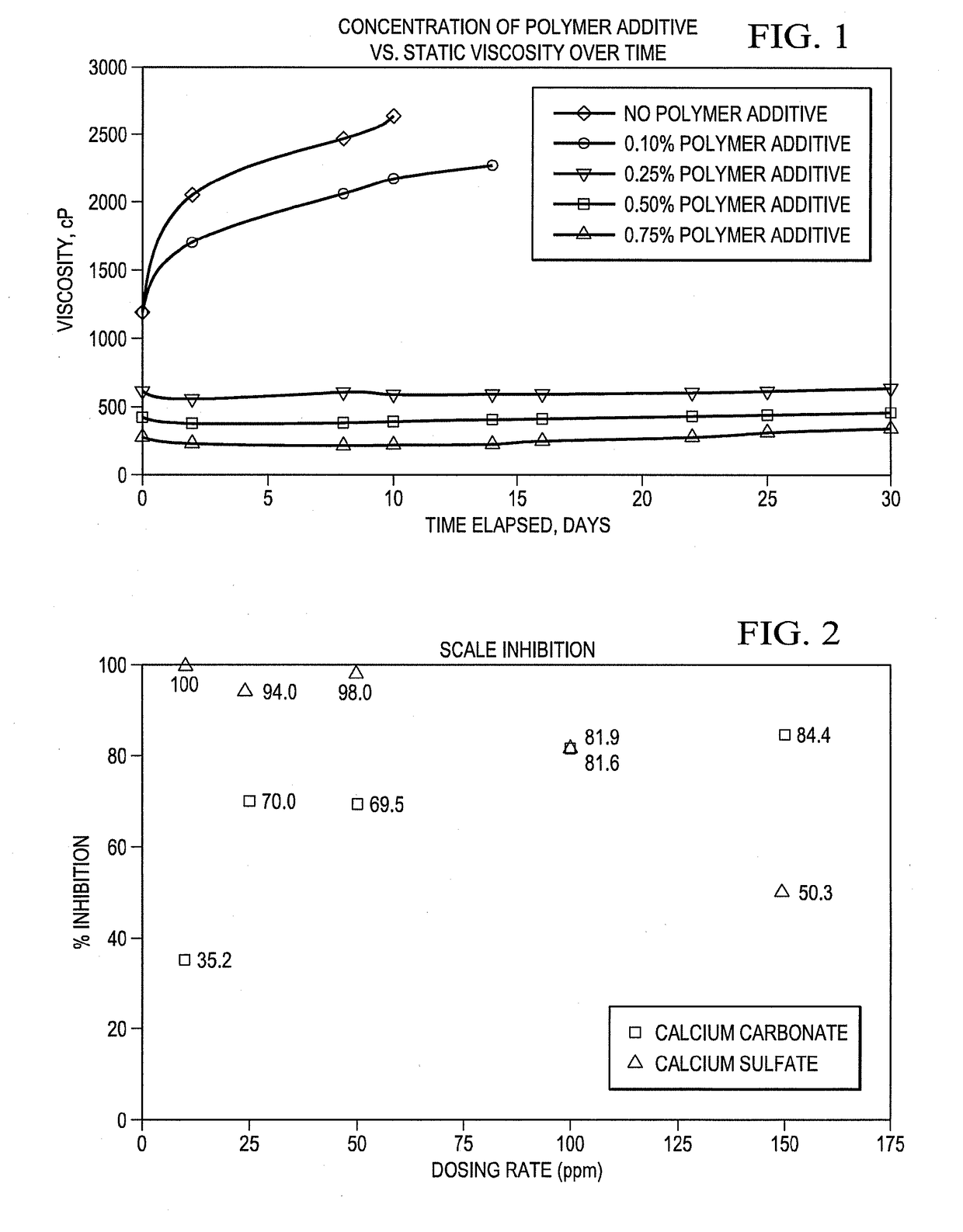

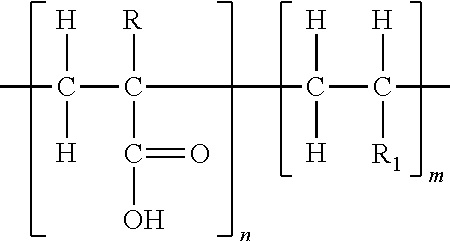

InactiveUS20180065887A1Resists hard packingEasily redispersibleWater softeningWater/sewage treatmentCalcium hydroxideMetallurgy

A calcium hydroxide slurry is formed by combining a polymer additive with lime and water to form an aqueous slurry. The slurry so produced is viscostable, resists hard packing even after prolonged storage, is easily redispersed and has antiscaling properties. The amount of lime used is between 35 to 55% by weight of the slurry. The polymer additive is a polycarboxylate dispersing agent and is added in an amount between about 0.1 to 3% by weight of lime.

Owner:LHOIST NORTH AMERICA INC

Methanesulfonic acid-ammonium hydrogen fluoride acid liquid system and preparation method and application thereof

InactiveCN105950129APrevent precipitationAvoid harmFluid removalDrilling compositionHydrogen fluorideOrganic acid

The invention provides a methanesulfonic acid-ammonium hydrogen fluoride acid liquid system. The acid liquid system is prepared from components, by weight of 100 g of the solution, as follows: 1-95.6 g of methanesulfonic acid, 0.6-3 g of ammonium hydrogen fluoride, 0.6-3 g of organic acid, 0.15-0.2 g of a ferrous stabilizer, 0.5 g of a discharge aiding agent for acidification, 0.5 g of a foaming agent, 0.5 g of a clay stabilizer, 1.5-2 g of a corrosion inhibitor for acidification, 0.05-0.1 g of a composite scale inhibitor and the balance of solvent water. The provided methanesulfonic acid-ammonium hydrogen fluoride acid liquid system has good corrosion capability, has a certain retardance effect, a deep acidification function on a reservoir and a protection function on an underground tubular column and also has a good anti-scaling function.

