Patents

Literature

53results about How to "Guarantee environmental requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

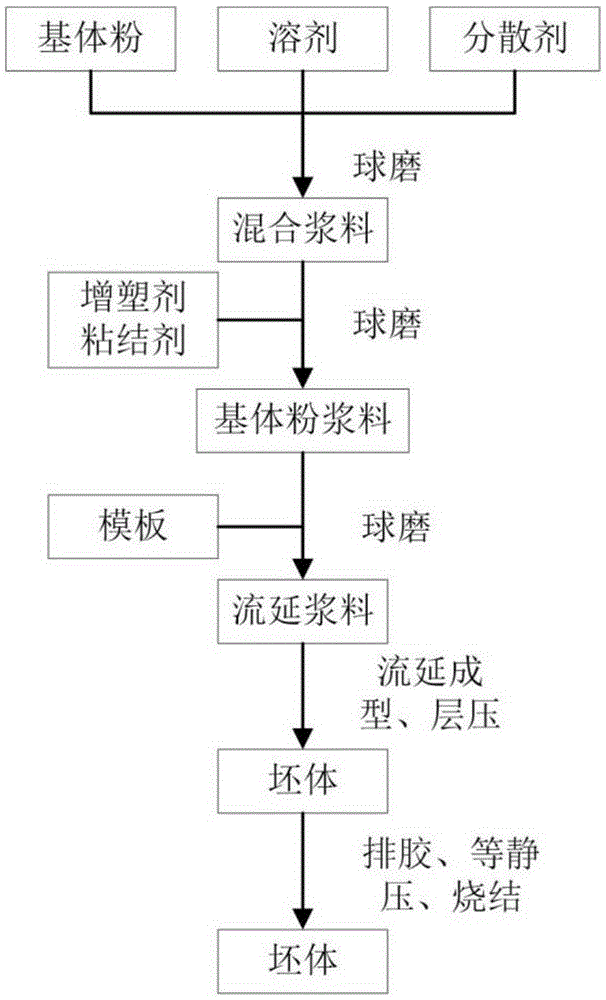

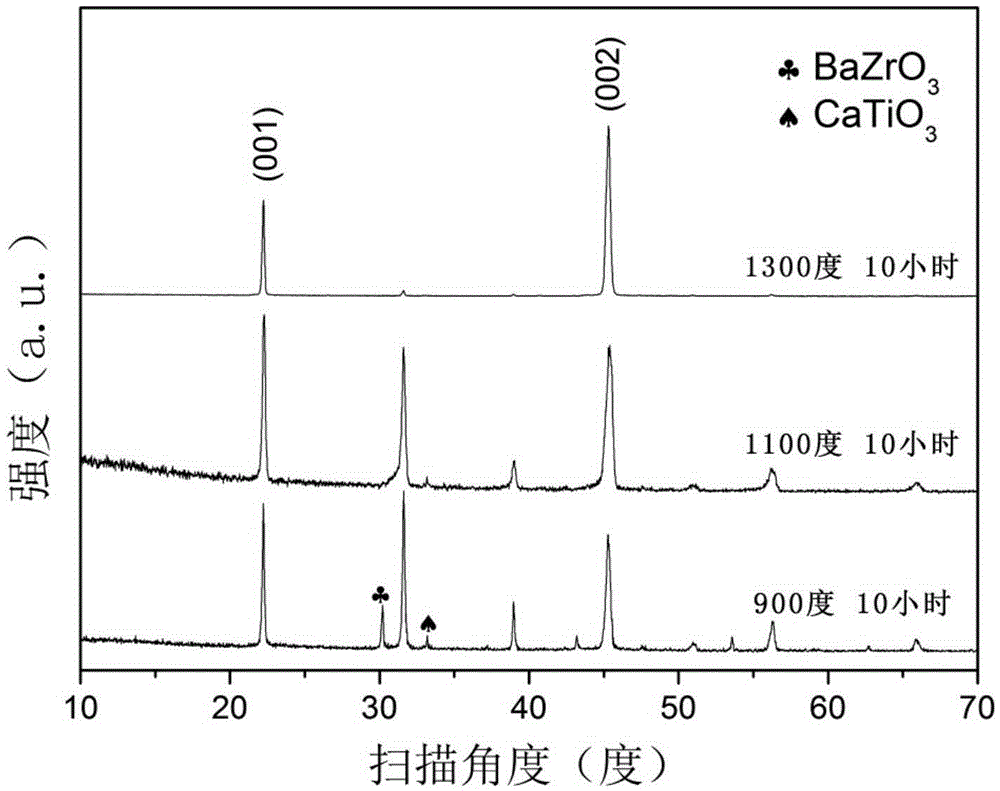

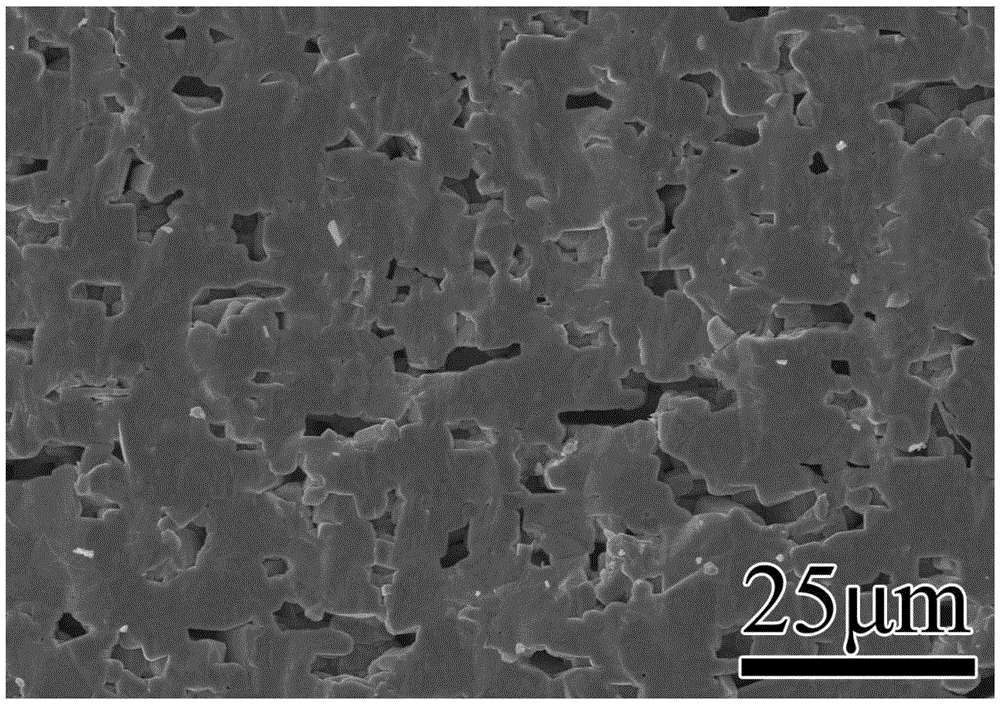

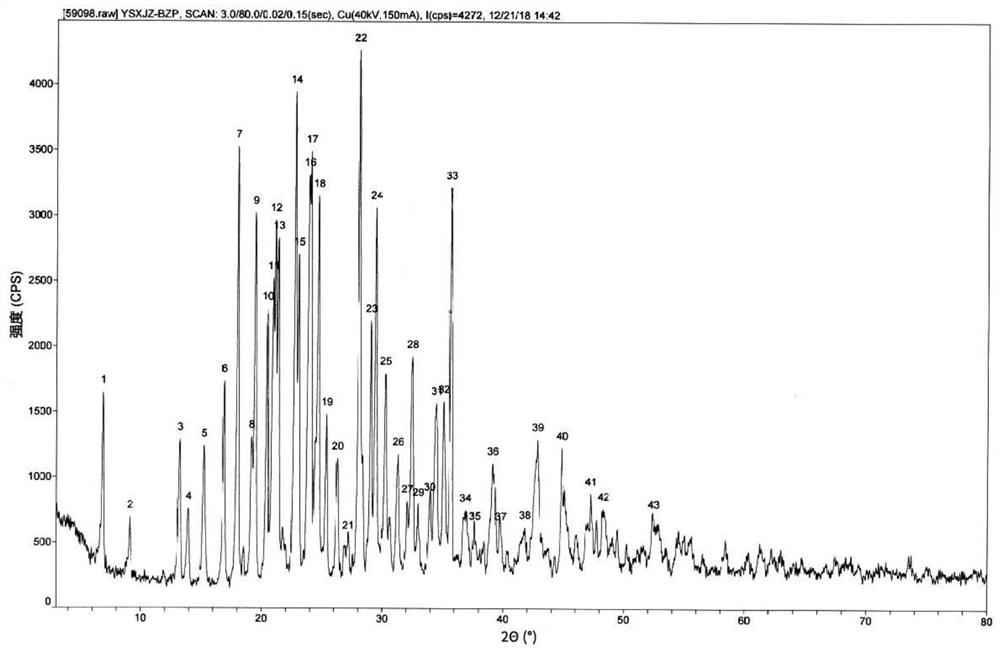

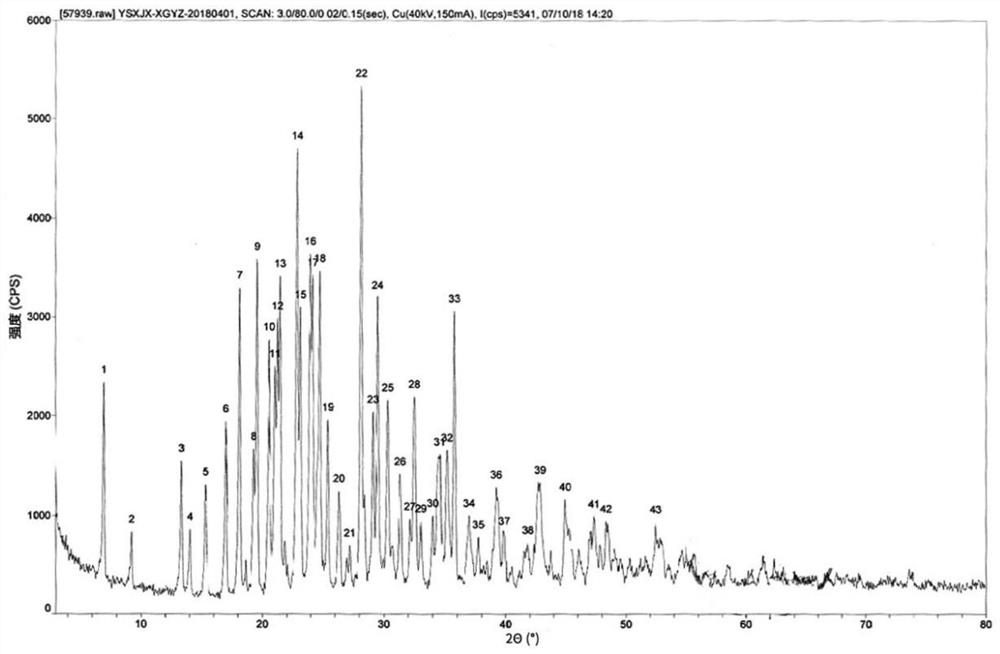

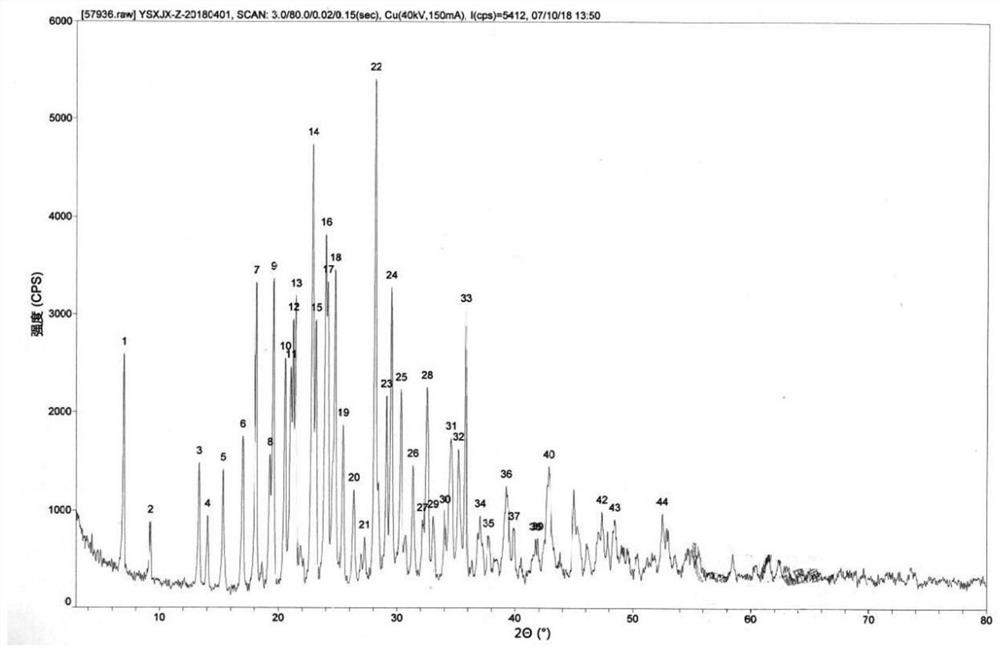

Preparation method of barium calcium zirconate titanate lead-free piezoelectric textured ceramic

The invention relates to a preparation method of a barium calcium zirconate titanate lead-free piezoelectric textured ceramic. The composition of the barium calcium zirconate titanate lead-free piezoelectric textured ceramic is Ba0.85Ca0.15Ti0.90Zr0.10O3. During preparation, no lead oxide is used, and the environmental requirement can be guaranteed to the utmost extent; and compared with the ceramic with the same components prepared in the prior art, XRD (X-ray diffraction) characterization proves that crystal particles of the ceramic are arranged along the <001> direction, so that a material can fully utilize the anisotropy of a piezoelectric material, the piezoelectric coefficient of the material is improved, the texture degree of the material is as high as 96%, and the piezoelectric constant of the material can be more than 290 pC / N. The preparation method of the barium calcium zirconate titanate lead-free piezoelectric textured ceramic can avoid separate preparation of a template and slurry, and unchanged material composition can be accurately guaranteed.

