Patents

Literature

85 results about "Synthetic monomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet curing coating for metal plating surface protection

ActiveCN1803942AHigh surface hardnessImprove water resistanceLiquid surface applicatorsCoatingsFiberCoated surface

The related UV solidifying paint for metal coated surface protection comprises: 10-30% epoxy acrylate and 5~20% urethane acrylate both as active oligomer, 10-30% composite adhesion reinforced resin as the mixture of thermalplastic acrylic resin with AA monomer modified by H3PO4 as one of synthetic monomer and fiber resin, 30~65% diluent, 5~20% active diluent, 1~10% light initiator, and 0.1~1% auxiliary agent. This invention solves the adhesion problem of UV paint on smooth metal surface very well, and contains other index up to protective and decorative requests.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

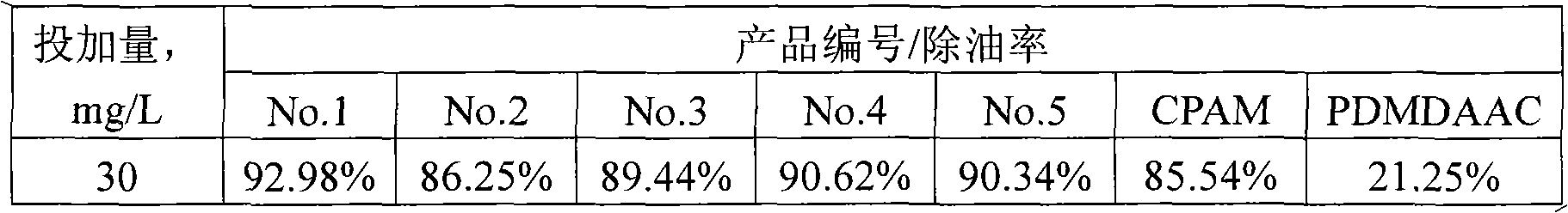

Cation-type hydrophobic association polymer and its preparation method and application

InactiveCN101260174AHigh molecular weightGood product stabilityWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationButyl acrylateUrea

The invention discloses a cation type hydrophobic association polymer and a preparation method and application thereof. Through adopting acrylamide, dimethyl diallyl ammonium chloride and butyl acrylate as synthesis monomer, the cation type hydrophobic association polymer is made through a common free radical micelle polymerization method and making use of a composite initiation system and additive auxiliary agent urea. Moreover, the cation type hydrophobic association polymer, which has the characteristics of high molecular weight, excellent product stability, strong adsorption bridging capacity of colloid matter, good flocculation effect, wide application scope, less generated sludge and hydrophobic association function, etc., can be widely used in the treatment of oil field oily wastewater.

Owner:SHANDONG UNIV

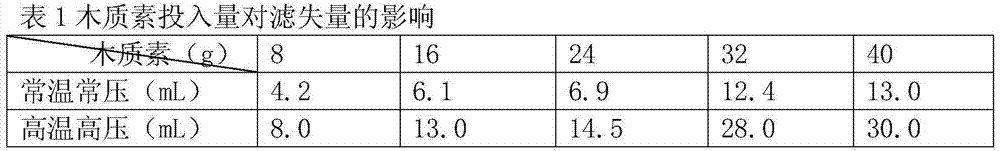

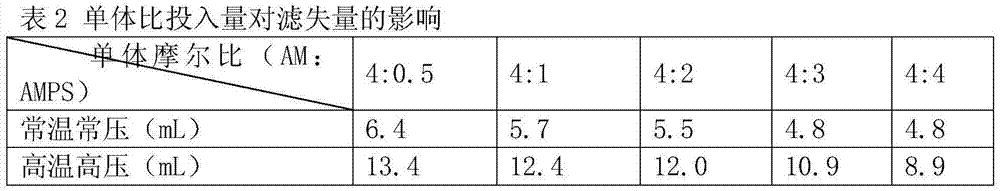

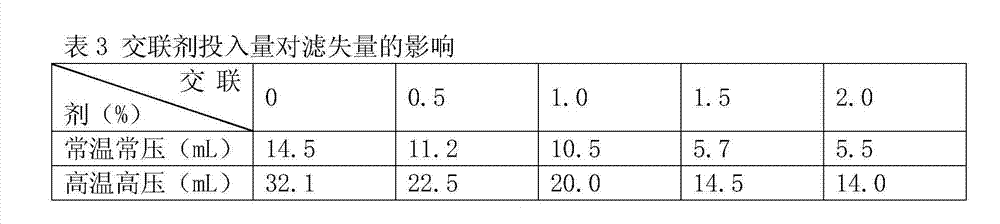

Filtrate loss reducer for high-temperature-resistant oil field drilling fluid and preparation method thereof

InactiveCN104119845AWide variety of sourcesLow costDrilling compositionSynthetic monomerPotassium peroxodisulfate

The invention relates to a filtrate loss reducer for high-temperature-resistant oil field drilling fluid, a preparation method of the filtrate loss reducer, and application of a treatment agent. A novel high-temperature-resistant filtrate loss reducer is synthesized by implementing the following steps: adopting lignin, acrylamide and 2-acrylamide-2-methyl propanesulfonate as synthetic monomers; enabling the synthetic monomers to perform graft copolymerization under the initiation of potassium peroxodisulfate, ammonium ferrous sulfate hexahydrate and hydrogen peroxide respectively; adding a crosslinking agent, namely N,N-methylene bisacrylamide to enhance the stabilizing force of the synthetic monomers under high temperature condition. The filtrate loss reducer disclosed by the invention adopts waste materials of a paper-making factory, is extensive in source and low in cost, and can be used for absorbing the excellent viscosity reduction capacity of lignin; the introduced acrylamide and 2-acrylamide-2-methyl propanesulfonate can be used for improving the precipitation capacity at a high temperature; N,N-methylene bisacrylamide is added as the crosslinking agent to ensure that a network structure is formed, the high temperature resistance can be improved, an oil and gas layer can be protected from collapsing, and the service life of an oil well can be prolonged. A product disclosed by the invention is applied to the oil field drilling fluid.

Owner:JILIN UNIV

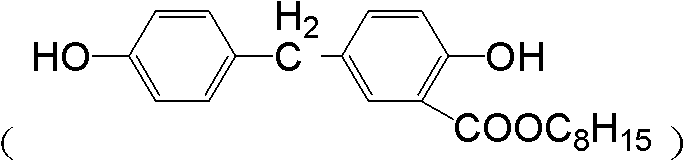

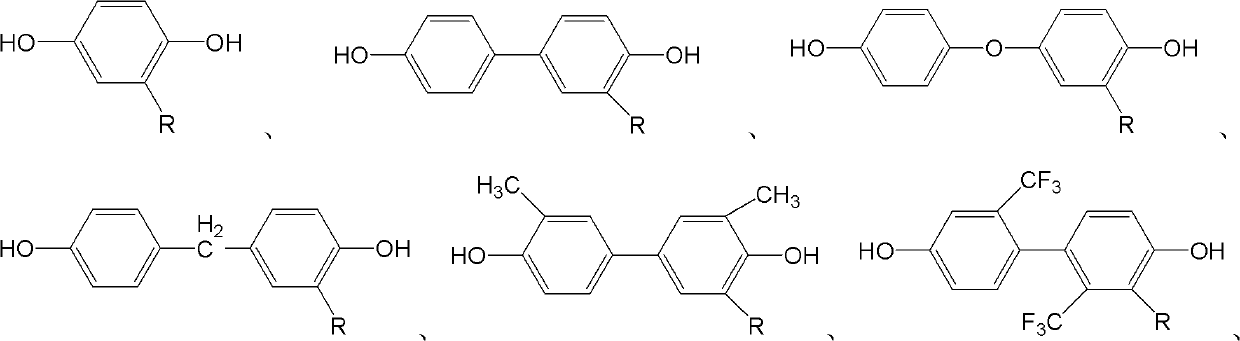

Side substitution aromatic ester diphenol, preparation method and preparation method of mesomorphic epoxy monomer

InactiveCN101845005AShort reaction cycleOrganic compound preparationGroup 5/15 element organic compoundsArylEpoxy

The invention relates to side substitution aromatic ester diphenol, a preparation method and a preparation method of a mesomorphic epoxy monomer. The side substitution aromatic ester diphenol has a general formula shown in the specification of the invention, wherein X stands for an aryl group with side substitution. In the preparation method of an aromatic ester mesomorphic epoxy monomer by using the side substitution aromatic ester diphenol, a synthetic period of the monomer is greatly shortened, the raw materials of the synthetic monomer are cheap and are easy to obtain, and the preparation method is simple and convenient.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

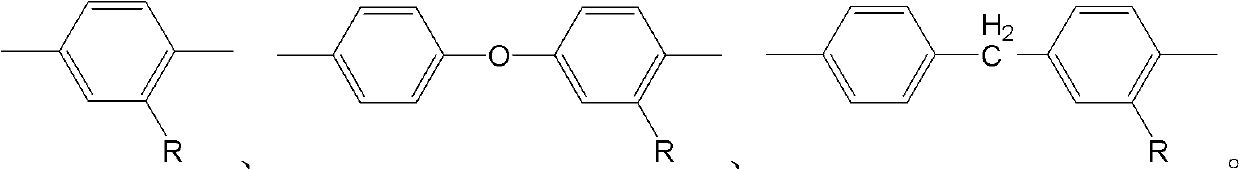

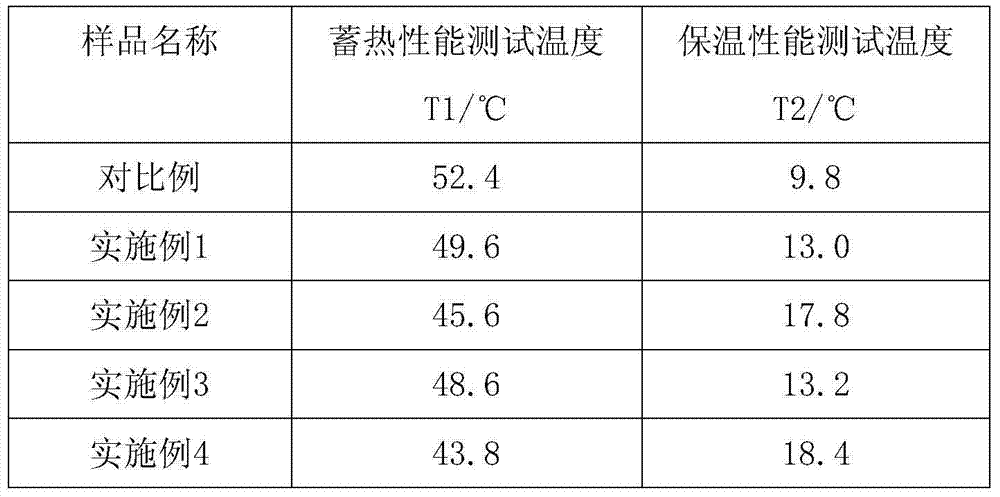

Heat accumulation and preservation polyurethane elastic fibers containing phase change microcapsules and preparation method of heat accumulation and preservation polyurethane elastic fibers

ActiveCN104726957AThermoregulationImprove insulation effectMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to heat accumulation and preservation polyurethane elastic fibers containing phase change microcapsules and a preparation method of the heat accumulation and preservation polyurethane elastic fibers. According to the heat accumulation and preservation fibers, the heat accumulation and preservation performance of polyurethane fibers can be improved by adding 0.5-5wt% of the phase change microcapsules into polyurethane elastic fibers. The preparation method specifically comprises the following steps: (1) preparing the phase change microcapsules with nuclear shell structures by adopting a suspension polymerization method; (2) performing condensation and polymerization by taking polyether diol and diisocyanate as synthetic monomers to form prepolymer, dissolving the prepolymer by adding a solvent, and adding mixed amine to perform chain extension reaction and chain termination reaction on the prepolymer to obtain a polyurethane urea solution; and (3) adding the prepared phase change microcapsules together with other auxiliary agents into the polyurethane urea solution, performing mixed curing, and treating a spinning stock solution subjected to curing by virtue of a dry spinning technology to prepare the heat accumulation and preservation polyurethane elastic fibers. The polyurethane elastic fibers prepared by the method provided by the invention contain a certain proportion of a phase change material, the fibers prepared by the method provided by the invention or textiles of the fibers have excellent heat accumulation and preservation performances.

Owner:ZHEJIANG HUAFENG SPANDEX

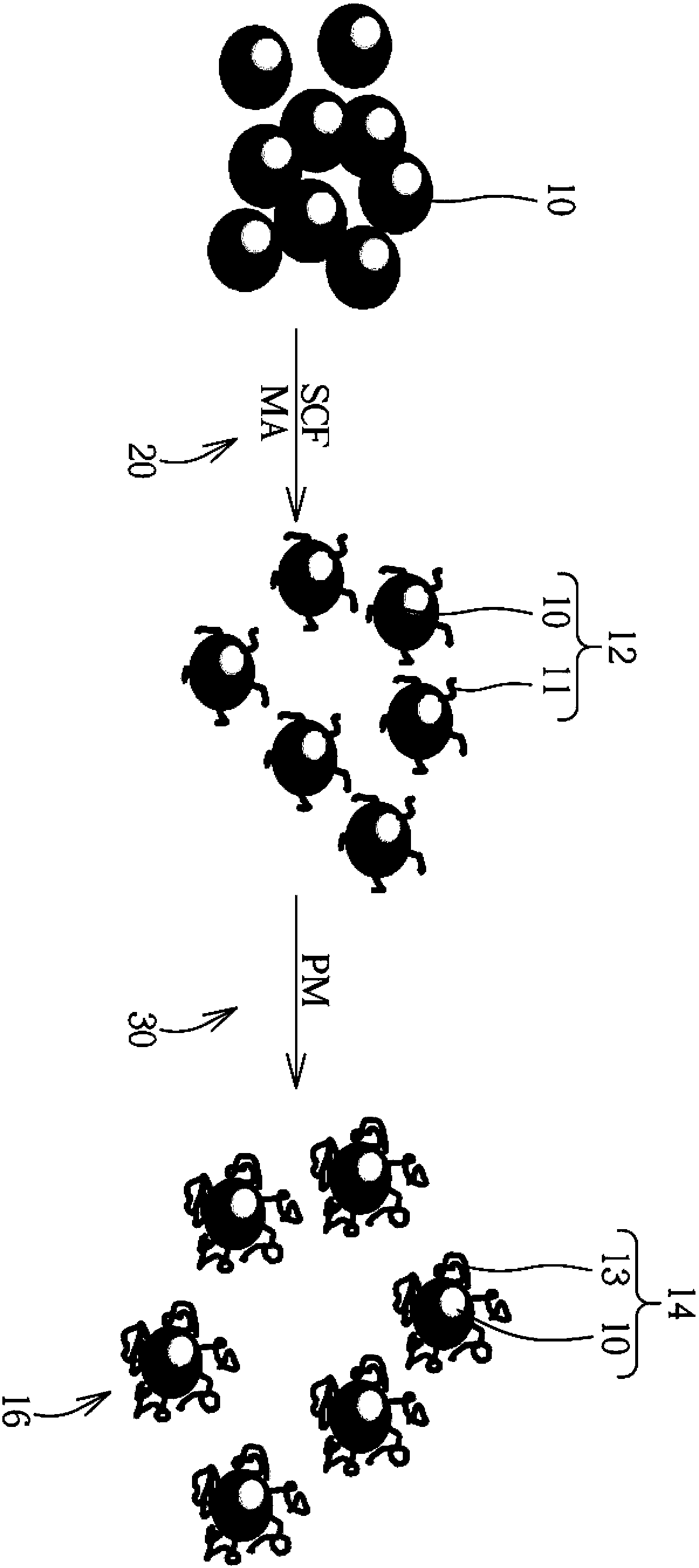

Preparation method of covalent organic framework/carbon nitride composite material and application thereof

ActiveCN108246339ASimple preparation processShort synthesis timeWater treatment compoundsWater contaminantsNano catalystCarbon composites

The invention discloses a preparation method of a covalent organic framework / carbon nitride composite material and application thereof. Firstly, a covalent organic framework material is synthesized byusing p-phenylenediamine and triformyl phloroglucinol as synthetic monomers through a room-temperature solid-phase method, then the covalent organic framework material and carbon nitride are mixed, stirred and dried in methyl alcohol, and pyrolysis is carried out under the protection of inert gas to obtain a target product. The covalent organic framework / carbon nitride composite material disclosed by the invention is large in specific surface area, high in nitrogen doping amount and rich in pore structure and can effectively remove toxic organic pollutants in water by constructing a novel Fenton-like system, and new application of the covalent organic framework material in the field of catalysis is expanded; unavoidable metal ion leaching in the activating process of a metal nano catalystis overcome; and the preparation method has the advantages of simple process, easiness for repeated operation, controllable structure, suitability for large-scale production and the like.