Owner:PETROCHINA CO LTD

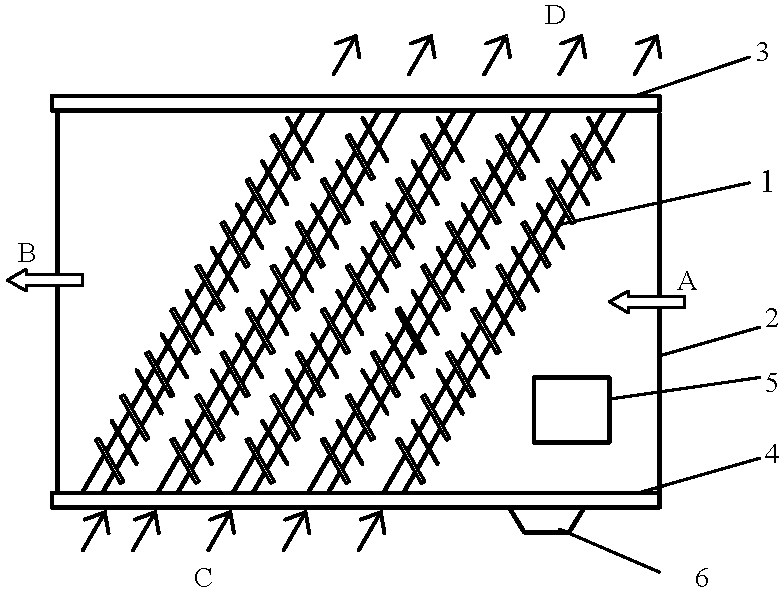

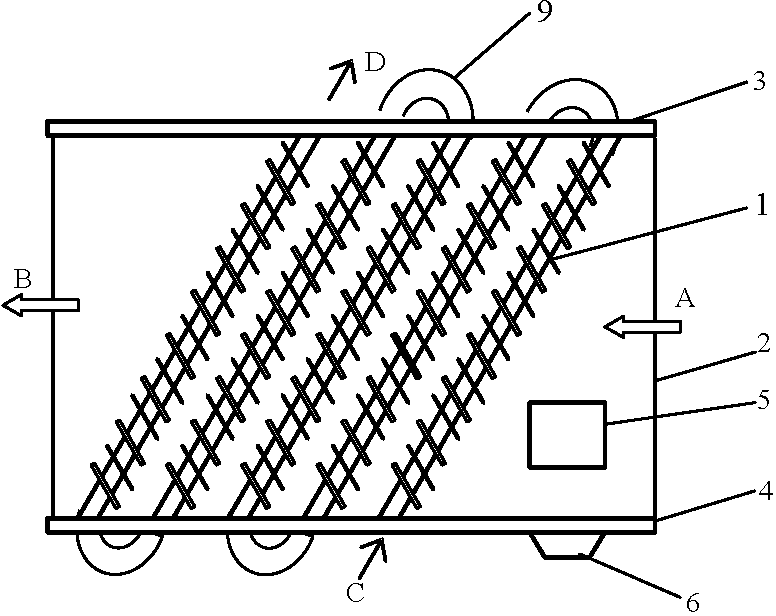

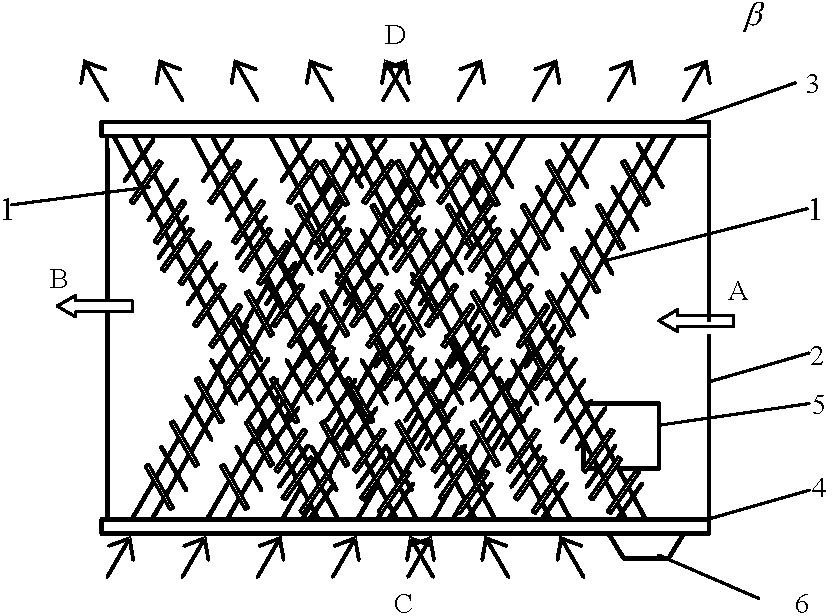

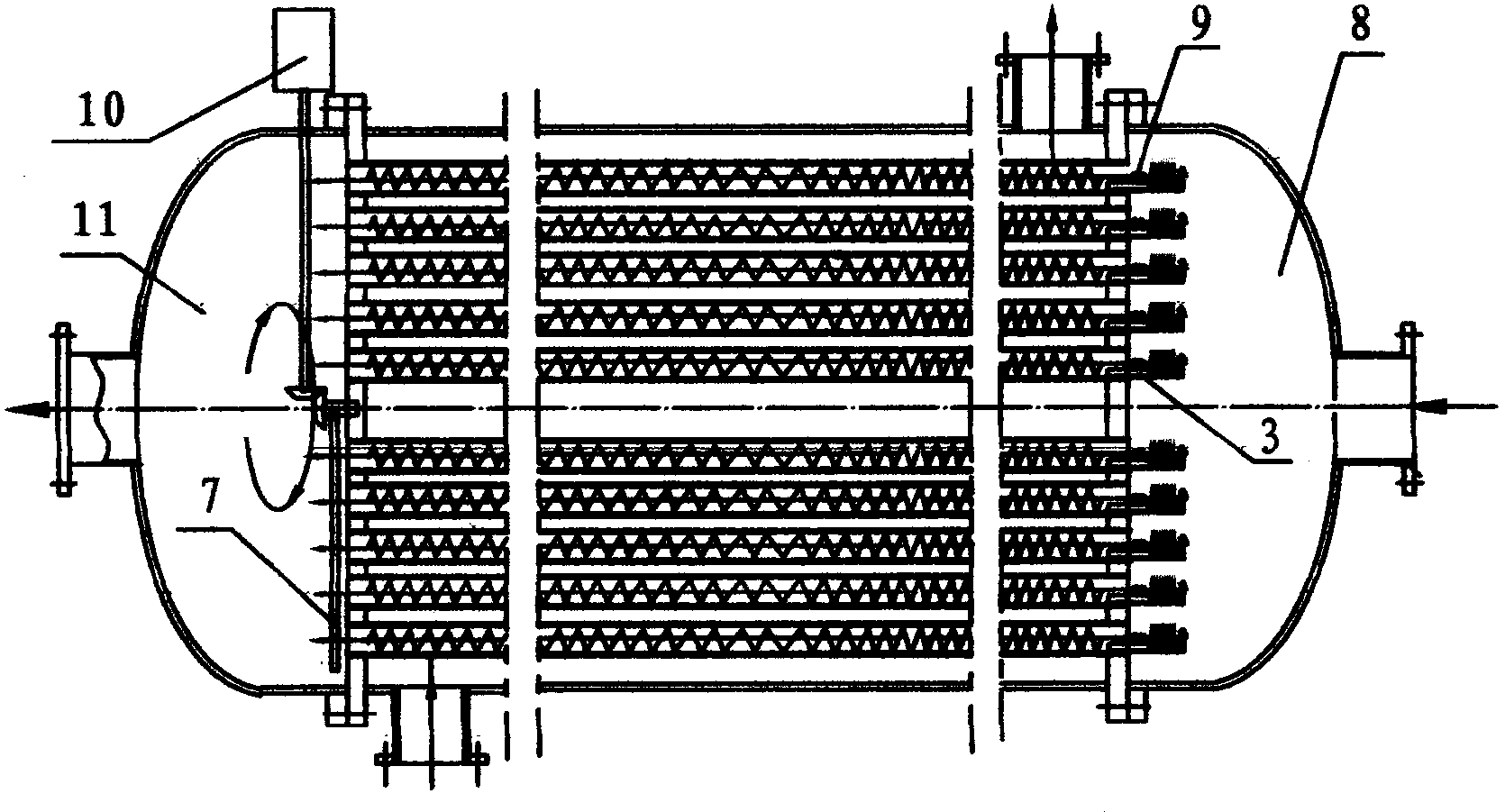

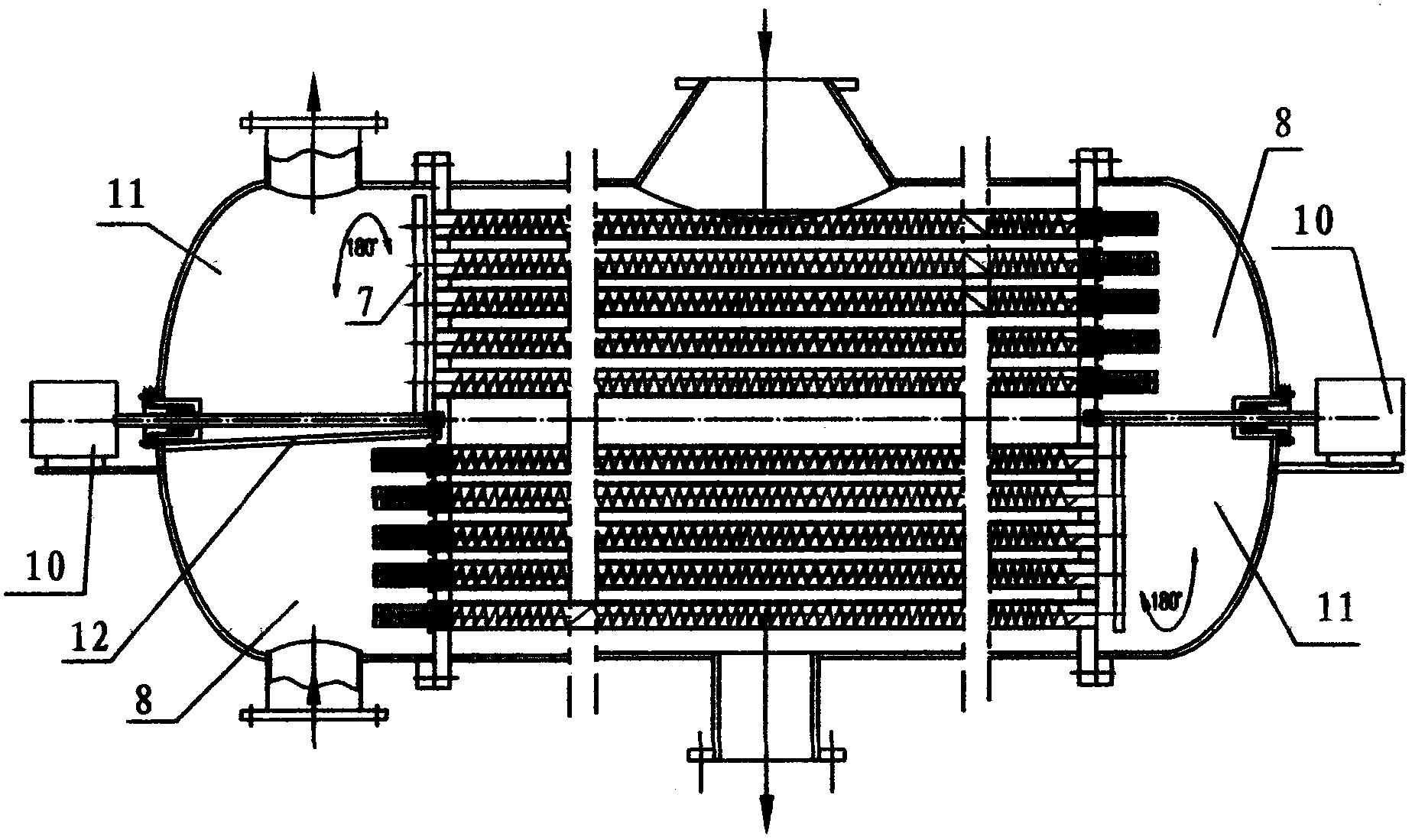

Inclined-fin-tube heat exchanger

ActiveCN103591832AExtended service lifeReduce or avoid operational maintenanceCorrosion preventionStationary tubular conduit assembliesVertical planeEngineering

The invention discloses an inclined-fin-tube heat exchanger. The inclined-fin-tube heat exchanger comprises a heat exchanger shell, tube sheets and a plurality of inclined fin tubes, wherein tube internal medium inlets and tube internal medium outlets are formed in the sides of the tube sheets respectively, a tube external medium inlet and a tube external medium outlet are formed in the two opposite sides of the heat exchanger shell respectively, the inclined fin tubes are arranged in the mode of being inclined from the tube external medium inlet to the tube external medium outlet and / or in the mode of being inclined from the tube external medium outlet to the tube external medium inlet, and the flowing direction of tube external media and the flowing direction of tube internal media are in inclined intersection; or, the inclined fin tubes are set to be of a bent fin tube structure, and the flowing direction of the tube external media and the flowing direction of the tube internal media are in partially inclined intersection and partially perpendicular intersection; or, an inclined angle is formed between the flowing direction of the tube external media and the horizontal plane, and an inclined angle is formed between the flowing direction of the tube internal media and the vertical plane. Compared with the prior art, the inclined-fin-tube heat exchanger has the advantages that the heat exchange effect and the scale prevention effect are good, the frequency of operation maintenance of fin ash blowing through shutdown of the heat exchanger can be reduced, or the operation maintenance of fin ash blowing through shutdown of the heat exchanger can be avoided; the structure is simple, and the service life of the inclined fin tubes can be prolonged.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