Owner:TIANJIN UNIV

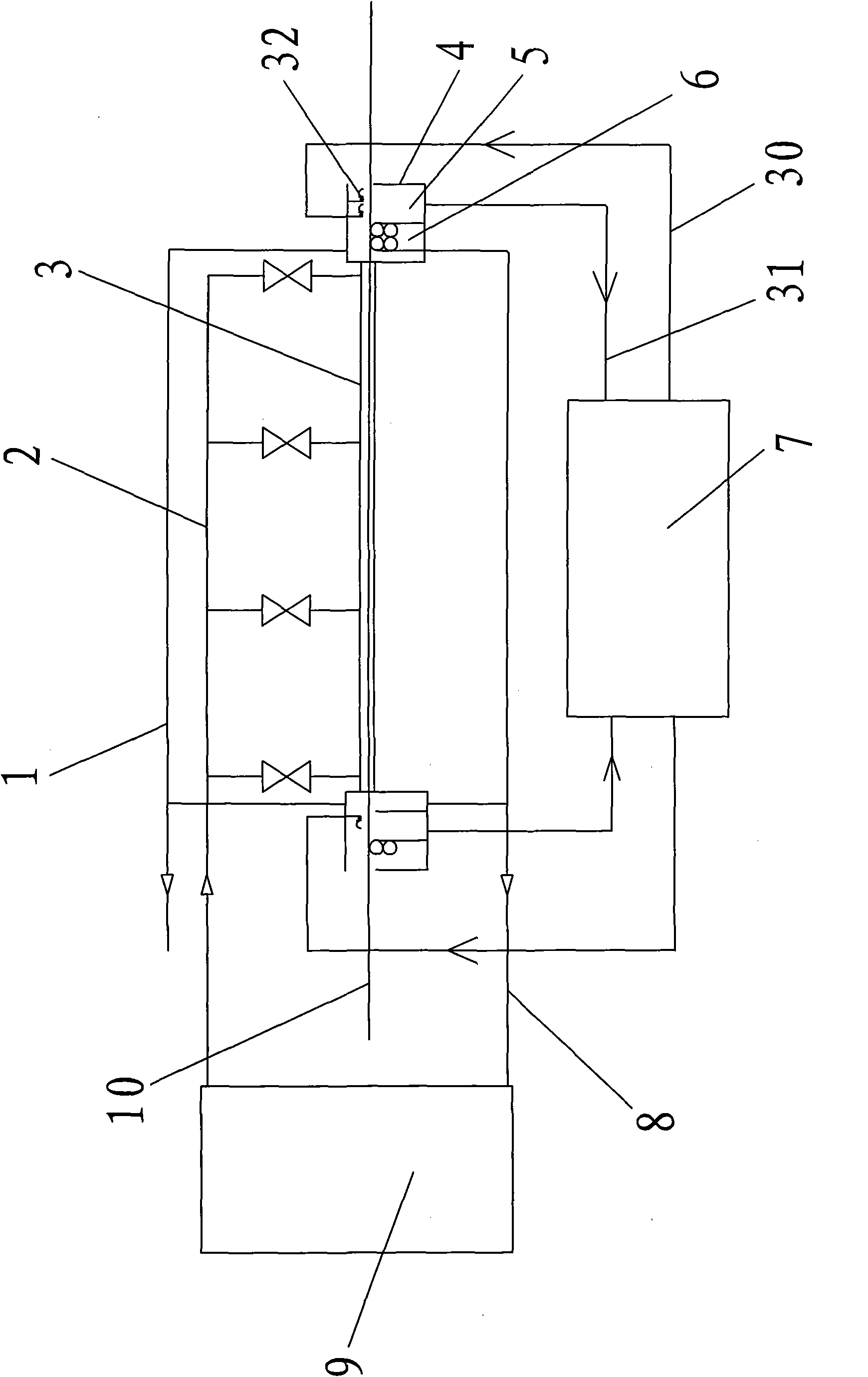

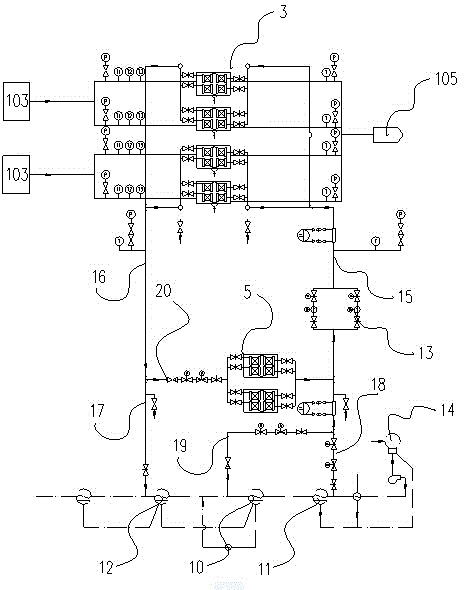

Environment-friendly steel wire pickling bath

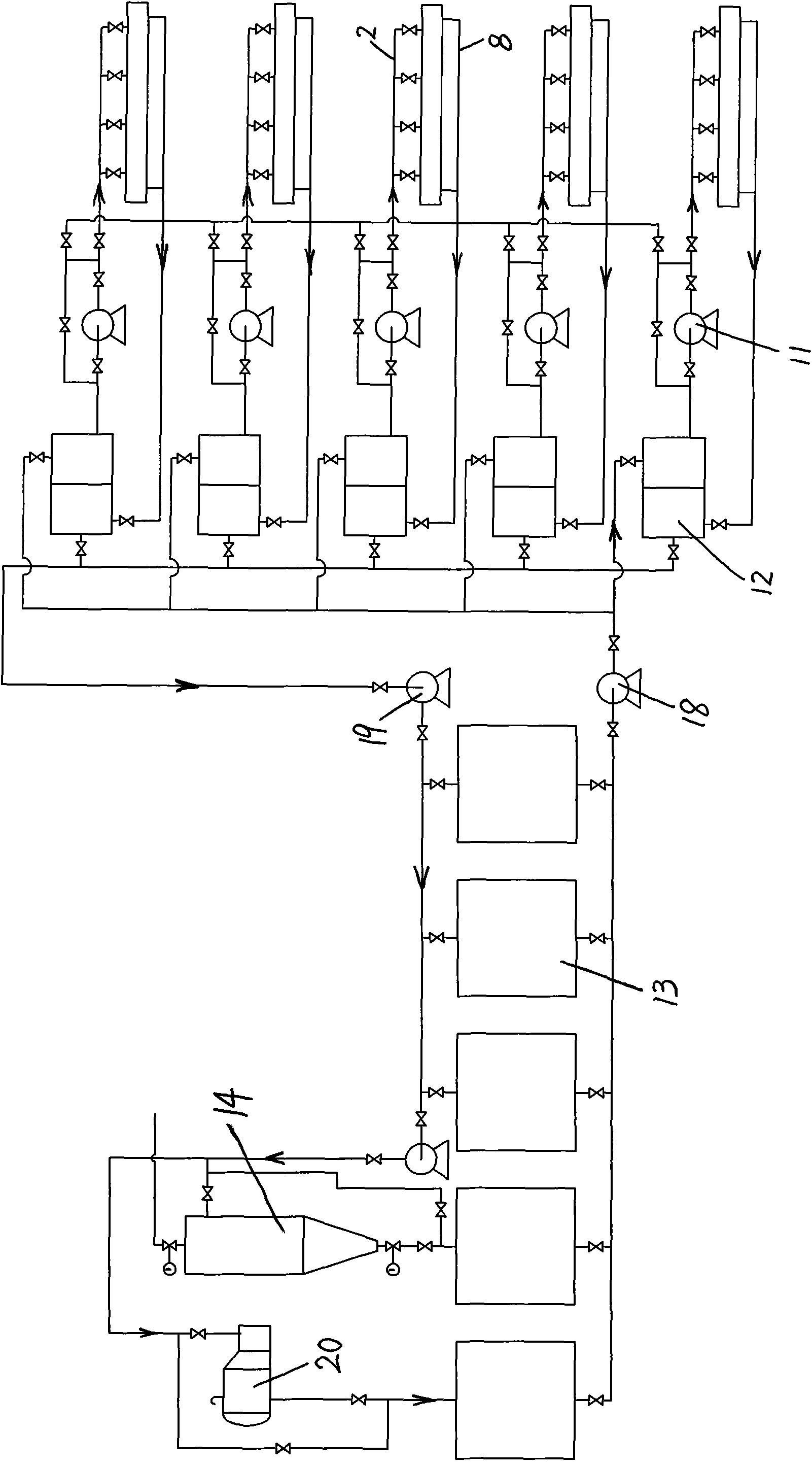

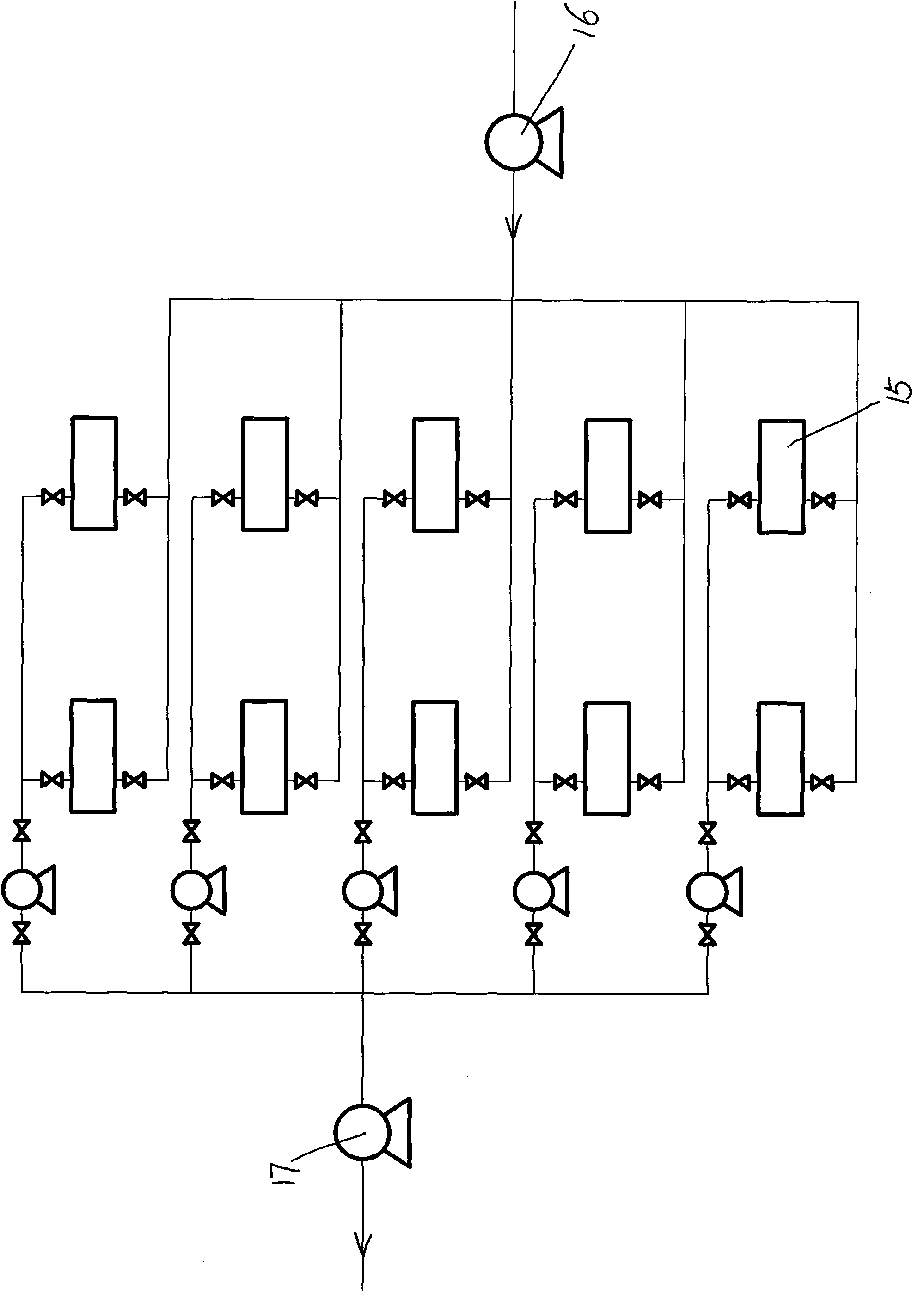

The invention discloses an environment-friendly steel wire pickling bath which comprises a water circulating device and an acid liquor circulating device. The pickling bath consists of a plurality of horizontally arranged pickling pipelines, and the pickling pipelines consist of PE (Polyethylene) pipes. A UHMV-PE (Ultra High Melt Viscosity-Polyethylene) layer is arranged on the inner wall of each pickling pipeline, acid adding pipes are uniformly connected at intervals on the top faces of the pickling pipelines, and the acid adding pipes are communicated with the acid liquor circulating device. Both ends of each pickling pipeline are respectively connected with a liquor collecting tank, a steel wire drawing device is arranged in the liquor collecting tank, and a steel wires pass through the pickling pipelines and the steel wire drawing devices in the two liquor collecting tanks. An acid return tank and a water return tank are also arranged in the liquor collecting tank, the acid return tank is communicated with both ends of the pickling pipeline, and the bottom face of the acid return tank is connected with the acid liquor circulating device through an acid return pipe. A water spray device for spraying water to the surfaces of the steel wires is arranged above the water return tank, the water spray device is connected with the water circulating device through a water inlet pipe, and the bottom face of the water return tank is connected with the water circulating device through a water return pipe. The top faces of the two liquor collecting tanks are respectively connected with air exhaust pipes.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

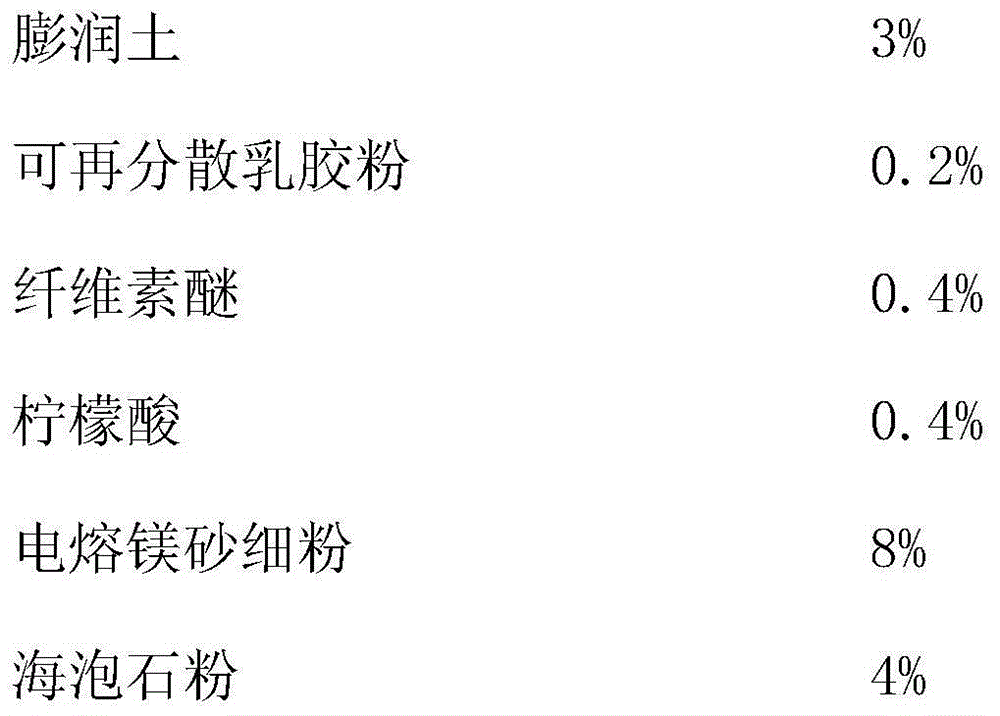

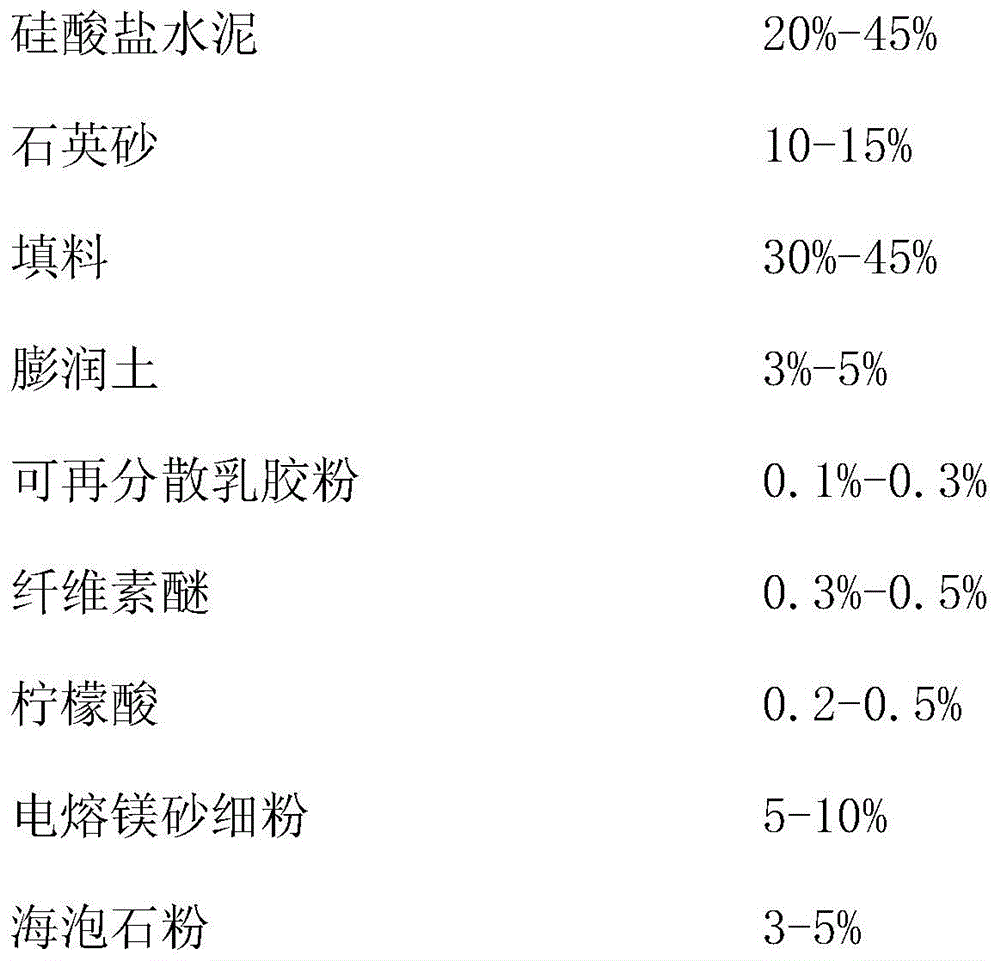

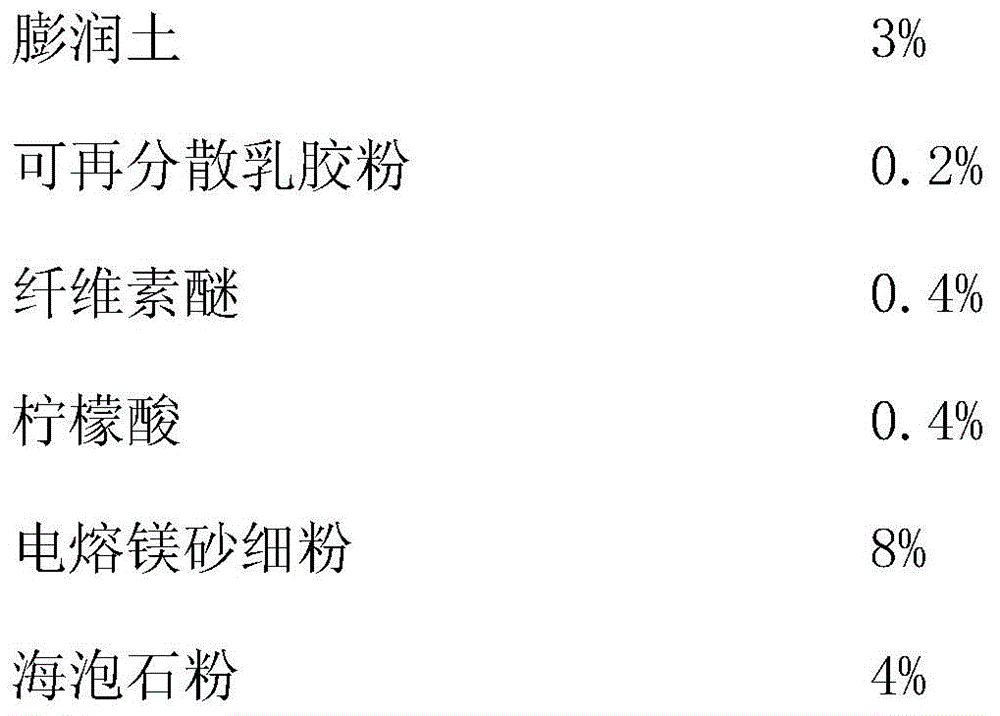

Fireproof dry-mixed mortar for exterior wall

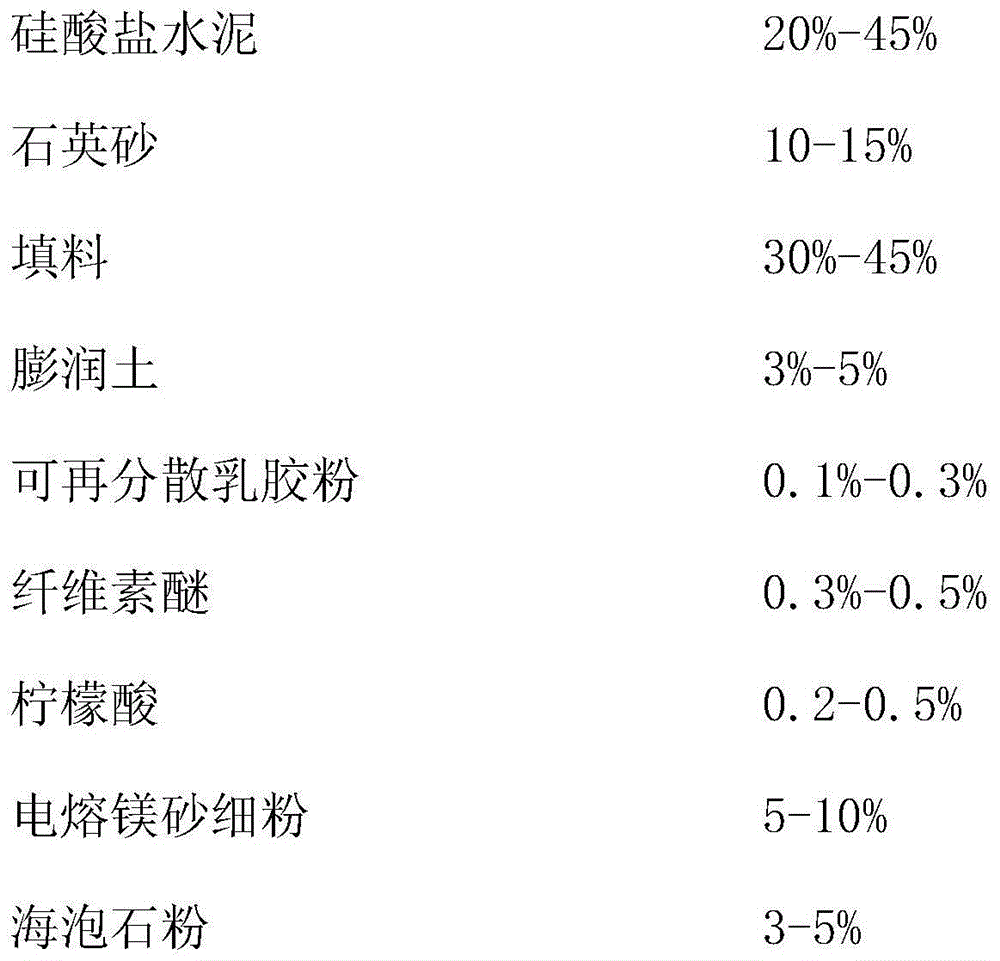

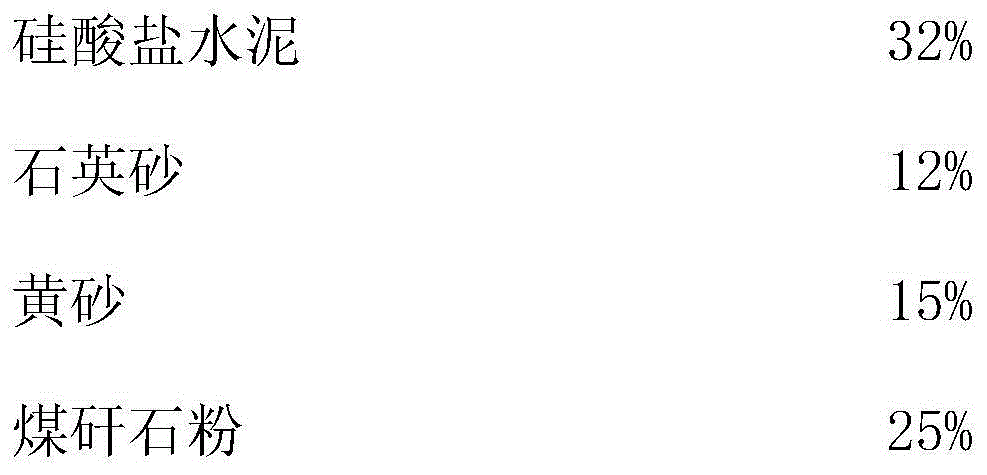

The invention discloses fireproof dry-mixed mortar for an exterior wall. The fireproof dry-mixed mortar is composed of the following components in percentage by weight: portland cement, quartz sand, filler, bentonite, redispersible latex powder, cellulose ether, citric acid, fine fused magnesite powder and sepiolite powder. The fireproof dry-mixed mortar has a favorable adhesive force with a fundamental plane, and materials are economic and practical, so that the cost can be reduced; meanwhile, a base layer treated by using the material cannot bulge and flake, so that a construction site can be kept clean, and the requirement for environment friendliness can be better met; and part of yellow sand is replaced with gangue, so that the pollution can be relieved, the cost can be reduced, and the fireproof effect can also be achieved.