Owner:HEFEI UNIV OF TECH

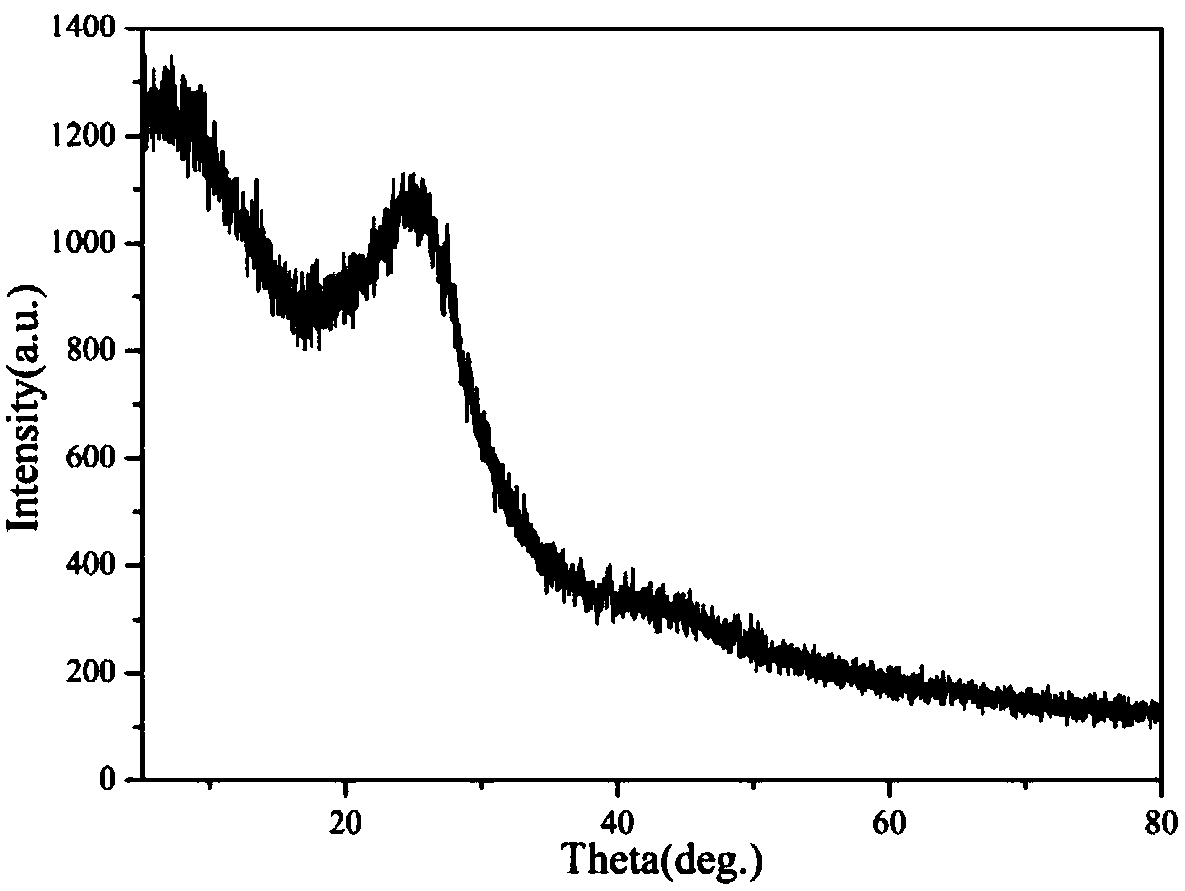

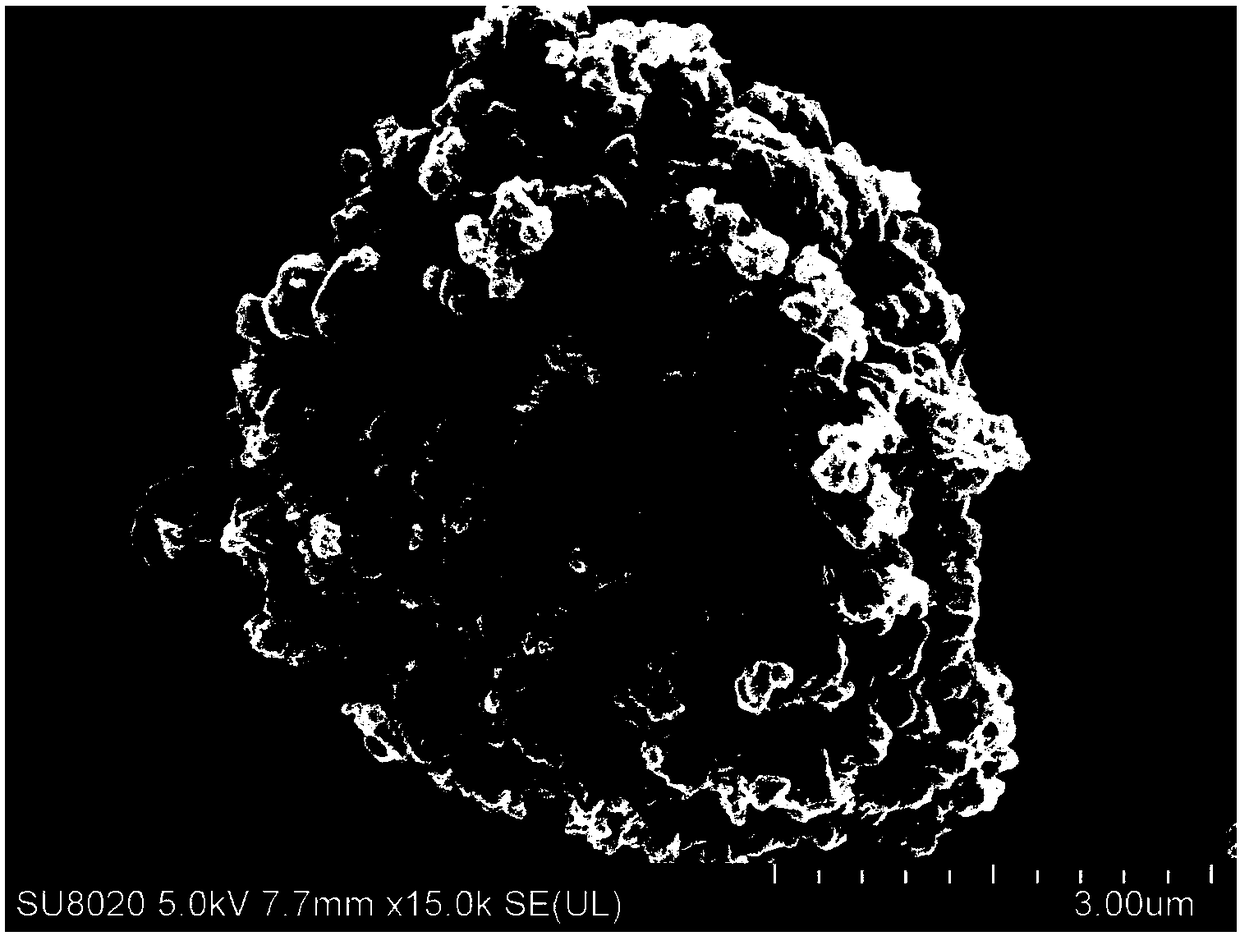

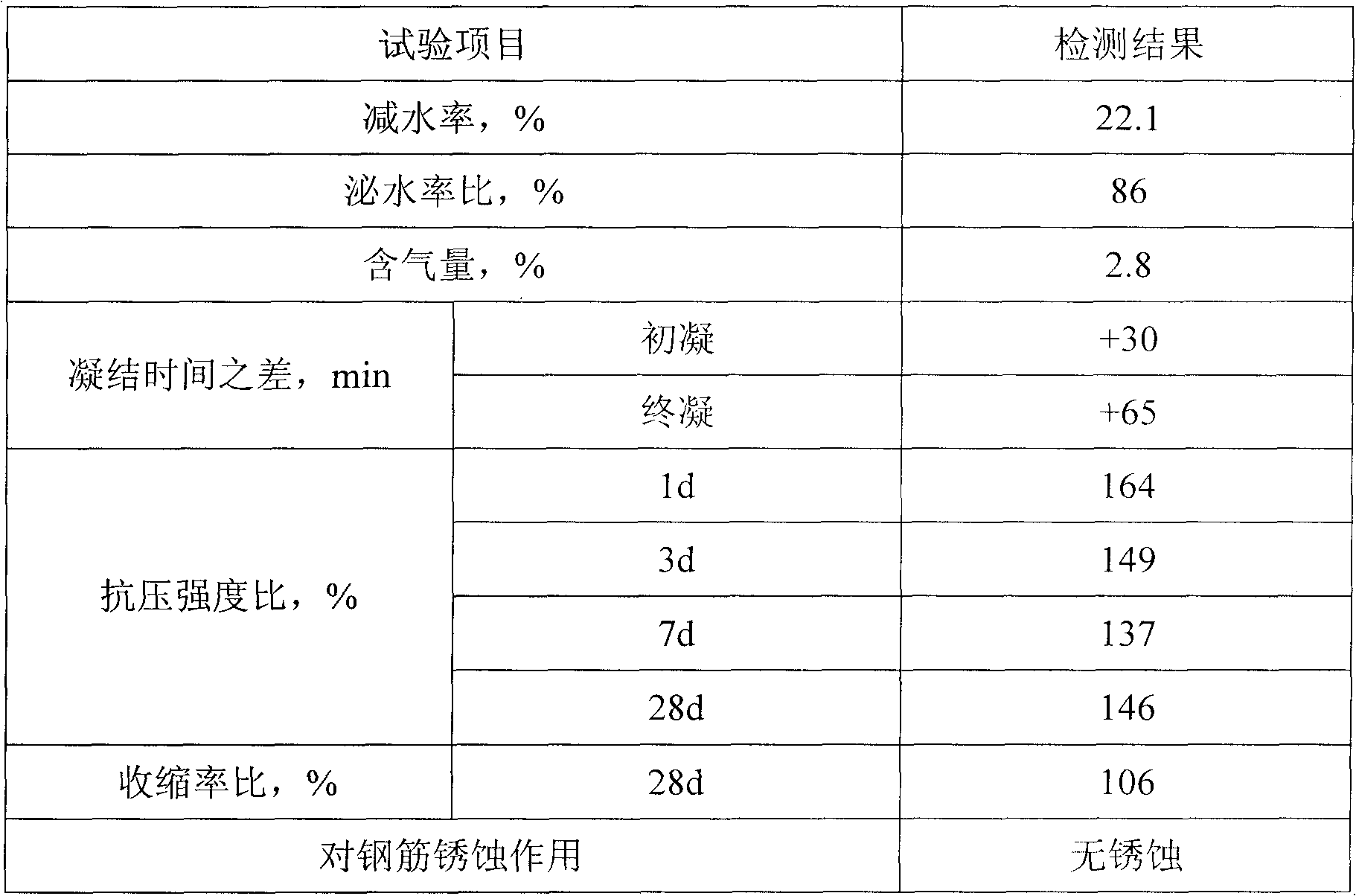

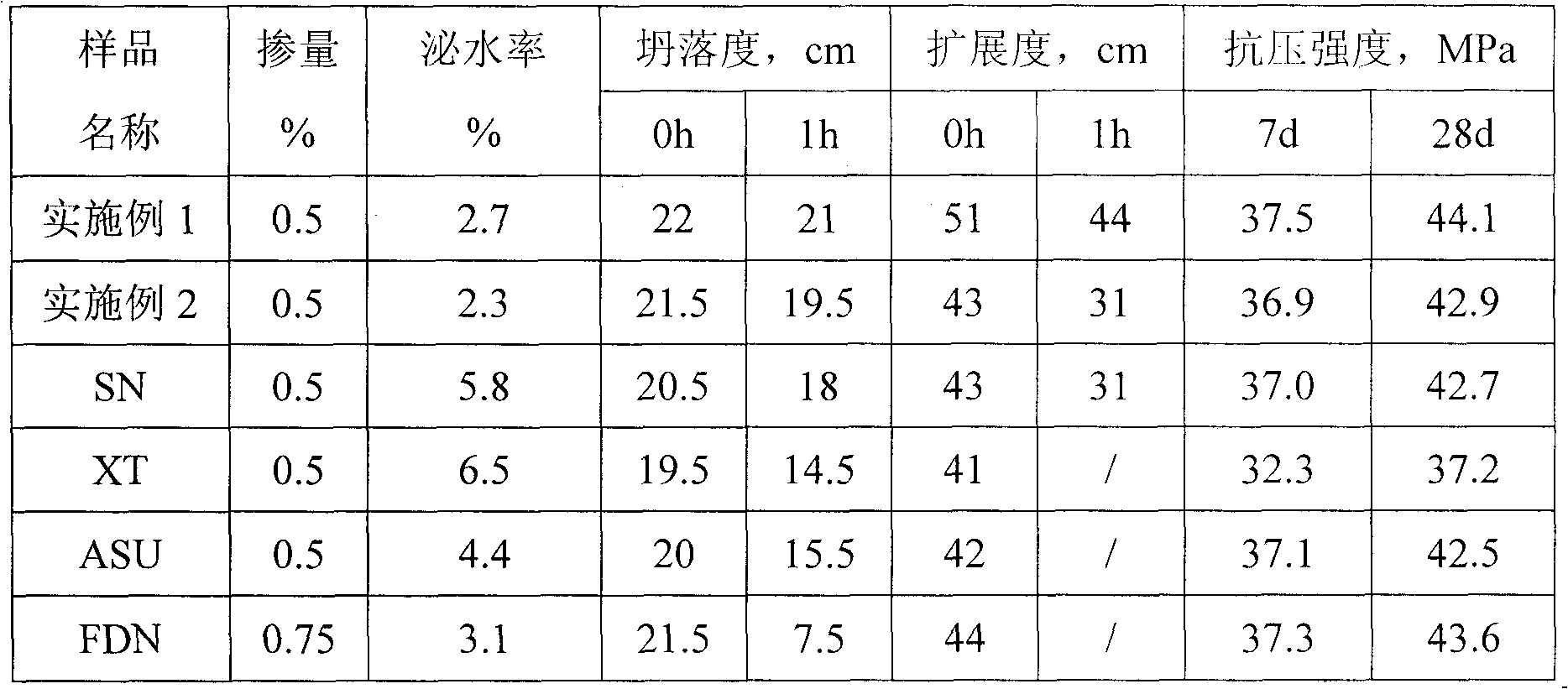

Low-cost modified amino-sulfonic acid-based high-efficiency water reducer and preparation method thereof