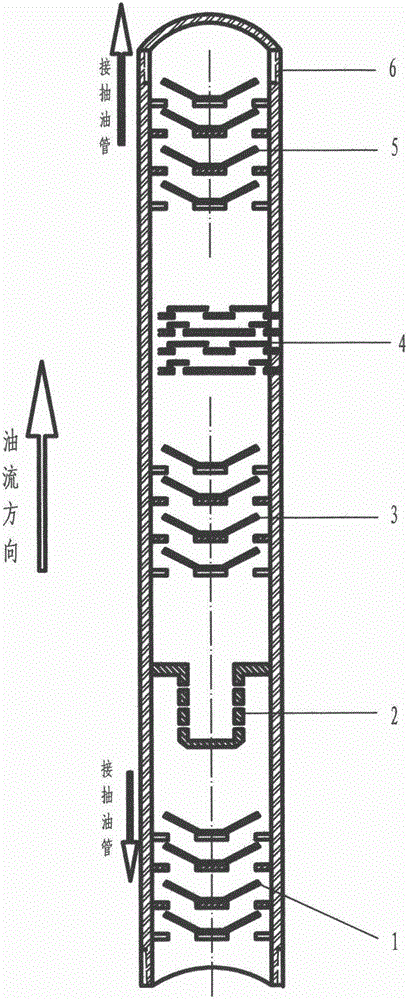

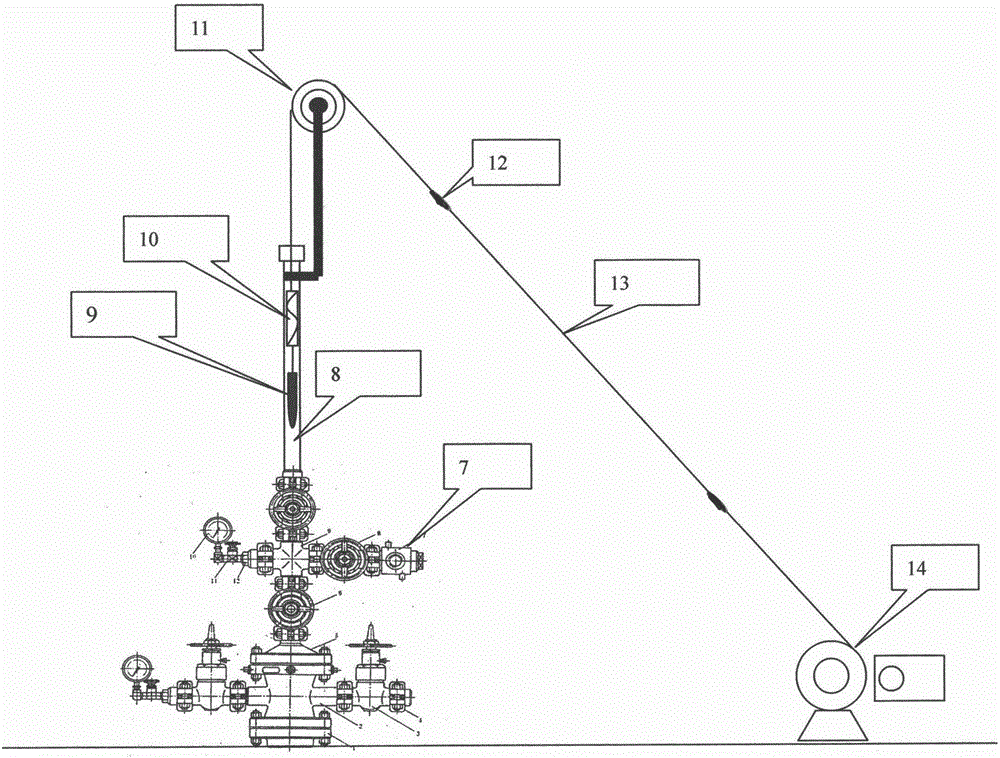

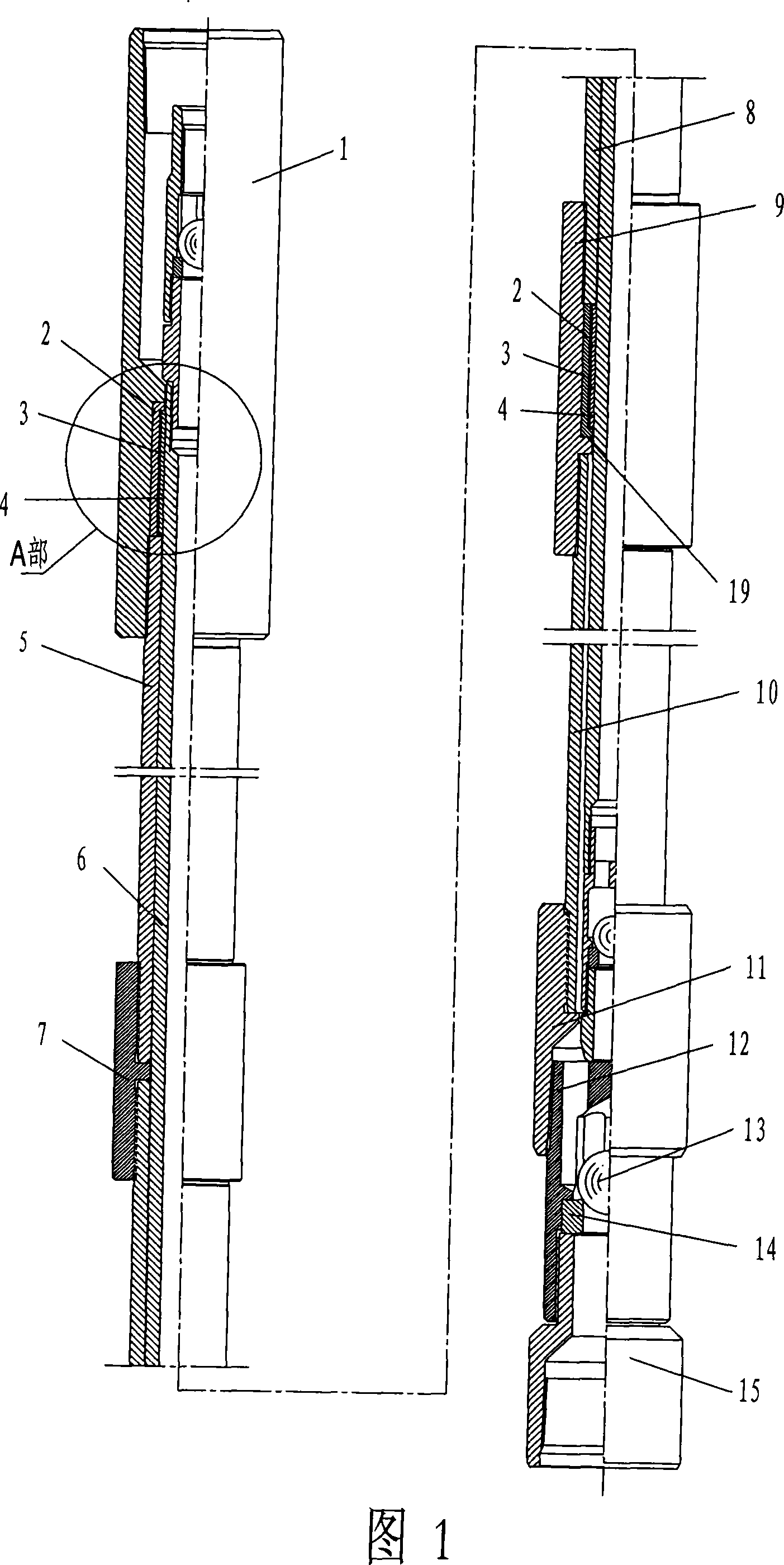

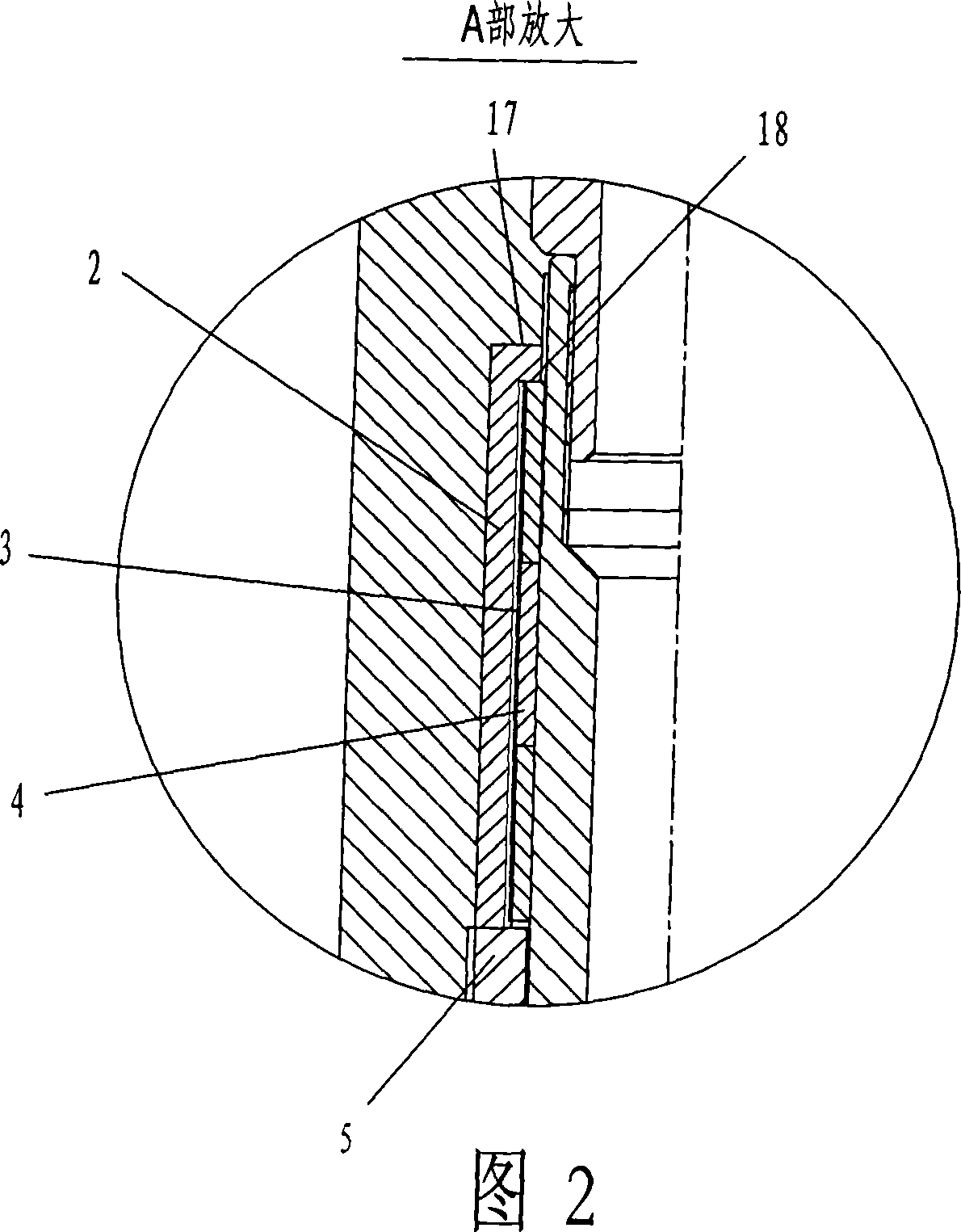

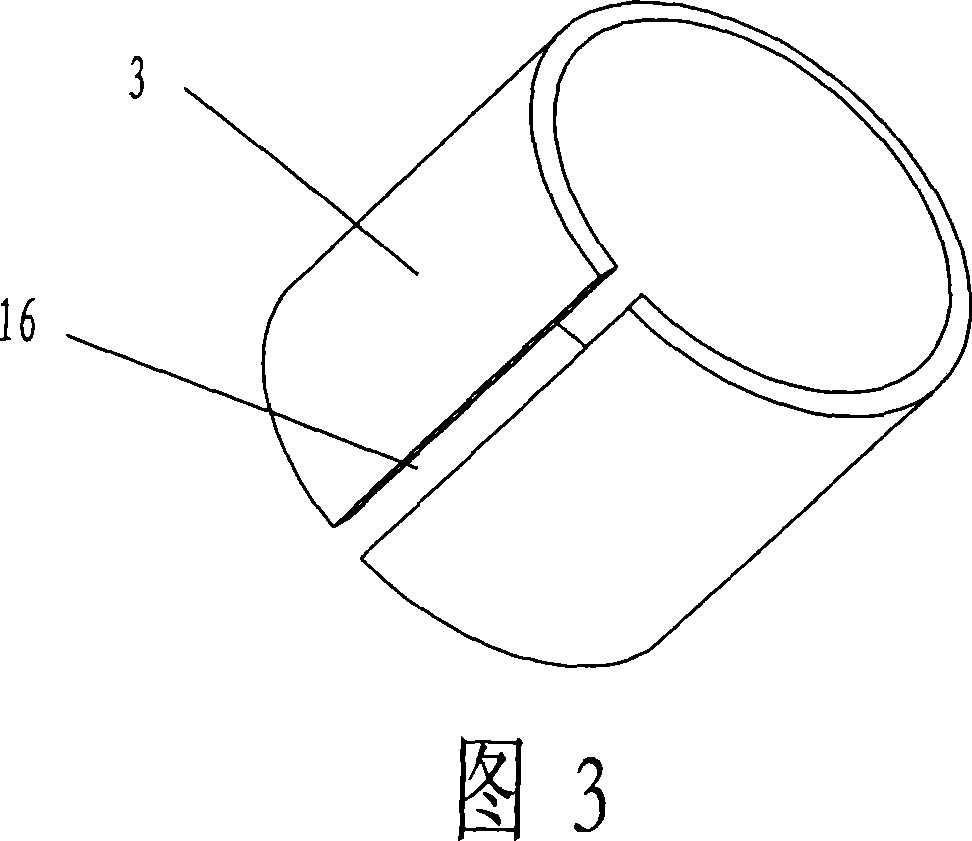

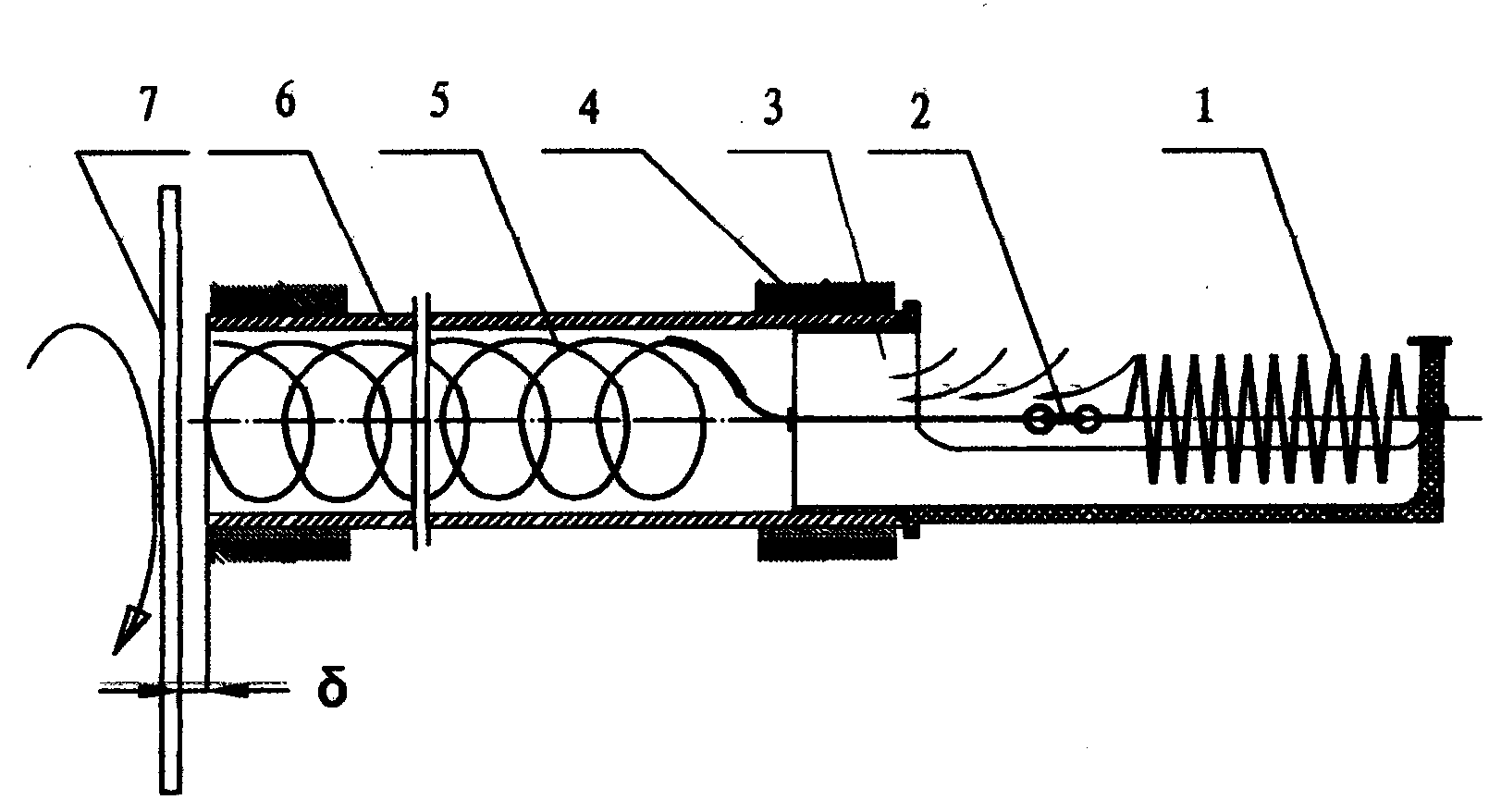

Paraffin-prevention and viscosity-reduction rectifier of oil field flowing well

PendingCN105909204AAchieve decentralizationRealize the shielding effectCleaning apparatusVibration devicesWaxPhase mixing

A paraffin-prevention and viscosity-reduction rectifier of an oil field flowing well is suitable for extracting oil from an oil field high-pressure well, and the long-standing, big and difficult problem that paraffin and scale of a flowing well are scraped and removed through manual work since the beginning of the oil exploitation history is solved. The rectifier is a tubular tool and mounted in the position about one thousand meters under a paraffin-troubled well section of the well. A first-level vortex rectifier body, an impinging stream phase mixing device, a second-level vortex rectifier body, an impact type acoustic oscillator and a third-level vortex rectifier body are mounted in the rectifier from bottom to top, a large-cluster laminar-flow condensed phase state of flowing oil, gas and water can be treated to form a fine-cluster milky eddying turbulence phase state, all heterogeneous components are made to wrap one another, refining, scattering and shielding of paraffin crystals and scale crystals are achieved, the physical state, the physical property, the flow state and the flow speed of produced liquid are optimized, and the phenomenon that the well is blocked by gathered paraffin and scale crystals on the oil tube wall is fundamentally eliminated; and meanwhile, the viscosity of the produced liquid is greatly lowered, the in-well burble procedure is effectively prolonged, manual paraffin and scale scraping and removing are omitted, workover treatment is reduced, oil extraction cost is lowered, and production and efficiency are improved.

