Inclined-fin-tube heat exchanger

A finned tube heat exchanger and finned tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problem that the heat exchanger fails to achieve the design effect, is difficult to remove, and affects heat exchange. Efficiency and other issues, to achieve long-term stable and effective heat exchange effect, good anti-scaling effect, and avoid the effect of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

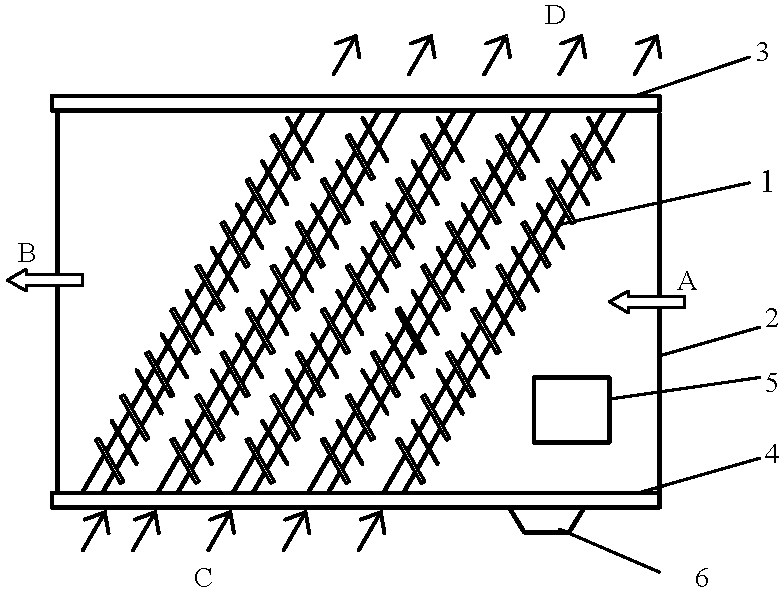

[0042] One of the specific implementations of an oblique finned tube heat exchanger of the present application, see figure 1 As shown, it includes a heat exchanger shell 2, an upper tube sheet 3, a lower tube sheet 4, and several oblique finned tubes 1 passing through the upper tube sheet 3 and the lower tube sheet 4, wherein the The side of the tube plate is respectively provided with the inlet C of the medium in the tube and the outlet D of the medium in the tube, and the two opposite sides of the heat exchanger shell 2 are respectively provided with the inlet A of the medium outside the tube and the outlet B of the medium outside the tube. 1. It is arranged obliquely from the inlet A of the medium outside the tube to the outlet B of the medium outside the tube, and the flow direction of the medium outside the tube intersects obliquely with the flow direction of the medium inside the tube. This structure makes the flue gas ash or air dust slide down from the inclined finned...

Embodiment 2

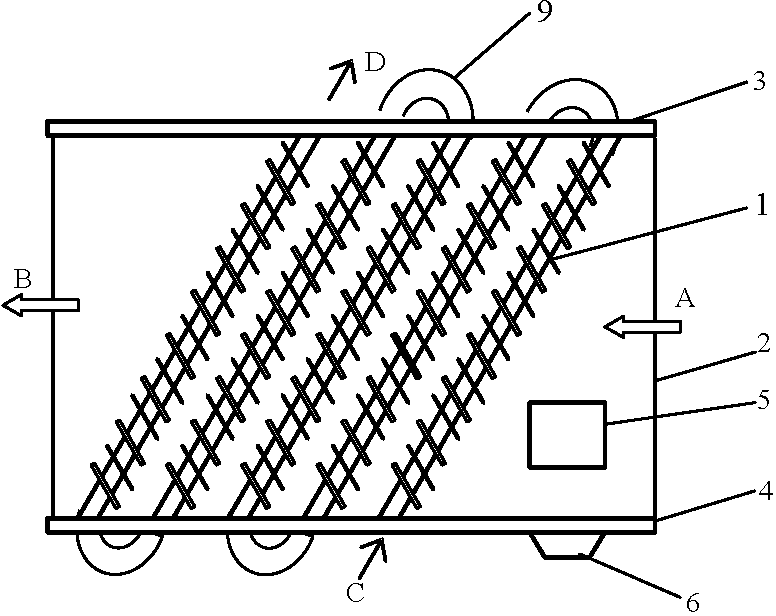

[0048] The second specific embodiment of an oblique finned tube heat exchanger of the present application, see Figure 4 As shown, it includes a heat exchanger shell 2, a tube plate and several oblique finned tubes 1, wherein, the tube plate side is respectively provided with a tube medium inlet C and a tube medium outlet D, and the heat exchanger shell The two opposite sides of 2 are respectively provided with the inlet A of the medium outside the tube and the outlet B of the medium outside the tube. The inclined finned tube 1 is set as a bent finned tube structure, and the flow direction of the medium outside the tube is partially inclined to the flow direction of the medium inside the tube. Intersect, partially perpendicularly intersect. The oblique finned tubes 1 in this structure are bent tubes, which can be bent once, twice or three times. The bent finned tube structure can accurately utilize the flow rate of the medium in different parts of the heat exchanger shell 2, ...

Embodiment 3

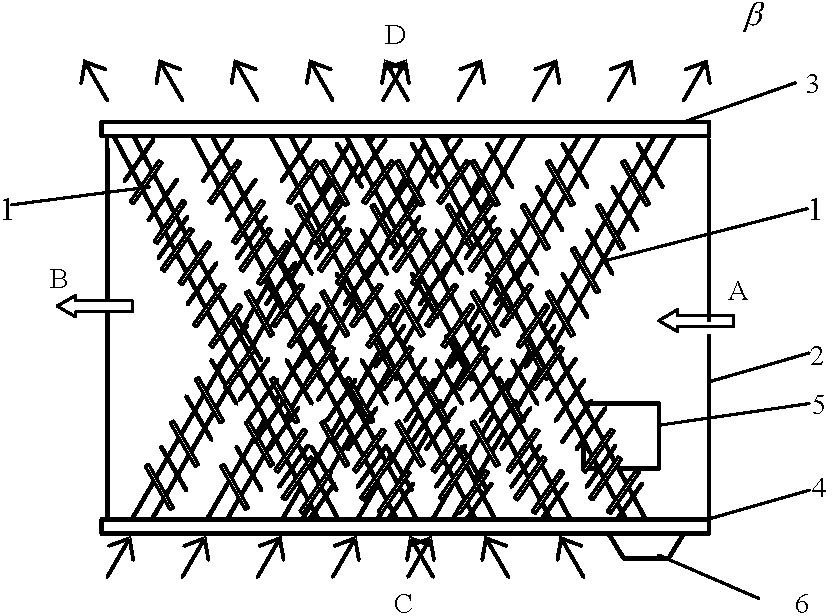

[0052] The third specific embodiment of an oblique finned tube heat exchanger of the present application, see Figure 5 As shown, it includes a heat exchanger shell 2, a tube plate and several oblique finned tubes 1, wherein, the tube plate side is respectively provided with a tube medium inlet C and a tube medium outlet D, and the heat exchanger shell The two opposite sides of 2 are respectively provided with an outer medium inlet A and an outer medium outlet B, and an inclination angle is set between the flow direction of the outer medium and the horizontal plane and between the flow direction of the inner medium and the vertical plane. This structure is also applied to the arrangement structure of the straight fins of the straight heat exchange tubes, that is, the overall central axis of the heat exchanger is an inclined structure, even if the fins are not inclined on the base pipe 102 in the traditional heat exchanger structure, the heat exchange tubes It is also perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com