Patents

Literature

54results about How to "High dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coke oven reconstruction

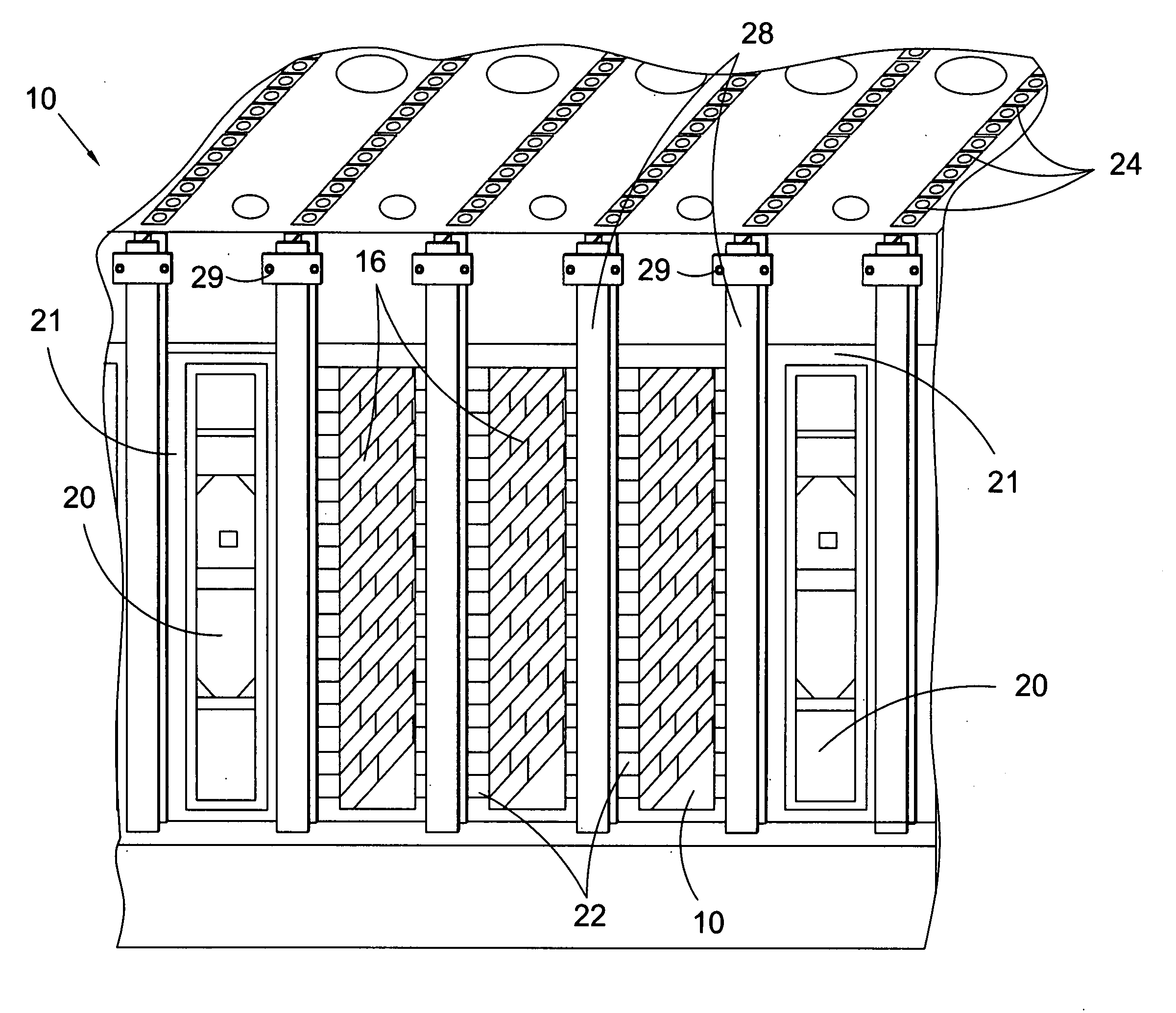

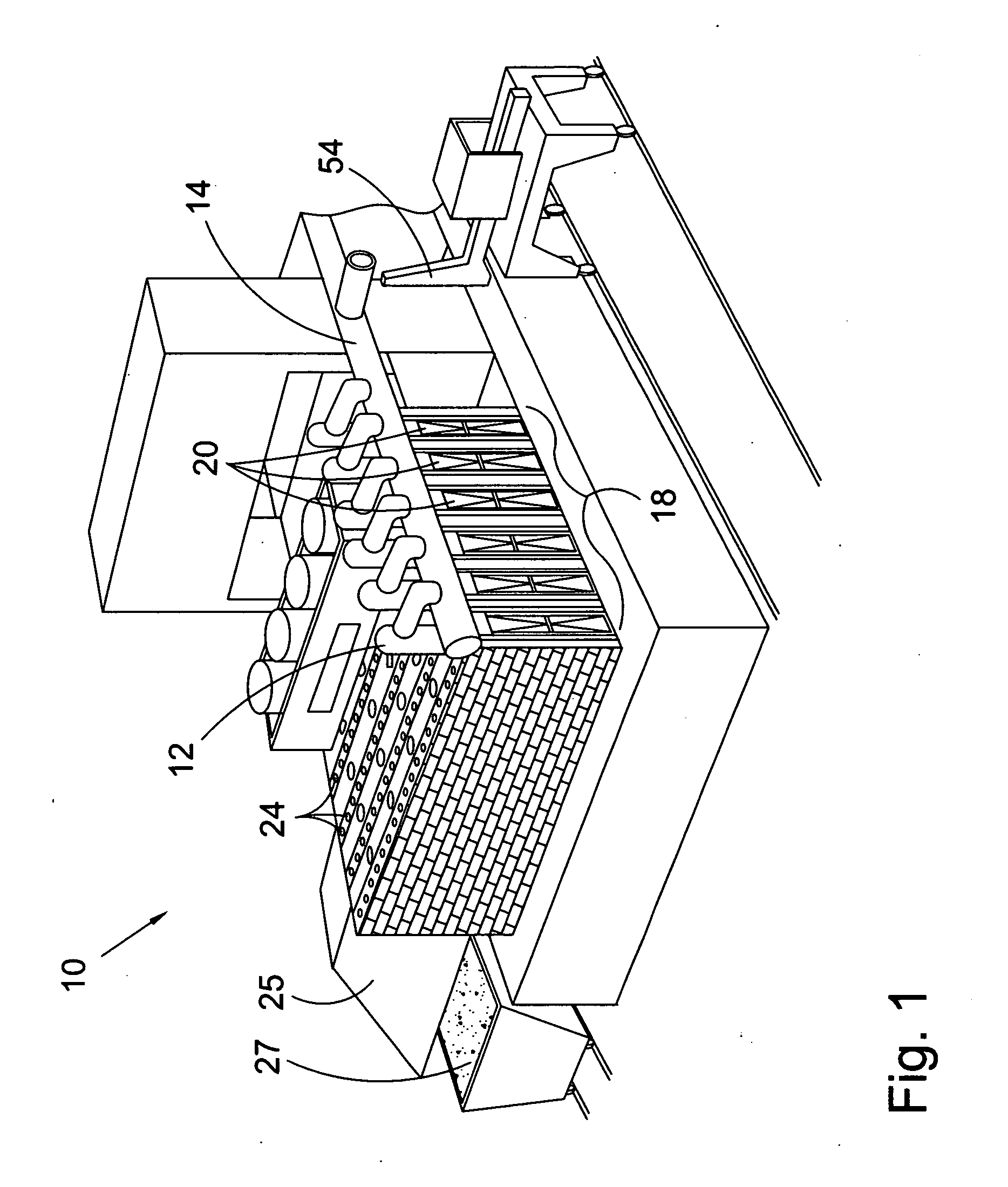

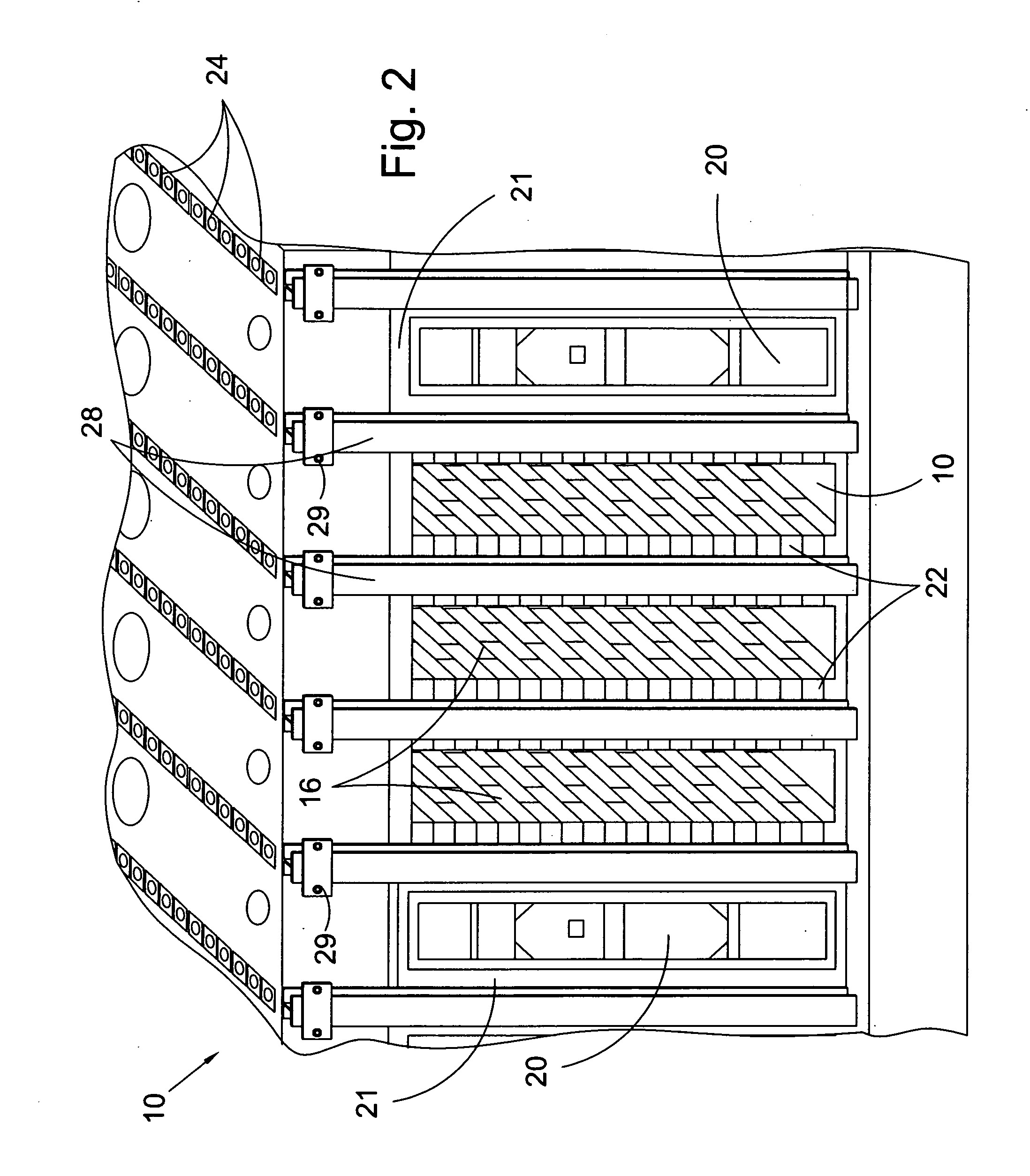

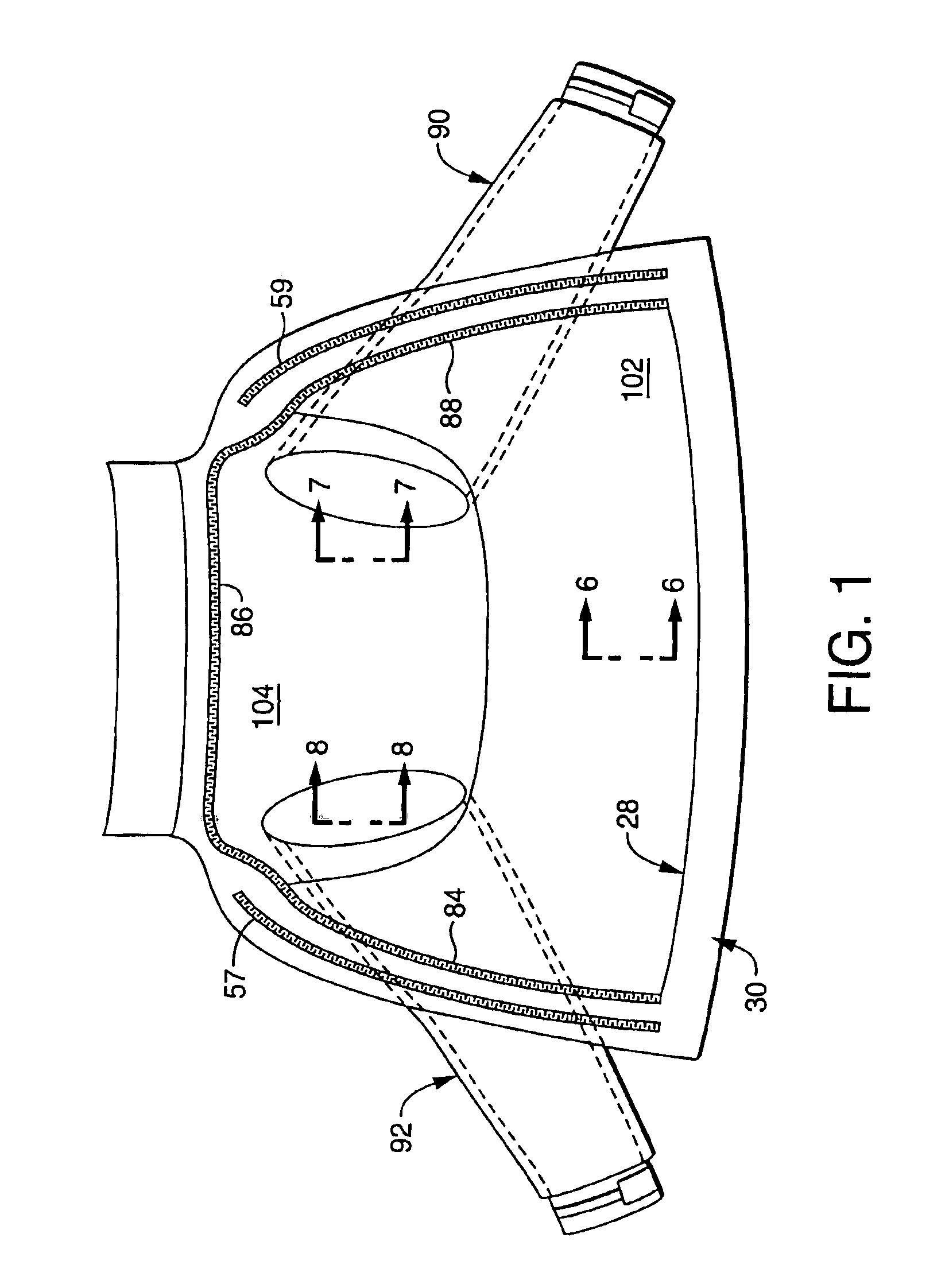

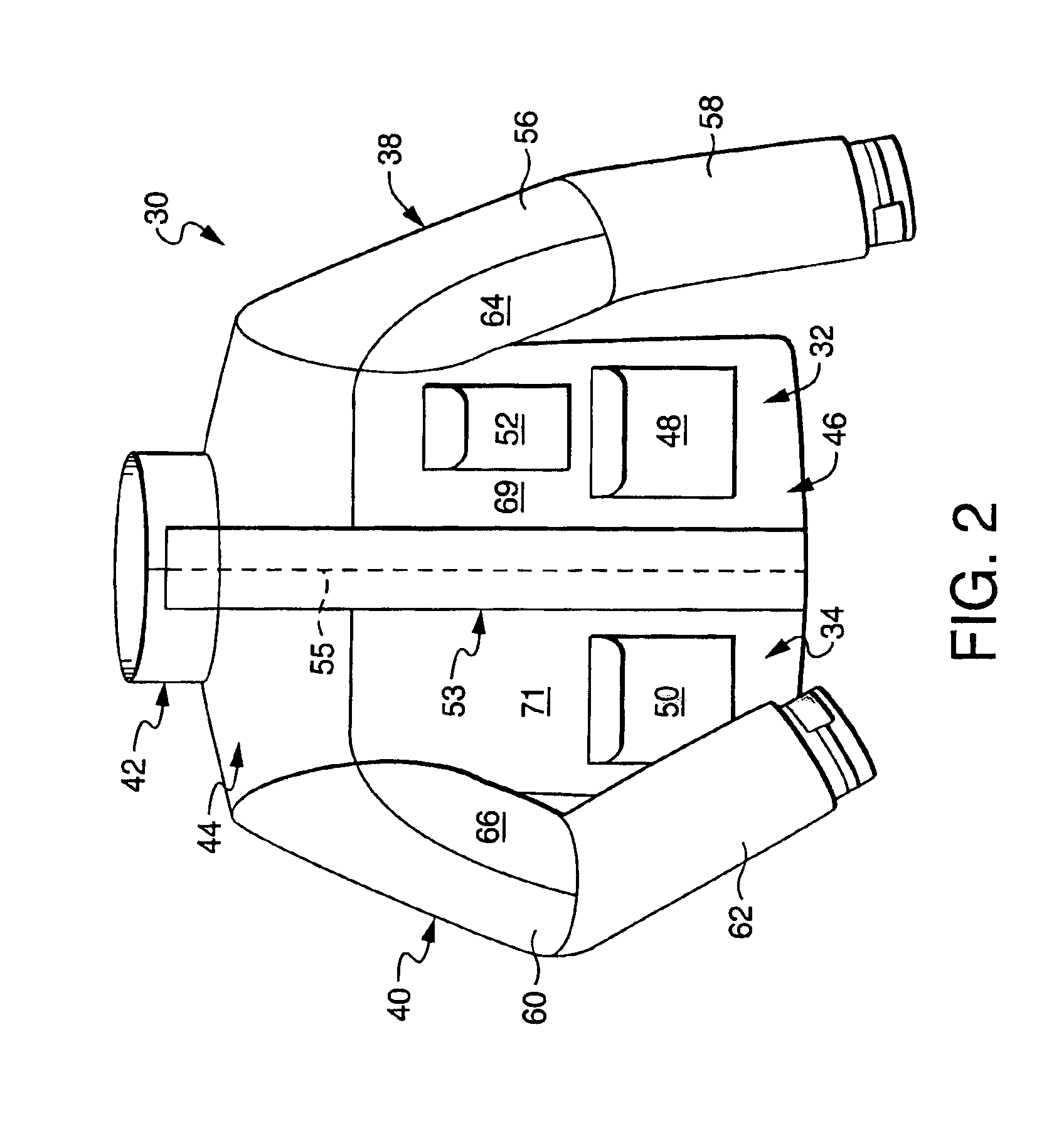

ActiveUS20080169578A1High dimensional stabilityRepair time be approximately halvedConstruction materialCoke oven brickworkEngineeringCoke oven

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

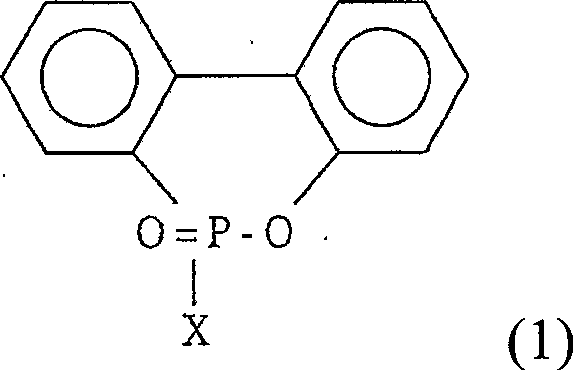

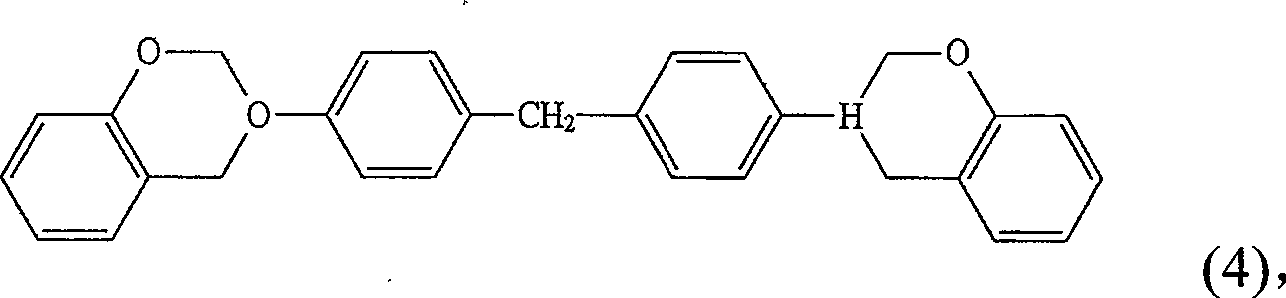

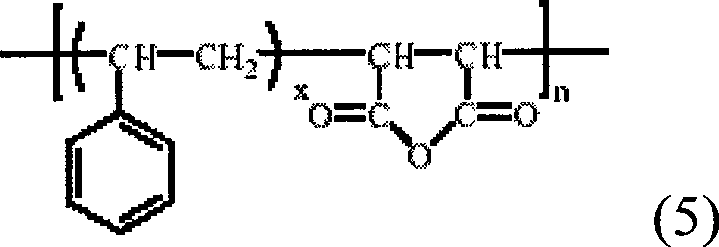

Phosphorous epoxy resin composition

ActiveCN100523081CIncrease flame retardancyImprove heat resistanceLiquid surface applicatorsOther chemical processesEpoxyHeat resistance

The phosphorus-containing epoxy resin composition of the present invention comprises: (A) phosphorus-containing epoxy resin, (B) curing agent, (C) one or more epoxy resins and (D) inorganic filler material; Wherein with component ( Based on the total weight of A), (B) and (C), the hardener of the component (B) includes 15 to 30% by weight of a benzoxazine compound, and 2.5 to 9% by weight of styrene-maleic di anhydride copolymer. The phosphorus-containing epoxy resin composition of the present invention uses a specific content of benzoxazine compound and styrene-maleic anhydride copolymer as a hardener, not only has good flame retardancy and heat resistance, but also has a high dimension Stability, low moisture absorption and excellent electrical properties are suitable for making prepregs, adhesive sheets, semiconductor packaging materials, copper foil laminates, printed circuit boards, and semiconductor packaging substrates.

Owner:ELITE MATERIAL

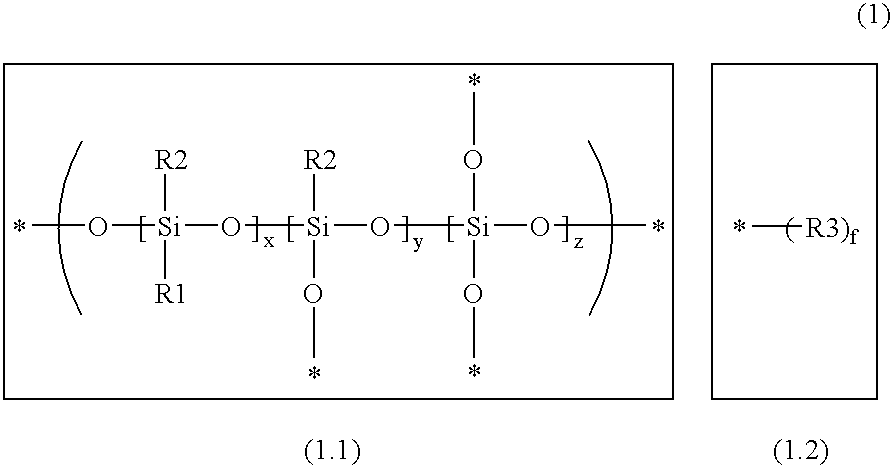

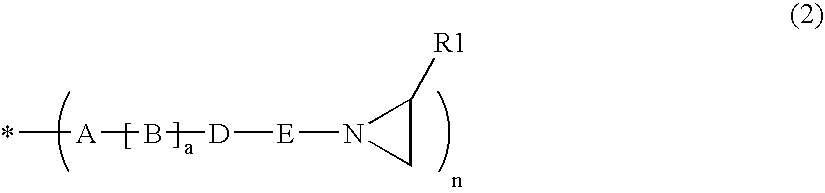

Aziridinosilicones and the use thereof

InactiveUS6906117B2Promote reproductionImprove accuracyImpression capsDental impression compositionsHeteroatomMedicinal chemistry

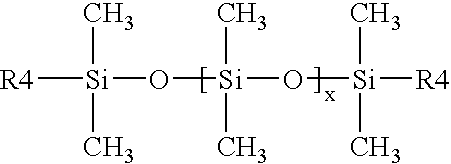

Arizidinosilicones of the general formula (1), wherein R1 represents H, C1-C12 alkyl, C2-C12 alkenyl, C2-C12 alkinyl, C7-C15 alkaryl, C7-C15 aralkyl, C3-C12 cycloalkyl and these groups can be substituted with Cl or F partially, completely or in a mixed manner and / or may contain 0 to 5 heteroatoms selected from O, N, S, R2 represents a group of the selection of R1 and / or R4, and R3 represents SiRl3 or SiR12R4, and wherein R4 represents formula (2), and A represents an (n+1) radical saturated, unsaturated or aromatic, linear, branched or cyclic hydrocarbon group that may contain 0 to 5 heteroatoms selected from O, N, S and that includes 1 to 18 carbon atoms, B is selected from O, S, NR1, D is selected from C(O)O, C(O)NR1, C(O), C(O)C(O), C(O)(CH2)m(C(O), C(S)NR1, CH2, E represents a diradical saturated or unsaturated, linear, branched or cyclic hydrocarbon group that may contain 0 to 5 heteroatoms selected from O, N, S and that includes 0 to 18 carbon atoms, a is 0 or 1, f is an integer from 2 to 1000, n, m is an integer from 1 to 10, and x, y, z each represents 0 or an integer, the sum of which should range between 1 and 10000, with the proviso that, if x is larger 0, y or z is smaller or equal x, preferably smaller or equal 0.05 times x, and especially preferred 0.02 times x. The invention also relates to the use of arizidinosilicones.