Owner:邓海波

Antiscaling alloy oil sucking pump

ActiveCN101074664AIncrease freedomWell formedPositive displacement pump componentsFlexible member pumpsAlloyEngineering

The invention discloses an alloy anti-fouling oil extractor including the short pump canister and long plunger piston. The up connecting hoop is connected to the short pump canister top; which is fixed with the up scraping device; the lower is connected with the down connecting hoop which the lower is connected with the up lengthen pipe which the lower is connected with the up lengthen pipe connecting hoop which is fixed with the down scraping device. The up lengthen pipe connecting hoop lower is connected with the down lengthen pipe which the lower is connected with the lower lengthen pipe hoop which the lower is connected with the fixed valve cover which the lower is connected with the fixed valve seat joint; the alloy welding layer is sprayed on the inner side of the short pump canister, the up lengthen pipe and the down lengthen pipe. The invention can resist the abrasion, the rotten and dirty. The up and down scraping devices and the scraping ring, the valve ball, the valve seat are made by the hard alloy material. The invention can avoid block the pump to improve the using life.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Single-component primer-topcoat ship corrosion and pollution prevention coating and preparation method

InactiveCN109082195AImprove adhesionImprove anti-corrosion performanceAntifouling/underwater paintsPaints with biocidesPollution preventionMaterials science

The invention belongs to a single-component primer-topcoat ship corrosion and pollution prevention coating which is prepared from, by weight, 50-60 parts of modified epoxy resin, 20-25 parts of silicon resin, 15-20 parts of polyester resin, 16-20 parts of phenolic curing agents, 10-15 parts of polyacrylate leveling agents, 3-5 parts of wetting agents, 10-15 parts of titanium dioxide, 0.5-1.5 partsof 2-methylimidazole, 0.5-1.5 parts of benzoin, 3-5 parts of graphene, 4-8 parts of isothiazolinone, 20-25 parts of cuprous oxide, 4-8 parts of sterilizing agents, 2-4 parts of n-zinc oxide, 20-25 parts of n-ferrite and 15-20 parts of wollastonite powder. The coating has high adhesive force and high salt water and salt fog corrosion resistance and is good in weather resistance and high and low temperature resistance, and the coating serves as a corrosion and pollution prevention coating of a ship armor.

Owner:孟鋆辉

Ultra-light resin lens and manufacturing method thereof

InactiveCN106483587AImprove image qualityImprove wear resistanceOptical elementsImaging qualityMegasonic cleaning

The invention discloses an ultra-light resin lens and a manufacturing method thereof. The ultra-light resin lens comprises a lens body; a film coating structure is arranged on the surface of the lens body; and the film coating structure comprises a wear-resisting layer, an ultraviolet absorbing layer, an antireflection film layer and an antifouling film coating layer sequentially from inside to outside. The lens manufacturing method comprises the following steps: 1) the resin monomer and the accessories are stirred, mixed, filtered and cast at a constant temperature; 2) heating and curing are carried out; 3) cleaning and finishing are carried out; 4) ultrasonic cleaning is carried out; 5) annealing processing is carried out; 6) checking is carried out; 7) the antireflection film layer is coated; and 8) a finished product is packaged when qualification is realized. The ultra-light resin lens and the manufacturing method thereof have the beneficial effects that the resin lens is high in imaging quality and clear in imaging; the wear-resisting performance of the resin lens is greatly improved; the lens can be protected from being scratched easily; the use effects of the lens are improved; the service life is prolonged; after the antifouling film coating layer is added, the antifouling effects are good, and stains such as a fingerprint and hand scale left on the surface of the lens substrate can be avoided; and wearing by the user is more comfortable and safe.

Owner:江苏凯越眼镜有限公司

Detergent

InactiveCN102020362AReasonable compositionGood antifouling effectScale removal and water softeningALLYL SUCROSEMirabilite

The present invention discloses a detergent, which is prepared by mixing trisodium phosphate, sodium carbonate, polyacrylic acid, hydrogen peroxide, valonea extract and mirabilite. The invention has advantages of low production cost and good descaling effect.

Owner:刘文军

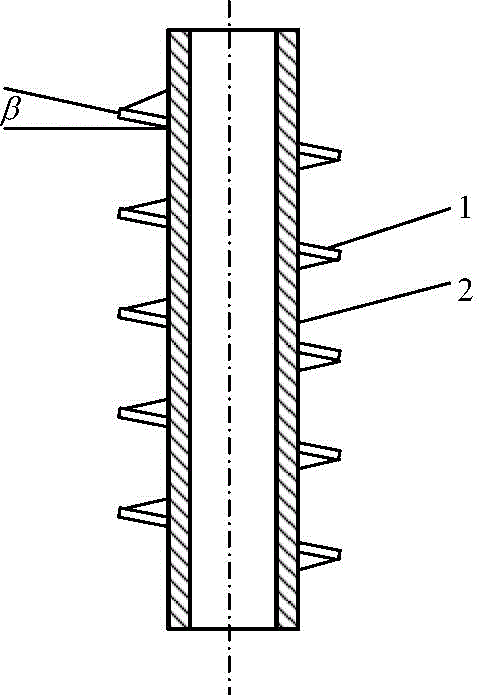

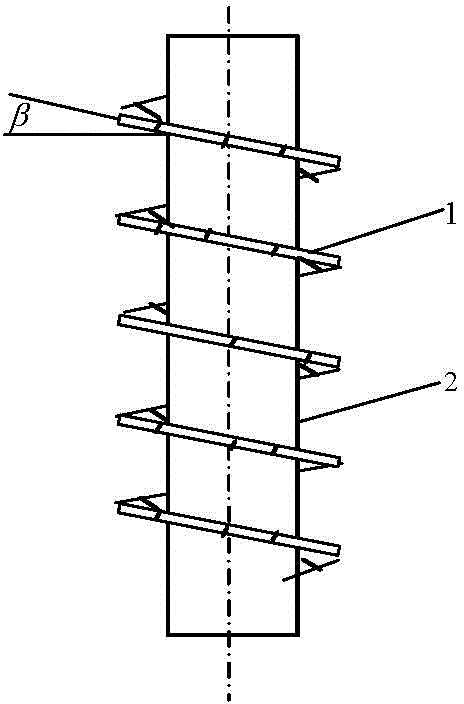

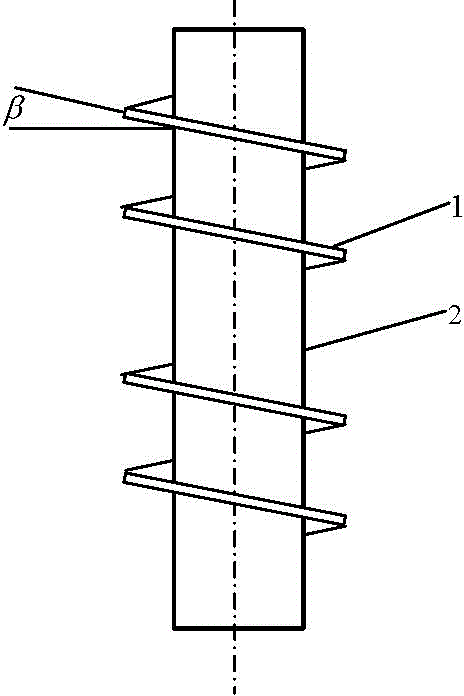

Slant finned tube

ActiveCN103557736AExtended service lifeReduce or avoid operational maintenanceTubular elementsEngineeringMechanical engineering

The invention discloses a slant finned tube. A plurality of fin bodies comprise slant planes and fin center holes formed in the inner sides of the slant planes, and the plurality of fin bodies are inclined to the outer wall surface of a base tube and continuously or intermittently arranged in a surrounding manner in the axial direction of the base tube; or the fin bodies comprise umbrella-shaped bodies and fin center holes formed in the middles of the umbrella-shaped bodies, and the outer wall surface of the base tube is tightly sleeved with the fin bodies through the fin center holes; or the fin bodies comprise slant ring-surface fins and flanging arranged at the end parts of the slant ring-surface fins, the outer wall surface of the base tube is sleeved with the slant ring-surface fins through inner rings, and the slant ring-surface fins are tightly connected with the outer wall surface of the base tube. After the slant finned tube is used, smoke ash or air dust can slide from the slant planes of the fins and cannot be accumulated, so that the scale prevention effect is good, long-term stable and effective heat transfer effect is maintained, and conditions of frequent shutdown caused by dust removal of the heat exchanger and operational maintenance for blowing fin ash can be reduced or avoided; and meanwhile, the slant finned tube has the characteristics that the structure is simple and the service life of the finned tube is prolonged.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Device for automatic cleaning of hard scale in heat exchange tubes

ActiveCN103542767ASimple structureLow fluid resistanceRotary device cleaningReciprocating motionContinuous rotation

The invention discloses a device for automatic cleaning of hard scale in heat exchange tubes. According to the device for automatic cleaning of the hard scale in the heat exchange tubes, a steel wire cleaning helix in each heat exchange tube is installed on an inlet fixing frame or on a fixing hole plate of an inlet pipe box after being connected with a soft tightening spring in series. The steel wire cleaning helix vibrates violently in the radial direction when the device operates, and then the hard scale and crystal salt scale can be removed violently. A rotary stop vane or a stop vane which swings and rotates back and forth which is driven by a power head or a power blade is installed in an outlet pipe box, outlet resistance is increased sharply when the stop vane skims over an outlet of each heat exchange tube, the flow rate inside each tube is decreased greatly, and the tightening spring contracts to drive the steel wire cleaning helix to retract and move by a distance which is larger than the length of the screw pitch of the steel wire cleaning helix. The uniformity of scale cleaning is effectively improved due to the reciprocating motion of the steel wire cleaning helix. The steel wire cleaning helix also serves as a convective heat transfer augmentation element inside the corresponding tube, and the heat transfer augmentation amplitude is more than one time that of a continuous rotation steel wire helix. Therefore, the device for automatic cleaning of the hard scale in the heat exchange tubes has the advantage that continuous and efficient operation of heat-transfer equipment (such as evaporators, crystallizers and condensers) can be guaranteed for a long time.

