Patents

Literature

480 results about "Diphenyl sulfone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

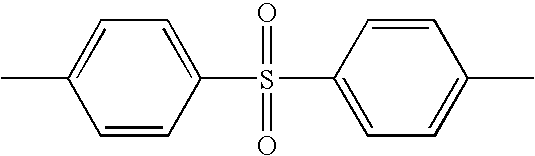

Diphenyl sulfone is an organosulfur compound with the formula (C₆H₅)₂SO₂. It is a white solid that is soluble in organic solvents. It is used as a high temperature solvent. Such high temperature solvents are useful for processing highly rigid polymers, e.g., PEEK, which only dissolve in very hot solvents.

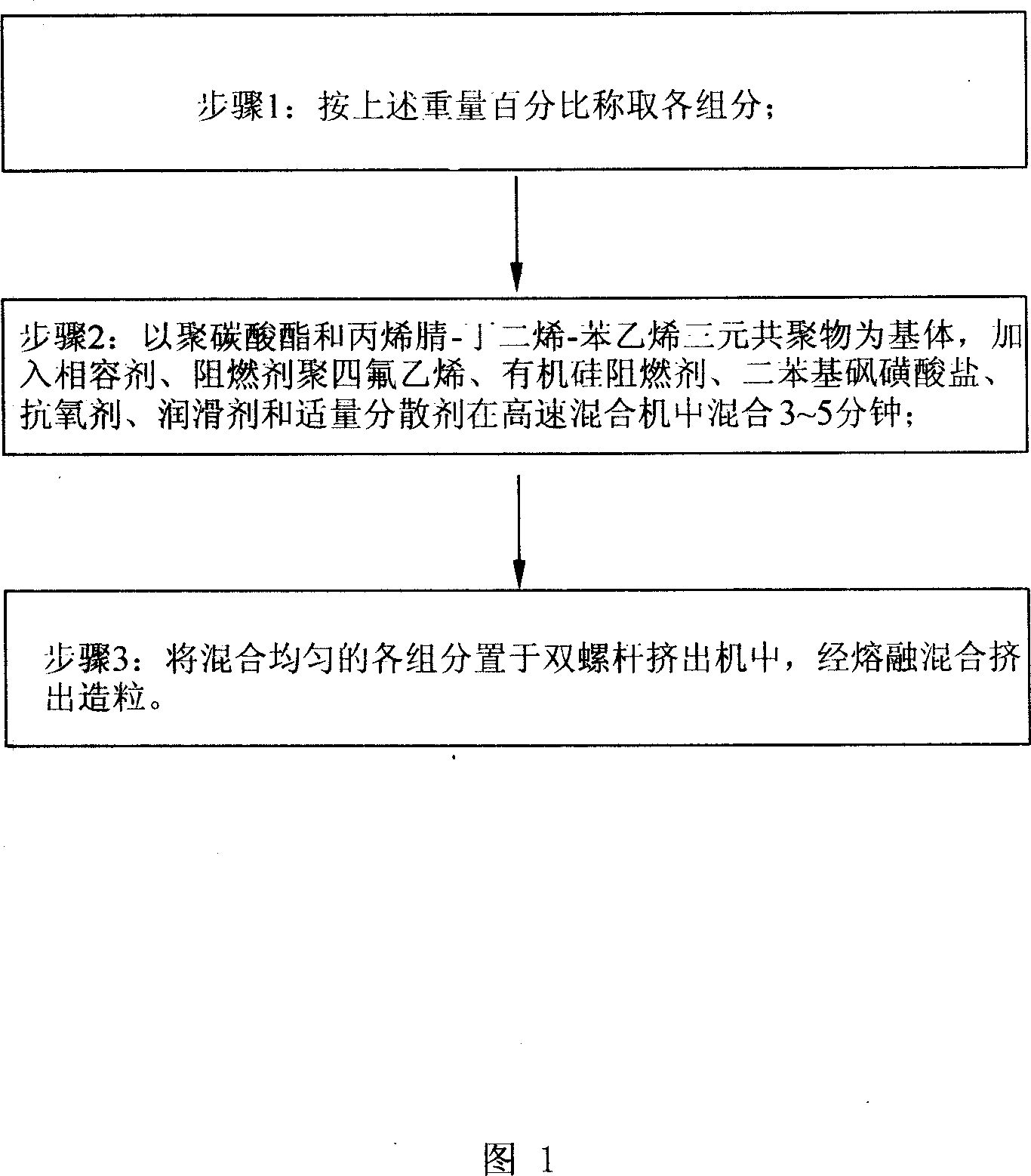

Fire retardant PC/ABS alloy material without halide and phosphate and its prepn process

The fire retardant PC / ABS alloy material without halide and phosphate consists of polycarbonate 65.5-91.2 wt%, acrylonitrile-butadiene-styrene ternary copolymer 6-17 wt%, compatilizer 1.0-4.0 wt%, fire retardant PTFE 0.3-1.5 wt%, organosilicon fire retardant 1.0-8.0 wt%, diphenyl sulfone sulfonate 0.1-1.0 wt%, antioxidant 0.1-1.0 wt% and lubricant 0.2-2.0 wt%. The present invention also provides the preparation process of the alloy material. The alloy material is environment friendly, and may be applied widely in automobile industry, electronic industry, electric industry and mechanical industry.

Owner:SHENZHEN KEJU NEW MATERIAL

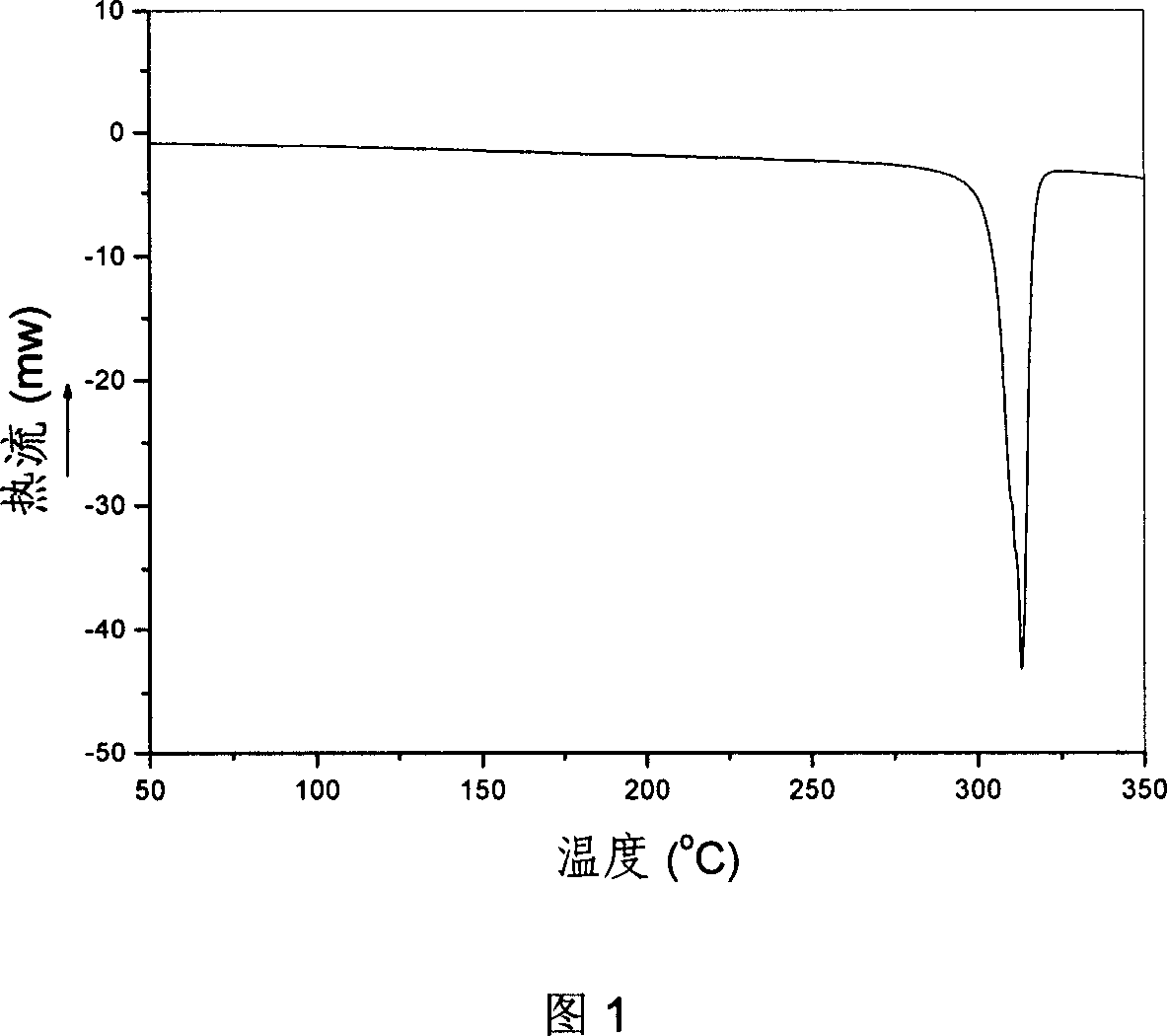

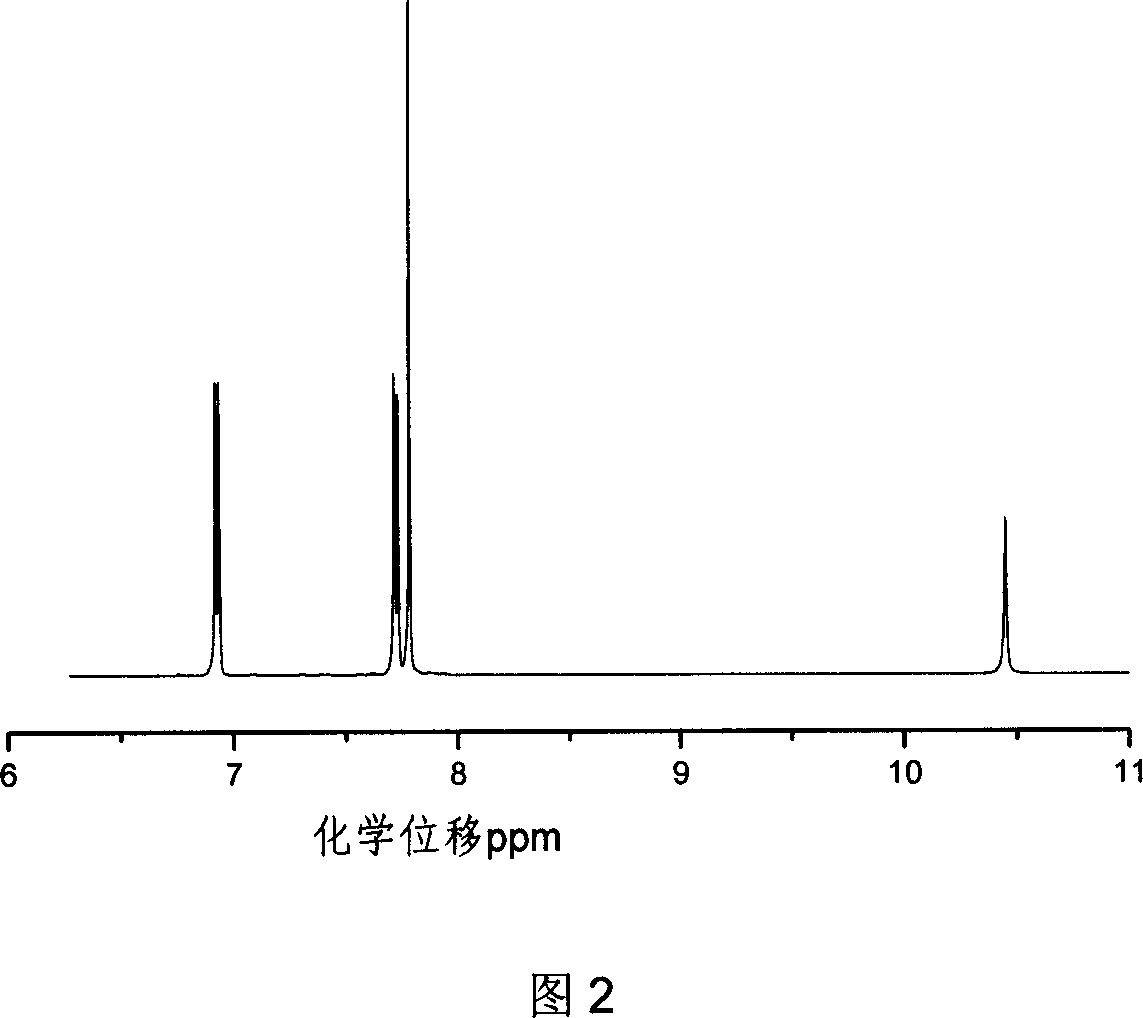

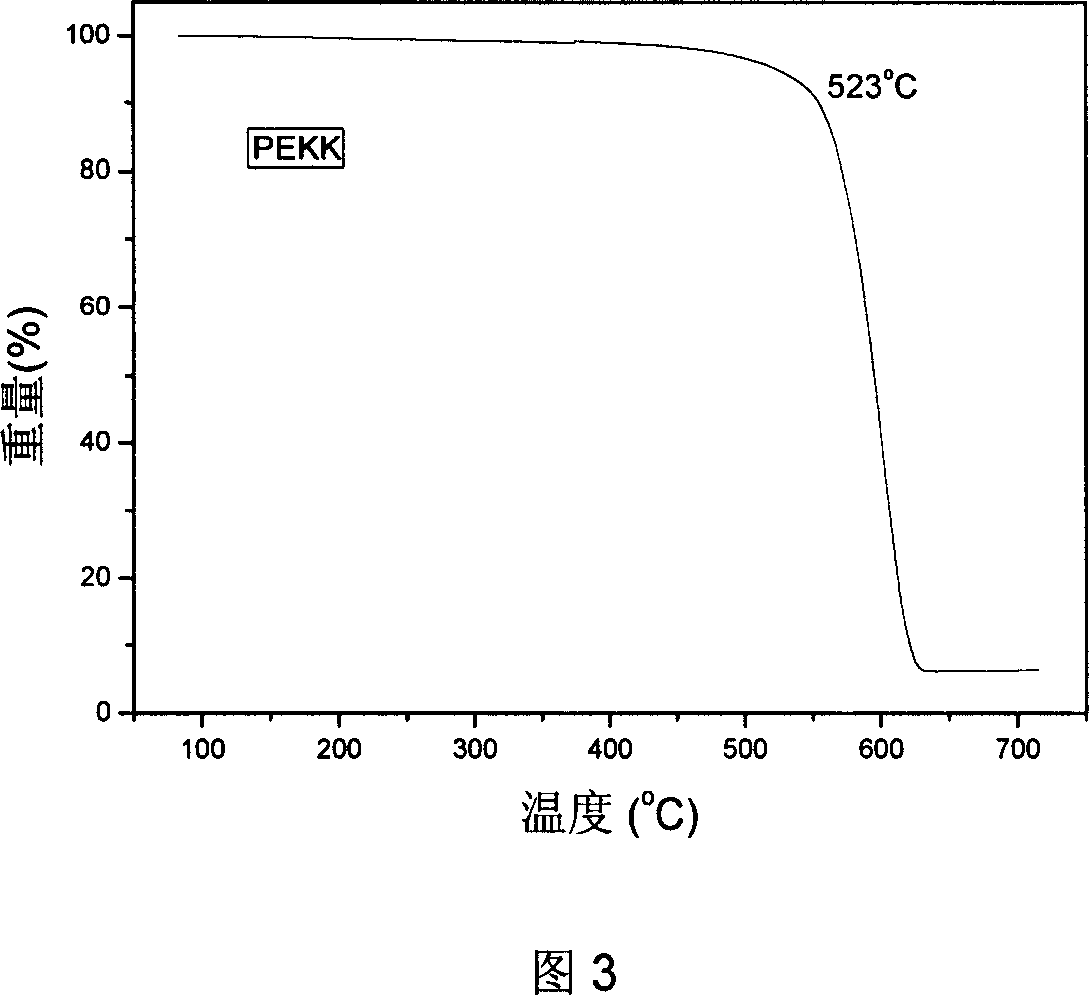

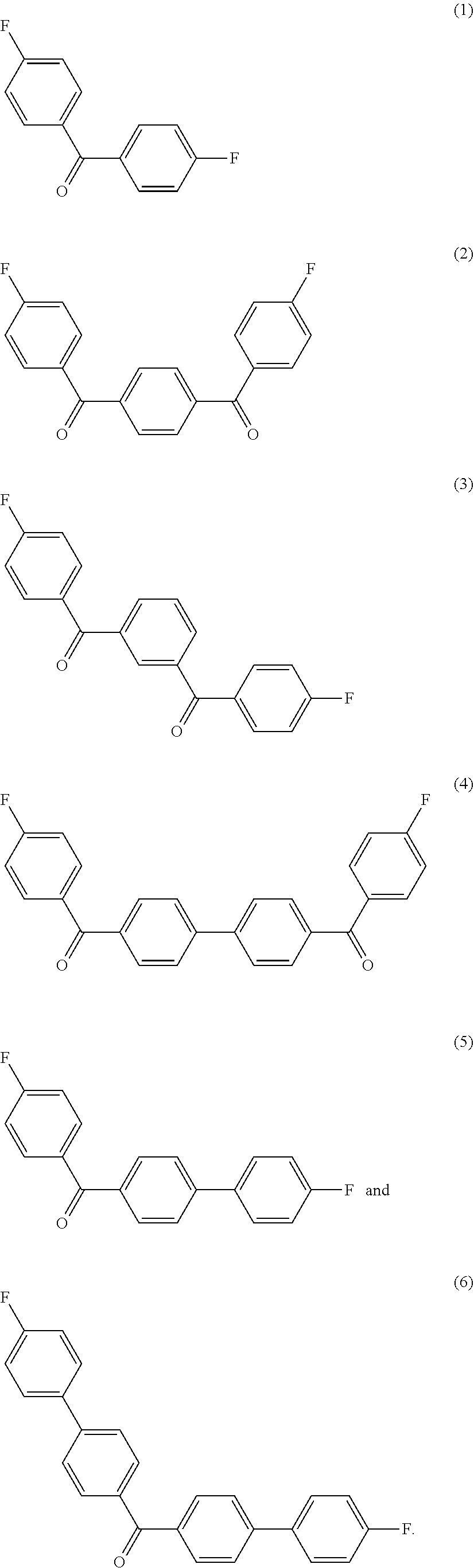

Prepn process of poly (ether-ketone-ketone) as high performance polymer

The present invention belongs to the field of polymer material, and is especially the preparation process of poly(ether-ketone-ketone) prepared through polymerizing bisphenol and bifluoric monomer. The preparation process includes adding bis-(4-hydroxybenzoyl)-benzene, bis-1, 4-(4-fluorobenzoyl)-benzene or bis-1, 3-(4- fluorobenzoyl)-benzene, Na2CO3 as salt-forming agent and diphenyl sulfone as solid solvent into flask with mechanical stirrer, thermometer and nitrogen duct; introducing high purity nitrogen, heating to 100-130 deg.c and stirring to melting solid matter completely; heating slowly to react; pouring the reaction product into water to separating out white solid; crushing, washing with acetone and water for several times, drying at 80-150 deg.c for 10-20 hr to obtain polymer in the yield over 90 %.