Owner:3M INNOVATIVE PROPERTIES CO

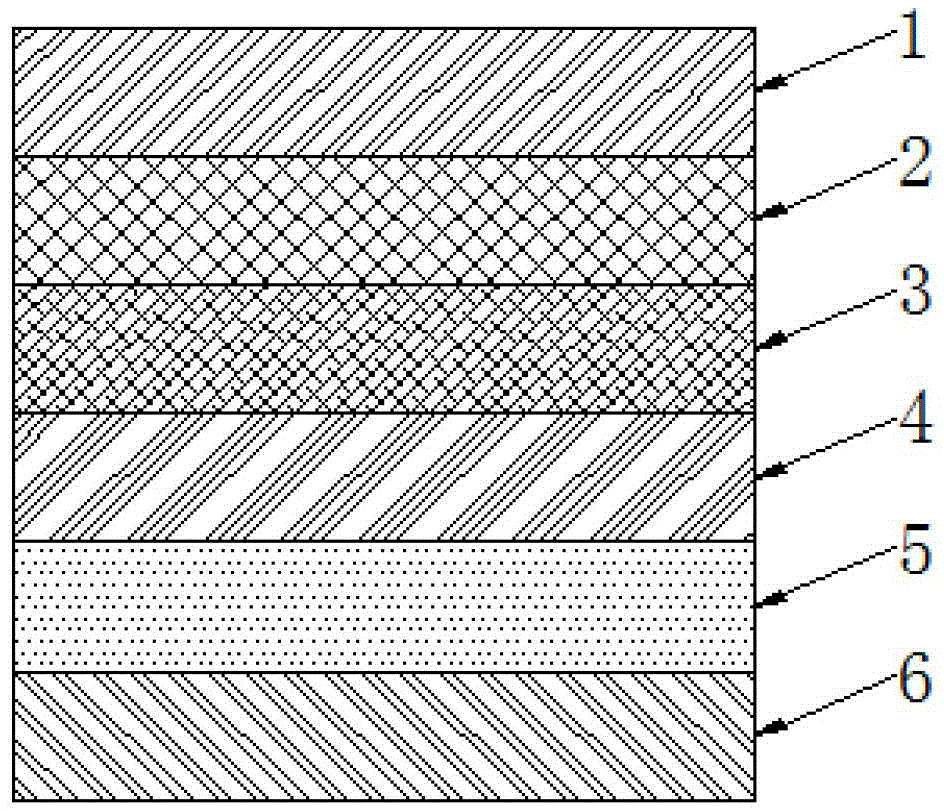

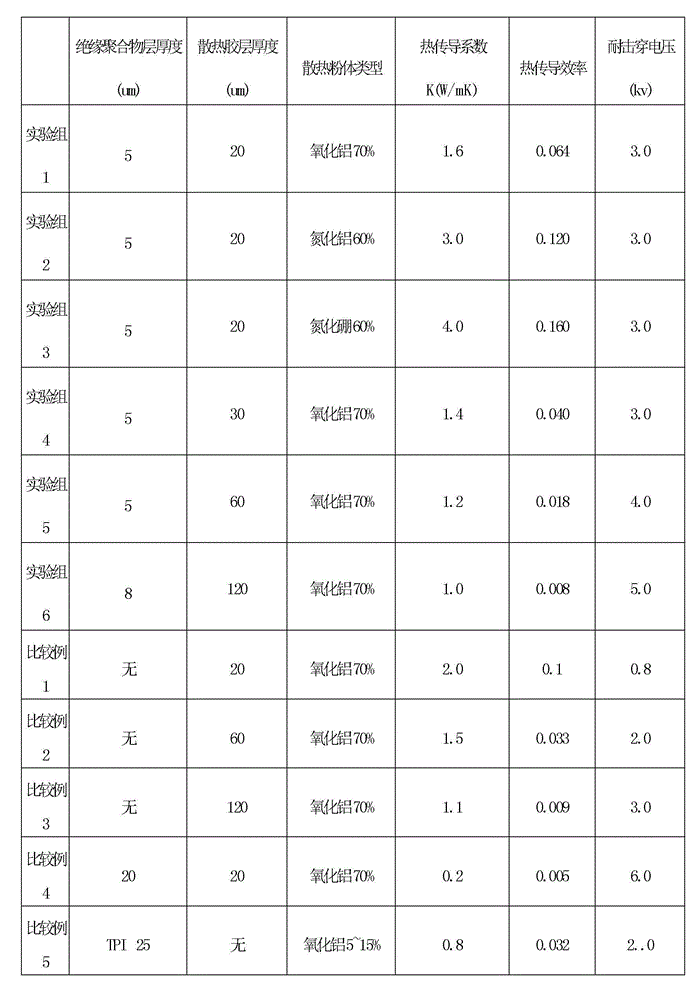

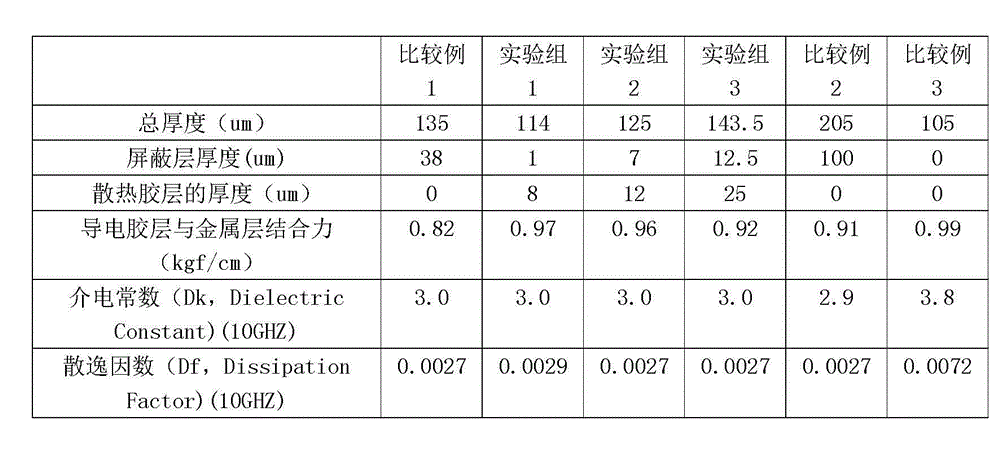

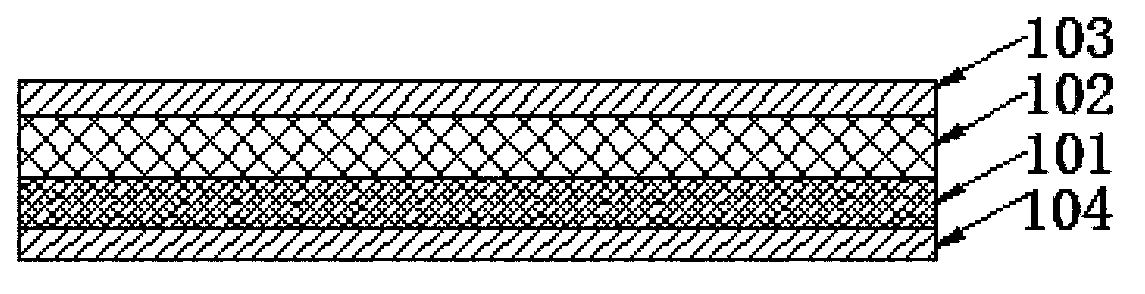

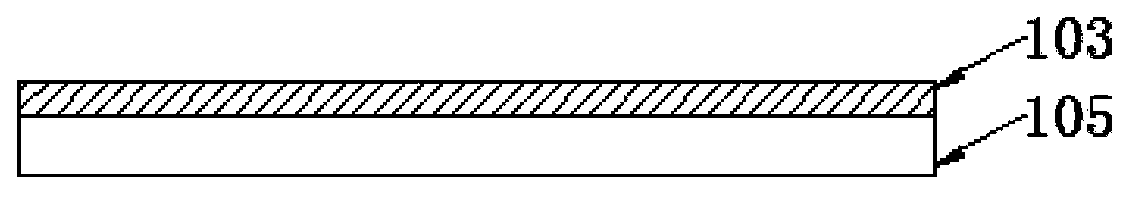

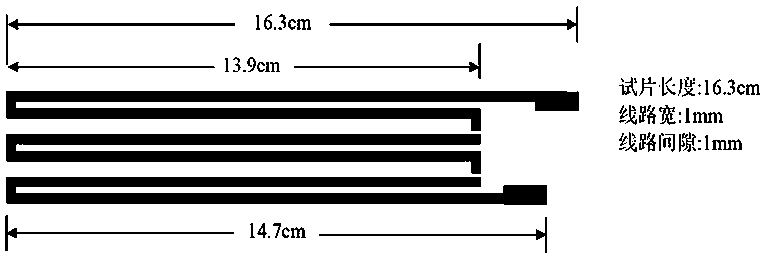

Composite electromagnetic-shielding copper clad laminate with heat conduction effect and manufacture method thereof

ActiveCN103144377AHigh dimensional stabilityUnable to resolve feverLamination ancillary operationsLaminationElectricityMulti material

The invention discloses a composite electromagnetic-shielding copper clad laminate with a heat conduction effect and a manufacture method of the composite electromagnetic-shielding copper clad laminate. The composite electromagnetic-shielding copper clad laminate, manufactured by utilizing the manufacture method, comprises a copper foil layer, an insulated polymer layer, a metal shielding layer, an electric conduction glue layer and a sixth stacking layer which are sequentially overlapped, wherein the sixth stacking layer is a metal layer or a release material layer. The composite electromagnetic-shielding copper clad laminate simultaneously has high heat dissipation and electromagnetic-shielding functions, can be applied to electronic products with relatively strict requirements on electromagnetic compatibility and is further used for solving the problem that the heat of electronic products cannot be timely dissipated. According to the composite electromagnetic-shielding copper clad laminate with the heat conduction effect and the manufacture method of the composite electromagnetic-shielding copper clad laminate with the heat conduction effect, a mode for using a conventional copper foil base material in a manner of being matched with shielding films and radiating electronic components is replaced, and original combination of multiple materials is replaced by a composite material, so that the material cost is saved, the thickness of products is decreased, the production process links are decreased, and the integral size stability of the base material of the products can be better improved.

Owner:SONGYANG ELECTRONICS MATERIAL KUSN

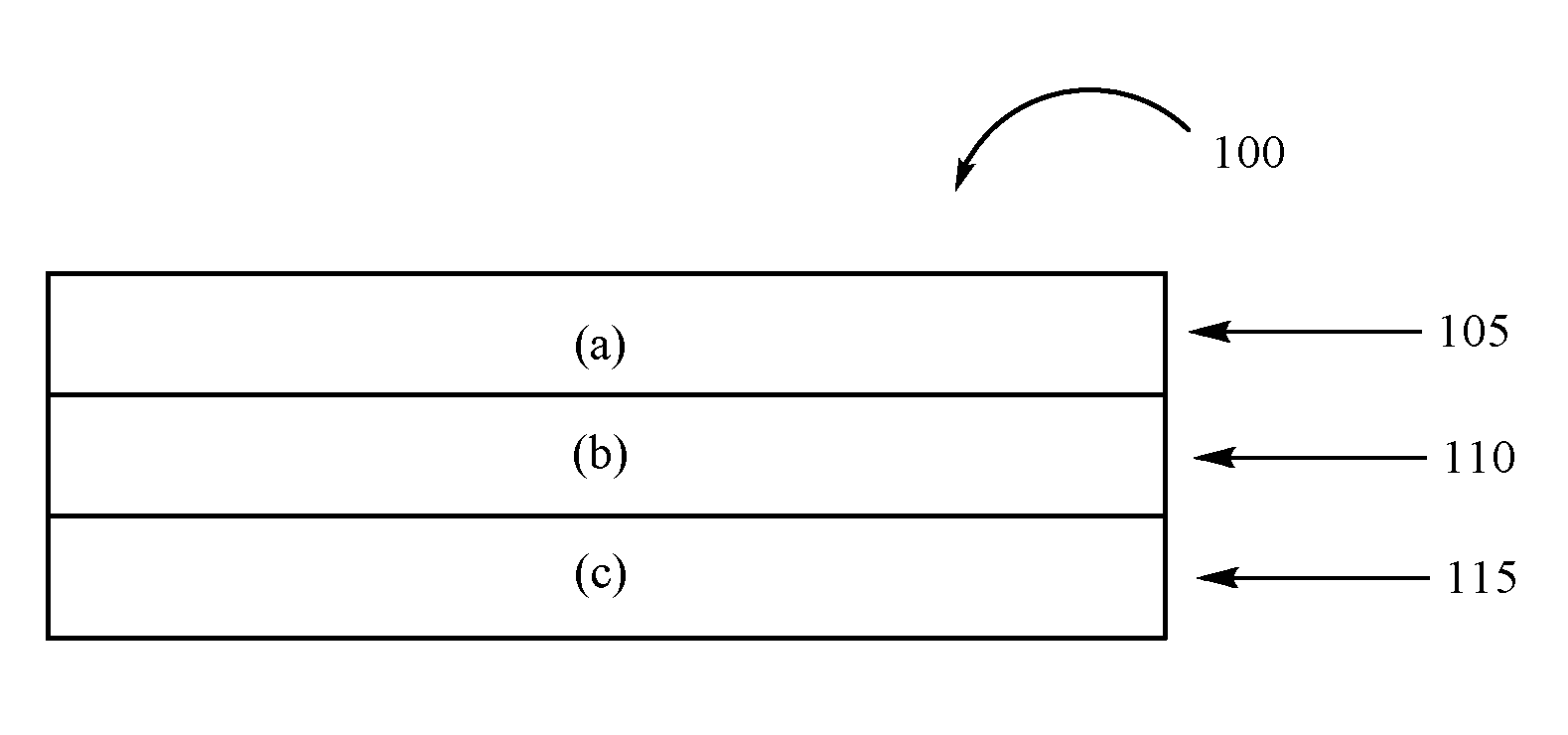

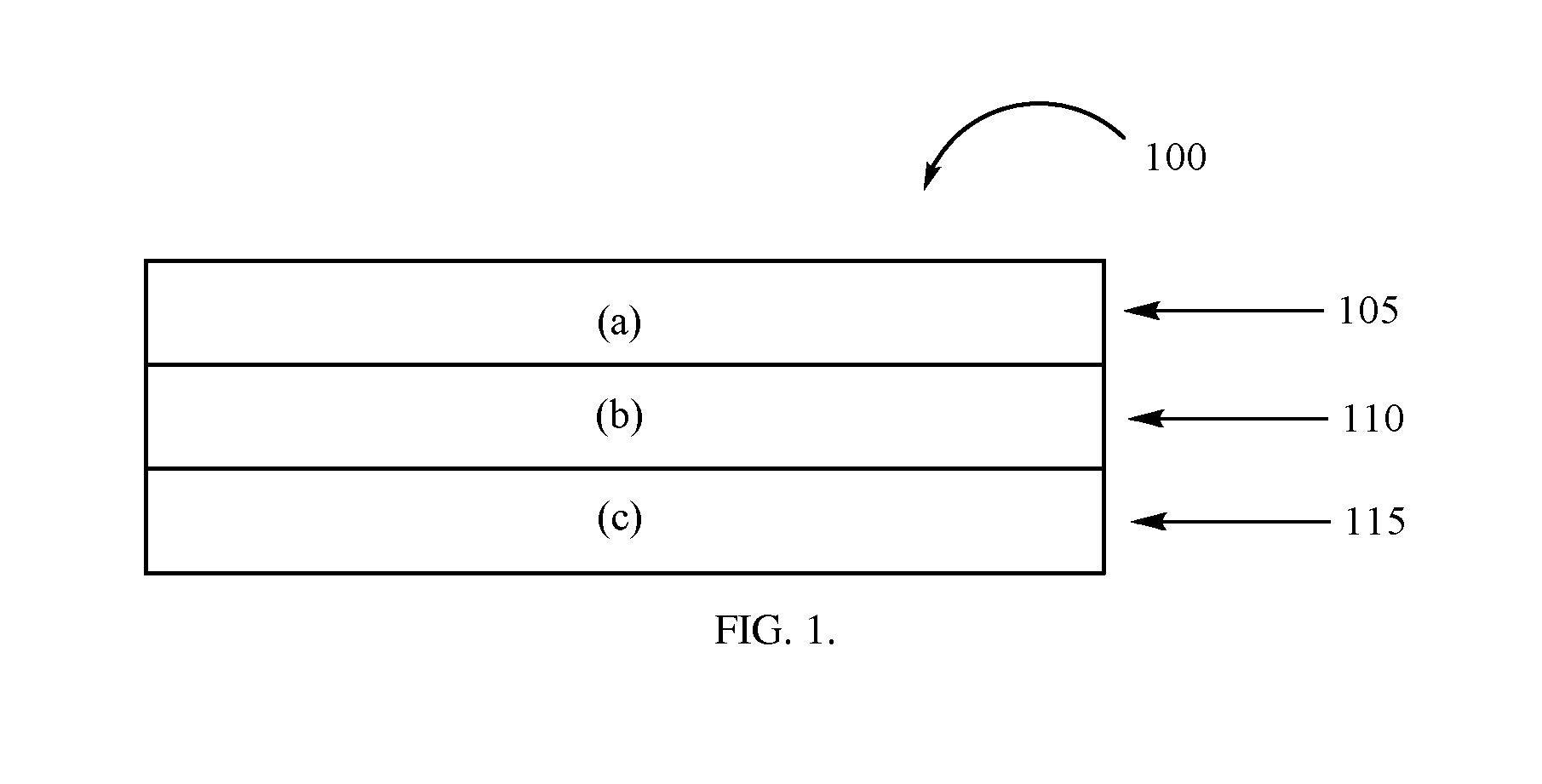

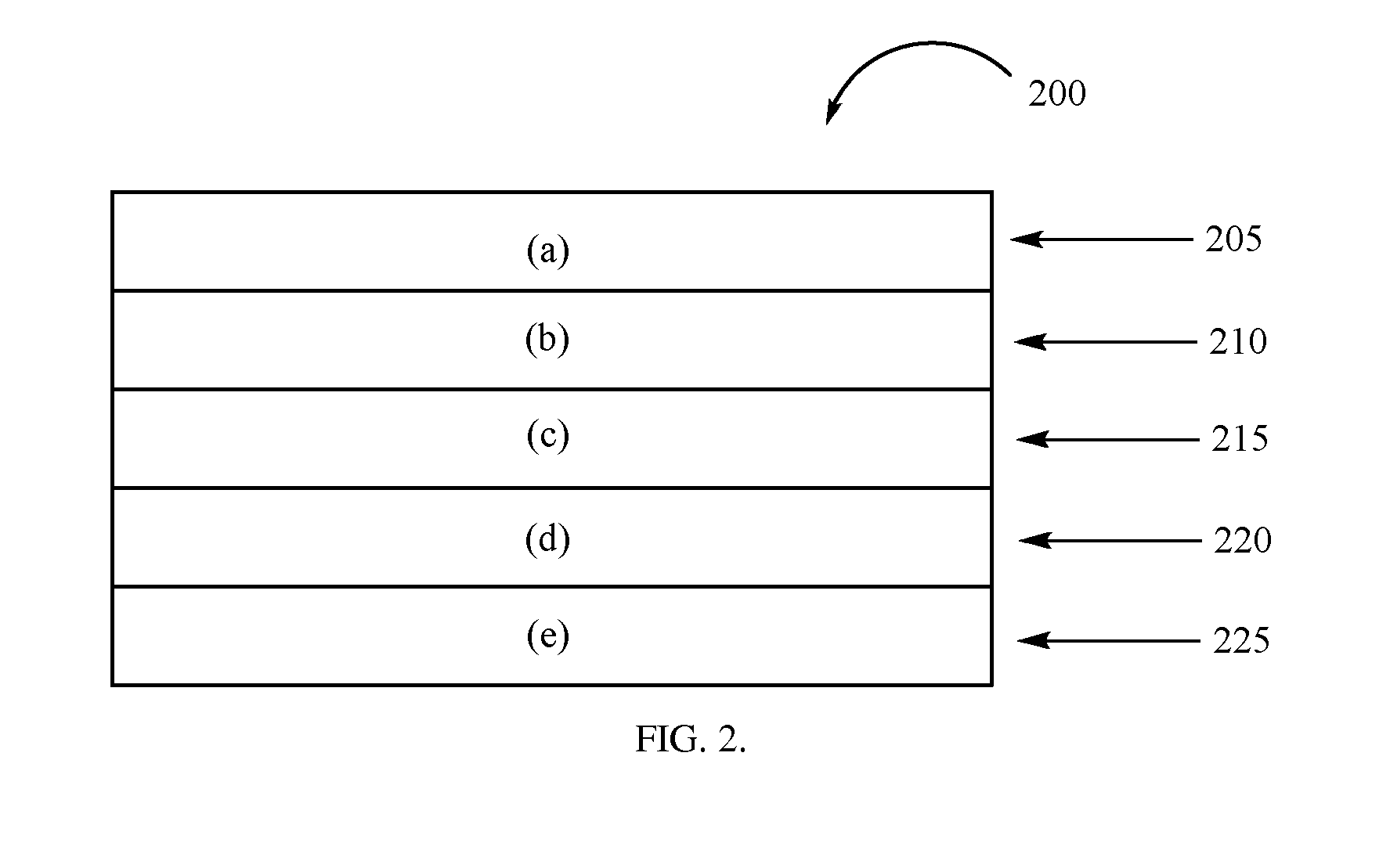

Multilayered structure and balloon including the same

InactiveUS20150336652A1High strengthHigh tensile strengthSynthetic resin layered productsDomestic containersNorborneneCyclo olefin polymer

Various embodiments of the present invention relate to a multilayered structure and balloon including the same. In various embodiments, the present invention provides a multilayered structure including at least one A layer (a) including a linear olefin polymer or copolymer, at least one B layer (b) including a cyclic olefin polymer or copolymer, and at least one A layer (c) including a linear olefin polymer or copolymer. The cyclic olefin polymer or copolymer of the at least one B layer is a polymer or copolymer of a substituted or unsubstituted norbornene.

