Cleaning and roughening device and method for remanufacturing waste rubber conveying belt

A conveyor belt and waste rubber technology, which is applied in the field of conveyor belt remanufacturing, can solve the problems of affecting the removal effect of the rubber covering layer, damage to the tool, residual glue of the belt core layer, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

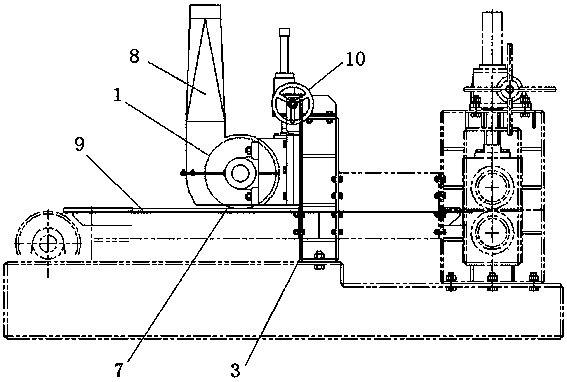

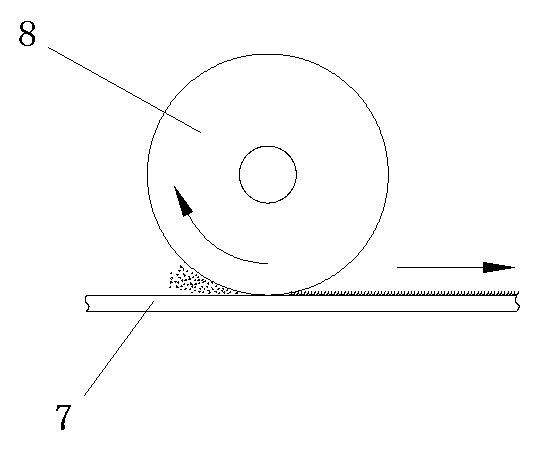

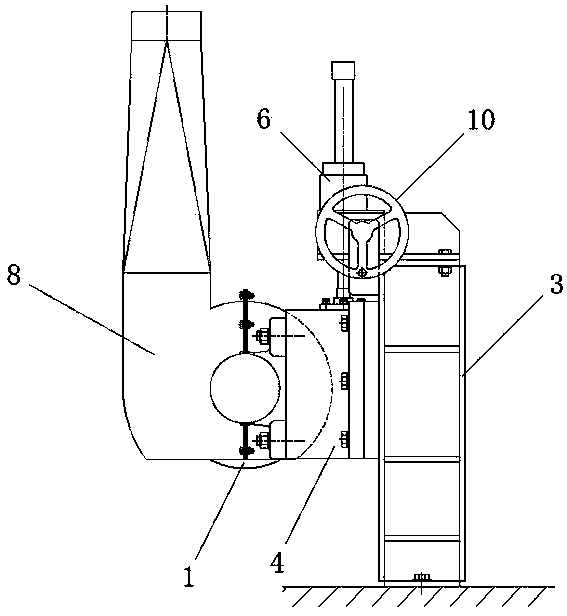

[0025] Such as figure 1 , image 3 and Figure 4 As shown, the present invention provides a cleaning and deburring device for remanufacturing waste rubber conveyor belts, which is suitable for rubber conveyor belts with cotton canvas cores, polyester canvas cores and polyester canvas cores. The device includes a cylindrical brush roller 1, a gear motor 2, a door frame 3 and a brush roller bracket 4, the door frame 3 is fixedly installed on the production line, and the gear motor 2 drives the cylinder brush roller 1 to rotate for cleaning and brushing. Hair waste rubber conveyor belt; in order to guide the conveyor belt 7 to pass through the friction roller surface under the cylinder brush roller 1, a material guide plate 9 for guiding the conveyor belt 7 is arranged under the cylinder brush roller 1, so as to prevent the conveyor belt 7 from passing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com