Owner:JILIN UNIV

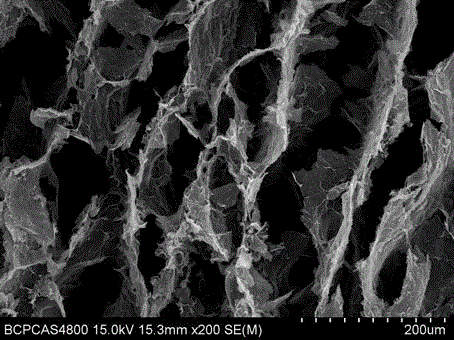

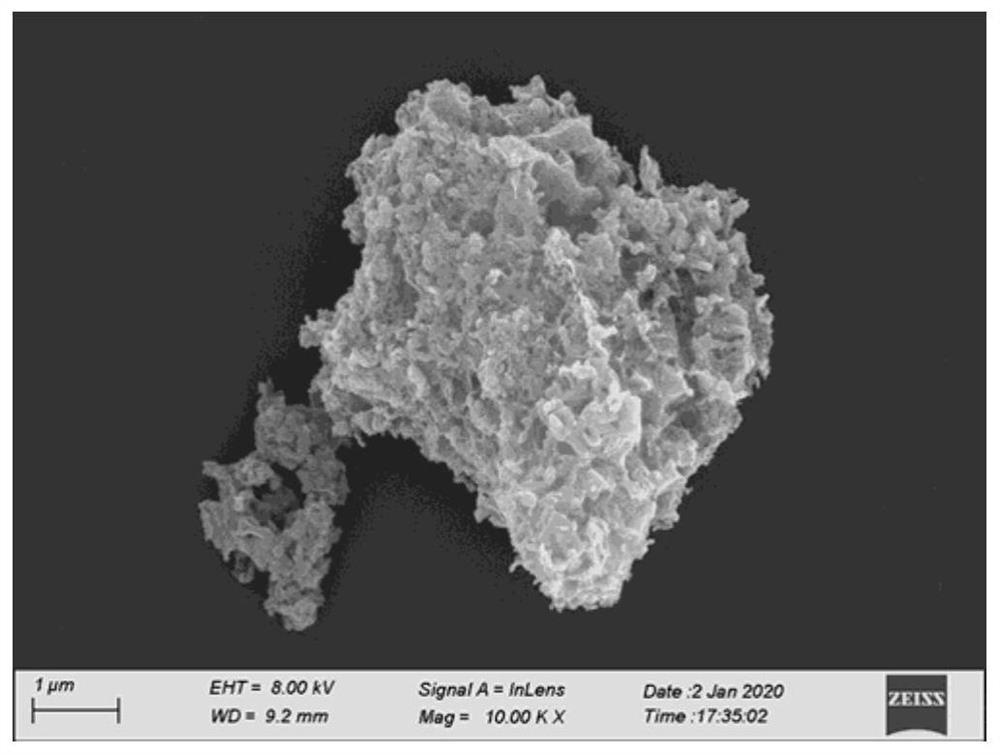

Method for preparing graphene aerogel and application thereof

The invention discloses a method for preparing graphene aerogel and application thereof, and relates to the technical field of graphene materials. The method includes steps of uniformly mixing graphene oxide dispersion liquid and amine curing agents with one another to obtain graphene oxide mixed liquid; hermetically heating the obtained graphene oxide mixed liquid to obtain the graphene aerogel. The amine curing agents are one type of or a plurality of types of diaminodiphenyl-methane, diamino diphenyl sulfone, diethylenetriamine, triethylenetetramine, diethylaminopropylamine and m-phenylenediamine. The graphene aerogel prepared by the aid of the method can be applied to epoxy resin, so that graphene aerogel / epoxy resin composite materials with high conductivity and excellent mechanical properties can be obtained. The method and the application have the advantages that the graphene aerogel prepared by the aid of the method is internally of a uniform macroporous structure and is high in porosity; the amine curing agents are adopted in preparation procedures, accordingly, the epoxy resin interface bonding can be improved, and the conductivity and the mechanical properties of the epoxy resin can be enhanced.

Owner:BEIJING UNIV OF CHEM TECH

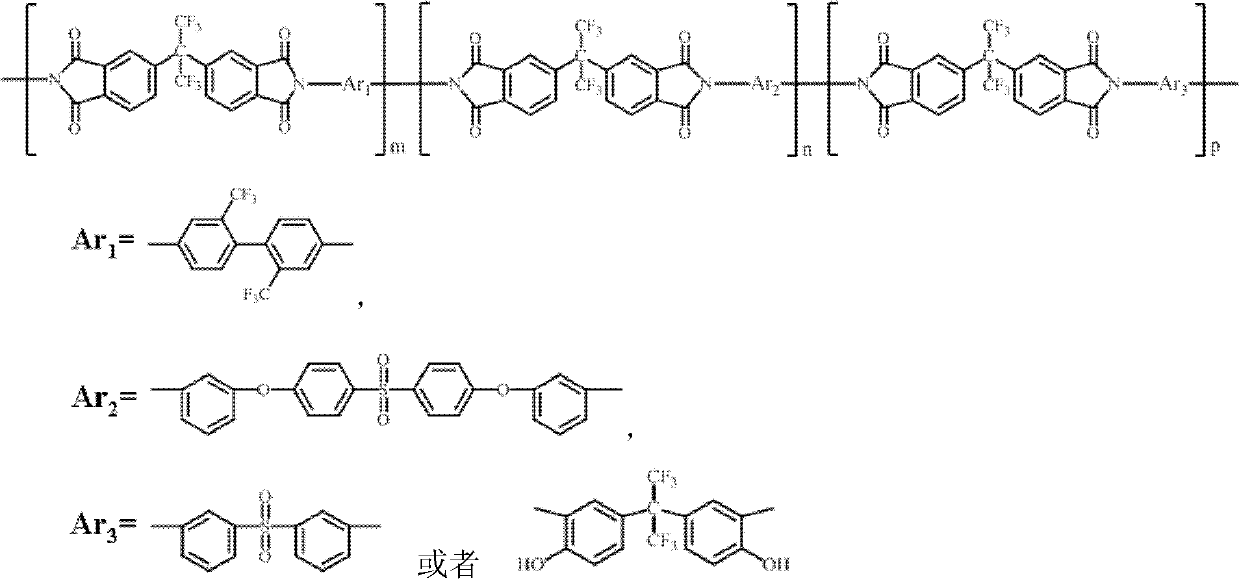

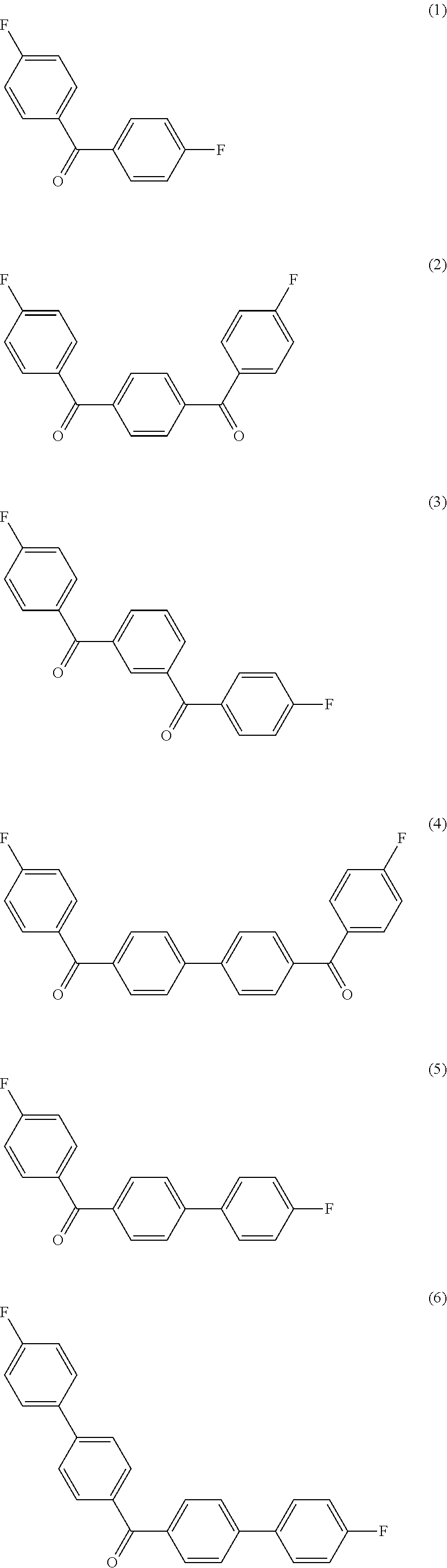

Method for preparing graphene polyphosphazene nano composite material

The invention belongs to the technical field of a nano graphene functional material and relates to a method for preparing a graphene polyphosphazene nano composite material. The method comprises the following steps of: performing a reaction of natural graphite and strong acid and a strong oxidizing substance to generate graphite oxide; carrying out ultrasonic dispersion on the graphite oxide to prepare graphene oxide; adding a reducing agent (hydrazine hydrate) to carry out reduction so as to obtain graphene; ultrasonically dispersing the graphene into a specific solvent; sequentially adding phosphonitrilic chloride trimerl, 4,4'-dihydroxy diphenyl sulfone and triethylamine; and performing an ultrasonic reaction for a certain time and carrying out simple post treatment to obtain the graphene polyphosphazene nano composite material. The method has a simple technological process, low cost and high yield. In the prepared composite material, graphene is uniformly coated by polyphosphazene. The composite material has good nano functionality, stable structure performance and wide application prospect.

Owner:JIANGSU UNIV

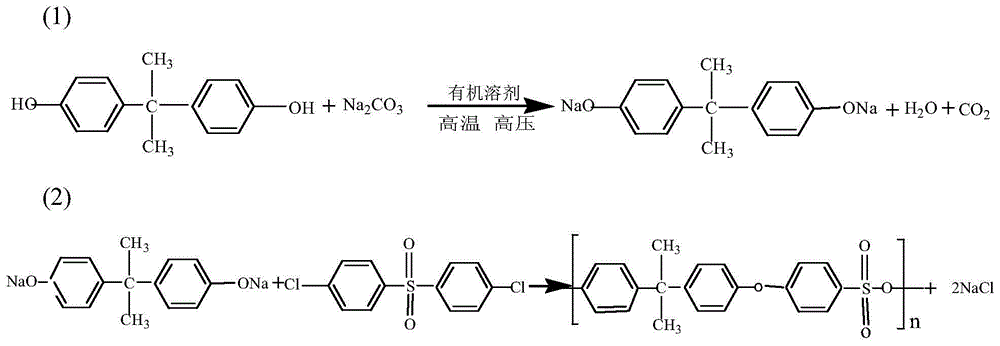

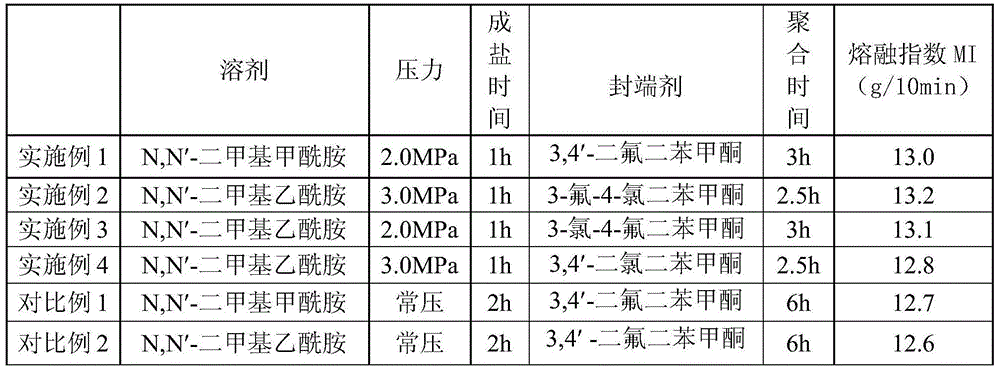

Industrial synthetic method of low-color high-transmittance polysulfone resin

The invention discloses an industrial synthetic method of low-color high-transmittance polysulfone resin. The method comprises the following steps: by taking 4,4-dichloro-diphenyl sulfone and bisphenol A as reaction monomers, a low-boiling-point organic substance as a solvent, sodium carbonate as a salt forming agent and 3,4'-dichloro-benzophenone as an end capping agent, raising the pressure in a kettle to 2.0-3.0MPa under the protection of an inert gas, and performing polymerization reaction at 200-210 DEG C to obtain a polymerized mucus; and cooling the polymerized mucus, then crushing the polymerized mucus, filtering, then washing to remove the solvent and byproduct salts, and drying. By adopting the synthetic process disclosed by the invention, the problem that the low-boiling-point solvent cannot meet requirements for polymerization during polymerization under a normal pressure condition is solved, the polymerization time is shortened, water-carrying agents including benzene, methylbenzene and dimethylbenzene and the like, which are required to be added during polymerization at normal pressure are avoided, the production cost is reduced, the process steps of recovering and separating these substances in an after treatment process are avoided, and the polysulfone resin prepared by the process disclosed by the invention has very low color and high transmittance, so that the application area of the product is enlarged.

Owner:JIANGMEN YOUJU NEW MATERIALS

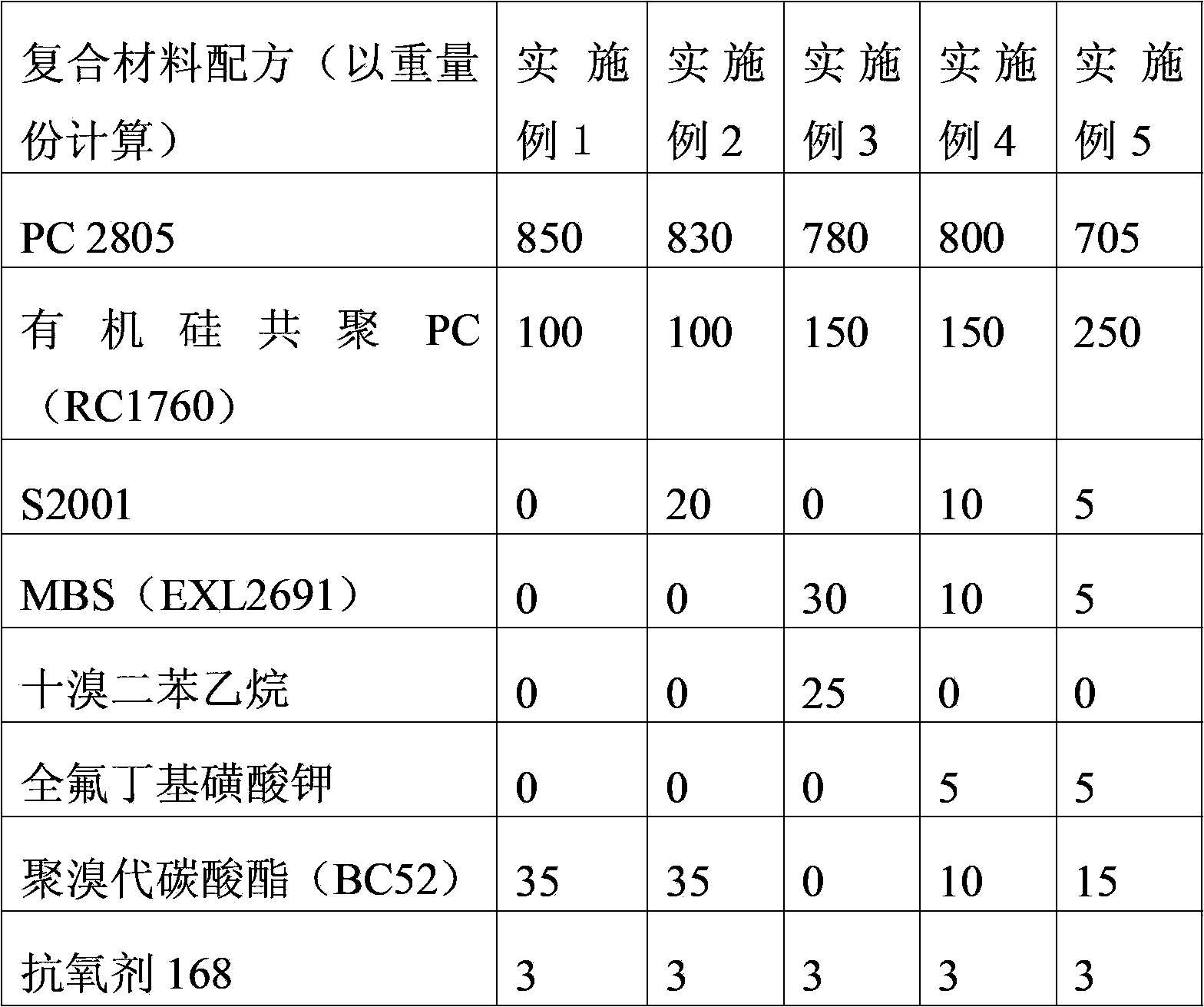

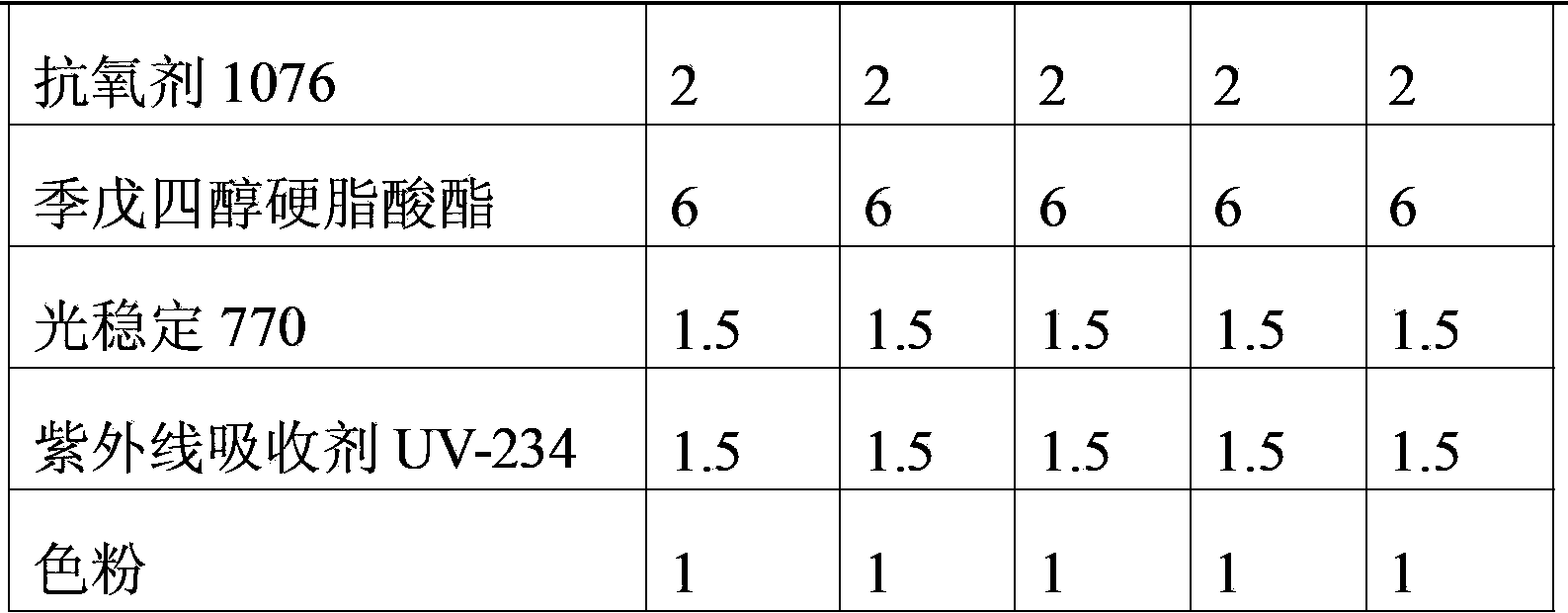

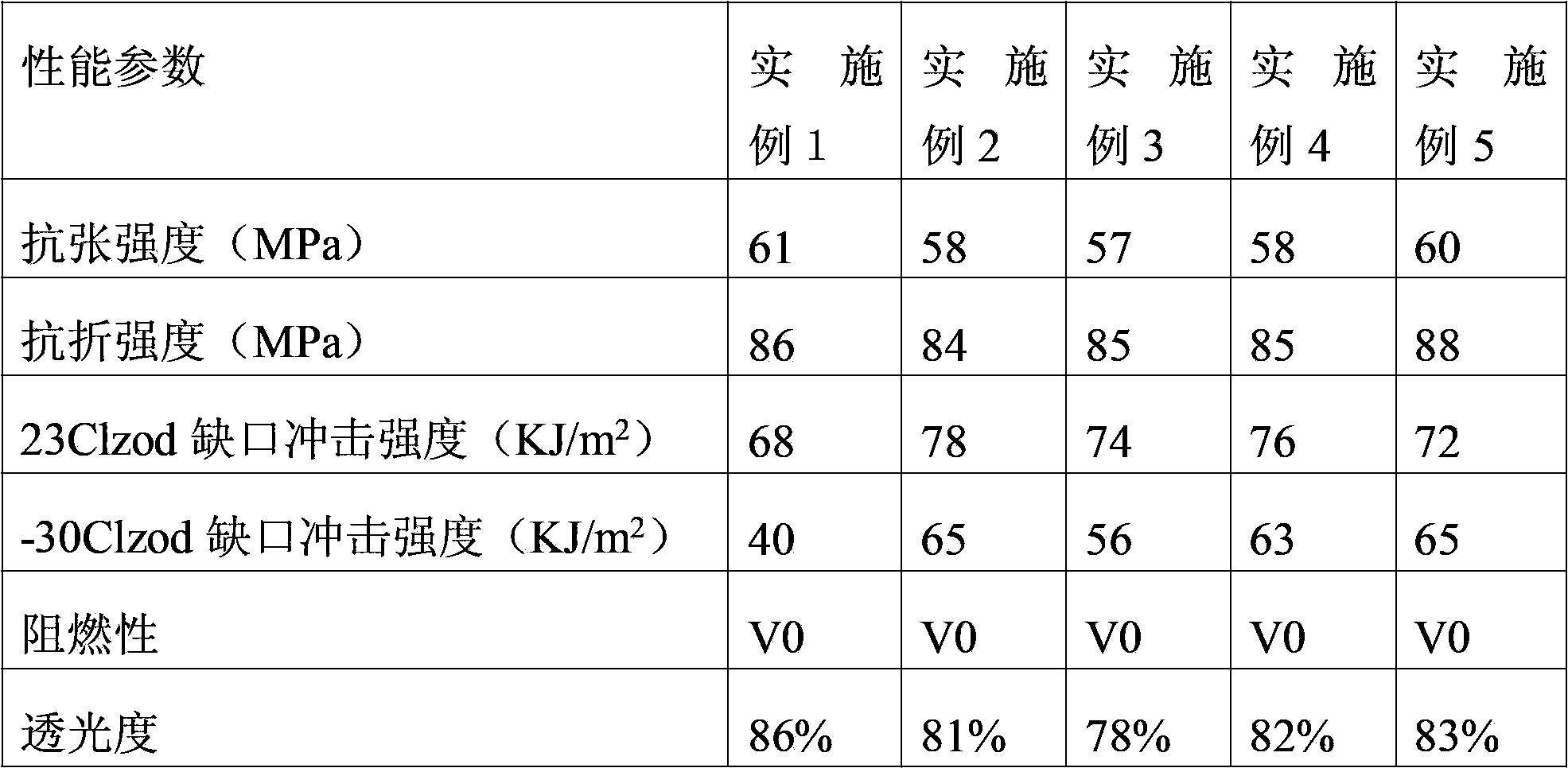

High-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and preparation method thereof

