Preparation method for polyamide acid resin and preparation method for double-sided flexible copper-clad plate

A polyamic acid resin, flexible copper clad laminate technology, applied in chemical instruments and methods, lamination, electronic equipment, etc., can solve the problems of high machine cost, decreased tear strength, copper foil peeling, etc., and achieve good dimensional stability , The effect of small change in tear strength and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

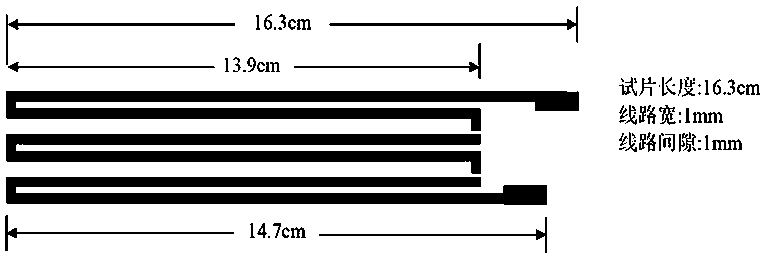

Image

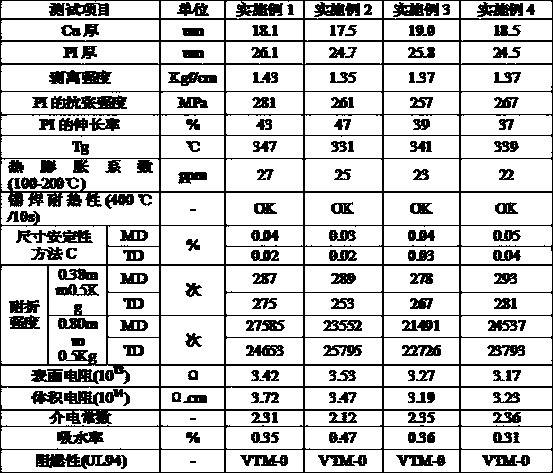

Examples

Embodiment 1

[0034] A kind of preparation method of polyamic acid resin, described polyamic acid resin is prepared as follows:

[0035] (1) In a three-neck vessel with nitrogen, add 1095 grams of N-methylpyrrolidone, then add 43.5 grams (equivalent to 0.40 moles) of p-phenylenediamine and 29.0 grams (equivalent to 0.10 moles) of 1,3-bis( 4-aminophenoxy)benzene, stirred and dissolved at 50°C until completely dissolved to obtain an aromatic diamine solution with a mass concentration of 6.6%;

[0036] (2) After cooling the aromatic diamine solution in step 1 to 10°C, add 119.2 grams (equivalent to 0.405 moles) of 3,3',4,4'-biphenyltetracarboxylic dianhydride at 100 rpm After stirring at a rotational speed for 2 hours, 31.0 g (equivalent to 0.10 moles) of 4,4-oxodiphthalic anhydride was added, and the stirring was continued at a rotational speed of 100 rpm for 8 hours to obtain a polyamic acid resin;

[0037] (3) The polyamic acid resin prepared in step 2 was left to defoam, and the measured ...

Embodiment 2

[0046] A kind of preparation method of polyamic acid resin, described polyamic acid resin is prepared as follows:

[0047] (1) Add 1530 grams of dimethylacetamide to a three-neck vessel with nitrogen gas, then add 60.5 grams (equivalent to 0.03 moles) of 4,4'-diaminodiphenyl ether and 86.5 grams (equivalent to 0.20 moles) 4,4'-bis(4-aminophenoxy)diphenyl sulfone, stirred and dissolved at 40°C until completely dissolved to obtain an aromatic diamine solution with a mass concentration of 9.0%;

[0048] (2) After cooling the aromatic diamine solution in step 1 to 0°C, add 43.5 grams (equivalent to 0.20 moles) of pyromellitic anhydride, stir at 150 rpm for 2 hours, then add 107.5 grams (equivalent to 0.30 mol) of diphenylsulfone-3,3`,4,4`-tetracarboxylic dianhydride, and continued stirring at a speed of 150 rpm for 7 hours to obtain a polyamic acid resin;

[0049] (3) The polyamic acid resin prepared in step 2 was left to defoam, and the measured solid content was 15.2%, and the ...

Embodiment 3

[0058] A kind of preparation method of polyamic acid resin, described polyamic acid resin is prepared as follows:

[0059] (1) Add 1080 grams of dimethylacetamide to a three-neck vessel with nitrogen gas, then add 30.5 grams (equivalent to 0.15 moles) of 4,4'-diaminodiphenyl ether and 38.0 grams (equivalent to 0.35 moles) For p-phenylenediamine, stir and dissolve at 50°C until completely dissolved to obtain an aromatic diamine solution with a mass concentration of 6.3%;

[0060] (2) After cooling the aromatic diamine solution in step 1 to 20°C, add 27.5 grams (equivalent to 0.125 moles) of pyromellitic anhydride, stir at 250 rpm for 1.5 hours, then add 99.0 grams (equivalent to Add 0.35 mol) of 3,3',4,4'-biphenyltetracarboxylic dianhydride, and continue stirring at a speed of 250 rpm for 6 hours to obtain a polyamic acid resin;

[0061] (3) The polyamic acid resin prepared in step 2 was left to defoam, and the measured solid content was 15.8%, and the viscosity was 15300CPS. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com