Owner:浙江建装工程技术研究有限公司

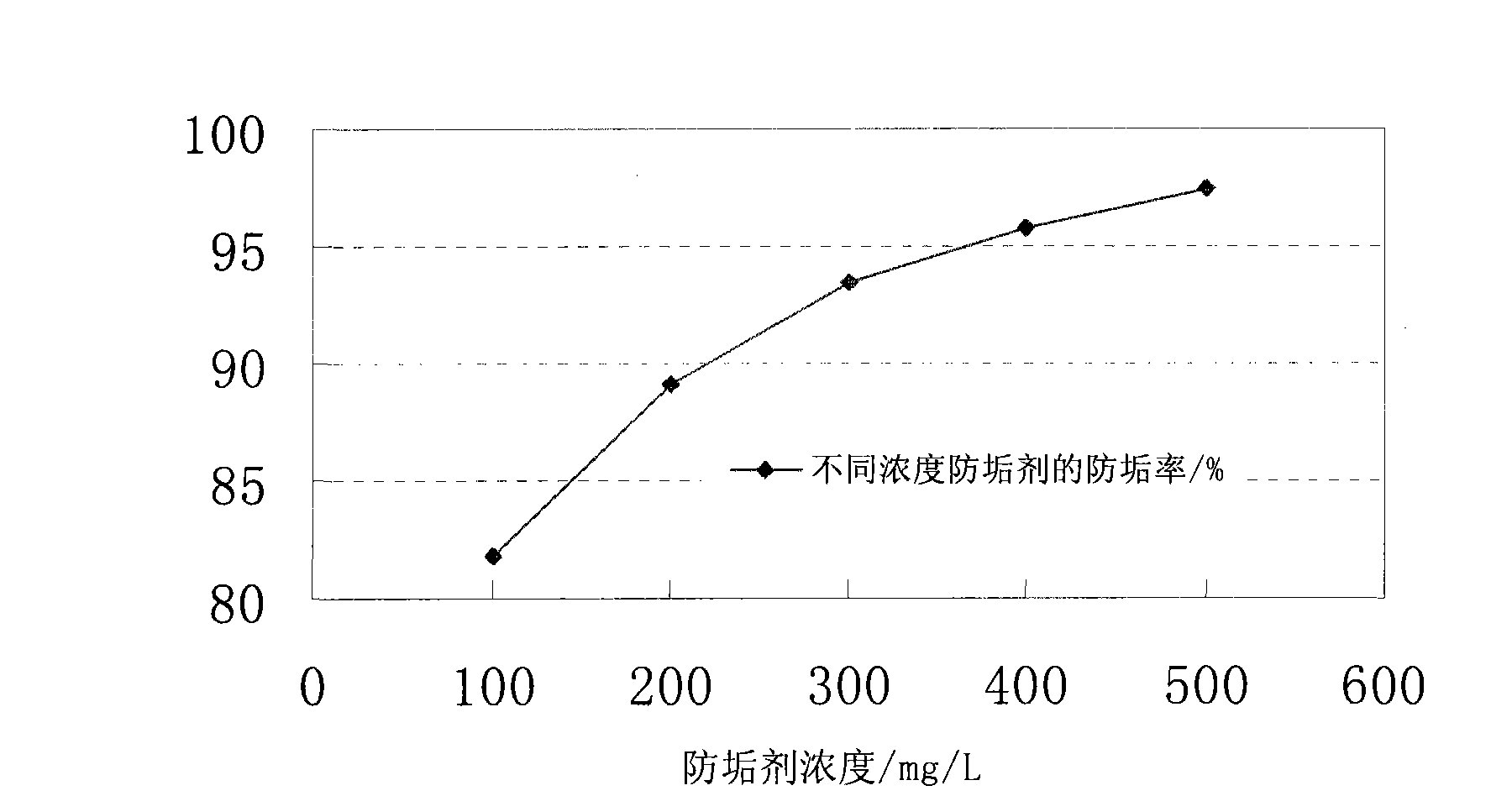

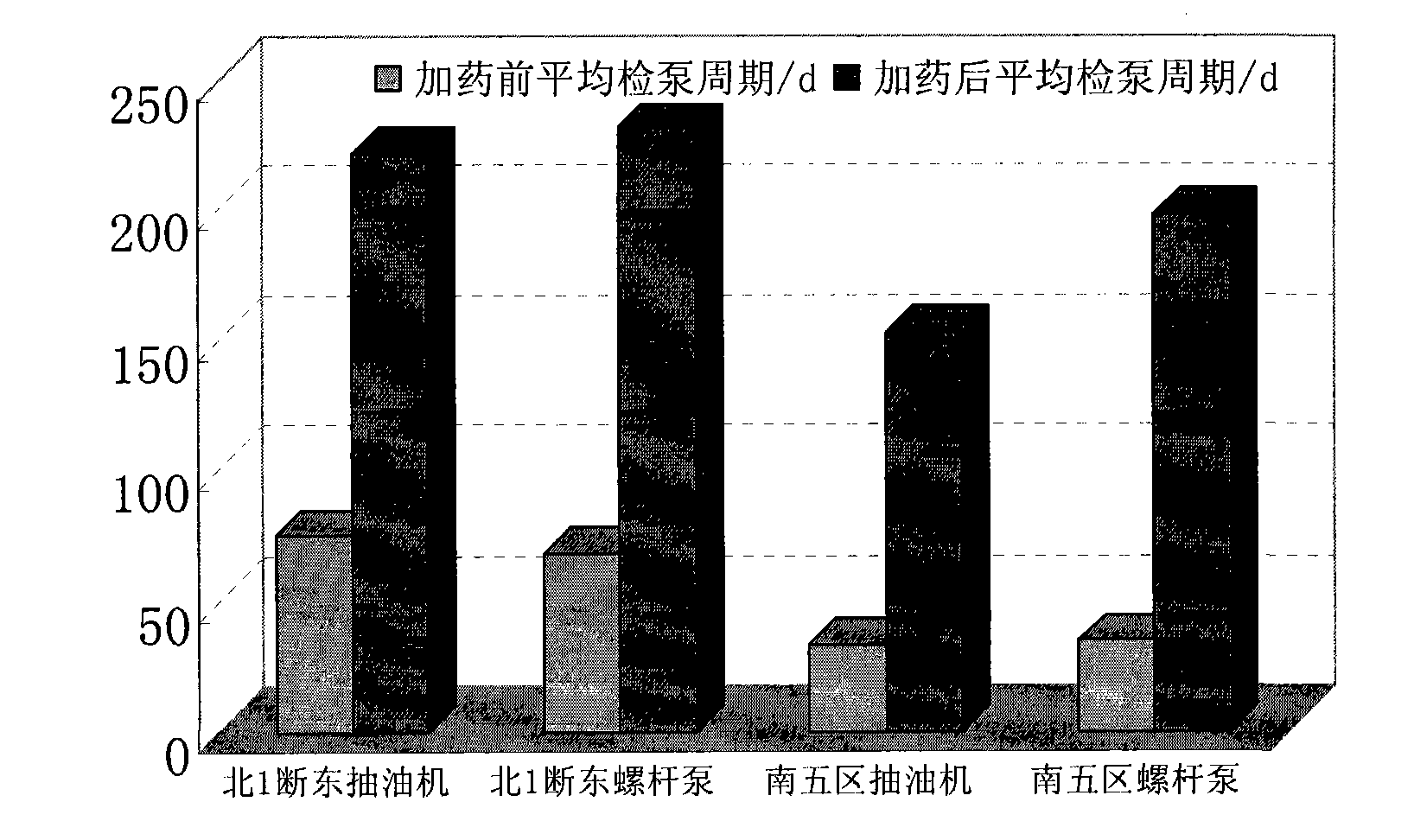

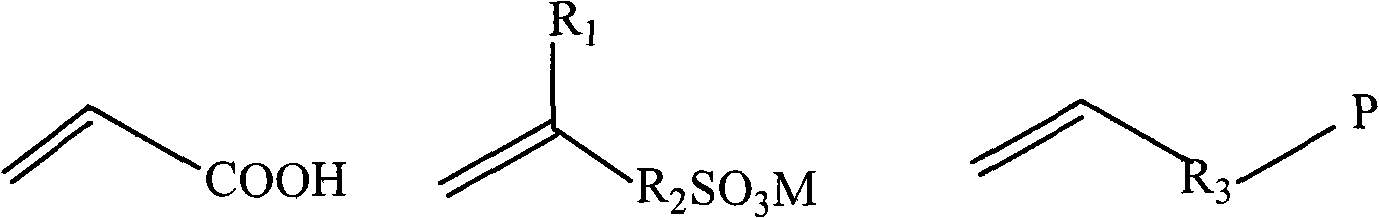

Anti-scaling agent for oil well silicate scale

ActiveCN101665684AIncrease the use concentrationLow anti-fouling rateDrilling compositionCompound aSide chain

The invention discloses an anti-scaling agent for oil well silicate scale. The anti-scaling agent is prepared by compounding a component A, a component B and water according to the mass ratio of 1:1:2, wherein the component A represents random terpolymer the side-chain of which has carboxylic acid, sulfonic acid and carboxylic acid ester functional groups, and the component B represents phosphinocarboxylic acid compound containing a phosphoric acid group-PO(OH)2 and a carboxylic acid group-COOH. The invention is applied to the scaling prevention of a strong base ASP flooding block productionwell, efficiently prevents the silicate from scaling at a pump, a bar pipe and the like, reduces the frequency of operation because of scaling and prolongs the pump inspection period of the productionwell.

Owner:PETROCHINA CO LTD +1

Preparation method for marine microorganism antifouling paint

InactiveCN104927546AImprove migration efficiencyHigh migration efficiencyAntifouling/underwater paintsPaints with biocidesWater basedOxygen

The invention discloses a preparation method for a marine microorganism antifouling paint. The paint is prepared from the following components in parts by weight: 20-80 parts of ABS rubber powder, 10-79 parts of AS resin I, 1-10 parts of water-based color paste, 0.5-5 parts of a chemical resistant modifier, 5-25 parts of a heat resistant, 0.1-1 part of an oxygen agent, 0.1-1 part of a lubricant, 10-20 parts of a silane coupling agent, 0.1-2 parts of a plastifying accelerant, 10-20 parts of a flatting agent, 4-6 parts of an antifreezing agent, 0.1-0.2 part of a defoamer, 10-20 parts of deionized water, 1-10 parts of inorganic nanoparticles, 10-15 parts of a marine biofilm, 10-15 parts of dinoflagellate, 10-15 parts of dunaliella salina, 5-10 parts of barnacle and 5-10 parts of mussels. The preparation method disclosed by the invention is simple and convenient in process, low in production cost and good in antifouling effect, has certain corrosion resisting and heat resisting properties, and is free of environmental pollution.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Seawater/fresh water biofouling preventing method using high-voltage pulsed electric field

InactiveCN103865307AGood antifouling effectReduced Conductivity RequirementsVessel cleaningHullsHigh resistanceEngineering

The invention relates to the seawater / fresh water biofouling preventing field, in particular to a method for preventing facilities from seawater / fresh water biofouling via the damage of high-voltage electric field to organisms by applying a high-voltage pulsed electric field to a high-resistance conductive coating. The conductive coating layer is wired to a high-voltage pulse power supply, so that the applied high-voltage electric field acts on the high-resistance conductive coating, sterilization and anti-fouling operations are carried out under the applied voltage electric field, the peak of the applied high-voltage pulse voltage is 1000V-50000V, time of each acting is more than 0.001 second. The surface of the conductive coating can be insulated, i.e., no current is required to pass through seawater or freshwater. A metal surface needs to be insulated before the conductive coating is applied to the metal surface. The method is applied to prevention and control of biofouling of marine facilities and ships, is capable of effectively killing microbes on the surfaces of materials, preventing the formation of microbial membranes and inhibiting the attachment of algae and macro-organisms such as barnacles.

Owner:HAINAN UNIVERSITY +1

Temperature-resistant type barium strontium sulfate anti-scaling agent for oil field and preparation method thereof

