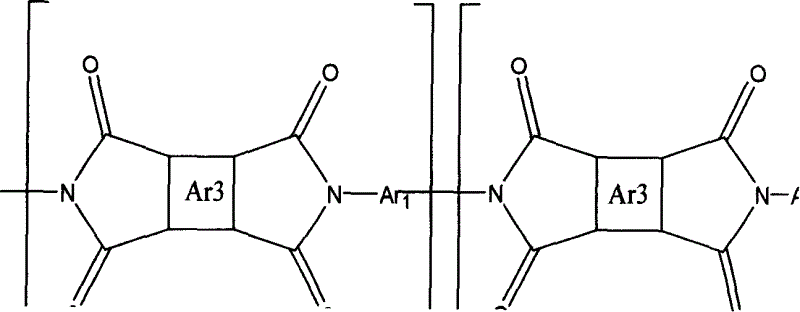

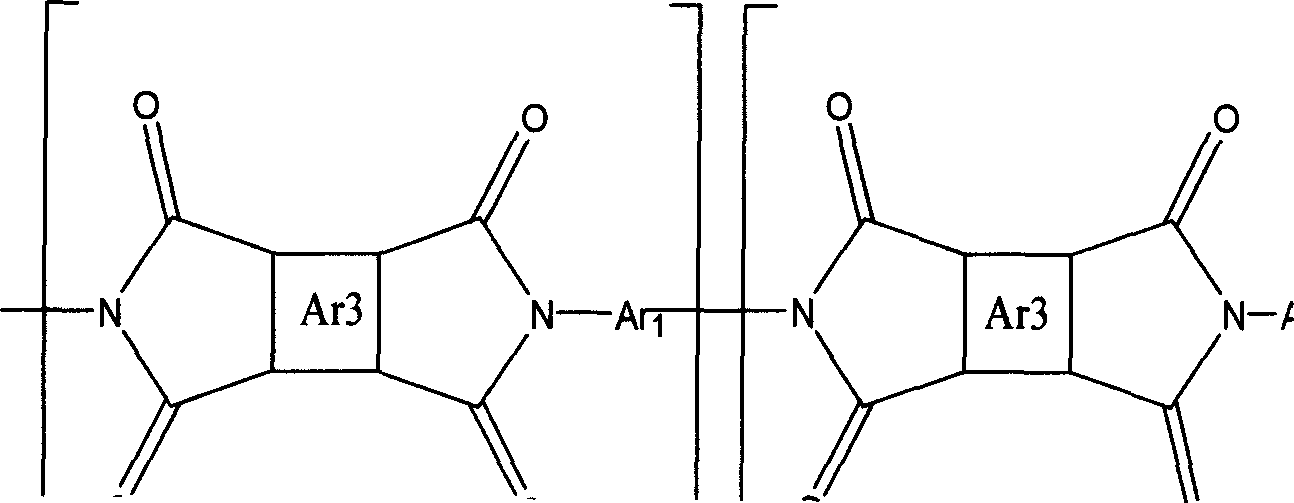

Process for preparing water base developing photosensitive polyimide material

A photosensitive polyimide and water-based technology, which is applied in the field of preparation of water-based developing photosensitive polyimide materials, can solve the problems of poor heat resistance, poor glue stability, poor degree of amination, etc., and achieves high sensitivity performance, good film formation and the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 6.44g of refined BTDA (0.020 mole) in 25ml of N-dimethylacetamide, add 1.28g of methanol (0.040 mole) under stirring, react at room temperature for 8 hours, and then add 4.76g of refined thionyl chloride (0.040 mole) , reacted at room temperature for another 5 hours, and added 5.21 HDMMDA (0.020 mol) at a low temperature of -10° C. to obtain a polyamic acid resin solution.

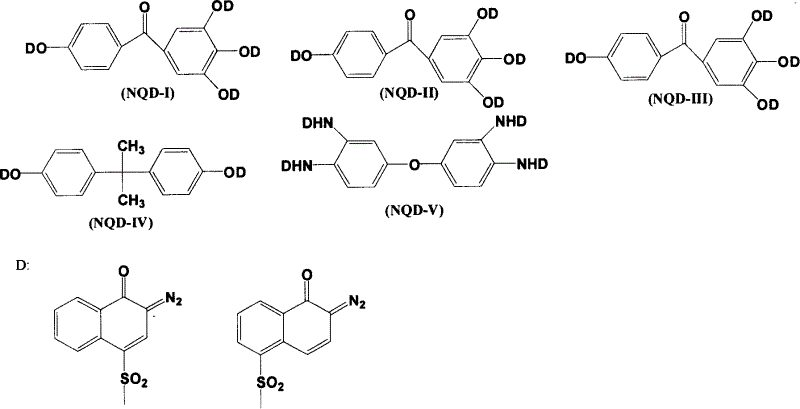

[0029] The above polyamic acid resin was immersed in ethanol, filtered, soaked twice with deionized water and absolute ethanol, and dried naturally. Then the dried resin was dissolved in a mixed solvent with a volume ratio of N-methylpyrrolidone / γ-butyrolactone of 2:1, and 1.5 g of NQD-I derivative was added to form a 20% polyamic acid resin solution.

[0030] The above polyamic acid resin solution was coated on a polished silicon wafer by spin coating, dried at 80°C for 20 minutes, then exposed to ultraviolet light at 365nm (i-line) to 436nm (g-line) for 4 minutes, and oxidized in 1% hydro...

Embodiment 2

[0032] Dissolve 5.88g of refined BPDA (0.02 mole) in 36ml of dimethylacetamide, add 1.84g of ethanol (0.04 mole) under stirring, react at room temperature for 10 hours, then add refined thionyl chloride 4.76g (0.040 mole), React at room temperature for another 6 hr, then add 2.44 g of HOTOL (0.01 mol) and 2.00 g of ODA (0.01 mol) at a low temperature of -15° C., and react for 5 hr to obtain a polyamic acid resin solution.

[0033] The above-mentioned polyamic acid resin was immersed in ethanol, filtered, soaked with deionized water and absolute ethanol for 3 times, and dried naturally. Then the dried resin is dissolved in a mixed solvent with a volume ratio of N-methylpyrrolidone / ethylene glycol monobutyl ether of 2:1, and 1.8 g of NQD-II derivatives are added to form a 20% polyamic acid resin solution

[0034] The above polyamic acid resin solution was coated on a polished silicon wafer by spin coating, dried at 80° C. for 20 minutes, and then exposed to ultraviolet light of ...

Embodiment 3

[0036]Dissolve refined 3.6g PMDA (0.020 mole) in 70ml N-methylpyrrolidone, add 2.40g propanol (0.040 mole) under stirring, react at room temperature for 8 hours, then add refined thionyl chloride 4.76g (0.040 mole) , react at room temperature for another 6 hr, then add 2.44 g of HOTOL (0.01 mol) and 2.00 g of ODA (0.01 mol) at a low temperature of -20° C., and react for 5 hr to obtain a polyamic acid resin solution.

[0037] The above-mentioned polyamic acid resin was immersed in ethanol, filtered, soaked with deionized water and absolute ethanol for 3 times, and dried naturally. Then the dried resin is dissolved in a mixed solvent with a volume ratio of N-methylpyrrolidone / ethylene glycol monobutyl ether of 2:1, and 1.4 g of NQD-III derivatives are added to form a 20% polyamic acid resin solution

[0038] The above polyamic acid resin solution was coated on a polished silicon wafer by spin coating, dried at 80° C. for 20 minutes, and then exposed to ultraviolet light of 365 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com