ActiveCN103788610AImprove low temperature impact resistanceEnhance and improve low temperature impact resistanceMold fillingPotassium

The invention discloses a high-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and a preparation method thereof. The composite material comprises following components by weight: 700-850 parts of polycarbonate resin, 100-250 parts of organosilicone co-polymer PC, 0-30 parts of a low-temperature-impact modifying agent and 10-14 parts of a flame retardant. The low-temperature-impact modifying agent is one of an organosilicone type flexibilizer and an acrylate type flexibilizer or a mixture of the organosilicone type flexibilizer and the acrylate type flexibilizer. The flame retardant is one of or a mixture of several compounds selected from decabromodiphenylethane, poly(bromocarbonate), potassium perfluorobutane sulfonate or diphenylsulfonesulfonate. The organosilicone co-polymer PC is polycarbonate resin obtained by copolymerization of bisphenol A and organosilicone and has a relative molecular weight of 20000-30000. The preparation method of the composite material is also provided. According to the composite material and the preparation method, the low-temperature-impact-resistant performance of the PC resin is largely enhanced, and the composite material has excellent flame retardance and can preserve the high transparency of the material itself. In addition, the material has advantages of easy mold filling, low processing temperature, short processing and forming period, and the like.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

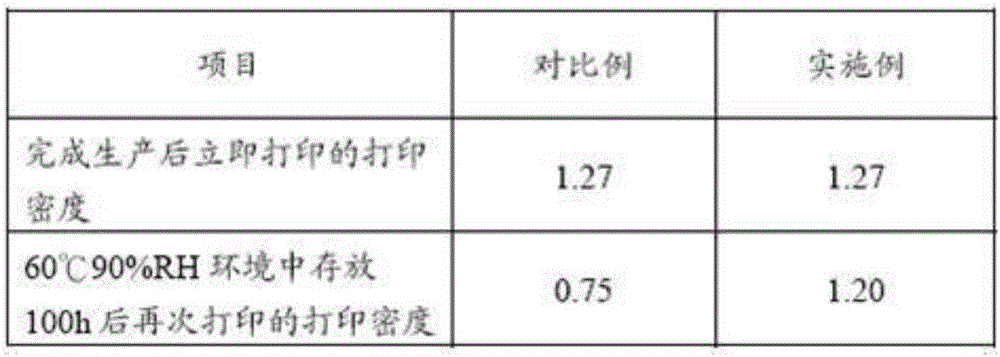

Anti-counterfeiting heat-sensitive paper and method for producing same

InactiveCN106192561APrevent infiltrationBreaking bondCoatings with pigmentsCoatingsPolyvinyl alcoholAcrylic resin

The invention discloses anti-counterfeiting heat-sensitive paper which comprises body paper layers, pre-coated layers, surface coated layers and protective layers. The pre-coated layers are coated on the body paper layers, and the surface coated layers and the protective layers are formed on the surfaces of the pre-coated layers; the pre-coated layers contain fillers, adhesive and color developing agents, a mass ratio of the fillers to the adhesive to the color developing agents is 100:5-35:1-15, and the fillers are at least one type of light calcium carbonate, silicon dioxide, calcined kaolin, flake argil and hollow plastic pigment; the adhesive is at least one type of styrene-butadiene latex, styrene acrylic resin, starch, polyvinyl alcohol and acrylic resin; the color developing agents are at least one type of bisphenol A and 4, 4'-dihydroxy diphenyl sulfone.

Owner:GUANGDONG SONGYANG RECYCLE RESOURCES

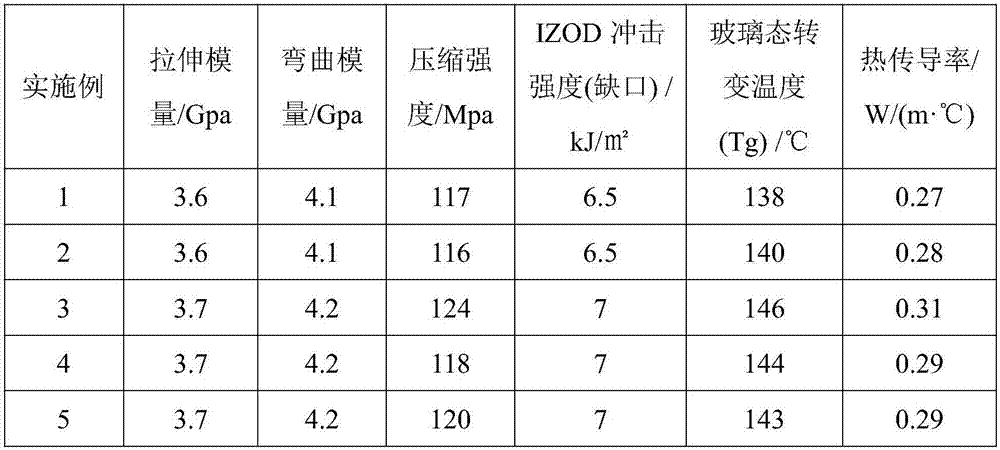

Epoxy resin silica sol, epoxy resin organic-inorganic nano hybrid material and preparation method thereof

The invention discloses epoxy resin silica sol which is characterized by being prepared from the following components: epoxy resin, organic silicon, silane coupling agent, organic solvent and ammonia water at a molar ratio of 1:(0.1-2):(0.01-2):(0.9-18):(0.001-0.06). The invention also discloses a preparation method of the epoxy resin silica sol. The invention also discloses an epoxy resin organic-inorganic nano hybrid material adopting the epoxy resin silica sol, which is characterized in that the epoxy resin curing agent is one or more of methylhexahydrophthalic anhydride, methylhexahydrophthalic anhydride acid, 4,4-diaminodiphenylmethane and 4,4-diamino diphenyl sulfone. The invention also discloses a preparation method of the epoxy resin organic-inorganic nano hybrid material. The product provided by the invention has excellent insulating property, and the method is stable and efficient.

Owner:上海上惠纳米科技有限公司

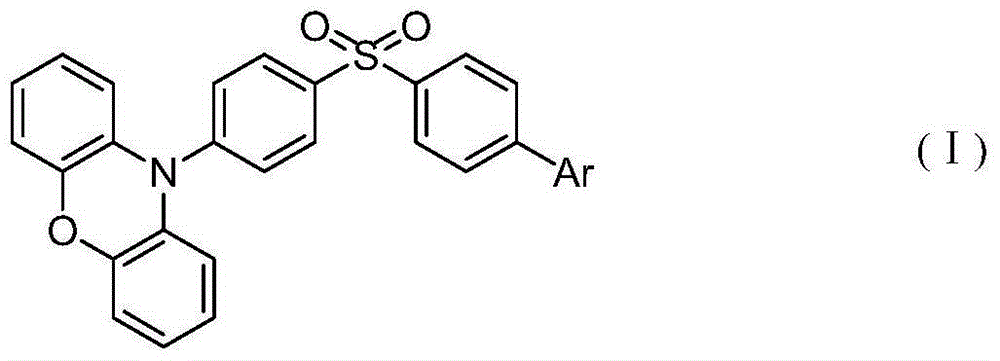

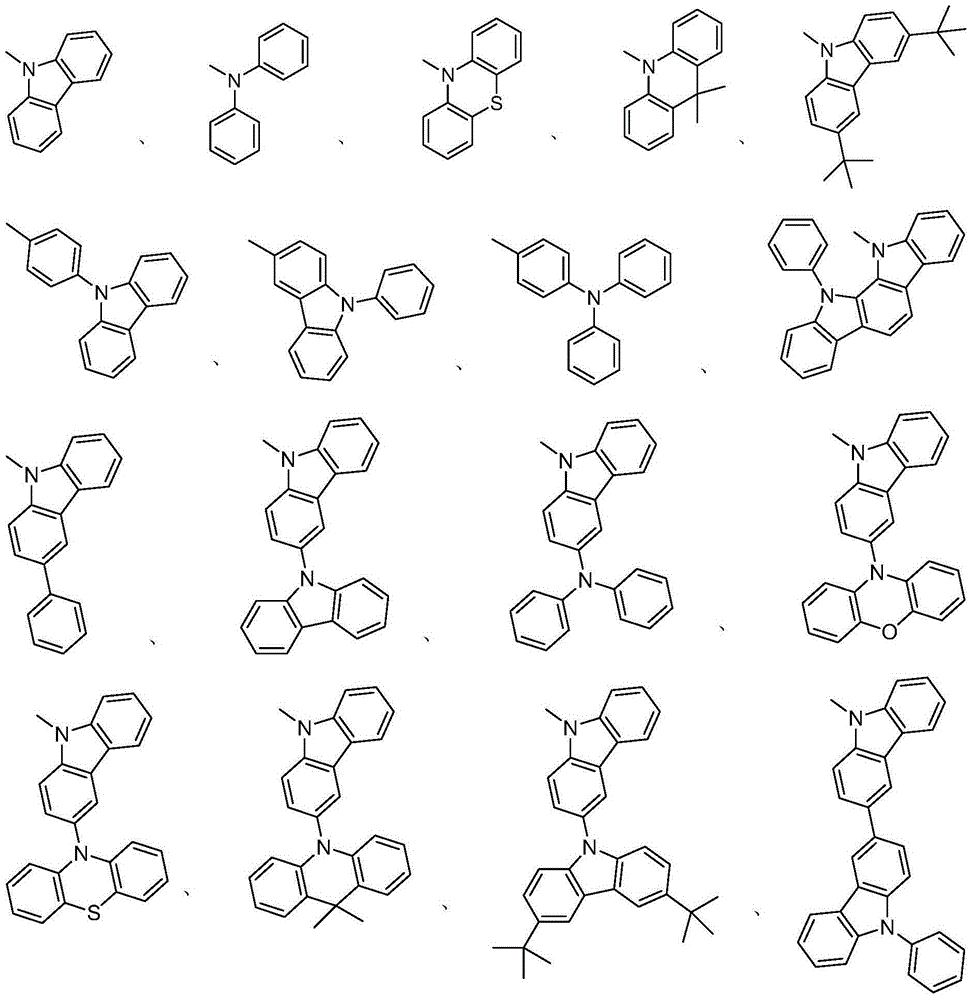

Asymmetrical thermal-activation-delayed aggregation-induced emission material based on diphenyl sulfone phenoxazine, as well as synthesis method and application of material

ActiveCN105038764AHas aggregation-induced luminescent propertiesHigh thermal decomposition temperatureOrganic chemistrySolid-state devicesSynthesis methodsNon doped

The invention discloses an asymmetrical thermal-activation-delayed aggregation-induced emission material based on a diphenyl sulfone phenoxazine, as well as a synthesis method and application of the material. A core structure of the material comprises a diphenyl sulfone unit and a phenoxazine group, and further comprises an electronic structure unit made from aryl heterocyclic groups except a phenoxazine substituent. The synthesis method and the purification process of the material are simple, the thermal performance, luminous performance and the like of an end product can be adjusted according to the connection of different groups, the obtained emission material has thermal-activation-delayed fluorescent and aggregation-induced emission performance at the same time, is good in heat stability, higher in glass transition temperature and excellent in luminous performance. A non-doped OLED device manufactured by using the emission material as the luminous layer is high in luminous brightness and good in stability, so that the luminous efficiency and the service life of the OLED device can meet the practical requirements.

Owner:SUN YAT SEN UNIV

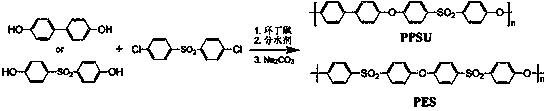

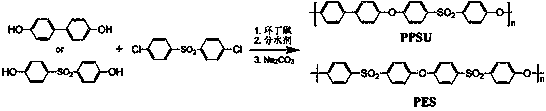

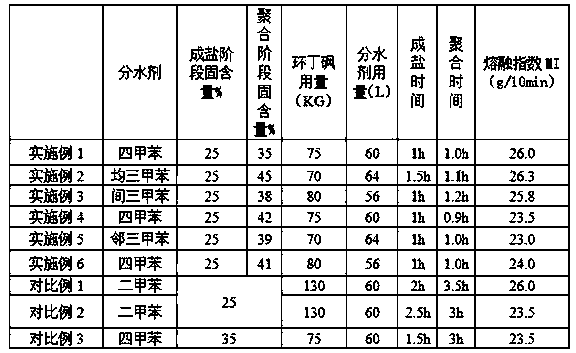

Industrial synthesis method of polyarylether sulfone resin

The invention discloses an industrial synthesis method of polyarylether sulfone resin, which comprises the following steps: with 4,4'-dichlorodiphenyl sulfone and 4,4'-biphenol or 4,4'-dihydroxy diphenyl sulfone as reaction monomers, sulfolane as a solvent and sodium carbonate as a salt forming agent, adding the solvent into a reaction kettle filled with nitrogen protection, stirring and heating to 60-80 DEG C, and sequentially adding the reaction monomers, wherein the solid content of the system is 20-45%; after all monomers are dissolved, adding the salt forming agent into the system, then adding a dehydrating agent, stirring and heating to 200-210 DEG C, and performing a salt forming reaction for 1-2 hours; after the salt forming reaction is over, heating to 220-240 DEG C, and performing a constant-temperature polymerization reaction for 1-2.5 hours to obtain polymer mucus; cooling the polymer mucus with water, and grinding into powder; filtering, boiling with deionized water, washing to remove the solvent and the byproduct salt, and drying to obtain the polyarylether sulfone resin. The method disclosed by the invention can greatly shorten the reaction time, increase the productivity, reduce the consumption of raw materials, save the cost and reduce the energy consumption.

