Composite-structure copper foil substrate and making method thereof

A technology of copper foil substrate and manufacturing method, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve problems such as cracking board, poor bonding force, complicated process, etc., and achieve high dimensional stability , easy processing, high stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

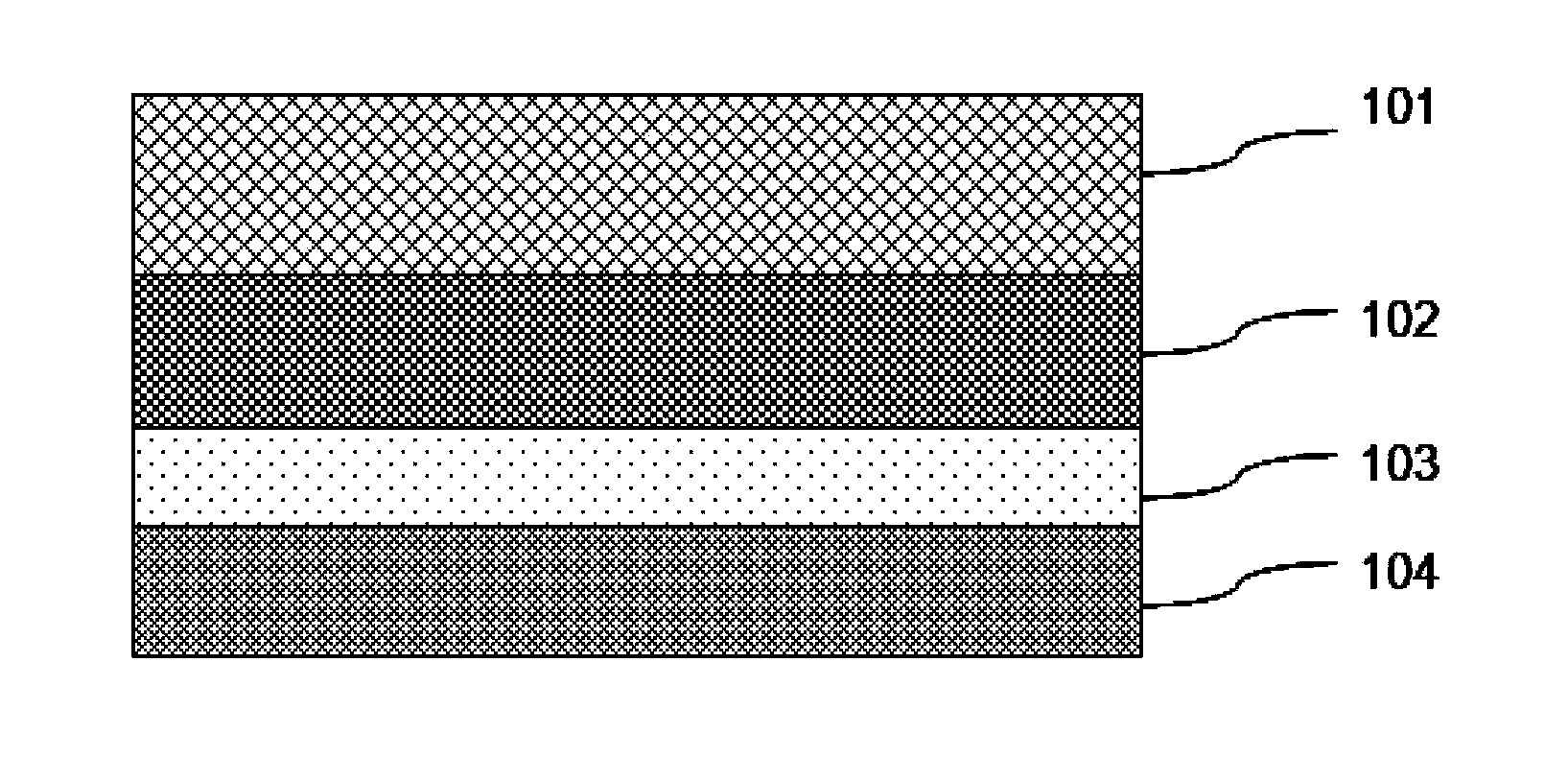

[0026] Embodiment 1: A composite structure copper foil substrate, such as figure 1 As shown, it consists of a copper foil layer 101, a black polymer layer 102, a black adhesive layer 103 and a black reinforcing layer 104, wherein the black polymer layer 102 is sandwiched between the copper foil layer 101 and the black adhesive layer Between layers 103, the black adhesive layer 103 is sandwiched between the black polymer layer 102 and the black reinforcing layer 104, and the sum of the thicknesses of the black polymer layer and the black adhesive layer is 6 to 50 microns.

