Industrial synthesis method and application of high-fluidity polyether ether ketone resin

A polyetheretherketone resin, high fluidity technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of restricting the use and processing of polyetheretherketone coatings, increasing product raw materials, and uncontrollable processes, and achieving molecular weight distribution. Narrow range, good capping effect, and weak side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

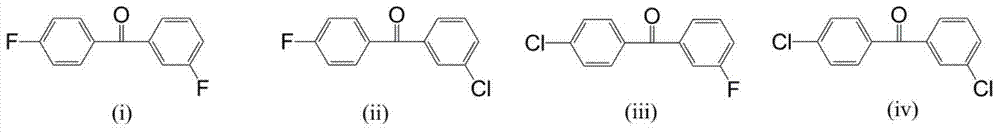

Image

Examples

Embodiment 1

[0028] In a nitrogen-protected 200-liter stainless steel reaction kettle equipped with a high-efficiency stirrer, first add 90.00Kg of diphenyl sulfone, 30.00Kg of 4,4'-difluorobenzophenone and 16.00Kg of sodium carbonate, then start stirring, and heat up to 135°C After the monomers are completely dissolved, add 14.00Kg of hydroquinone to the system, continue stirring evenly, then raise the temperature to 200°C, react for 1.5 hours, then raise the temperature to 250°C, react for 1 hour, then raise the temperature to 275°C, react After 1 hour, heat up to 315°C, polymerize for 2 hours, add 1.10Kg of 3,4'-difluorobenzophenone, and continue the reaction for 20 minutes to obtain polymerized slime; cool the polymerized slime with water and pulverize it into powder, and filter Add ethanol to the powder and boil it under reflux for 1 hour, repeat this 10 times, then boil it with deionized water for 1 hour, repeat this 10 times until the chloride ion content in the water is below 5ppm, ...

Embodiment 2

[0033] In a nitrogen-protected 200-liter stainless steel reaction kettle equipped with a high-efficiency stirrer, first add 90.00Kg of diphenyl sulfone, 30.00Kg of 4,4'-difluorobenzophenone and 16.00Kg of sodium carbonate, then start stirring, and heat up to 135°C After the monomers are completely dissolved, add 14.00Kg of hydroquinone to the system, continue stirring evenly, then raise the temperature to 200°C, react for 1.5 hours, then raise the temperature to 250°C, react for 1 hour, then raise the temperature to 275°C, react After 1 hour, raise the temperature to 315°C, polymerize for 2 hours, add 832g of 3,4'-difluorobenzophenone, and continue the reaction for 20 minutes to obtain a polymerized slime; cool the polymerized slime with water and pulverize it into powder, and filter the Add ethanol to the powder and boil under reflux for 1 hour, repeat this 10 times, then boil with deionized water for 1 hour, repeat this 10 times until the chloride ion content in the water is ...

Embodiment 3

[0038]In a nitrogen-protected 200-liter stainless steel reaction kettle equipped with a high-efficiency stirrer, first add 90.00Kg of diphenyl sulfone, 30.00Kg of 4,4'-difluorobenzophenone and 16.00Kg of sodium carbonate, then start stirring, and heat up to 135°C After the monomers are completely dissolved, add 14.00Kg of hydroquinone to the system, continue stirring evenly, then raise the temperature to 200°C, react for 1.5 hours, then raise the temperature to 250°C, react for 1 hour, then raise the temperature to 275°C, react After 1 hour, raise the temperature to 315°C, polymerize for 2 hours, add 1.387Kg of 3,4'-difluorobenzophenone, and continue the reaction for 20 minutes to obtain a polymerized slime; cool the polymerized slime with water and pulverize it into powder, and filter the Add ethanol to the powder and boil it under reflux for 1 hour, repeat this 10 times, then boil it with deionized water for 1 hour, repeat this 10 times until the chloride ion content in the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com