Owner:JIANGMEN YOUJU NEW MATERIALS

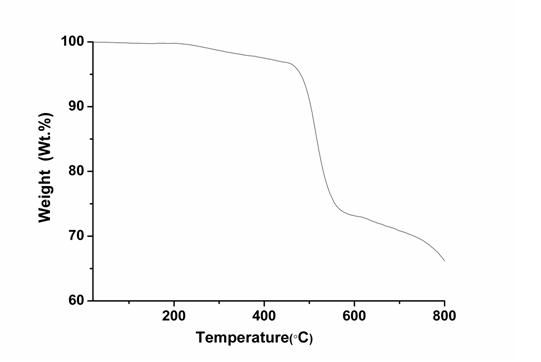

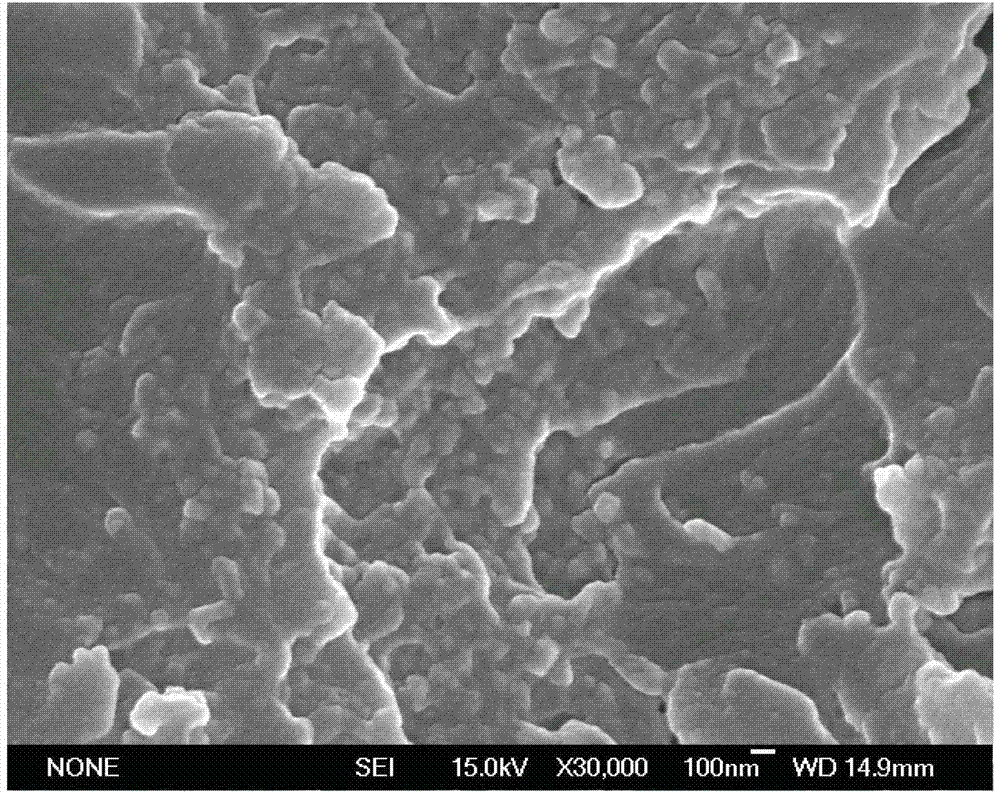

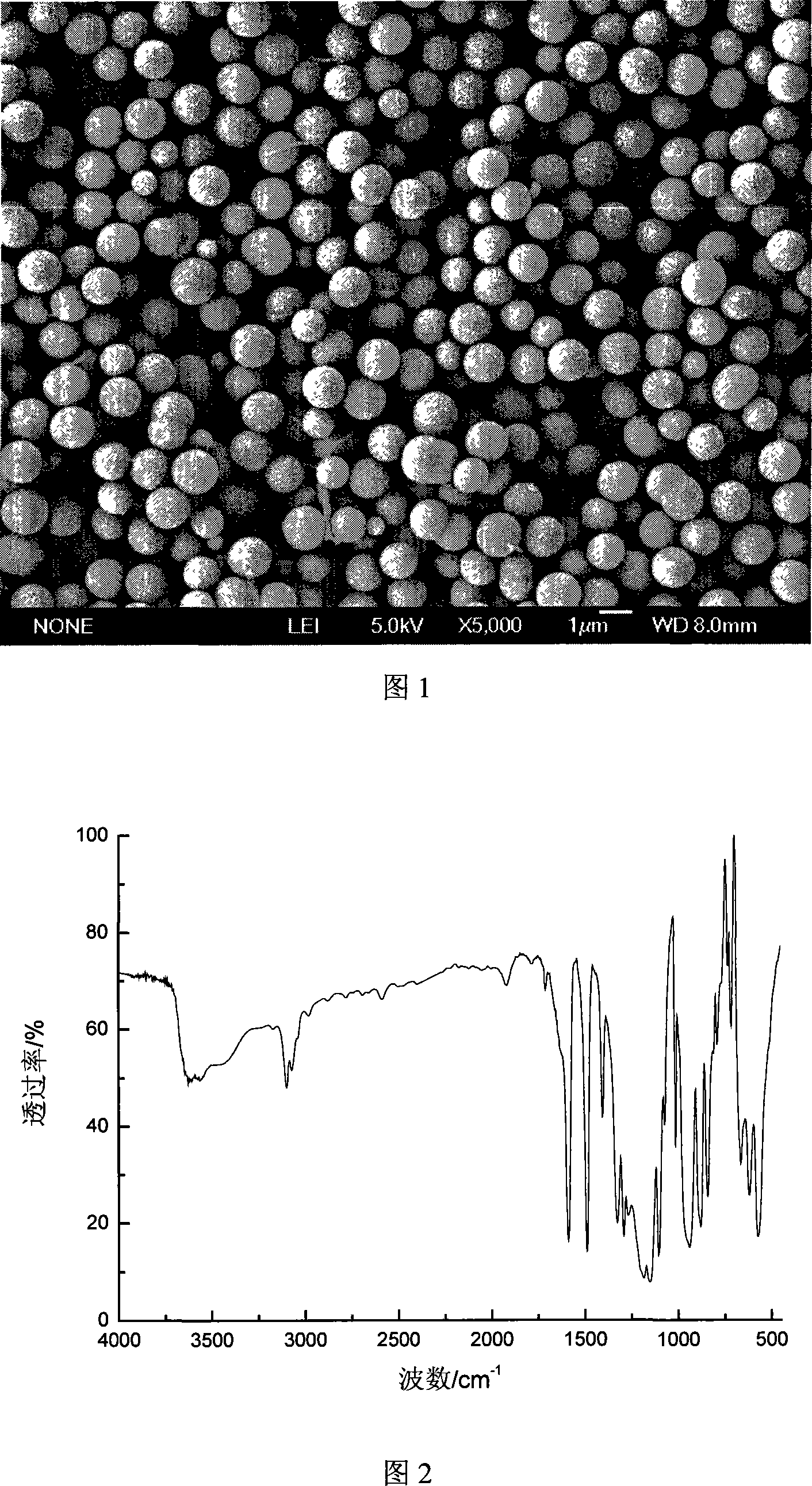

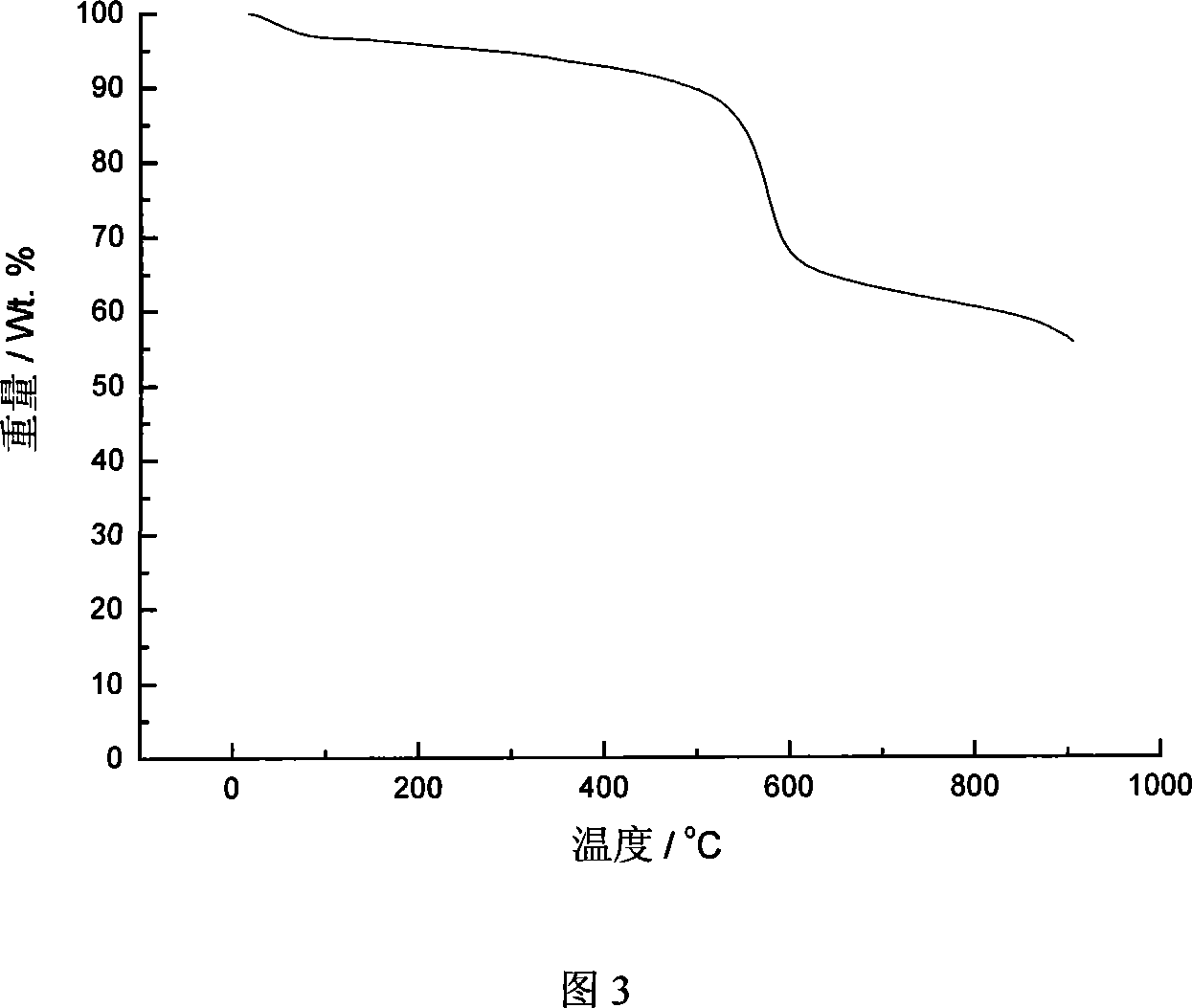

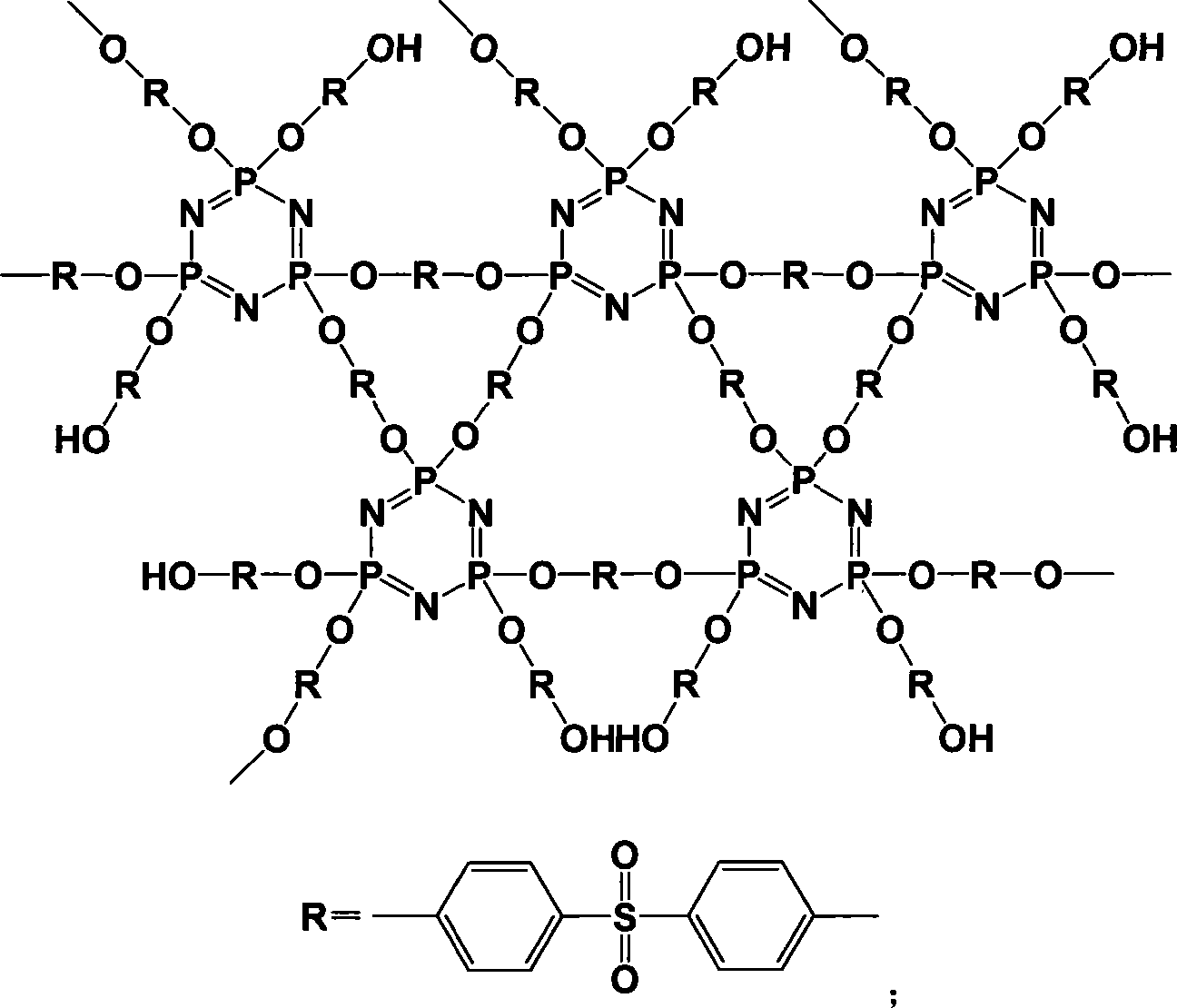

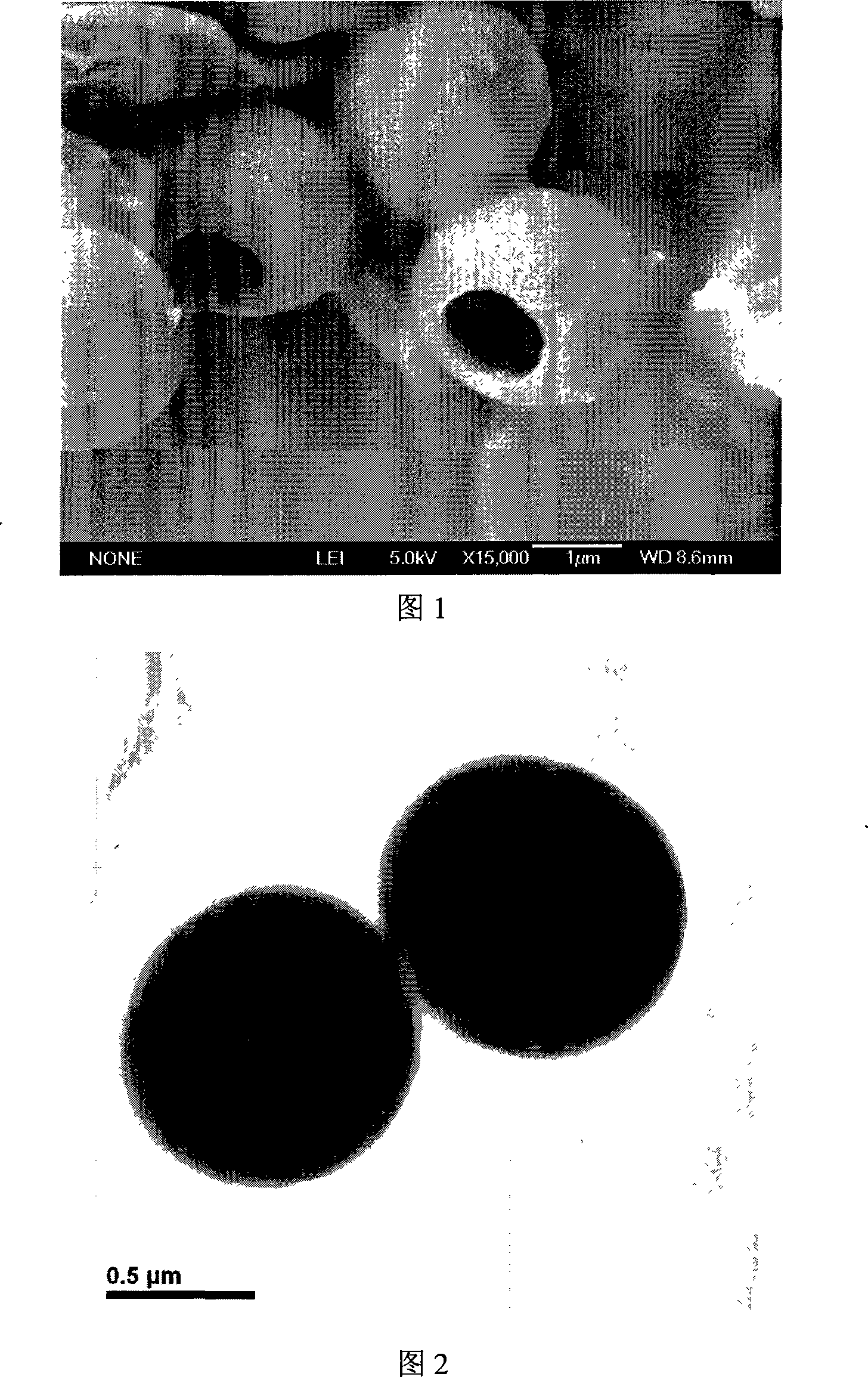

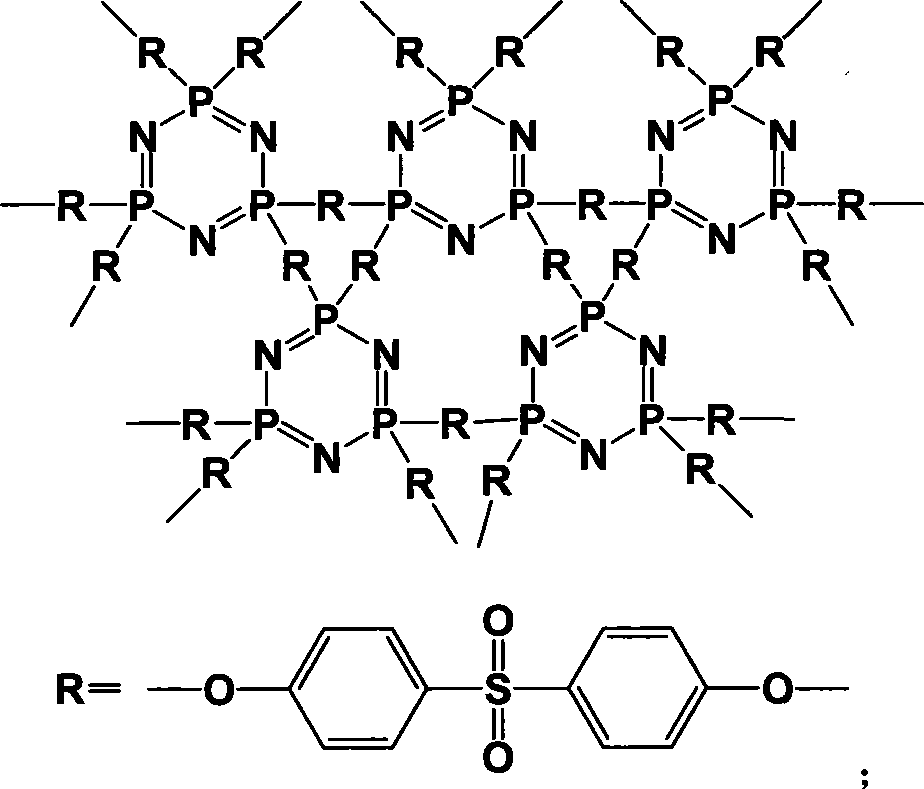

Surface modified microballons of containing phosphazene, and preparation method

InactiveCN101092484APromote degradationGood biocompatibilityCatalyst carriersPharmaceutical non-active ingredientsChemical structureControlled release

This invention discloses a method for preparing surface-modified microspheres containing phosphazene, whose chemical structure in shown in this invention. The diameters of the microspheres are 0.3-2.0 mu.m, and the specific surface areas are 10-30 m2 / g. The method comprises: condensing hexachlorocyclotriphosphazene and 4, 4'-dihydroxy diphenyl sulfone in the presence of an acid binding agent to obtain crosslinked microspheres. The method is simple, and suitable for mass production. The obtained microspheres can be used in controlled release of drugs, high-efficiency catalyst carriers, novel electric materials, novel optical materials, and flame retardant materials.

Owner:SHANGHAI JIAO TONG UNIV

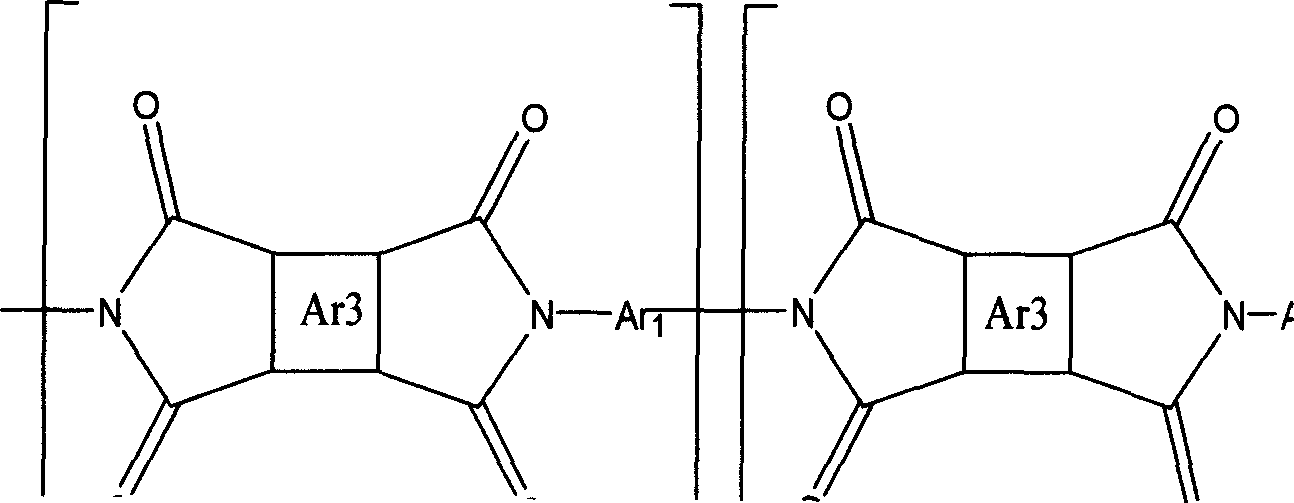

Colorless and high transparent flexible polyimide film and preparation method thereof

The invention relates to a colorless and high transparent flexible polyimide film, belonging to the technical field of polymer materials, wherein the colorless and high transparent flexible polyimide film is prepared by the following steps of dissolving 2,2'-bis(trifluoromethyl) diamino biphenyl and 4,4'-bis(3-aminophenoxy)-diphenyl sulfone in a polar solvent, adding 4,4'-(hexafluoroisopropylidene) diphthalic anhydride into the solution, stirring for 24 hours at room temperature to obtain a polyamide acid solution, spreading the solution on a plate to form a film, drying, curing and strippingthe film in water. Polyimide provided by the invention has high molecular weight and high solubility; the polyimide film provided by the invention has the advantages of high transparency, high heat resistance, low thermal expansion and low-temperature curing capability and is suitable for flexible displays, optical device protective films and substrate materials of transparent conductive films.

