Polyether ketone resin and method for preparing same by polymerization termination

A technology of polymerization termination and polyether ketone, which is applied in the field of preparation of new polyether ketone resin and its polymerization termination, can solve the problems of difficulty in controlling the melt index of the final product, fast polymerization reaction speed, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

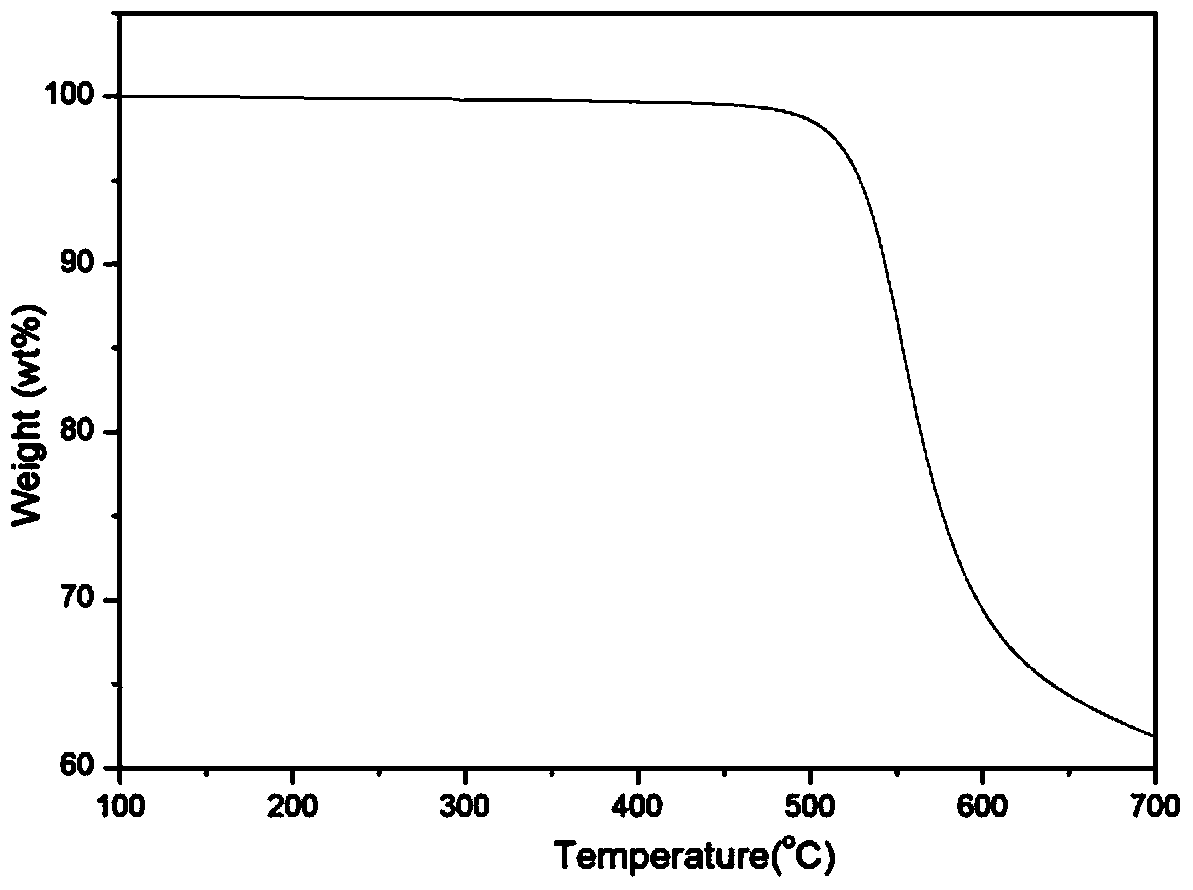

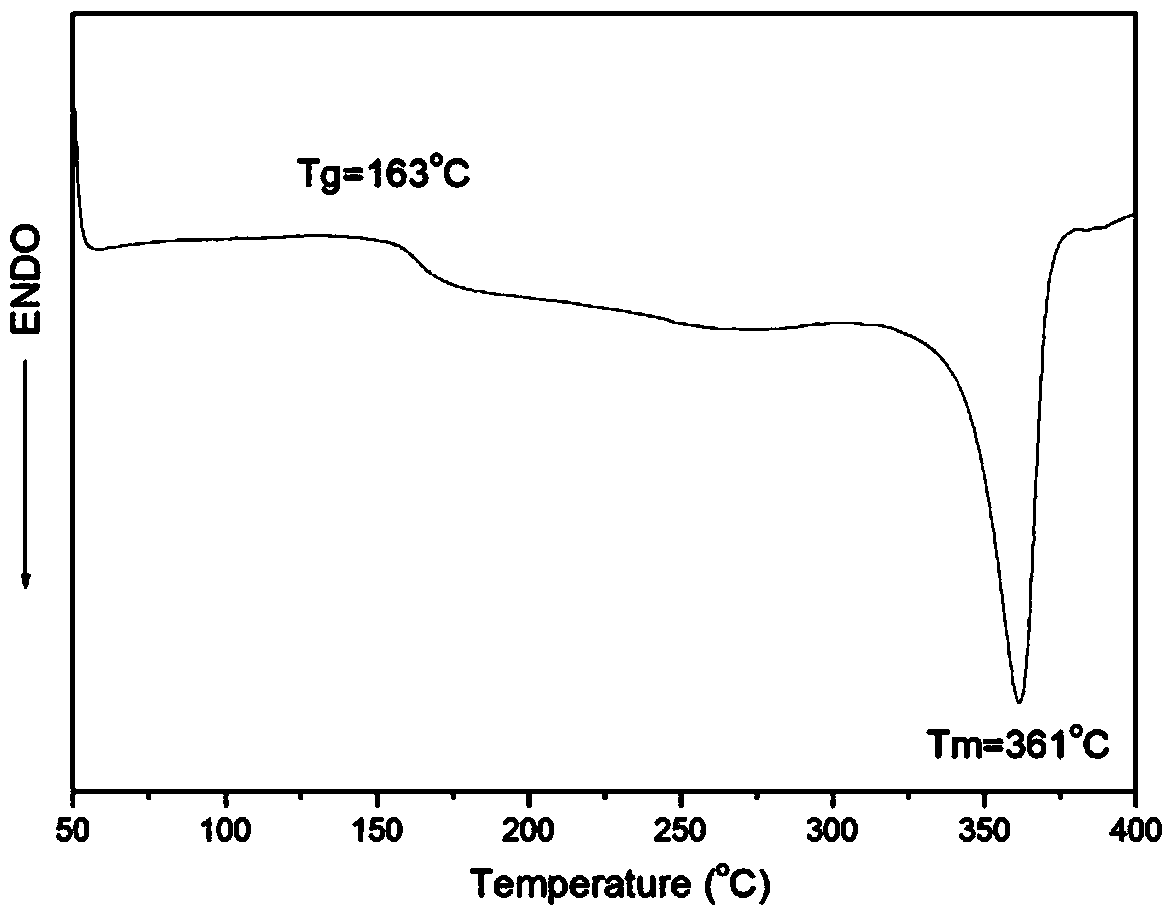

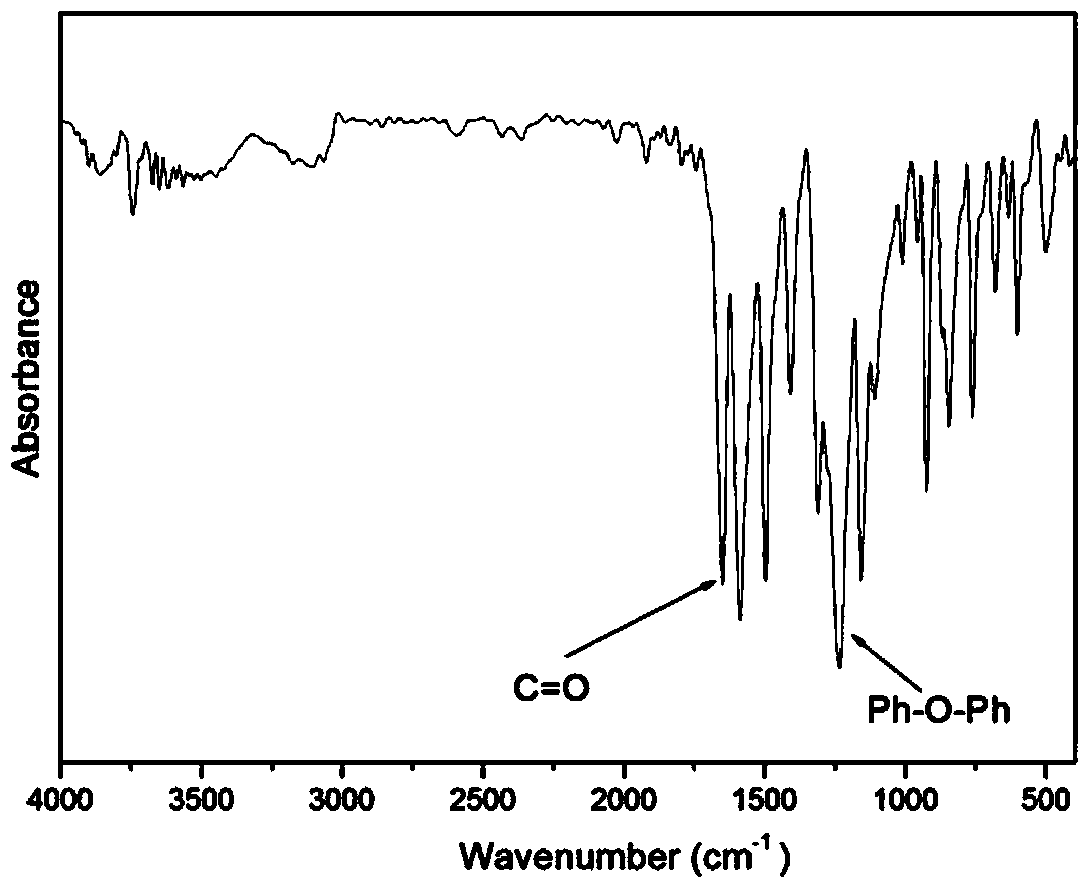

[0024] Add 134.00 g of diphenyl sulfone into a three-necked flask equipped with mechanical stirring and a thermometer, protect it with nitrogen, heat to 160°C, add 44.47 g of 4,4'-difluorodiphenyl ketone, 1.41 g of anhydrous potassium carbonate and anhydrous 25.23g of sodium carbonate water, then heated to 165°C, added 42.84g of p-4,4'-dihydroxybenzophenone, continued to heat to 