Owner:DEQING YANGTAI BUILDING MATERIAL

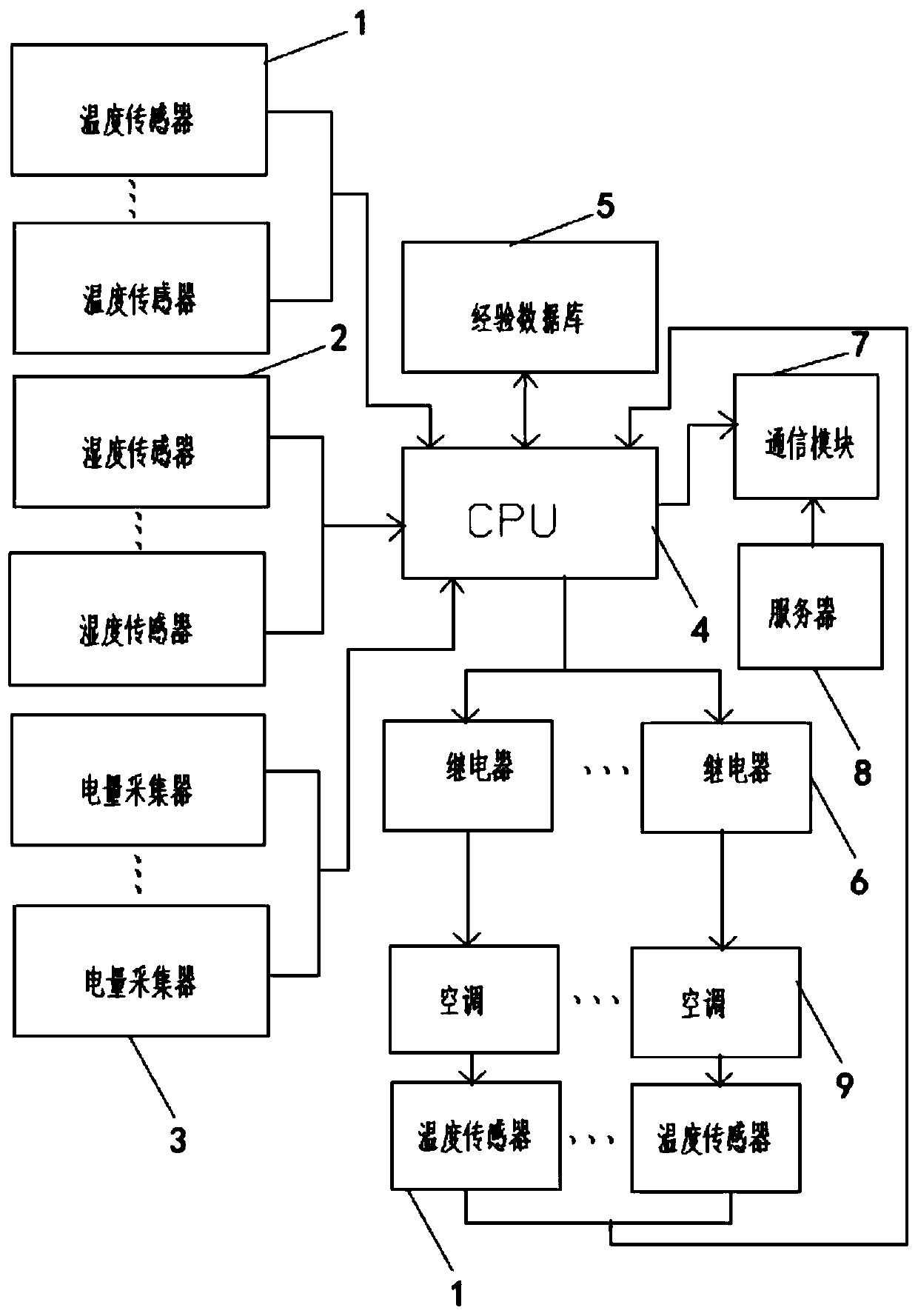

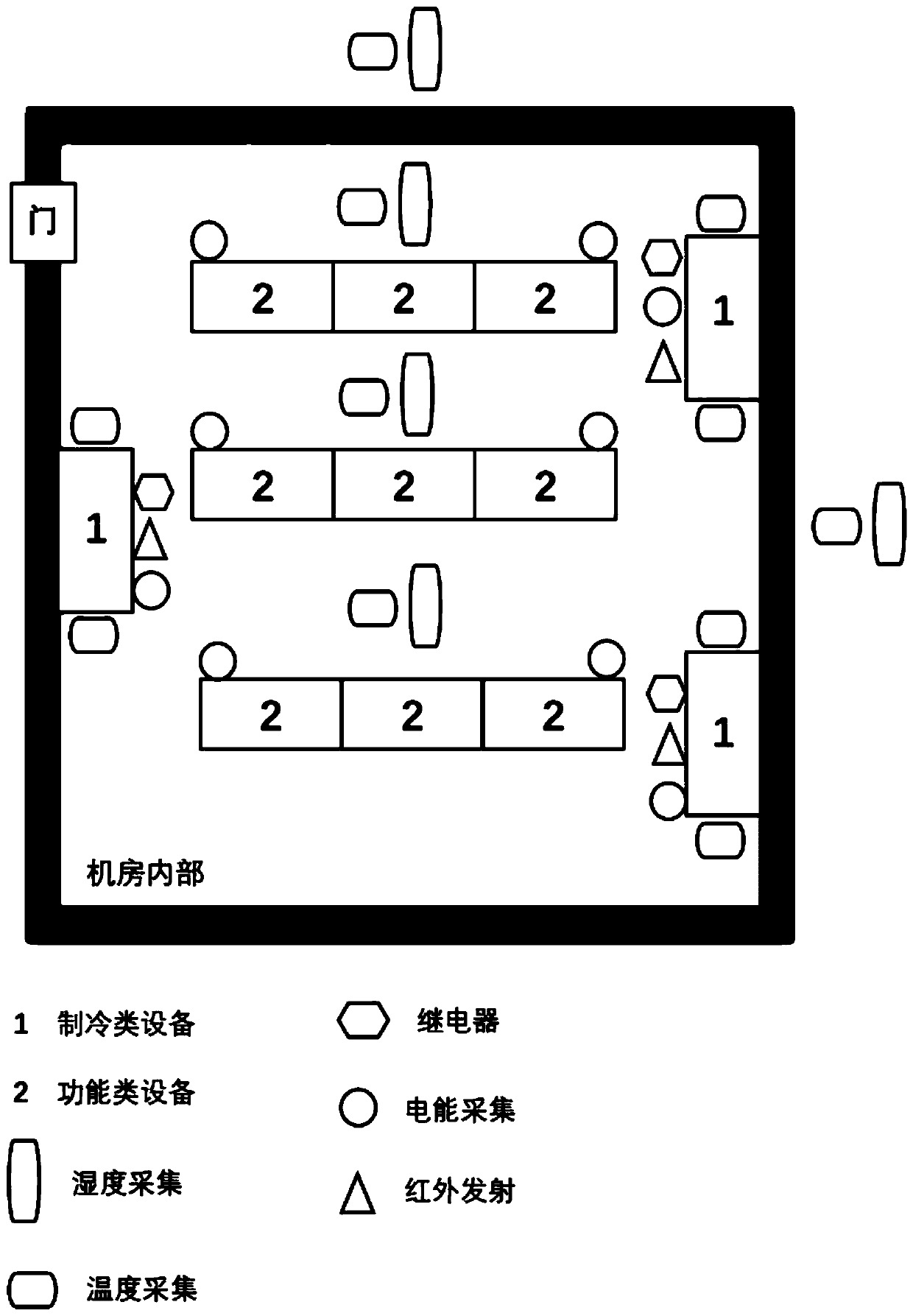

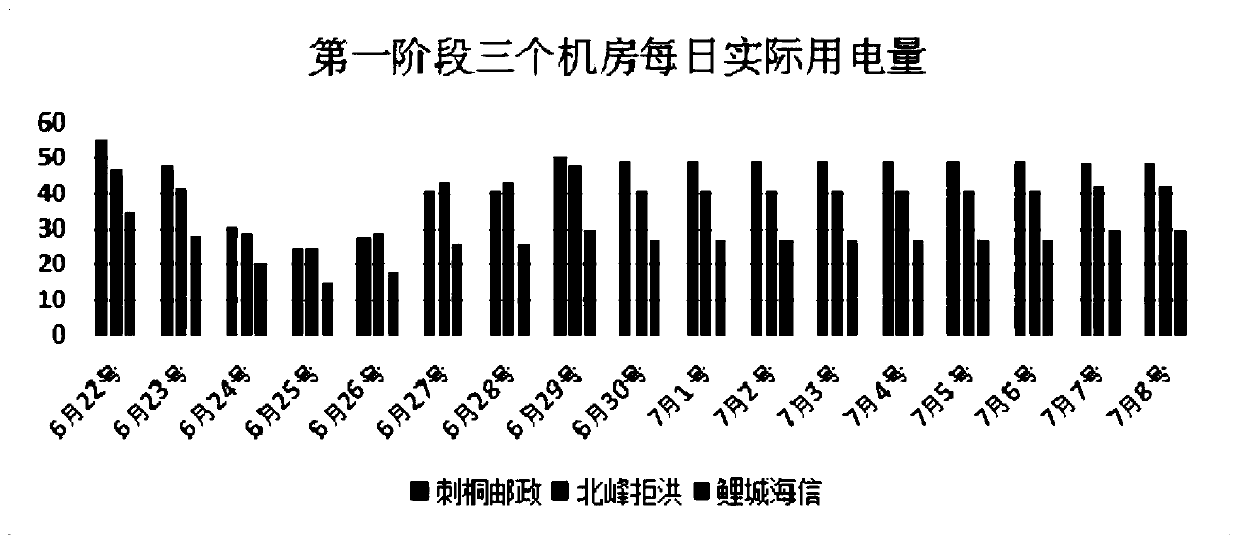

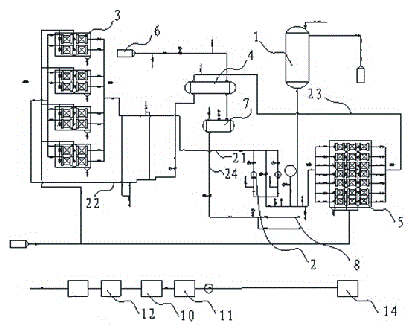

Communication machine room air conditioner energy saving method and device

PendingCN110925960AGuarantee environmental requirementsGuarantee the temperature required by the environmentMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringRefrigeration

The invention relates to the technical field of communication equipment, and provides a communication machine room air conditioner energy saving method and device. The communication machine room air conditioner energy saving method comprises the following steps that firstly, the power utilization amount of various facilities in a communication machine room at various time moments is detected in real time, the total heating amount is calculated, and a heat source Q1 is obtained; secondly, the heat dynamic value of the exterior of the communication machine room to the interior of the room at various time moments is dynamically detected in real time, and a heat source Q2 is obtained; thirdly, the changes of temperature and humidity relative to time are calculated and analyzed, the machine room temperature change gradient at various time periods is calculated in combination with the size of the machine room and the heat source Q1 in step S1 and the heat source Q2 in step S2 at the same time moment, and the machine room heat capacity C*M is obtained; fourthly, the actual refrigerating amount of various air conditioners is detected and calculated in real time; and fifthly, according to collection parameters, the temperature dynamic changing tendency of various areas in the communication machine room is predicted, a monitoring point is about to be reached, the air conditioners in thecommunication machine room are started in advance for refrigeration or the refrigerating amount is reached, the monitoring point requirement is quitted, air conditioner refrigeration is closed in advance, and accordingly the communication machine room internal environment requirement is met. The communication machine room air conditioner energy saving method and device solve the problem that the communication machine room air conditioner energy saving effect is not ideal.

Owner:FUJIAN NANHONG COMM TECH

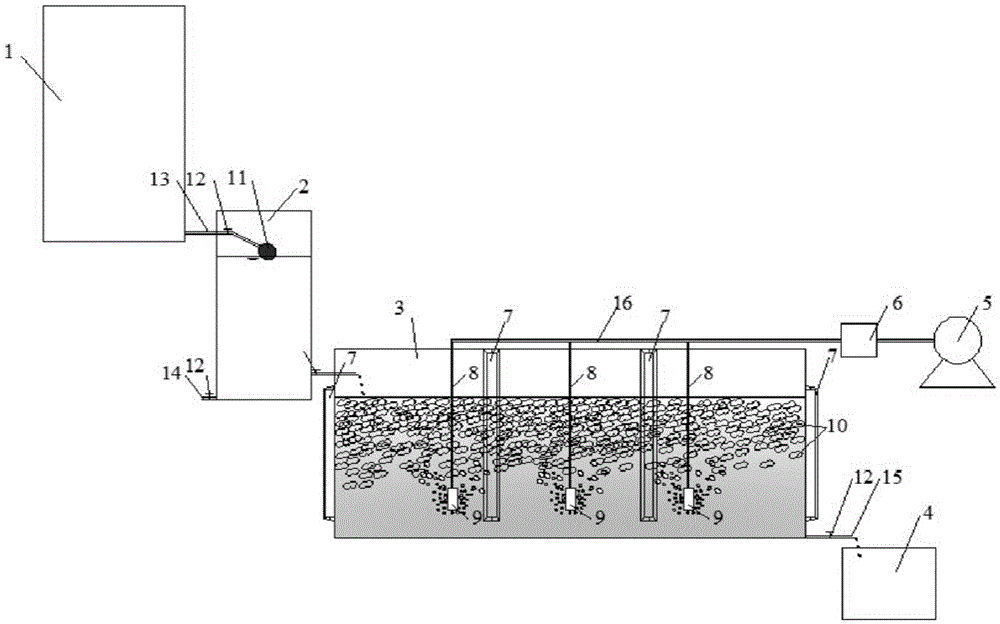

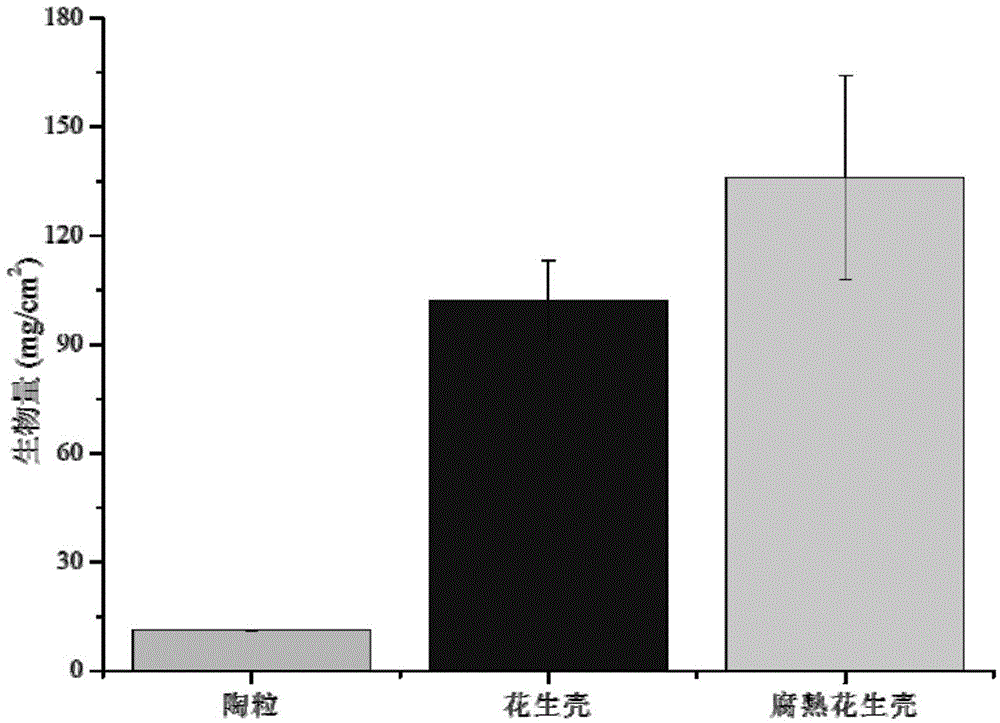

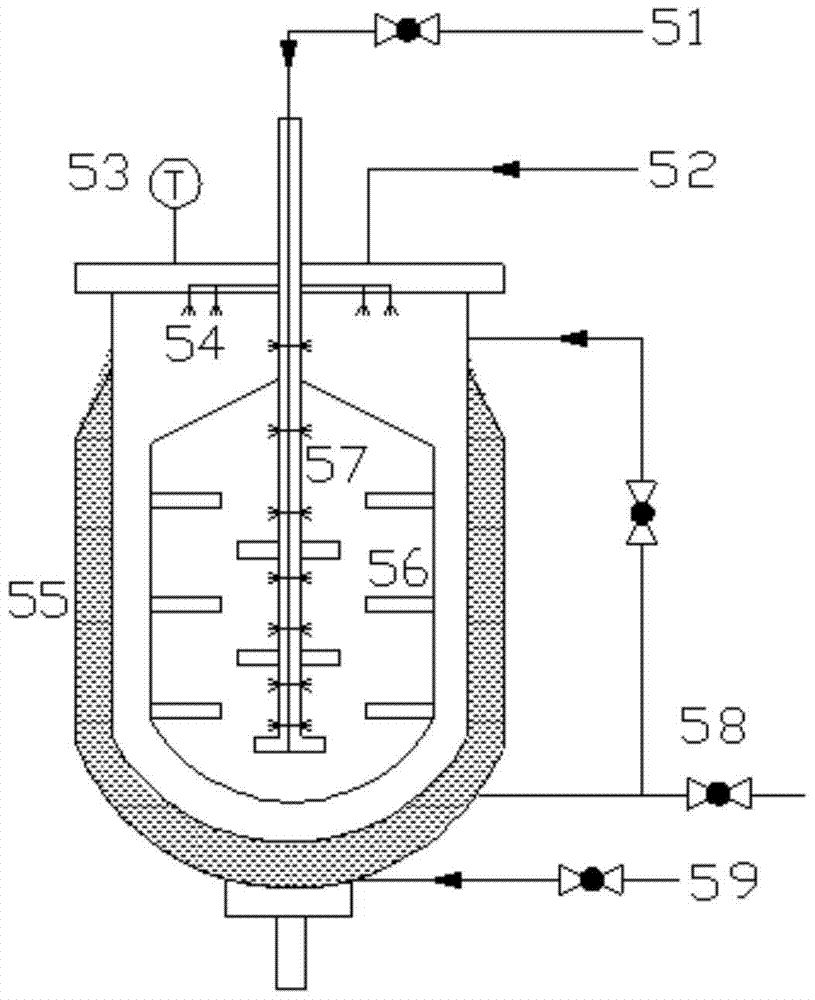

Method and device for culturing periphyton

InactiveCN104789472ANot easy to degradeExtended service lifeBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlDrip irrigation

The invention discloses a method and a device for culturing periphyton. The method for culturing the periphyton comprises the following steps: (1), preparation of a modified carrier, wherein the carrier more favorable for periphyton adhesion is prepared by modifying agricultural byproducts; (2) periphyton culture, wherein water flow is controlled through a floating valve, nourishment is supplied through drip irrigation, and secondary metabolites of the periphyton are taken away while the nourishment in a periphyton culture tank meets microbial growth, so that the periphyton can be massively propagated; (3) control on a key environmental condition, wherein efficient periphyton culture is realized by controlling growth influence factors of the periphyton. The device is capable of automatically controlling sample introduction and realizing integration of periphyton culture and reaction. The selected materials can be all obtained locally and are low in cost and remarkable in effect; the method is suitable for efficient periphyton culture and provides a scientific basis for promotion of application of the periphyton to the natural water body remediation and agricultural area-source pollution control.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Clean preparation method of guanidinoacetic acid

InactiveCN103193681AAvoid it happening againThorough responseOrganic chemistryOrganic compound preparationEnvironmental resistanceSolvent

The invention discloses a preparation method of guanidinoacetic acid. The method comprises the following steps: performing reaction on glycine and hydrogen cyanamide under the alkaline condition; and performing centrifugal separation on the reaction system after reacting, thereby obtaining a solid phase and a liquid phase, wherein the solid phase is guanidinoacetic acid while the liquid phase is a solvent. The method has the advantages that (1) the clean solvent is adopted, and solvent resulting in environmental pollution is not utilized; (2) the raw material matched with hydrogen cyanamide is excessive properly, so that hydrogen cyanamide can react fully and completely; (3) based on the characteristics of hydrogen cyanamide, the reaction solution is concentrated, so that possible trace waste gases can be removed; and (4) a centrifugation mother solution is recycled totally, so that the zero discharge is achieved. Therefore, the environmental protection requirement is satisfied while ammonia and guanidine acetic acid in the mother solution are recycled. As a result, the yield is improved; and the consumption is lowered.