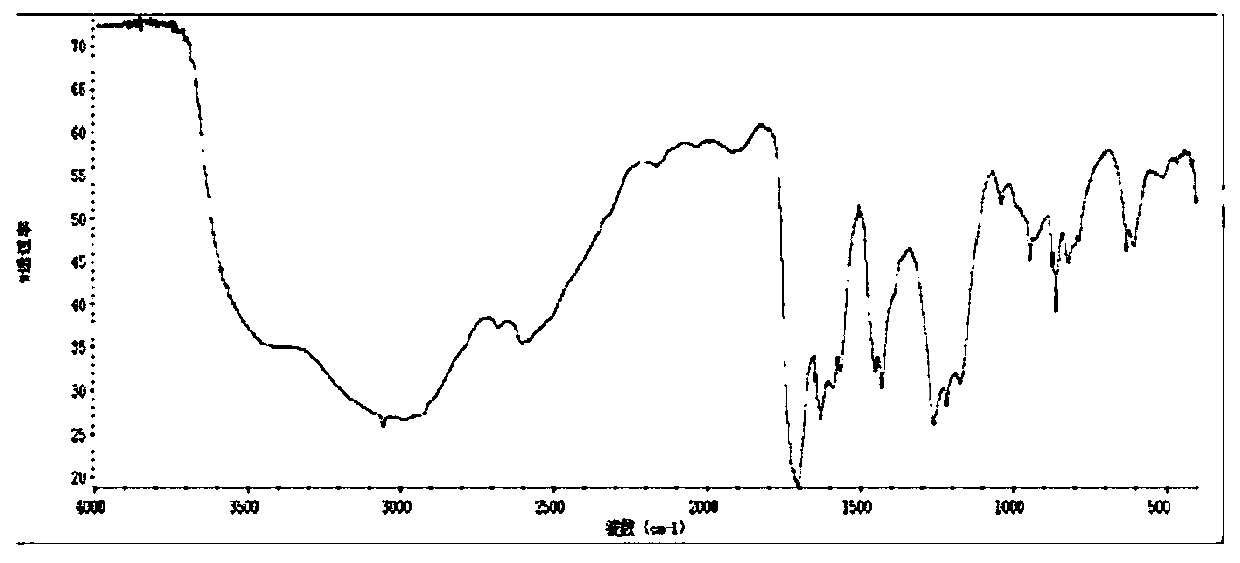

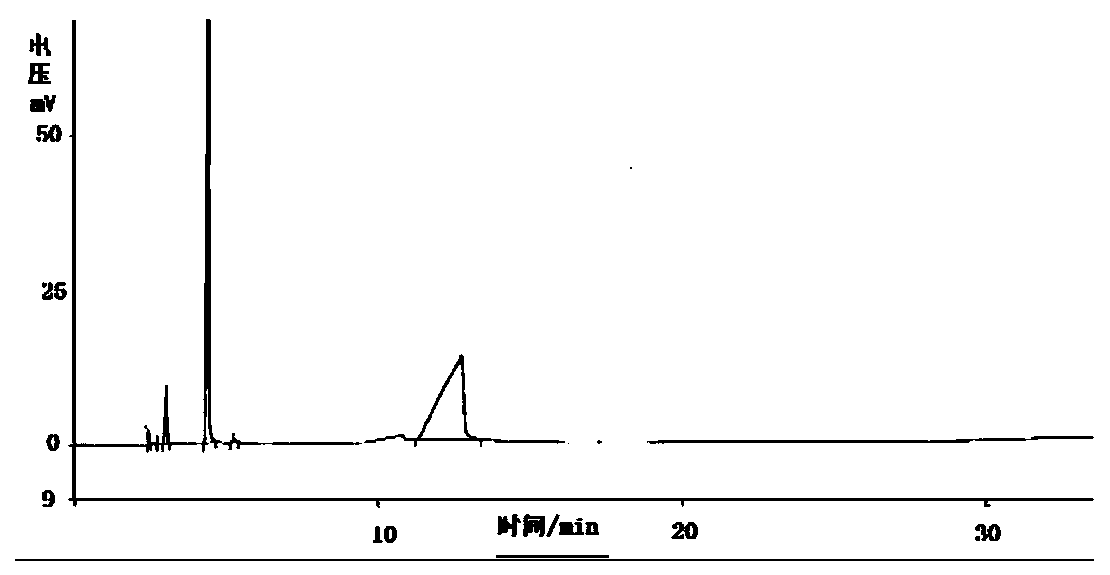

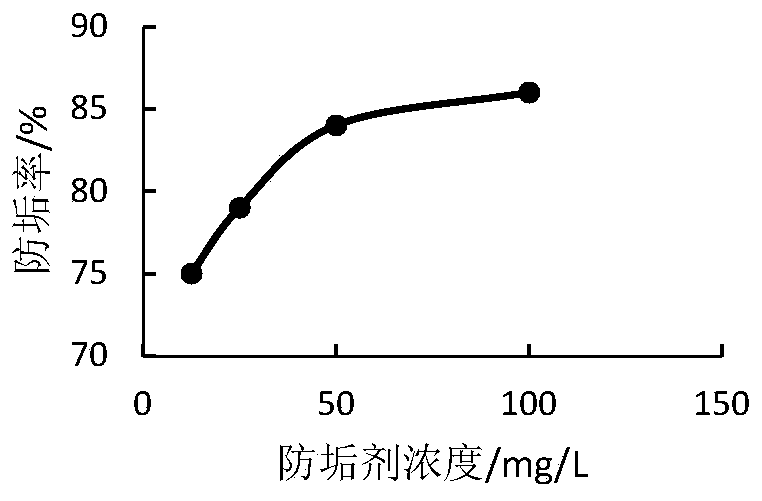

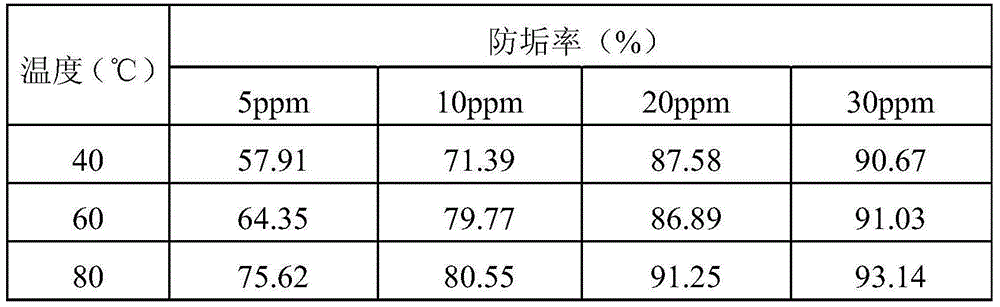

ActiveCN109748405AGood antifouling effectMaintain anti-fouling rateWaste water treatment from quariesScale removal and water softeningSynthetic monomerMaleic anhydride

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Scale inhibitor and preparation method thereof

ActiveCN104591412AGood antifouling effectInhibition formationScale removal and water softeningDiluentStrontium

The invention discloses a scale inhibitor and a preparation method thereof. The scale inhibitor disclosed by the invention is composed of modified polyepoxysuccinic acid, organic phosphonate and a diluent, wherein the mass ratio of the modified polyepoxysuccinic acid to the organic phosphonate to the diluent is (1.0 to 1.5): (1.5 to 2.0): (7.0 to 7.5). The preparation method comprises the following steps: mixing the modified polyepoxysuccinic acid, the organic phosphonate and the diluent to obtain the scale inhibitor. The scale inhibitor solution disclosed by the invention has the beneficial effects that scale inhibiting effect is good and inorganic scales such as calcium, magnesium, strontium and barium are effectively prevented from being formed; the adsorption amount of the scale inhibitor solution disclosed by the invention is low; during a process of injecting the scale inhibitor solution in a stratum, a small amount of the scale inhibitor solution is only adsorbed by minerals in the stratum, so that the utilization efficiency of the scale inhibitor can be effectively increased; the scale inhibitor solution disclosed by the invention is long in acting distance, long in validity period, and capable of reducing a construction frequency to achieve the purposes of reducing a cost and improving effects.

Owner:CHINA NAT OFFSHORE OIL CORP +1

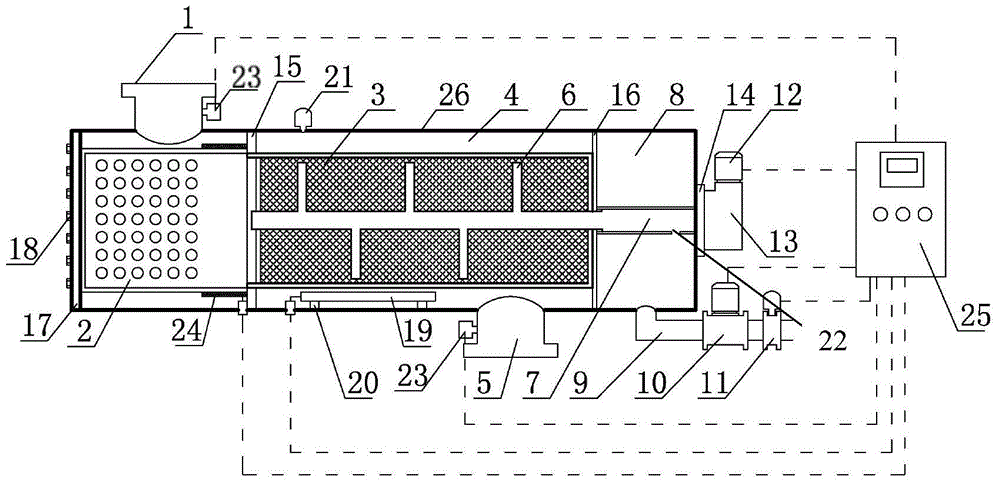

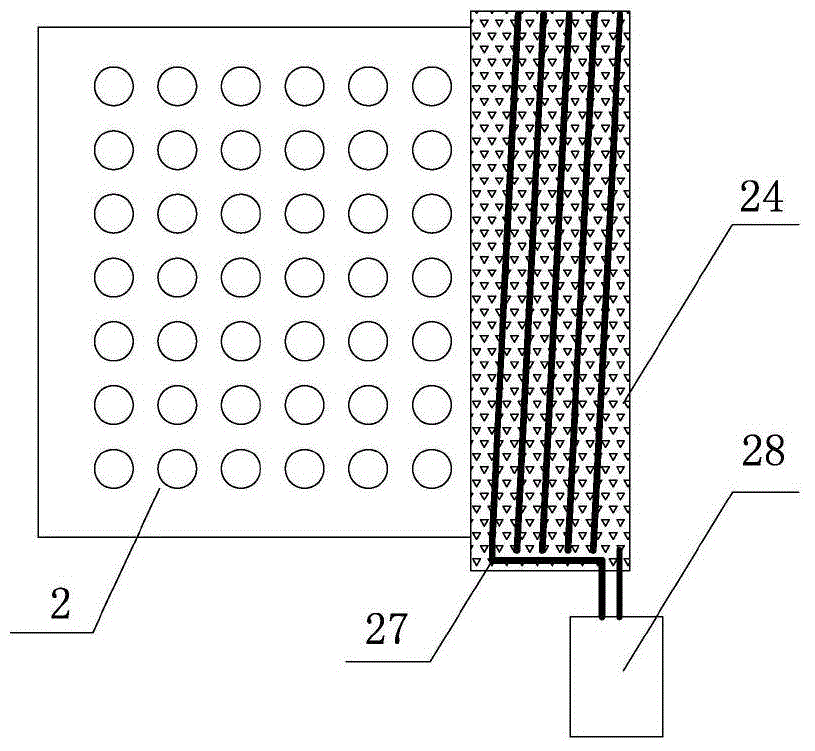

Anti-scale method and device of filter used in ship ballast water management system

ActiveCN104973719AReduce backwash frequencyReduce dosageMultistage water/sewage treatmentStationary filtering element filtersControl systemWater filter

The invention discloses an anti-scale method and device of a filter used in a ship ballast water management system. The device comprises a coarse filter screen, a fine filter screen, a back-washing unit, a sewage discharge unit, and a control system; the coarse filter screen, a first partition plate, the fine filter screen, another partition plate, and the sewage discharge unit are horizontally arranged in the filter cavity; a control unit is part of main control equipment; the first partition plate between the fine filter screen and the coarse filter screen and the filter cavity form a filtering cavity, a water inlet is arranged on the filter shell, is above the coarse filter screen, and is communicated with the filter cavity; and a water outlet is arranged in the filter shell and is communicated with the filtering cavity. The device also comprises a variable-frequency processing unit, which is composed of a signal generator controlled by the control system and electromagnetic coils, and the electromagnetic coils are winded around the coarse filter screen. The provided anti-scale method and device solve the problem that conventional ship ballast water filter is easily obstructed during the application process, and the anti-scale device has the advantages of high integration level, small volume, and high intelligentization degree, and can meet the application requirements of a ship ballast water management system.

Owner:SUNRUI MARINE ENVIRONMENT ENG

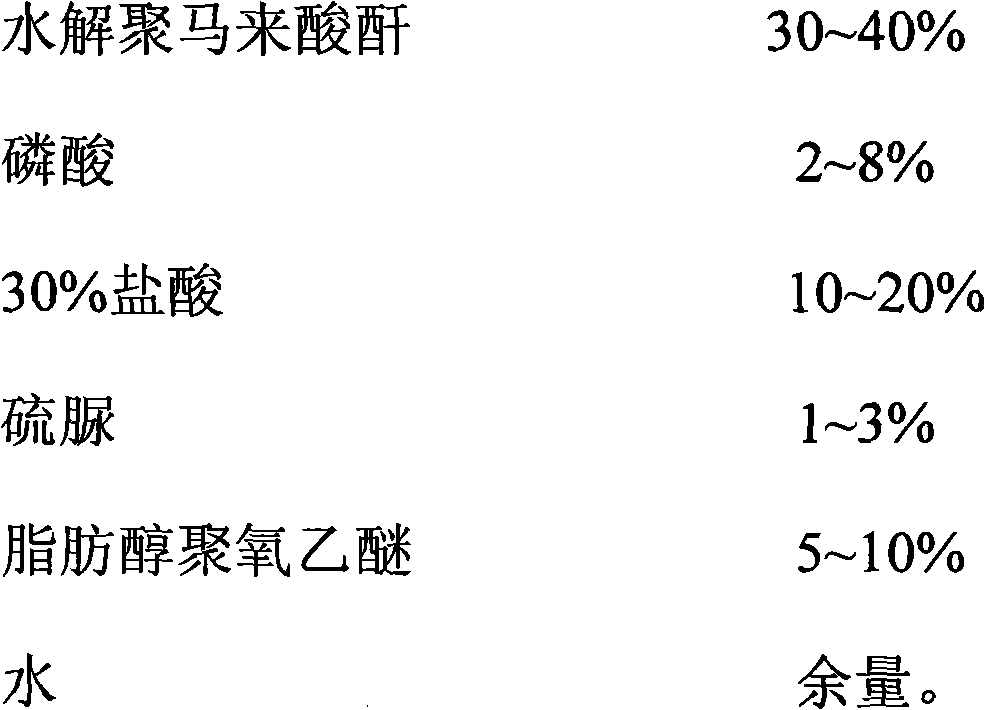

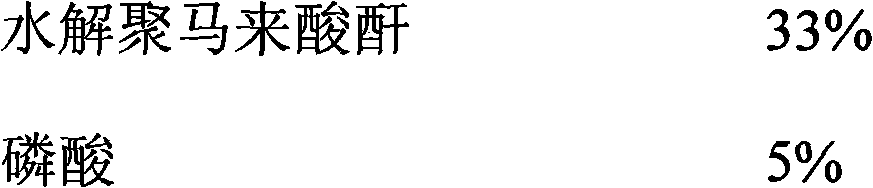

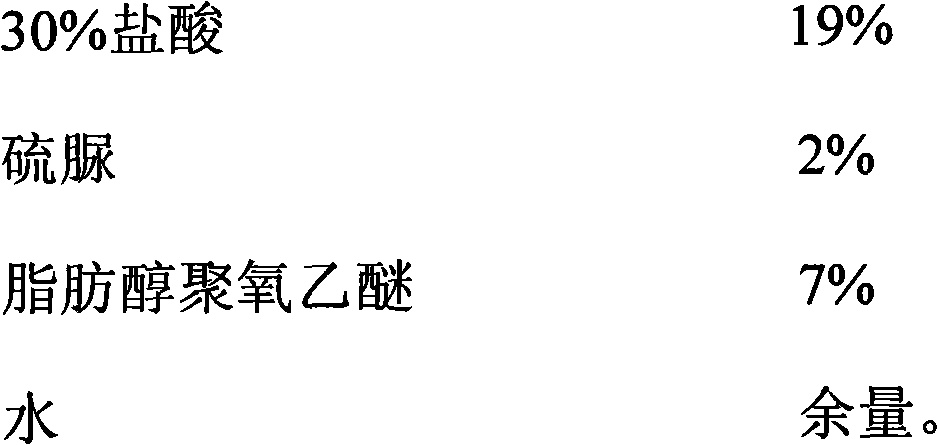

Multifunctional cleaning scale remover

InactiveCN102041200AReasonable compositionGood antifouling effectOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsPhosphoric acidPolymaleic anhydride

The invention discloses a multifunctional cleaning scale remover, which is prepared by mixing hydrolytic polymaleic anhydride, phosphoric acid, 30 percent hydrochloric acid, thiourea, fatty alcohol polyoxyethylene ether and water. The multifunctional cleaning scale remover is low in production cost and good in scale removing effect.