Owner:TSINGHUA UNIV

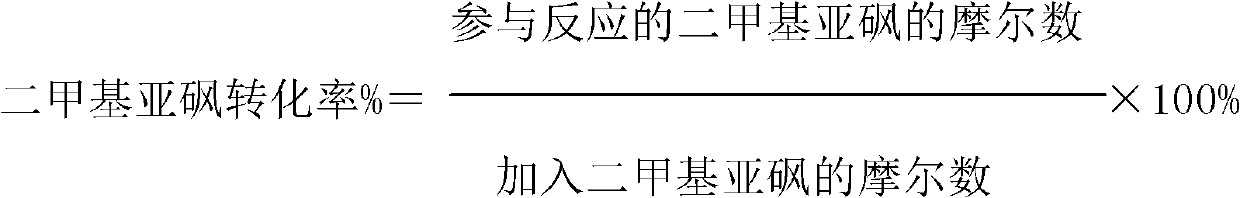

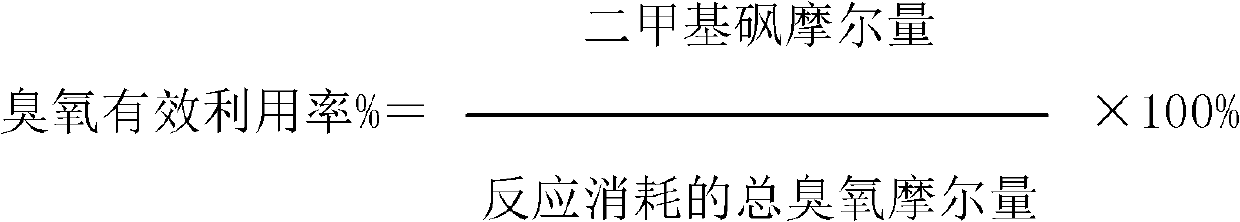

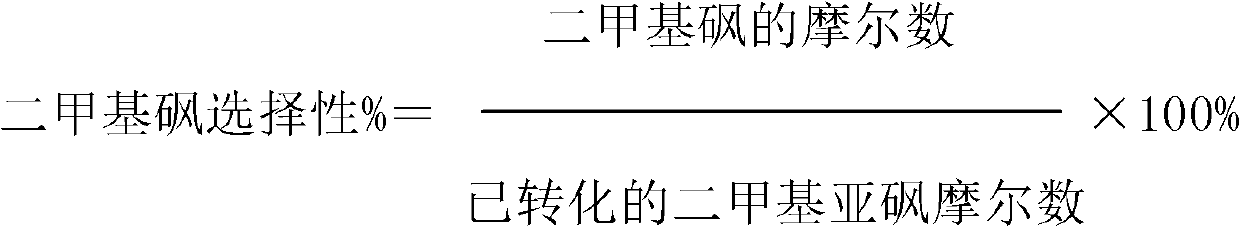

Method for preparing dimethyl sulfone from dimethyl sulfoxide

ActiveCN103288692AImprove effective utilizationOvercoming complexityOrganic chemistryOrganic compound preparationOxidizing agentReaction conditions

The invention discloses a method for preparing dimethyl sulfone from dimethyl sulfoxide. The method comprises the following step: contacting dimethyl sulfoxide and an oxidant under the oxidizing reaction conditions. The method is characterized in that the oxidant is ozone-containing gas. According to the method, the selectivity of dimethyl sulfone is high, and especially the effective utilization rate of ozone is greatly improved in the presence of a titanium-containing catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Industrial synthesis method of poly(aromatic ether sulfone) resin with high solid content

The invention discloses an industrial synthesis method of a poly(aromatic ether sulfone) resin with a high solid content. The synthesis method comprises the following steps: taking 4,4'-dichlorodiphenyl sulfone and 4,4'-biphenol or 4,4'-dihydroxyl diphenyl sulfone as the reaction monomers, sulfolane as the solvent, and sodium carbonate as the salt forming agent, adding the solvent into a reactor filled with nitrogen gas, then stirring, heating to a temperature of 60 to 80 DEG C, orderly adding the reaction monomers, fully dissolving the monomers, adding the salt forming agent into the reactor, then adding a water separating agent, keeping on stirring, heating to a temperature of 200 to 210 DEG C, carrying out salt forming reactions for 1 to 2 hours; completely evaporating the water separating agent after the salt forming reactions, then transporting the salt forming reaction products to a polymerization reactor to carry out reactions; wherein the solid content of the system in the salt forming phase is 20% to 25%, and the solid content of the system in the polymerization phase is 35% to 45%; cooling the polymerization sticky liquid after the polymerization reactions, grinding into powder, filtering, then boiling and washing with deionized water to remove the solvent and byproduct namely the salt, and finally drying so as to obtain the target product. The synthesis technology can reduce the using amount of solvent sulfolane, shortens the polymerization time, and increases the output.

Owner:JIANGMEN YOUJU NEW MATERIALS

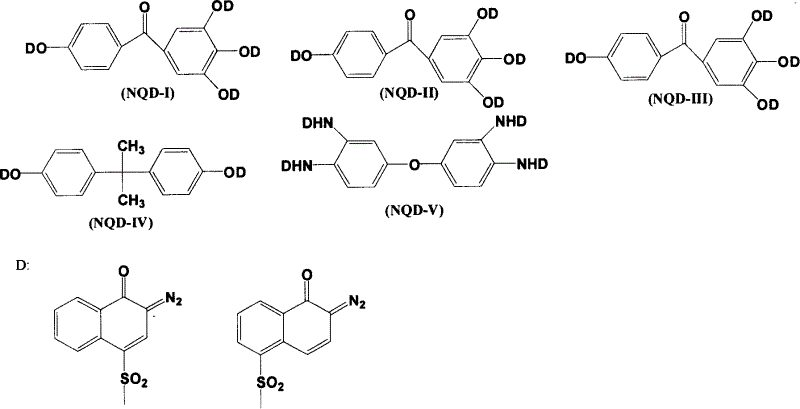

Process for preparing water base developing photosensitive polyimide material

InactiveCN1648154AHigh photosensitivityGood film formingPhotosensitive materials for photomechanical apparatusWater basedBenzoic acid

The present invention belongs to the preparation process of water base developing photosensitive polyimide material. Aromatic dialphanyl diacyl chloride, 3,5-diamino benzoic acid, 4, 4'-diamino-3, 3'-dihydroxy diphenyl methane and 4, 4'-diamino-3, 3'-dihydroxy diphenyl sulfone are polymerized to produce polyamate as one kind of imide prepolymer. The prepolymer has characteristic viscosity of 0.35-0.50, and when 2-diazo naphthoquinone derivative as photosensitizer is added, the prepolymer becomes excellent photosensitive material with high photosensitive performance, good filming performance and high heat resistance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Waterborne anticorrosive coating and preparation method

InactiveCN105176313AReduce surface tensionIncrease wettabilityAnti-corrosive paintsEpoxy resin coatingsMeth-Sodium phosphates

The invention discloses a waterborne anticorrosive coating. The waterborne anticorrosive coating comprises the following components: waterborne epoxy resin emulsion, a pigment filler, a film forming assistant, a leveling agent, a defoaming agent, a thickening agent, a dispersing agent, water and a curing agent, wherein the pigment filler is mixture of iron oxide red and zinc phosphate which are mixed according to a mass ratio of 1:1; the film forming assistant is glycol; the leveling agent is polyacrylic acid or hydroxymethyl cellulose; the defoaming agent is tributyl phosphate; the thickening agent is hydroxymethyl cellulose; the dispersing agent is sodium hexametaphosphate; the curing agent is one of diethylenetriamine, m-phenylenediamine, modified phenolic amine and diamino diphenyl sulfone (DDS). The invention further discloses a preparation method of the waterborne anticorrosive coating, the coating has good anticorrosive performance, the preparation method is simple and feasible and the cost is low.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

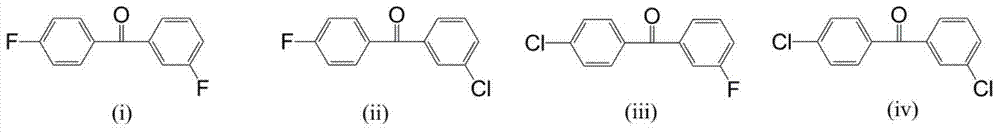

Industrial synthesis method and application of high-fluidity polyether ether ketone resin

InactiveCN104497240ANo depolymerizationAvoid rejoiningAnti-corrosive paintsViscous liquidSynthesis methods

The invention discloses an industrial synthesis method of high-fluidity polyether ether ketone resin. The industrial synthesis method comprises the following steps: in a reaction vessel, adding diphenyl sulfone, 4,4'-difluorobenzophenone and an alkali metal salt forming agent, starting stirring, heating until the monomer is completely dissolved, adding hydroquinone into the system, further uniformly stirring, heating, carrying out polymerization reaction, finally adding an end-capping reagent and further reacting to obtain a polymeric viscous liquid; cooling the polymeric viscous liquid with water, pulverizing into powder and filtering the powder, boiling the filtered powder with an organic solvent and deionized water, repeatedly washing and filtering to remove the solvent and by-product salt and drying to obtain polyether ether ketone resin, wherein the end-capping reagent is selected from one or more of 3,4'-difluorobenzophenone, 3-chloro-4-fluorobenzophenone, 3-fluoro-4-chlorobenzophenone and 3,4'-dichlorobenzophenone. The polyether ether ketone resin prepared by the industrial synthesis method has the advantages of low chroma, low melt viscosity, high fluidity and easiness in mold processing and can be used for preparation of heat-resistant and anti-corrosion coating and injection molded parts.

Owner:JIANGMEN YOUJU NEW MATERIALS

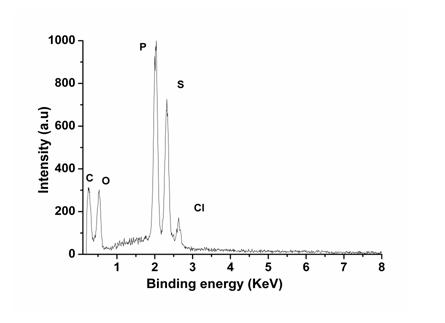

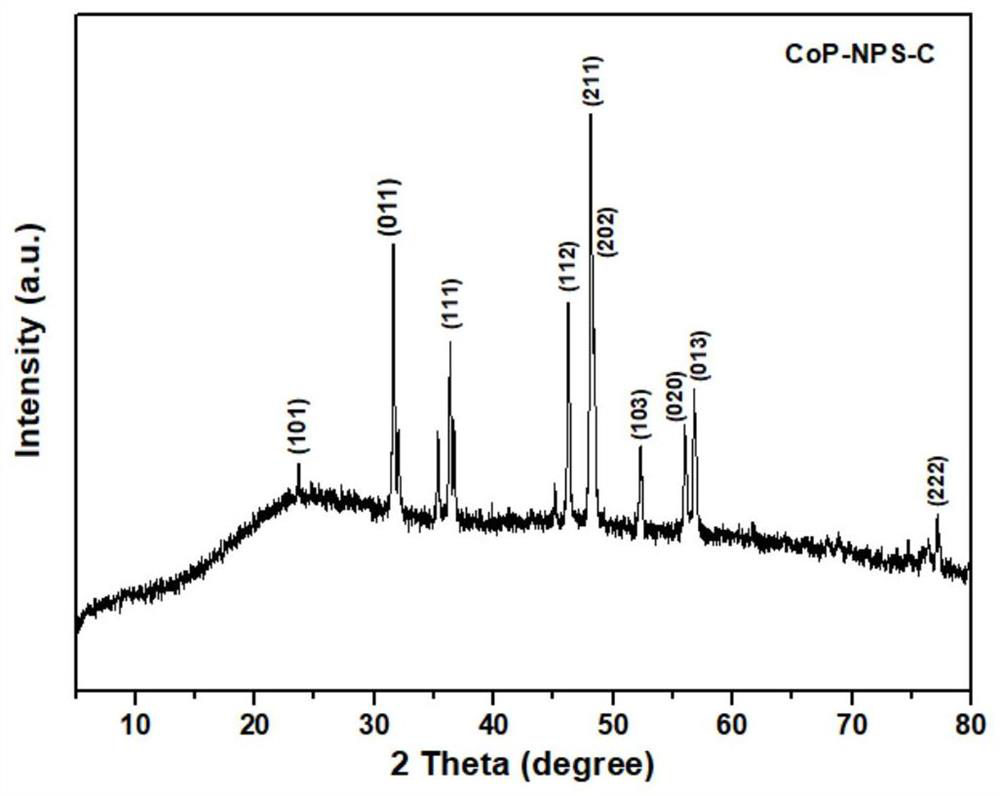

Nitrogen-phosphorus-sulfur co-doped porous carbon loaded metal phosphide nano composite material as well as preparation method and application thereof

ActiveCN111717902AHigh catalytic activityImprove catalytic stabilityMaterial nanotechnologyPhysical/chemical process catalystsPorous carbonOrganic compound

The invention discloses a nitrogen-phosphorus-sulfur co-doped porous carbon loaded metal phosphide nano composite material as well as a preparation method and application thereof. The preparation method of the material comprises the following steps: S1, uniformly mixing a metal salt, a carbon source compound and a swelling agent, and pyrolyzing in an inert gas atmosphere to obtain M-g-C3N4; S2, dispersing the M-g-C3N4 in a solvent to obtain a suspension A, then dropwise adding a mixed solution B in which phosphonitrilic chloride trimer and 4,4-dihydroxy diphenyl sulfone are dissolved into thesuspension A, and carrying out a mixing reaction; dropwise adding an alkaline auxiliary agent, uniformly mixing and reacting, and after the reaction is finished, separating to obtain M-g-C3N4@PZS; andS3, performing high-temperature pyrolysis on the M-g-C3N4@PZS in an inert gas atmosphere to obtain the nitrogen-phosphorus-sulfur co-doped porous carbon loaded metal phosphide nano composite materialMPx-NPS-C. The material is simple to prepare and high in general applicability; and the prepared material shows excellent performance in catalytically activating H2O2, PMS and PS to degrade complex organic compounds, and the application of the metal phosphide material in advanced oxidation water treatment is broadened.

Owner:SUN YAT SEN UNIV

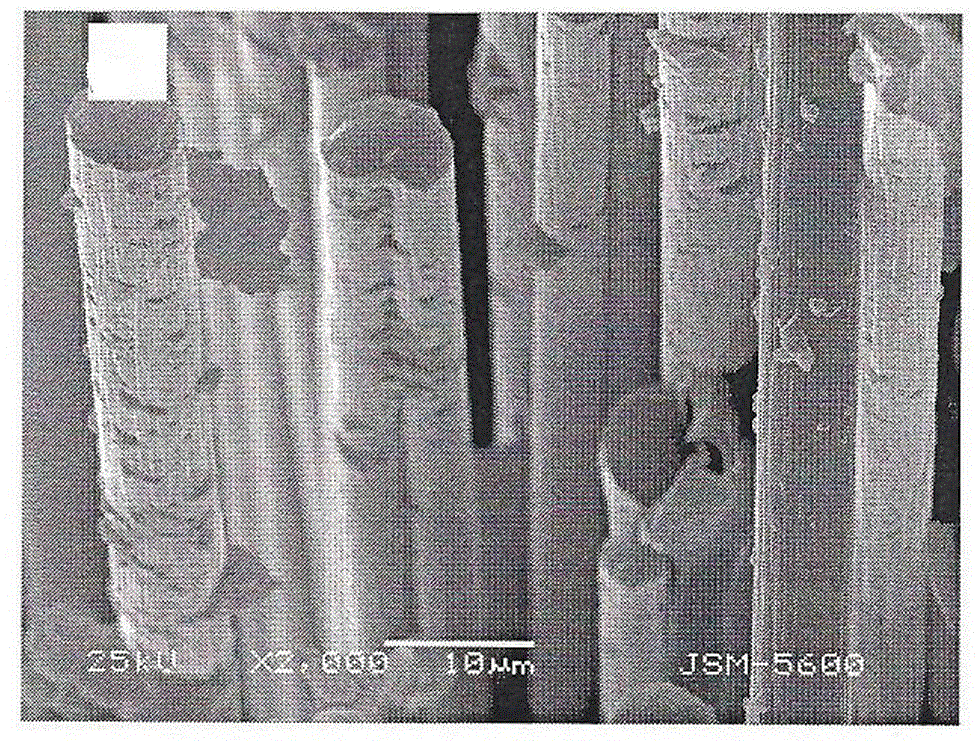

Preparation method of carbon fiber reinforced polyether ether ketone composite material

InactiveCN103602039AFlexible shape processingHigh strengthCarbon fibresSynthetic resin layered productsFiberCarbon fibers

The invention discloses a preparation method of a carbon fiber reinforced polyether ether ketone composite material. The method disclosed by the invention comprises: weaving carbon fibers to a 2D (Two-Dimensional) woven plain or twill preform, then, soaking the woven preform in acetone for 48 hours, ultrasonically treating the preform for 20 minutes through a mixed acid of sulfuric acid and nitric acid, cleaning the preform through deionized water and drying the preform; dissolving diphenyl sulfone in a proper amount of acetone, then adding polyether ether ketone powder, evaporating out the acetone and drying the powder to obtain a polyether ether ketone / diphenyl sulfone mixture; weighing a proper amount of mixture, carrying out hot pressing on the mixture to obtain a pure thin polyether ether ketone rein slice at a temperature of 390 DEG C and at a pressure of 3-4 MPa; alternatively paving the dry preform and the thin polyether ether ketone rein slice in a mold according to such a proportion that the carbon fiber volume fraction is 30-70%, heating up to 380-390 DEG C at a speed of 10-15 DEG C / min, preserving heat for 30 minutes, then, pressurizing to 2-3 MPa, and preserving heat for 30 minutes; and cooling a product in the mold at a moderate cooling speed of 10-15 DEG C / min, meanwhile, pressurizing to 4-5 MPa, further maintaining the pressure for 3 hours, and demolding to obtain a woven carbon fiber / polyether ether ketone composite material.

Owner:CHANGCHUN UNIV OF TECH

Method for preparing 4, 4'-dichloride diphenyl sulfone

InactiveCN1623982AReduced free enthalpy (ΔG)Reduce the temperatureOrganic chemistryOrganic compound preparationSulfur trioxideCondensation reaction

A process for preparing 4,4'-dichlorodiphenyl sulfone features that the coupling agent of SO3 is used to lower the free enthalpy of sulfonating and condensating reactions and the catalyst of sulfonating and condensating reactions is used to lower the activating energy of reaction, resulting in low reaction temp, short time and high quality of product.