ActiveCN101805144AImprove easy bleedingImprove the defects of the bottomLiquid productSuperplasticizer

The invention discloses a low-cost modified amino-sulfonic acid-based high-efficiency water reducer and a preparation method thereof. The preparation method comprises the following steps of: adding 25-35 parts by weight of water into a reaction kettle, heating the water to 65-70 DEG C, inputting 10-17 parts by weight of interaction sulfanilic acid, 9-14 parts by weight of industrial waste phenolic residue and 3-5 parts by weight of pH value regulator, and raising the temperature to 85-90 DEG C while stirring; dropwise adding 18-26 parts by weight of formaldehyde within 15-30min, and keeping the temperature to be 92-95 DEG C for 2-6h; and adding 1-2 parts by weight of pH value regulator and 15-22 parts by weight of straw pulp black liquor, keeping the temperature within 85-90 DEG C for 2-4h, and cooling to the room temperature to obtain a liquid product. The product is prepared by utilizing a rough industrial product and industrial wastes with lower price as synthesis monomer and modifiers, thereby improving the inherent defects of mixing amount sensitivity and easy bleeding and bottom pushing of concrete of the amino-sulfonic acid-based high-efficiency water reducer, lowering the production cost of the water reducer, fully utilizing the industrial wastes and reducing the environmental pollution.

Owner:NANJING RUIDI HIGH TECH

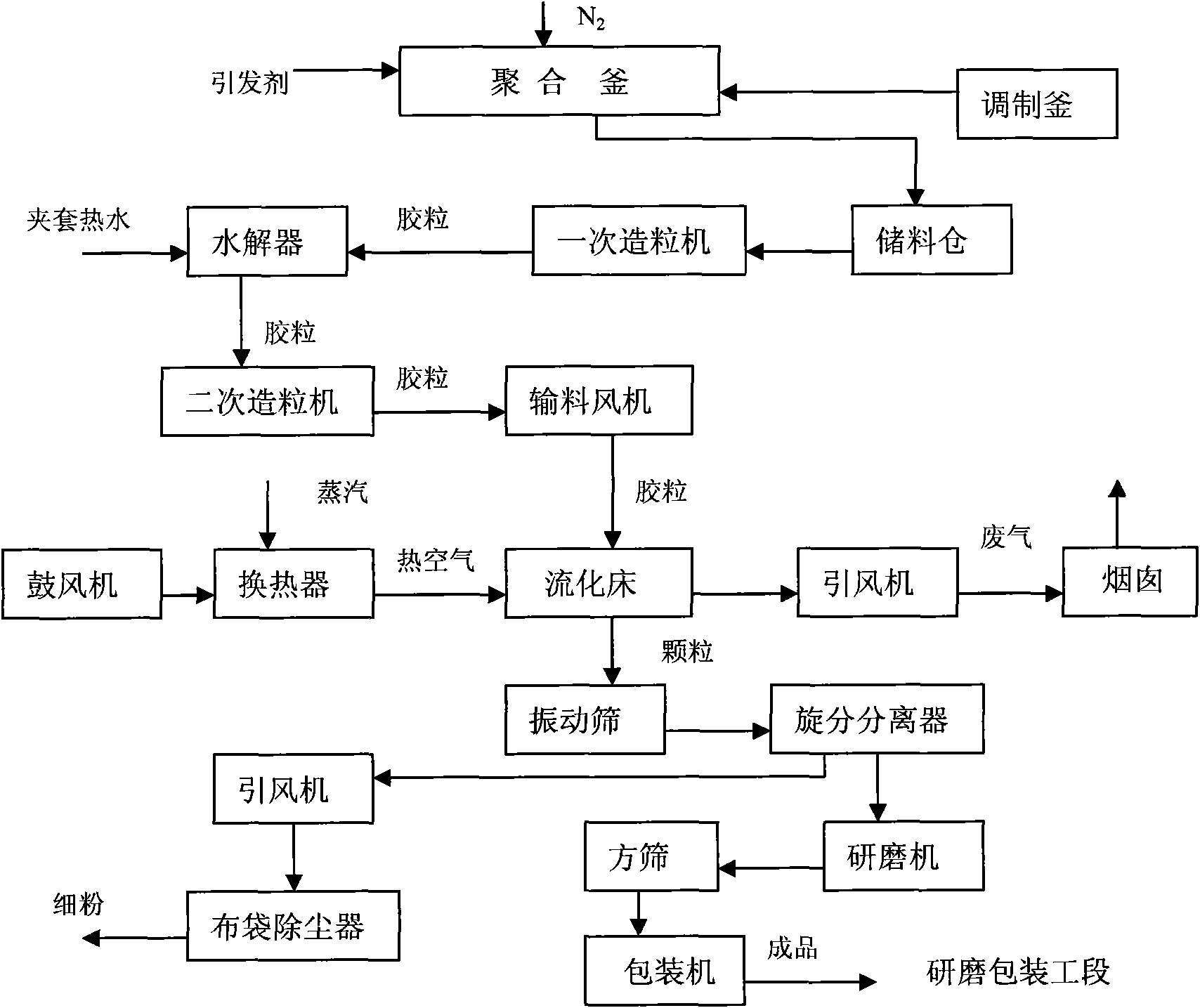

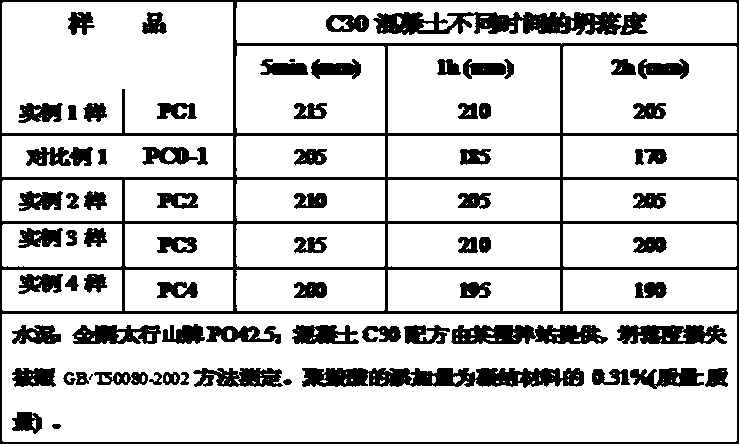

Preparing method of lowering residual monomer content of ultra high molecular weight anion-type polyacrylamide

ActiveCN101649022AMeet the requirements of high-quality flocculantsMeet the requirements of superior productsWater/sewage treatment by flocculation/precipitationFluidized bed dryingSynthetic monomer

The invention relates to a preparing method of lowering residual monomer content of ultra high molecular weight anion-type polyacrylamide. The invention has the technical scheme as follows: acrylamide(AM), 2-acrylamide-2-methylpropane sulfonic acid (AMPS) and acrylic acid (AA) are taken as a synthetic monomer; a kettle-type chunk polymerization technology, a complex initiation system, hydrolyzerposthydrolysis and fluidized bed drying preparation are adopted; acrylamide dry powder is white power-type particle; polyacrylamide colloidal particles in a hydrolyzer are transmitted to a static fluidized bed for drying after pelleting by a secondary pelletizer, are crushed by a grinder and are packaged into bags. The invention has the beneficial effect that the content of a residual monomer is controlled below 0.05%, which can satisfy the technical requirements of three-time adoption, sewage treatment and raw water treatment.

Owner:DONGYING BAOMO ENVIRONMENT ENG CO LTD

High molecular weight degradation polymer and preparation method thereof

The invention relates to a macromolecule degradated polymer and its producing method belonging to material technical field. The polymer contains more than two monomers such as hydroxy acid or lactone or lactide formed by hydroxy acid, binary carboxylic acid or binary acid anhydride, aliphatic diamine or aromatic diamine, diatomic alcohol. The molecule chain of the polymer contains benzene ring. The molar ratio of the benzene ring monomer to polymer is 1-40%. The weight-average molecular weight of the polymer is more than 80000. The invention has the following process: adding the synthesis monomer material into the reaction vessel in proportion for a polymerization reaction, getting polyprotic oligomer with a certain polymeric level at 120-200 DEG C, with a vacuum degree of 10000Pa-100000Pa for 0.5-5 hours; polymerizing the polyprotic oligomer in vacuum with a vacuum degree of 1-50 Pa, at 150-300 DEG C for 10-50 hours in a catalytic environment, finally getting the target polymer. The invention can be widely used for fiber product, piece product, foaming product, injection molding product, membrane product and etc.

Owner:马鞍山同杰良生物材料有限公司

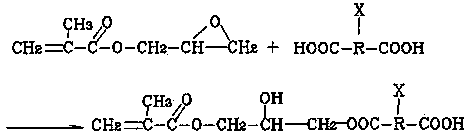

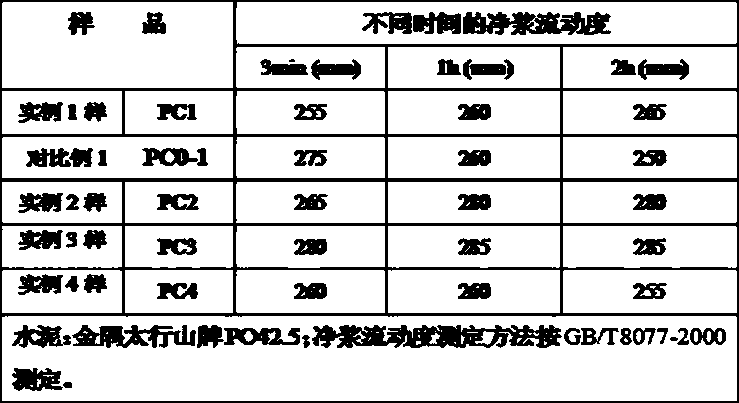

Preparation method of polycarboxylic acid high-performance cement water reducing agent

The invention relates to a preparation method of a polycarboxylic acid high-performance cement water reducing agent, which comprises the following steps: preparing reactants glycidyl methacrylate and multielement organic acid; mixing acrylic acid, alkenyl polyethenoxy ether big monomer, the reactants and a calculated amount of deionized water into mixed monomers, respectively dropwisely adding an initiator water solution and the mixed monomers at polymerization reaction temperature by using the deionized water as the substrate, carrying out polymerization reaction, cooling, and neutralizing to obtain the polycarboxylic acid high-performance cement water reducing agent. The reactants glycidyl methacrylate and multielement organic acid are introduced into the water reducing agent structure as the synthetic monomers; and the prepared cement water reducing agent has favorable dispersivity in the early stage and can be hydrolyzed into multielement organic acid under alkaline conditions, and the side chain of the polycarboxylic acid can generate new carboxyl groups, thereby enhancing the slump retaining property and water reducing rate of the cement water reducing agent and greatly lowering the production cost of the cement water reducing agent.

Owner:河北凯美思建筑材料有限公司

Meeting with water, inflated rubber made from resin capable of inflating if absorbing water, and preparation method

In the present invention, resin expending on water absorption is prepared by polymerization of synthetic monomer of propenoic acid ester containing polyoxyvinyl ether, catalyst, initiator and cross-linking agent; rubber expending on water contact is prepared from resin expending on water absorption, polychloroprene, filler, softener, promoter and antiager through mixing and valcanizing.

