Slant finned tube

A finned tube and fin technology, which is applied in the field of heat exchange equipment, can solve the problems that the heat exchanger fails to achieve the design effect, affects the heat exchange efficiency, and is difficult to remove, and achieves long-term stable and effective heat exchange effect and extended use. Long life and good anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

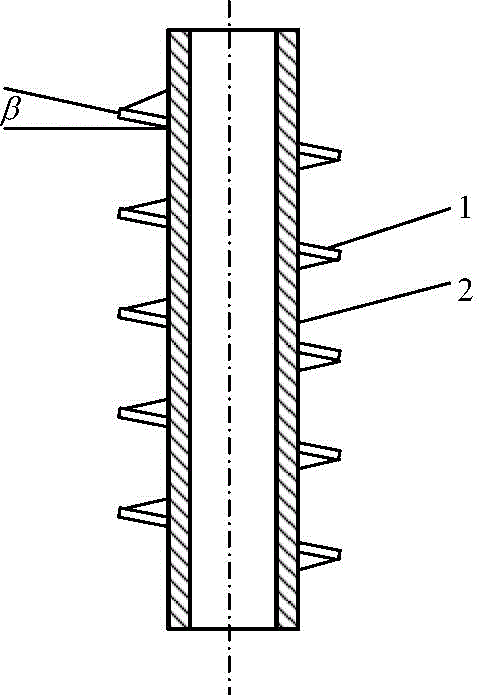

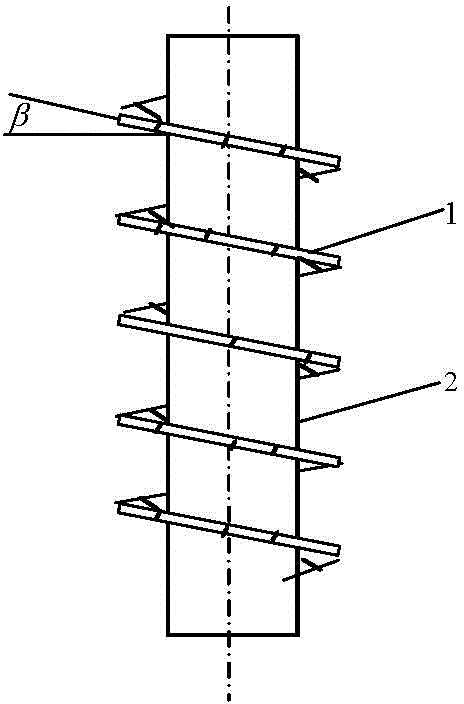

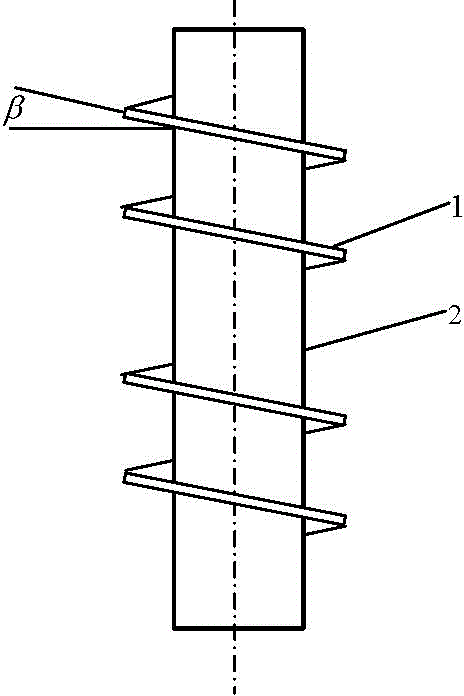

[0038] One of the specific implementations of an oblique finned tube of the present application, see figure 1 As shown, it includes a base pipe 2 and several fin bodies 1 arranged on the base pipe 2, wherein the fin body 1 includes an inclined surface and a fin center hole arranged inside the inclined surface, so The central hole of the fin is closely connected with the outer wall of the base tube 2, and the plurality of fin bodies 1 are arranged continuously around the outer wall of the base tube 2 along the axial direction of the base tube 2 (such as figure 2 shown) or a discontinuous surround setting (such as image 3 shown). In the discontinuous surrounding arrangement, the distance between each fin body 1 can be set at equal or unequal lengths, depending on the specific operating conditions. Usually, discontinuous surroundings with unequal lengths are more conducive to improving the heat transfer efficiency of finned tubes . This structure makes the flue gas ash or a...

Embodiment 2

[0044] The second specific embodiment of an oblique finned tube of the present application, see Figure 4As shown, it includes a base pipe 2 and several fin bodies 1 arranged on the base pipe 2, wherein the fin body 1 includes an umbrella body and a fin center hole arranged in the middle of the umbrella body, so The fin body is tightly fit on the outer wall surface of the base pipe 2 through the central hole of the fin. The fin bodies 1 are independently inserted into the base pipe from the pipe end for assembly and fitting. This structure makes the flue gas ash or air dust slide down from the inclined umbrella surface of the finned umbrella body and cannot accumulate, so that the anti-fouling effect is good, so that the heat exchange effect can be kept stable and effective for a long time, and it can reduce or avoid the dust caused by the removal of the heat exchanger. The operation and maintenance of frequent shutdown and blowing fin ash, but also has the characteristics of...

Embodiment 3

[0048] The third specific embodiment of an oblique finned tube of the present application, see Figure 7 and Figure 8 As shown, it includes a base pipe 2 and several fin bodies 1 arranged on the base pipe 2, wherein the fin body 1 includes inclined annular fins and fins arranged at the ends of the inclined annular fins. Flange 8 , the inclined annular fin is sheathed on the outer wall surface of the base pipe 2 through its inner ring, and is closely connected with the outer wall surface of the base pipe 2 . Flange 8 can be arranged upwards, also can be arranged downwards. The annular shape of the inclined annular fins can be a ring shape with a trapezoidal cross-section, or a ring shape with a triangular cross-section. The above-mentioned structure is more conducive to the sliding of smoke ash or air dust.

[0049] This structure makes the flue gas ash or air dust slide down from the inclined umbrella surface of the finned umbrella body and cannot accumulate, so that the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com