Owner:北京君德同创生物技术股份有限公司

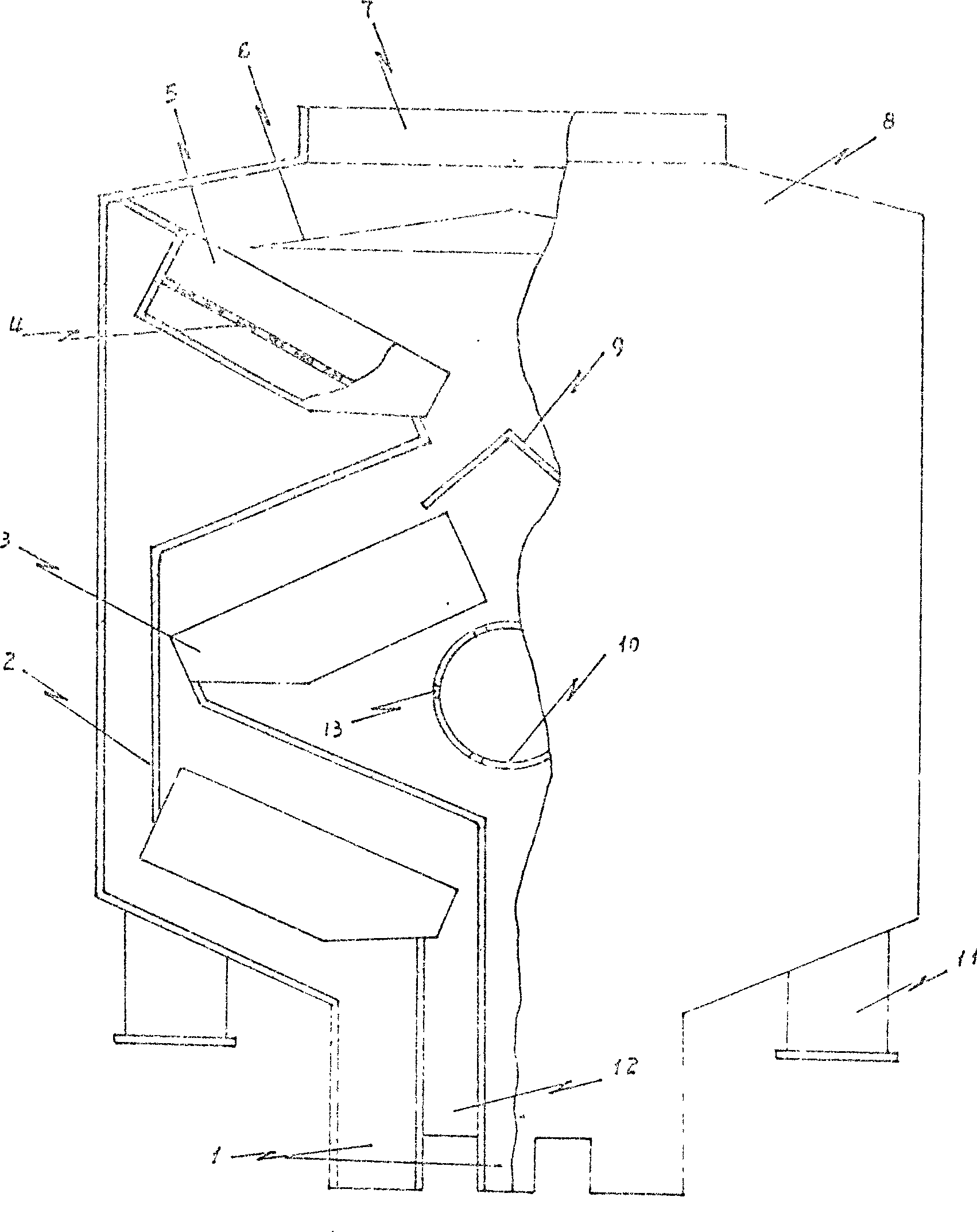

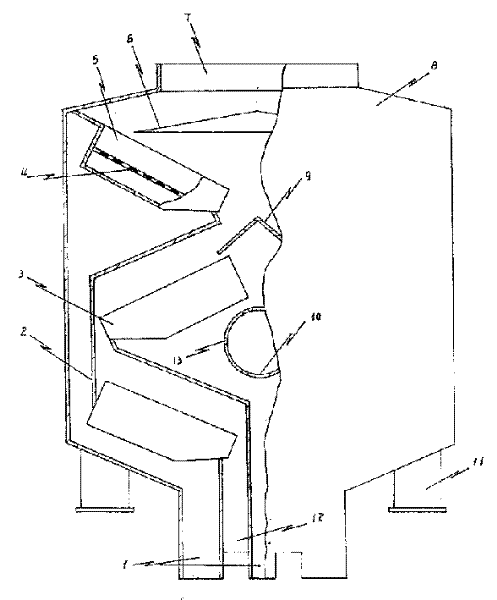

Method of reducing area covered by vibrating sieve and vibrating sieve

InactiveCN1432437AReduce installation landGuarantee environmental requirementsSievingScreeningDistributorMaterial Separation

The vibrating sieve includes sieve box of several sieve units, each of which has material feeding port, screening outlet, oversize material outlet, distributor, sieve plate and sieve surface, and vibrating source connected to the sieve box. The present invention features that the sieve units inside the sieve box are zigzag arranged from top to bottom through head-to-tail connection. There may be several sieve boxes and the oversize material and the screenings between different sieve units are separated with partition board. There may be material separation board and aspiration channel with aspiration port inside the sieve box. The method of the present invention can reduce the area covered by the vibrating sieve effectively without affecting sieving efficiency and precision.

Owner:孙功民

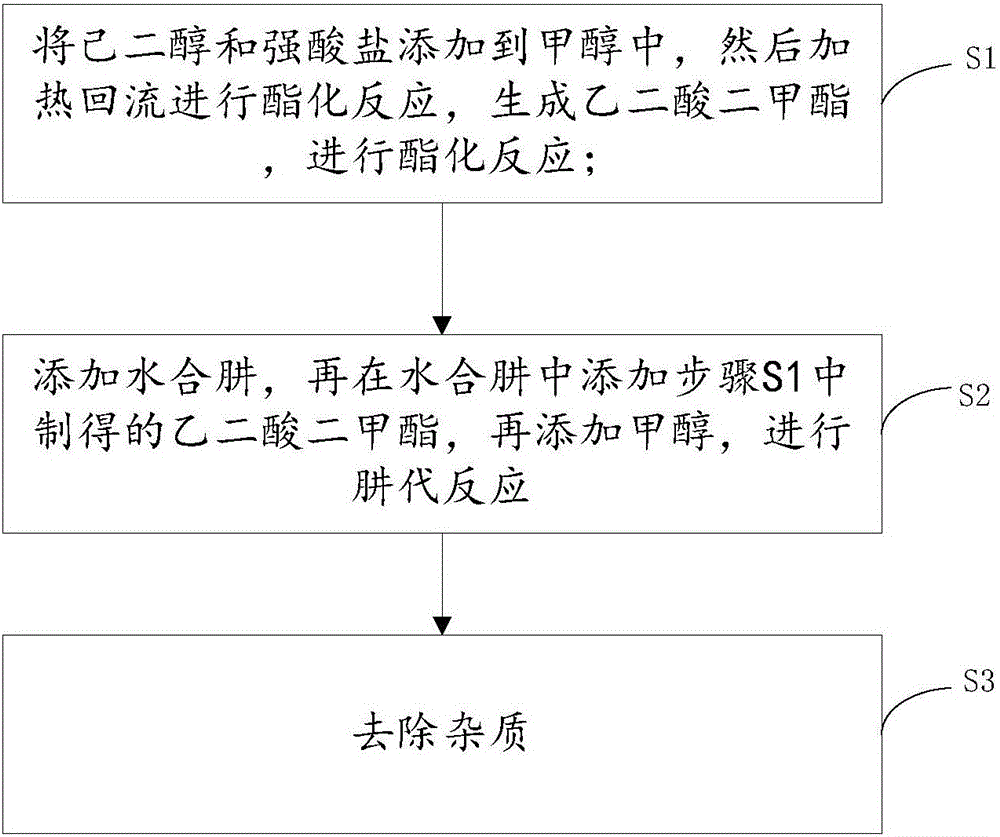

Preparation method of adipic acid dihydrazide

InactiveCN106117079AHigh yieldReduce contentHydrazide preparationHydrazine compoundEsterification reaction

The invention provides a preparation method of adipic acid dihydrazide. The preparation method is characterized by comprising steps as follows: S1: hexanediol and strong acidic salt are added to methanol and then subjected to heating reflux for an esterification reaction, dimethyl oxalate is produced, and the esterification reaction is performed; S2: hydrazine hydrate is added, dimethyl oxalate prepared in the step S1 is added to hydrazine hydrate, and methanol is added for a hydrazine substitution reaction; S3: impurities are removed. The yield of adipic acid dihydrazide can be increased, and the content of free hydrazine is reduced.

Owner:潍坊芝麻开门化工有限公司

Slag-forming constituents used for lead and lead-base alloy fusion casting

The invention relates to a slag-forming constituent in casting lead and lead-base alloy, which comprises 35-70wt% of CaF2, 3-5wt% of Na3AlF6, 3-8wt% of KCl, 8-10wt% of NaCl, 2-5wt% of ZnCl2, 20-50wt% of C powder and 3-5wt% of NH4Cl. The invention makes use of the principle that inorganic salt can improve interfacial force and boundary tension between lead fondant and oxidate so as to de-slag in casting and using of lead-base product, improve quality of casting and using, ensure slag to carry on powder, and recovery metal efficiently. The invention the properties of simple preparation, low input of apparatus and capital and extensive usages such as lead ingot casting, lead-base alloy product casting and lead-base product later usage.

Owner:株洲冶炼集团有限责任公司

Slag-forming constituents used for lead and lead-base alloy fusion casting

The invention relates to a slagging agent for melting and casting of lead and lead-based alloys. Its composition and weight percentage are: CaF245%~70%, Na3AlF63%~4%, KCl 3%~5%, NaCl 8%~10%, ZnCl22%~3%, C powder 12%~35%, NH4Cl 2 %; The present invention utilizes some inorganic salts to improve the surface tension and interfacial tension principle between the lead melt and the oxide, and adopts a reasonable proportion to make lead ingots and lead-based alloys fully Slag removal and purification can improve the quality of smelting and use, and ensure that the slag body is powdery after salvaging slag, with very little metal entrainment, and the entrained metal can flow out effectively, further recovering metal, and at the same time ensuring good environmental protection and safety. The preparation of the invention is simple, and the input equipment and capital are less. It can be used for melting and casting of lead ingots, melting and casting of lead-based alloy products and later use of lead-based products.

Owner:株洲冶炼集团有限责任公司

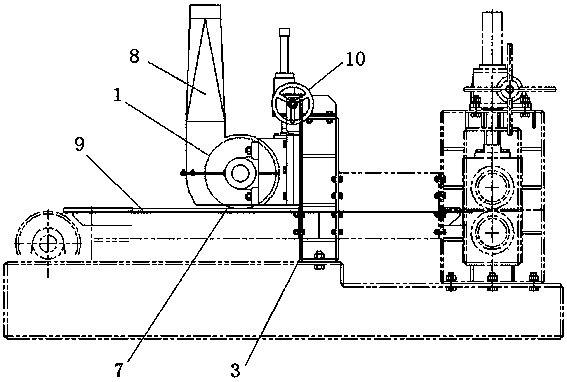

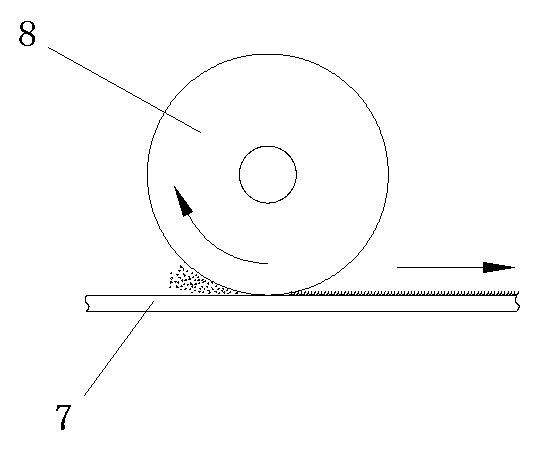

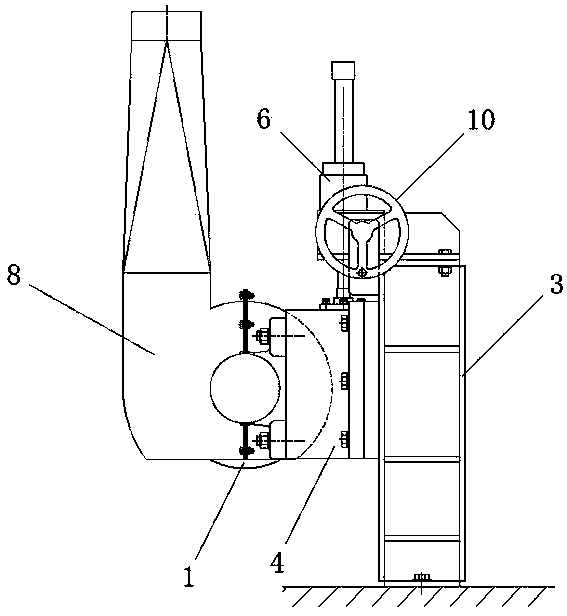

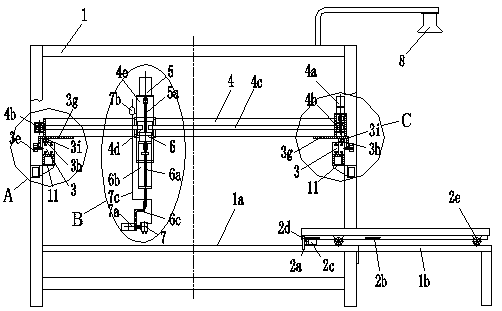

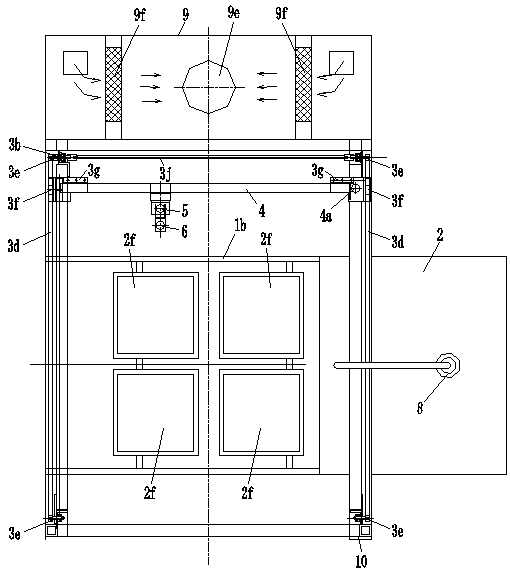

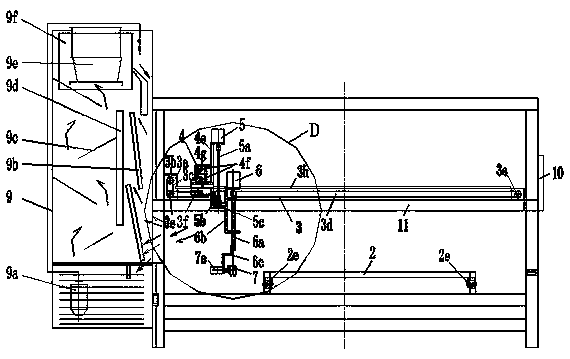

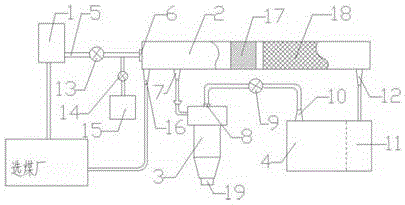

Cleaning and roughening device and method for remanufacturing waste rubber conveying belt

ActiveCN103639129AClean up the hair and handle it wellEasy to control the degree of hair removalDirt cleaningCleaning using toolsProduction lineFiber

The invention discloses a cleaning and roughening device and method used for remanufacturing a waste rubber conveying belt. The cleaning and roughening device comprises a door-shaped rack fixedly installed on a production line, a cylinder brush roll used for cleaning and roughening the waste rubber conveying belt and a speed reduction motor driving the cylinder brush roll to rotate. A suspension board is installed on a door beam of the door-shaped rack, a brush roll support parallel to the door beam of the door-shaped rack is arranged on the portion, below the suspension board, of the door-shaped rack, and a lifting mechanism capable of enabling the brush roll support to move up and down is arranged on the suspension board. The cylinder brush roll and the speed reduction motor are respectively arranged on the brush roll support, the lower transmission portion of the cylinder brush roll is in contact with the conveying belt passing through the door-shaped rack, and the axial direction of the lower transmission portion of the cylinder brush roll is perpendicular to the motion direction of the conveying belt. According to the cleaning and roughening device and method for remanufacturing the waste rubber conveying belt, the cylinder brush roll is installed on an assembly line device, the cylinder brush roll rotates at high speed to carry out comprehensive cleaning on the surface of the conveying belt, cleaning speed is high, and efficiency is high; meanwhile, fibers on the surface layer of the conveying belt are picked up, a fluff layer is formed, and the scraping procedure and the rubber-coating procedure of the next step are facilitated.