200°C for 1 hour, gradually raised the temperature to 250°C for 35 minutes, and then reacted for 1 hour at 280°C hours, and finally heated to 320 ° C for 4 hours. A mixture of 0.22 g of phenol and 5 g of diphenylsulfone was then added. After continuing the reaction for 10 minutes, it can be found that the viscosity of the reaction solution no longer increases with the reaction time, which proves that the monophenolic compound can effectively terminate the polymerization reaction. After continuing the reaction for 30 minutes, the product was poured into water. Crush and filter the product with a pulve...

Embodiment 2

[0026] Just change "add the mixture of 0.22g phenol and 5g diphenyl sulfone" in Example 1 to "add the mixture of 0.30g phenol and 5g diphenyl sulfone", and the rest are the same as the method in embodiment 1, and can also obtain the present invention. Polyether ketone ketone polymer. The melt index of the test material is 42g (melt index meter, 400°C, 5 kg pressure). Since the reaction of Example 2 is exactly the same as that of Example 1, only the amount of phenol input at the end of the reaction is different, which proves that the monophenolic compound can break the polyether ketone chain and reduce the molecular weight of the resin. The thermal performance of the material is the same as that of Example 1.

Embodiment 3

[0028] Just change "add the mixture of 0.22g phenol and 5g diphenyl sulfone" in Example 1 to "add 0.22g of phenol", and the rest are the same as the method in Example 1, and the polyether ketone ketone polymer of the present invention can also be obtained . The melt index of the test material is 25g (melt index meter, 400° C., 5 kg pressure), which proves that the monophenolic compound regulates the molecular weight of the resin. The thermal performance of the material is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com