Owner:JIANGSU CHEM RES INST

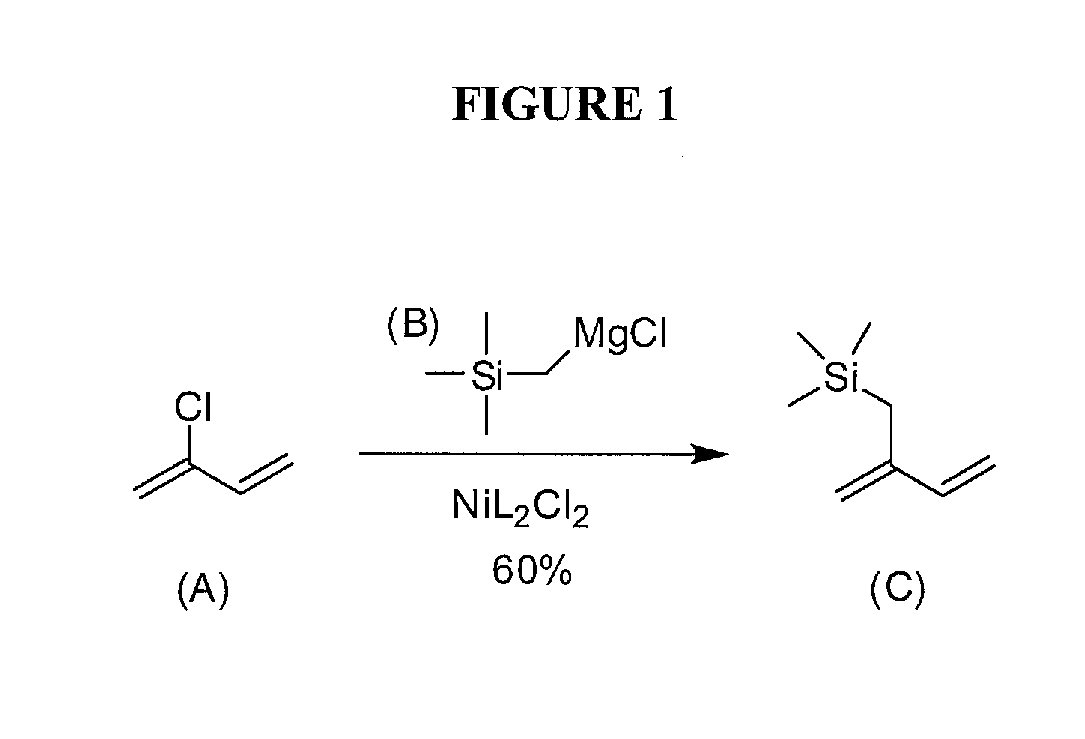

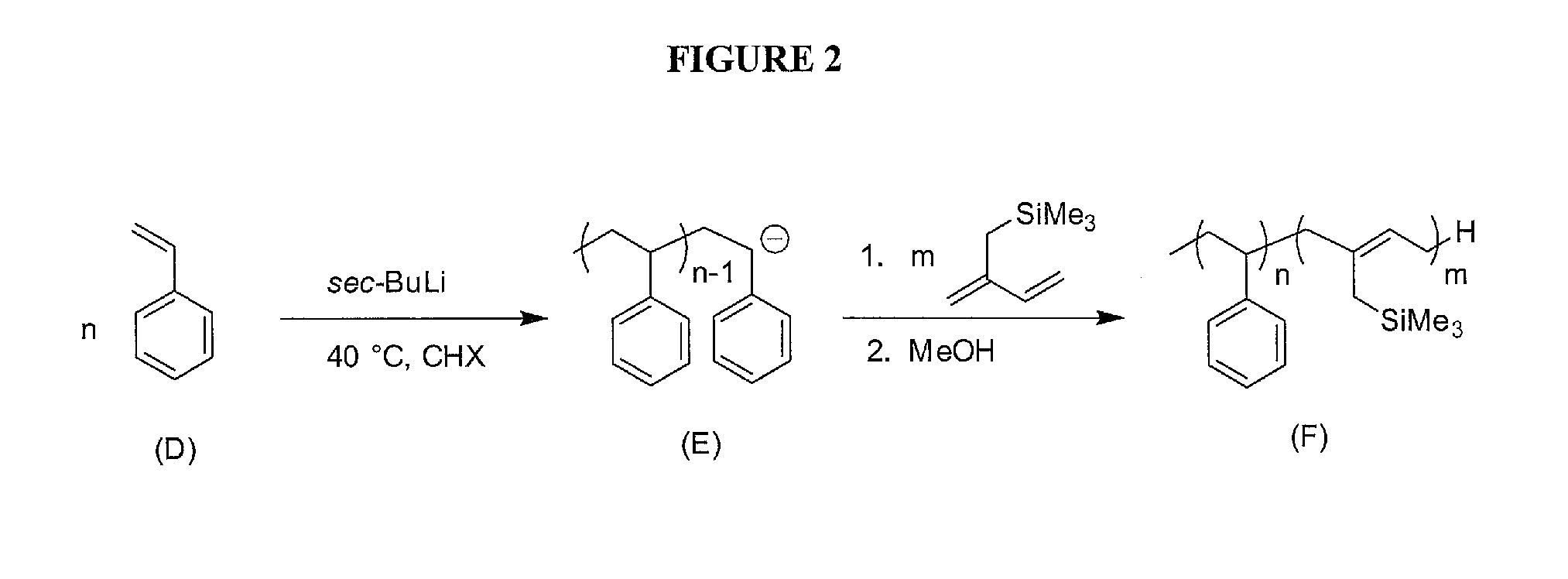

Silicon-containing block co-polymers, methods for synthesis and use

The present invention describes the synthesis of silicon-containing monomers and copolymers. The synthesis of a monomer, trimethyl-(2-methylenebut-3-enyl)silane (TMSI) and subsequent synthesis of diblock copolymer with styrene, forming polystyrene-block-polytrimethylsilyl isoprene, and synthesis of diblock copolymer Polystyrene-block-polymethacryloxymethyltrimethylsilane or PS-b-P(MTMSMA). These silicon containing diblock copolymers have a variety of uses. One preferred application is as novel imprint template material with sub-100 nm features for lithography.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

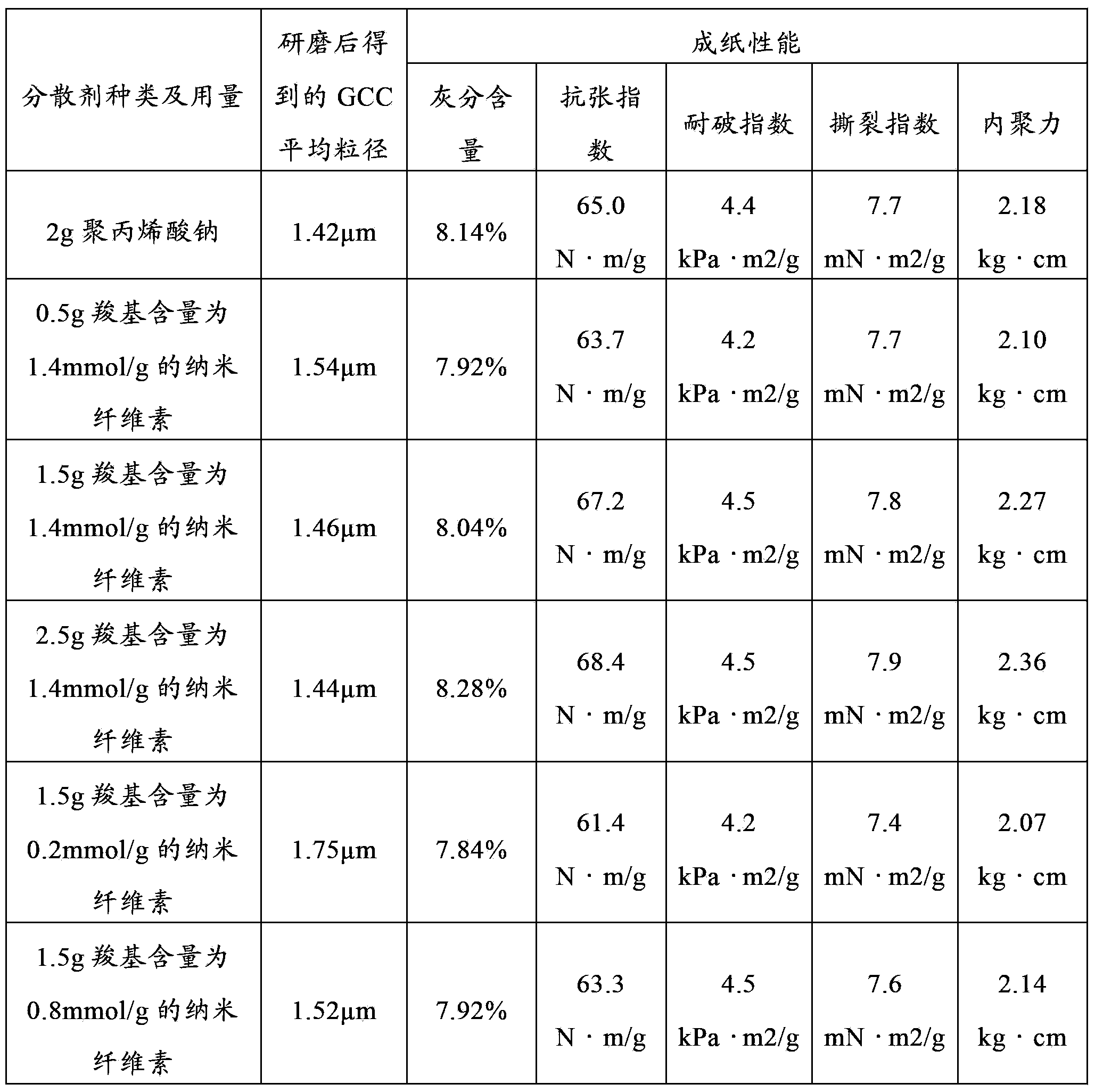

Ground calcium carbonate production process, ground calcium carbonate suspension and paper

ActiveCN104343043AAvoid damageLarge specific surface areaSpecial paperPaper/cardboardALLYL SUCROSESynthetic monomer

The invention relates to a ground calcium carbonate suspension production process. The ground calcium carbonate suspension production process comprises the following steps: providing a nano-crystalline cellulose solution of which the surface carboxyl content is 0.2-1.5mmol / g and the diameter is smaller than or equal to 100 nanometers; and providing calcium carbonate to be ground, preparing a mixed solution by taking the nano-crystalline cellulose solution as a dispersing agent according to a mixing proportion of adding 1-10kg by oven dry weight of the nano-crystalline cellulose solution into 1 ton of calcium carbonate, and grinding the mixed solution to obtain a ground calcium carbonate suspension. According to the ground calcium carbonate solution production process, the nano-crystalline cellulose solution of which the surface carboxyl content is 0.2-1.5mmol / g and the diameter is smaller than or equal to 100 nanometers is taken as the dispersing agent, instead of conventional sodium polyacrylate and salts thereof, so that the grain size of finished ground calcium carbonate meets the requirement, and damage to the skin and the respiratory tract of a person caused by a synthetic monomer in the preparation and use processes of polyacrylic acid and salts thereof is effectively avoided. The invention further relates to the ground calcium carbonate suspension and paper.

Owner:GOLD EAST PAPER JIANGSU

Kinetic natural gas hydrate inhibitor and preparation method thereof

InactiveCN104263340AGenerate delays and even blockInhibitory ExcellencePipeline systemsDrilling compositionSulfite saltAcrylonitrile

The invention belongs to the technical field of preparing chemical reagents and in particular relates to a kinetic natural gas hydrate inhibitor and a preparation method thereof. The hydrate inhibitor is obtained by performing a free radical solution polymerization reaction on N-vinyl pyrrolidone (NVP), acrylamide (AM) and acrylonitrile (AN) which are used as synthesis monomers in the presence of ammonium persulfate and sodium sulfite which are used as initiators. The kinetic natural gas hydrate inhibitor is capable of reducing the hydrate generation temperature to a larger extent and prolonging the induction time and is suitable for the recovery and transportation of oil and gas fields; besides, the kinetic natural gas hydrate inhibitor is convenient to synthesize, low in cost, prone to biodegrade, and wide in application prospect.

Owner:西南石油大学化学化工学院 +2

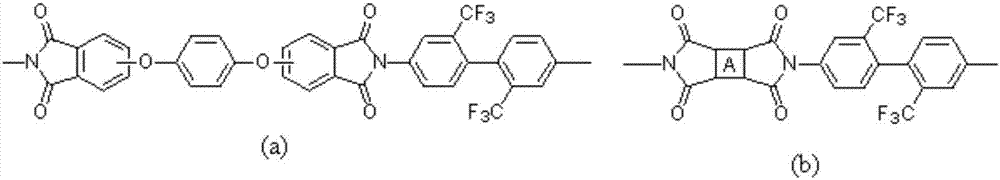

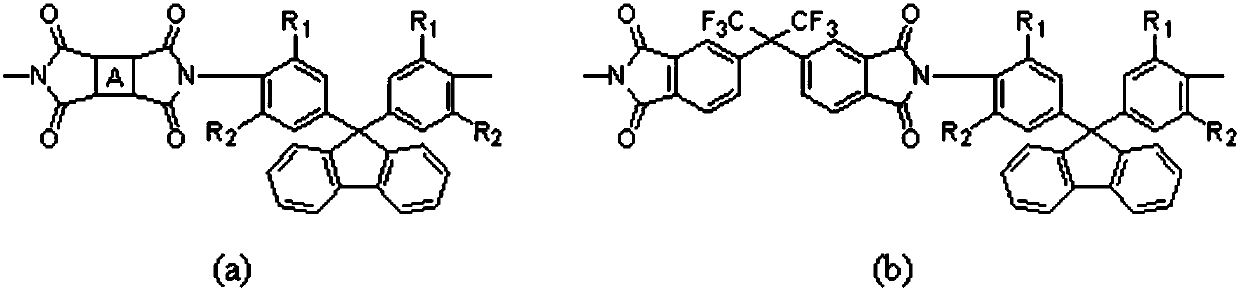

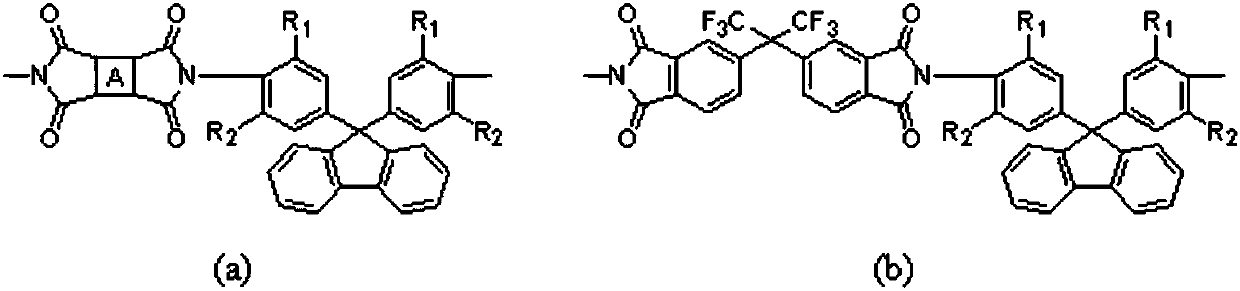

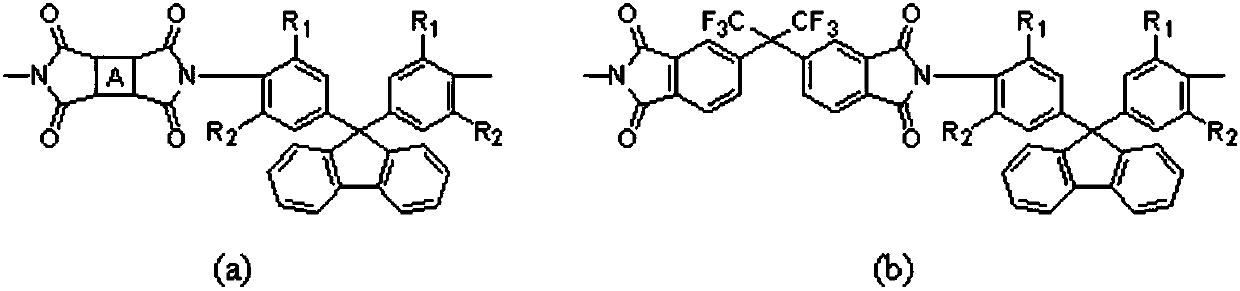

Polyimide polymer, transparent polyimide thin film and preparation method of transparent polyimide thin film

InactiveCN107459649AObstructed close packingImprove flex resistanceSynthetic monomerStructural formula

In order to solve the problem of poor flexibility of the existing transparent polyimide thin film, the invention provides a polyimide polymer, a transparent polyimide thin film and a preparation method of the transparent polyimide thin film. The polyimide polymer has a structural formula (a) shown in the description; the transparent polyimide thin film has a structural formula (b) shown in the description; in the structural formula (a), oxygen atoms in the molecular chain are positioned in a 3nd bit or 4th bit of a benzene ring; in the structural formula (b), A is a residual group of 3,3,4,4-Biphenyltetracarboxylic dianhydride. Synthesis monomers of the thin film comprise dianhydride and diamine; the dianhydride comprises 1,4-bis(3,4-dicarboxyphenoxy)benzene dianhydride and 3,3,4,4-Biphenyltetracarboxylic dianhydride; the diamine comprises 2,2'-bis(trifluoromethyl)-[1,1'-biphenyl]-4,4'-diamine. The transparent polyimide thin film provided by the invention has the advantages that a relatively flexible 1,4-bis(3,4-dicarboxyphenoxy)benzene dianhydride structure unit is introduced into a high-rigidity structure unit, so that the anti-deflection performance of the thin film can be greatly improved; the characteristics of high light transmission rate, good mechanical performance, high heat resistance, good anti-deflection performance and the like are realized.

