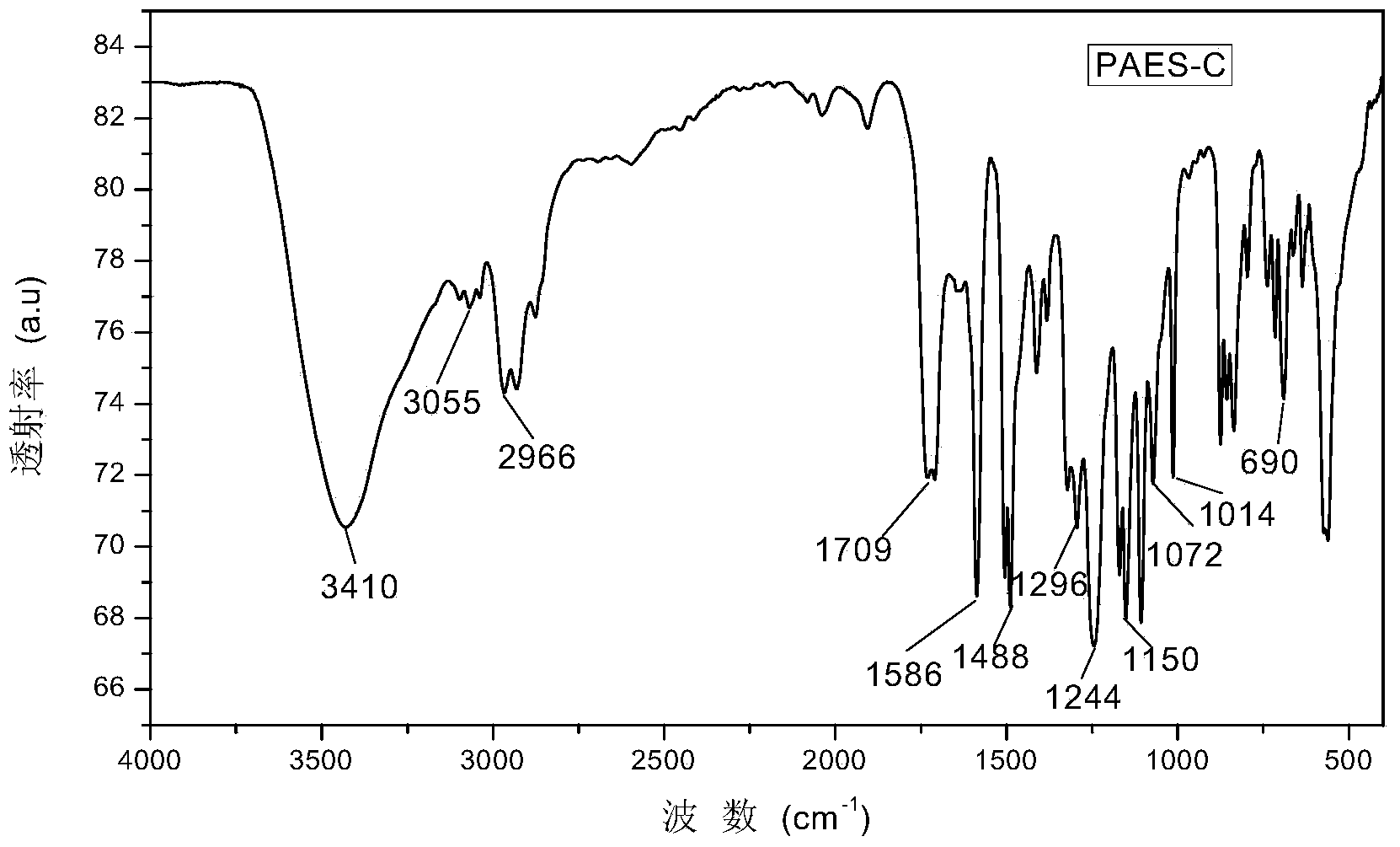

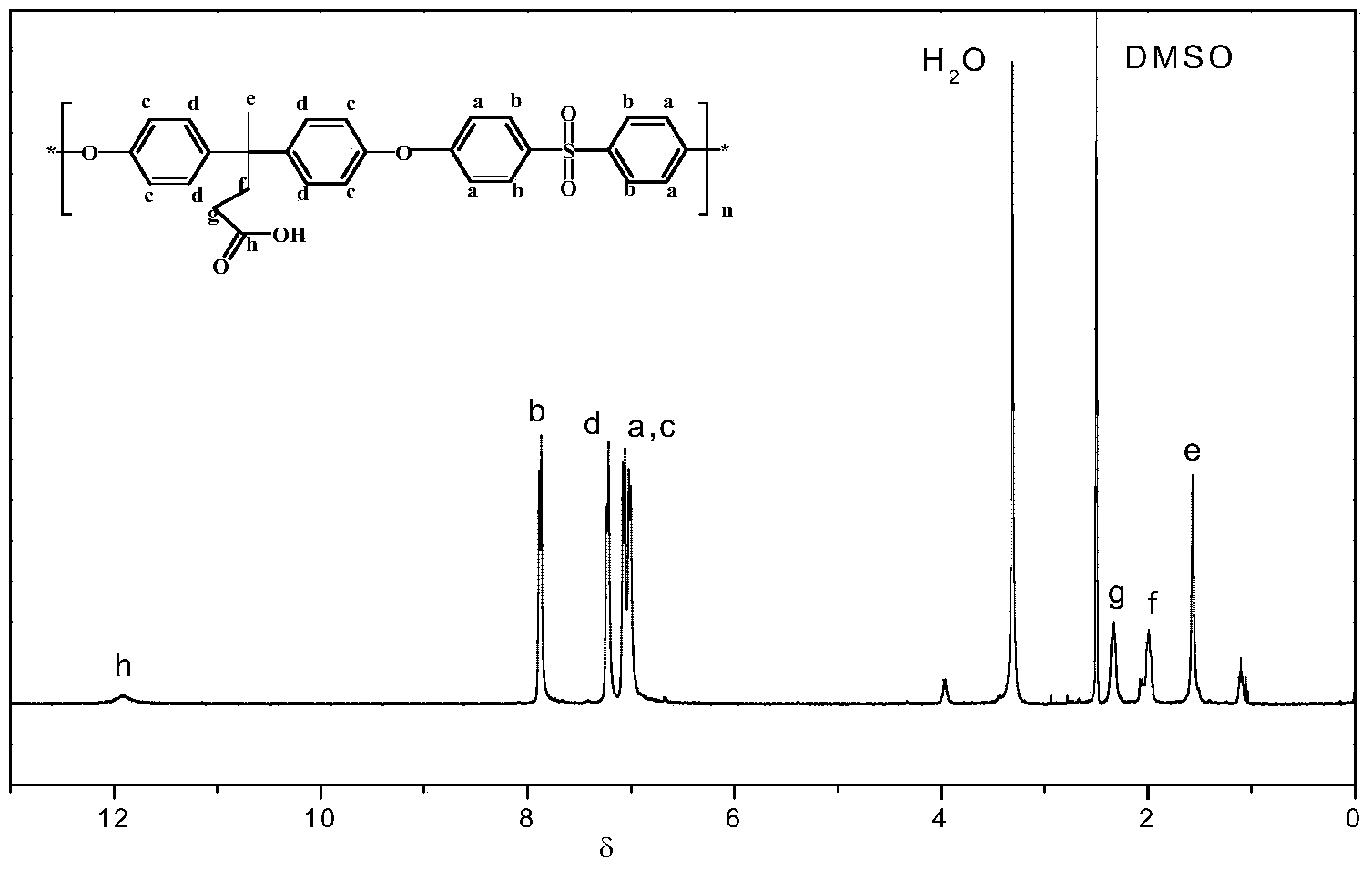

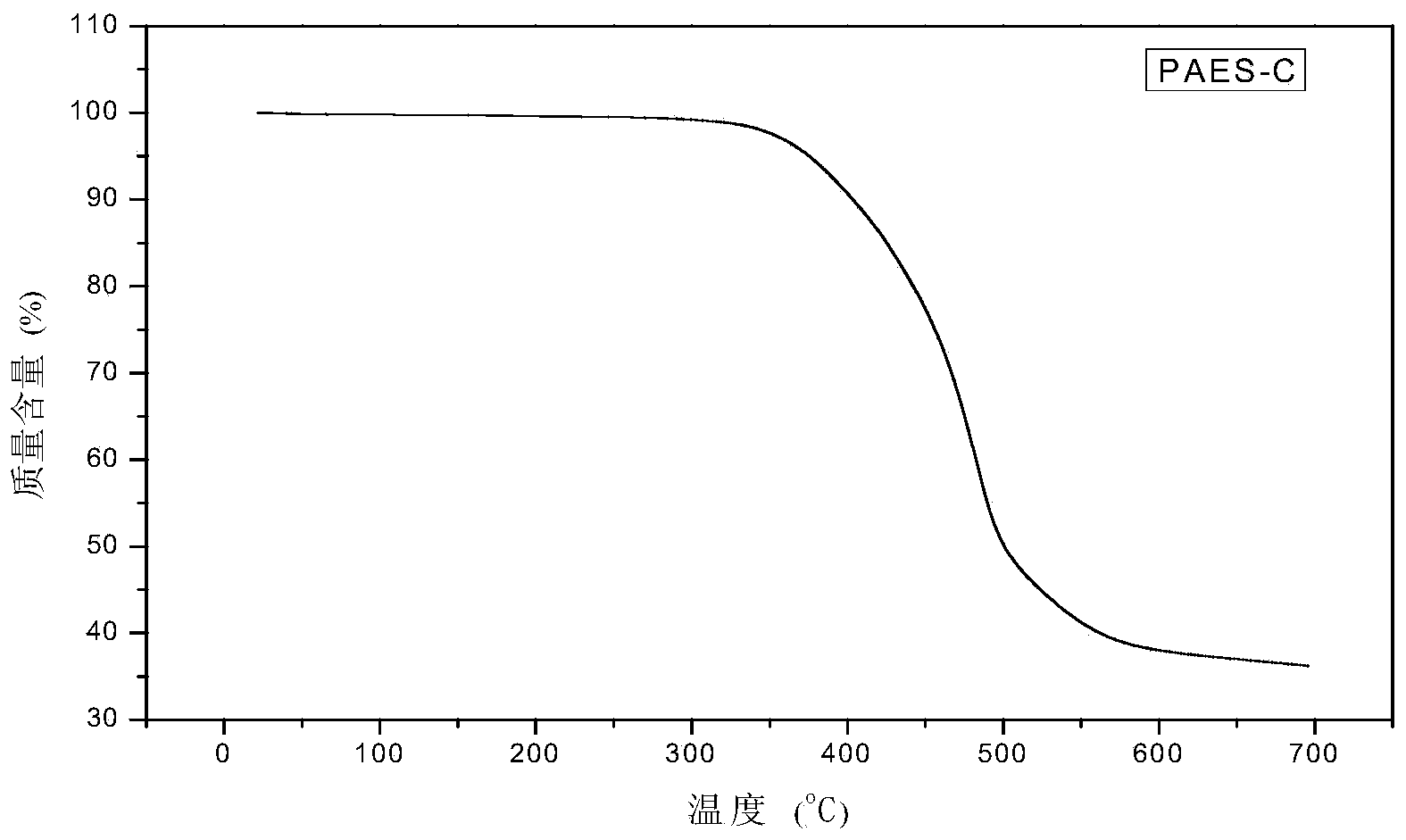

Preparation method and application of high molecular weight polyether sulphone polymer with side group containing carboxyl

A high molecular weight, polyaryl ether sulfone technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of low polymer molecular weight, difficulty in obtaining high molecular weight polymers, etc. High molecular weight, excellent mechanical properties, overcoming the effect of low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]In a four-necked flask with a stirrer, a thermometer, a reflux condensing device, a water separator, and a nitrogen pipe, under the protection of nitrogen, mix 1.4316g of bisphenolic acid, 1.0365g of anhydrous potassium carbonate, and 0.14g of potassium hydroxide . 5mL of toluene, then raised the temperature to 150°C for 2.5h of water separation, after the completion of water separation, raised the temperature to 175°C at a rate of 2min / °C for 18h of polycondensation reaction, collected the precipitate at room temperature and added THF / hydrochloric acid (volume ratio 5: 4) Dilute the mixed solution, add 5 times the volume