Owner:CHINA NAT ELECTRIC APP RES INST +1

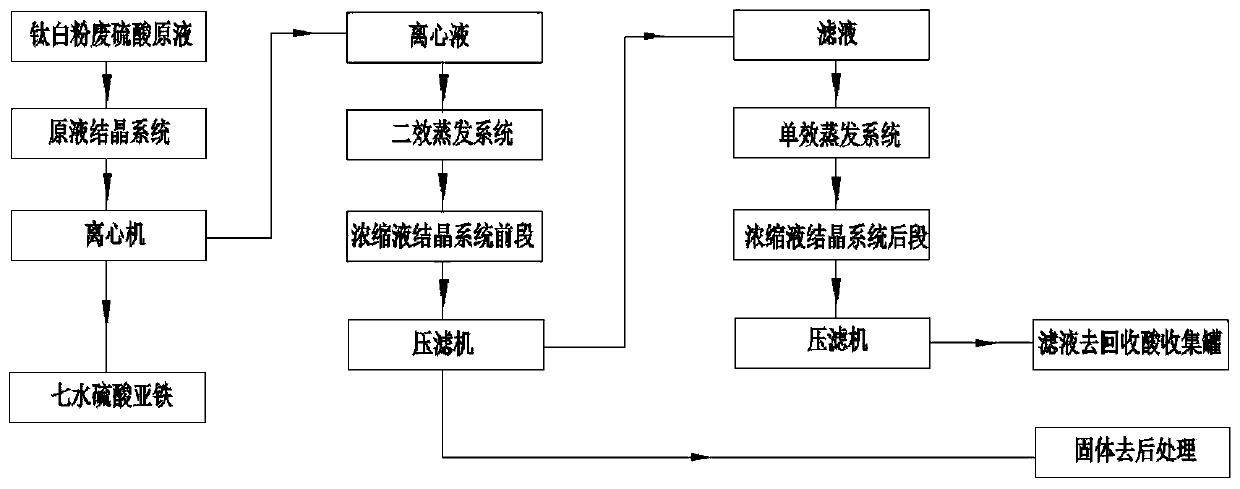

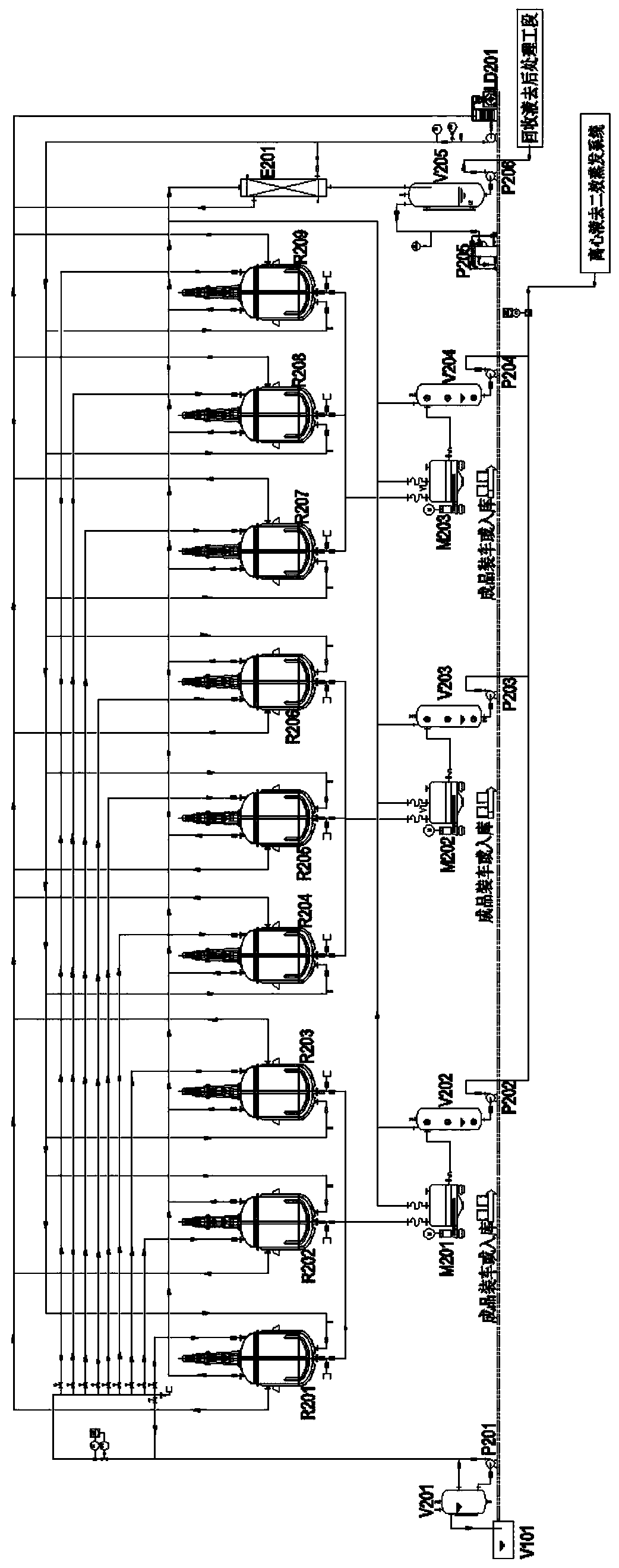

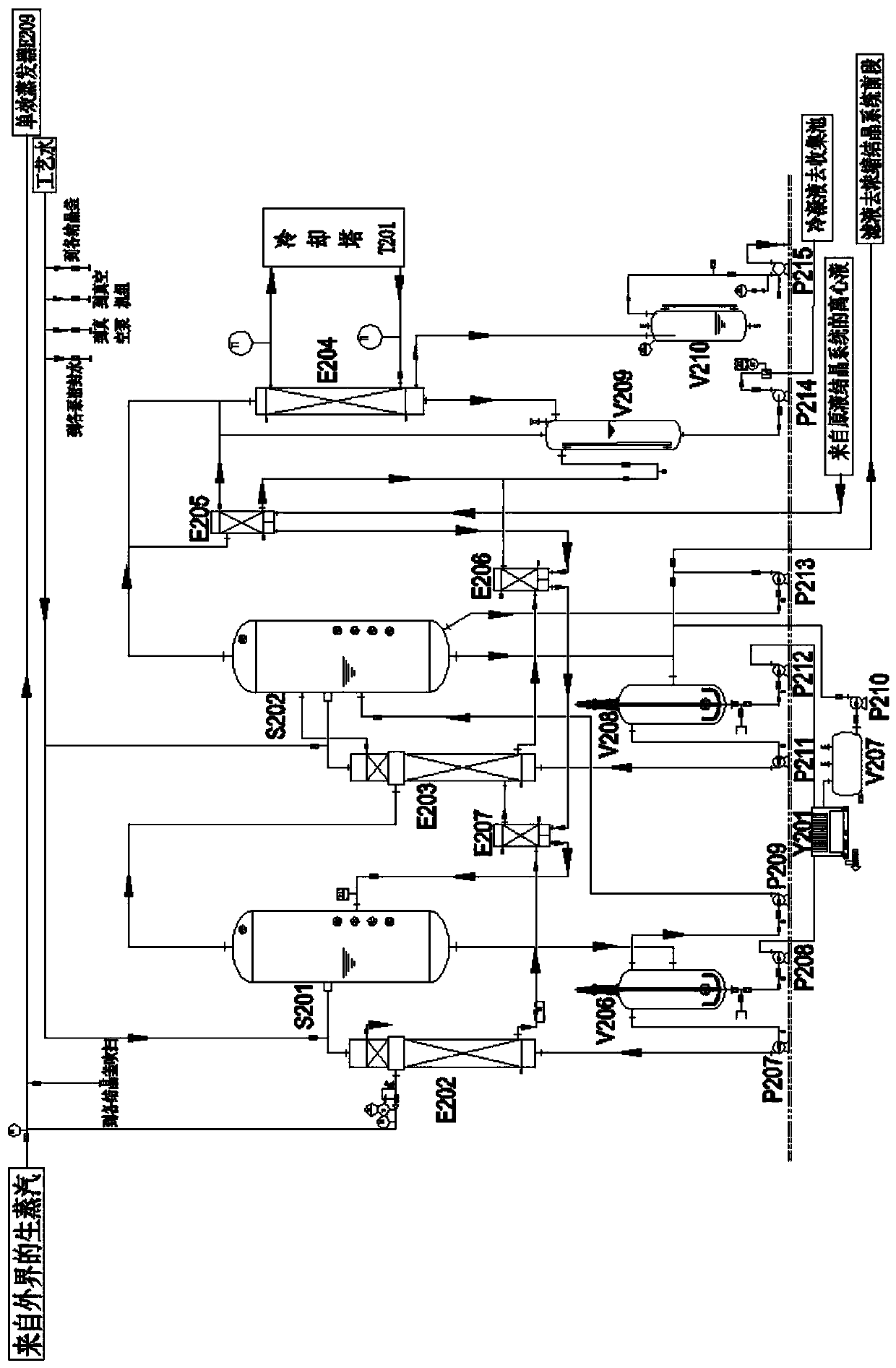

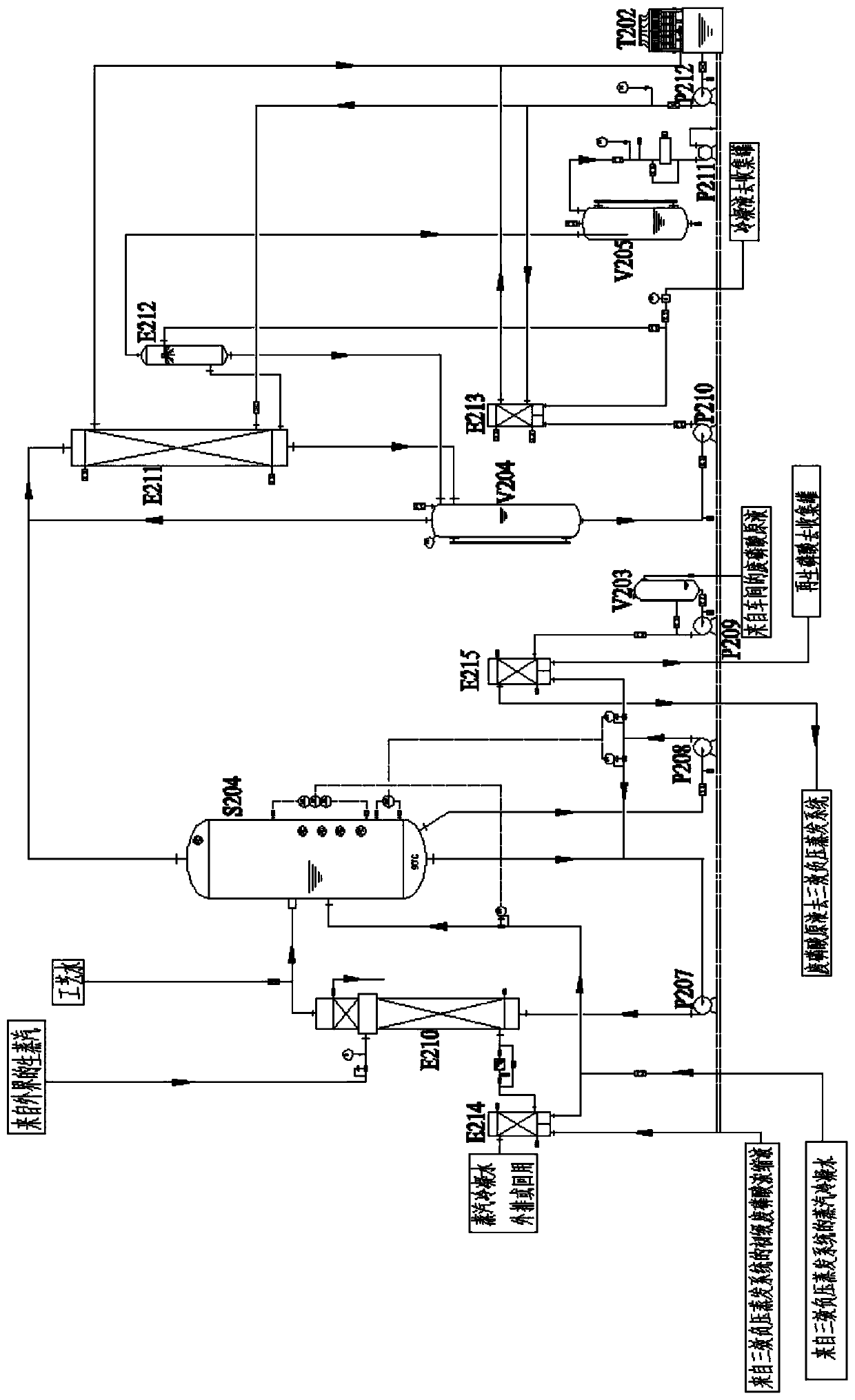

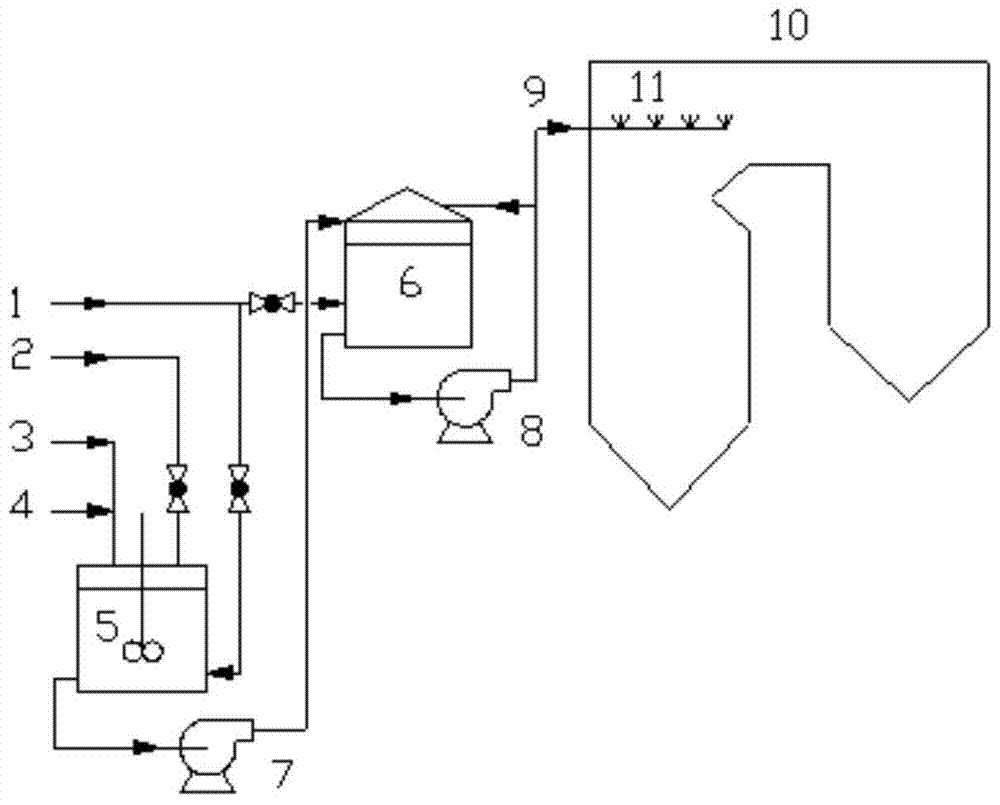

Three-stage negative pressure evaporation crystallization treatment process and device for titanium dioxide waste sulfuric acid

PendingCN111517397AHigh recovery ratePut an end to crystallizationWater/sewage treatment by centrifugal separationTitanium and titanyl sulfatesFerrous sulfate ironPhysical chemistry

The invention discloses a three-stage negative pressure evaporation crystallization treatment process and a device for titanium dioxide waste sulfuric acid. The process comprises the following steps:crystallizing and separating of ferrous sulfate in a titanium dioxide waste sulfuric acid stock solution by using a stock solution crystallization system is carried out, and centrifugally separating are carried out to obtain a ferrous sulfate heptahydrate solid and mother liquor; through the cooperative cooperation of a double-effect evaporation system, a single-effect evaporation system and a concentration and crystallization system, the possibility of crystallization and blockage of materials in the evaporator is eliminated, and the stable operation of the device is ensured; centrifugate from the stock solution crystallization system is evaporated and concentrated in the double-effect evaporation system to improve acidity and then is introduced into a front section of the concentration and crystallization system; cooling, crystallizing and filter pressing are carried out to obtain a large amount of sulfate solids; wherein the mass concentration of sulfuric acid in filtrate reaches 50%, the filtrate is continuously introduced into the single-effect evaporation system for forced circulation, the concentration of waste sulfuric acid is increased to the maximum extent, the concentrated waste sulfuric acid solution is introduced into the rear section of the concentration and crystallization system, cooling crystallization is performed, a large amount of sulfate solids are obtained through filter pressing, and a regenerated sulfuric acid solution with the mass concentration larger than or equal to 70% is obtained.