Owner:马炳荣

Preparation method of high-purity polyether-ether-ketone resin

Owner:YIBIN TIANYUAN GRP CO LTD

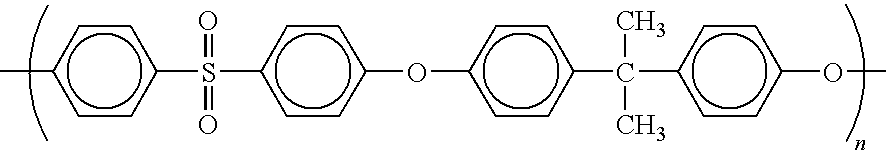

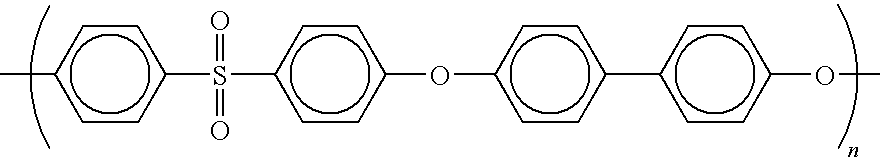

Transparent and flame retardant polysulfone compositions

ActiveUS20090283476A1High transparencyReduce heat releaseUltrafiltrationWater/sewage treatment bu osmosis/dialysisDiphenyl sulfonePolysulfone

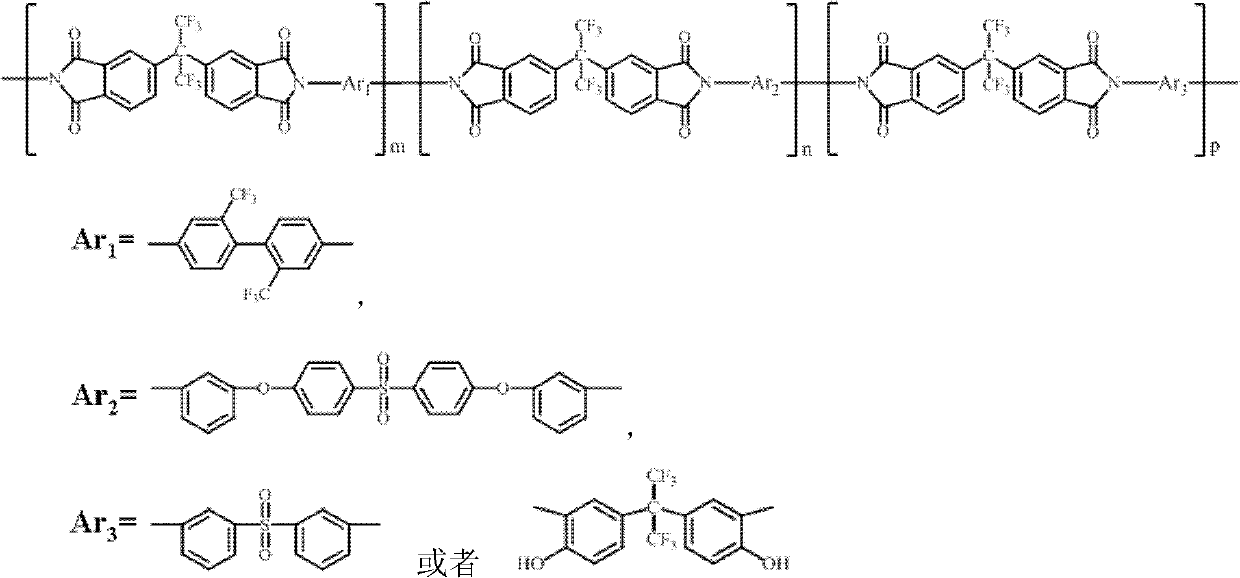

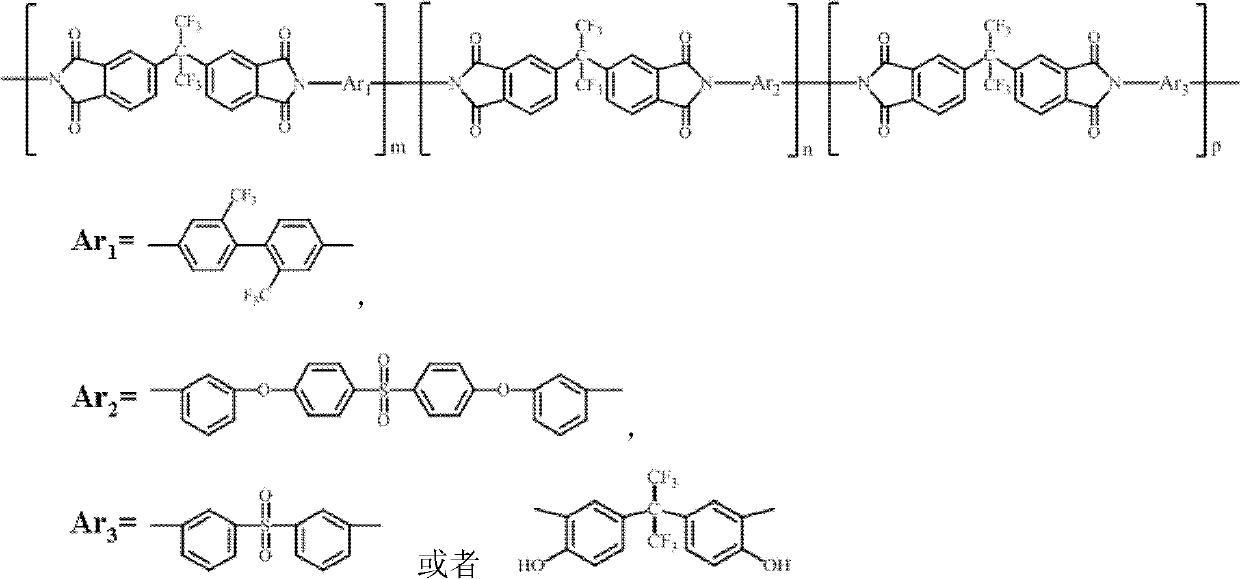

A polysulfone having a first polyphenylene sulfone unit (i.e. PPSU unit) based on one biphenol group and one diphenyl sulfone group and a second sulfone unit (i.e. PSU-AF unit) based on one hexafluorobisphenol A group and one diphenylsulfone group. The polysulfone is transparent and has a total heat release and peak heat release of less than 65 kW·min / m2 and 65 kW / m2, respectively. Compositions containing the polysulfone and articles made by molding and / or extruding the polysulfone.

Owner:SOLVAY ADVANCED POLYMERS LLC

Papers containing fibrids derived from diamino diphenyl sulfone

This invention relates to papers made with fibrids containing a polymer or copolymer derived from a monomer selected from the group consisting of 4,4′diaminodiphenyl sulfone, 3,3′diaminodiphenyl sulfone, and mixtures thereof. Such papers have high thermal stability and accept ink more readily than papers made solely with aramid fibrids.

Owner:DUPONT SAFETY & CONSTR INC

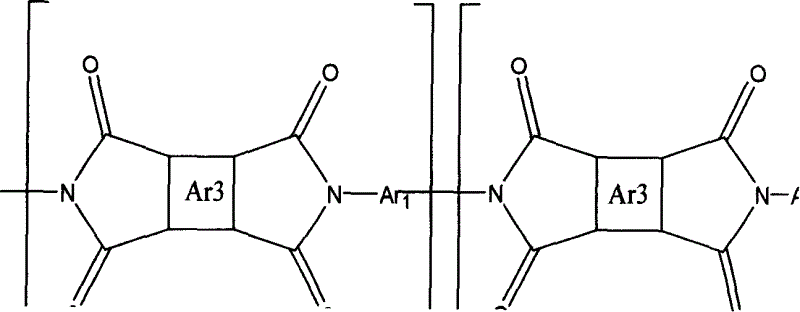

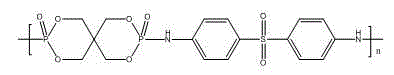

Reactive epoxy resin flame-retardant curing agent containing phosphorus and nitrogen and preparation method thereof

The invention relates to a chemical synthesis agent and a preparation method thereof and provides a reactive epoxy resin flame-retardant curing agent containing phosphorus and nitrogen and a preparation method thereof. Raw materials for preparation of the curing agent comprise pentaerythritol, phosphorus oxychloride and 4,4-diamino diphenyl sulfone (DDS). The preparation method for the curing agent comprises the following two steps: step 1, reacting pentaerythritol (PER) with phosphorus oxychloride (POCl3) under certain conditions so as to produce a phosphorus-containing intermediate, i.e., pentaerythritol bisphosphorate diphosphoryl choloride (SPDPC); and step 2, subjecting SPDPC and DDS to a stirring reaction for a certain period of time under the condition of introduction of inert gas and subjecting a product to filtration, washing, drying and the like so as to obtain a white powder which is a phosphorus-nitrogen intumescent flame retardant. The reactive epoxy resin flame-retardant curing agent has high heat stability, expansibility and char yield and can be used as a flame retardation additive to a plurality of polymer materials so as to improve the flame retardant property of the polymer materials. The preparation method provided by the invention has the advantages of simple production conditions, high product purity, high yield and simple and convenient post treatment.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

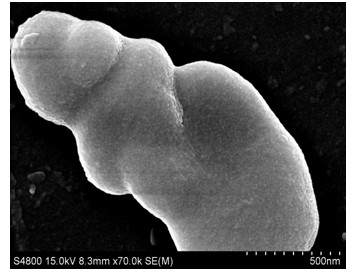

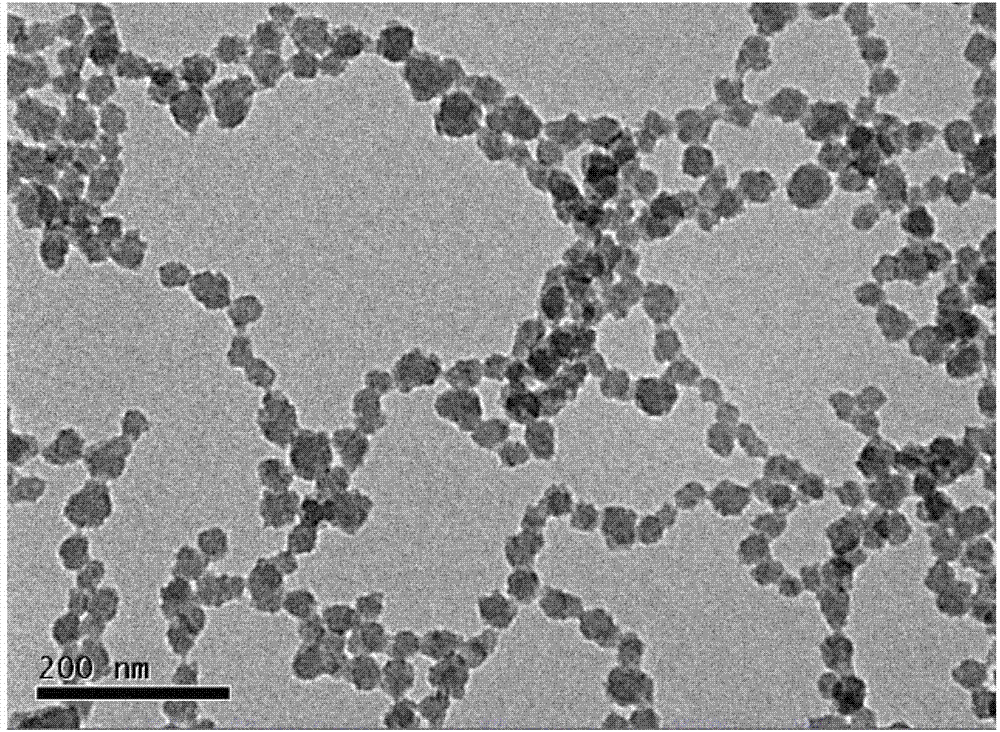

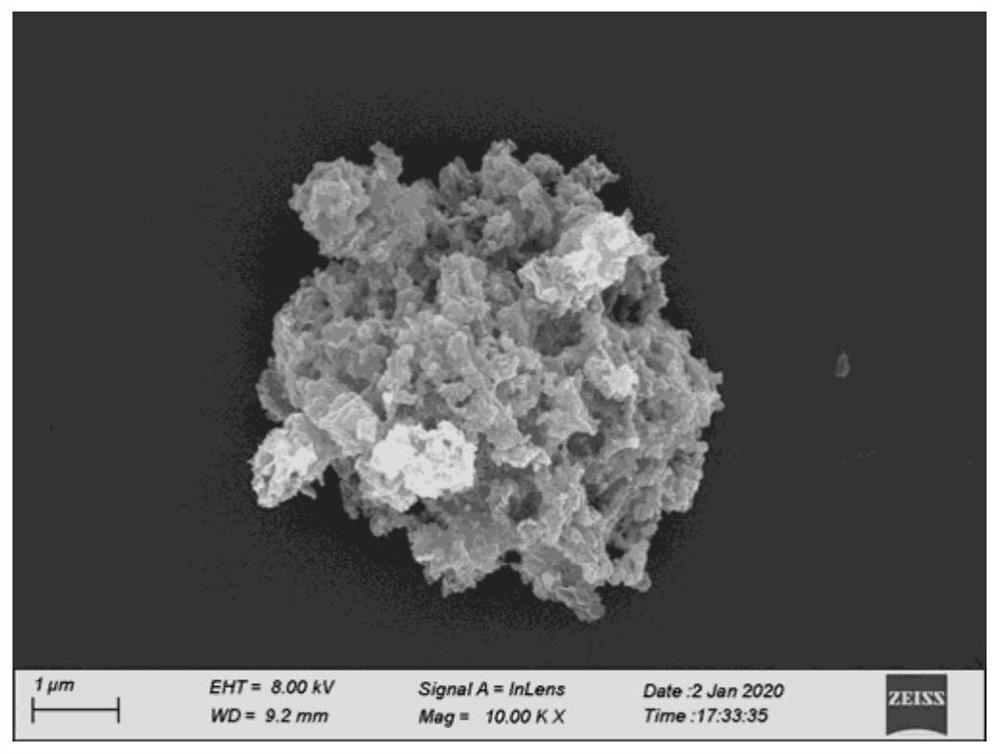

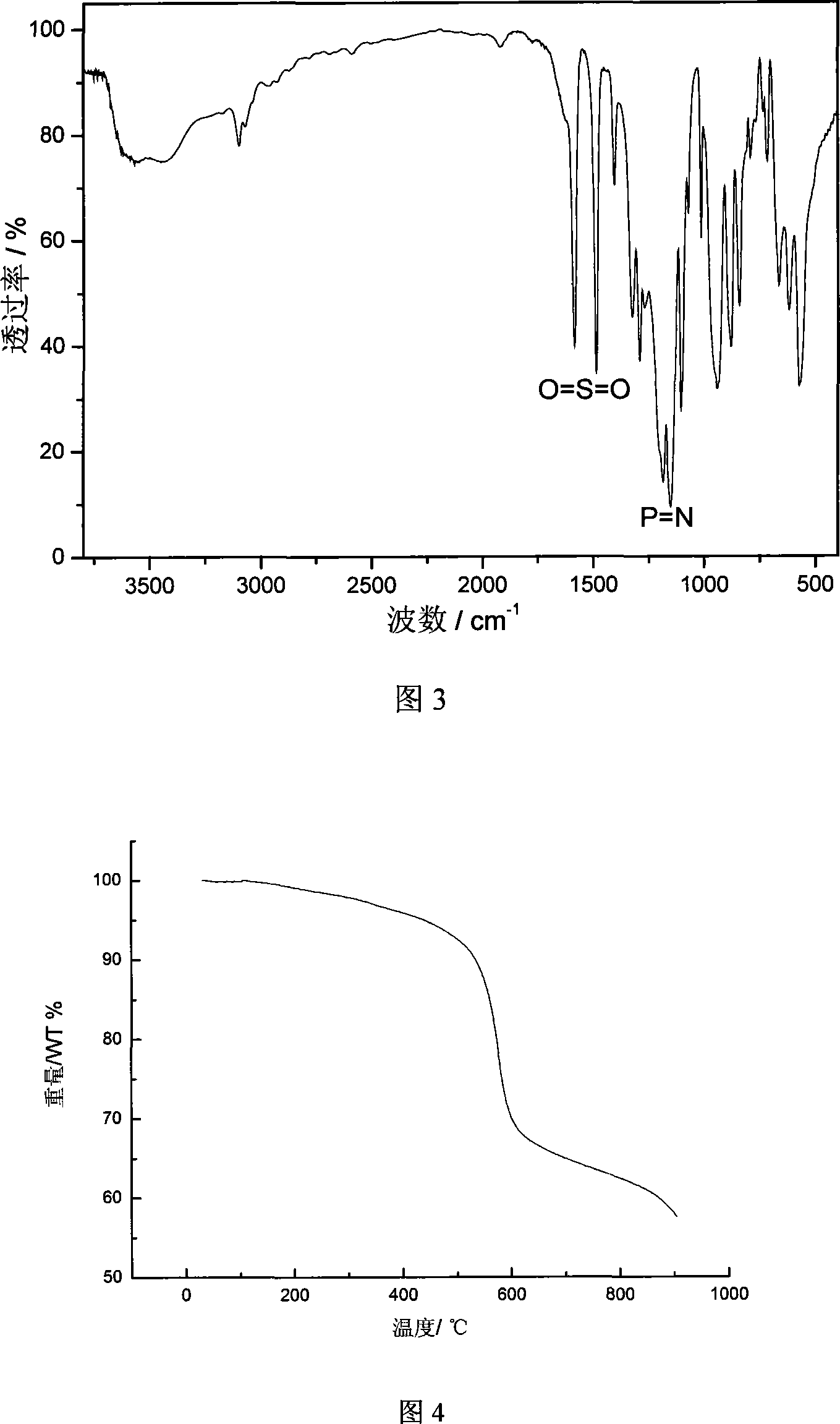

Hollow micro-ball containing phosphazene and preparing method

InactiveCN101070389ALoose internal structureDense surface structurePharmaceutical non-active ingredientsPolymer sciencePtru catalyst

The present invention discloses a kind of phosphazenes-containing hollow microsphere as shown in the following figure, and its preparation method; specifically, the diameter of the hollow microsphere is 0.3-2.0mu m, and the internal hollow diameter of the hollow microsphere is 100-800 nm. The phosphazenes-containing hollow microsphere which has a body-type crosslinking structure, can be produced by crosslinking condensation reaction under the function of acid binding agent, and controllable hydrolysis, in sequence, between hexachlorocyclotriphosphazene and 4, 4'-dihydroxy diphenyl sulfone; the preparation method is novel, simple and feasible, which can be large scale prepared in industrial applications.The phosphazenes-containing hollow microsphere can be used in controlling drug release, efficient catalyst carriers, new photoelectric material, flame retardant materials, etc.

Owner:SHANGHAI JIAO TONG UNIV

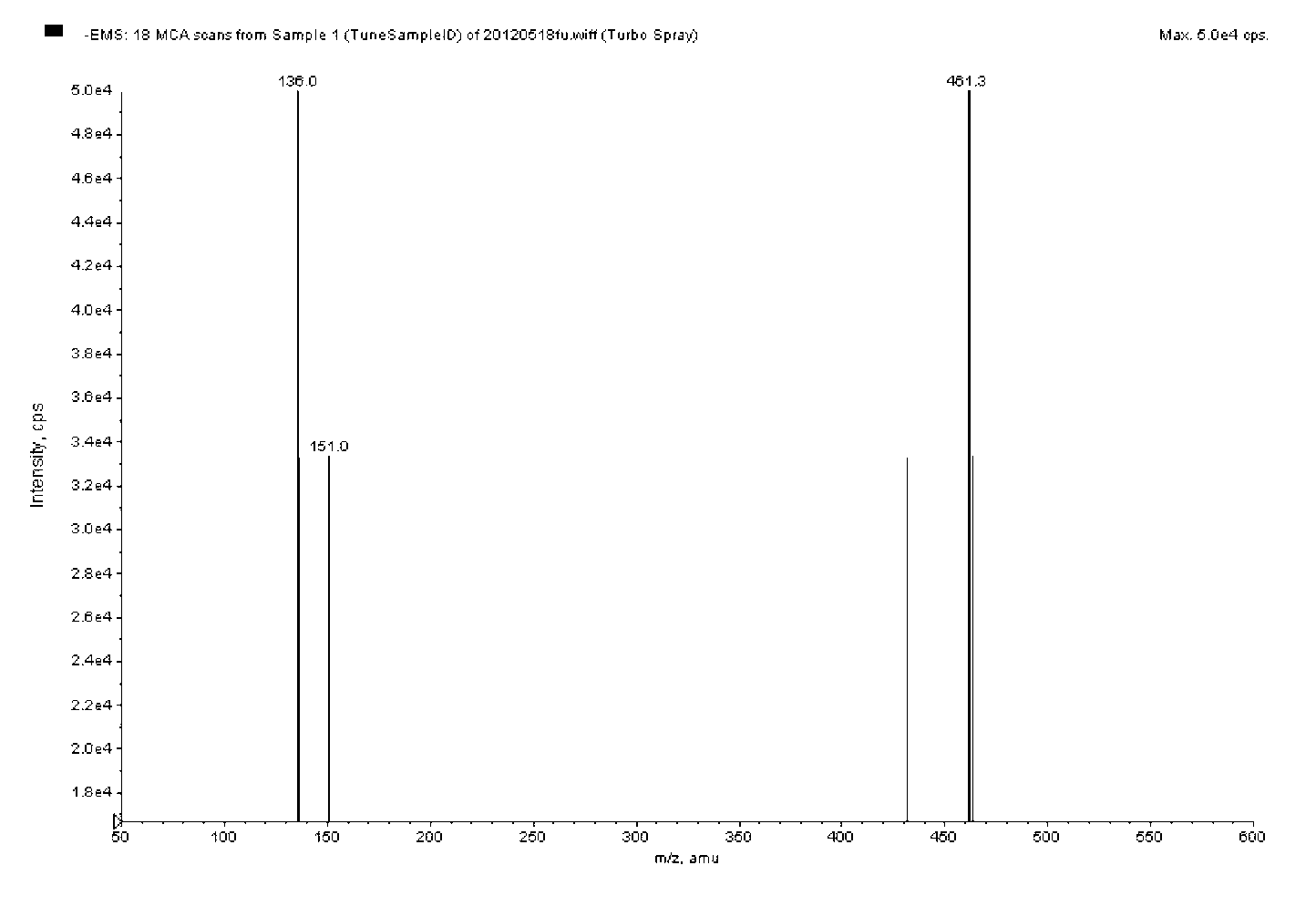

High purity diphenyl sulfone, preparation and use thereof for the preparation of a poly(aryletherketone)

The presence of certain impurities in diphenyl sulfone have a deleterious effect on the properties of the poly(aryletherketone)s produced therein, including one or more of color, melt stability, molecular weight, crystallinity, etc. and here identify those impurities and provide processes for the removal of such impurities.