Owner:NINGBO CHANGYANG TECH

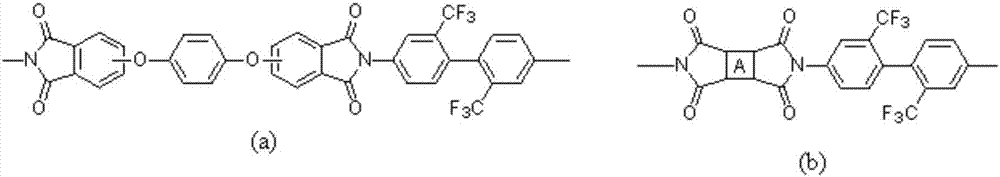

Polyimide resin and transparent polyimide film

In order to solve the problem that the solubility of existing polyimide resin is poor, the invention provides polyimide resin and transparent polyimide film. The polyimide resin and transparent polyimide film comprise structural units (a) and (b), in the structural unit (a), A is a residue of dianhydride, the residue of the dianhydride comprises dianhydride residue containing benzene rings; in thestructural units (a) and (b), R1 and R2 independently represent hydrogen atoms, halogen atoms, nitrile groups, nitro groups, alkyl groups, alkoxy groups or benzodiazepines substituent groups. A synthetic monomer of the film comprises dianhydride and diamine, the dianhydride comprises dianhydride containing benzene rings; the diamine is selected from fluorenediamine. The polyimide resin has good solubility; the transparent polyimide film prepared from the polyimide resin has the advantages of high transmittance, good heat resistance and the like.

Owner:NINGBO CHANGYANG TECH

Method for producing natural essence for Luzhou-flavor wine from fermented grain waste of wine by solid/liquid combined fermentation

ActiveCN102226128AEnhance the sense of natureEnhanced sense of solidityFood processingAlcoholic beverage preparationRed yeast riceFlavor

The invention discloses a method for producing natural essence for Luzhou-flavor wine from fermented grain waste of wine by solid / liquid combined fermentation, which comprises the following steps: adding saccharifying enzyme, acid protease, high-temperature-resistant active dry yeast, medium-temperature yeast and cellulase into fermented grain waste of wine; carrying out solid-state fermentation in a cellar; adding rhizopus, red yeast rice, high-temperature yeast, fermented grain waste wine and concentrated hexanoic acid fermentation liquid; carrying out solid / liquid combined fermentation in the cellar; and carrying out extractive distillation on the fermented unstrained wine, carrying out sectionalized concentration, blending and compounding to obtain the natural essence product for Luzhou-flavor wine. The invention has the advantages of low cost and short production cycle, and can treat 35000t of fermented grain waste per year if a production scale of 8000t / a is formed, thereby performing a huge function on regional environmental protection; and meanwhile, the natural essence can be used as a seasoning liquid for brewage so as to avoid temporary fragrance caused by adding synthetic monomer essence, thereby enhancing the natural sensation and solid-state sensation of wine and enhancing the quality of wine.

Owner:SICHUAN YINFAN BIOTECH LTD

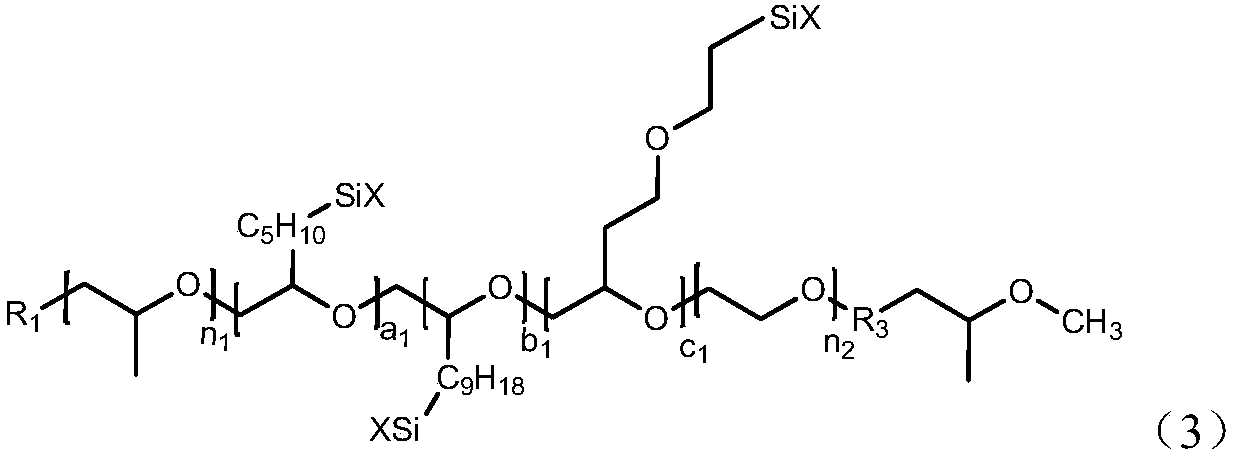

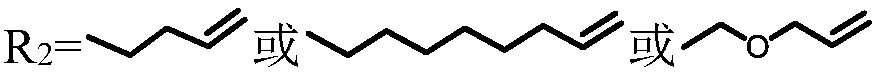

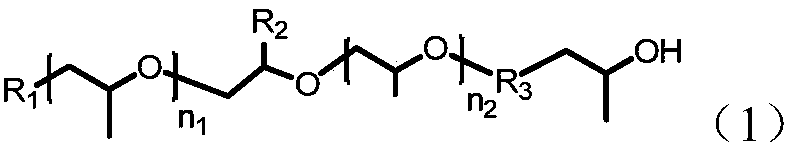

Polyether with controllable silicon content and preparation method and application thereof

The invention discloses modified polyether with controllable silicon content and a preparation method thereof and an application thereof of polyether as a sealant. According to the invention, monohydric alcohol or dihydric alcohol are used as a starting agent, an unsaturated bond-containing epoxy structural monomer and conventional polyether synthesis monomer are used, a compound having one or more double bonds is firstly synthesized, and after a methoxy group is used for terminating, a hydrosilylation is carried out to obtain the silicon-modified polyether with the controlled silicon content.The method adopts the conventional hydrosilylation and a stepwise polymerization reaction, and the provided synthesis steps are simple and easy to realize, and the method has high yield; the composition of the traditional sealant is changed from the source, and the obtained product has excellent characteristics of bonding properties, weather resistance, durability and mechanical properties (hightear strength, breaking strength and modulus, moderate elongation at break and hardness), and can achieve different use ranges by controlling the structure of the polyether.