Owner:江苏泰特联合环保科技有限公司

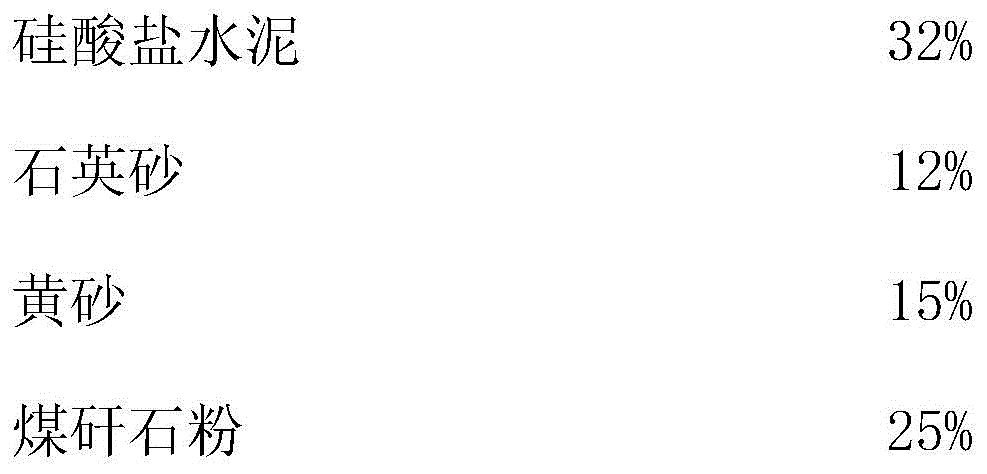

Fireproof exterior wall dry-mixed mortar

The invention provides a fireproof exterior wall dry-mixed mortar. The fireproof interior wall dry-mixed mortar comprises the following components: Portland cement, quartz sand, a filling material, bentonite, redispersible emulsion powder, cellulose ether, and citric acid. The product has good adhesion to a base surface, the materials are economic and practical, so that cost is saved, at the same time after the base is treated by the material, phenomena of empty drum and shell do not exist, cleaning of construction site is guaranteed, and environmental protection requirements are met; gangue replaces parts of yellow sand, so that pollution is reduced, cost is reduced, and fireproof effects are realized.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

Fireproof interior wall dry-mixed mortar

The invention provides a fireproof interior wall dry-mixed mortar. The fireproof interior wall dry-mixed mortar comprises the following components: Portland cement, quartz sand, a filling material, bentonite, redispersible emulsion powder, cellulose ether, citric acid, and nanoscale titanium dioxide. The product has good adhesion to a base surface, the materials are economic and practical, so that cost is saved, at the same time after the base is treated by the material, phenomena of empty drum and shell do not exist, cleaning of construction site is guaranteed, and environmental protection requirements are met; gangue replaces parts of yellow sand, so that pollution is reduced, cost is reduced, and fireproof effects are realized.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

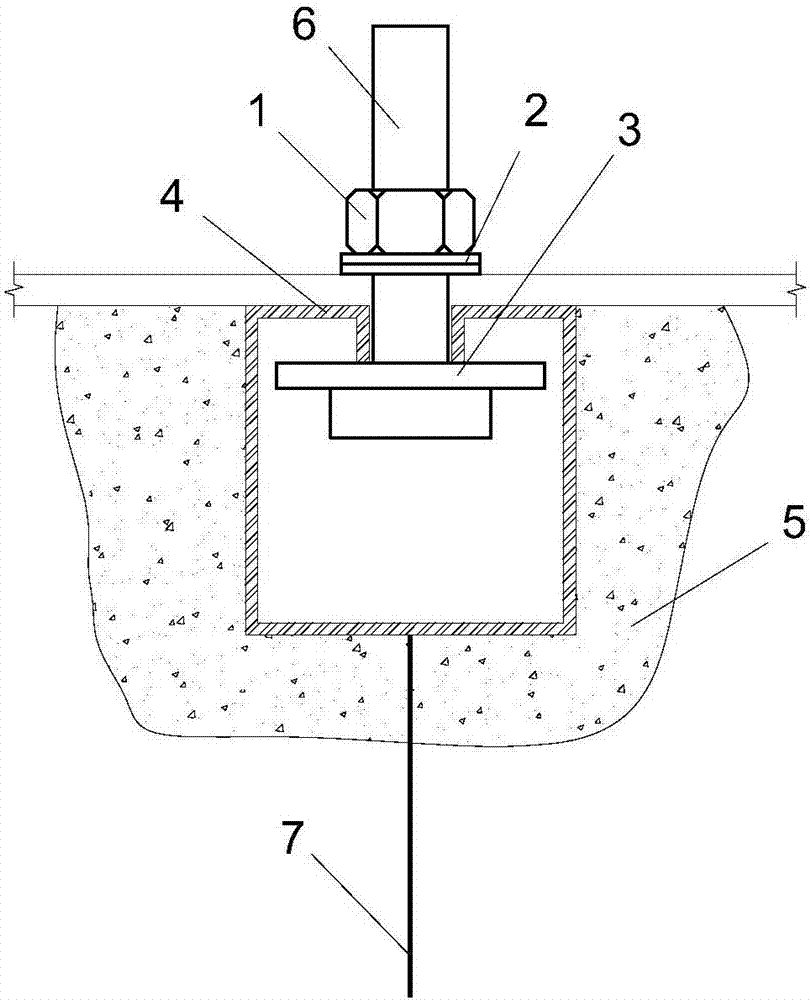

Mounting structure and method of electrical cubicle

PendingCN107039897AStrong connectionQuick installationSubstation/switching arrangement casingsScrew threadThreaded fastener

The invention relates to a mounting structure and method of an electrical cubicle. The mounting structure is provided with a stripy metal fixing part which is arranged in concrete, wherein the stripy metal fixing part is of a hollow structure, and an opening is axially formed in the upper end of the stripy metal fixing part; a thread fastening part which extends out from the opening is arranged in the hollow structure; a nut is arranged at the extended part of the thread fastening part and fits the thread fastening part; the bottom part of the thread fastening part is clamped to the lower edge of the opening of the stripy metal fixing part. With the adoption of the mounting structure, the electrical cubicle can be simply and quickly mounted, so that the mounting efficiency of the electrical cubicle can be greatly improved; in addition, the position is easily adjusted, thus the mounting operation space is greatly reduced; and the environmental protection requirement is met in the mounting process.

Owner:四川电力设计咨询有限责任公司

Efficient production method of bromhexine hydrochloride

PendingCN112266329AReduce dosageImprove responseAmino compound purification/separationAmino preparation from aminesAlcoholCyclohexylamines

The invention belongs to the technical field of biological medicines, and particularly relates to an efficient production method of bromhexine hydrochloride. The production method of bromhexine hydrochloride comprises the following steps: (1) reducing 3,5-dibromo-2-aminobenzaldehyde by a reducing agent to obtain an intermediate 3,5-dibromo-2-aminobenzyl alcohol; (2) reacting the intermediate 3,5-dibromo-2-aminobenzyl alcohol with N-methylcyclohexylamine, and then carrying out salt forming reaction to obtain a bromhexine hydrochloride crude product; and (3) purifying the bromhexine hydrochloride crude product to obtain the bromhexine hydrochloride.

Owner:江西亿友药业有限公司

WGGH (Water Gas Gas Heater) system

ActiveCN104654339AEnsure safety and no corrosionWith environmental protection functionLighting and heating apparatusCombustion technology mitigationGas heaterFlue gas

The invention discloses a WGGH (Water Gas Gas Heater) system. The system comprises an FGC (Flue Gas Cooler), an FGR (Flue Gas Reheater), a two-point water taking loop and a condensate pipe, wherein one water taking point of the two-point water taking loop is connected to the condensate pipe in front of an eighth low pressure heater, and another water taking point of the two-point water taking loop is connected to the condensate pipe between a sixth low pressure heater and a seventh low pressure heater; the pipeline after water taking of the two-point water taking loop is connected to a first main loop through a main water taking loop. By using a two-point condensate feeding mode, a water return pipeline is additionally arranged to control the mixing temperature after the two-point water taking and guarantee that a heated surface of a heat exchanger is not corroded and the temperature of heat medium water and gas does not deviate from a design value; the environmental protection requirement of zero emission can be guaranteed through the WGGH system; the WGGH system is used as a temperature adjusting system indispensable for super clean emission, so great economic benefit is brought.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

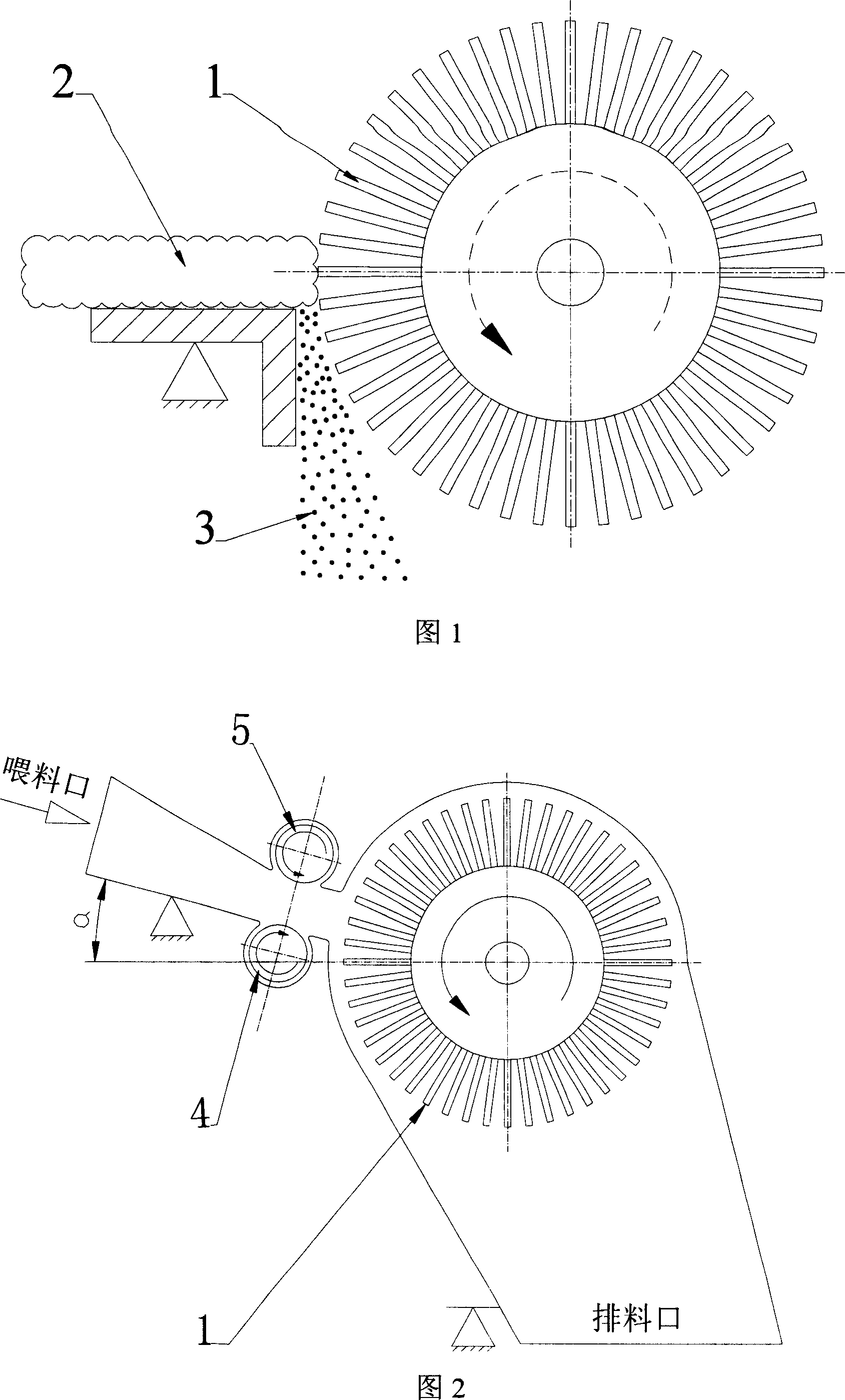

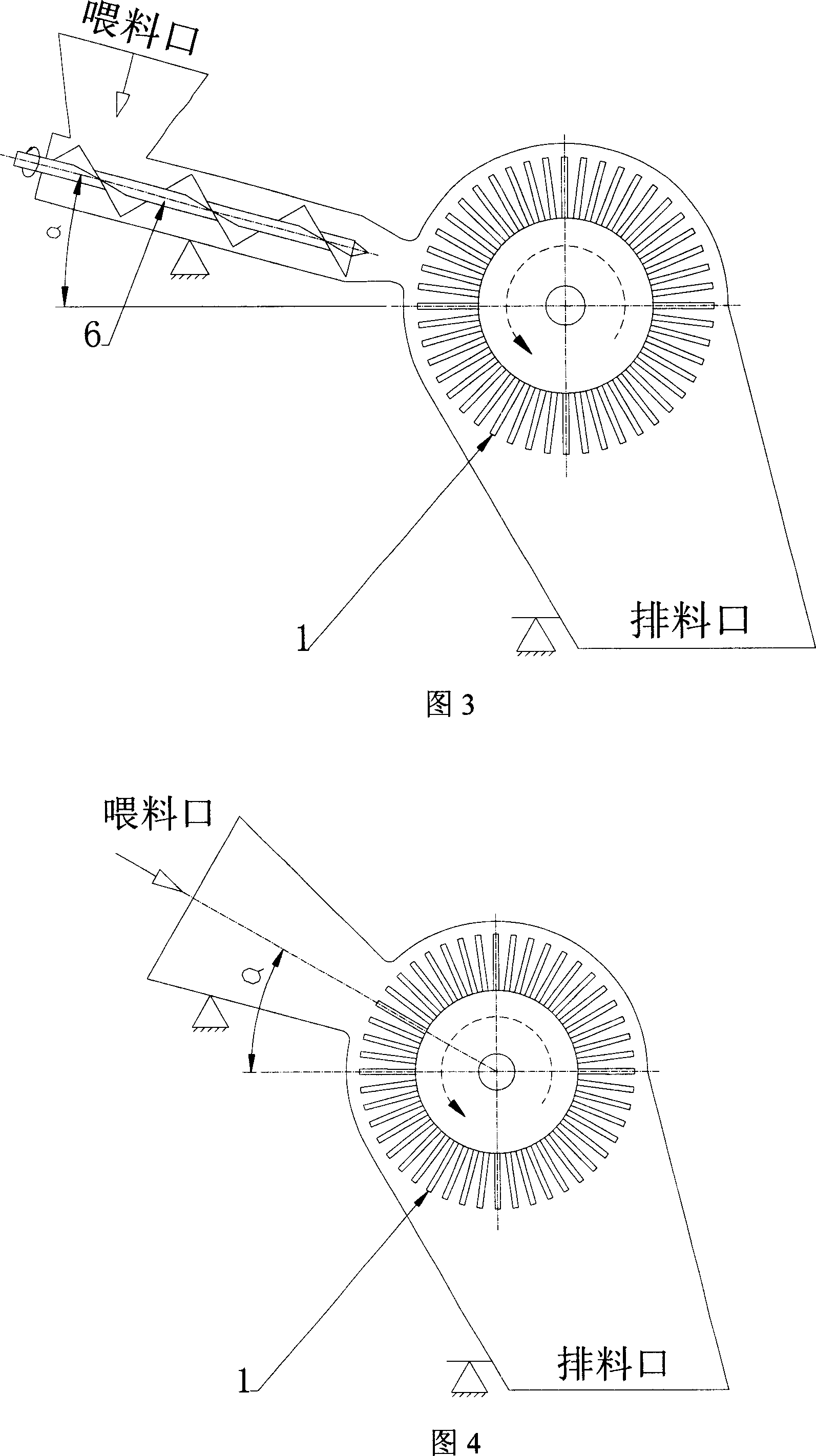

Polyurethane hard foam brush type disintegrating machine

InactiveCN100998962AEfficient crushingAvoid overheating and meltingPlastic recyclingGrain treatmentsEngineeringMechanical engineering

A brush-type pulverizer for pulverizing hard polyurethane is composed of a machine frame, a casing with feeding unit and discharging outlet, a driver, and a pulverizing unit installed in said casing via supporter and bearings. Said pulverizing unit consists of a wheel hub and a brush-type pulverizing wheel linked with said driver.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