Owner:VIAFLEX INC

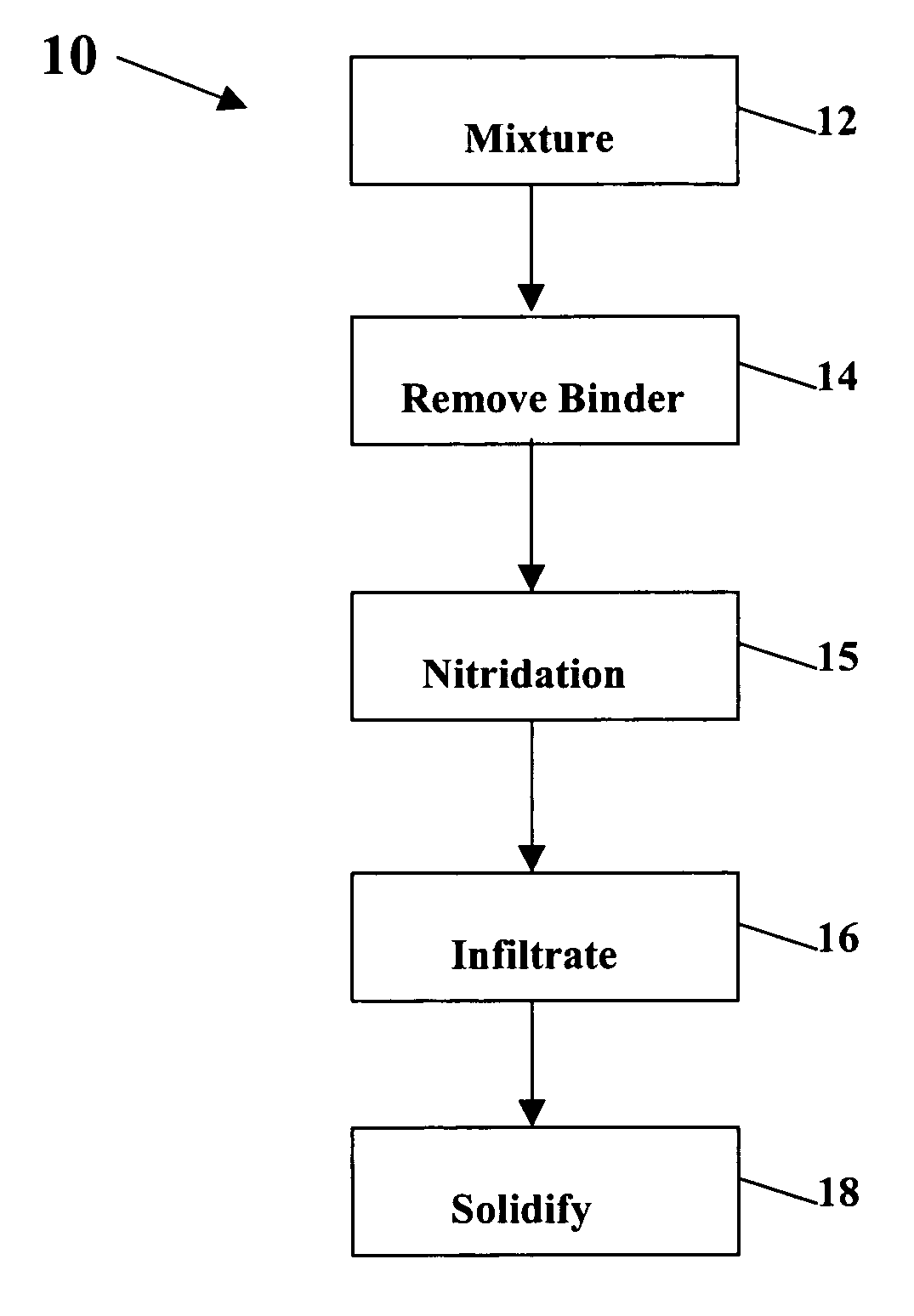

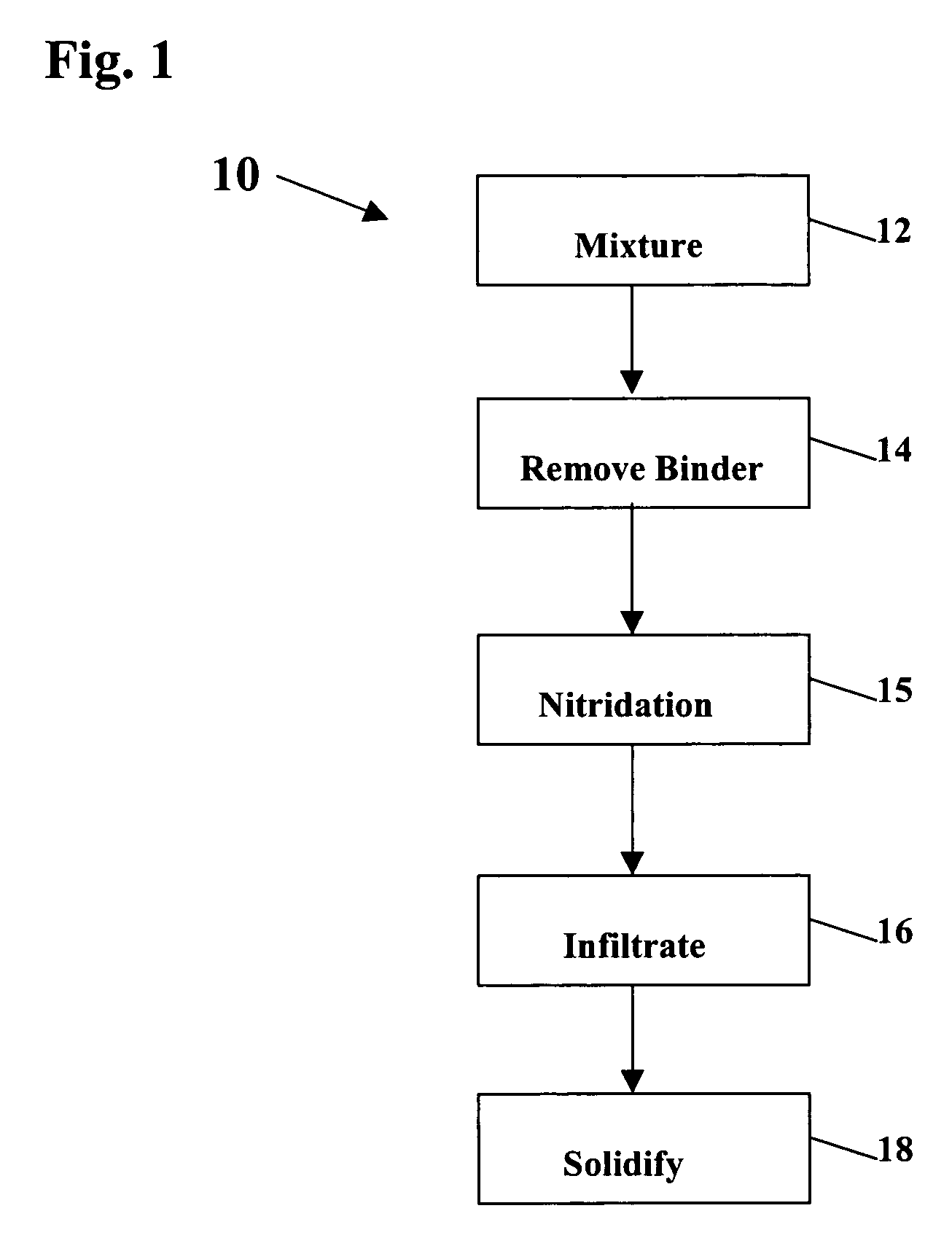

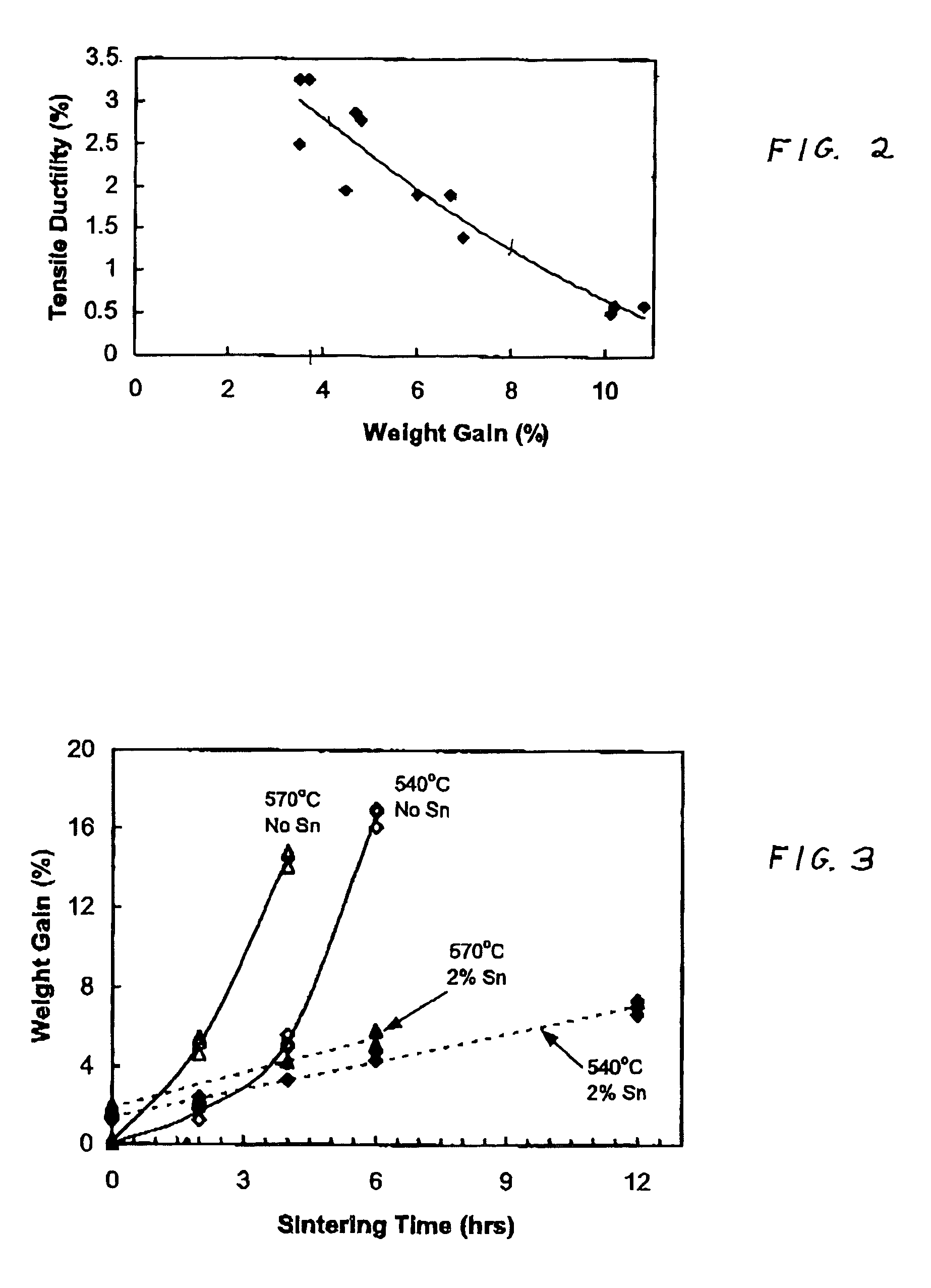

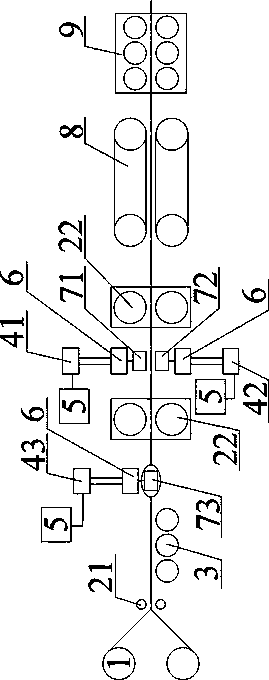

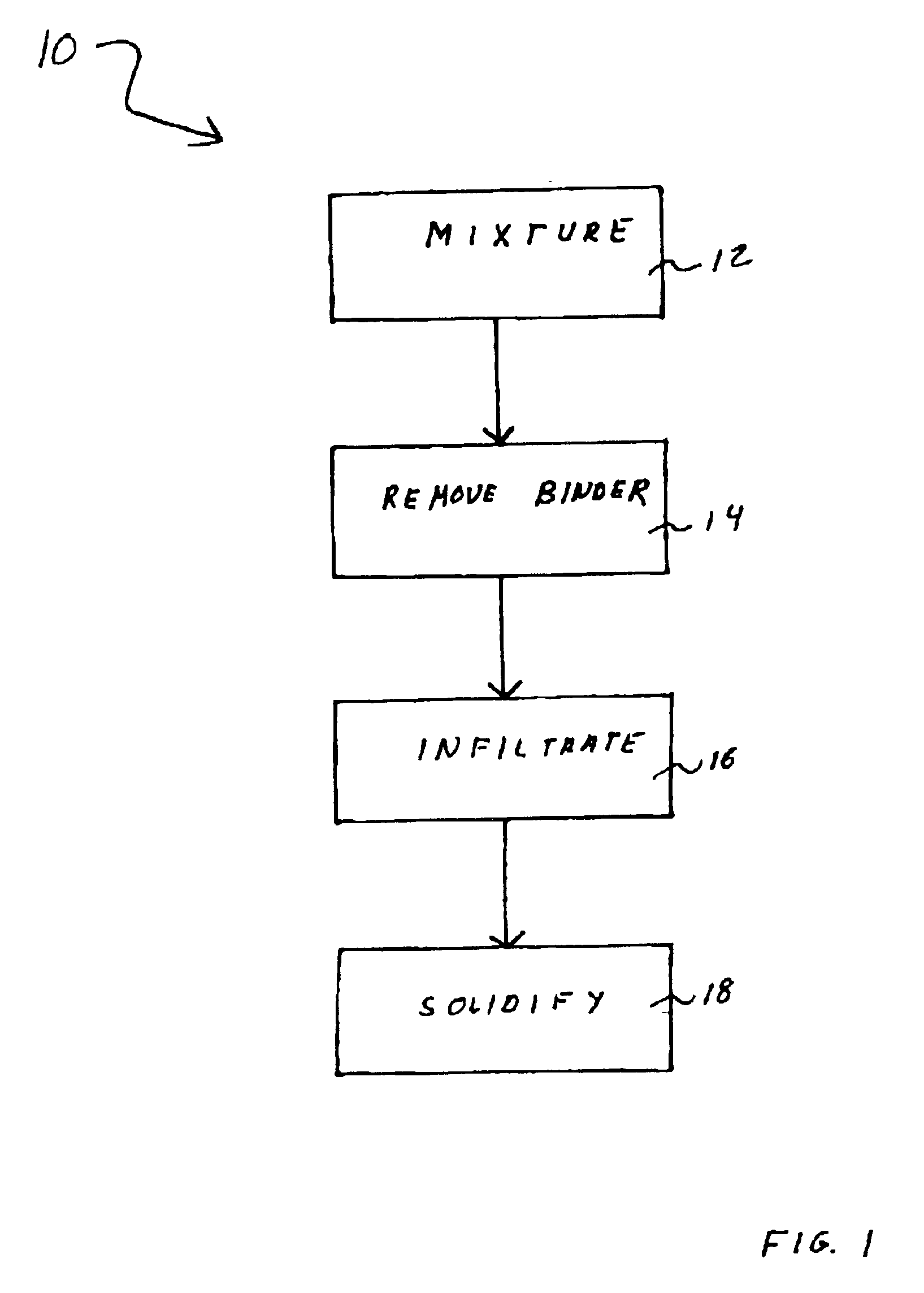

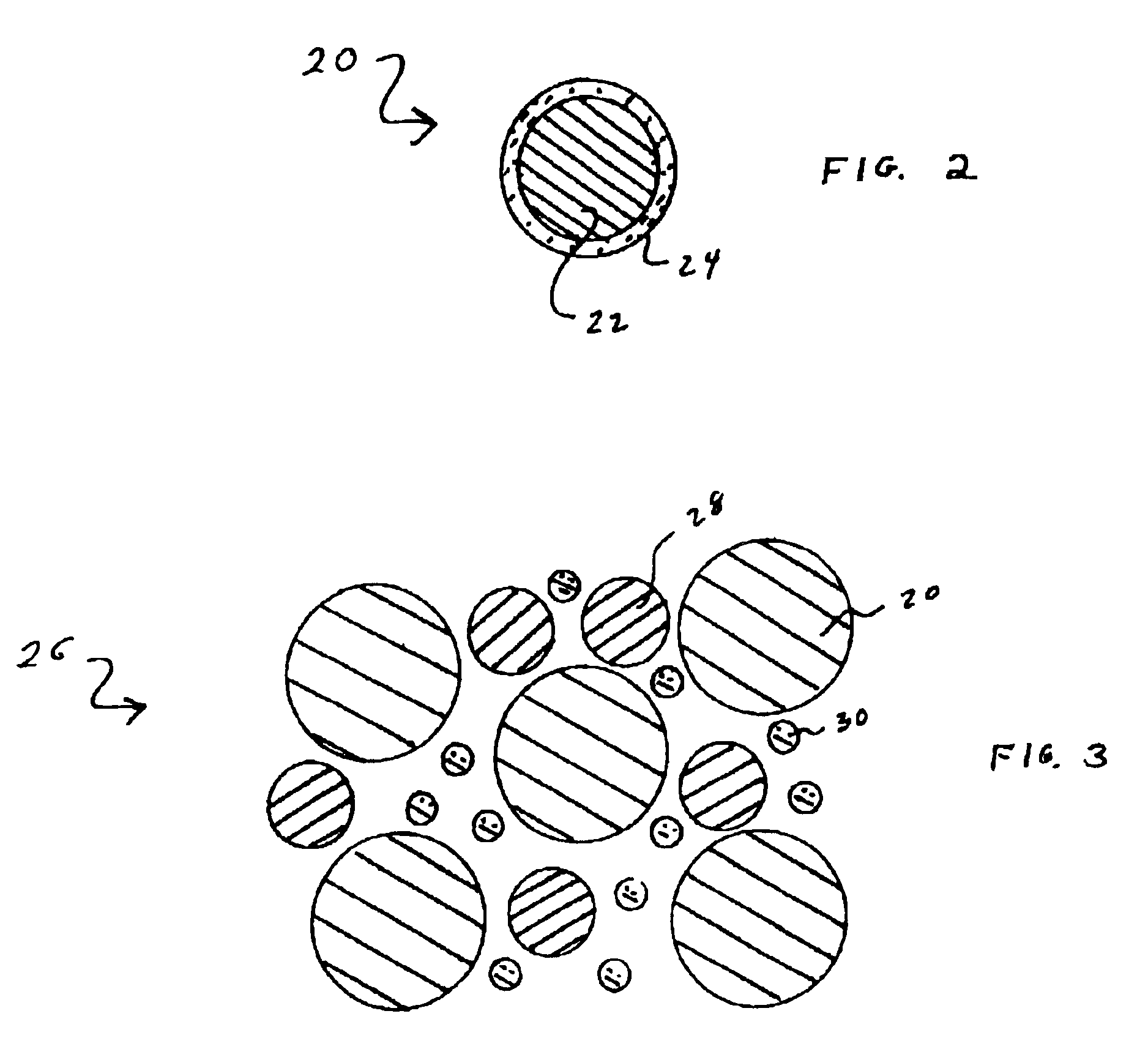

Infiltrated aluminum preforms

InactiveUS7036550B2Easy to manufactureGood dimensional stabilityAdditive manufacturing apparatusOperating means/releasing devices for valvesSelective laser sinteringHigh density

A method for the manufacture of a three-dimensional object includes the steps of forming a mixture that contains a binder and a least one of aluminum or a first aluminum-base alloy into a green composite, removing the binder from said green composite, forming a porous perform structure, reacting the aluminum or first aluminum base alloy with nitrogen to form a rigid and continuous skeleton and infiltrating the porous structure with molten aluminum or second aluminum base alloy to form the three-dimensional object with near theoretical density. The green composite may be formed by an additive process such as computer aided rapid prototyping, for example, selective laser sintering. The method facilitates the rapid manufacture of aluminum components by an inexpensive technique that provides high dimensional stability and high density.

Owner:QUEENSLAND UNIV OF

Five-layer co-extruded fiber felt reinforced plastic composite board and manufacturing method thereof

InactiveCN103448337AChange in mechanical strengthMeet different functional needsLamination ancillary operationsSynthetic resin layered productsFiberWeather resistance

The invention relates to the field of film or sheet products produced by plastic or plastic state substance, in particular to a five-layer co-extruded fiber felt reinforced plastic composite board. The five-layer co-extruded fiber felt reinforced plastic composite board is composed of plastic layers and fiber felts and is characterized in that there are three plastic layers and two fiber felts, the three plastic layers are respectively arranged in parallel, the three plastic layers are respectively a top layer, an intermediate layer and a bottom layer, a layer of fiber felts is respectively lined between the top plastic layer and the intermediate plastic layer and between the intermediate plastic layer and the bottom plastic layer, and the plastic layer is prepared from any one of polypropylene, polyethylene and rigid polyvinyl chloride. The five-layer co-extruded fiber felt reinforced plastic composite board provided by the invention is high in strength, low in density, good in weather resistance and wide in range of application.

Owner:林世平

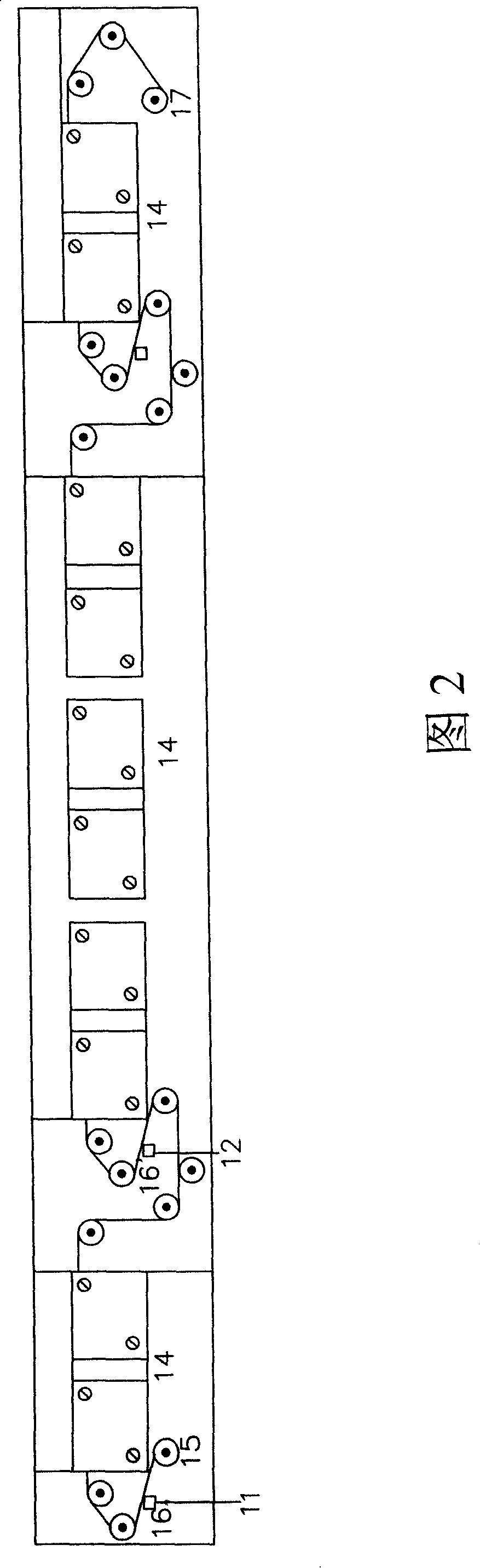

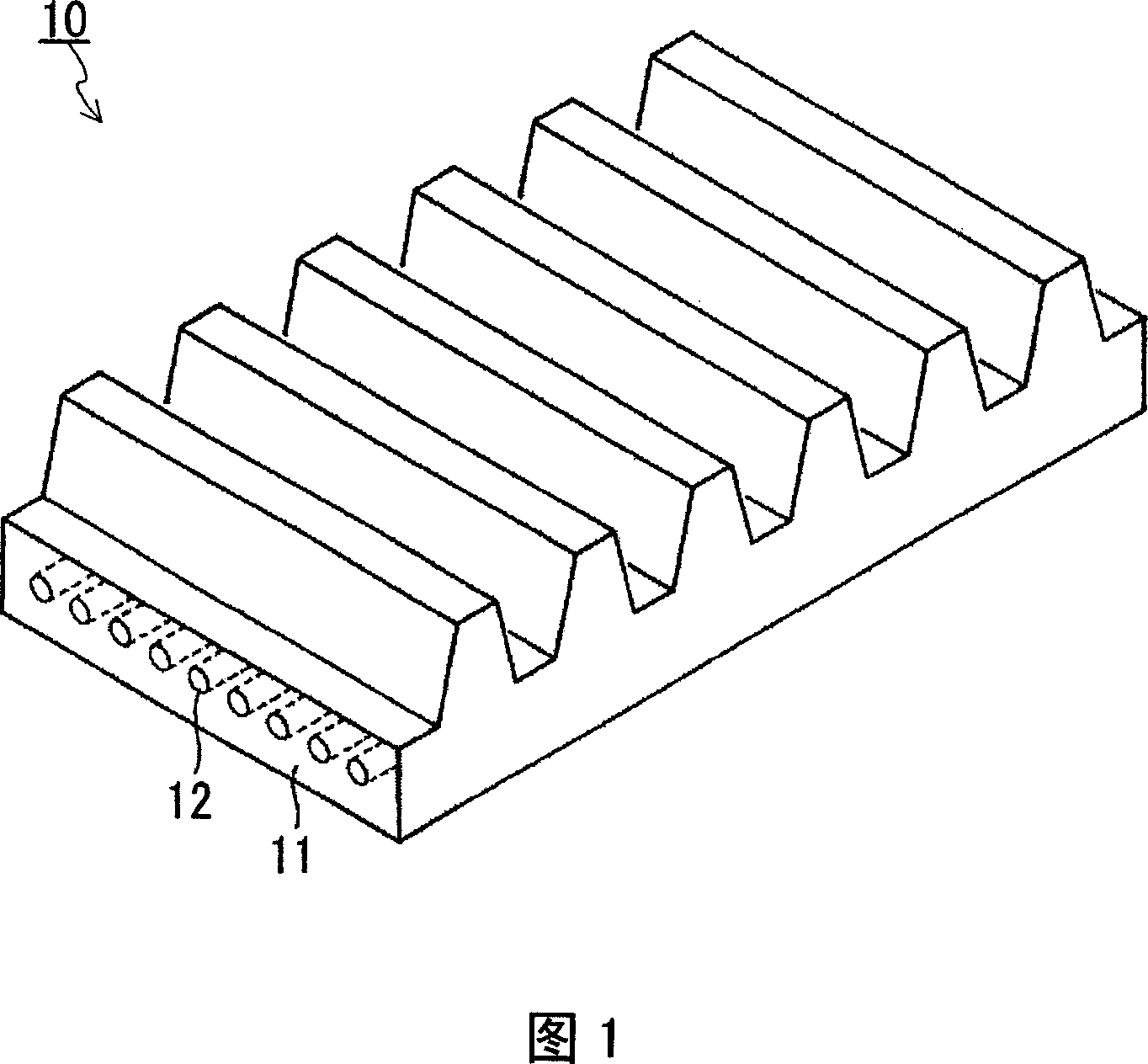

Mold, process for its production, and process for producing base material having transferred micropattern

