Fire retardant PC/ABS alloy material without halide and phosphate and its prepn process

A technology of alloy materials and flame retardants, which is applied in the field of halogen-free and phosphorus-free flame-retardant PC/ABS alloy materials and its preparation, can solve the problems of environmental pollution and non-environmental protection, and achieve the effect of moderate cost and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

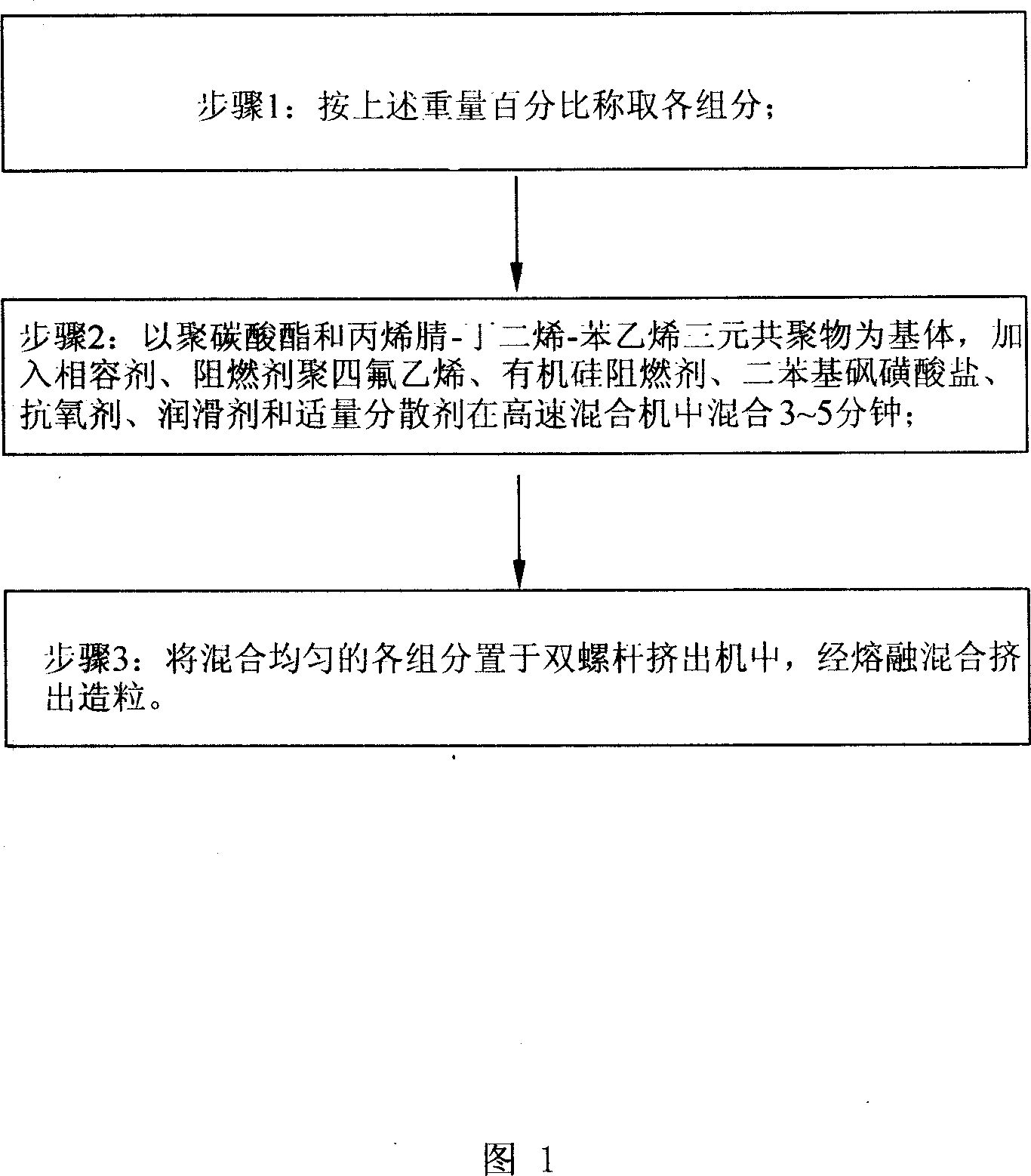

Method used

Image

Examples

Embodiment 1

[0034] By weight percentage, resin polycarbonate (PC) 91.2%, acrylonitrile-butadiene-styrene terpolymer (ABS) 6.0%, compatibilizer (SMA) 1.0%, flame retardant PTFE 0.3%, Silicone flame retardant 1.0%, diphenyl sulfone sulfonate KSS 0.1%, antioxidant tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester 0.05%; Antioxidant (2,4 di-tert-butylphenyl) phosphite triester is 0.05%, lubricant ethylene bis stearamide (EBS) 0.2%, mix in high-speed mixer for 4 minutes;

[0035] Put the homogeneously mixed components in a twin-screw extruder, melt, mix, extrude and granulate;

[0036] Twin-screw extruder Zone 1 temperature: 230~235℃, Zone 2 temperature: 240~245℃, Zone 3 temperature: 250~255℃, Zone 4 temperature: 250~260℃, Zone 5 temperature: 240~245℃, Six zone temperature: 230~235℃, residence time 1-2 minutes, host speed: 300-350rpm.

Embodiment 2

[0038] By weight percentage, resin polycarbonate (PC) 87.0%, acrylonitrile-butadiene-styrene terpolymer (ABS) 7.0%, compatibilizer (SMA) 3.0%, flame retardant PTFE 0.5%, Silicone flame retardant 1.5%, diphenyl sulfone sulfonate KSS 0.5%, antioxidant tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester 0.1%; antioxidant (2,4 di-tert-butylphenyl) phosphite triester is 0.1%; lubricant ethylene bis stearamide (EBS) 0.3%, mixed in a high-speed mixer for 4 minutes;

[0039] Put the homogeneously mixed components in a twin-screw extruder, melt, mix, extrude and granulate;

[0040]Twin-screw extruder Zone 1 temperature: 230~235℃, Zone 2 temperature: 240~245℃, Zone 3 temperature: 250~255℃, Zone 4 temperature: 250~260℃, Zone 5 temperature: 240~245℃, Six-zone temperature: 230-235°C, residence time 1-2 minutes, host speed: 300-350rpm.

Embodiment 3

[0042] By weight percentage, resin polycarbonate (PC) 83.5%, acrylonitrile-butadiene-styrene terpolymer (ABS) 9.4%, compatibilizer (SMA) 3.0%, flame retardant PTFE 0.6%, Silicone flame retardant 2.5%, diphenyl sulfone sulfonate KSS 0.5%, antioxidant tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester 0.1%; antioxidant (2,4 di-tert-butylphenyl) phosphite triester is 0.1%; lubricant ethylene bis stearamide (EBS) 0.3%, mixed in a high-speed mixer for 4 minutes;

[0043] The uniformly mixed raw materials are placed in a twin-screw extruder, melted, mixed, extruded and granulated;

[0044] Twin-screw extruder Zone 1 temperature: 230~235℃, Zone 2 temperature: 240~245℃, Zone 3 temperature: 250~255℃, Zone 4 temperature: 250~260℃, Zone 5 temperature: 240~245℃, Six-zone temperature: 230-235°C, residence time 1-2 minutes, host speed: 300-350rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com