A kind of industrial synthesis method of end-capped dendritic polyaryl ether sulfone resin with high thermal stability

A high thermal stability, polyaryl ether sulfone technology, applied in the field of polymer materials, can solve the problems of low impact strength of light-transmitting resin, low light transmittance of polyether sulfone, and shortening the service life of plastics, etc. The effect of viscosity, saving purchasing cost and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

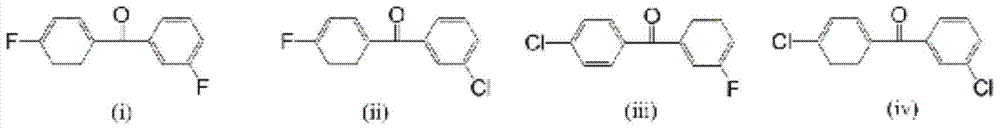

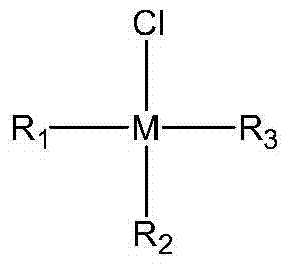

[0035]In a 200L stainless steel reaction kettle equipped with a nitrogen pipe, a condensing separator and a high-efficiency stirrer, first add 110.00KG sulfolane, then start stirring and raise the temperature to 80°C, and then add 25.30KG 4,4′-dichlorodiphenylsulfone in sequence , 16.80KG 4,4′-biphenyldiphenol, after the monomers are completely dissolved, add 10.50KG sodium carbonate to the system when the temperature rises to 100°C, then add 10.0 liters of mesitylene, and continue stirring to raise the temperature to 200°C , the salt-forming reaction begins, the water generated in the system azeotropes with mesitylene, cooling water begins to drip from the condenser tube, and layers are separated in the water separator. Minutes to ensure the complete salt formation reaction, the salt formation stage is 1 hour, after the salt formation is completed, the temperature is raised to 230°C, and the temperature is maintained for 1.5 hours, and 174.0g 3,4'-difluorobenzophenone and 30.0...

Embodiment 2

[0038] Same as Example 1, except that 3-fluoro-4-chlorobenzophenone replaces 3,4'-difluorobenzophenone, methyltrichlorosilane replaces phenyltrichlorosilane, and tetramethylbenzene replaces mesitylene, Other conditions are the same.

[0039] The obtained PPSU resin melt index MI=28.0g / 10min (365.0°C, 5KG).

Embodiment 3

[0041] Same as Example 1, except that 3-chloro-4-fluorobenzophenone replaces 3,4'-difluorobenzophenone, and phenyltrichloromethane replaces phenyltrichlorosilane, other conditions are the same.

[0042] The obtained PPSU resin melt index MI=20.0g / 10min (365.0°C, 5KG).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com