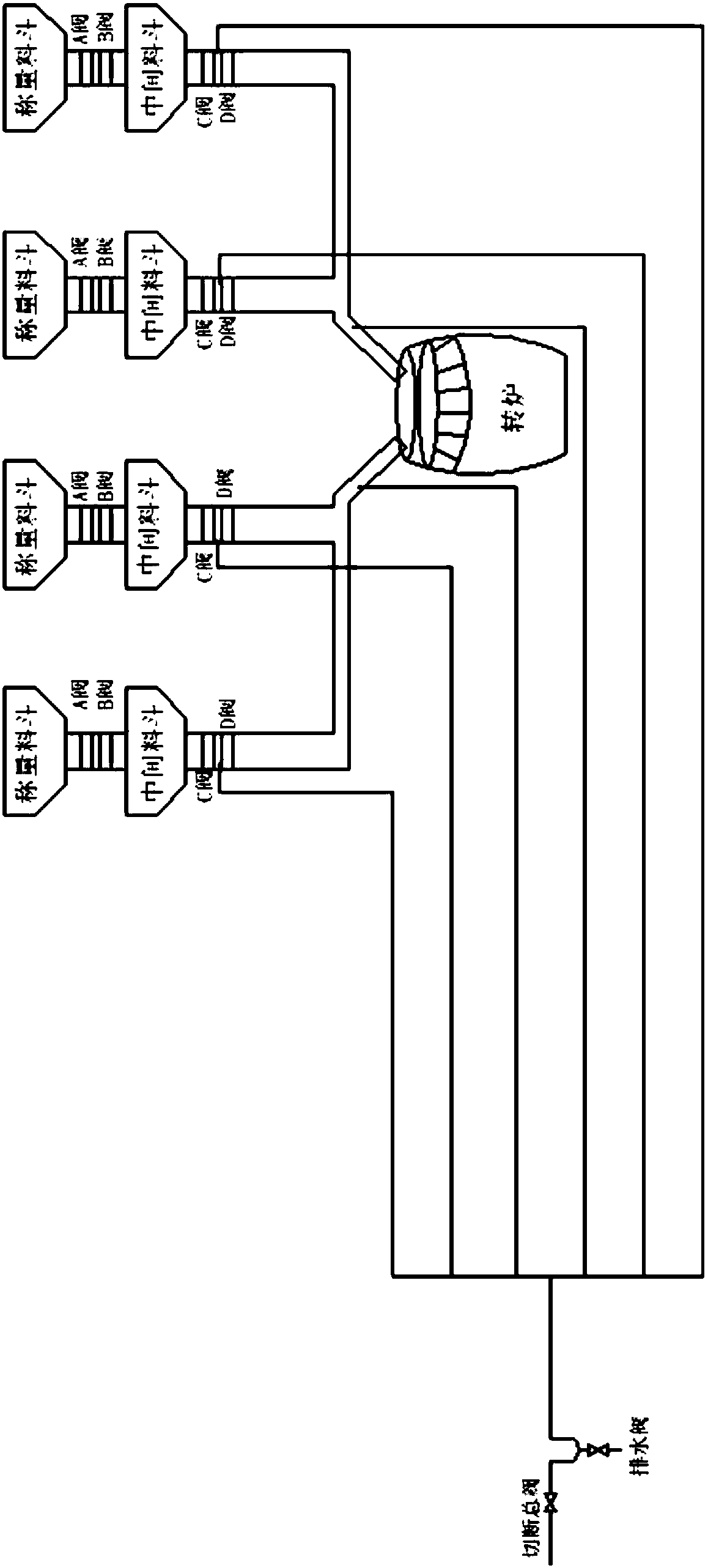

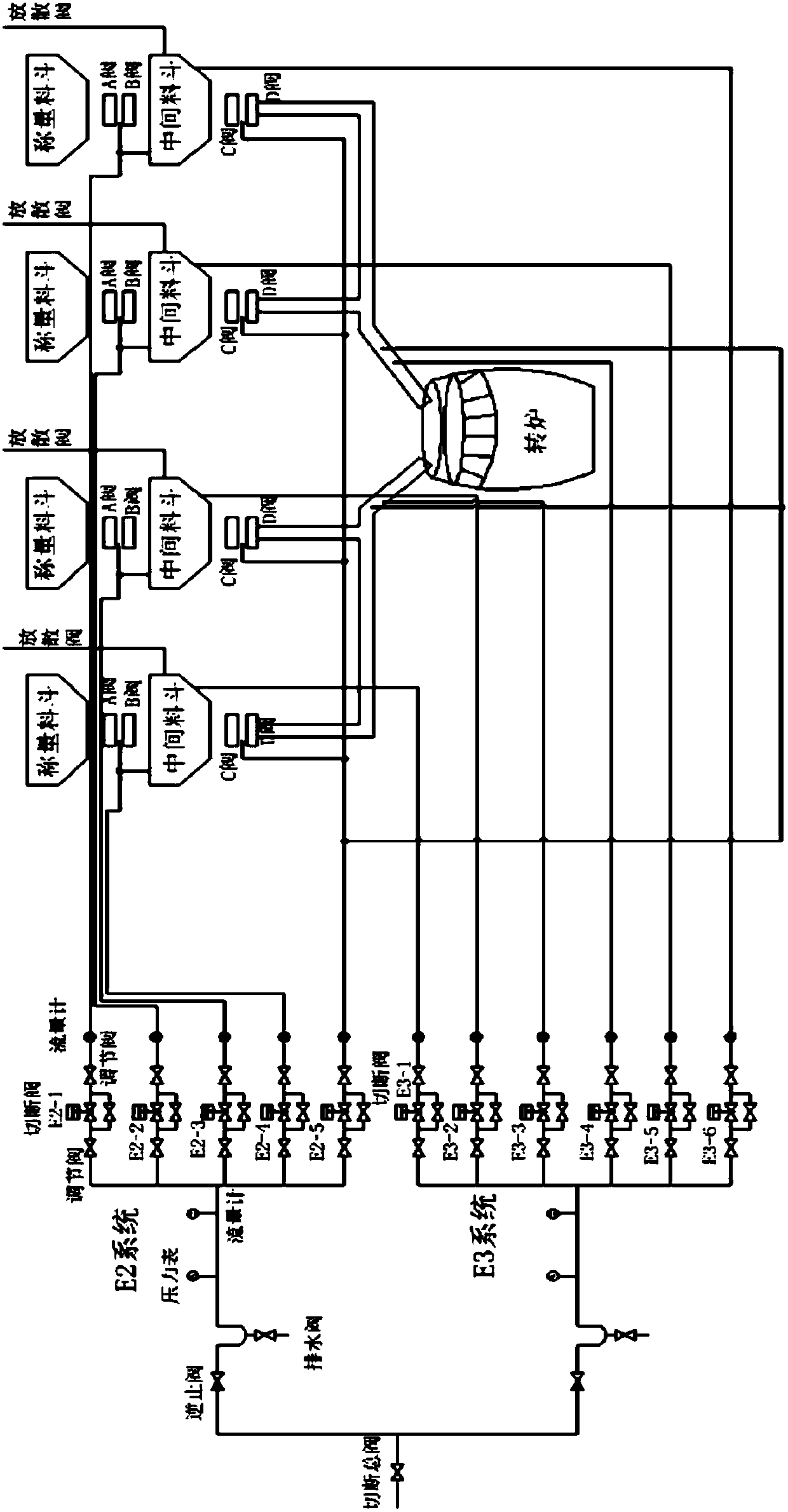

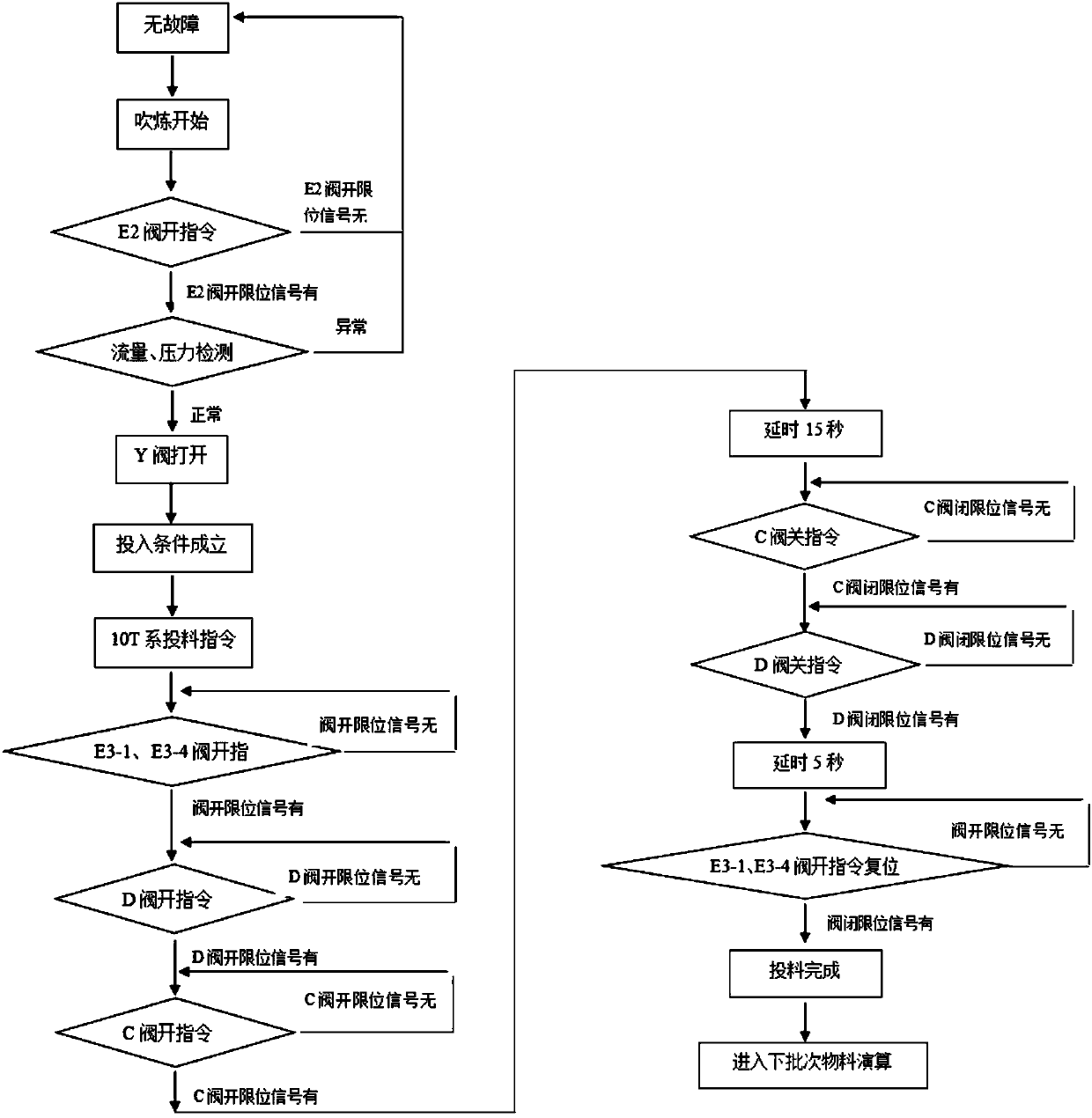

Nitrogen sealing device for auxiliary material and control method for nitrogen sealing of auxiliary material

The invention discloses a nitrogen sealing device for an auxiliary material and a control method for nitrogen sealing of the auxiliary material. The nitrogen sealing device comprises an intake manifold, a cut-off main valve, a check valve, a drain valve, a pressure gauge, a flowmeter, a weighing funnel, an intermediate hopper, a converter, a feeding pipe, a valve A, a valve B, a valve C, a valve D, an intermediate bunker anti-explosion nitrogen sealing E2 system and an auxiliary material feeding pipeline nitrogen sealing E3 system. The nitrogen sealing device for the auxiliary material is easyto maintain, has high reliability, saves the usage amount of nitrogen, presents good use effect, lowers the risk assessment result of the danger source of the device and improves work efficiency. According to the control method for nitrogen sealing of the auxiliary material, a control program is modified so as to realize improvement meeting process requirements; and a nitrogen-seal nitrogen valveis opened only during normal smelting and is not opened at other time, so the requirements of environmental protection are met and the purpose of nitrogen conservation is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Work method for mini word paint spraying through gantry type five-axis linkage intelligent vision paint spraying machine

InactiveCN108855805AMove quicklyEvenly paintedLiquid surface applicatorsLiquid spraying apparatusActivated carbonSpray nozzle

The invention discloses a work method for mini word paint spraying through a gantry type five-axis linkage intelligent vision paint spraying machine, and belongs to the technical field of automatic advertisement three-dimensional word paint spraying. Gantry type five-axis linkage, a water curtain cabinet and an intelligent vision mechanism are adopted in the paint spraying machine. The water curtain cabinet purifies oil mist generated during paint spraying through a water curtain and an activated carbon filter. A pressure nozzle is adopted as a nozzle and connected with a pressure oil pot through an oil pipe. According to the work method for mini word paint spraying, 1-4 sets of trolley tabletop options are preset in a control screen, each set of specifications conform to specifications offour tabletops on a walking trolley, mini words are correctly arranged in any set or placed in all sets, the trolley drives the four tabletops to enter the paint spraying position, the nozzle is arranged by the proper angle to conduct scanning and paint spraying on the mini words from right to left in a diagonal line manner (oblique line manner) and then conducts scanning and paint spraying on the mini words from left to right in a diagonal line manner (oblique line manner). Due to the paint spraying manner, the speed is high, paint spraying is uniform, paint is saved, time is saved, and thewater curtain cabinet and the activated carbon are matched to remove the oil mist so that the environment protection requirement can be met.

Owner:DALIAN SHISHIDA CNC MACHINERY TECH

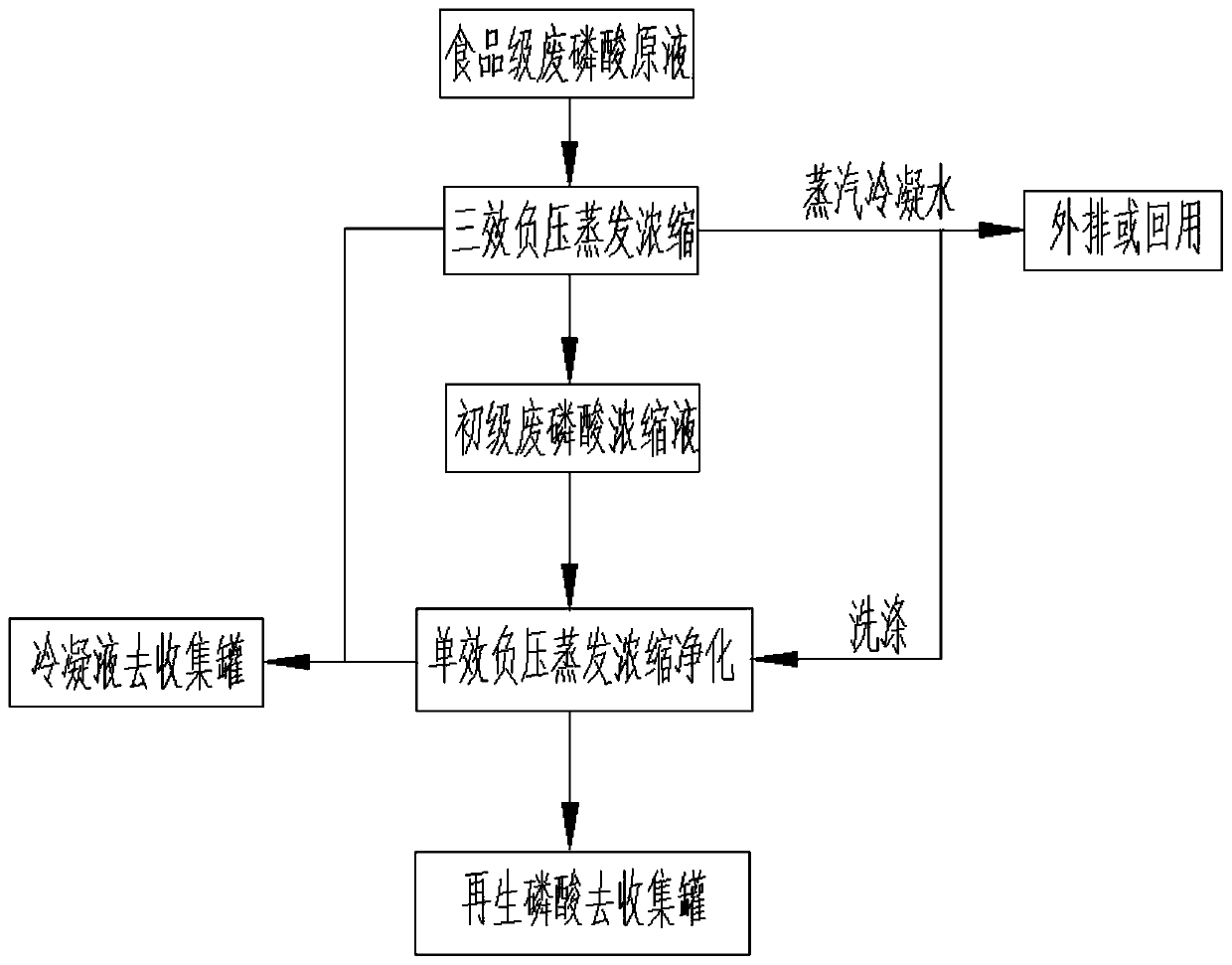

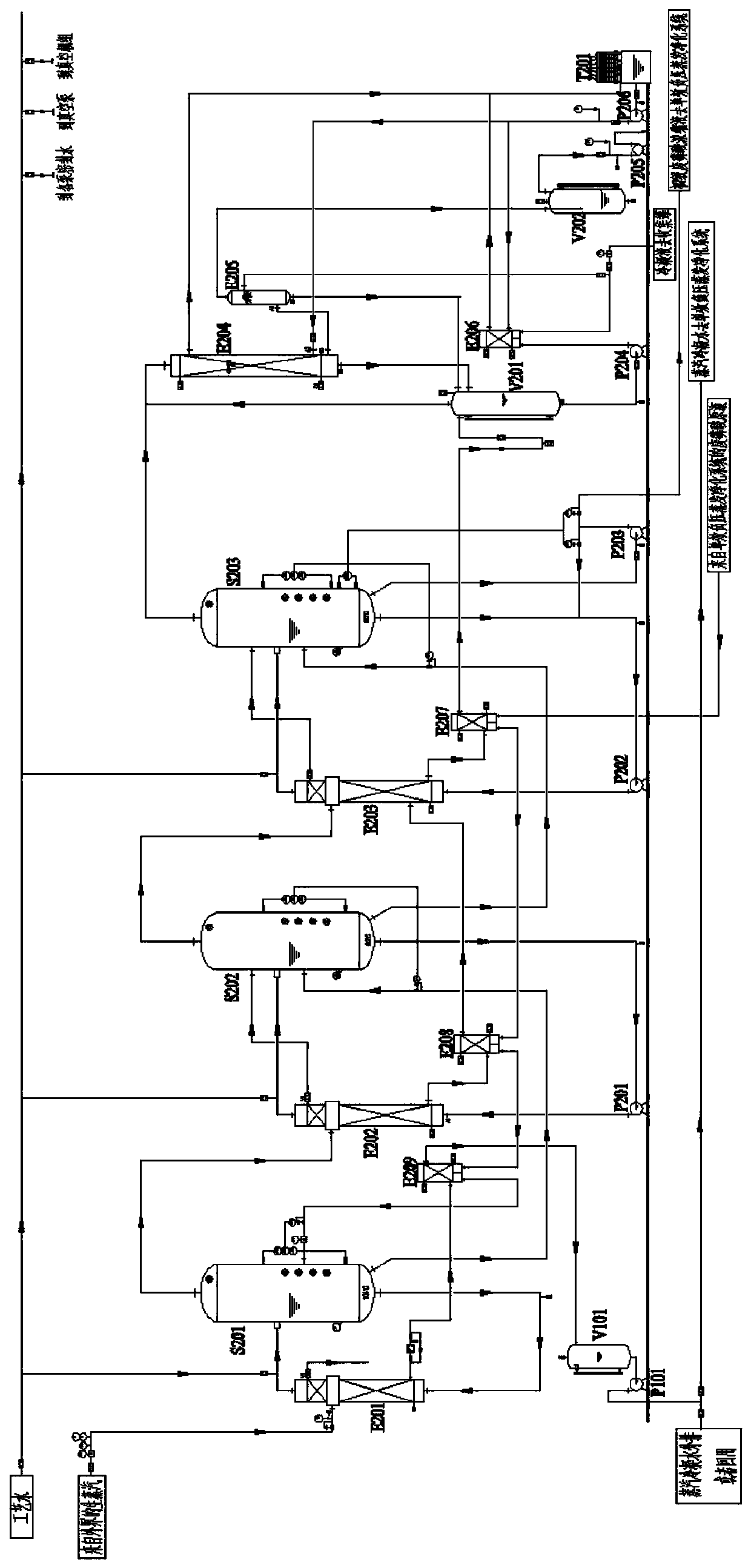

Two-stage negative-pressure evaporation, concentration and purification treatment process and device for food-grade waste phosphoric acid

PendingCN111514599AFor cost-effective processingMaximize recyclingEvaporator accessoriesPhosphorus compoundsO-Phosphoric AcidFood grade

The invention discloses a two-stage negative-pressure evaporation, concentration and purification treatment process and a device for food-grade waste phosphoric acid. The invention belongs to the technical field of waste phosphoric acid treatment. Food-grade waste phosphoric acid is treated by a triple-effect negative pressure evaporation concentration and single-effect negative pressure evaporation concentration purification technology; the recovered regenerated phosphoric acid is high in purity, the mass concentration is greater than or equal to 85%, and no adverse effect is generated on a production process when the recovered regenerated phosphoric acid is returned to a workshop for use, so that economic and efficient treatment of food-grade waste phosphoric acid and maximum recycling of phosphoric acid resources are realized; the steam heating average distribution coefficient is high, so that the repeated utilization rate is high; the characteristics of high heat transfer efficiency, short heating time and the like are realized; according to the process and the device, the total steam consumption of food-grade waste phosphoric acid treatment is 1 / 3 of that of common evaporationequipment, the total operation power is 1 / 2 of that of traditional evaporation equipment, the process and the device have the advantages of energy conservation, consumption reduction, low steam consumption, low cooling water circulation amount and the like, wet and latent heat is fully utilized, the raw steam consumption is reduced, and the operation cost is reduced.

Owner:江苏泰特联合环保科技有限公司

Slag-forming constituents used for zinc and zinc-base alloy fusion casting

The invention relates to a slag-forming constituent in fusing zinc and zinc-base alloy, which is used to slag off zinc or zinc-base alloy and clarify molten metal when zinc-base alloy is used. The slag-forming constituent comprises 55-75wt% of CaF2, 3-8wt% of Na3AlF6, 3-8wt% of KCl, 5-10wt% of NaCl, 5-20wt% of ZnCl2 and 5-15wt% of C powder. The invention improves interfacial force and boundary tension of slag and metal by using chlorine saline to separate slag from liquid metal efficiently, and reduces evaporation of slag under high and low temperature to reduce environmental contamination. The invention has an extensive usage such as zinc ingot casting, zinc-base alloy product casting and zinc-base product later usage.