of the diluted solution with 100°C deionized water for sedimentation, and wash the sediment repeatedly with 100°C deionized water to obtain a nearly white polymer; then dissolve the polymer in tetrahydrofuran to obtain a polymer To the solution, add hot ethanol with 15 times the volume of the polymer solution, stir, filter, collect the filter cake, add ...

Embodiment 2

[0035] In a four-necked flask with a stirrer, a thermometer, a reflux condensing device, a water separator, and a nitrogen pipe, under the protection of nitrogen, mix 1.4316g of bisphenolic acid, 1.0365g of anhydrous potassium carbonate, and 0.14g of potassium hydroxide , 10mL DMSO, 10mL DMAC and 10mL toluene were added to a 100mL reaction flask, reacted at room temperature for 3 hours, raised the temperature to 145°C to start water separation, after the water separation was completed, cooled to room temperature and added 1.4358g 4,4'-dichlorodiphenyl sulfone and 5mL Toluene, then raise the temperature to 150°C for 2.5 hours of water separation, after the completion of water separation, increase the temperature at a rate of 2min / °C to 175°C for 15 hours of polycondensation reaction, collect the precipitate at room temperature and add tetrahydrofuran / hydrochloric acid (5 / 4) to mix Dilute with liquid, add 5 times the volume of the diluent in 100°C deionized water for sedimentatio...

Embodiment 3

[0037] In a four-necked flask with a stirrer, a thermometer, a reflux condensing device, a water separator, and a nitrogen pipe, under the protection of nitrogen, mix 1.4316g of bisphenolic acid, 1.3821g of anhydrous potassium carbonate, and 0.28g of potassium hydroxide , 10mL DMSO, and 10mL DMAC were added to a 250mL reaction flask. After 2.5 hours of reaction at room temperature, 15mL of toluene was added and the temperature was raised to 150°C to start water separation. and 5mL of toluene, and then heated up to 150°C for 2.5h of water separation. After the water separation was completed, the temperature was raised to 175°C at a rate of 2min / °C for 9h of polycondensation reaction. The precipitate was collected at room temperature and added with tetrahydrofuran / hydrochloric acid (5 / 4 ) to dilute the mixed solution, add 5 times the volume of the diluted solution to settle with 100°C deionized water, and the sediment was washed repeatedly with 100°C deionized water to obtain a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com