Photosensitive resist for thermosensitive positive CTP plate, and preparation method thereof

A heat-sensitive positive image and photosensitive adhesive technology, which is applied in the field of photosensitive adhesive of heat-sensitive positive image CTP plate and its preparation, can solve the problems of poor photosensitive performance and development resistance, decreased adhesion, low sensitivity, etc., and achieves improved sensitivity. performance, improved viscosity, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment is cement, and the preparation method of described cement is as follows:

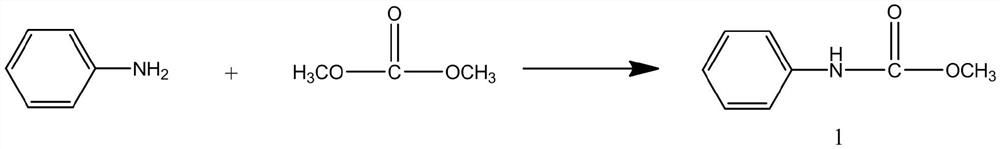

[0048] S1: Add dimethyl carbonate, aniline and anhydrous zinc acetate into a four-necked flask equipped with a stirrer and a condensing reflux tube, heat to boiling and reflux for 6 hours, cool to room temperature after the reaction, and vacuum filter the reaction product , the filtrate was distilled under reduced pressure to precipitate crystals, the crystals were washed twice with deionized water, placed in a vacuum drying oven, and dried to a constant weight at a temperature of 30°C to obtain intermediate 1; The dosage ratio of methyl ester, aniline and anhydrous zinc acetate is 30mL: 6mL: 0.3g;