Owner:WANHUA CHEM GRP CO LTD

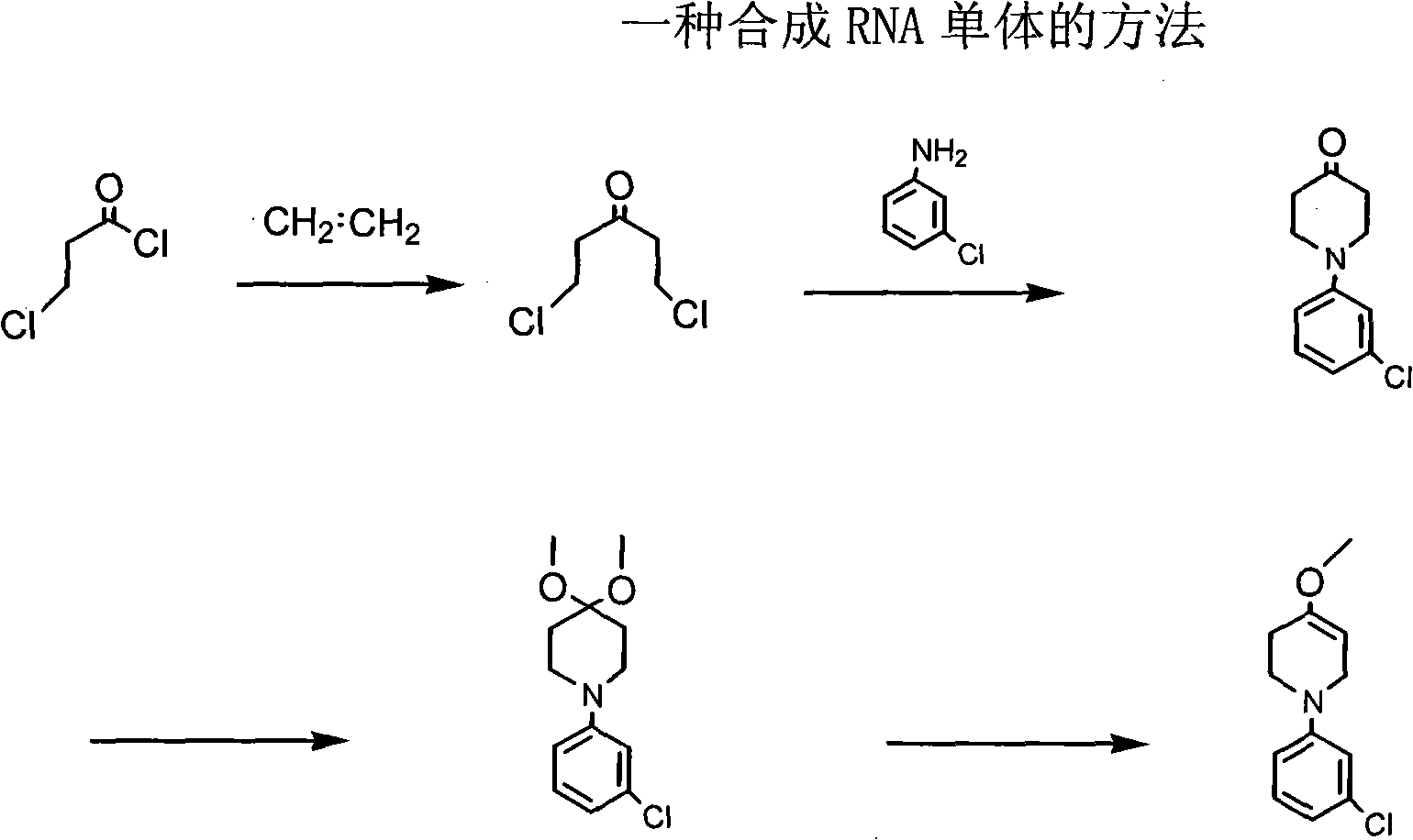

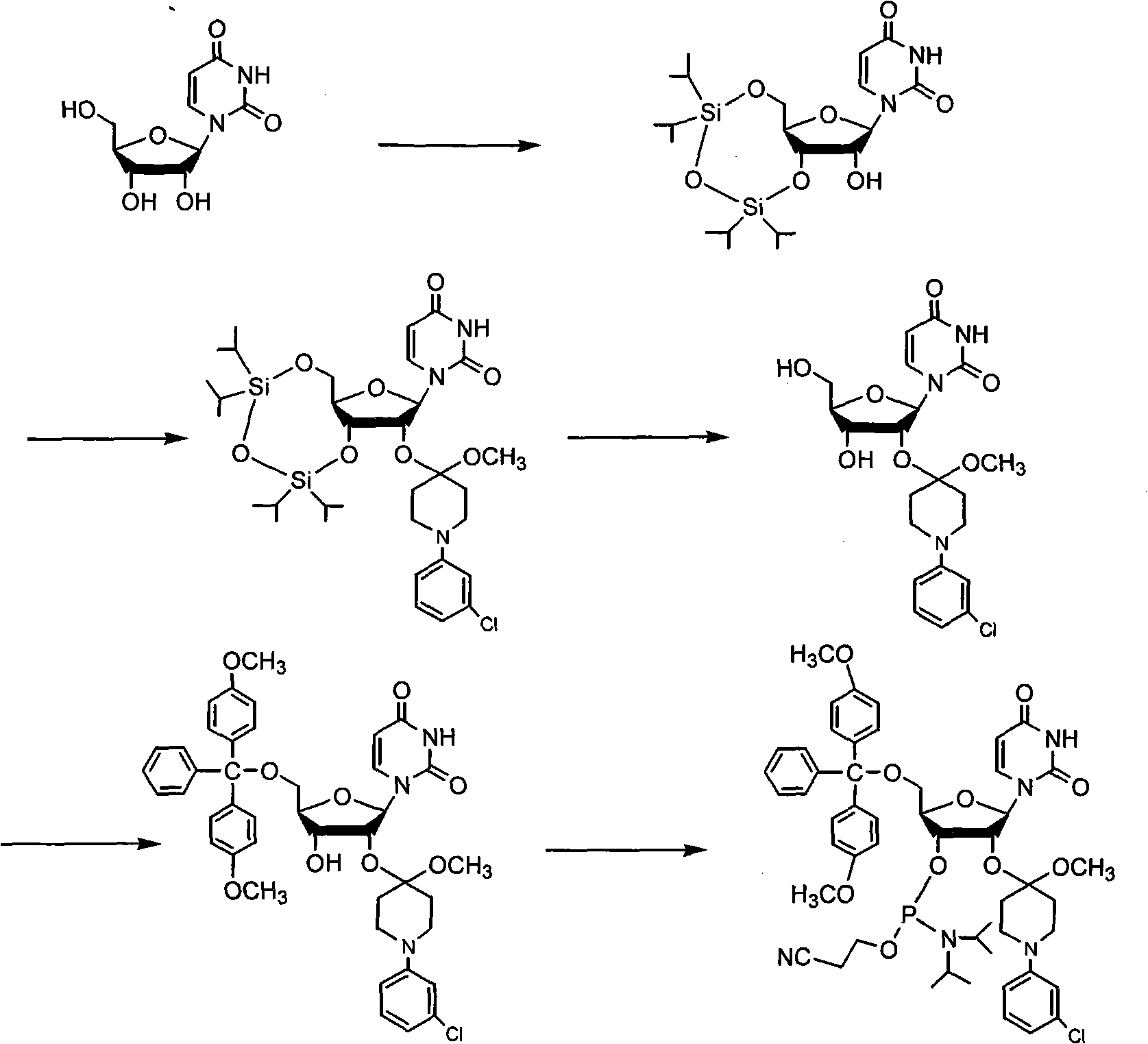

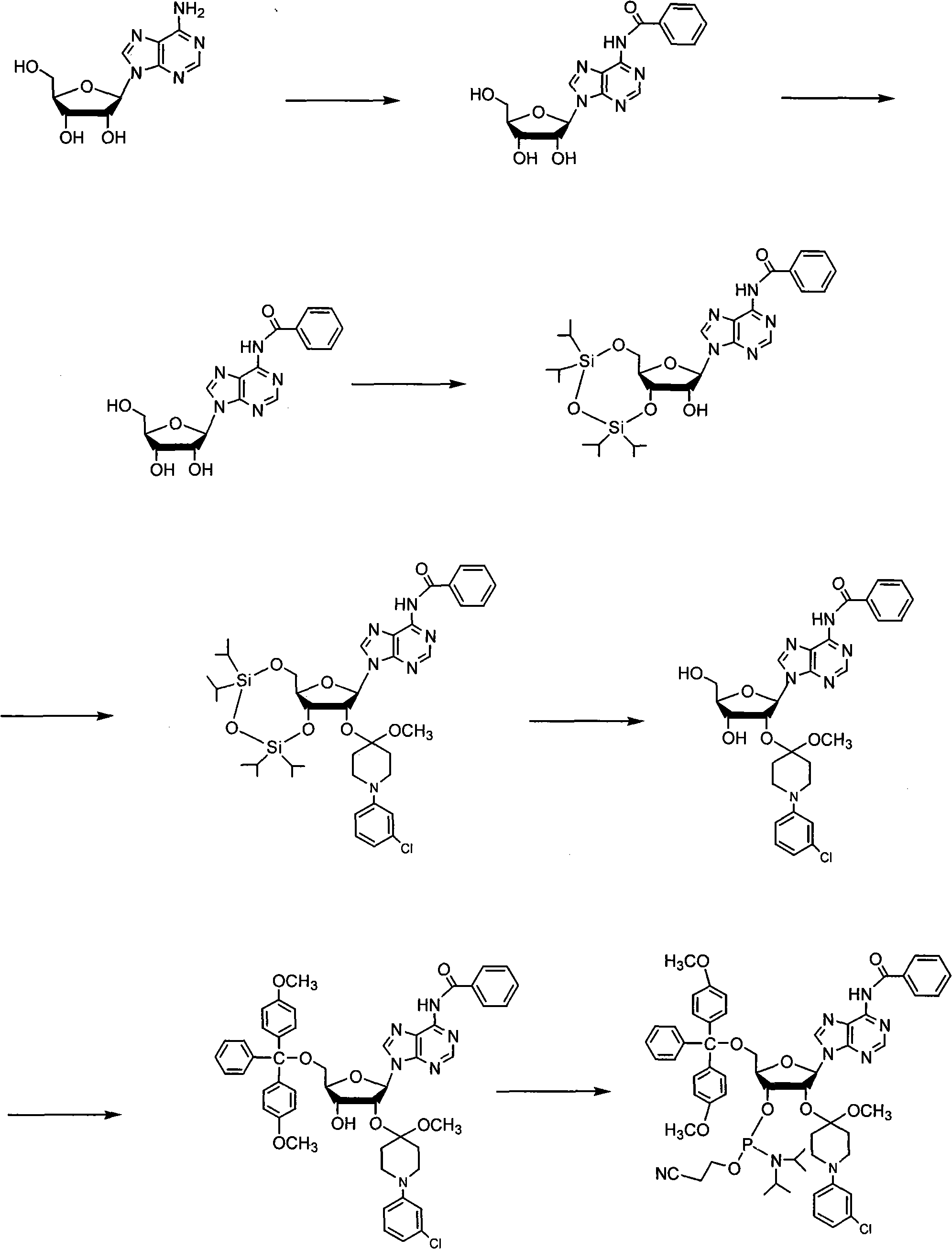

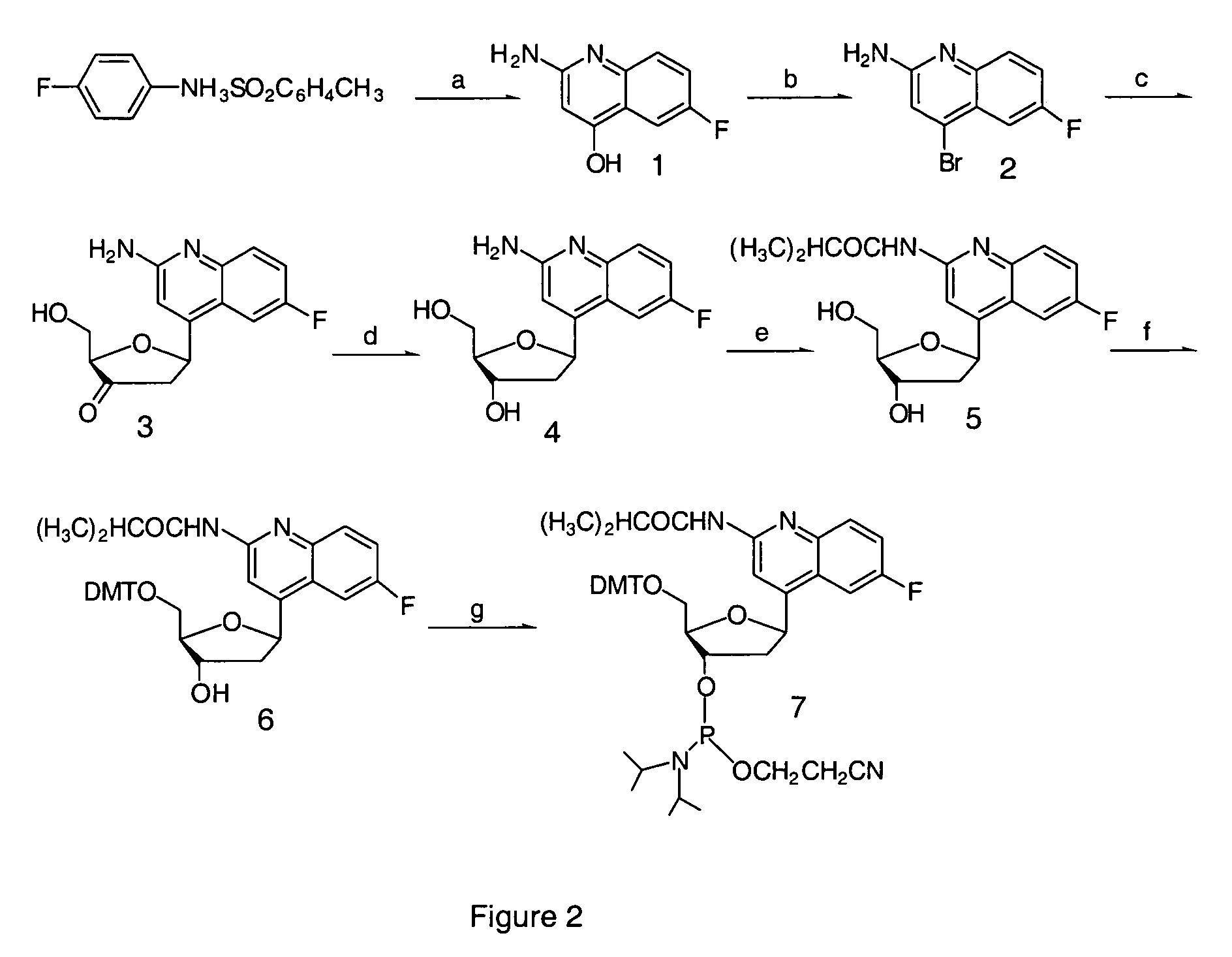

Process for synthesizing RNA monomer

The invention discloses a method for synthesizing monomers of RNA. The unique 2'-protecting groups of the synthesized monomers of the RNA adopted in the method are regarded as starting points and the structure of the synthesizing monomers of the RNA is different from the structure of previous synthesizing monomers of the RNA. The method is characterized in that the protecting groups are stable in acid de-protection conditions and alkaline de-protection conditions, and after solid phase synthesis is finished, on condition that the protection group of 5'-DMT is removed and the 2'-protecting group is still on the chain, high-pressured liquid phase purification can be carried out. Regarding the products after first grade purification, the 2'-protecting groups can be completely removed in proper conditions, which can be annealed to become a double strand with another complementary strand after further purification, and the purity of the RNA oligonucleotide produced after the synthesis and purification can be above 97 percent; furthermore the purification recovery rate can be above 55 percent.

Owner:SHANGHAI GENECHEM

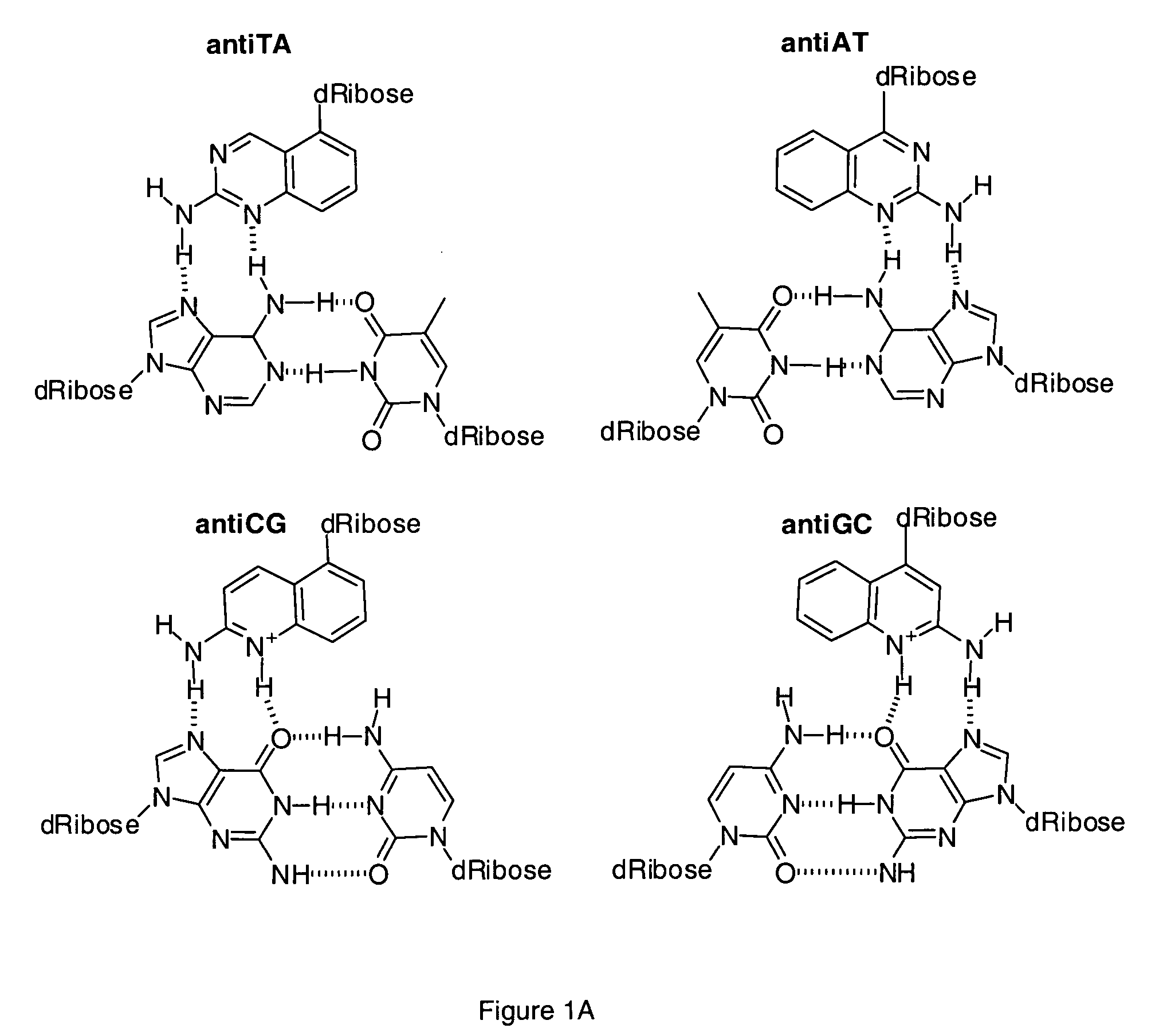

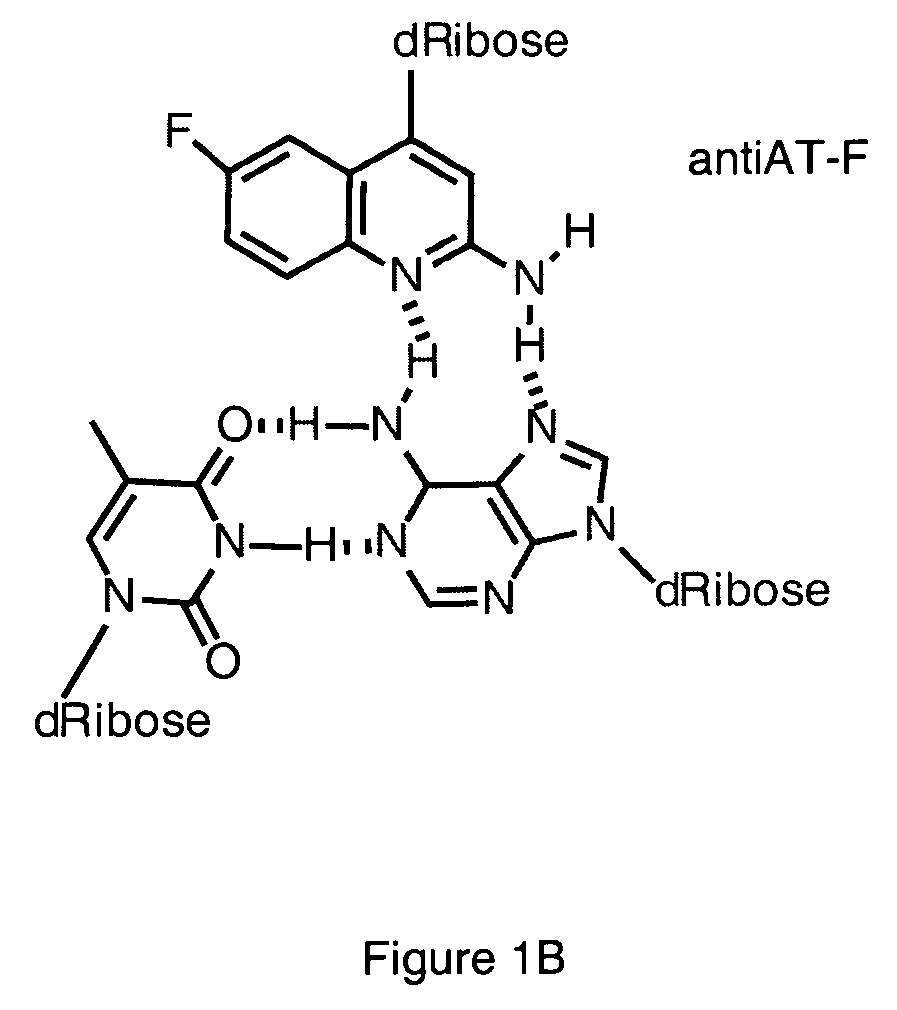

Halogenated aminoquinolines and methods for forming DNA triplexes

Novel synthetic monomers that have the capacity to be assembled into defined oligomers which bind with sequence specificity to duplex Watson-Crick DNA via a triple helix motif are provided.