Owner:陆立新

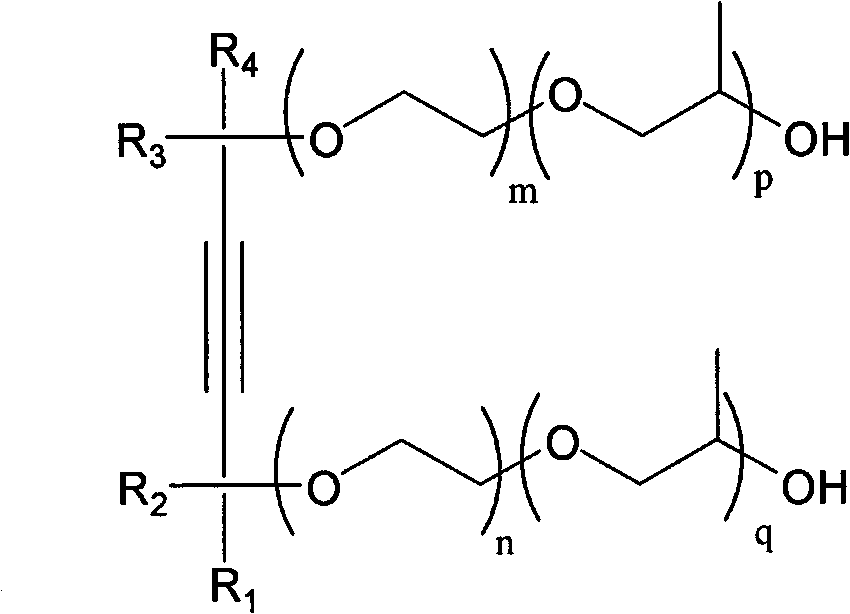

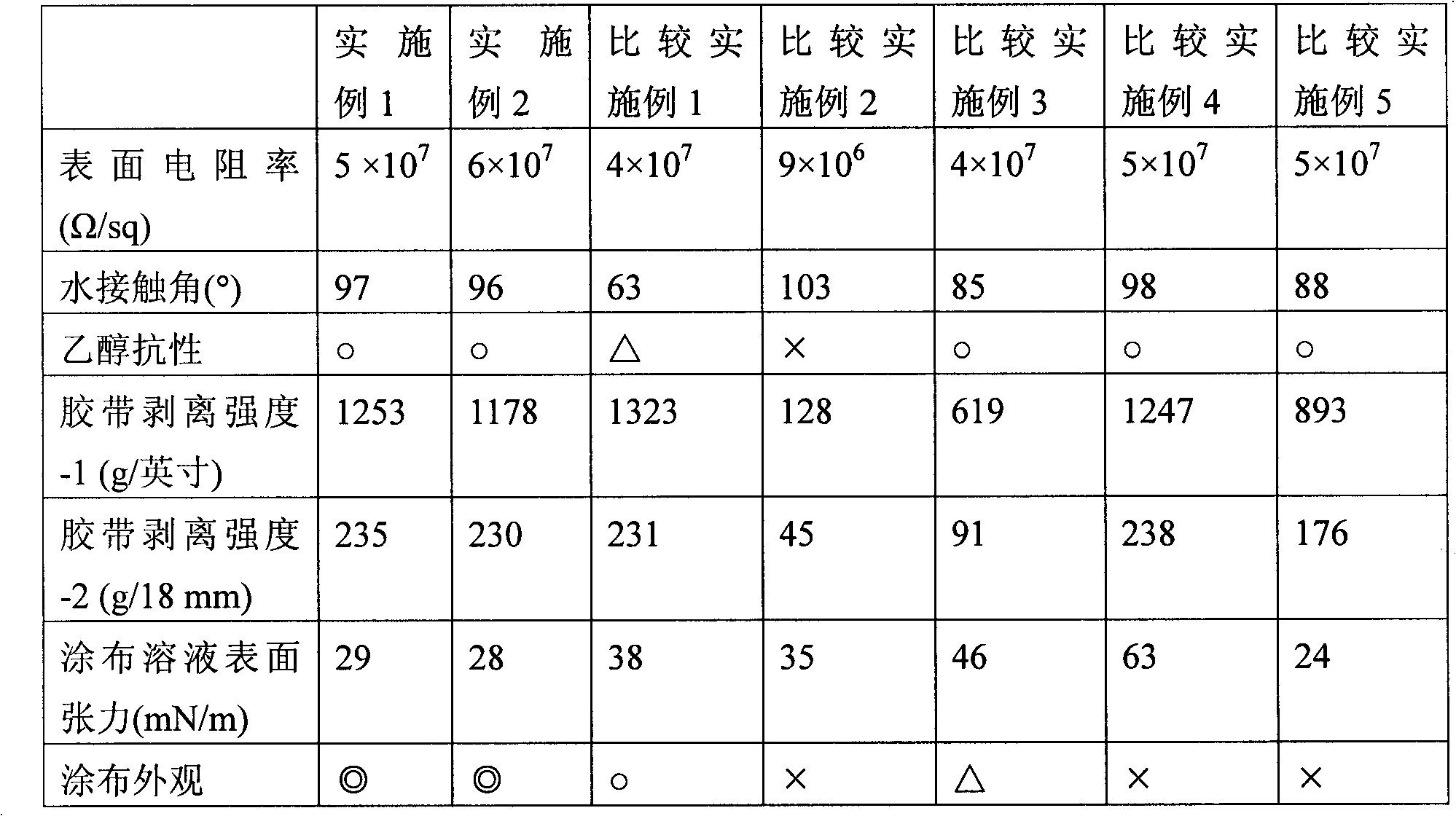

Antistatic polyester film with acetylenediol surfactant and preparing method thereof

InactiveCN101921540AControl Anti-Scale PerformanceControl Peel StrengthPolyurea/polyurethane coatingsElectrically-conductive paintsCross-linkPolyester

The invention provides an antistatic coating composition for reducing coating defects, wherein the composition comprises, by weight, 100 parts of conductive polymer resin, 100-1000 parts of water dispersive polyurethane resin composed of anionic polyether polyurethane dispersion which contains at least one functional group selected from the following group of hydroxyl, amine, alkyl and carboxyl, 100-1000 parts of any cross-linking agent resin selected from the following group of isocynate, carbonyl imide, oxazoline and melamine compound, and 10-100 parts of fluororesin. The composition also comprises 0.001-1 parts of acetylenediol surfactant on the basis of 100 parts of all the said component resin. In addition, the invention provides an antistatic polyester film, which is prepared by coating the antistatic coating composition on one side or two sides of a polyester film during the in-line coating process. The antistatic polyester film is excellent in the tape peel force, the anti-scaling property and the solvent resistance and the physical property of the antistatic polyester film do not become worse significantly due to the property of the surfactant.

Owner:TORAY ADVANCED MATERIALS KOREA

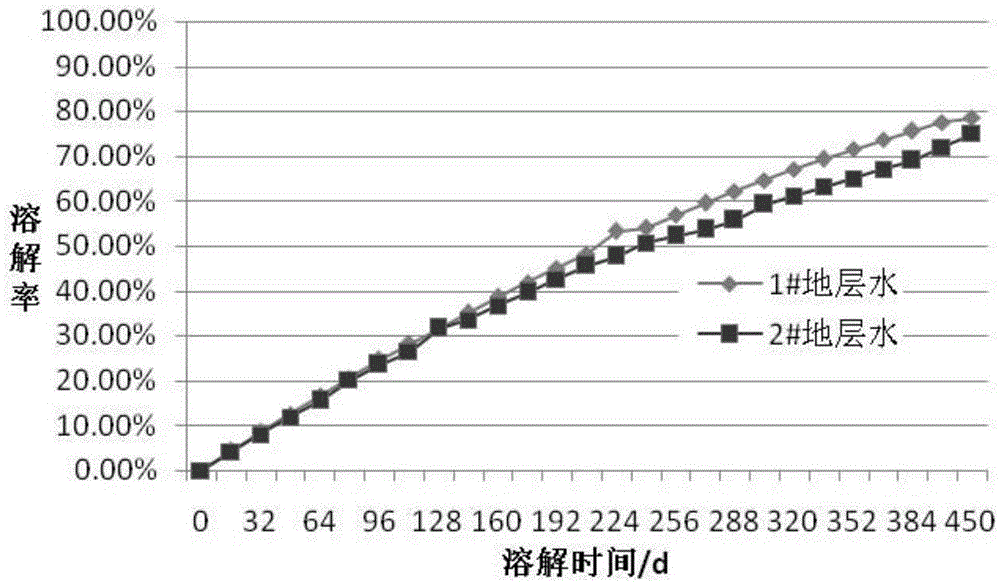

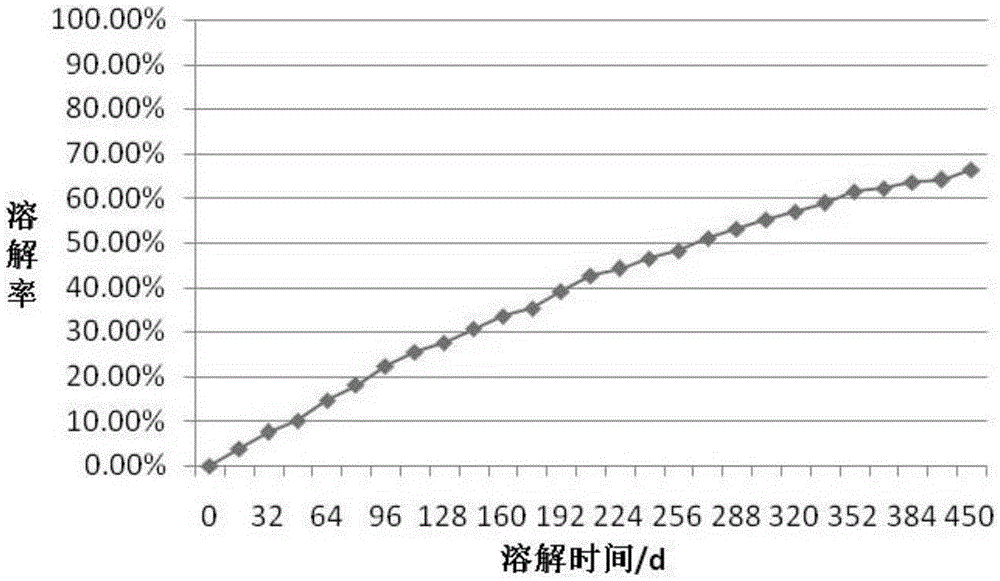

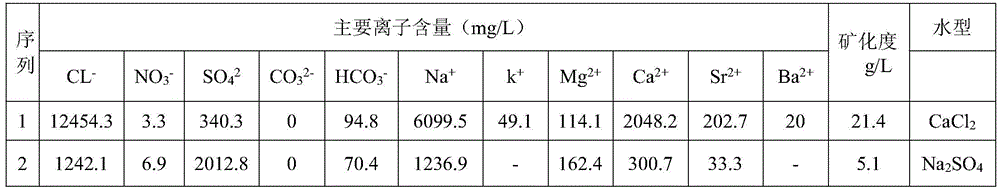

Scale inhibitor formula for intraformational multi-crack fracturing for oilfields and preparation method

ActiveCN105602539AGood compatibilityExpand the scope of actionDrilling compositionAdhesiveRelease time

The invention provides a scale inhibitor formula for intraformational multi-crack fracturing for oilfields. The scale inhibitor formula comprises, by weight, 30-50% of coating agent, 45-65% of scale inhibitor and 2-5% of adhesive. The scale inhibitor is high in compatibility and applicable to formation water of formations at different temperatures and in different ranges of pH and mineralization degree; the acting range is large, the antiscale radius can be enlarged, the valid period of scale prevention is prolonged, and all-sided scale prevention for immediate vicinity of wellbores, production wellbores and surface pipelines is achieved; the release time is long, the dissolving time in oil and water is more than 400 days, the scale-inhibition effect is good, and the scale inhibition rate reaches over 92.2%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