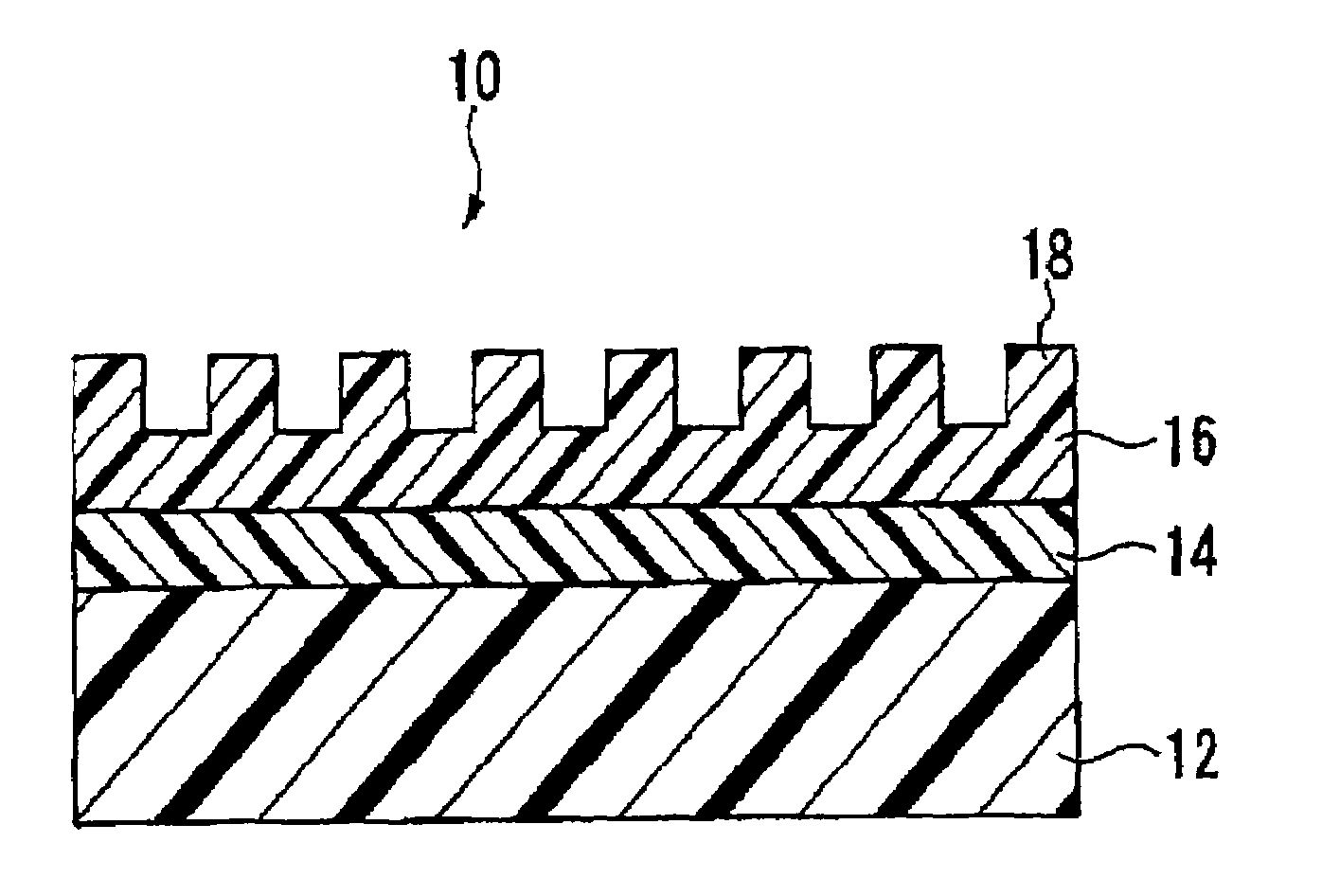

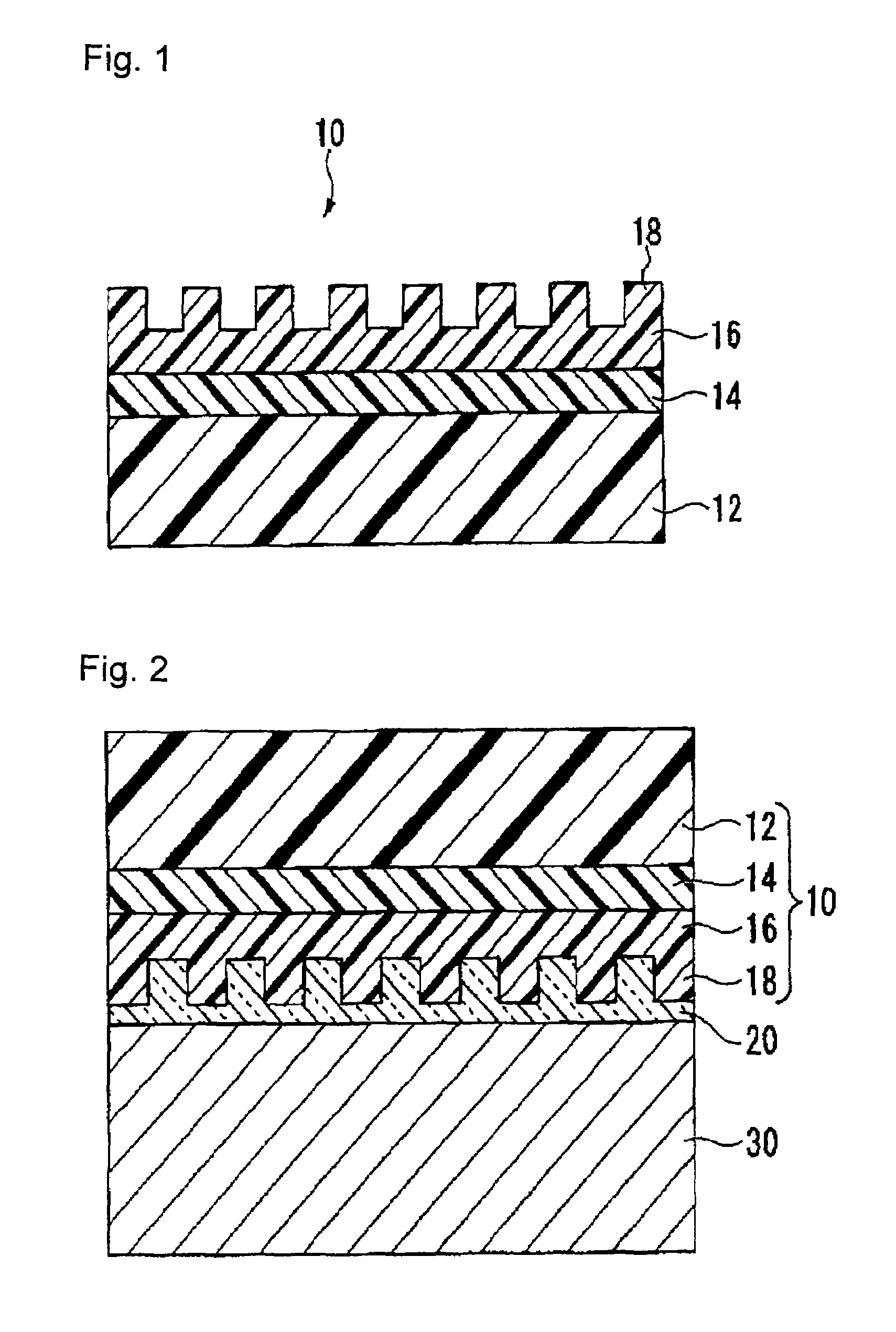

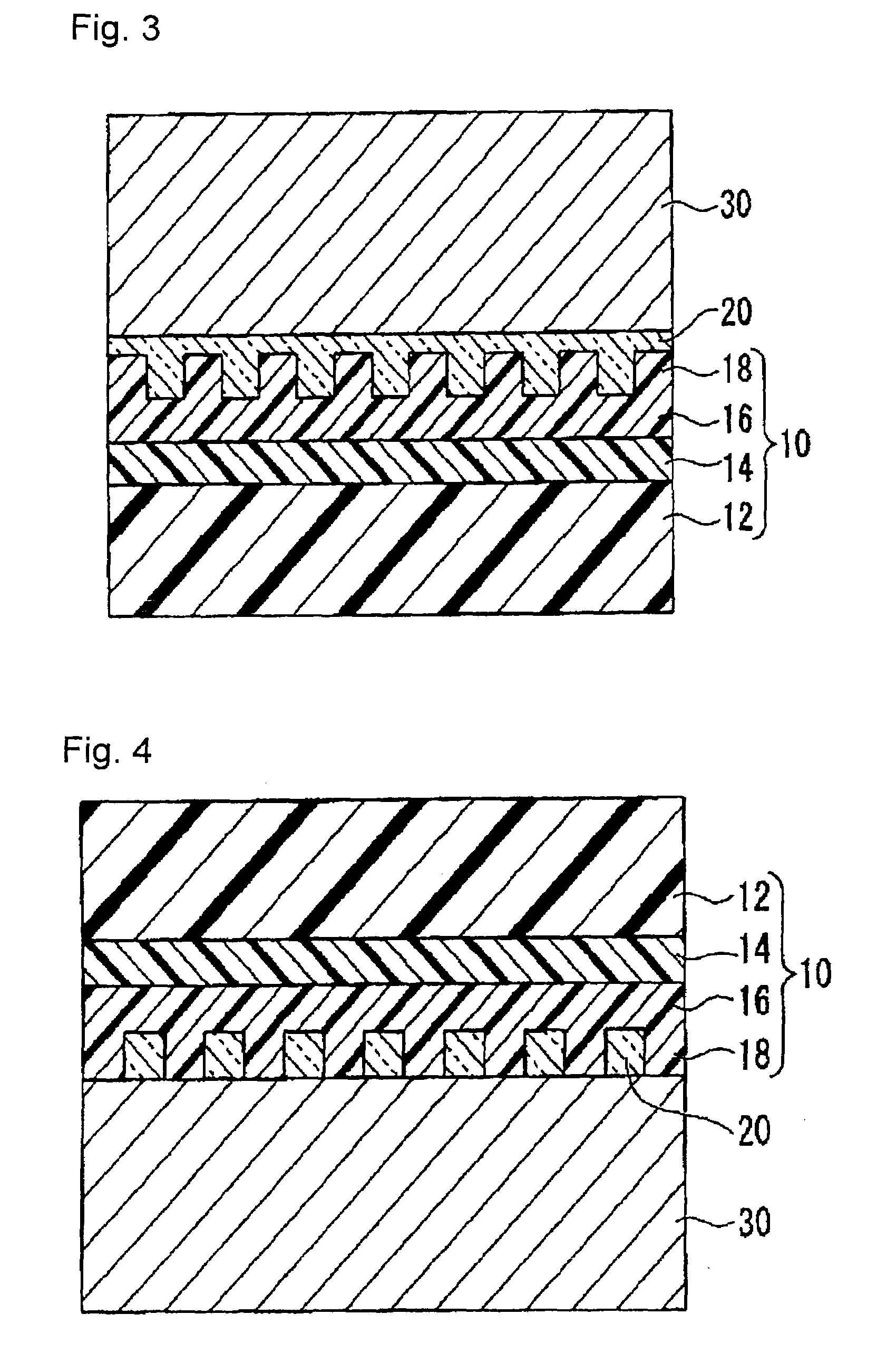

InactiveUS20090302507A1Good dimensional stabilityHighly precise micropatternOptical articlesAuxillary shaping apparatusHeat deflection temperatureSurface layer

To provide a mold having optical transparency, release properties, mechanical strength, dimension stability and a highly precise micropattern, and having less deformation of the micropattern; and a process for producing a base material with a transferred micropattern having less deformation of the transferred micropattern, capable of transferring highly precise micropattern of the mold.A mold 10 comprising a transparent substrate (A) 12 having chemical bonds based on the functional groups (x) on the surface having an interlayer (C) 14 formed, having a difference in linear expansion coefficient (absolute value) of less than 30 ppm / ° C. from the linear expansion coefficient of the following fluoropolymer (I), and further having a heat distortion temperature of from 100 to 300° C.; an interlayer (C) 14 made of a fluoropolymer (II) having a fluorinated alicyclic structure in its main chain and further having reactive groups (y) reactive with the functional groups (x); and a surface layer (B) 16 having a micropattern on the surface, made of a fluoropolymer (I) having a fluorinated alicyclic structure in its main chain and having substantially no reactive groups (y).