Owner:株洲冶炼集团有限责任公司

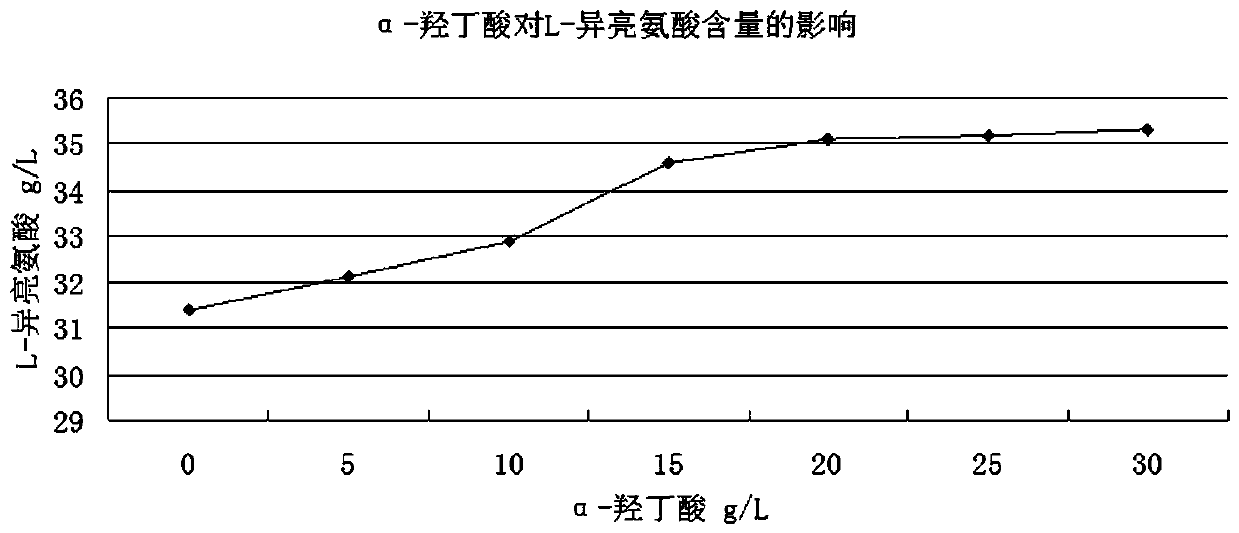

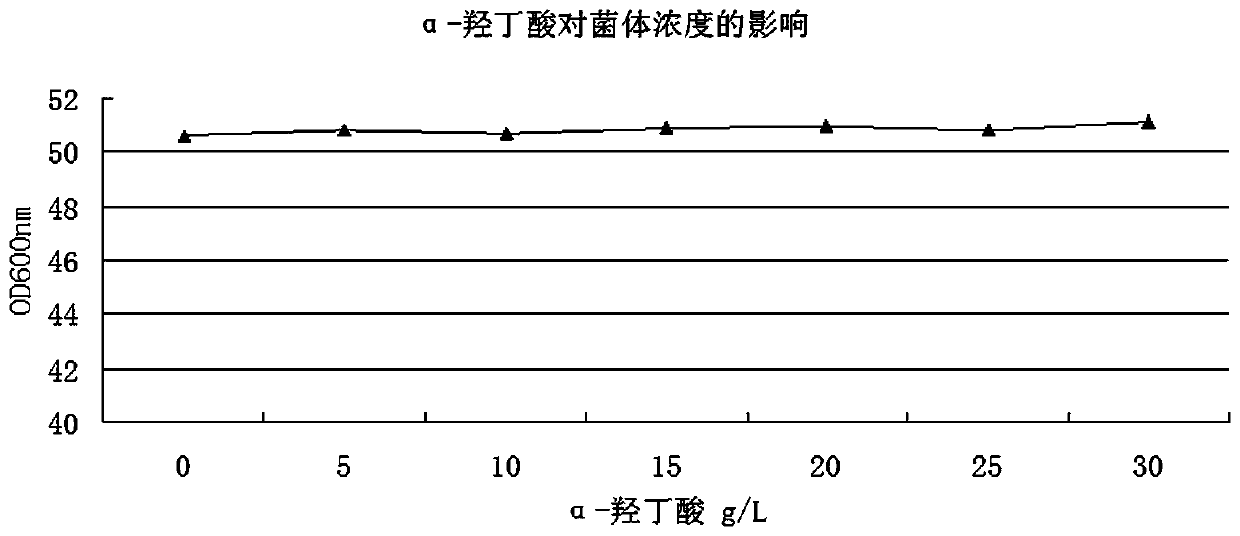

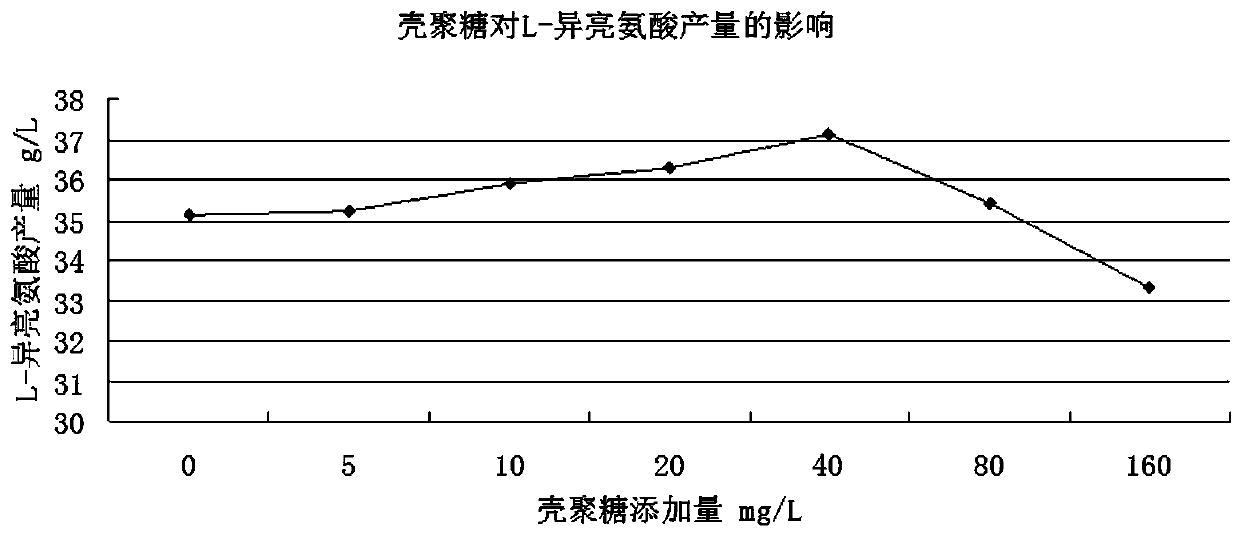

Production technology of L-isoleucine

ActiveCN110607330AIncrease productionGuarantee hygienic requirementsOrganic compound preparationChemical industryDissolutionFermentation

The invention belongs to the technical field of production of L-isoleucine, and discloses a production technology of L-isoleucine. The production technology of the L-isoleucine comprises the followingsteps of step (1) fermentation, step (2) concentration and re-dissolution, step (3) first decoloration, step (4) secondary decoloration and step (5) edulcoration and crystallization. The production technology of the L-isoleucine is simple and feasible, and the yield and purity of the L-isoleucine are improved.

Owner:XINJIANG FUFENG BIOTECH

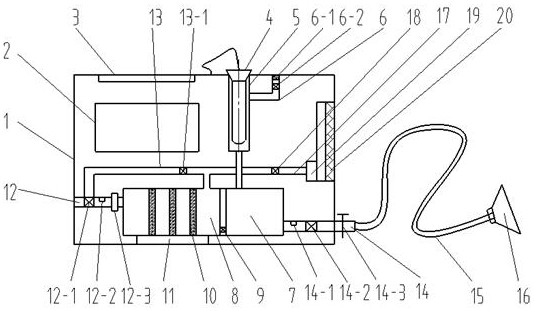

An Intelligent Ozone Therapeutic Instrument

ActiveCN110201308BGuarantee security requirementsGuarantee environmental requirementsDispersed particle separationMedical devicesMedicineControl cell

The invention relates to the field of medical equipment, and especially relates to an intelligent ozone therapeutic apparatus, which comprises a body, a control unit, a manipulation display unit, an ultraviolet radiator, an ozone generating chamber, an ozone storage chamber and an ozone catalytic chamber; the ultraviolet radiator is controlled by the control unit to generate ozone in the ozone generating chamber and stored in the ozone storage chamber, after the ozone concentration detected by a second ozone concentration detector reaches a treatment standard, the control unit can control a fourth one-way valve to open, and treatment disc is close to the diseased part for treating the diseased part; after the treatment is finished, the fourth one-way valve is closed, a solenoid valve, a second one-way valve and a exhaust fan on a first exhaust pipe are opened under the control of the control unit, the residual ozone in the ozone storage chamber can be catalyzed into safe gas through the ozone catalytic chamber, and discharged into the atmosphere, the ozone entering the air during the treatment can be sucked into the ozone catalytic chamber for purification, and the use safety and environmental requirements of ozone can be ensured through various means.

Owner:张雪梅 +1

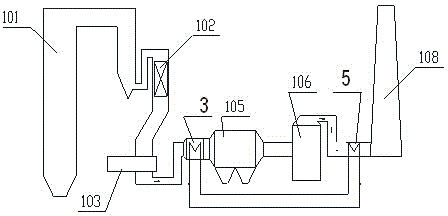

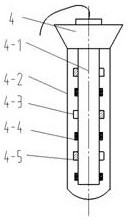

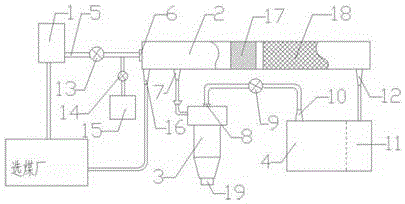

Device for producing power plant fuel by use of coal slime slurry from coal preparation plant and technology thereof

The invention belongs to the technical field of coal preparation plant's coal slime slurry processing and slime comprehensive utilization, and specifically relates to a device for producing power plant fuel by the use of coal slime slurry from a coal preparation plant and a technology thereof. The device for producing power plant fuel by the use of coal slime slurry from a coal preparation plant comprises a coal slime slurry buffer pool, a flocculant tank, a horizontal decanter centrifuge drying all-in-one machine, a gas-solid separator and a power plant boiler. The coal slime slurry buffer pool is connected to a feed inlet of the horizontal decanter centrifuge drying all-in-one machine, a gas mixed drier outlet of which is connected to the gas-solid separator. A gas outlet at the upper end of the gas-solid separator is connected to a feedback gas inlet of the power plant boiler. A shaft flue at the upper end of the gas-solid separator is connected to a high temperature gas inlet of the horizontal decanter centrifuge drying all-in-one machine. The flocculant tank is connected to a feed pipe. The device is an integrated system for direct production of low-moisture high-quality power plant fuel. The production flow is simplified; investment in equipment and system is reduced; and production and operational cost is decreased.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

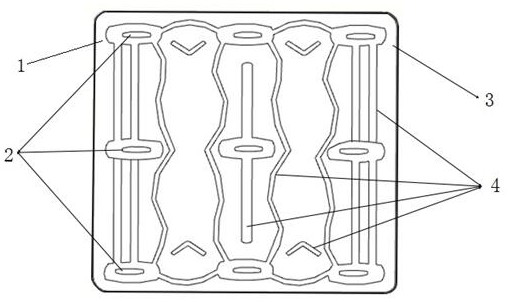

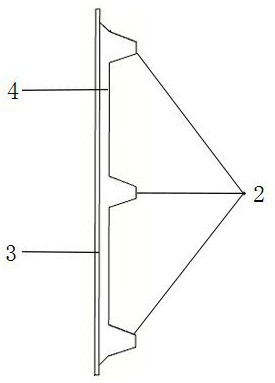

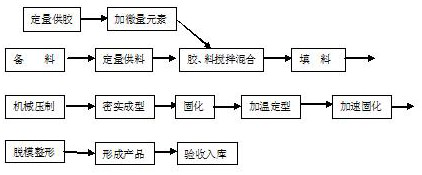

Artificial composite tray for logistics and preparation method thereof

PendingCN114313537AEfficient use ofGuaranteed StrengthRigid containersAdhesive cementLogistics management

The invention discloses an artificial composite tray for logistics and a preparation method thereof, the artificial composite tray for logistics comprises a tray surface and at least four circular-truncated-cone-shaped hollow bottom feet, the tray surface is integrally pressed and formed, the bottom feet protrude towards the same side of the tray surface, and a fork hole is formed between every two adjacent bottom feet; edge ribs protruding towards the same side of the disc face are pressed on the peripheral edge of the disc face. According to the artificial composite tray for logistics, crushed materials of waste materials such as straw, wood chips and saw dust and modified urea-formaldehyde resin glue are pressed, cured, heated and shaped to be integrally formed, and the strength and stability of the tray are guaranteed; meanwhile, local materials can be used, waste such as straw is effectively utilized, and the manufacturing cost of the tray is reduced. A certain amount of free urea is formed in the adhesive, so that the free urea captures and absorbs free formaldehyde existing in adhesive preparation and formaldehyde released during thermocuring of the composite tray, emission of harmful gas in production and use is greatly captured and eliminated, and the adhesive becomes an environment-friendly product.

Owner:郑全成

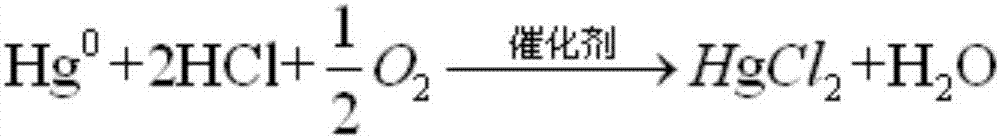

A kind of sncr-based combined mercury removal method and device

ActiveCN105268300BMeet the requirements of emission standardsEasy to transformDispersed particle separationMixersProcess equipmentFlue gas

The invention provides an SNCR-based combined mercury removal device, which can effectively combine two flue gas treatment technologies, and achieve the purpose of denitrification and mercury removal while reducing costs. It includes two sets of independent metering systems, a set of solution preparation system connected to the output ends of the two sets of metering systems, and a solution delivery system and a solution injection system sequentially connected to the output ends of the solution preparation system; the solution injection system includes injection inlets and spray guns; The injection inlet is set on the furnace in the SNCR system, and the spray gun is connected to the injection inlet and extended into the furnace for setting; two sets of metering systems are used to measure urea and ammonium chloride solids according to the demand for removing NOx and zero-valent mercury . Combining mercury removal technology with SNCR to obtain the superiority of two-in-one technology and develop advanced SNCR technology. On the basis of the original facilities, no additional process equipment is added except for the metering system, making the process more simple, economical, and economical. Capital cost.

Owner:CHINA HUANENG GRP CO LTD +1

Device and process for producing power plant fuel with coal precipitation plant coal slime slurry

The invention relates to the technical field of coal precipitation plant coal slime slurry treatment and coal slime comprehensive utilization, and specifically relates to a device and a process for producing a power plant fuel with coal precipitation plant coal slime slurry. The device comprises a coal slime slurry buffering tank, a flocculant tank, a horizontal screw centrifugation drying integrated machine, a gas-liquid separator, and a power plant boiler. The coal slime slurry buffering tank is connected with the feeding port of the horizontal screw centrifugation drying integrated machine. A gas mixing dry material outlet on the horizontal screw centrifugation drying integrated machine is connected with the gas-solid separator. A gas outlet on the upper end of the gas-solid separator is connected with a feedback gas inlet of the power plant boiler. A shaft flue is connected with a high-temperature gas inlet on the horizontal screw centrifugation drying integrated machine. The flocculant tank is connected with a feeding pipe. The device is an integrated system for directly producing low-water high0quality power plant fuel. The production process is simplified. Equipment, system investment and production operation costs are reduced.

Owner:邵杰

A kind of fireproof exterior wall dry powder mortar

The invention discloses fireproof dry-mixed mortar for an exterior wall. The fireproof dry-mixed mortar is composed of the following components in percentage by weight: portland cement, quartz sand, filler, bentonite, redispersible latex powder, cellulose ether, citric acid, fine fused magnesite powder and sepiolite powder. The fireproof dry-mixed mortar has a favorable adhesive force with a fundamental plane, and materials are economic and practical, so that the cost can be reduced; meanwhile, a base layer treated by using the material cannot bulge and flake, so that a construction site can be kept clean, and the requirement for environment friendliness can be better met; and part of yellow sand is replaced with gangue, so that the pollution can be relieved, the cost can be reduced, and the fireproof effect can also be achieved.

Owner:DEQING YANGTAI BUILDING MATERIAL

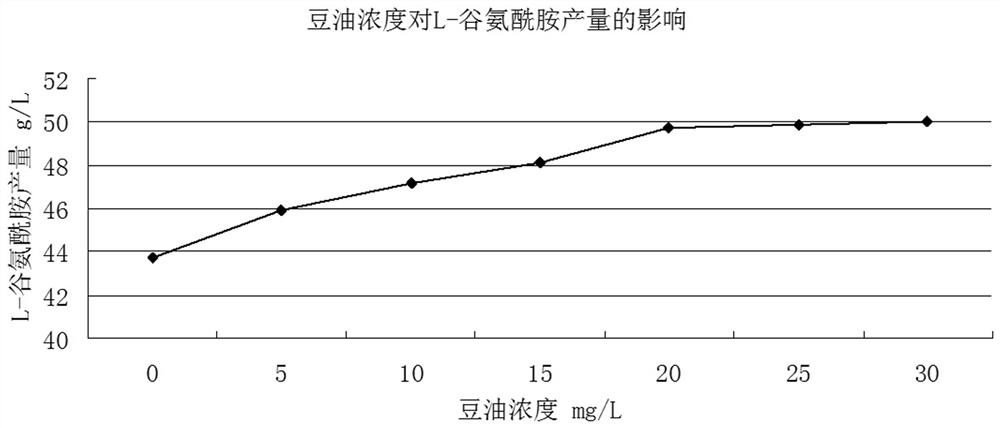

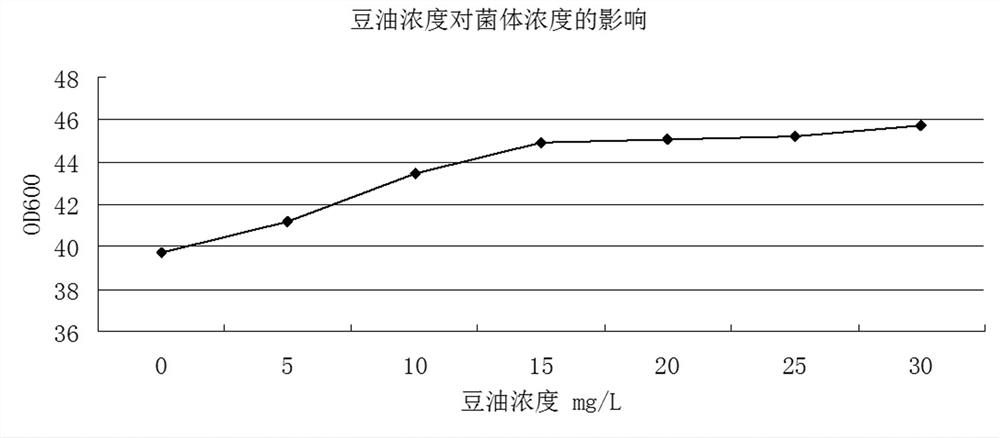

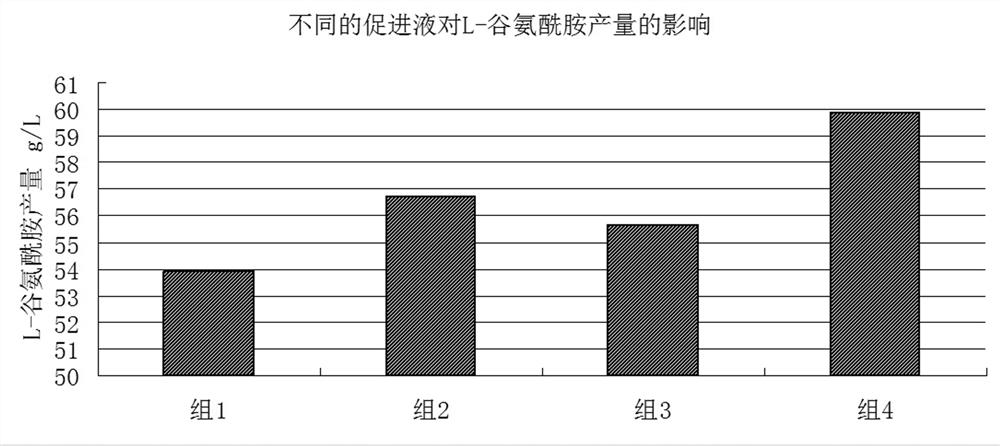

A method for producing, separating and extracting L-glutamine

ActiveCN111057727BImprove fermentation yieldReduce solubilityMicroorganism based processesCarboxylic acid amide separation/purificationFluidized bed dryingActivated carbon

The invention belongs to the production field of L-glutamine, and discloses a method for producing, separating and extracting L-glutamine, which includes the following steps: 1) fermentation, 2) ceramic membrane filtration, 3) concentration and redissolution, 4) Simulated moving bed chromatography, 5) Activated carbon decolorization, 6) Refining concentration, crystallization and centrifugation, 7) Fluidized bed drying. The invention improves the output, purity, extraction yield, product quality and production efficiency of L-glutamine, and at the same time, reduces the amount of acid and alkali, reduces the discharge of waste water and waste, and reduces the pressure on environmental protection.

Owner:XINJIANG FUFENG BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com