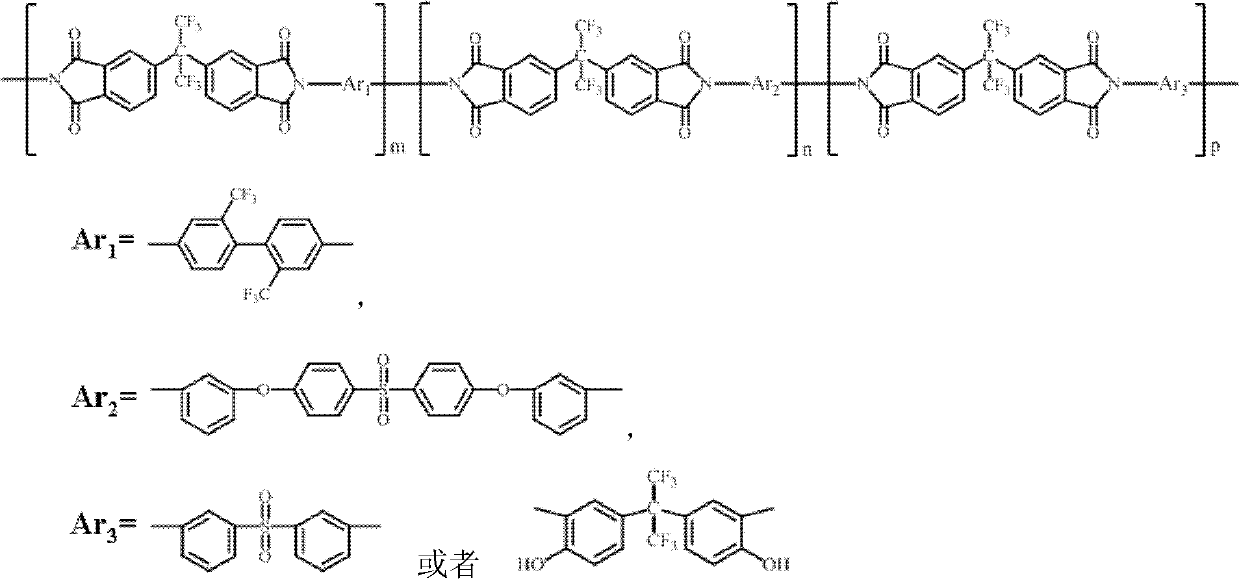

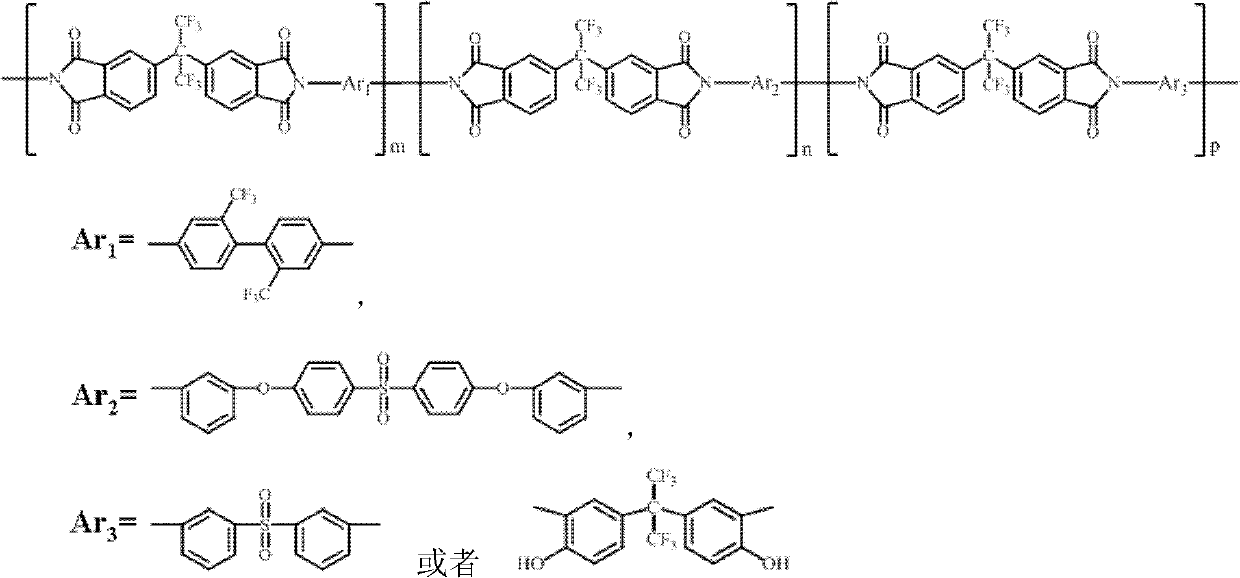

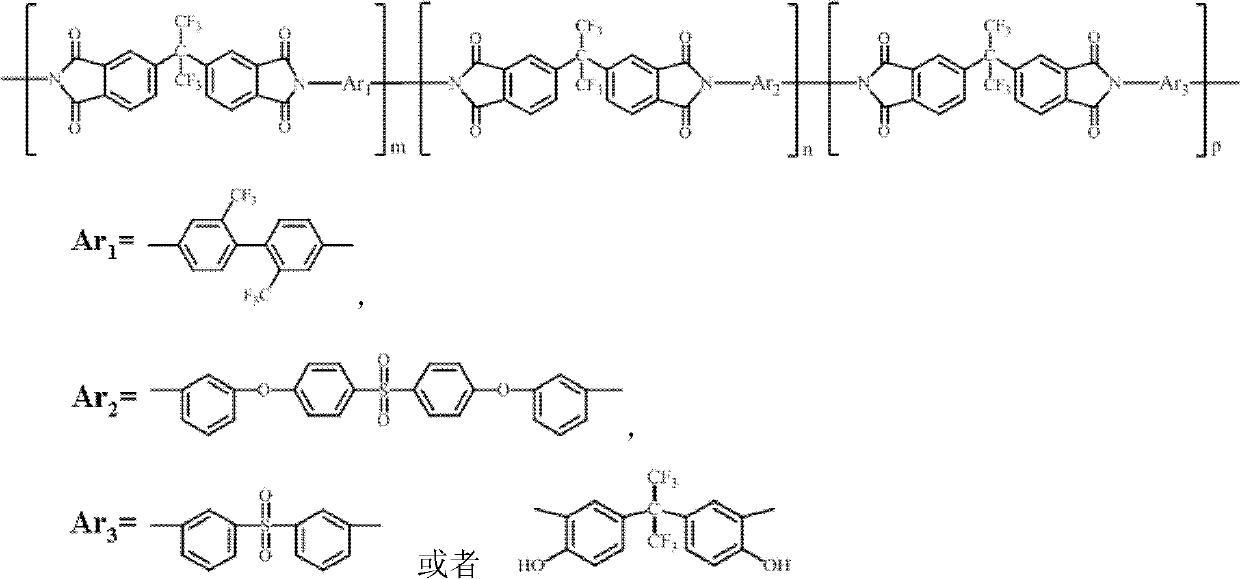

Colorless and high transparent flexible polyimide film and preparation method thereof

A technology of polyimide film and polyamic acid, which is applied in the field of colorless and highly transparent flexible polyimide film and its preparation, can solve the problems of unknown light transmittance and the like, and achieve high heat resistance and high light transmittance. , the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The above-mentioned colorless highly transparent flexible polyimide film has four different preparation methods, wherein the first method comprises the following steps:

[0033] (2-1) 2,2'-bis(trifluoromethyl)diaminobiphenyl and 4,4'-bis(3-aminophenoxy)diphenylsulfone are dissolved in a polar solvent, wherein 2 , the molar ratio of 2'-bis(trifluoromethyl)diaminobiphenyl and 4,4'-bis(3-aminophenoxy)diphenylsulfone is (1~8):1, add in the solution 4,4'-(hexafluoroisopropylene) diphthalic anhydride, the addition ratio is: 4,4'-(hexafluoroisopropylene) diphthalic anhydride and 2,2'-bis(trifluoromethyl)diaminobiphenyl and 4,4'-bis(3-aminophenoxy)diphenyl sulfone in a ratio of 1:1 to the total moles of diphenyl sulfone, stirred and reacted at room temperature for 24 hours to obtain a polyamic acid solution, and the amount of the above-mentioned polar solvent was based on polyamic acid Solid content 20wt% calculation in the amic acid solution;

[0034] (2-2) Lay the above pol...

Embodiment 1

