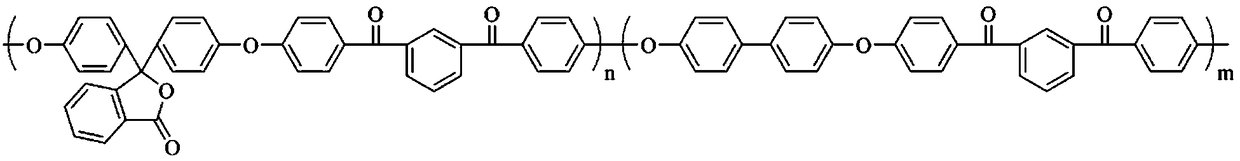

Novel crystallizable polyether ether ketone resin capable of dissolving side groups containing phthalein and preparation method thereof

A new type of polyetheretherketone ketone resin, applied in the field of polymer materials, can solve the problems of limited application and poor resin solubility, and achieve the effects of diverse radiation resistance, high heat resistance level, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

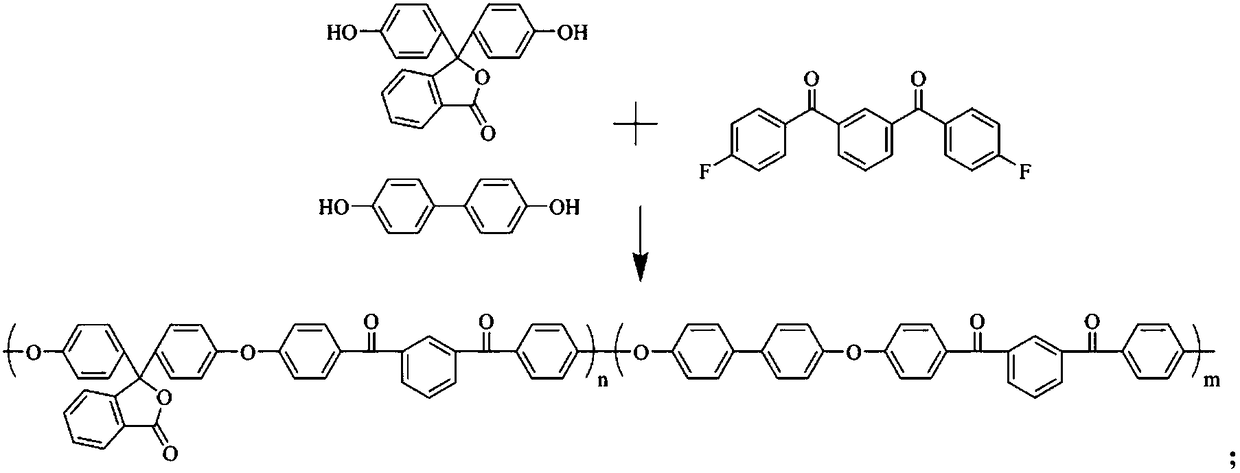

Method used

Image

Examples

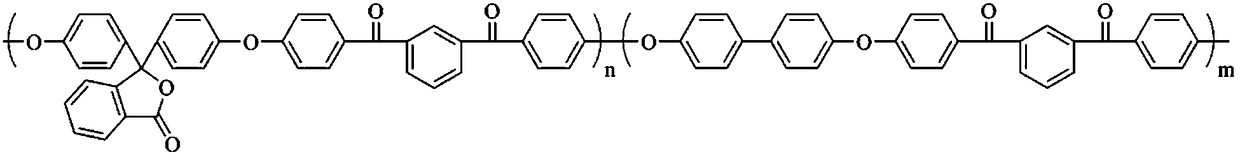

Embodiment 1

[0020] Under the condition of nitrogen protection, add 0.01 mol of mixed bisphenol with a molar ratio of phenolphthalein to 4,4'-dihydroxybiphenyl of 9:1 in a three-neck flask with a stirrer, nitrogen inlet and condenser, in the structural formula n / ( The ratio of n+m) is 0.9, 0.01mol of dihalogen monomer 1,3-bis(4'-fluorobenzoyl)benzene, and potassium carbonate that is 1 times the total molar weight of mixed bisphenol monomers is used as a catalyst, and an appropriate amount is used Toluene is used as a water-carrying agent, and an appropriate amount of sulfolane is used as a solvent. Keep the temperature at 110°C for 1 hour, then distill off the toluene, and raise the temperature to 175°C for 4.5 hours. After the final post-treatment, a new crystallizable and soluble polyetheretherketone-ketone resin containing phthalein side groups is obtained. The crystallinity of the corresponding resin is 2%, and the number average relative molecular weight is 30,000. The thermal tensi...

Embodiment 2

[0022] According to the same operating procedure as in Example 1, under the condition of nitrogen protection, a mixture of phenolphthalein and 4,4'-dihydroxybiphenyl with a molar ratio of 5:5 was added to a three-necked flask with a stirrer, a nitrogen inlet and a condenser. 0.01 mol of phenol, the ratio of n / (n+m) in the structural formula is 0.5, 0.01 mol of dihalogen monomer 1,3-bis(4'-fluorobenzoyl)benzene, and the total molar weight of mixed bisphenol monomer is 1.2 twice as much potassium carbonate as a catalyst, an appropriate amount of toluene as a water-carrying agent, and an appropriate amount of sulfolane as a solvent. Keep the temperature at 120°C for 2 hours, then distill off the toluene, and raise the temperature to 200°C for 6 hours. After the final post-treatment, a new crystallizable and soluble polyetheretherketone-ketone resin containing phthalein side groups is obtained. The crystallinity of the corresponding resin is 20%, and the number-average relative m...

Embodiment 3

[0024] According to the same operating procedure as in Example 1, under the condition of nitrogen protection, a mixture of phenolphthalein and 4,4'-dihydroxybiphenyl with a molar ratio of 1:9 was added to a three-necked flask with a stirrer, a nitrogen inlet and a condenser. 0.01 mol of phenol, the ratio of n / (n+m) in the structural formula is 0.1, 0.01 mol of dihalogen monomer 1,3-bis(4'-fluorobenzoyl)benzene, and the total molar weight of mixed bisphenol monomer is 1.4 twice as much potassium carbonate as a catalyst, an appropriate amount of toluene as a water-carrying agent, and an appropriate amount of sulfolane as a solvent. Keep the temperature at 130°C for 3 hours, then distill off the toluene, and raise the temperature to 240°C for 10 hours. After the final post-treatment, a new crystallizable and soluble polyetheretherketone-ketone resin containing phthalein side groups is obtained. The crystallinity of the corresponding resin is 40%, and the number-average relative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com