Anti-counterfeiting heat-sensitive paper and method for producing same

A thermal paper, base paper layer technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of increased process and increased energy consumption, and achieve the effect of excellent color development performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

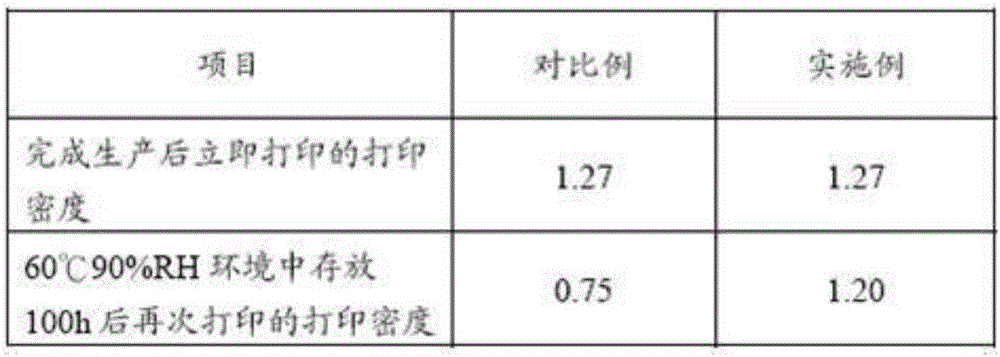

Examples

Embodiment 1

[0023] An anti-counterfeiting thermal paper, comprising a base paper layer, a precoat layer coated on the base paper layer, and a top coat layer and a protective layer formed on the surface of the precoat layer;

[0024] The precoat layer contains fillers, adhesives and color developers, wherein the mass ratio of fillers, adhesives and color developers is 100:5-35:1-15, and the fillers are light calcium carbonate, silicon dioxide, calcined At least one of kaolin, flaky clay and hollow plastic pigment; the adhesive is at least one of styrene-butadiene latex, styrene acrylic resin, starch, polyvinyl alcohol and acrylic resin; the color developer is bisphenol A and 4 , at least one of 4′-dihydroxydiphenylsulfone,

[0025] The composition of the top coat is: 10-40 parts of filler, 10-25 parts of adhesive, 15-45 parts of developer solution, 15-40 parts of sensitizer solution, 5-25 parts of leuco dye solution, 5-15 parts of lubricant; 10-40 parts of oxidizing agent, 10-40 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com