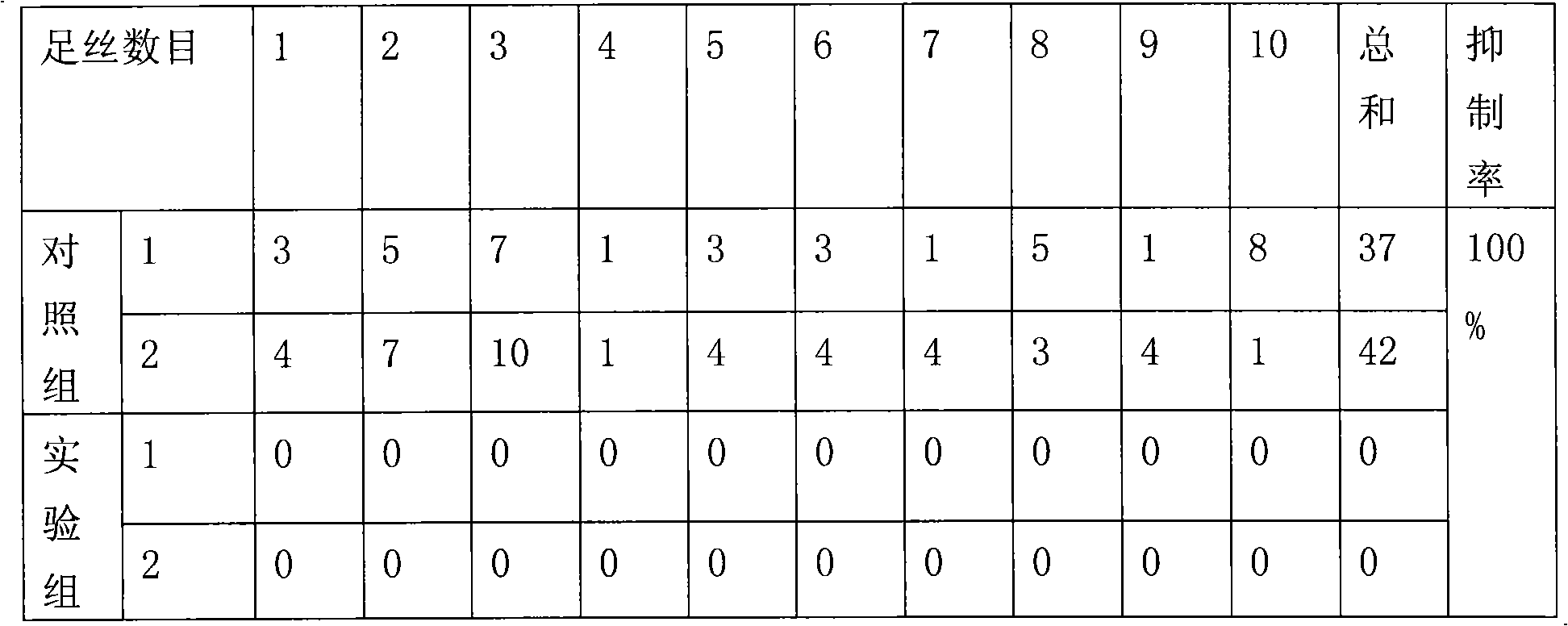

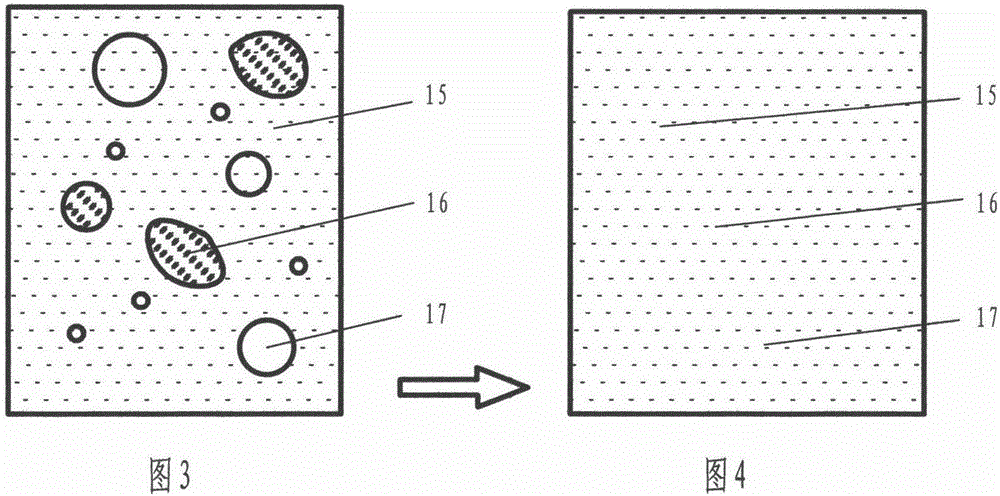

Preparation method of cylindrical box body with antifouling property for deep and open sea net cage

ActiveCN111657197AGood antifouling effectAntifouling effectiveElectroconductive/antistatic filament manufactureClimate change adaptationOpen seaHigh density

The invention provides a preparation method of a cylindrical box body with the antifouling property for a deep and open sea net cage. The method comprises the following steps of A, preparing an antifouling netting, which comprises three aspects of preparing a modified high-density polyethylene composite material, preparing an antifouling monofilament bundle and processing the antifouling netting;B, preparing an anti-abrasion netting from a polyamide netting coated with a polyurea coating; and C, preparing the cylindrical box body, which comprises three aspects of side net processing, bottom net processing and cylindrical box body processing. According to the cylindrical box body with the antifouling property for the deep and open sea net cage obtained by the preparation method, the antifouling property of the cylindrical box body can be greatly improved and the water resistance of the cylindrical box body and the attachment area of fouling organisms can be reduced on the premise of keeping the netting strength of a side net unchanged, fouling organism attachment of the cylindrical box body and net breaking fish escape accidents under severe sea conditions can be greatly reduced, and green development and modern construction of the deep and open sea net cage culture industry are realized.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Anti-fouling agent for aqueous coating material

ActiveCN104403396AGood antifouling effectImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesKetoneNuclear chemistry

The invention relates to use of 5-(4-hydroxy phenylmethyl) thiazolidin-2,4-dione serving as an anti-fouling agent in an aqueous coating material. The aqueous anti-fouling coating material disclosed by the invention has a relatively good anti-fouling effect and has broad prospects in industrial application.

Owner:江阴市天邦涂料股份有限公司

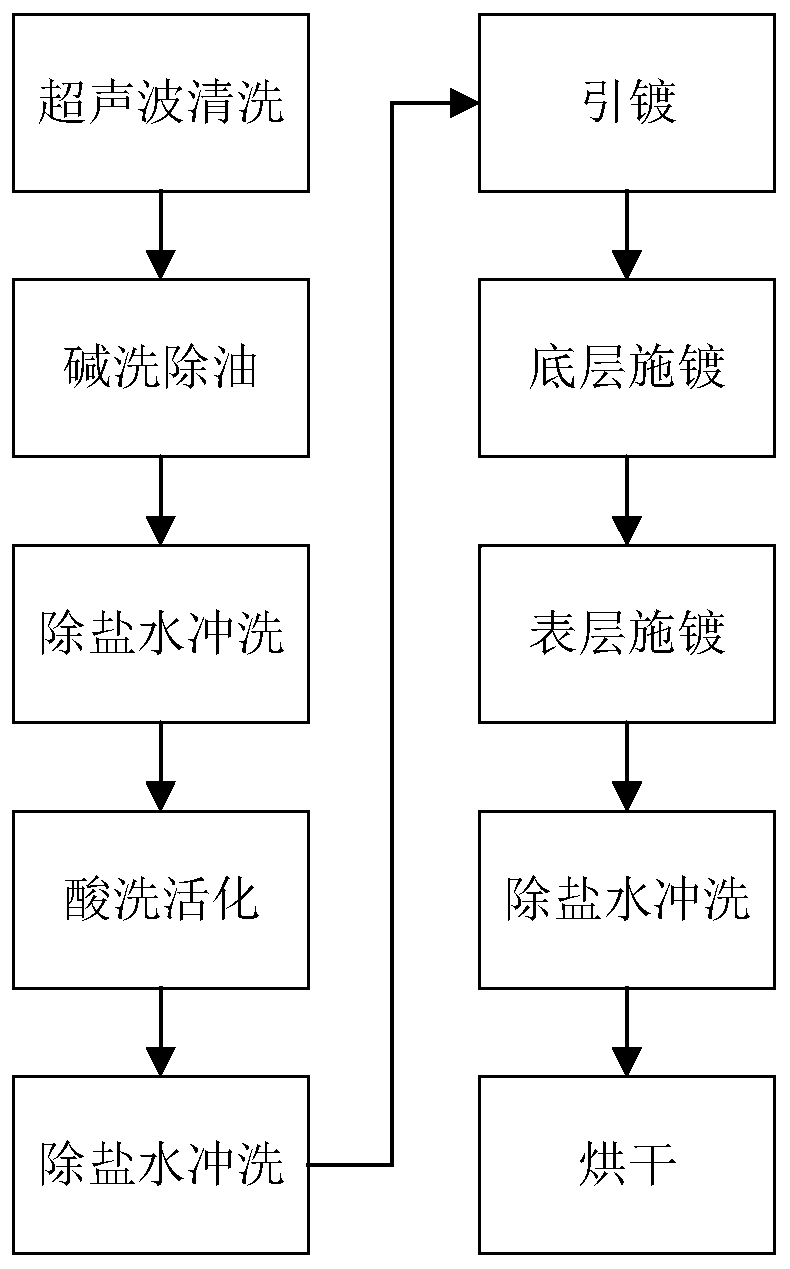

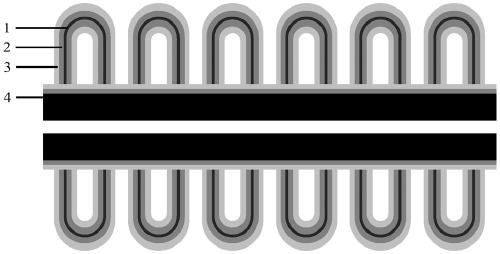

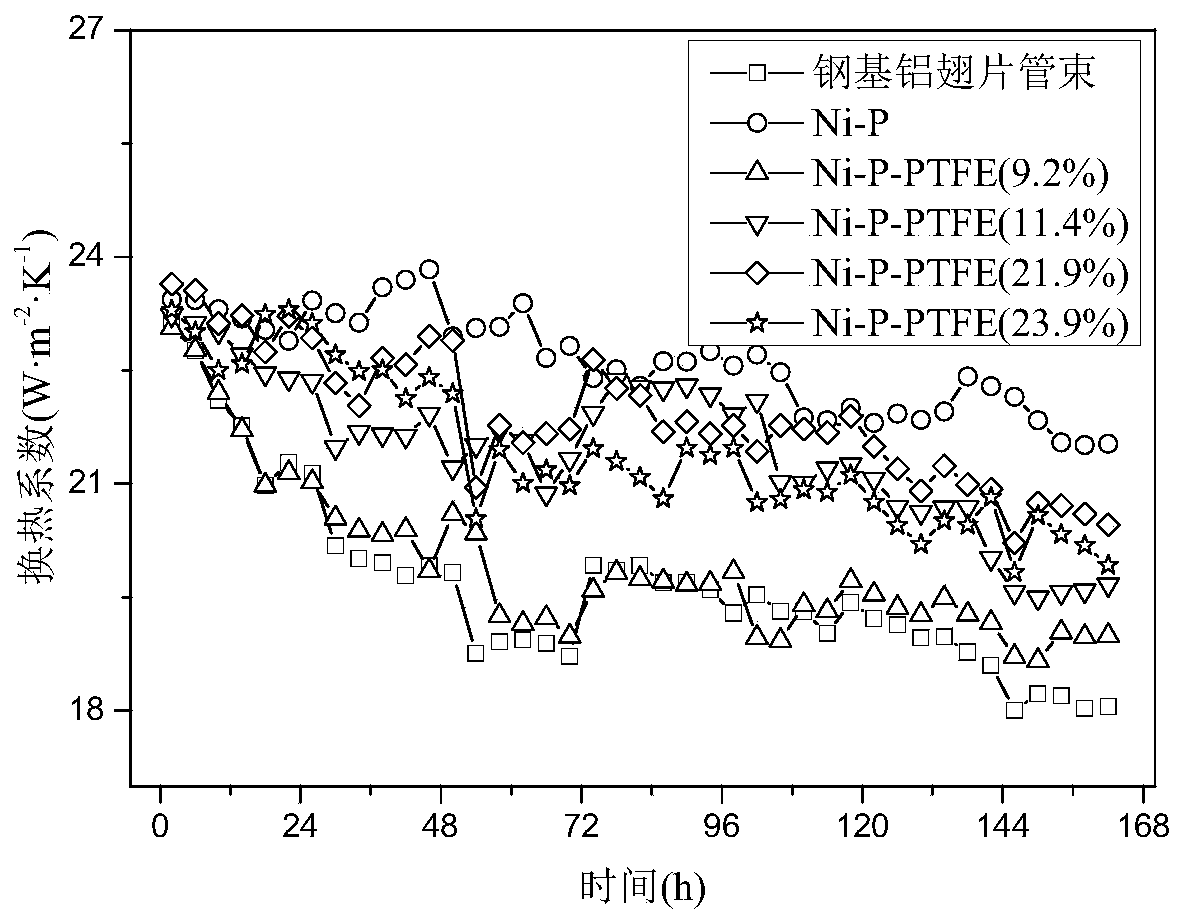

Design and preparation method of air cooler steel-based aluminum finned tube bundle anti-scaling nano composite coating

ActiveCN111046553AThe design and preparation method is scientific and reasonableImprove applicabilityLiquid/solution decomposition chemical coatingDesign optimisation/simulationCorrosionComposite coating

The invention relates to a design and preparation method of an air cooler steel-based aluminum finned tube bundle anti-scale nano composite coating, which is characterized by comprising the followingsteps: designing the air cooler steel-based aluminum finned tube bundle anti-scale nano composite coating, preparing the air cooler steel-based aluminum finned tube bundle anti-scale nano composite coating and the like, and the method is scientific and reasonable, strong in applicability and good in effect. By adopting the method, the service life of the steel-based aluminum finned tube bundle canbe prolonged, the corrosion aging rate is reduced, the cost is saved, repeated maintenance and cleaning are not needed, the cleaning period is prolonged, and the efficiency of the air cooler is improved.

Owner:NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com