[0049] Dissolve 5.77g (0.018mol) of 2,2'-bis(trifluoromethyl)diaminobiphenyl and 1.95g (0.005mol) of 4,4'-bis(3-aminophenoxy)diphenylsulfone in After 71g of N-methyl-2-pyrrolidone was completely dissolved, 10.21g (0.023mol) of 4,4'-(hexafluoroisopropene) diphthalic anhydride was added to the above solution at room temperature, and stirred for 12 hours to obtain a solid A polyamic acid solution with a content of 20 wt%. Add 71g of xylene to the polyamic acid solution, stir evenly, raise the temperature to 170°C, keep the reflux reaction for 12 hours, cool down to room temperature after the reaction, pour the solution into 710mL of methanol to settle, and place the precipitate in a vacuum drying oven In drying at 80°C for 12 hours, a white powdery polyimide was obtained. The polyimide powder is dissolved in 71g N-methyl-2-pyrrolidone to obtain a polyimide solution with a solid content of 20wt%, and the polyimide solution is spread on a flat plate, followed by drying at 80°C for...

Embodiment 2

[0052] Dissolve 3.6g (0.011mol) of 2,2'-bis(trifluoromethyl)diaminobiphenyl and 4.86g (0.011mol) of 4,4'-bis(3-aminophenoxy)diphenylsulfone in In 73g of γ-butyrolactone, after being completely dissolved, add 9.77g (0.022mol) 4,4'-(hexafluoroisopropene) diphthalic anhydride to the above solution at room temperature, and stir for 12 hours to obtain a solid content of 20wt % polyamic acid solution. Add 73g of xylene to the polyamic acid solution, stir evenly, raise the temperature to 170°C, keep the reflux reaction for 12 hours, cool down to room temperature after the reaction, pour the solution into 730mL of methanol to settle, and place the precipitate in a vacuum drying oven In drying at 80°C for 12 hours, a white powdery polyimide was obtained. The polyimide powder is dissolved in 73g gamma-butyrolactone to obtain a polyimide solution with a solid content of 20wt%, and the polyimide solution is spread on a flat plate, followed by drying at 80°C for 2 hours, and then drying a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com