Owner:ASAHI GLASS CO LTD

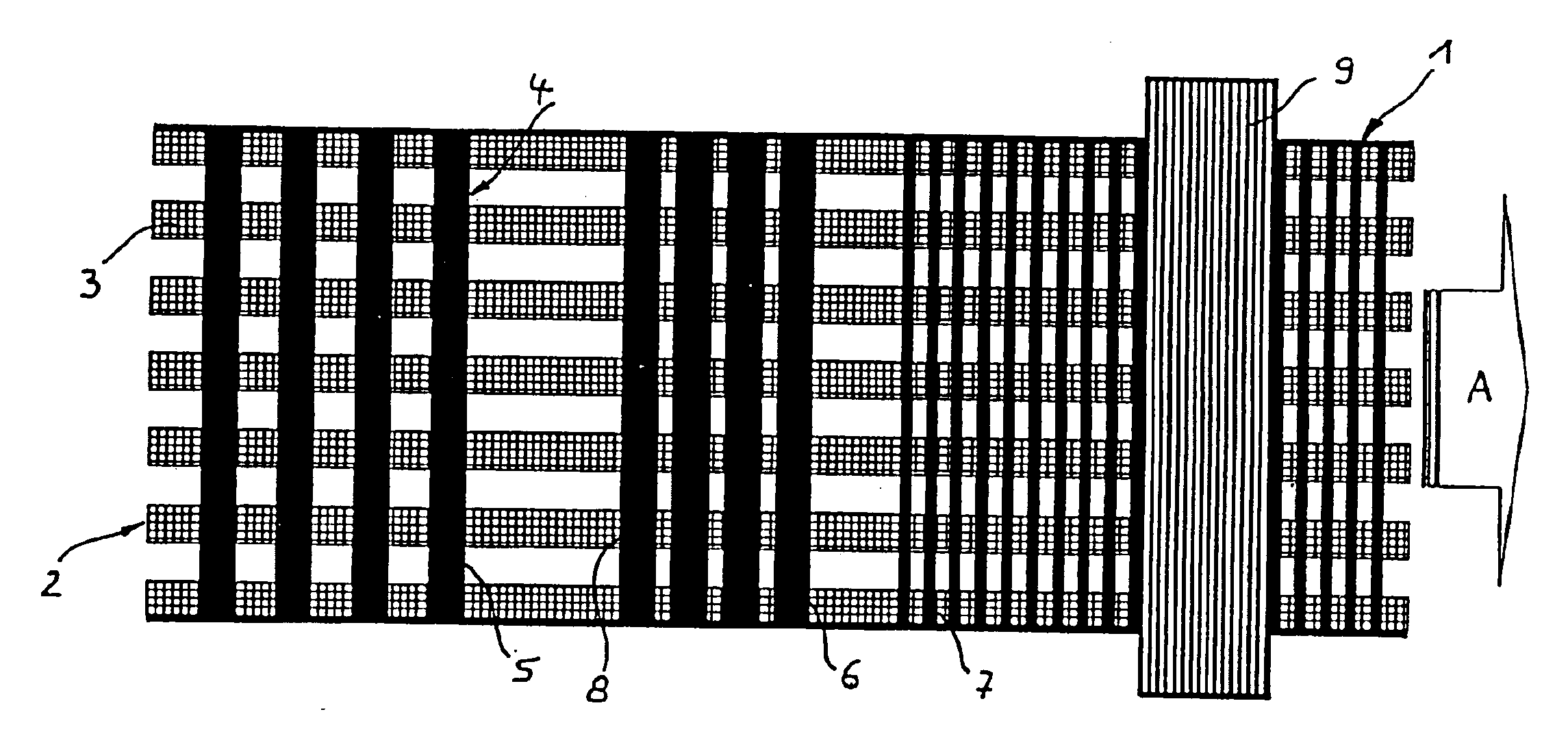

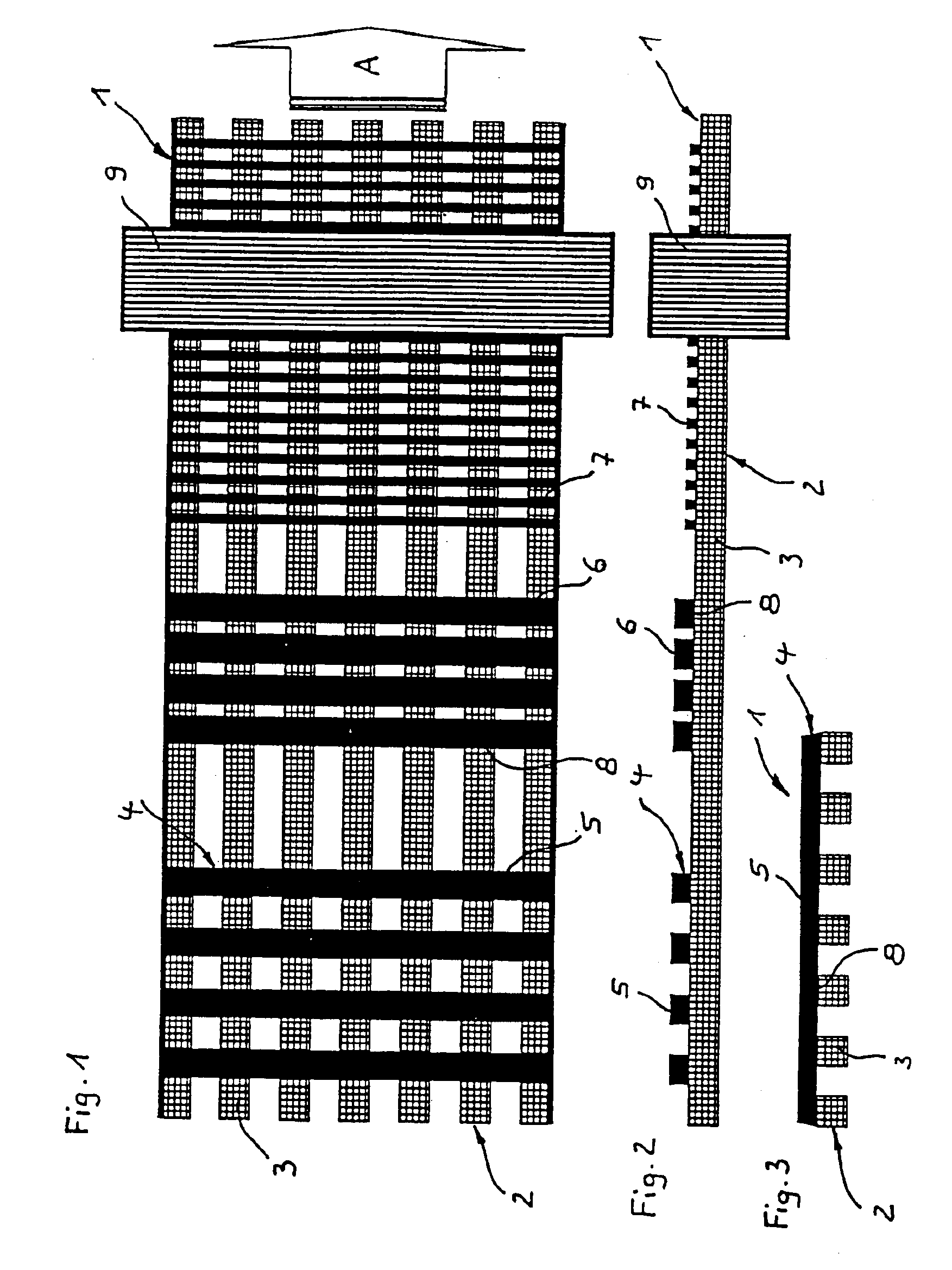

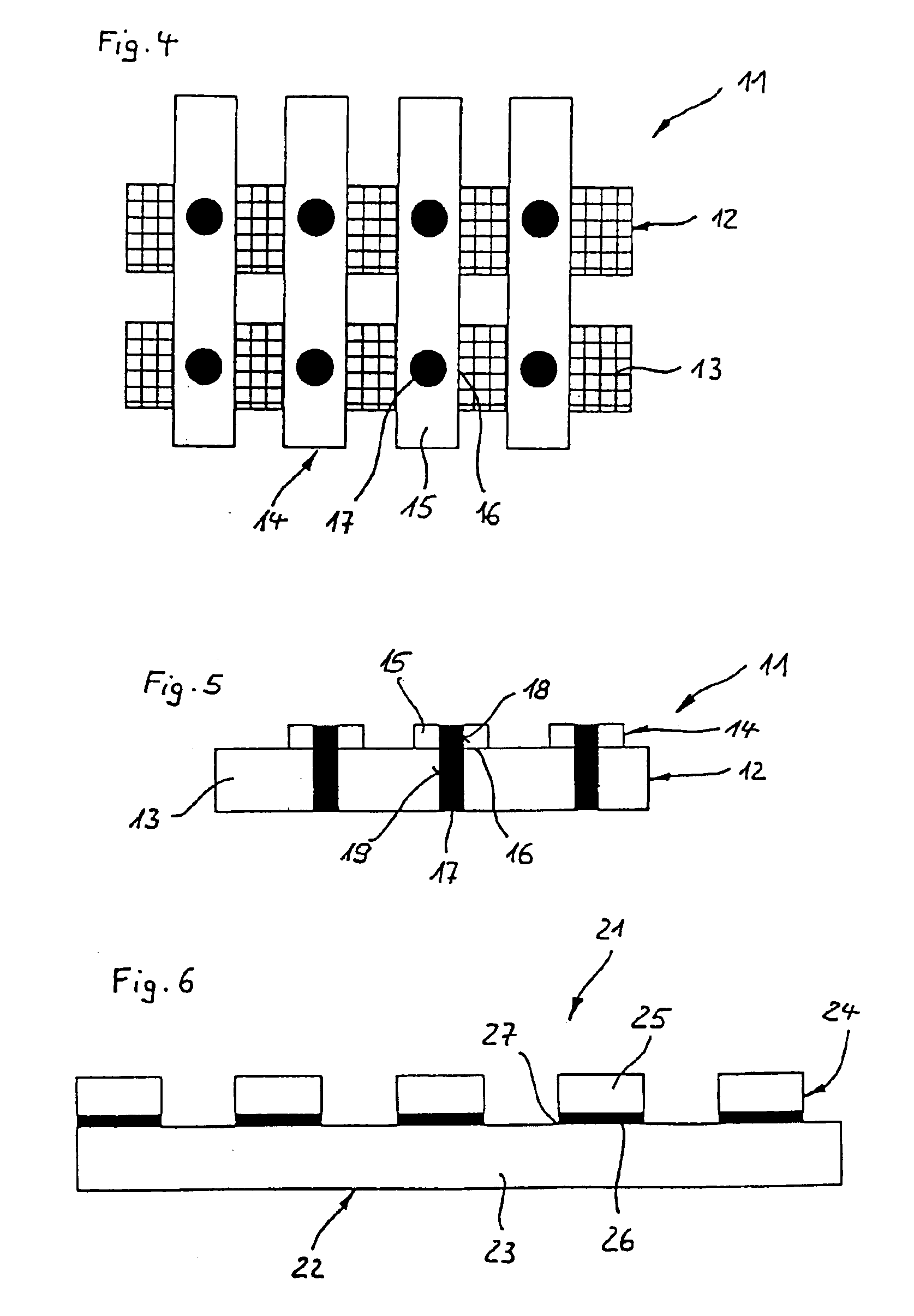

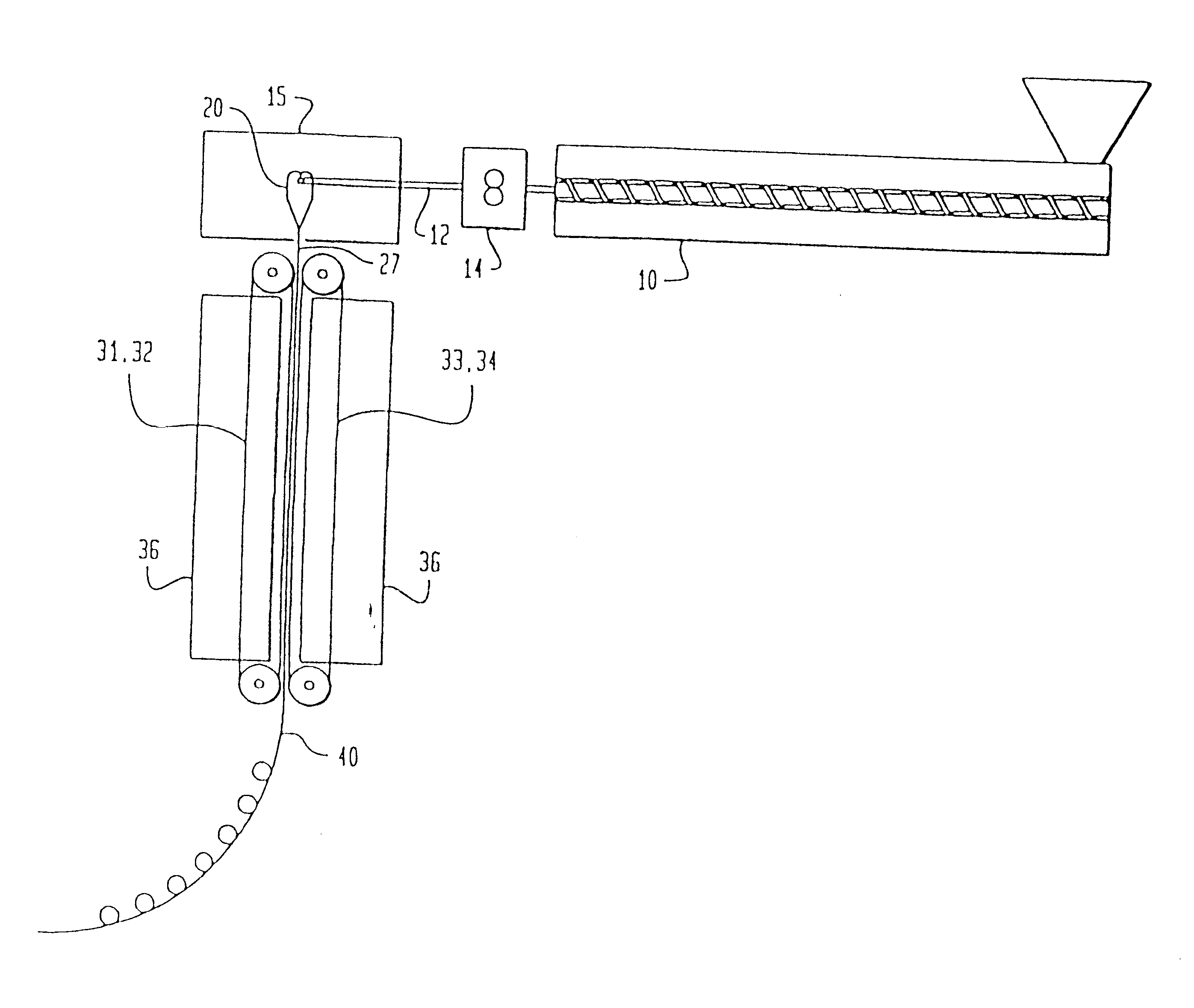

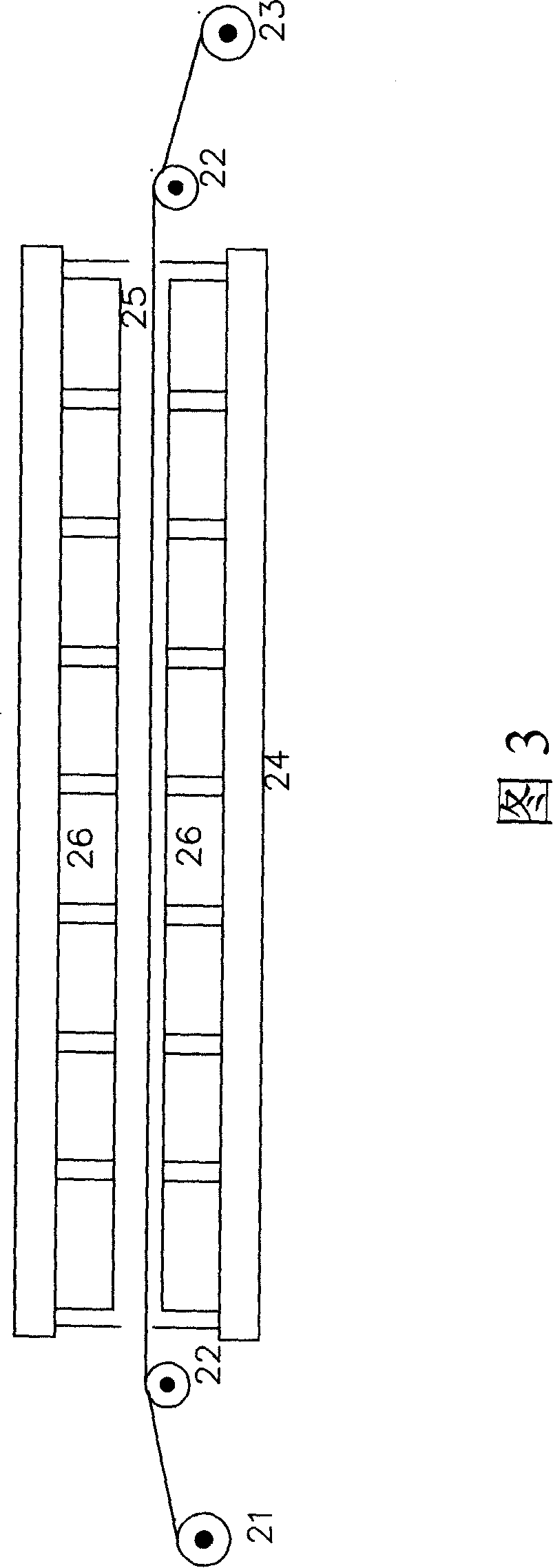

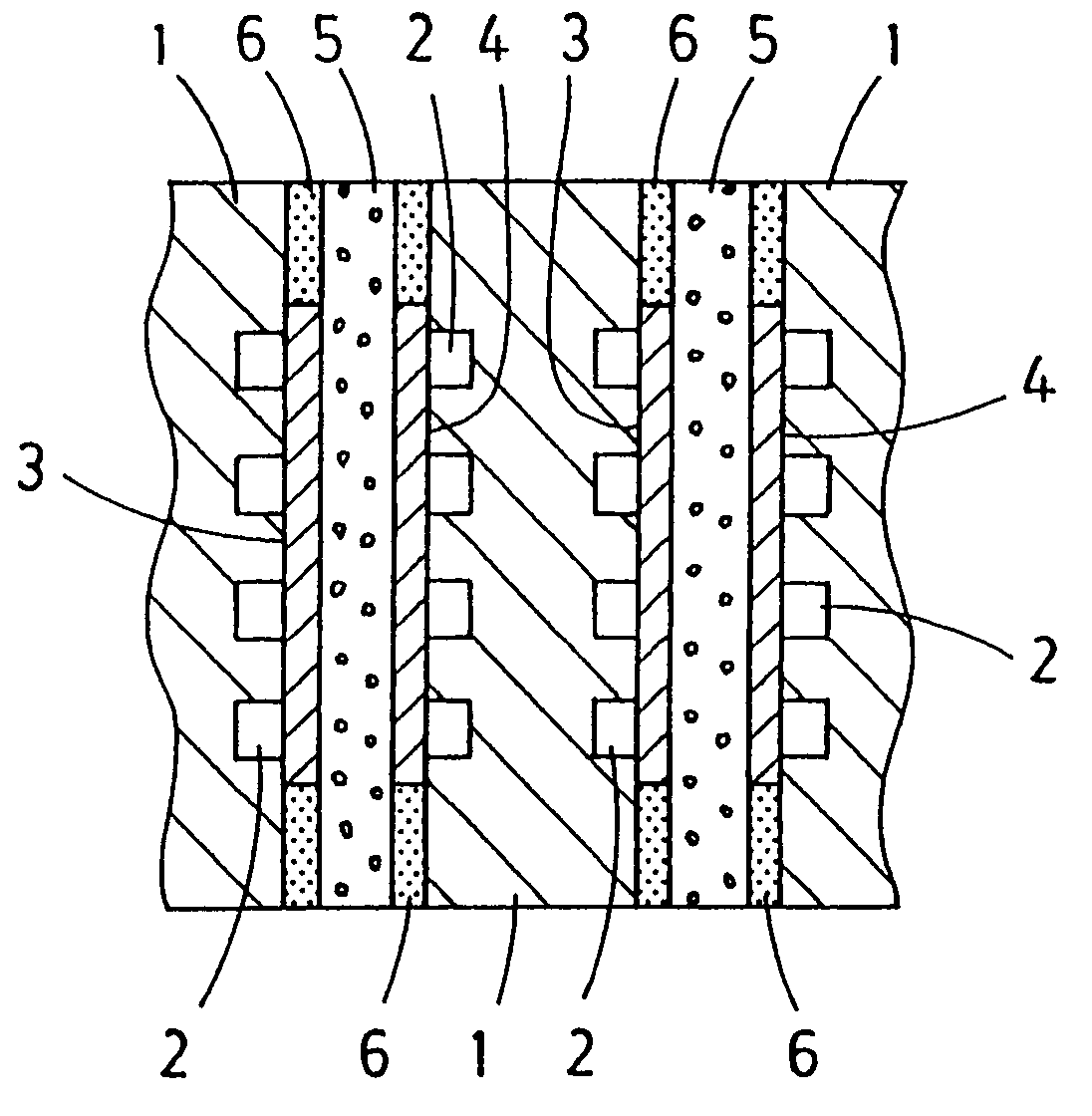

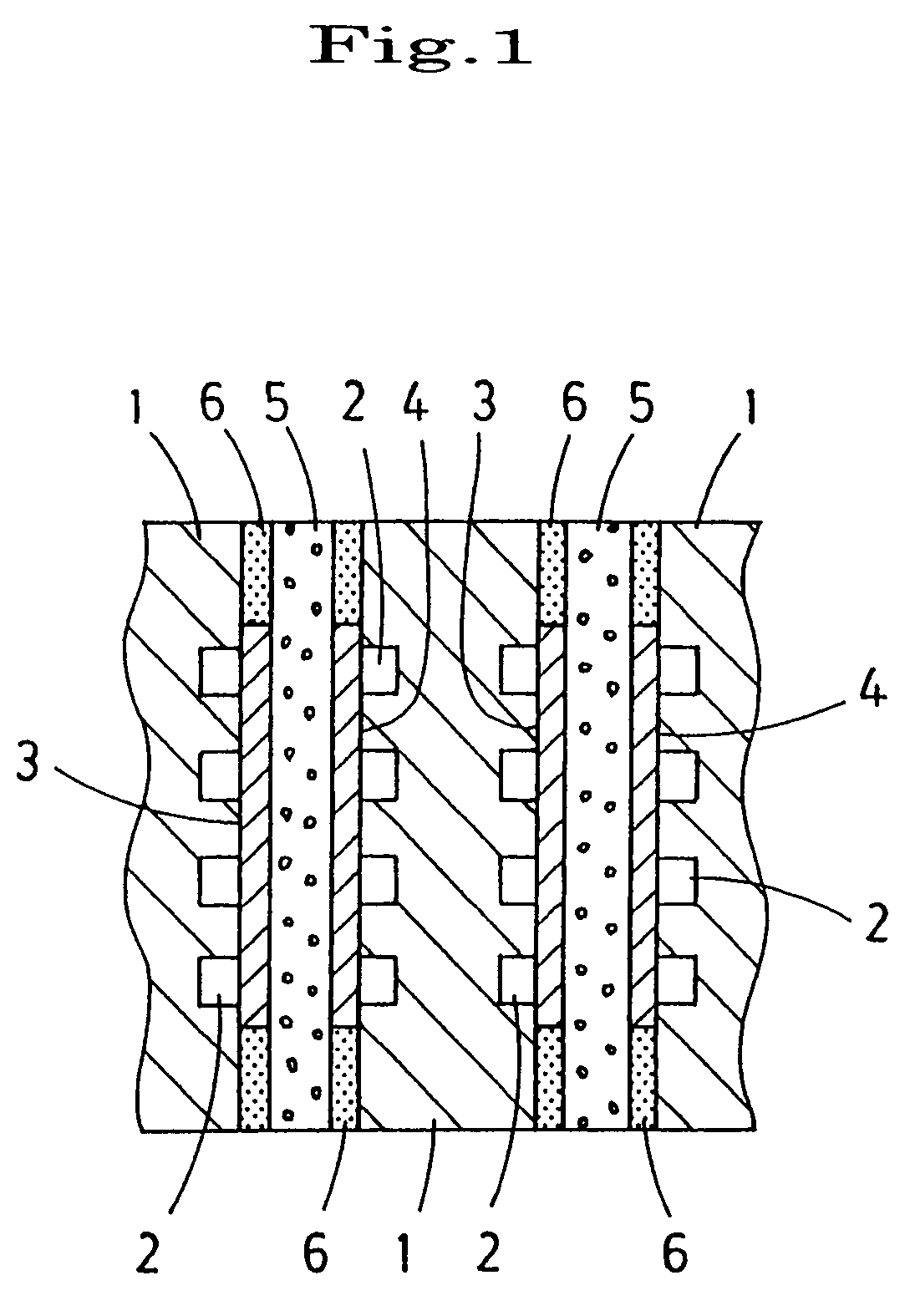

Paper machine clothing and a method of producing the same

ActiveUS6896771B2High dimensional stabilityBelow the melting point of the filament materialCellulosic plastic layered productsLaminationTransverse filamentCross point

This invention relates to porous paper machine clothing (1, 11, 21) for de-watering a paper web in a paper machine, comprising a filament lay-up made of at least one layer (2, 12, 22) of longitudinal filaments (3, 13, 23) and at least one layer (4, 14, 24) of transverse filaments (5, 6, 7; 15; 25) which cross the longitudinal filaments (3, 13, 23), wherein the longitudinal and transverse filaments (3, 13, 23; 5, 6, 7; 15; 25) are single-component filaments, which is characterised in that the longitudinal and transverse filaments (3, 13, 23; 5, 6, 7; 15; 25) are fused at crossing points (8, 16, 27) to each other and / or to parts (17, 18, 19) joining them as a result of heating to the melting temperature which is restricted to said crossing points (8, 16, 27).The invention further relates to a method of producing porous paper machine clothing such as this.

Owner:HEIMBACH GMBH & CO KG

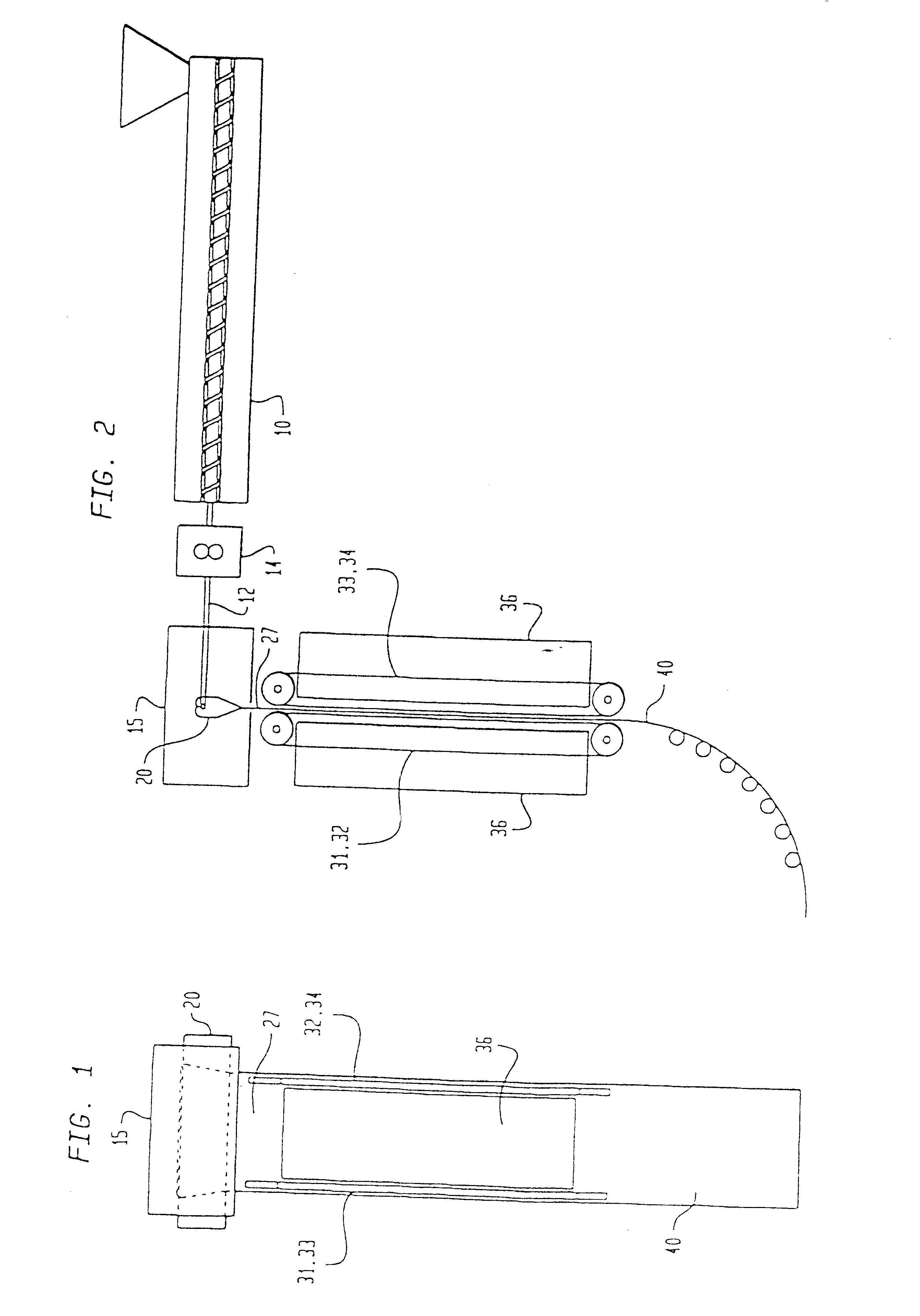

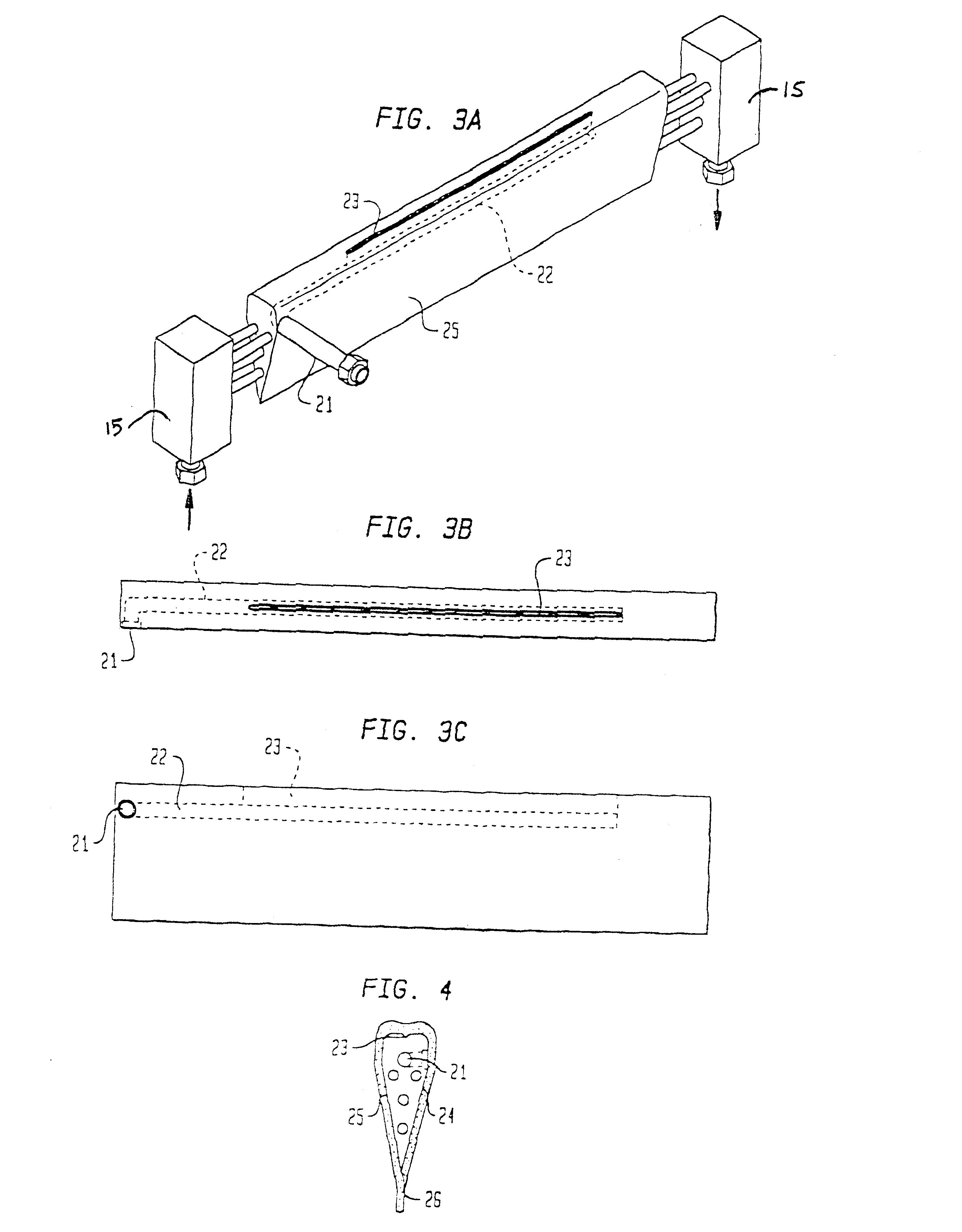

Process and apparatus for forming plastic sheet

InactiveUS6451403B1Avoid mistakesLow birefringenceRecord carriersMagnetic materials for record carriersEngineeringMechanical engineering

Owner:ROHM & HAAS CO

Manufacture method of flexible glue-free double-face copper clad

InactiveCN102909934AReduce defectsImprove yieldLaminationLamination apparatusCopper foilThermosetting polymer

The invention discloses a manufacture method of flexible glue-free double-face copper clad. The copper clad is of a five-layer structure respectively comprising copper clad, a thermoplastic polyimide layer, a thermosetting polyimide layer, a thermoplastic polyimide layer and copper clad. The manufacture method is that thermoplastic polyimide (TPI) solution is coated on two surface of a polyimide film respectively, and after drying, the polyimide film is once-pressed with the two layers of copper clad. The copper clad manufactured through the method is high in production efficiency and product yield and good in size stabilizing performance.

Owner:JIANGSU UNIV OF SCI & TECH

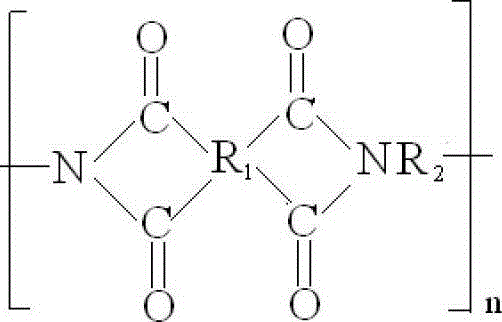

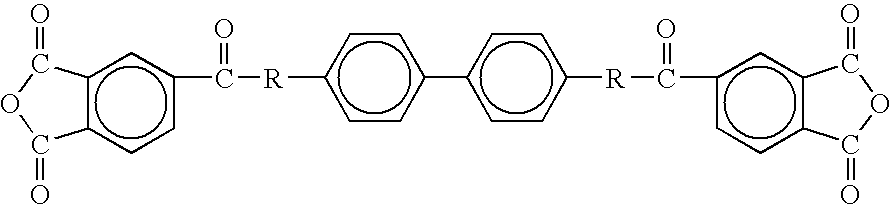

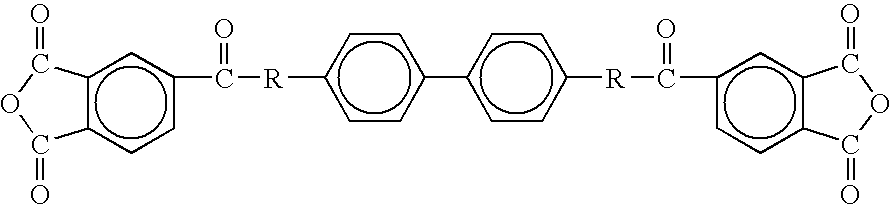

Soluble polyimide resin and method of preparing the same

InactiveUS20060287467A1High dimensional stabilityGood heat resistancePrinted circuitsChemistryOrganic solvent

The present invention provides a polyimide resin, which is prepared by epolycondensing a dianhydride monomer including at least a dianhydride represented by formula (I) wherein R is O or O(CH2)nO, n is an integer of 1 to 2 and a diamine monomer represented by formula (II) H2N—Ar—NH2 (II) wherein Ar is defined as in the text then imidizing the resulting polyamic acid resin to form a polyimide resin. Through using the dianhydride represented by formula (I) as the polymerizing unit, a biphenyl moiety and an ester moiety are introduced into the main chain of the polyimide resin, such that the resulting polyimide resin has lower moisture absorption and smaller linear thermal expansion coefficient and therefore have satisfactory heat resistance and dimensional stability, in addition, become more soluble in organic solvents.

