Temperature-resistant type barium strontium sulfate anti-scaling agent for oil field and preparation method thereof

A technology of anti-scaling agent and barium sulfate, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., to achieve good anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

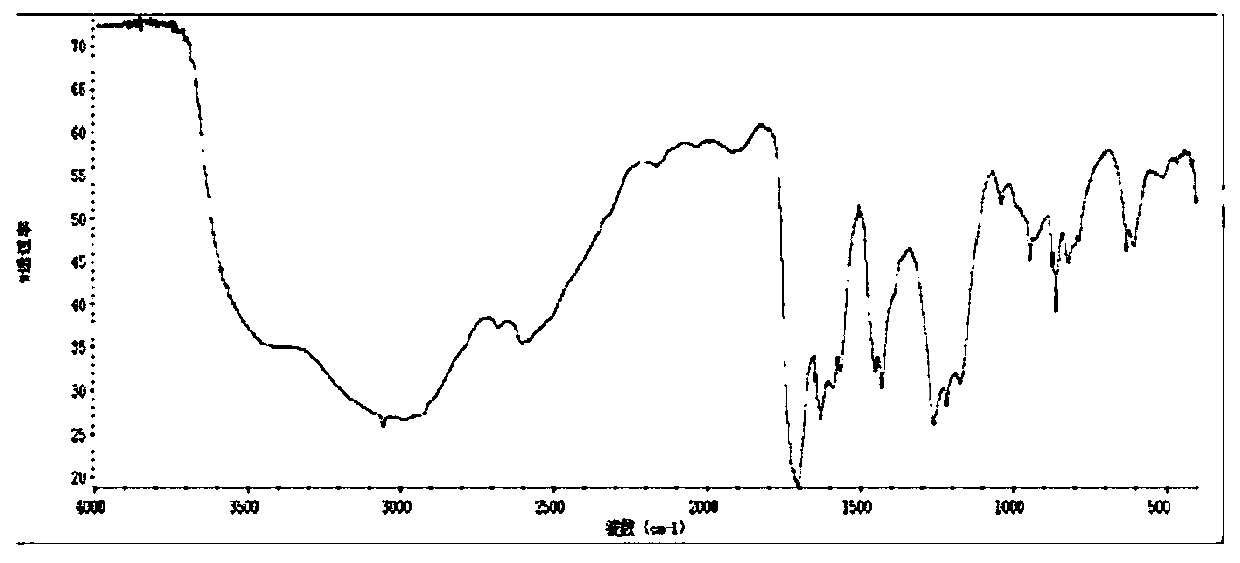

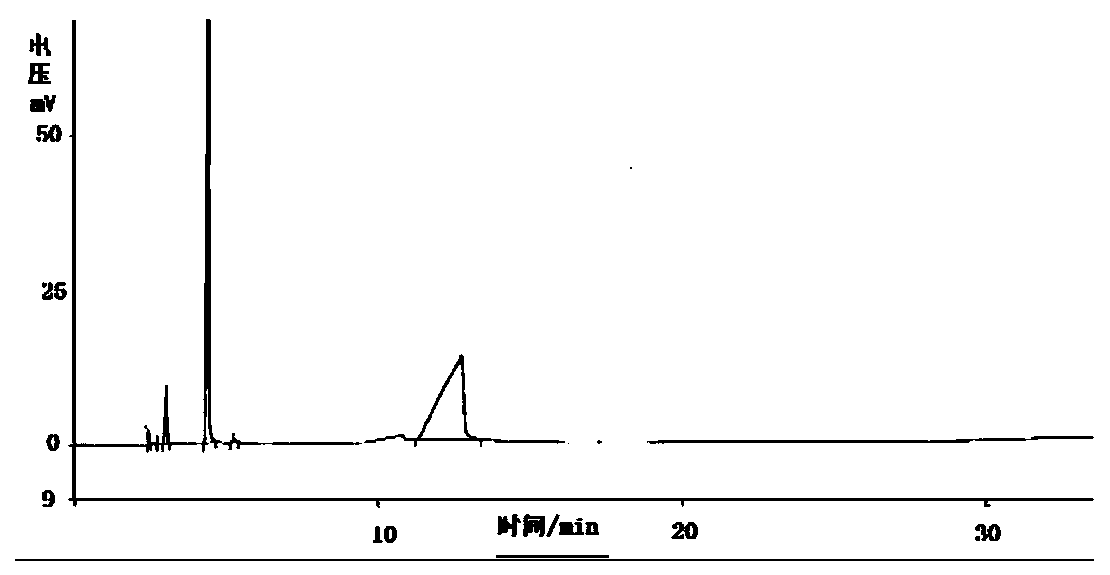

Method used

Image

Examples

Embodiment 1

[0027] The mass ratio of maleic anhydride, acrylic acid, methacrylic acid, 2-acrylamido-2-methylpropanesulfonic acid and ammonium persulfate is 30:50:5:14:1.

[0028] The preparation method comprises the following steps:

[0029] (1) Add maleic anhydride, ammonium persulfate and deionized water into a sealed constant temperature stirring device, heat and stir until they are completely dissolved.

[0030] (2) Raise the temperature to 90° C., add dropwise the mixture of acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid, and functional monomer methacrylic acid at a rate of 20 mL / L.

[0031] (3) After the dropwise addition, the mixture was continuously stirred for 5 h at a temperature of 90° C., cooled and concentrated, and then the supernatant liquid was removed to obtain the obtained product.

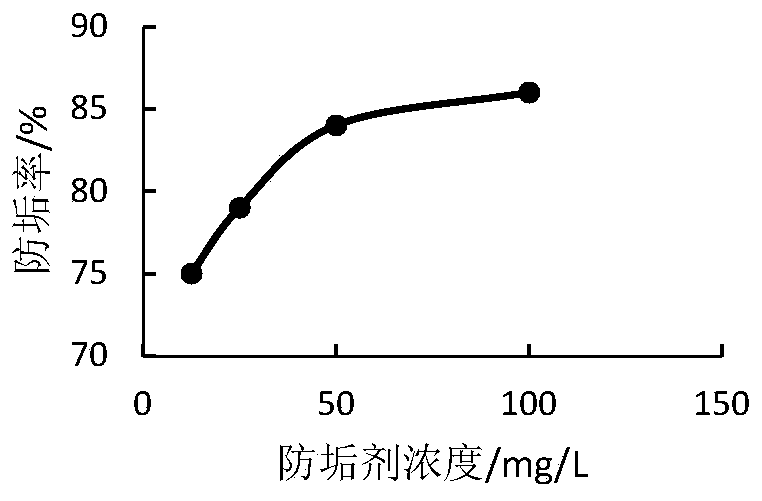

[0032] The anti-scaling rate was tested according to the anti-scaling rate test method at 50° C., and the anti-scaling rate was 84%.

Embodiment 2

[0034] The mass ratio of maleic anhydride, acrylic acid, methacrylic acid, 2-acrylamido-2-methylpropanesulfonic acid and ammonium persulfate is 30:52.5:5:12.5:1.5.

[0035] The preparation method comprises the following steps:

[0036] (1) Add maleic anhydride, ammonium persulfate and deionized water into a sealed constant temperature stirring device, heat and stir until they are completely dissolved.

[0037] (2) Raise the temperature to 80° C., and add the mixture of acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid and functional monomer methacrylic acid dropwise at a rate of 50 mL / L.

[0038] (3) After the dropwise addition, the mixture was continuously stirred for 1 h at a temperature of 80° C., cooled and concentrated, and then the supernatant liquid was removed to obtain the obtained product.

[0039] The anti-scaling rate was tested according to the anti-scaling rate test method at 50° C., and the anti-scaling rate was 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| anti-fouling rate | aaaaa | aaaaa |

| anti-fouling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com