[0027] In order to avoid quality problems such as insufficient bonding force and cracking of the flexible printed circuit board produced by the copper foil substrate, the composite structure copper foil substrate of the present invention can adjust the black adhesive layer in the copper foil substrate as required. composition and thickness. The material of the black adhesive layer of the copper foil substr...

Embodiment 2

[0038] Embodiment 2: A composite structure copper foil substrate, such as figure 1 As shown, it consists of a copper foil layer 101, a black polymer layer 102, a black adhesive layer 103 and a black reinforcing layer 104, wherein the black polymer layer 102 is sandwiched between the copper foil layer 101 and the black adhesive layer Between layers 103, the black adhesive layer 103 is sandwiched between the black polymer layer 102 and the black reinforcing layer 104, and the sum of the thicknesses of the black polymer layer and the black adhesive layer is 5 to 50 microns.

[0039]In order to avoid quality problems such as insufficient bonding force and cracking of the flexible printed circuit board produced by the copper foil substrate, the composite structure copper foil substrate of the present invention can adjust the black adhesive layer in the copper foil substrate as required. composition and thickness. The material of the black adhesive layer of the copper foil substra...

Embodiment 3 to 4

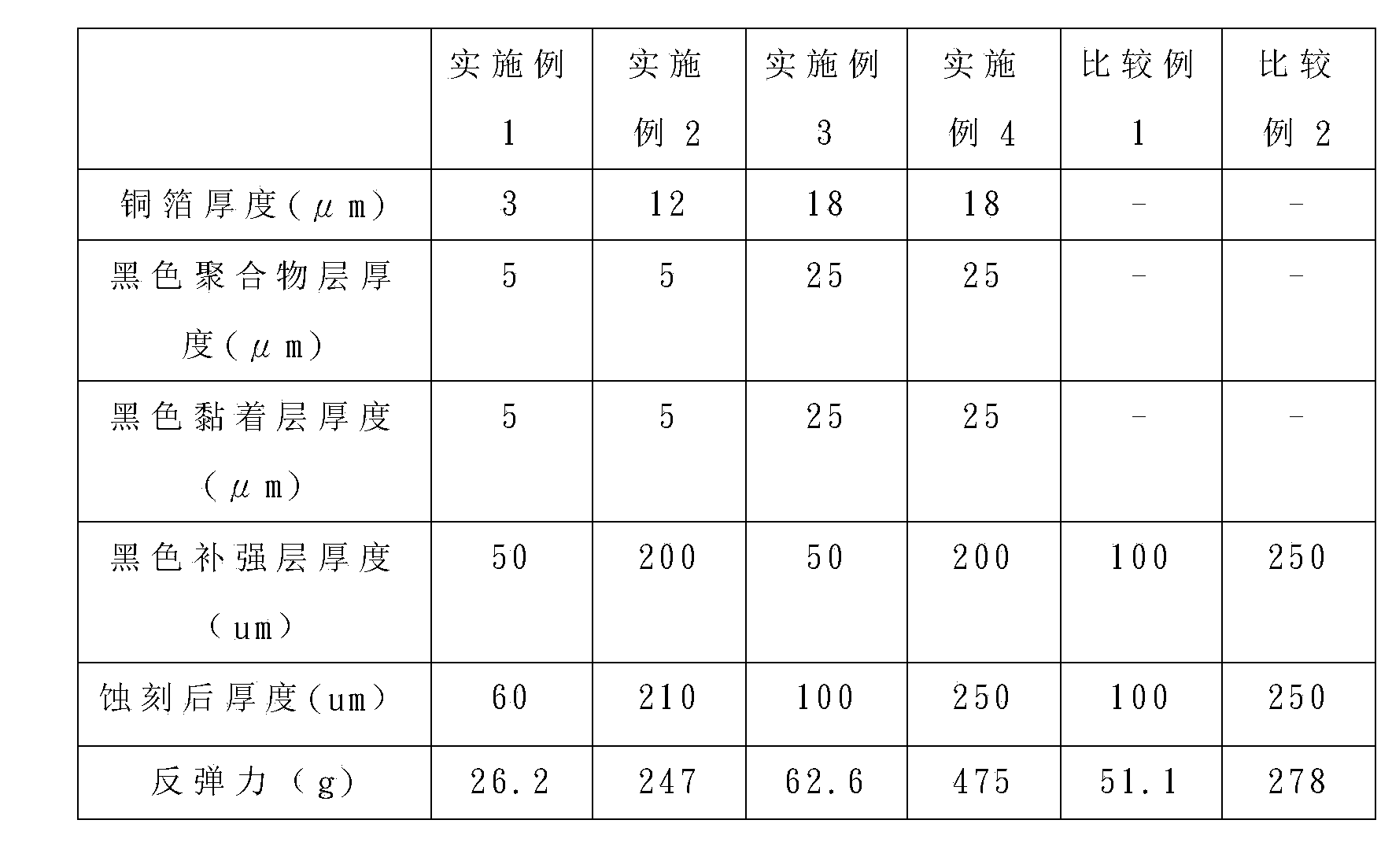

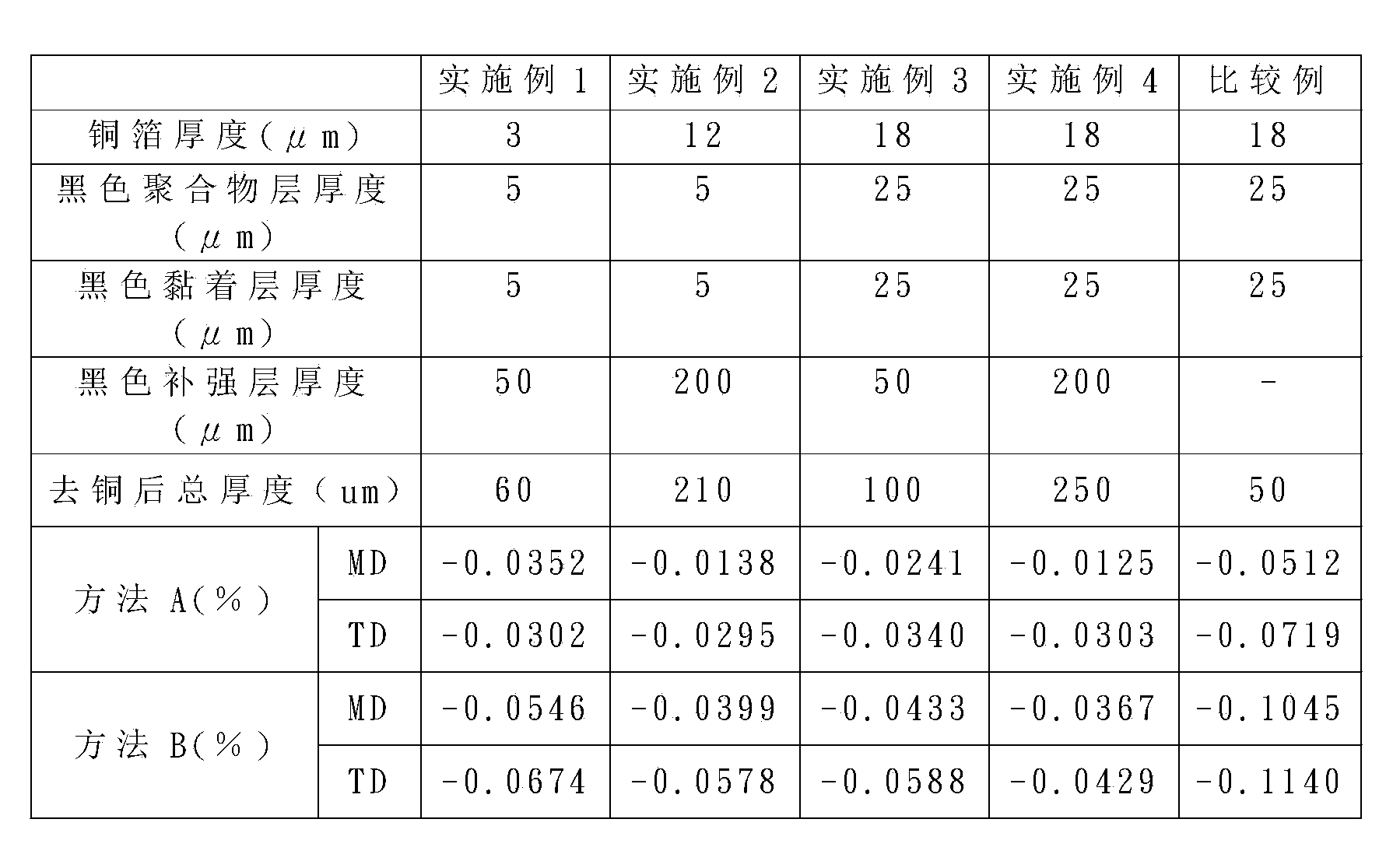

[0050] The same method as in Example 2 above was used to produce composite structural copper foil substrate products, the difference being that the thickness of the copper foil used was different and the thickness of the black polymer layer, the thickness of the black adhesive layer and the thickness of the black reinforcing layer were adjusted as shown in Table 1. Show.

[0051] The rebound force test of the composite structure copper foil substrate of the present invention is as follows:

[0052] The composite structure copper foil substrate of the present invention is used as an experimental group, and the copper foil layer of the composite structure copper foil substrate of the present invention is etched and removed for testing;

[0053] The simple reinforcing material was used as the control group;

[0054] Test conditions for rebound force test: Cut the test piece into 10mm×30mm test pieces, set the test R angle to 2.35 mm, measure each group of test pieces 5 times, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com