Owner:CHANG CHUN PLASTICS

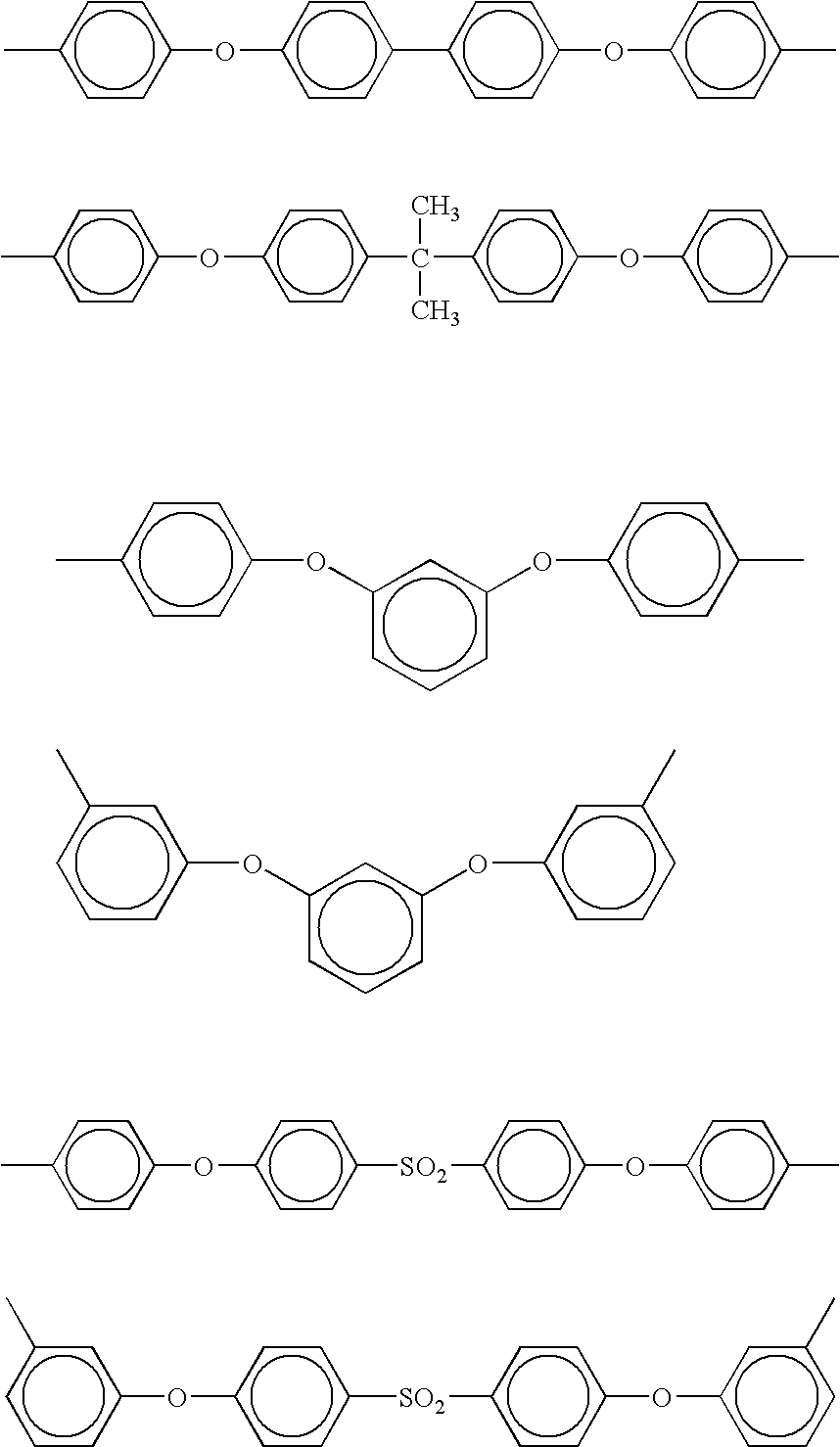

Polyimide compound soft board and its making method

InactiveCN101193495AExcellent adhesionExcellent mechanical properties with excellent adhesionLiquid surface applicatorsLaminationHeat resistancePolyamide

The invention relates to a compound soft board made of polyimide resin and a manufacturing method thereof. In the method, polyamide acid with the coefficient of thermal-expansion (CTE) above 20ppm after cyclization and the polyamide acid with the thermal-expansion coefficient below 20ppm after the cyclization are orderly smeared and arranged on metallic foil, and then the polyamide acid is heated and cyclized to form the polyimide, so that the compound soft board made of the polyimide resin used in printed circuit boards is obtained. The method provided by the invention requires no the adhesion agent for obtaining the compound soft board of polyimide with the outstanding adhesiveness, mechanical property, high heat resistance and high size stability without warping as well.

Owner:CHANG CHUN PLASTICS

Composition for cord coating, cord for rubber reinforcement made with the same, and rubber product made with the same

ActiveCN1938475AGood dimensional stabilityHigh bending fatigue resistanceRubber derivative coatingsCarbon fibresWater solubleSolid content

A composition for cord coating of the present invention comprises a latex of a first rubber, a phenol resin, and a water-soluble condensation product of resorcinol-formaldehyde so that a ratio of the first rubber to a solid content of the composition, a ratio of the phenol resin thereto, and a ratio of the water-soluble condensation product thereto are 30 to 95 wt.%, 0.01 to 30 wt.%, and 2 to 15 wt.%, respectively, wherein the first rubber is a nitrile group-containing highly saturated polymer rubber having an iodine value of 120 or less, and the above-described water-soluble condensation product is a novolac-type condensation product.

Owner:NIPPON SHEET GLASS CO LTD

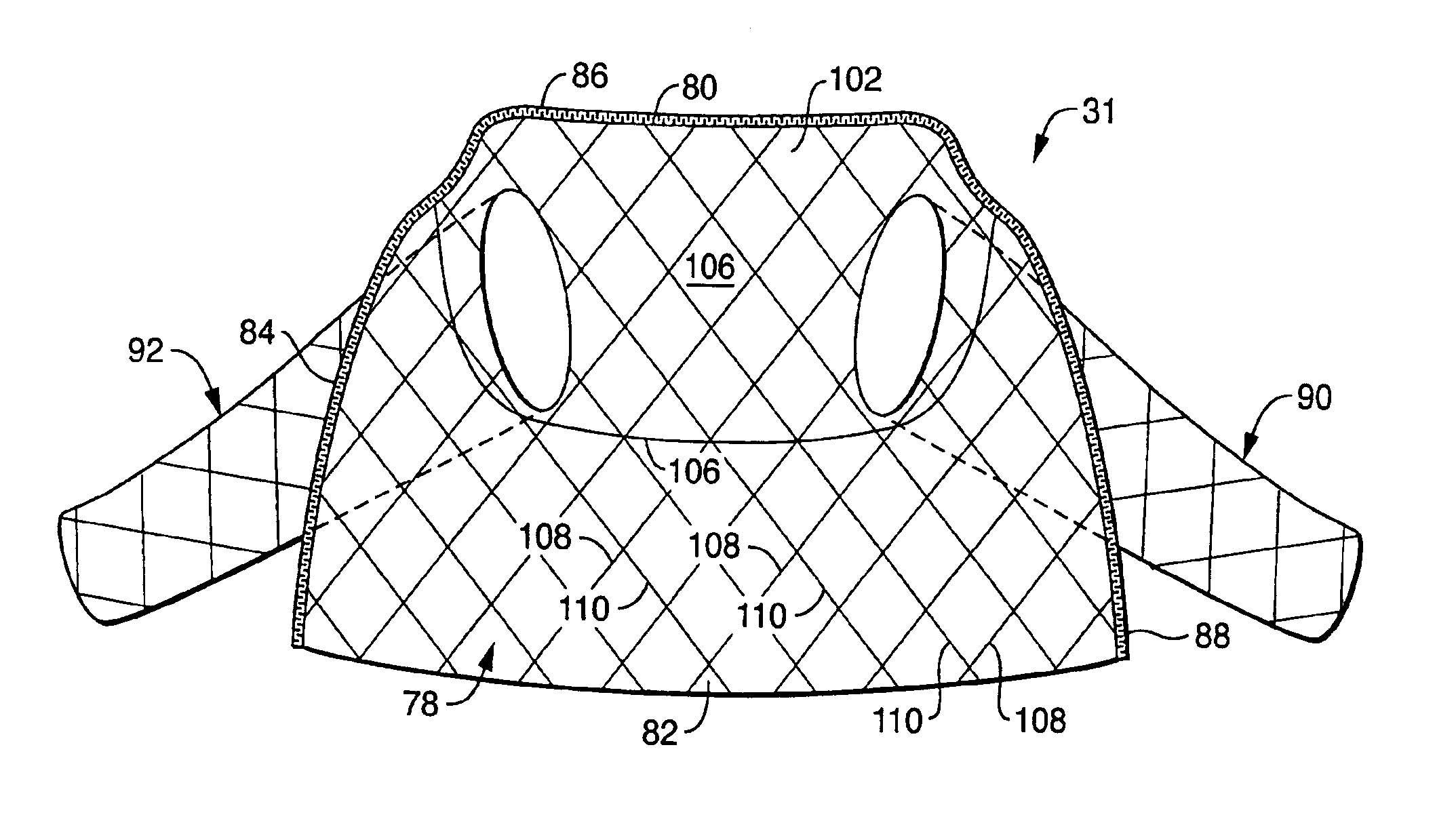

Crumple resistant lining and outerwear for use therewith

InactiveUS6898803B1Good dimensional stabilityReduce coefficient of frictionOvergarmentsProtective garmentEngineeringCoefficient of friction

A detachable lining for outerwear comprises a bodice, which includes an inner substantially full layer composed of a relatively rough fabric, an outer substantially full layer composed of a relatively smooth fabric, and an overlay partial layer composed of a relatively smooth fabric. The partial layer is superposed on the inner layer at an upper region of the bodice. The inner layer and outer layer are quilted together for enhancing dimensional stability and preventing bunching. The overlay partial layer has a relatively low coefficient of friction for encouraging sliding and preventing catching.

Owner:BLAUER MFG

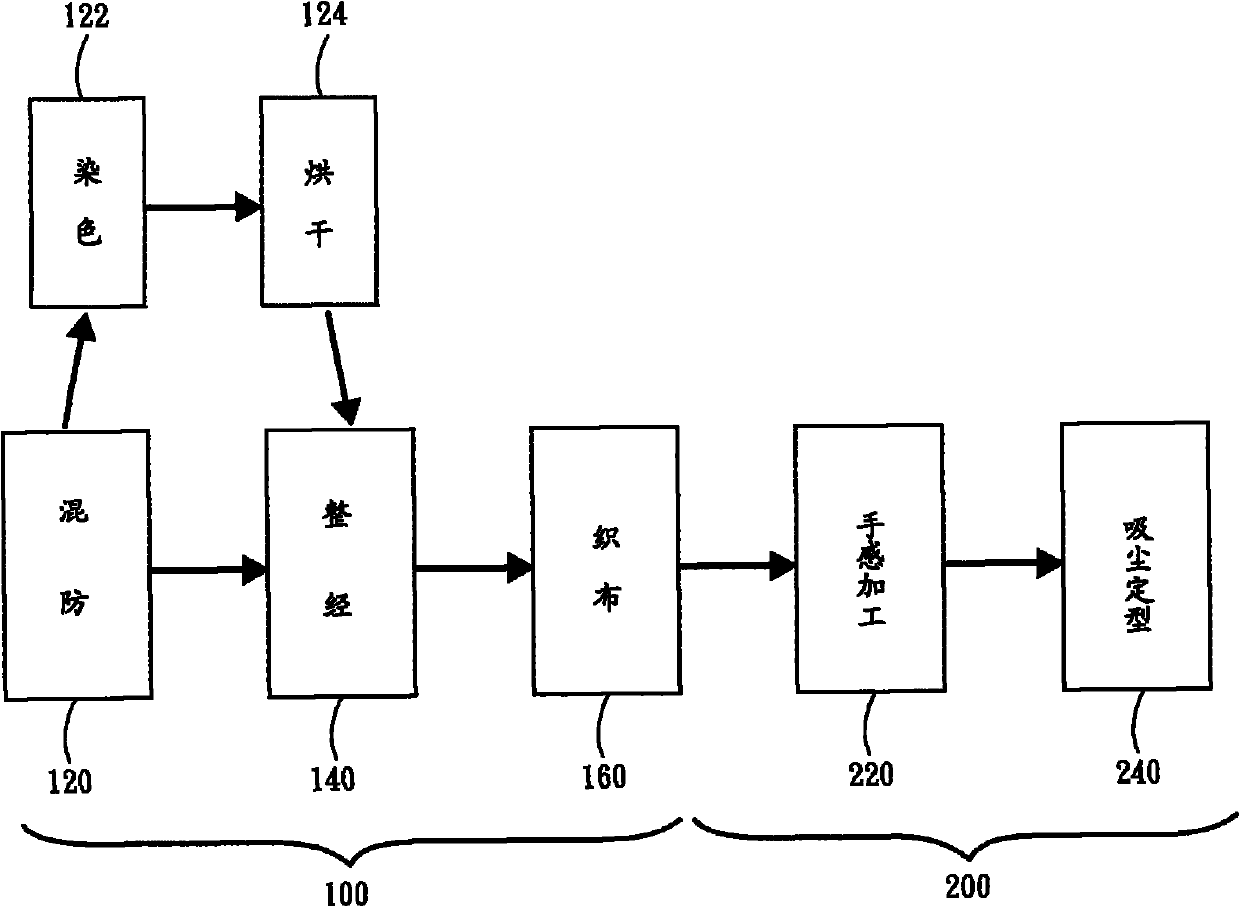

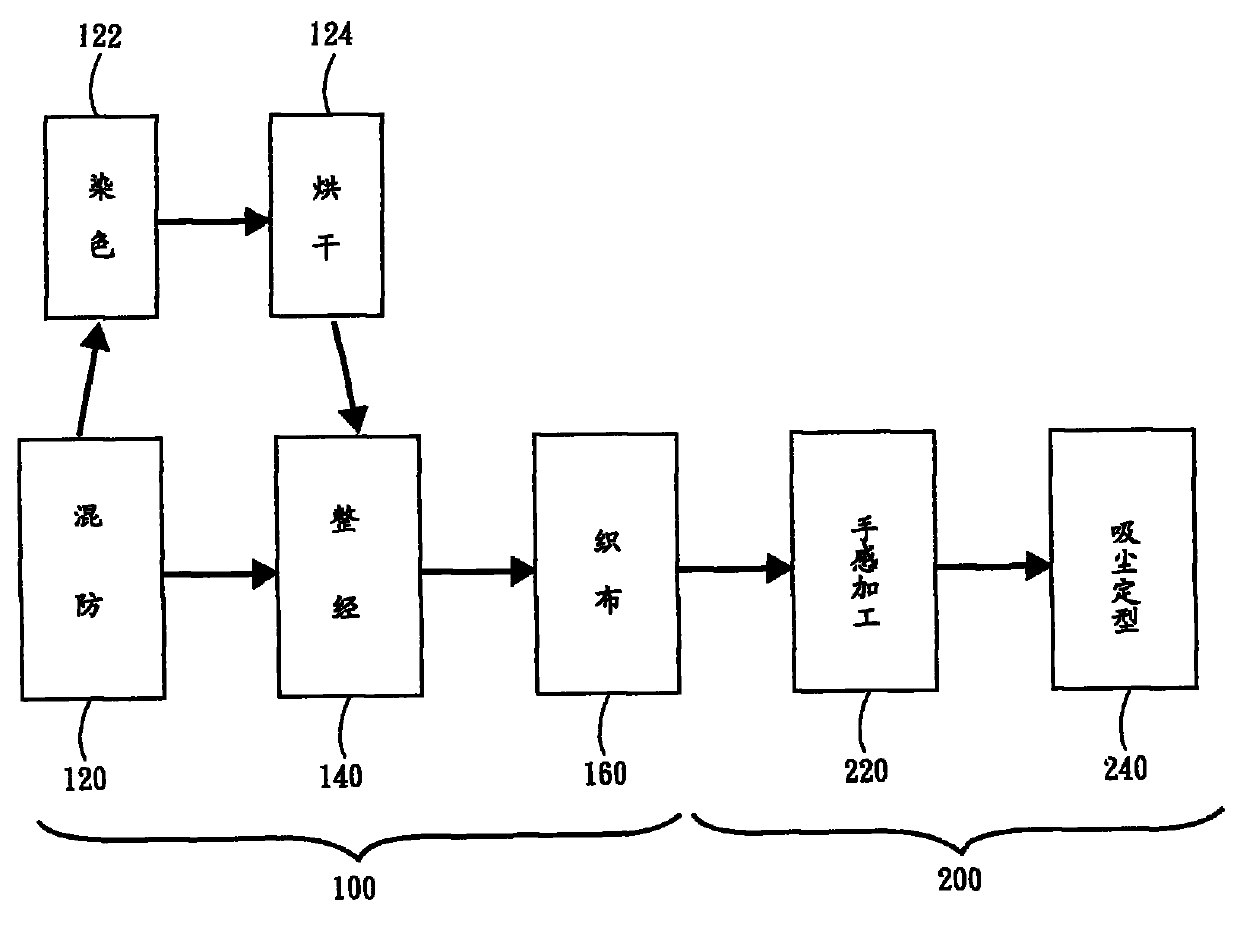

Environment-friendly high-flame-retarding blended conductive fabric and manufacturing process thereof

InactiveCN102199829AImprove flame retardant performanceNo environmental issuesFibre treatmentWoven fabricsYarnMetal fibers

The invention discloses an environment-friendly high-flame-retarding blended conductive fabric and a manufacturing process thereof, which are in accordance with safety standards for fabrics for air transportation. The environment-friendly high-flame-retarding blended conductive fabric comprises wool blended yarns and an environment-friendly flame retardant, wherein the wool blended yarns comprise wool yarns and non-wool yarns which may be artificial fibers or metal fibers; and the environment-friendly flame retardant comprises phosphates and nitrides and account for 5 to 30 percent of the weight of the environment-friendly high-flame-retarding blended conductive fabric. The manufacturing process comprises a weaving process and a finishing process of the wool blended yarns, wherein the finishing process comprises a step of adding the environment-friendly flame retardant which comprises the phosphates and nitrides and account for 5 to 30 percent of the weight of the wool blended yarns.

Owner:FUCHI TEXTILE

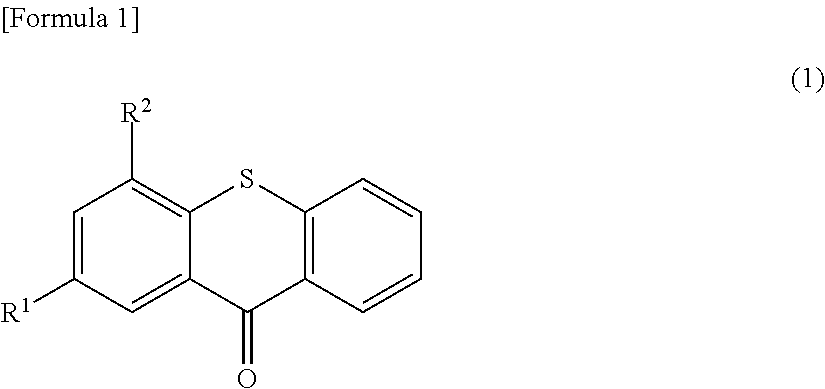

Anti-blue-ray radiation curing perfusion glue, anti-blue-ray lens, anti-blue-ray camera lens anti-blue-ray radiation curing optical plate

PendingCN109135586AHigh speed productionSave electricityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCamera lensThioketone

The invention discloses an anti-blue-ray radiation curing perfusion glue, which comprises acrylated acrylic resin, a reactive monomer, a radiation curing agent, a blue-ray absorbent, an ultraviolet absorbent and an auxiliary agent, the acrylated acrylic ester resin is acrylated acrylic series resin with or without reactive double bond; the reactive monomer is a mixture of a general monomer and anacrylic resin series reactive monomer with reactive double bond; the radiation curing agent is any one or two of organic phosphine and thioketone radiation curing agents; the auxiliary agent is a defoaming agent. Anti-blue-ray glasses prepared from the anti-blue-ray radiation curing perfusion glue can isolate a relatively large part of harmful ultraviolet and radiation rays, is suitable for viewing a mobile phone, a computer or a television, can greatly reduce the stimulation of harmful short-wave blue rays on eyes, can eliminate acor, fever, pain or other uncomfortable symptoms of the eyes, can relieve eyestrain and harm, and protect our precious eyes.

Owner:RAYLAND CHEM DG CO LTD

Additives For Improving Natural Oil Based Polyurethane Foam Peformance

Polyurethane foam compositions and processes to make flexible polyurethane foams are disclosed. Polyurethane foam is produced in the presence of additives comprising guanidine derivatives. Improvements in physical properties such as air flow, dimensional stability, tensile, tear, elongation and foam hardness is observed when these additives are present in polyurethane formulations. In addition, these additives can minimize polymer degradation under humid ageing conditions resulting in foam products with better mechanical properties.

Owner:EVONIK OPERATIONS GMBH

Separator material for solid polymer fuel cell and process for producing the same

InactiveUS7740990B2Prevent movementReduced activityNon-metal conductorsElectrode carriers/collectorsEpoxyEquivalent weight

A separator material suitable for a polymer electrolyte fuel cell and a method of producing the same. The separator material exhibiting gas impermeability, strength, dimensional stability during long-term use, and only a small degree of dissolution of organic substances which hinder the cell reaction. The separator material includes a graphite / cured resin molded product produced by binding a graphite powder using a mixed resin prepared by mixing an epoxy resin with a specific epoxy equivalent and a phenolic resin with a specific hydroxyl equivalent at a specific equivalent ratio and adding an imidazole compound without an amino group as a curing accelerator. The graphite / cured resin molded product has, when immersed in hot water at 90° C., a water absorption elongation percentage after 500 hours of immersion of a specific value or less and an amount of ammonium ions dissolved and an amount of TOC dissolved after 50 hours of immersion of specific values or less. The method of producing the separator material includes preforming a molding powder obtained by grinding a kneaded product of a mixed resin and a graphite powder to prepare a preform, and thermocompression-molding the preform in a mold.

