Nano powder and polyimide resin composition

A technology of nano-powder and polyimide, which is applied in the field of polyimide resin composition, can solve the problems of poor dispersion, insignificant effect of modified nano-powder, difficulty in scaling up the process, etc., and achieve good dispersion Performance and compatibility, low thermal expansion coefficient, high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment E1

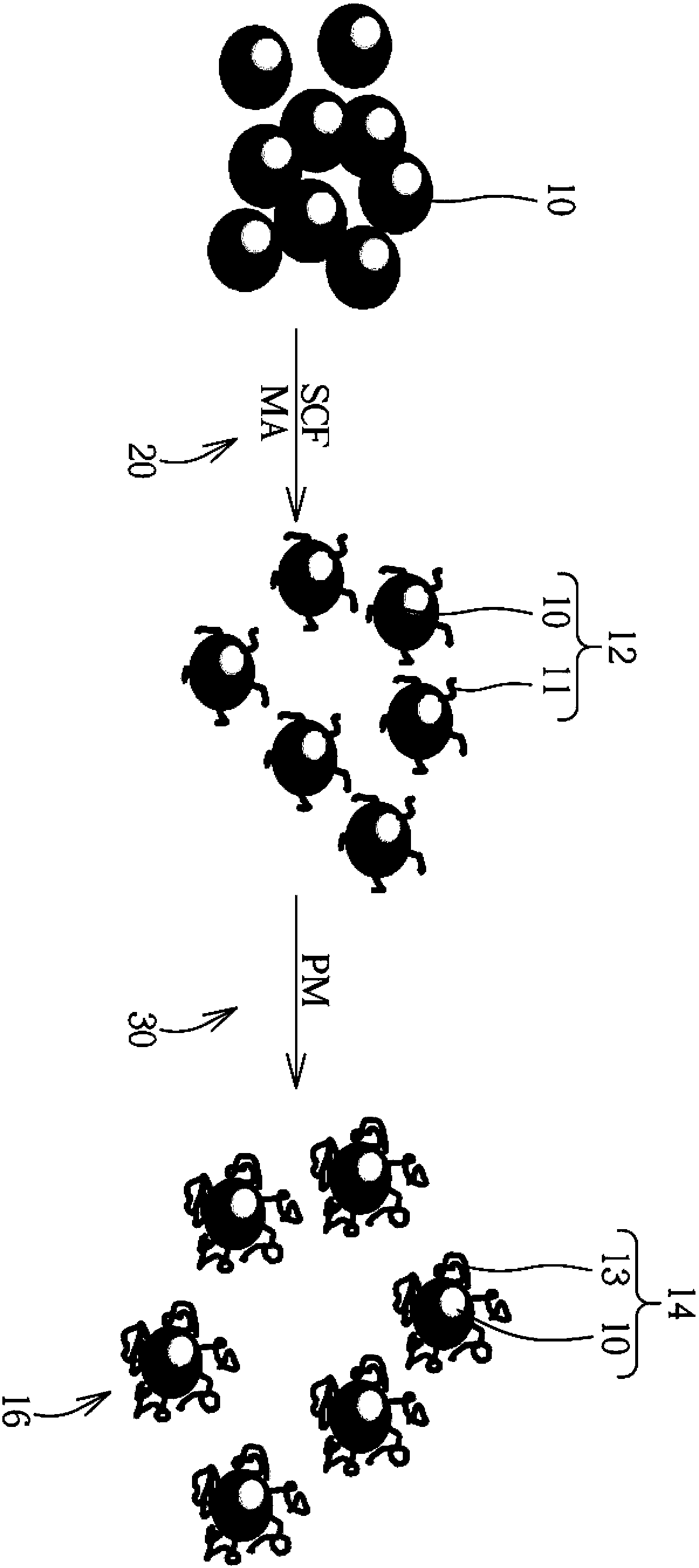

[0057] 1. Preparation of polymerized nanopowder

[0058] first surface modification

[0059] Put the nanoparticles into the reaction tank and fill with liquid carbon dioxide, soak and stir as pretreatment. Wherein, the material of the nanoparticles is silicon dioxide. A silane-based modifier with an amino group at the end and an auxiliary solvent are added. Wherein, the silane modifier is 3-aminopropyltriethoxysilane, and the auxiliary solvent is methanol. Next, the pressure and temperature of the reaction tank are increased until the liquid carbon dioxide is transformed into a carbon dioxide supercritical fluid, and the reaction is carried out at a certain speed for about 2 hours. Wherein, the pressure of the carbon dioxide supercritical fluid may be 73 bar to 200 bar (bar), and the temperature may be 40°C to 60°C. After the reaction, the reaction tank is depressurized and the powder material is taken out, and the nanoparticles are cleaned with an organic solvent capable ...

Embodiment E2

[0065] 1. Preparation of polymerized nanopowder

[0066] The preparation method of the polymerized nanopowder in this example is the same as that in Example E1.

[0067] 2. Preparation of polyimide resin composition

[0068] The method for preparing the polyimide resin composition in this example is roughly the same as in Example E1, except that polyamic acid A is replaced by polyamic acid B, and polyamic acid B is changed from 2, 3, 3', 4' - Composed of biphenyltetracarboxylic dianhydride (BPDA), p-phenylenediamine (PDA) and 4,4'-diaminodicyclohexylmethane (MBCHA).

Embodiment E3

[0070] 1. Preparation of polymerized nanopowder

[0071] The preparation method of the polymerized nanopowder in this example is the same as that in Example E1.

[0072] 2. Preparation of polyimide resin composition

[0073] The method for preparing the polyimide resin composition in this example is roughly the same as that of Example E1, except that the polyamic acid A is replaced by polyamic acid C, and the secondary surface modification added to the polyamic acid C solution The ratio of the quality nano-powder of the present invention is about 5% by weight, wherein polyamic acid C is composed of pyromellitic dianhydride (PMDA) and 3,4'-diaminodiphenyl ether (3,4'-ODA) composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com