Owner:BOARD OF RGT UNIV OF NEBRASKA

Process for high-efficiency synthesis of super branched polyester-amine

An efficient process for synthesizing the ultrabranched polyester-amine includes aminolysis of acid anhydride, acetylizing hydroxy to obtain nanometer N-(2-acetoxyethyl)-N-(1,3'-dicarboxy benzoyl) amine, putting it along with catalyst in reaction tube, heating reaction in N2 atmosphere, vacuumizing, and cooling. Its advantages are simple process and high yield.

Owner:TSINGHUA UNIV

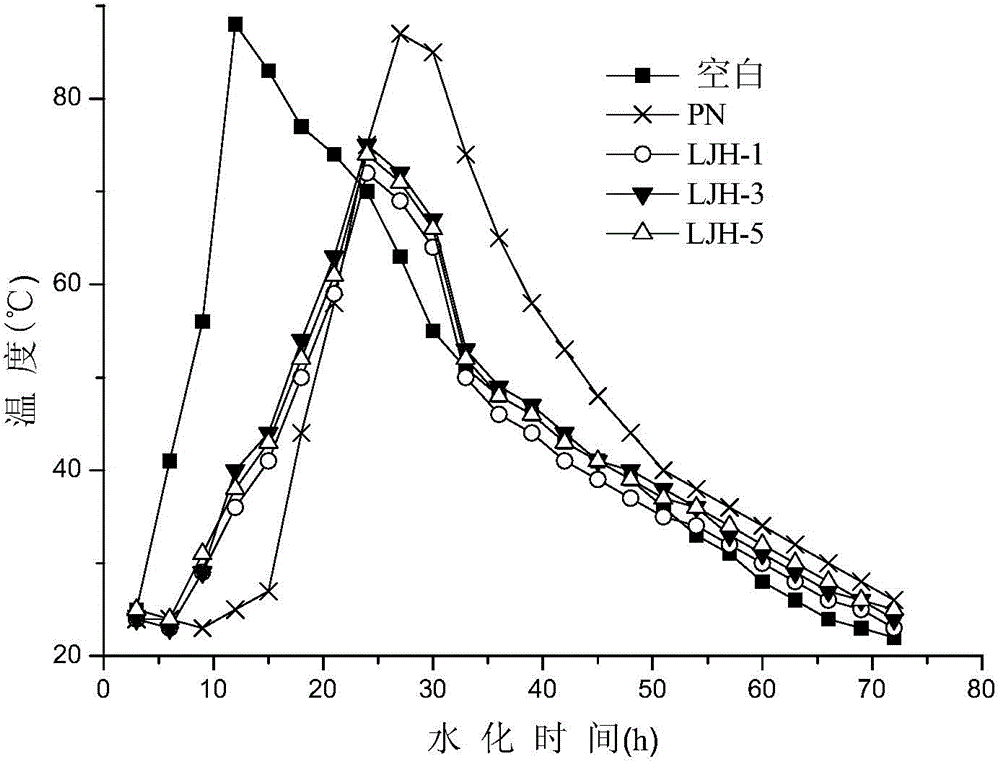

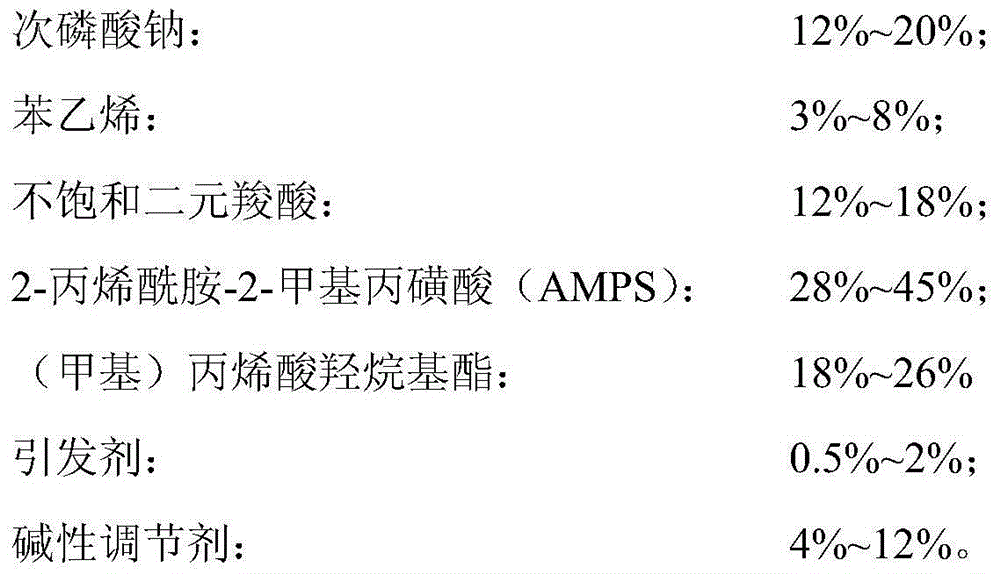

Organic phosphonate concrete plastic retaining agent and preparation method thereof

The invention relates to an organic phosphonate concrete plastic retaining agent and a preparation method thereof. The preparation method comprises the following steps: by taking the following components as synthetic monomers: 12-20 percent of sodium hypophosphite, 3-8 percent of styrene, 12-18 percent of unsaturated dicarboxylic acid, 18-26 percent of (methyl) hydroxyalkyl acrylate and 28-45 percent of 2-acrylamide-2-methyl propane sulfonic acid (AMPS), performing aqueous solution polymerization under the action of an initiator, thereby synthesizing an organic phosphonate copolymer. The hydroxyalkyl ester, carboxyl, acylamino, sulfo group and the like introduced into the molecular structure have a certain delayed coagulation effects and good plastic retaining effects. According to the invention, the aqueous solution normal-pressure production is adopted, the equipment requirement is low, the operation is convenient, the method is environmentally friendly, the industrial production is promoted, and the product does not contain chloride ions and does not have corrosion damage to steel bars in the concrete.

Owner:NANJING HYDRAULIC RES INST

Nano powder and polyimide resin composition

InactiveCN108395577AImprove heat resistanceHigh dimensional stabilityBulk chemical productionChemical synthesisNanoparticle

The present invention provides nano powder comprising a plurality of nanoparticles, and the surfaces of the nanoparticles have polymerized functional groups, wherein each polymerized functional groupcomprises a polyimide functional group, and the polymerized functional group base is produced by chemically synthesizing the nanoparticles with a synthetic monomer.

Owner:TAIFLEX SCI

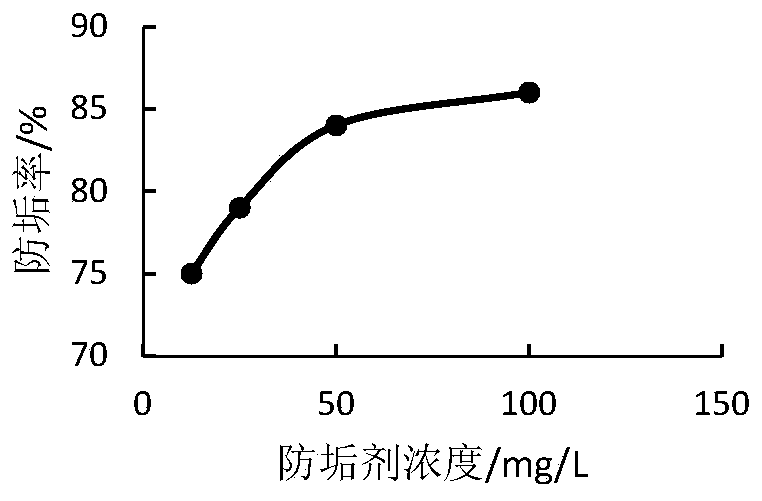

Temperature-resistant type barium strontium sulfate anti-scaling agent for oil field and preparation method thereof

ActiveCN109748405AGood antifouling effectMaintain anti-fouling rateWaste water treatment from quariesScale removal and water softeningSynthetic monomerMaleic anhydride

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

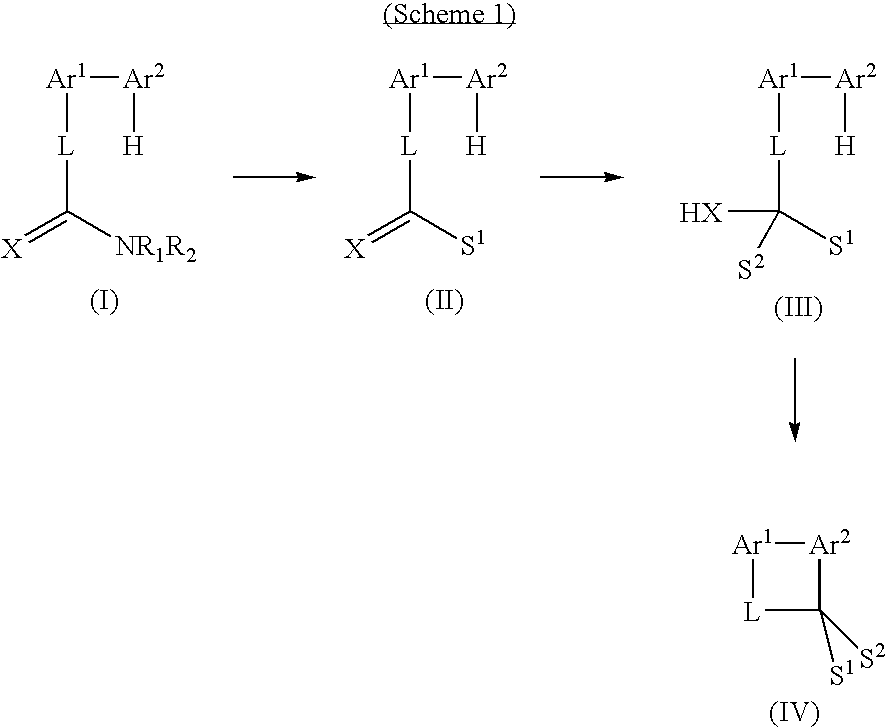

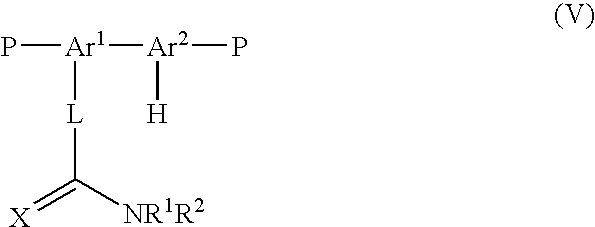

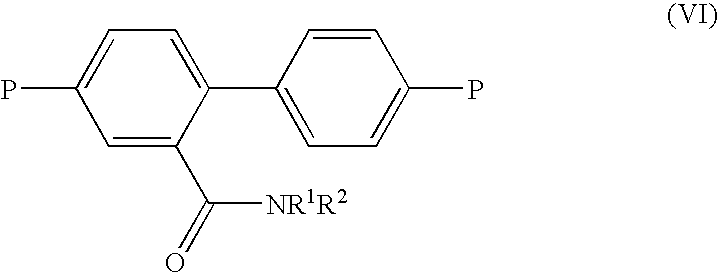

Method for the prodution of monomers useful in the manufacture of semiconductive polymers

ActiveUS20050240011A1Good flexibilityImprove solubilityImmunoglobulins against animals/humansAntibody ingredientsSynthetic monomerSemiconductor

The instant invention relates to a new method for the synthesis of monomers and their use inter alia in the manufacture of semiconductive polymers. Monomers, in particular, asymmetric monomers, such as asymmetric fluorene compounds, are valuable material in the manufacture of semiconductive polymers. The know methods for producing asymmetric monomers, such as asymmetric fluorene compounds, are expensive due to the formation of by-products. The method according to the present invention avoids the formation of such by-products and is described in more detail in claims 1 to 14.

Owner:MERCK PATENT GMBH

Medical care composite material and disposable injector prepared from medical care composite material

InactiveCN107815078AGuaranteed performanceImprove antibacterial propertiesInfusion syringesAntioxidantSynthetic monomer

The invention relates to a medical care composite material and a disposable injector prepared from the medical care composite material. Particularly, the medical care composite material is prepared from PLA (polylactic acid), toughening agents and antioxidants, wherein per 100 weight parts of PLA contains 10 to 50 parts of toughening agents and 0 to 1 part of antioxidants. All blending ingredientsare medical stage non-toxic products; synthetic monomers and corresponding polymers are safe and non-toxic on the human bodies; after 4 to 6 months under the compost conditions, the materials can beautomatically degraded into water and carbon dioxide; micromolecular plasticizers are not contained in blending resin; the danger of separation of compounds of the type, medicine liquid pollution andhuman body entering cannot occur. The medical care composite material is used as a special material for the disposable injector and is used for preparing the disposable degradable injector. The material has the advantages that the performance in aspects of bacterium resistance and degradation is obviously superior to that of pure polylactic acid raw materials. The formula is reasonable; the performance is stable; environment is not polluted; the mass production can be realized in a purified workshop.