Owner:SOLVAY ADVANCED POLYMERS LLC

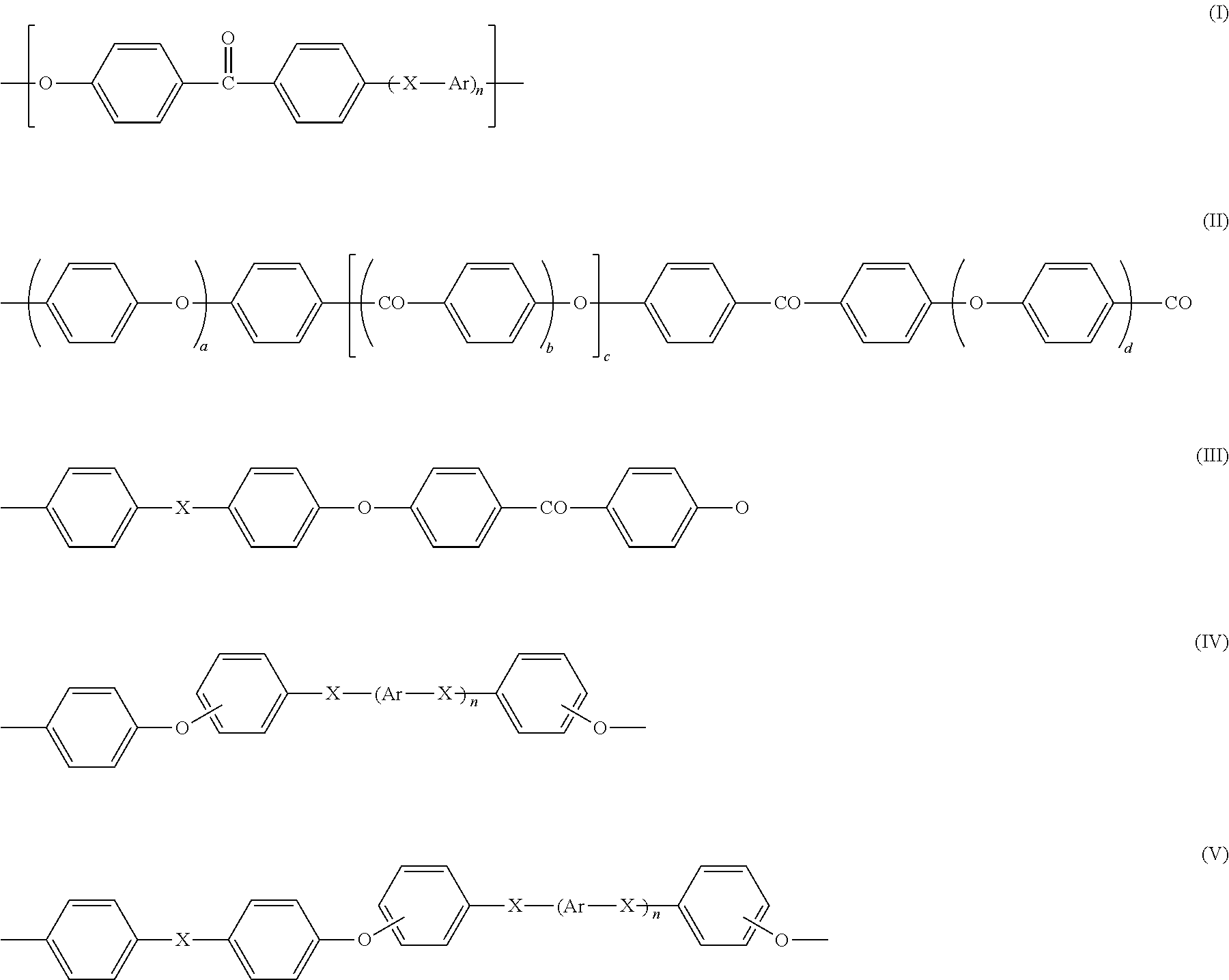

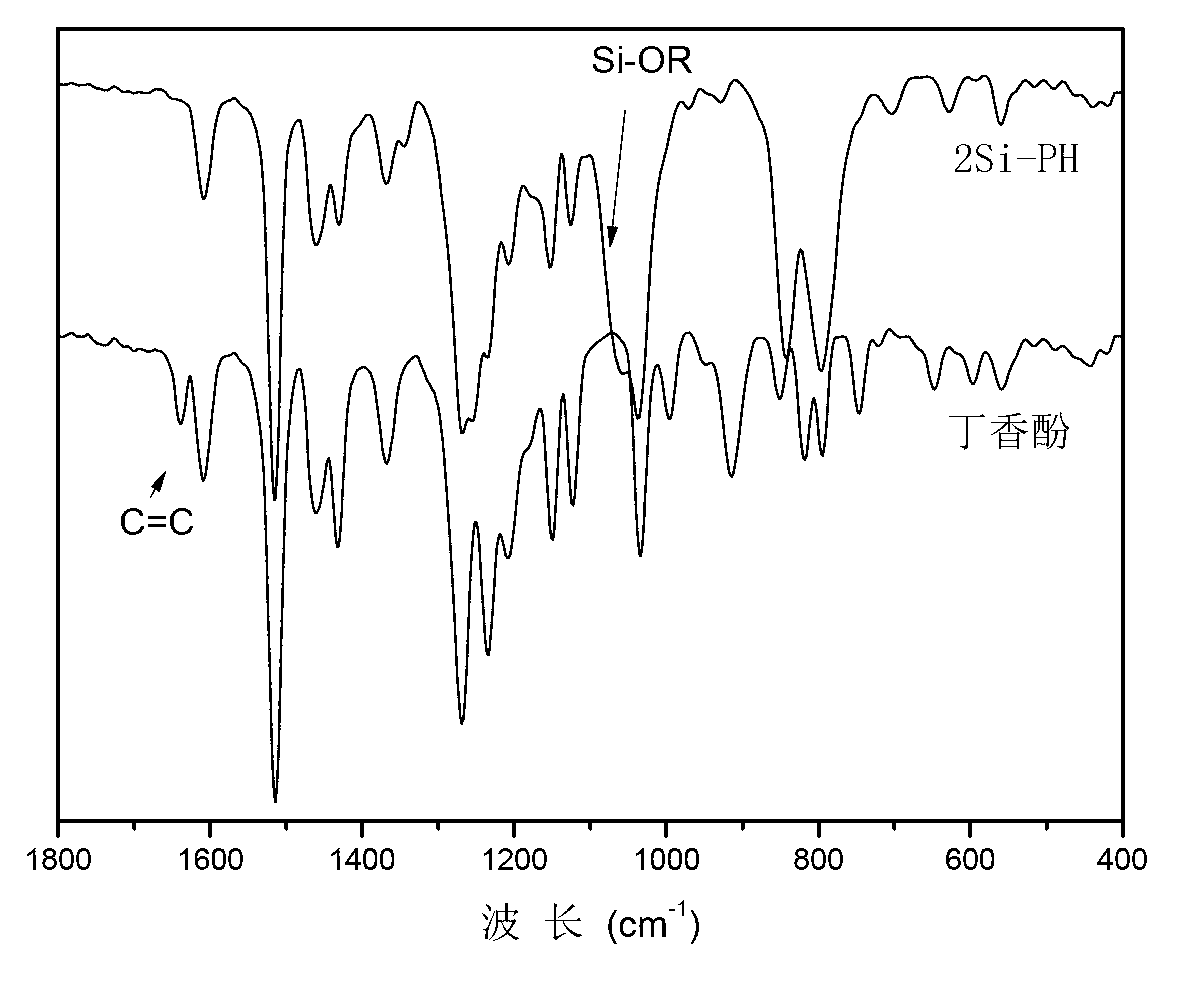

Polyarylether sulphone resin with Si-O-Si structure in main chain and preparation method of resin

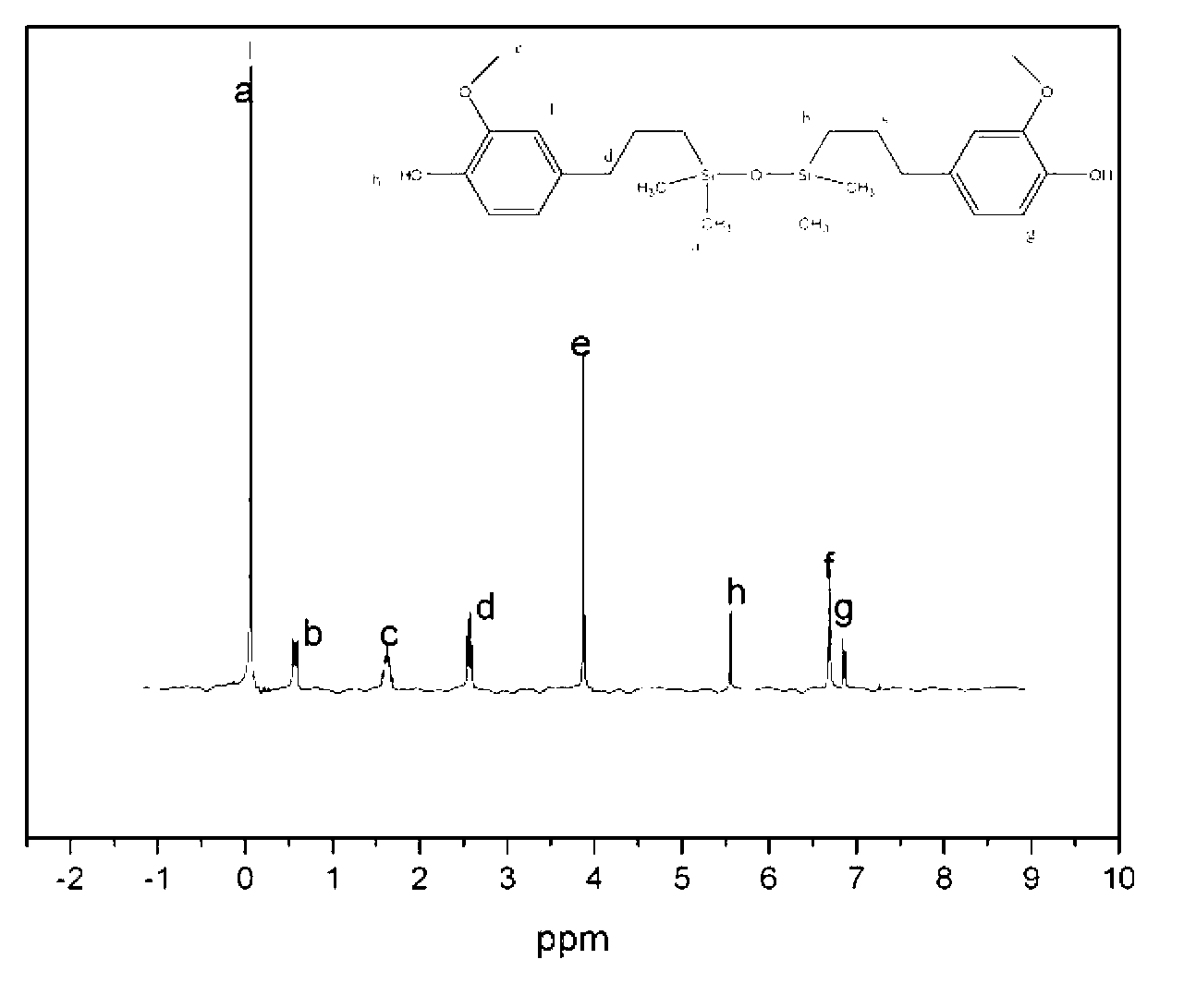

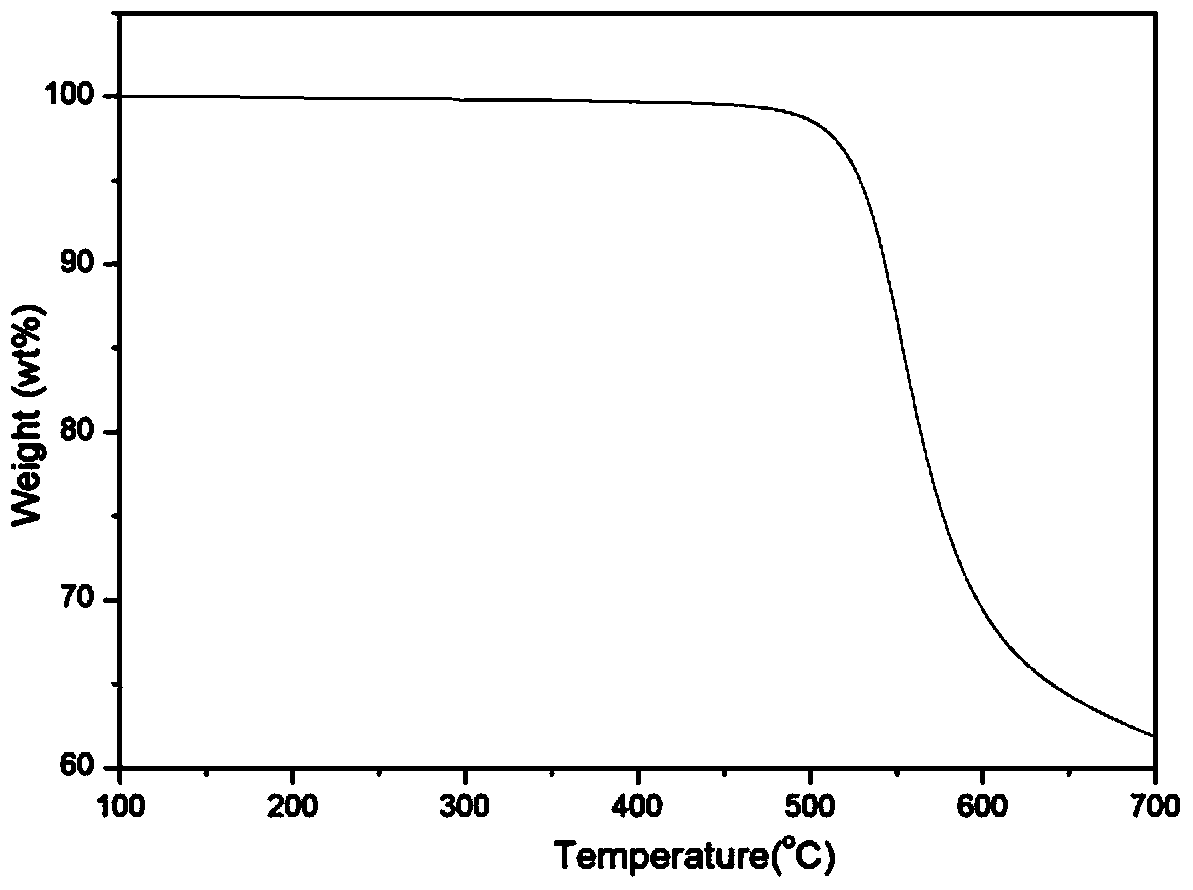

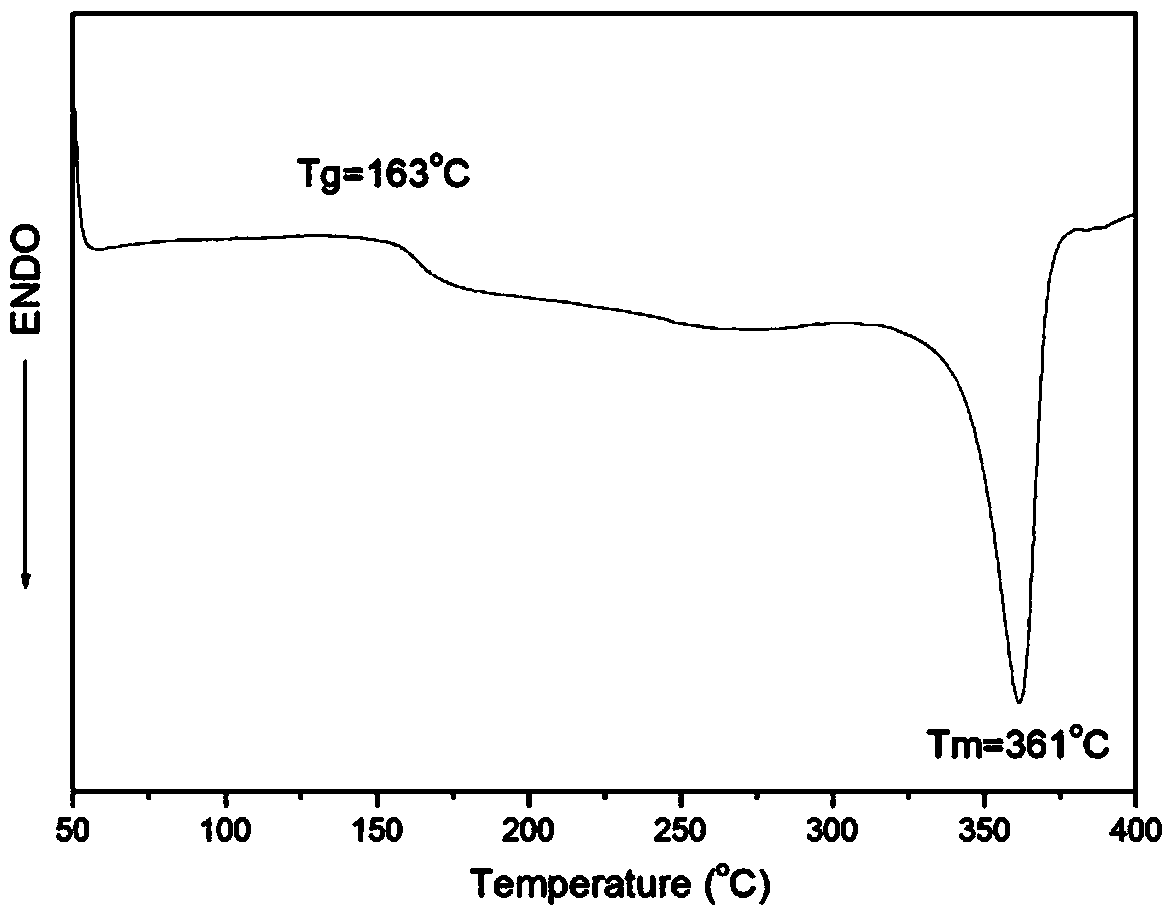

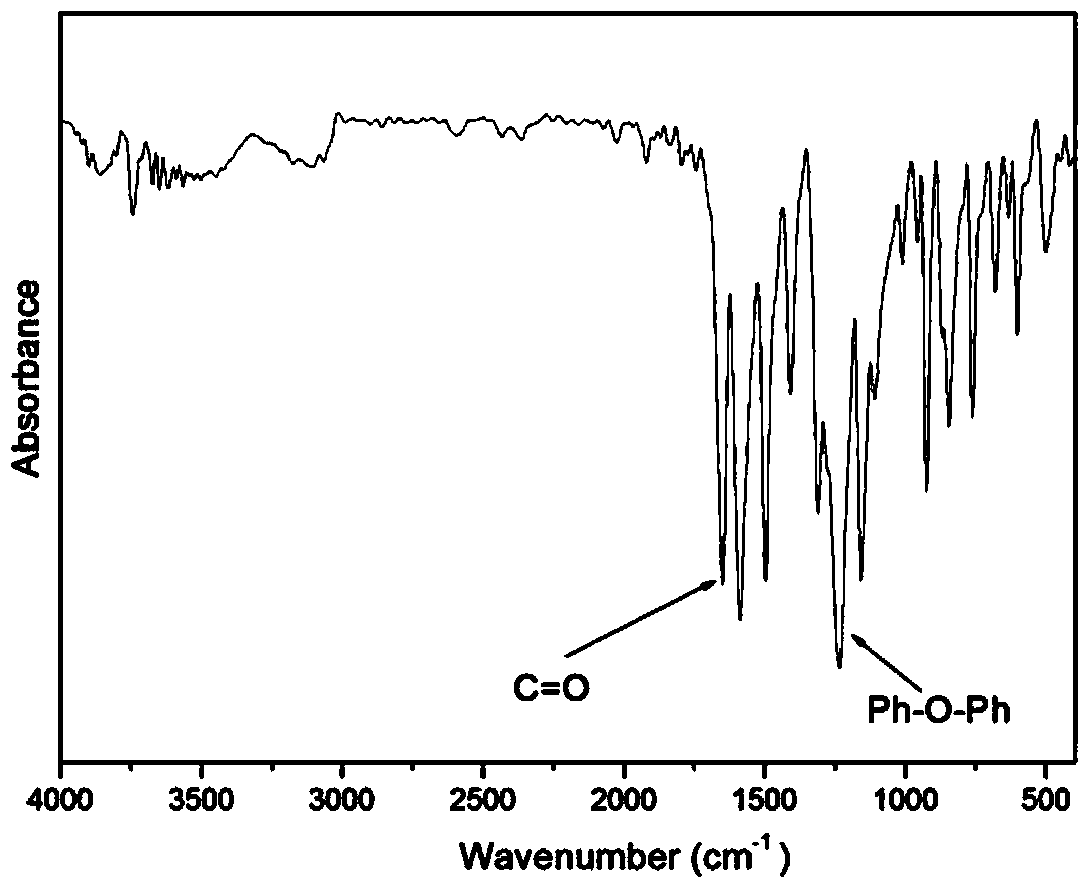

The invention relates to a polyarylether sulphone resin with a Si-O-Si structure in a main chain and a preparation method of the resin. The preparation method comprises the steps of: carrying out hydrosilylation reaction on a 1, 1, 3, 3-tetramethyl disiloxane-1, 3-bi (3-methoxy-4-propyl phenol) monomer with the Si-O-Si structure by taking 1, 1, 3, 3-tetramethyl dihydro-disiloxane and eugenol as raw materials, using toluene as a solvent for one-step synthesis; and carrying out random copolycondensation on the monomer, biphenol and dichloro-diphenyl sulfone under the condition that sulfolane is taken as a solvent to obtain the polyarylether sulphone resin. The preparation method is simple in synthetic route and available in raw materials; and the prepared polyarylether sulphone resin has excellent heat resistance, dissolubility and oxidation stability, thus the polyarylether sulphone resin is good in industrial application prospect.