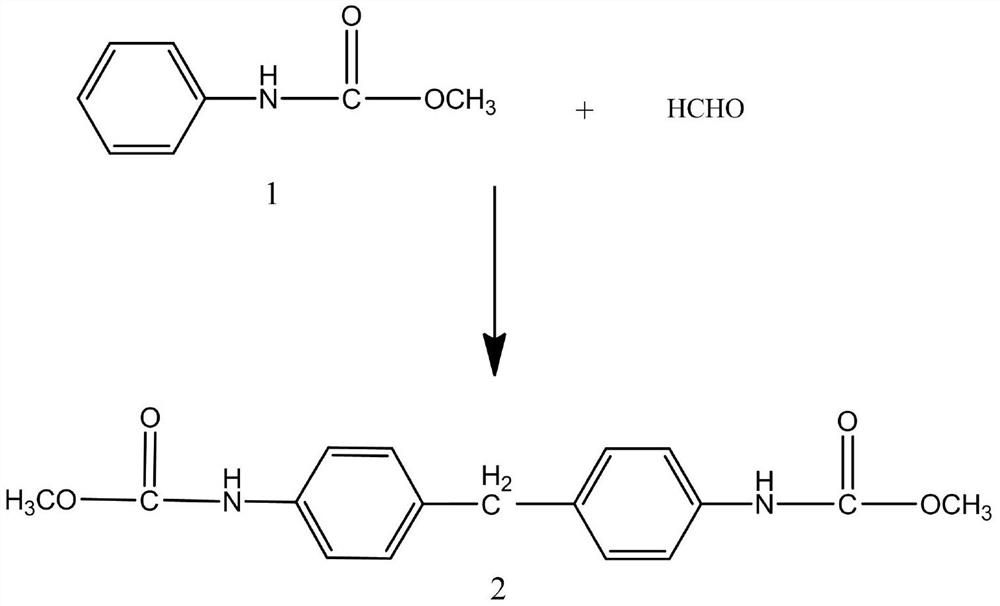

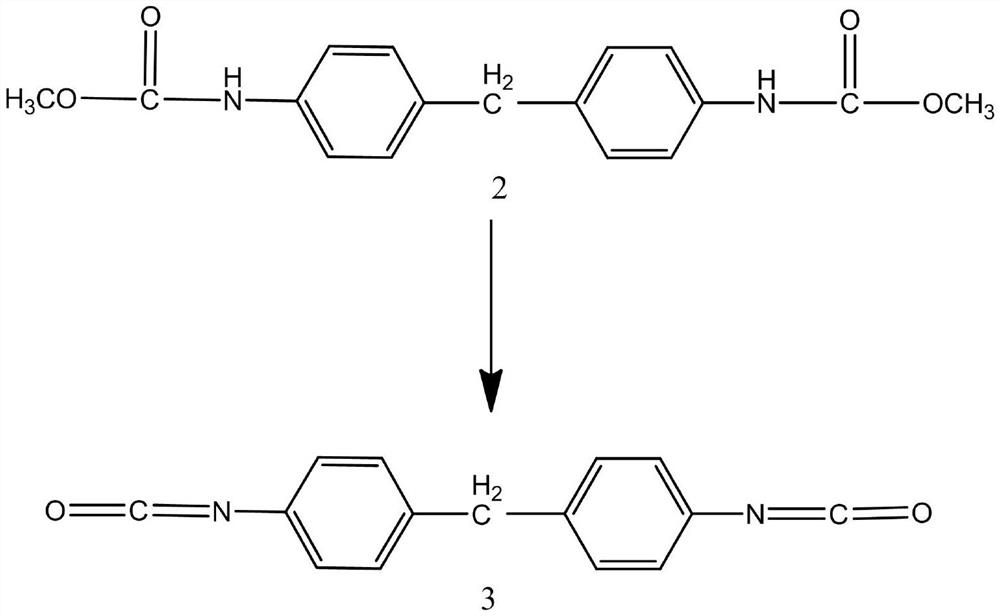

[0049] S2: Add intermediate 1 and hydrochloric acid solution into a four-necked flask equipped with a stirrer and a condensing reflux tube, heat up to 80°C, control the heating rate at 1°C / min, then add formaldehyde solution, and then stir at a speed of Under the condition of ...

Embodiment 2

[0053] The present embodiment is cement, and the preparation method of described cement is as follows:

[0054] S1: Add dimethyl carbonate, aniline and anhydrous zinc acetate into a four-necked flask equipped with a stirrer and a condensing reflux tube, heat to boiling and reflux for 8 hours, cool to room temperature after the reaction, and vacuum filter the reaction product , the filtrate was distilled under reduced pressure to precipitate crystals, the crystals were washed 3 times with deionized water, placed in a vacuum drying oven, and dried to a constant weight at a temperature of 40°C to obtain intermediate 1; The dosage ratio of methyl ester, aniline and anhydrous zinc acetate is 30mL: 6mL: 0.3g;

[0055] S2: Add intermediate 1 and hydrochloric acid solution into a four-necked flask equipped with a stirrer and a condensing reflux tube, heat up to 80°C, control the heating rate to 3°C / min, then add formaldehyde solution, and then stir at a speed of React at a constant t...

Embodiment 3

[0059] This embodiment is a method for preparing a photosensitive adhesive for a thermal positive CTP plate, comprising the following steps:

[0060] Step 1, preparation of infrared absorber:

[0061] A1. Preparation of aqueous dispersion: Add sodium polystyrene sulfonate and water into the reaction kettle and stir to dissolve, add 3,4-ethylenedioxythiophene, ferric chloride and potassium persulfate under stirring conditions, and dissolve at 60°C Undergo reaction 1h, obtain water dispersion liquid, standby;

[0062] A2. Preparation of infrared light absorber: add the water dispersion into the dispersing bucket, add nanometer metal oxide, and disperse with ultrasonic waves to obtain the infrared light absorber evenly, and set aside;

[0063] Step two, glue preparation:

[0064] Add matrix resin, film-forming resin, and binder from Example 1 into the reactor, heat to 80°C, stir at 800r / min, and add initiator, antioxidant, solubilizer, stabilizer, The chemical reaction between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com