Owner:丽水市莲都区君正模具厂

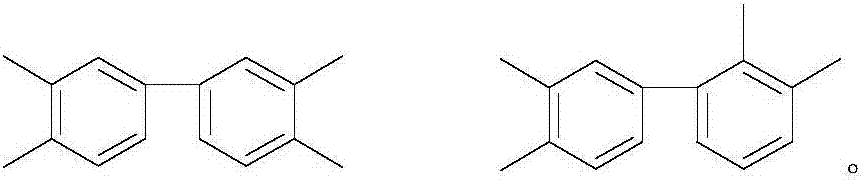

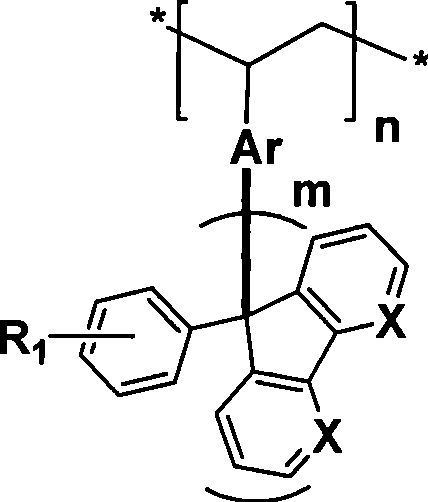

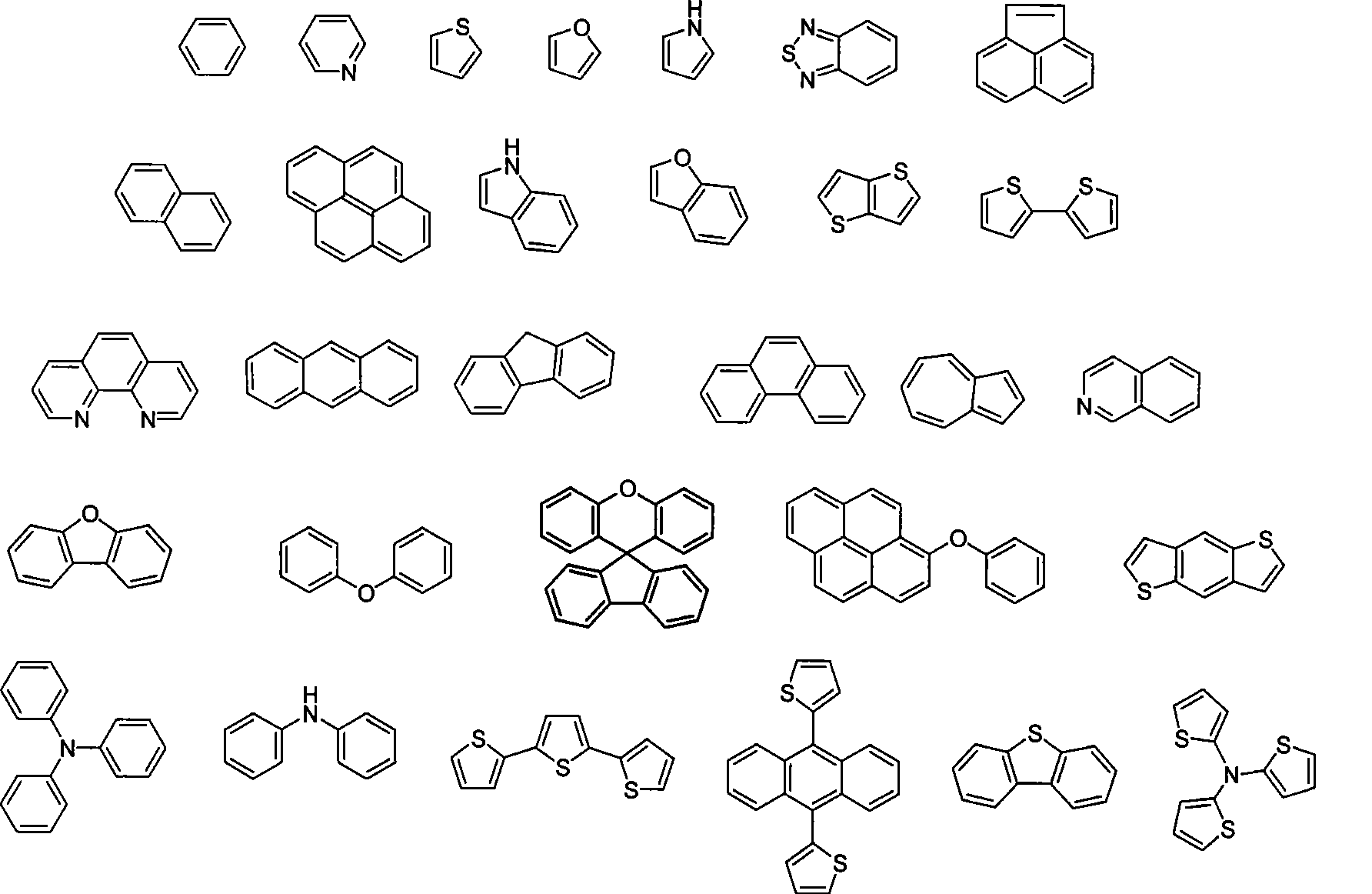

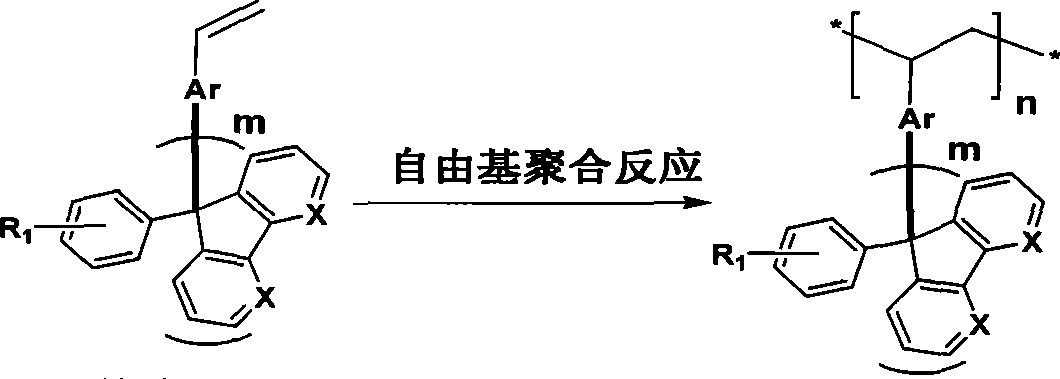

Poly (diaryl fluorene ethylene) material, as well as preparation and use method thereof

The invention discloses a polymeric (diaryl fluorene ethylene) material, a preparation method and an application method thereof, belong to the scientific and technical field of organic optoelectronic materials, in particular relates to a diaryl fluorine ethylene polymeric material and application of the polymeric material as a host material, a hole transport material, an electron transport material, a switch material and a tricolor luminescent material to the organic electron field, such as organic flash memory devices, photovoltaic cells and organic light emitting display. The polymeric material has the following structure. The polymeric material has the following advantages: (1) raw materials are cheap and the synthetic method is convenient as a monomer is synthesized by a Friedel-Crafts reaction; (2) diaryl fluorene has high thermal stability and vitrification point; (3) main chain of polyethylene has better flexibility and high solubility; and (4) stacking effect of the diaryl fluorene has better optoelectrical activity. Electroluminescent devices prepared from the material of the invention achieve satisfactory results in terms of brightness, luminous efficiency, voltage withstanding stability and the like.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD

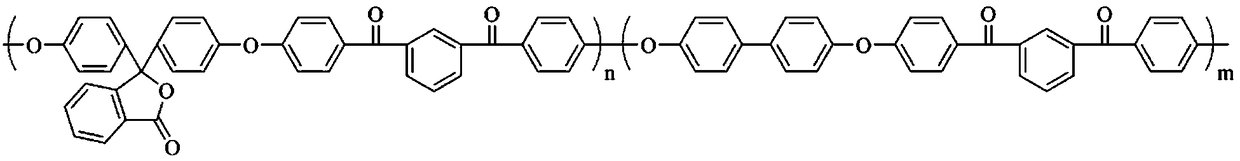

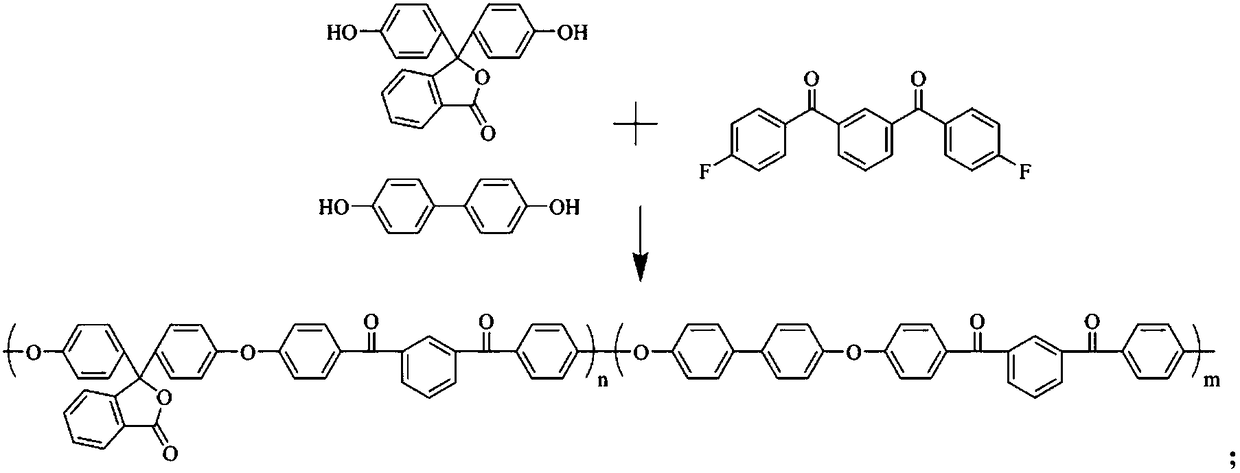

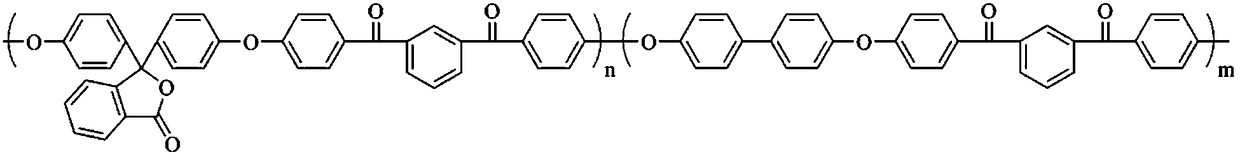

Novel crystallizable polyether ether ketone resin capable of dissolving side groups containing phthalein and preparation method thereof

The invention provides a novel crystallizable polyether ether ketone resin capable of dissolving side groups containing phthalein and a preparation method thereof, and belongs to the technical field of polymer materials. Under nitrogen protection conditions, mixed bisphenol and a dihalogen monomer of the equimolar ratio are used as a synthetic monomer, toluene or xylene is used as a water-carryingagent, potassium carbonate and / or sodium carbonate 1-1.4 times the total molar amount of a bisphenol monomer is used as a catalyst, and sulfolane or dimethyl sulfoxide is used as a solvent for the reaction. Synthesis is performed at 240 DEG C for 4.5-10 hours. The crystallinity of the resin is 2-40%, and the number average relative molecular weight is more than 30,000. The thermal tensile deformation rate of the resin at 250 DEG C is 0-400%, and the resin can be dissolved in 1,1',2,2'-tetrachloroethane and / or p-chlorophenol. The polyether ether ketone resin has the advantages of strong crystallization capacity, high molecular mass, good tensile performance, strong molecular orientation capability and excellent solubility.

Owner:DALIAN UNIV OF TECH

Medical polylactic acid composite material and disposable syringe prepared from same

InactiveCN107805373AGuaranteed performanceImprove antibacterial propertiesHigh volume manufacturingAntioxidant

The invention relates to a medical polylactic acid composite material and a disposable syringe prepared from the same, in particular to a medical degradable composite material. The composite materialcomprises, by weight, 100 parts of PLA (polylactic acid), 10-50 parts of a flexibilizer and 0-1 part of an antioxidant. All blend components are medical nontoxic products, synthetic monomers and corresponding polymers are totally nontoxic to human bodies, automatic degradation into water and carbon dioxide within 4-6 months under a composting condition can be realized, mixed resin is free of micromolecular plasticizers, and risks of separation, entering human bodies and liquid medicine contamination of the similar composites are avoided. The medical polylactic acid composite material serving as a special material for disposable degradable syringes is evidently superior to pure polylactic acid materials in antibacterial and degradation performance and can be used for preparation of the disposable degradable syringes. The medical polylactic acid composite material is reasonable in formulation, stable in performance, free of environment pollution and available for large-batch production in purification workshops.

Owner:丽水市莲都区君正模具厂

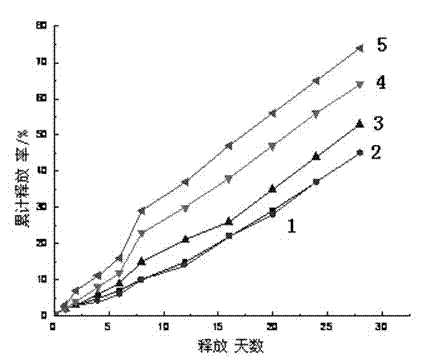

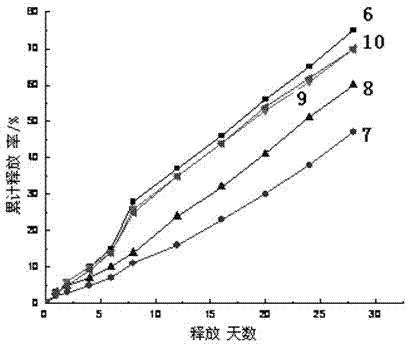

Novel controlled-release fertilizer coating agent and preparation method thereof

InactiveCN103755468AImprove convenienceTargeted optimizationFertilizer mixturesFunctional monomerSynthetic monomer

The invention discloses a novel controlled-release fertilizer coating agent and a preparation method thereof. The coating agent synthetic monomers mainly include rigid monomer with higher Tg, flexible monomer with lower Tg and functional monomer. Type and content of the functional monomer are changed, and functional groups with different hydrophilicity and content are introduced on a polymer chain, thus, a polymeric membrane has different permeability, control on release rate of fertilizer is realized, and requirements of crops in different growth cycles are satisfied. The coating material with such structure has good film-forming ability, water tightness and release control property to fertilizer, and wide adaptability.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com