Owner:JILIN UNIV

Polyether ketone resin and method for preparing same by polymerization termination

The invention relates to polyether ketone resin and a method for preparing the same by polymerization termination and belongs to the technical field of high molecular materials. The molecular weight of polyether ketone resin can be adjusted by the method. The method comprises the following steps: under nitrogen protection and stirring, heating diphenyl sulfone to 100-170 DEG C, adding a fluoro-substituted aromatic monomer and alkali carbonate, heating to 140-180 DEG C and adding a bisphenol monomer, and then carrying out programmed heating; then, adding a terminating reagent monophenol monomer or a mixture of the monophenol monomer and diphenyl sulfone and reacting for 5-120 minutes to obtain a polyether ketone polymer; finally, pouring the polyether ketone polymer into water, smashing the obtained solids by a smasher, and filtering; then, boiling, filtering the dried obtained solids by ethanol or acetone, repeatedly boiling and filtering for 5-6 times; then, boiling and filtering by distilled water and repeatedly boiling and filtering for 5-6 times; and finally, drying in an oven to obtain the refined polyether ketone polymer.

Owner:长春吉大特塑工程研究有限公司

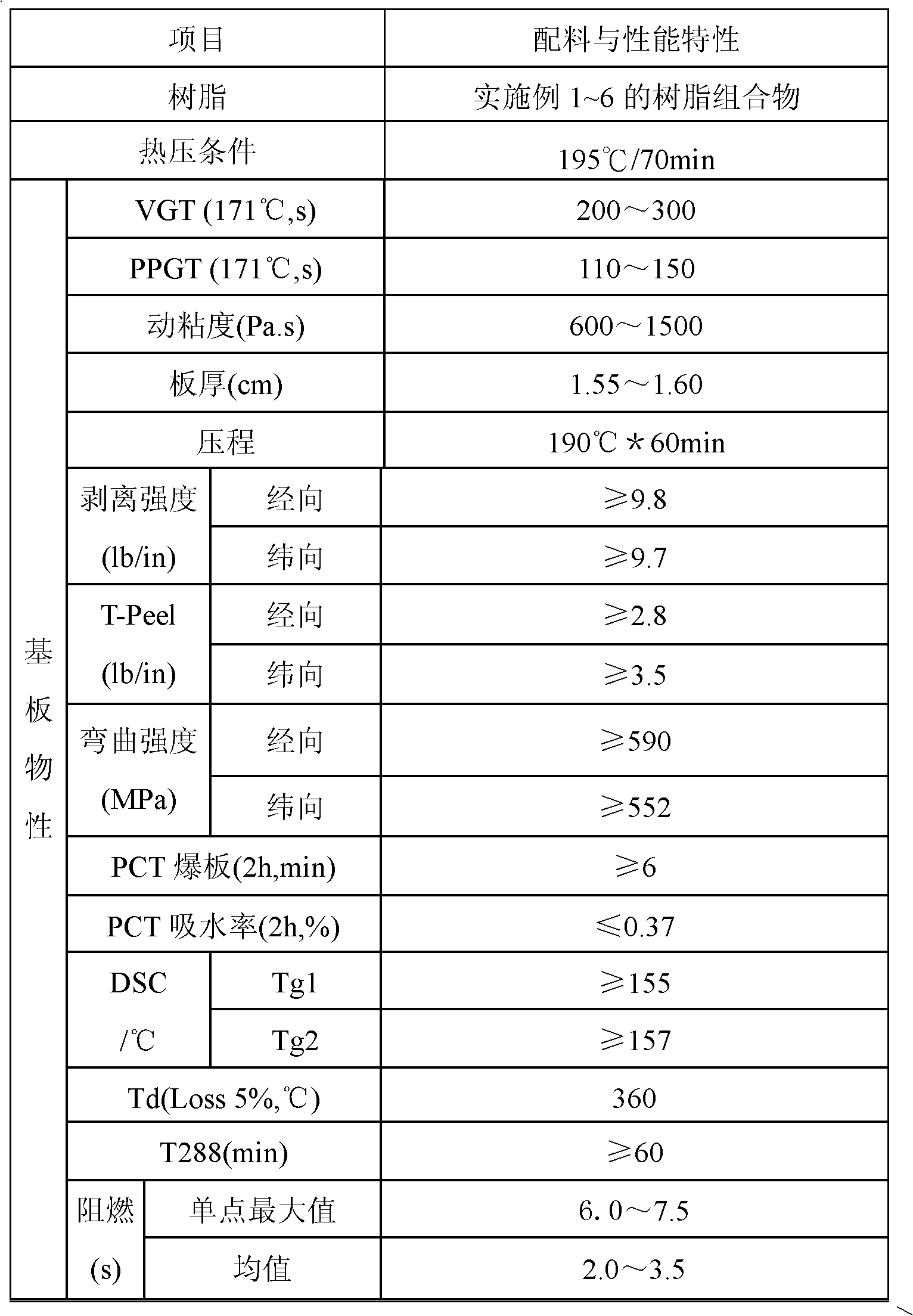

Halogen-free flame-retardant epoxy resin composition and application thereof

ActiveCN102051024AEasy to operateImprove flame retardant performanceCircuit susbtrate materialsMetal layered productsEpoxyPhosphor

The invention discloses a halogen-free flame-retardant epoxy resin composition comprising the following components in parts by weight: 40-70 parts by weight of phosphor-containing epoxy resin solution, 25-50 parts by weight of benzoxazine, 5-40 parts by weight of diamino diphenyl sulfone, 0.1-0.8 part by weight of curing accelerator and 20-200 parts by weight of filler. The epoxy resin composition disclosed by the invention has the advantages of favorable operability, favorable flame-retardant performance, excellent reactivity and the like and is used for preparing a printed circuit copper clad laminate, so that the copper clad laminate has the comprehensive performances of favorable heat resistance, excellent flame-retardant performance, low water absorption rate and the like.

Owner:EPOXY BASE ELECTRONICS MATERIAL

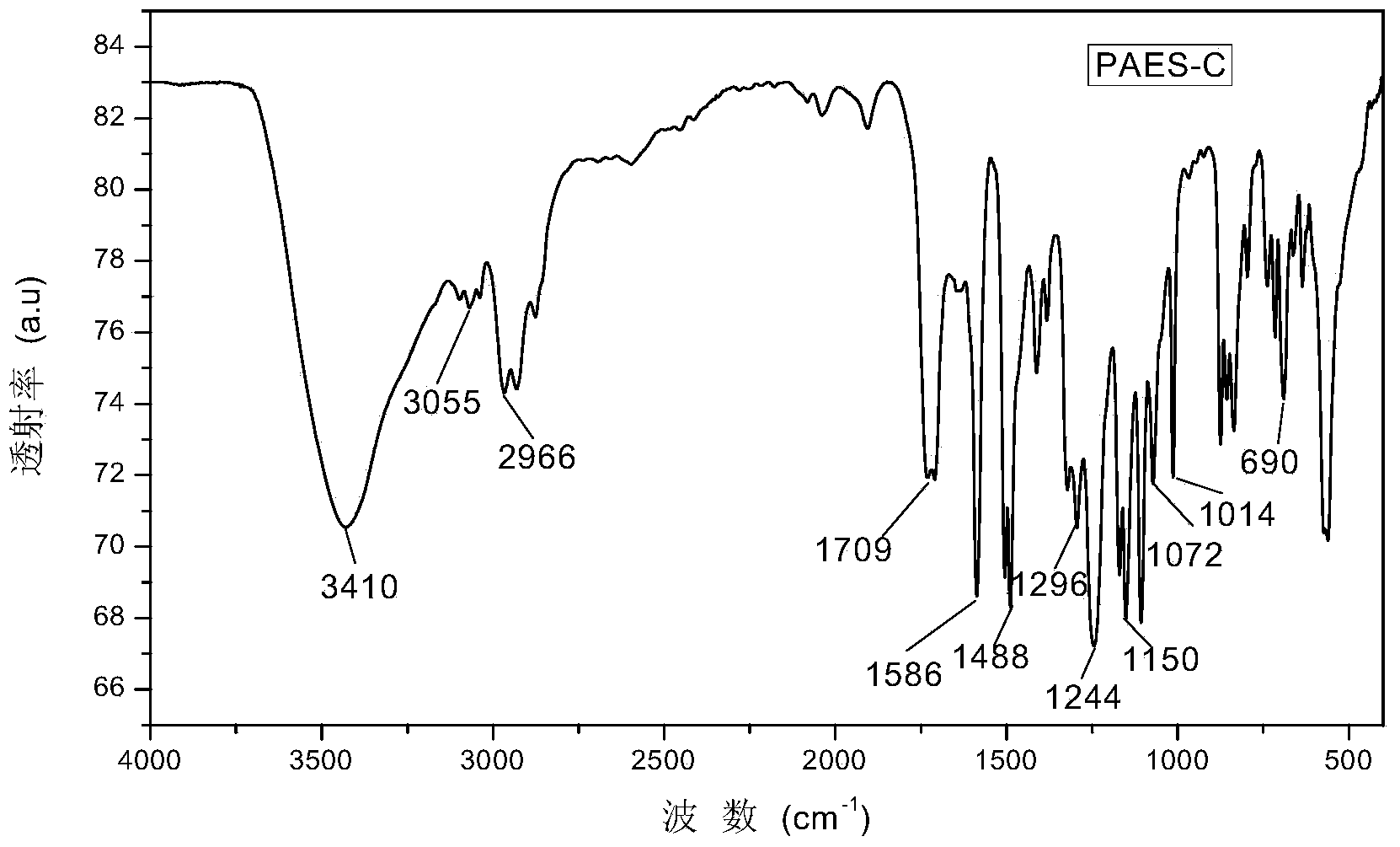

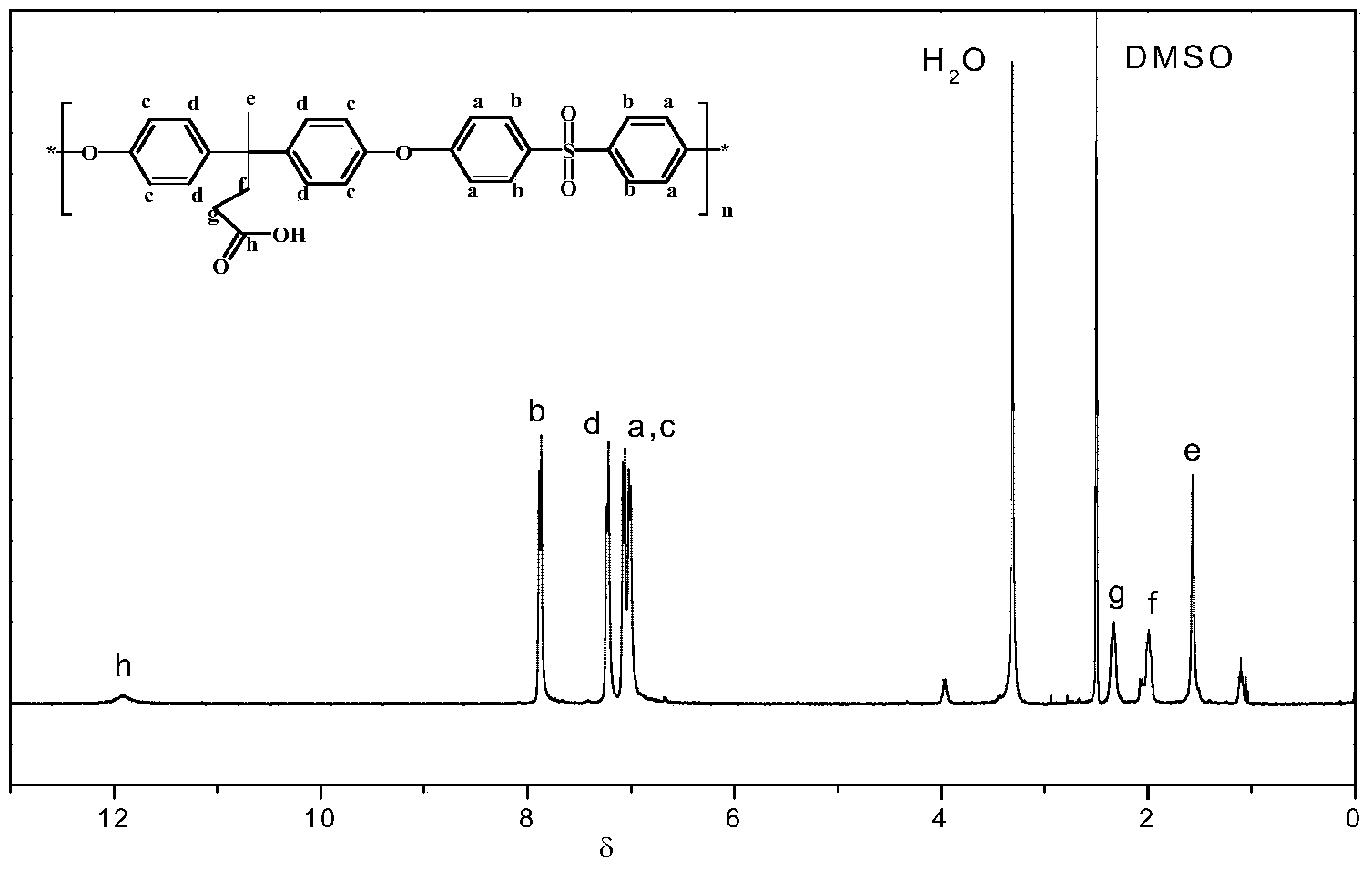

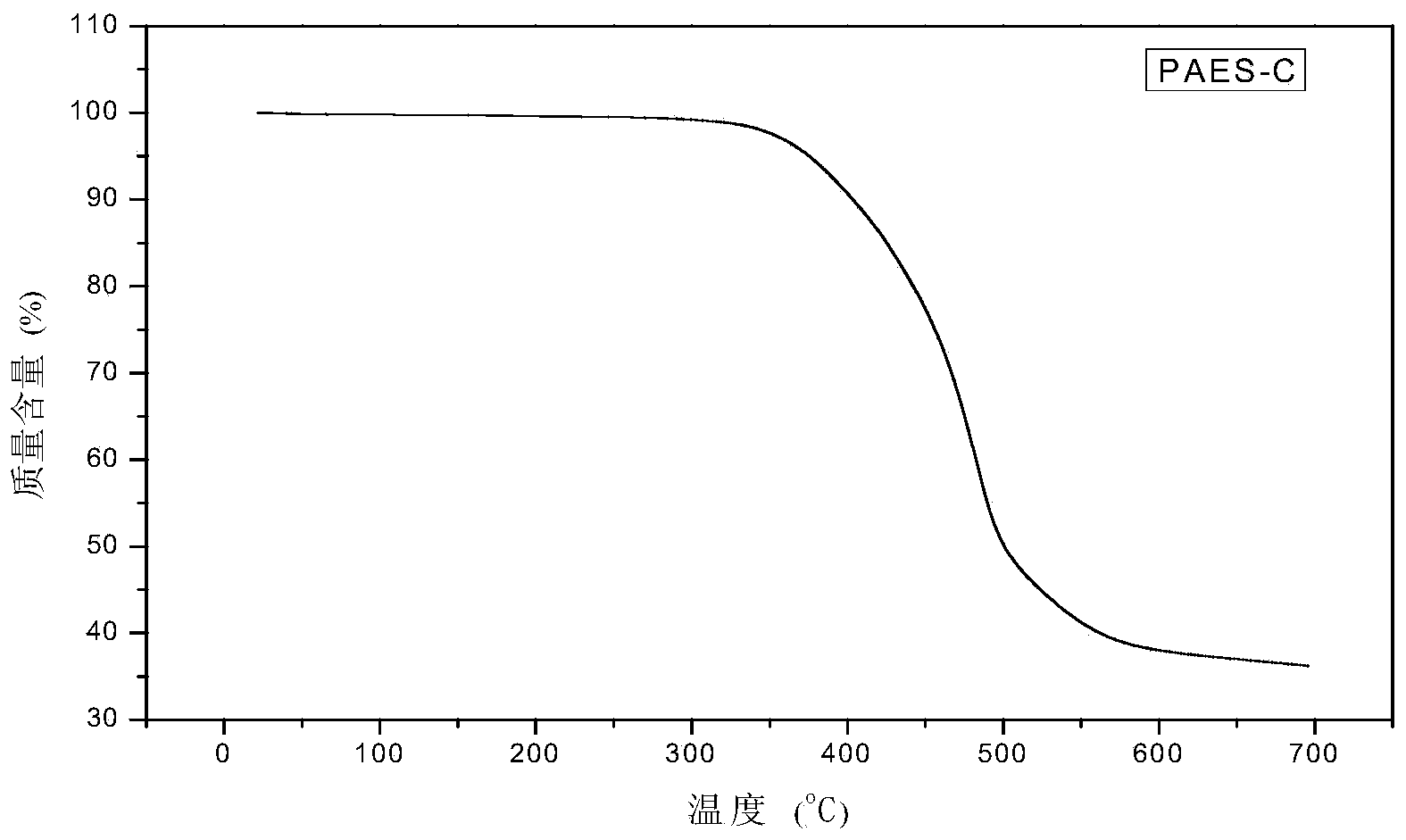

Preparation method and application of high molecular weight polyether sulphone polymer with side group containing carboxyl

InactiveCN104031260APromote formationImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionPolymer scienceFuel cells

The invention discloses a high molecular weight polyether sulphone polymer with a side group containing carboxyl and a preparation method of the high molecular weight polyether sulphone polymer with the side group containing the carboxyl. The preparation method comprises the steps that by adopting compound alkali and an inertia double-solvent, solution polycondensation is carried out on 4,4'-dichloro diphenyl sulfone and a diphenolic acid monomer, so that the high molecular weight polyether sulphone polymer with the side group containing the carboxyl is obtained. The high molecular weight polyether sulphone polymer with the side group containing the carboxyl has the advantages that weight-average molecular weight is 1000-150000 and tensile strength is 30-120MPa, and the high molecular weight polyether sulphone polymer with the side group containing the carboxyl has high molecular weight, easy film formation, good mechanical property, good thermal stability and high glass transition temperature; adsorbing capacity of the high molecular weight polyether sulphone polymer with the side group containing the carboxyl to Cu<2+> when pH is 1-7 is 0.02-2mmol / g, the high molecular weight polyether sulphone polymer with the side group containing the carboxyl can be reused after being regenerated, the adsorption rate of the regenerated polymer to Cu<2+> is still more than 90% of the adsorbing capacity of the high molecular weight polyether sulphone polymer with the side group containing the carboxyl to Cu<2+>, and the high molecular weight polyether sulphone polymer with the side group containing the carboxyl can be applied to preparation of a Cu<2+> adsorbing agent and has a broad application prospect in the aspects of water treatment field, membrane separation, fuel cells and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com