Owner:TOKAI CARBON CO LTD

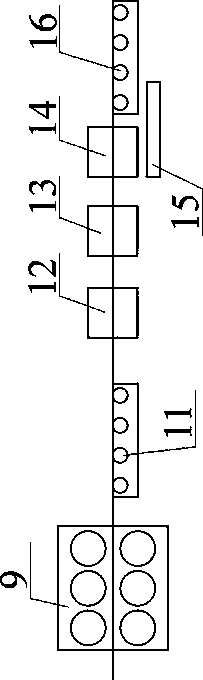

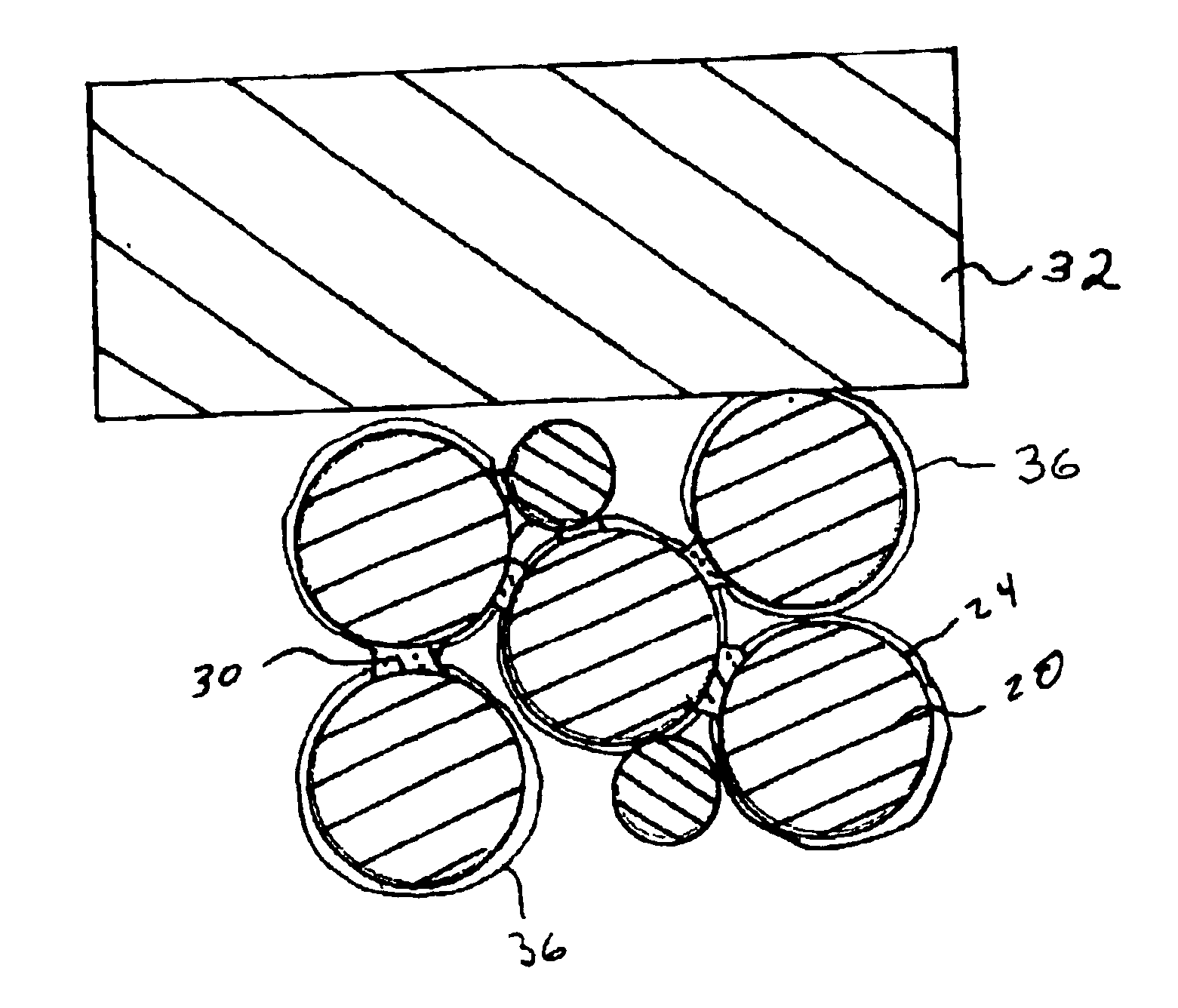

Wetting agent for infiltrated aluminum preforms

InactiveUS6848494B2Facilitate manufacturingHigh dimensional stabilityAdditive manufacturing apparatusComputer-aidedAluminium

A method for the manufacture of a three-dimensional object includes the steps of forming a mixture that contains a binder, a wetting agent, and a least one of aluminum or a first aluminum-base alloy into a green composite, removing the binder from said green composite forming a porous preform structure and infiltrating the porous preform structure with a molten second aluminum base alloy to form the three-dimensional object with near theoretical density. The wetting agent assists in wetting during infiltration. The green composite may be formed by an additive process such as computer aided rapid prototyping, for example selective laser sintering. The method facilitates the rapid manufacture of aluminum components by an inexpensive technique that provides high dimensional stability and high density.

Owner:3D SYST INC

Polymer powder for powder bed fusion methods

ActiveUS20170165913A1Improve coalescenceHigh dimensional stabilityAdditive manufacturing apparatusCoatingsSurface energyPolymer

A polymer powder having a surface energy of less than 35 mN / m is suitable for melting / sintering powder particles for layer-by-layer production of three-dimensional objects.

Owner:EVONIK OPERATIONS GMBH

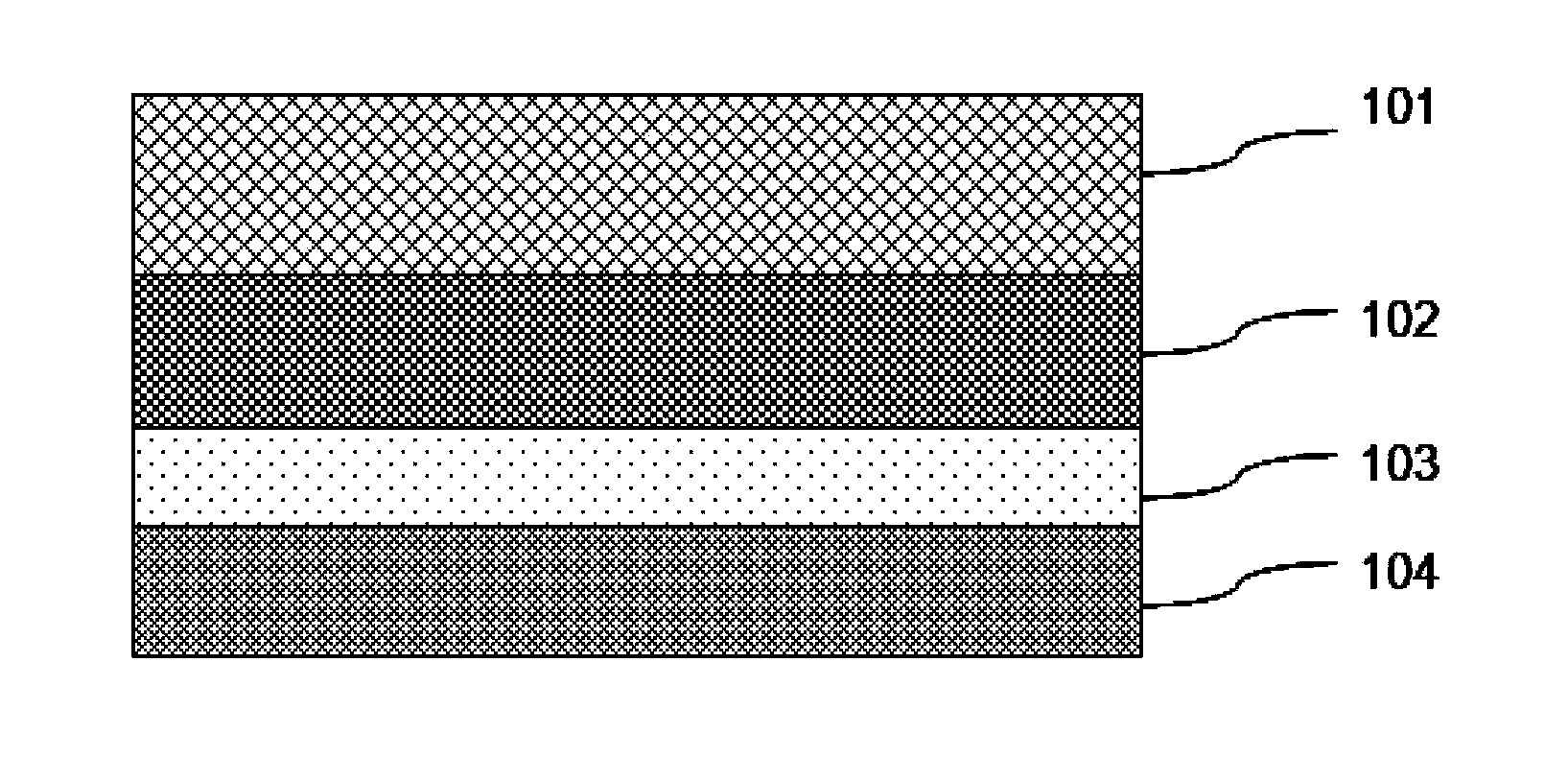

Combined ultrathin double-side copper foil substrate and making method thereof

InactiveCN103625037AHigh dimensional stabilityAdd flexiblyLaminationLamination apparatusMetallurgyCopper foil

The invention discloses a combined ultrathin double-side copper foil substrate and a making method thereof. The combined ultrathin double-side copper foil substrate is formed by a first copper foil layer, a polyimide layer, an adhesion layer and a second copper foil layer, the polyimide layer is arranged between the adhesion layer and the first copper foil layer, and the adhesion layer is arranged between the second copper foil layer and the polyimide layer, wherein the sum of the thicknesses of the polyimide layer and the adhesion layer is 8-25mum. The combined ultrathin double-side copper foil substrate has the advantages of lightness, thinness, high dimension stability, high buckling performance and low rebounding force; and the combined ultrathin double-side copper foil substrate is made through coating or transfer printing and low temperature stitching, so the making method has the advantages of simplicity, high yield and low cost.

Owner:KUSN APLUS TEC CORP

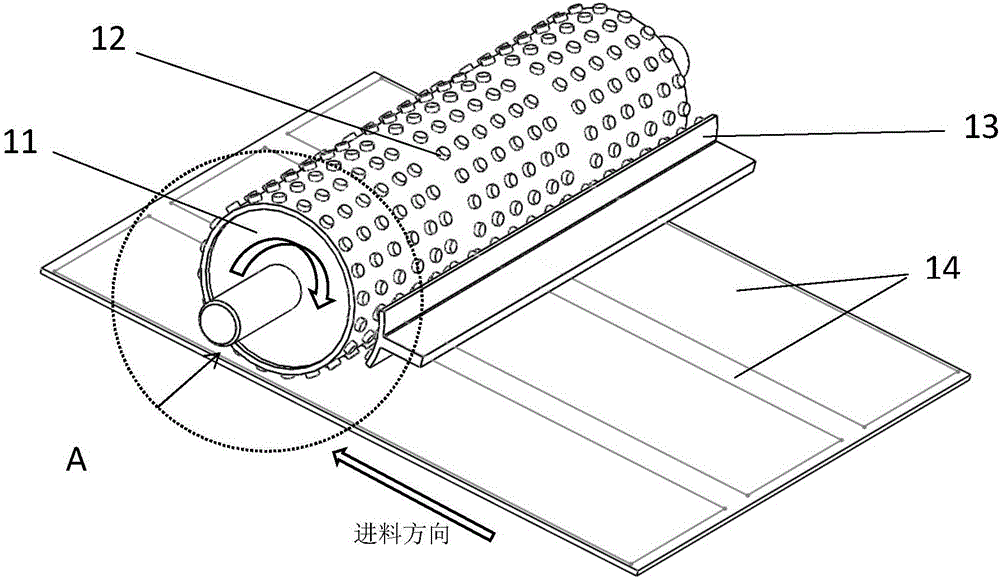

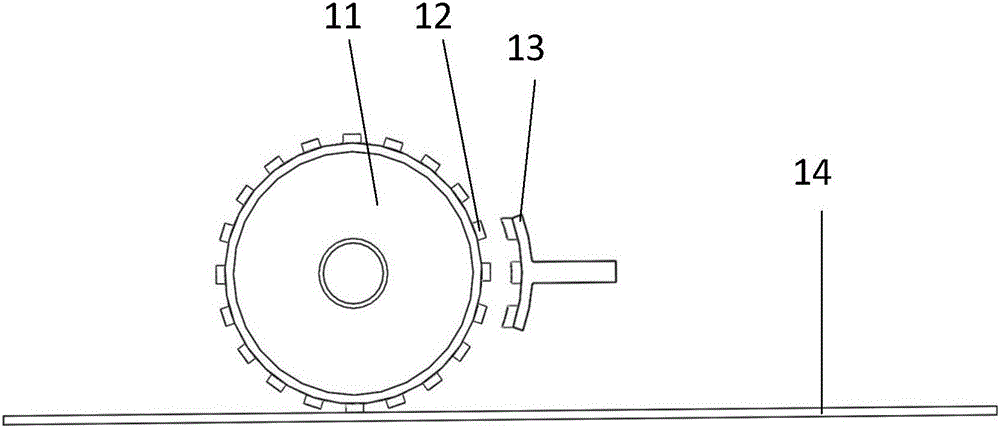

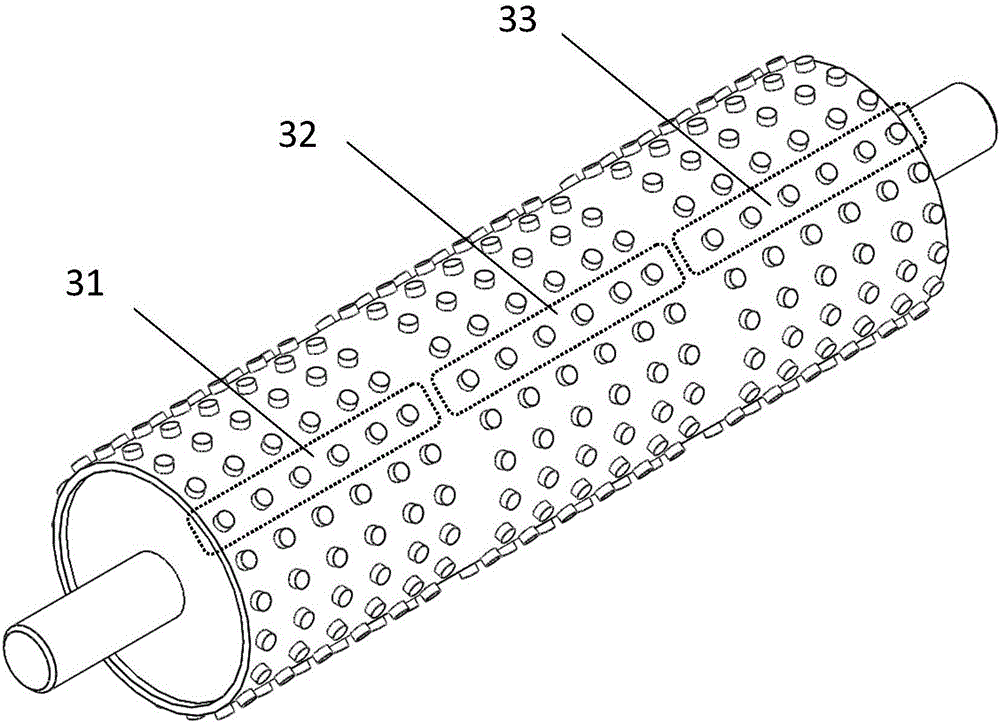

Continuous laminating method for composite floor

ActiveCN106827115AReduce warpageShort cycle of cold pressingOther plywood/veneer working apparatusLaminationRoom temperatureEngineering

The invention provides a continuous laminating method for a composite floor. The method comprises the steps that a base material, a surface plate and a bottom plate are selected and prepared; secondly, point type gluing is conducted on the base material through moisture curing reaction type polyurethane hot melt adhesive; thirdly, blank assembling is conducted, and the surface plate, the base material and the bottom plate are automatically and continuously assembled through accurate surface plate, base material and bottom plate positioning equipment, and are directly and automatically conveyed to enter a continuous press to be subjected to cold pressing; fourthly, continuous normal-temperature pressure applying is conducted; and fifthly, splitting is conducted, a floor blank obtained after cold pressing enters a multiple blade saw unit and is split into floor blank bodies equal in width, wherein a multiple blade saw is a composition unit of the continuous cold press and is arranged after the laminating procedure. The composite floor manufactured through the method has many beneficial effects that the glue spreading amount is small, glue spreading is uniform, the gluing strength is uniform, the inner stress of the floor is small, the size stability is high, free formaldehyde release is avoided, the product quality is high, and the cold pressing period is short; and the production technology is simple, energy consumption is low, the production efficiency is high, and continuous and automatic production can be achieved.

Owner:菲林格尔家居科技股份有限公司

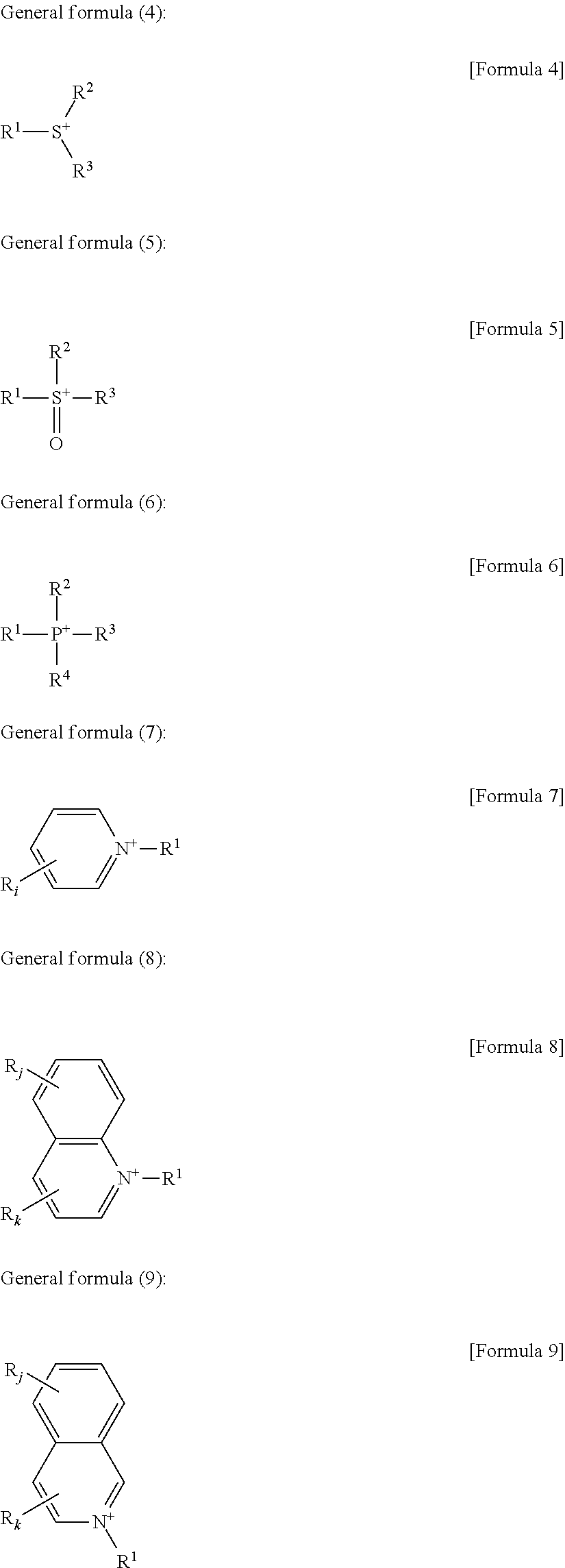

Active energy ray curable adhesive composition, polarizing film and method for producing same, optical film and image display device

InactiveUS20150116817A1Improve adhesionHigh levelLamination ancillary operationsNon-macromolecular adhesive additivesPolymer scienceOrganic chemistry

An active energy ray-curable adhesive composition comprising radically polymerizable compounds (A), (B) and (C) as curable components, wherein the radically polymerizable compound (A) has an SP value of 29.0 (kJ / m3)1 / 2 to 32.0 (kJ / m3)1 / 2; the radically polymerizable compound (B) has an SP value of 18.0 (kJ / m3)1 / 2 to less than 21.0 (kJ / m3)1 / 2; the radically polymerizable compound (C) has an SP value of 21.0 (kJ / m3)1 / 2 to 23.0 (kJ / m3)1 / 2, and the composition comprises 1.0 to 30.0% by weight of the radically polymerizable compound (A), 35.0 to 98.0% by weight of the radically polymerizable compound (B), and 1.0 to 30.0% by weight of the radically polymerizable compound (C) based on 100% by weight of the total amount of the composition.

Owner:NITTO DENKO CORP

High-strength coal gangue sintered porous brick

InactiveCN108046823AImprove mobility linkagesTake advantage ofCeramic materials productionCeramicwarePorosityBrick

The invention provides a high-strength coal gangue sintered porous brick. The high-strength coal gangue sintered porous brick is prepared from the following components in percentage: 15 to 35 percentof shale, 2 to 10 percent of waste plastic particles, 4 to 7 percent of vermiculite powder, 5 to 10 percent of alkaline mineral slag, 0.5 to 1.8 percent of magnesium borate whisker, and the balance ofcoal gangue, and is also prepared from 0 to 10 percent of modified diatomaceous earth and 0 to 3 percent of a dispersing agent. According to the high-strength coal gangue sintered porous brick, through reasonable proportion of the raw materials, flow coupling among the components is effectively improved, the comprehensive performance is remarkably improved, and the prepared product has the compressive strength of greater than 28.4 MPa and the porosity of greater than 35 percent; industrial waste is fully utilized; and the high-strength coal gangue sintered porous brick is environment-friendly, economical and high in economic benefit, and is suitable for industrial popularization.

