Anti-staining soaping agent for printing of activated dye and preparation method thereof

A technology of reactive dyes and soaping agents, applied in the direction of surface active detergent composition, dyeing method, detergent compounding agent, etc., can solve the problems of high cost, poor biodegradability of EDTA-disodium, and low preparation cost , to achieve the effect of reducing preparation cost, less types of raw materials, and good antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

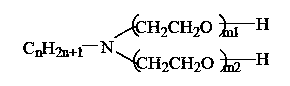

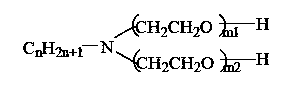

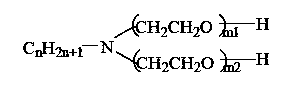

[0026] In this example, the raw materials for preparing the anti-staining soaping agent for reactive dye printing are 30 parts by weight of aliphatic amine polyoxyethylene ether (n=18, m1+m2=30), and 2 parts by weight of benzyl chloride , 0.5 parts by weight of sodium citrate, 65 parts by weight of water and 2.5 parts by weight of polyvinylpyrrolidone (type K30).

[0027] The preparation method of the anti-staining soaping agent for reactive dye printing in this embodiment consists of the following two steps.

[0028] (1) First, 30 parts by weight of aliphatic amine polyoxyethylene ether (n=18, m1+m2=30), 2 parts by weight of benzyl chloride, 0.5 parts by weight of sodium citrate and The number of parts is 65 parts of water, then heated up to 80-90°C and stirred for 3-4 hours, then vacuum distilled at 40-50°C for 1-2 hours, and cooled to 40-50°C to obtain the antifouling soaping agent raw material.

[0029] (2) Mix the antifouling soaping agent raw material in step (1) with 2...

Embodiment 2

[0031] In this example, the raw materials for preparing the anti-staining soaping agent for reactive dye printing are 40 parts by weight of aliphatic amine polyoxyethylene ether (n=18, m1+m2=60), and 1.7 parts by weight of benzyl chloride , 0.3 parts by weight of sodium gluconate, 55 parts by weight of water and 3 parts by weight of polyvinylpyrrolidone (type K30).

[0032] The preparation method of the anti-staining soaping agent for reactive dye printing in this embodiment consists of the following two steps.

[0033] (1) First, 40 parts by weight of aliphatic amine polyoxyethylene ether (n=18, m1+m2=60), 1.7 parts by weight of benzyl chloride, 0.3 parts by weight of sodium gluconate and The number of parts is 55 parts of water mixed, then heated to 80-90°C and stirred for 3-4 hours, then vacuum distilled at 40-50°C for 1-2 hours, and cooled to 40-50°C to obtain the antifouling soaping agent raw material.

[0034] (2) Mix the antifouling soaping agent raw material in step (...

Embodiment 3

[0036] In this example, the raw materials for preparing the anti-staining soaping agent for reactive dye printing are 50 parts by weight of aliphatic amine polyoxyethylene ether (n=18, m1+m2=60), 1.5 parts by weight of chloroethanol, It is composed of 0.5 parts by weight of gluconic acid, 0.5 parts by weight of sodium gluconate, 43.5 parts by weight of water and 4 parts by weight of polyvinylpyrrolidone (type K30).

[0037] The preparation method of the anti-staining soaping agent for reactive dye printing in this embodiment consists of the following two steps.

[0038] (1) First, 50 parts by weight of aliphatic amine polyoxyethylene ether (n=18, m1+m2=60), 1.5 parts by weight of chloroethanol, 0.5 parts by weight of gluconic acid, and parts by weight Mix 0.5 parts of sodium gluconate and 43.5 parts of water by weight, then heat up to 80-90°C and stir for 3-4 hours, then vacuum distill at 40-50°C for 1-2 hours, then cool down to 40-50°C, The raw material of the antifouling so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com