Owner:HEXIAN MINGSHENG ENVIRONMENTAL PROTECTION MATERIAL

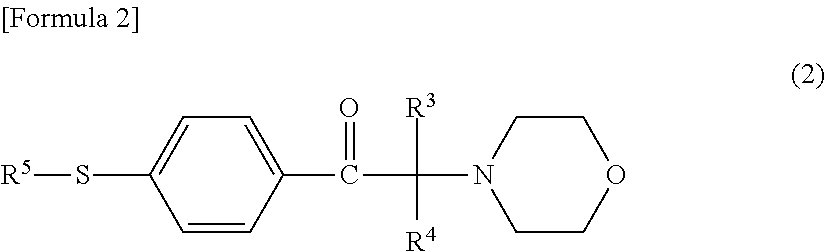

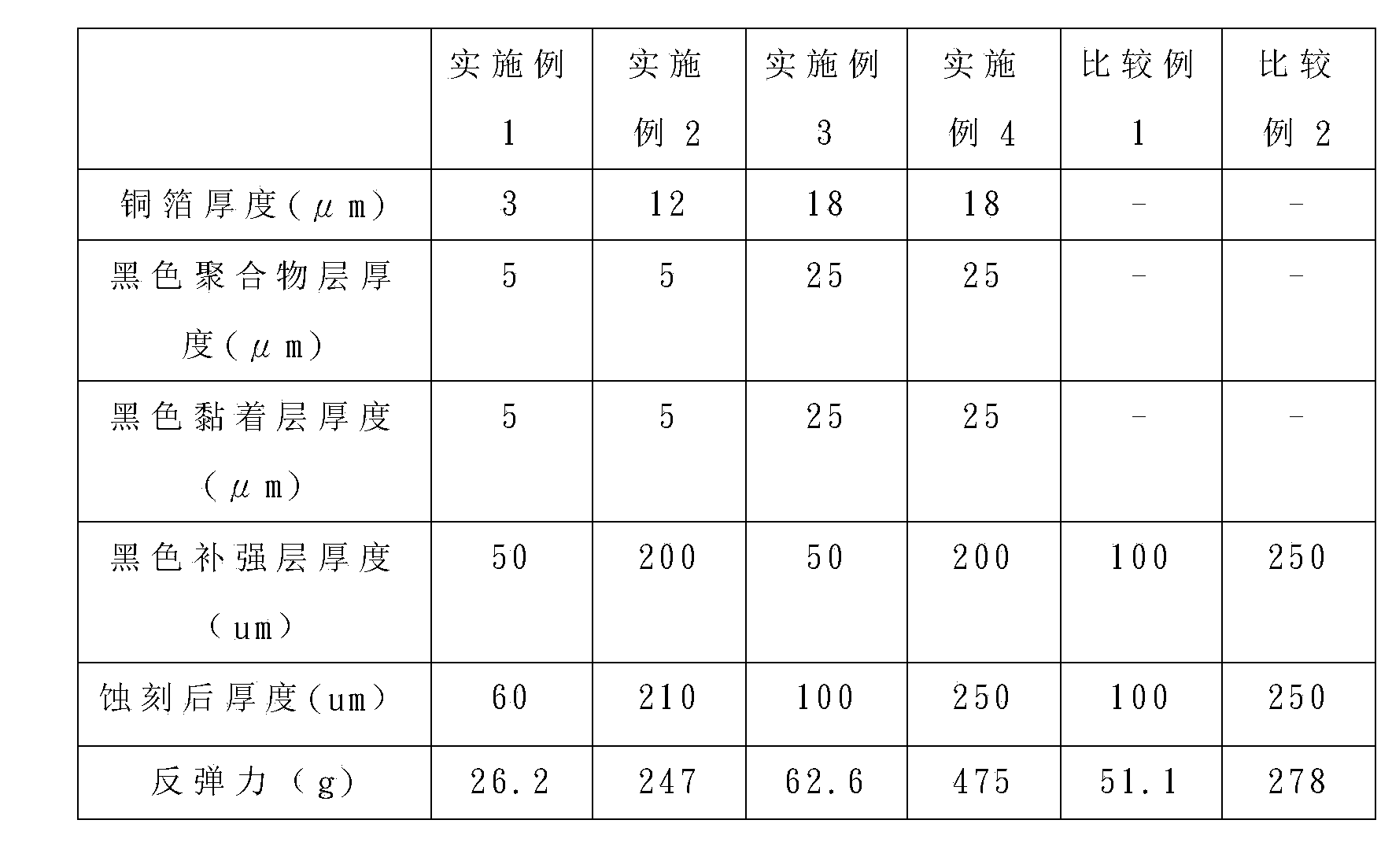

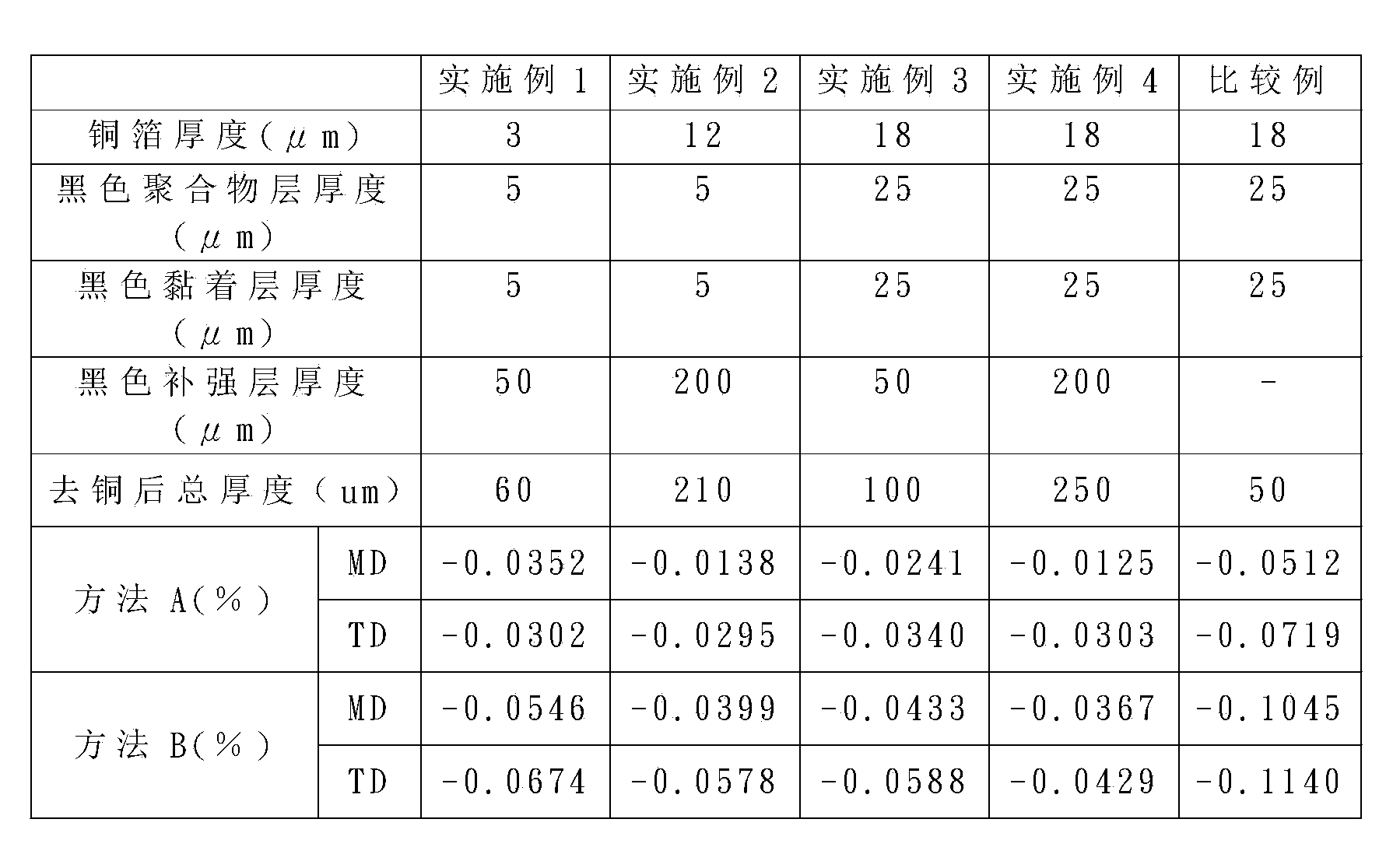

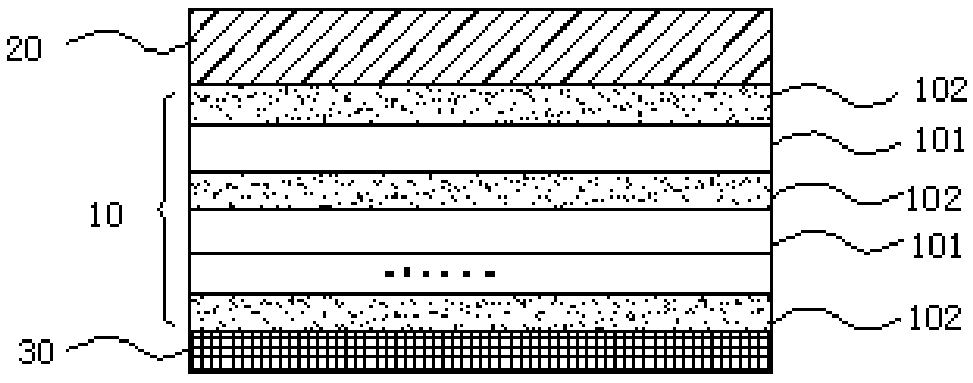

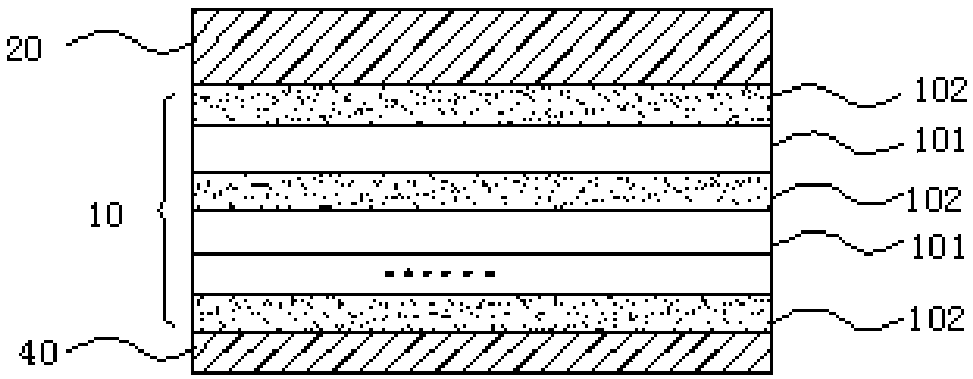

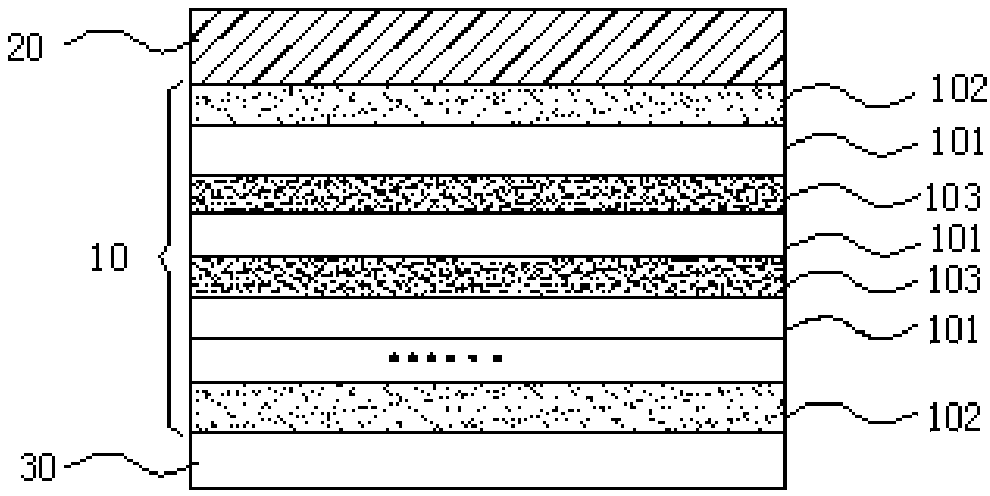

Composite-structure copper foil substrate and making method thereof

InactiveCN103625036AHigh dimensional stabilityIncrease stiffnessSynthetic resin layered productsLaminationCopper foilComposite structure

The invention discloses a composite-structure copper foil substrate and a making method thereof. The composite-structure copper foil substrate is formed by a copper foil layer, a black polymer layer, a black adhesion layer and a black strengthening layer, wherein the black polymer layer is arranged between the copper foil layer and the black adhesion layer, the black adhesion layer is arranged between the black polymer layer and the black strengthening layer, and the sum of the thicknesses of the black polymer layer and the black adhesion layer is 5-50mum. The composite-structure copper foil substrate is made through a simple method, and the thicknesses of the black adhesion layer and the black polymer layer can be adjusted according to the demands of FPC downstream factories to satisfy the demands of FPC clients, so the composite-structure copper foil substrate accords the demands of high dimensional stability, high stiffness and workability, and is especially suitable for relevant electronic products of mobile phone antenna plates and the like.

Owner:KUSN APLUS TEC CORP

Composite high-frequency substrate with characteristics of high Dk and low Df and preparation method thereof

PendingCN110662348AImprove insulation performanceHigh dimensional stabilityCircuit susbtrate materialsDielectricManufacturing technology

The invention discloses a composite high-frequency substrate with the characteristics of high Dk and low Df. The high-frequency substrate comprises a first copper foil layer and a core layer; the corelayer comprises a plurality of high-molecular polymer film layers and a plurality of dielectric adhesive layers; the dielectric adhesive layer comprises at least one of a first dielectric adhesive layer and a second dielectric adhesive layer; the first dielectric adhesive layer is an adhesive layer with a Dk value of 6-30 and a Df value of 0.002-0.020, the second dielectric adhesive layer is an adhesive layer with a Dk value of 15-100 and a Df value of 0.002-0.020, and the Dk value of the second dielectric adhesive layer is greater than the Dk value of the first dielectric adhesive layer; andthe core layer refers to a core layer with a Dk value of 6-50 and a Df value of 0.002-0.020. The laser drilling technology is better, the inward shrinkage condition is not likely to happen, the hygroscopicity is low, the insulativity is high, the size stability is high, the thermal stability is excellent, and the high Dk and low Df electrical property is better; normal press fit parameters can beused for being matched with quick press equipment or pressure transmission equipment, the cost advantage is achieved, and the thick film manufacturing technology is achieved.

Owner:KUSN APLUS TEC CORP

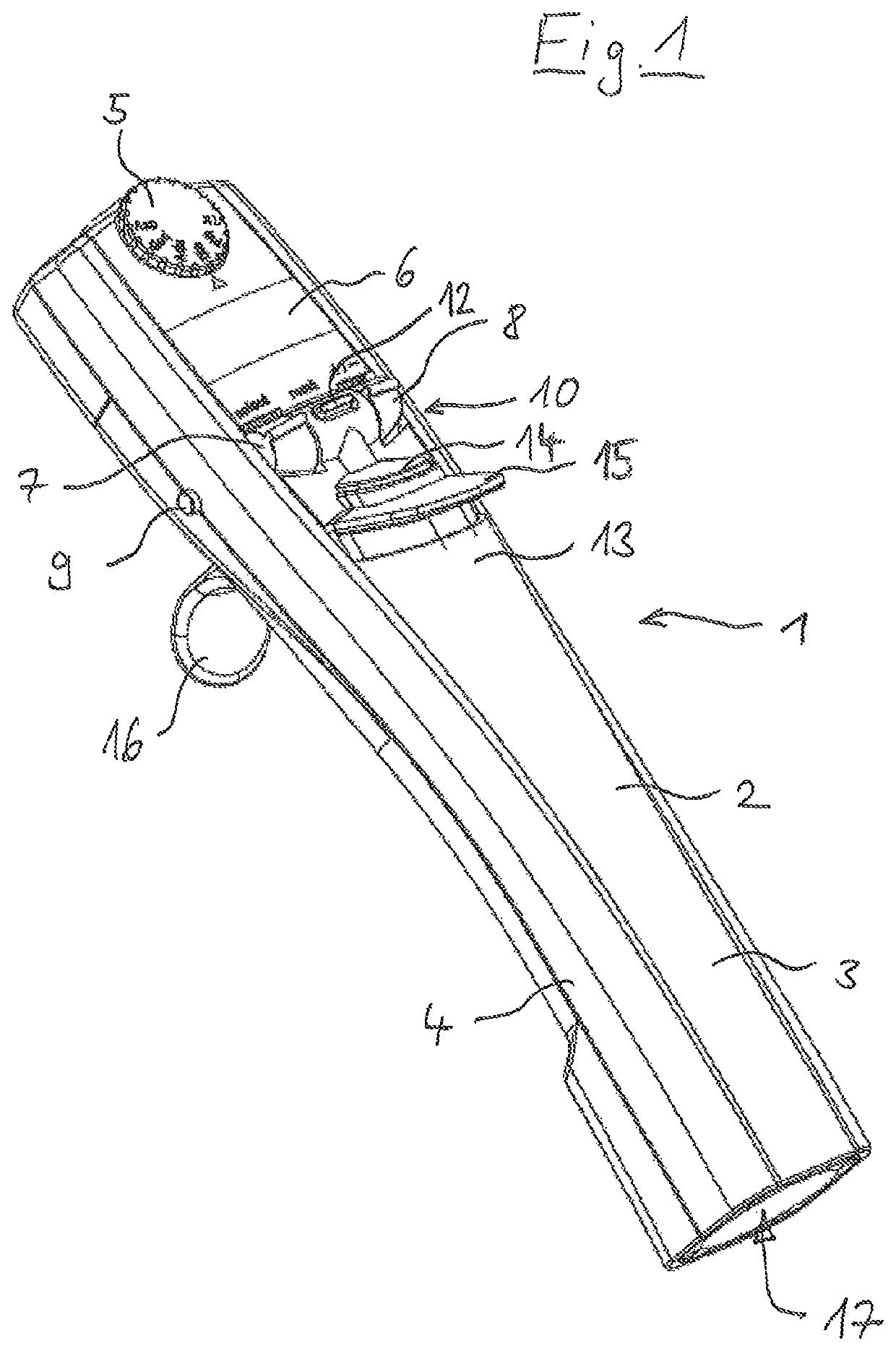

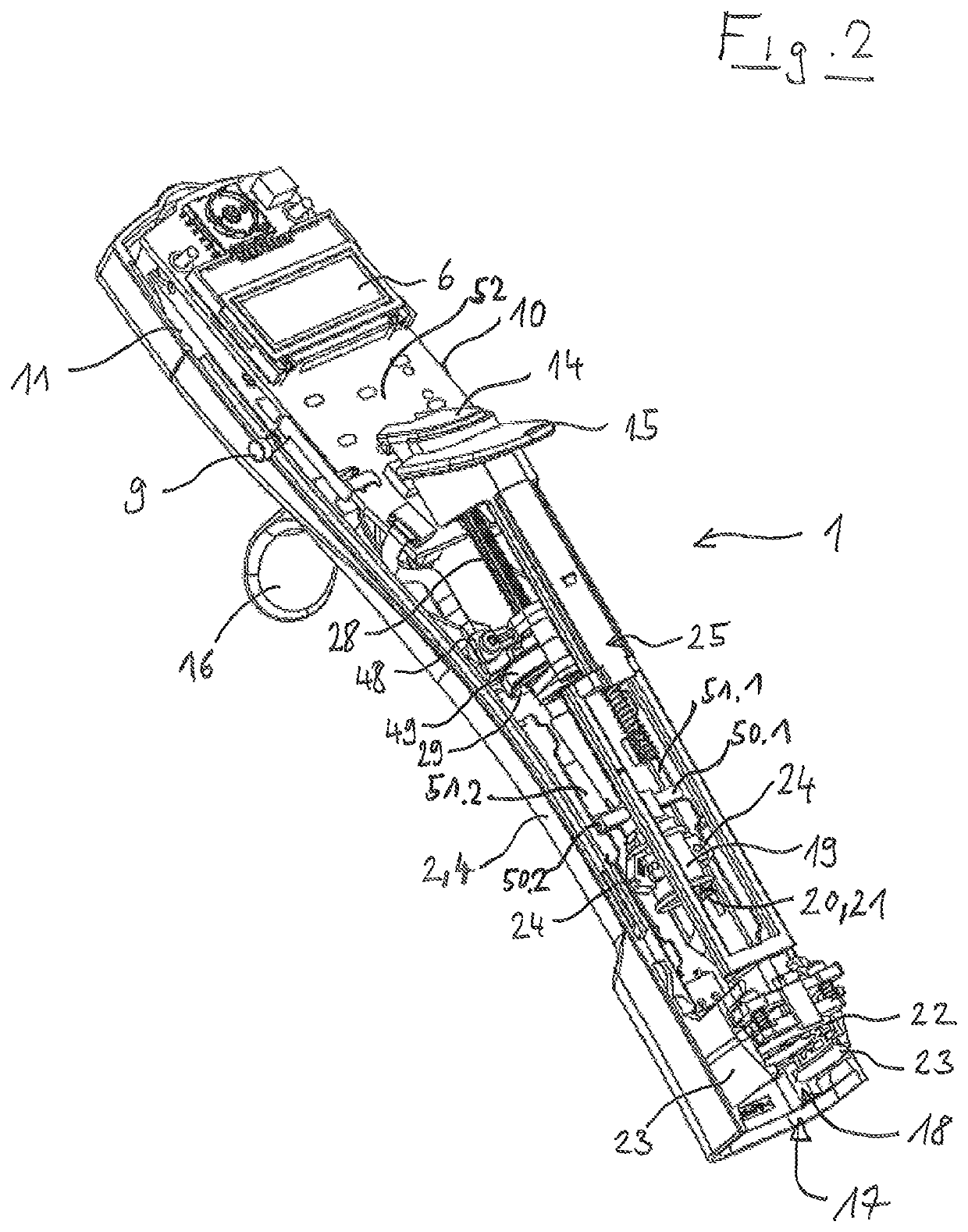

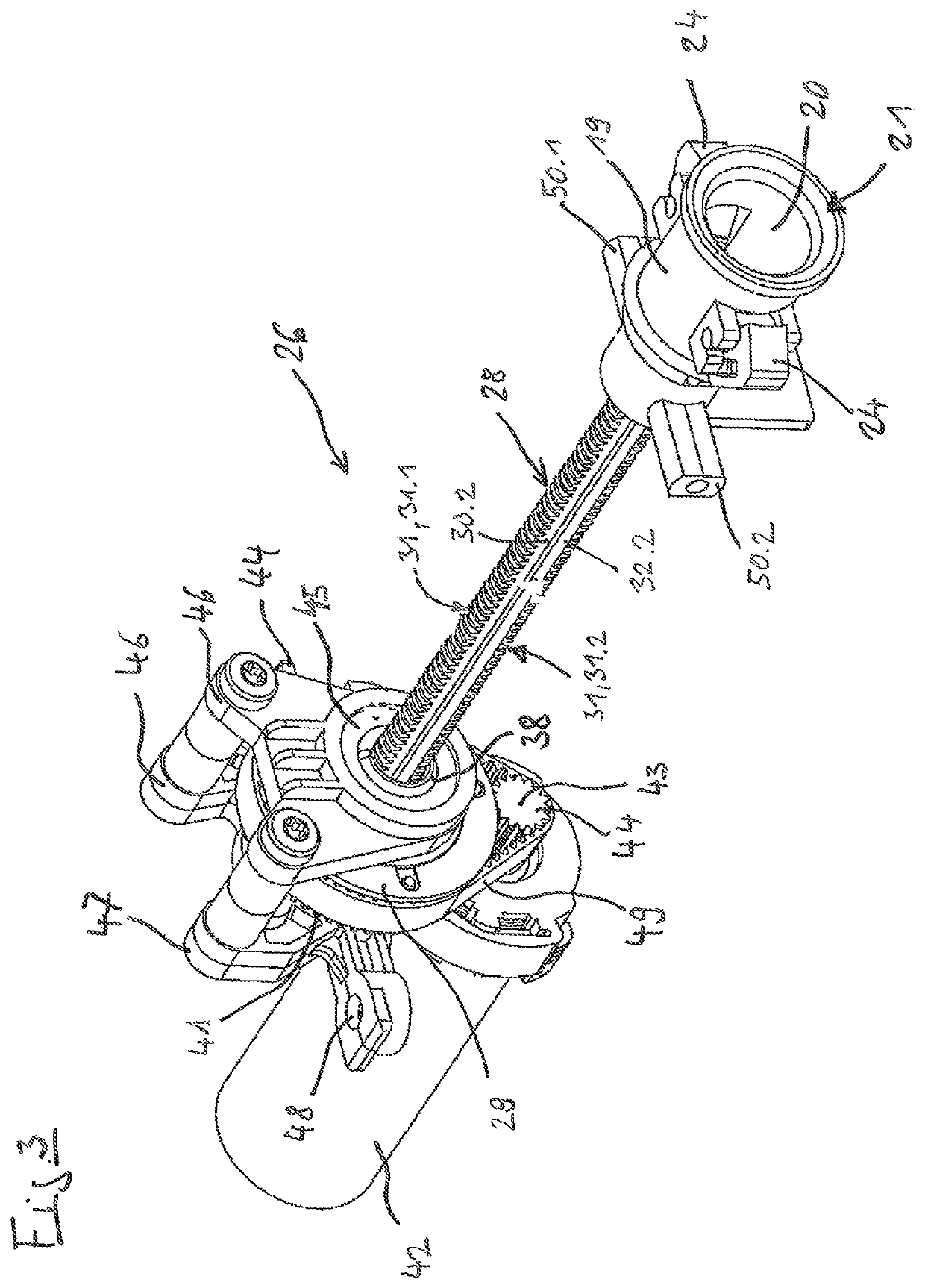

Electronic dosing drive

ActiveUS10758899B2Easy demoldingHigh dimensional stabilityGearingBurettes/pipettesPhysicsElectric drive

An electronic dosing drive comprising a support structure, a threaded spindle with an external thread for driving a plunger, at least one first guide element is firmly connected, and is guided parallel to the threaded spindle on a second guide element, a spindle nut having an internal thread is engaged with the external thread of the threaded spindle, an electric drive motor having a motor shaft is coupled with the spindle nut and is attached to the support structure, an electric control apparatus is connected to the electric drive motor, where the external thread of the threaded spindle has multiple threaded areas that are separated from each other by first flattenings on their circumference extending in the longitudinal direction, and the first flattenings have guide areas that abut the core diameter of the internal thread of the spindle nut.

Owner:EPPENDORF AG

Dental cement composition

ActiveUS20180071175A1Improve mechanical propertiesMinimal exothermic reactionImpression capsOrganic chemistryParticulatesHydrogen atom

Dental cement composition comprising (i) a particulate filler reactive with a polyacid in a cement reaction; (ii) a water-soluble polymerizable compound of the following formula (1), AXn (1) wherein A is a linker group containing at least n nitrogen atoms and optionally one or more acidic groups, X are moieties containing a polymerizable double bond and forming an amide bond with a nitrogen atom of A, which X may be the same or different and are represented by the following formula (2) wherein R1 and R2 are independent from each other and represent a hydrogen atom, a C1-6 alkyl group or a group —(CH2)m—Z, wherein Z is COOM, OPO3M2, PO3M2, SO3M, and M is independently a hydrogen atom or a metal atom, and m is an integer of from 0 to 6, L is a bond or a C1-6 alkylene group; and n is an integer of at least 1; provided that at least one X cannot be a (meth)acryl group; and (iii) an initiator system; optionally a polyacidic polymer having polymerizable double bonds; and optionally water.

Owner:DENTSPLY SIRONA INC

Preparation method for polyamide acid resin and preparation method for double-sided flexible copper-clad plate

InactiveCN109503836AImprove heat resistanceGood chemical resistanceLamination ancillary operationsLaminationHeat resistanceProton

The invention discloses a preparation method for polyamide acid resin and a preparation method for a double-sided flexible copper-clad plate. The preparation method for the polyamide acid resin is asfollows: under the protection of nitrogen, aromatic diamine monomer is dissolved into an aprotic polar solvent, and after stirring for dissolution at 25 DEG C to 50 DEG C, an aromatic diamine monomersolution with the mass concentration of 6 to 9 percent is obtained; after being cooled to 0 DEG C to 25 DEG C, the aromatic diamine monomer solution is added with an aromatic dianhydride monomer, wherein the molar ratio of the aromatic diamine monomer to the aromatic dianhydride monomer is (1:0.95) to (1:1.05), and after 6 to 10 hours of polymerization reaction, standing for defoaming is carried out, so that the polyamide acid resin is obtained. The invention further discloses the method for preparing the double-sided flexible copper-clad plate by utilizing the polyamide acid resin. Accordingto the invention, the reaction for preparing the polyamide acid resin is simple and controllable, and the polyamide acid resin has excellent heat resistance and chemical resistance; and the prepared double-sided flexible copper-clad plate has good heat resistance, high dimensional stability and excellent chemical resistance, and properties such as peel strength and elongation are excellent.

Owner:广东圣帕新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com