Two-stage negative-pressure evaporation, concentration and purification treatment process and device for food-grade waste phosphoric acid

A technology of negative pressure evaporation concentration and negative pressure evaporation, which is applied in the field of two-stage negative pressure evaporation concentration purification treatment process and device of food-grade waste phosphoric acid, can solve the problem of low utilization rate of phosphorus resources, poor economy and efficiency, and poor economy and other problems, to achieve the effect of saving raw steam consumption, low cooling water circulation, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

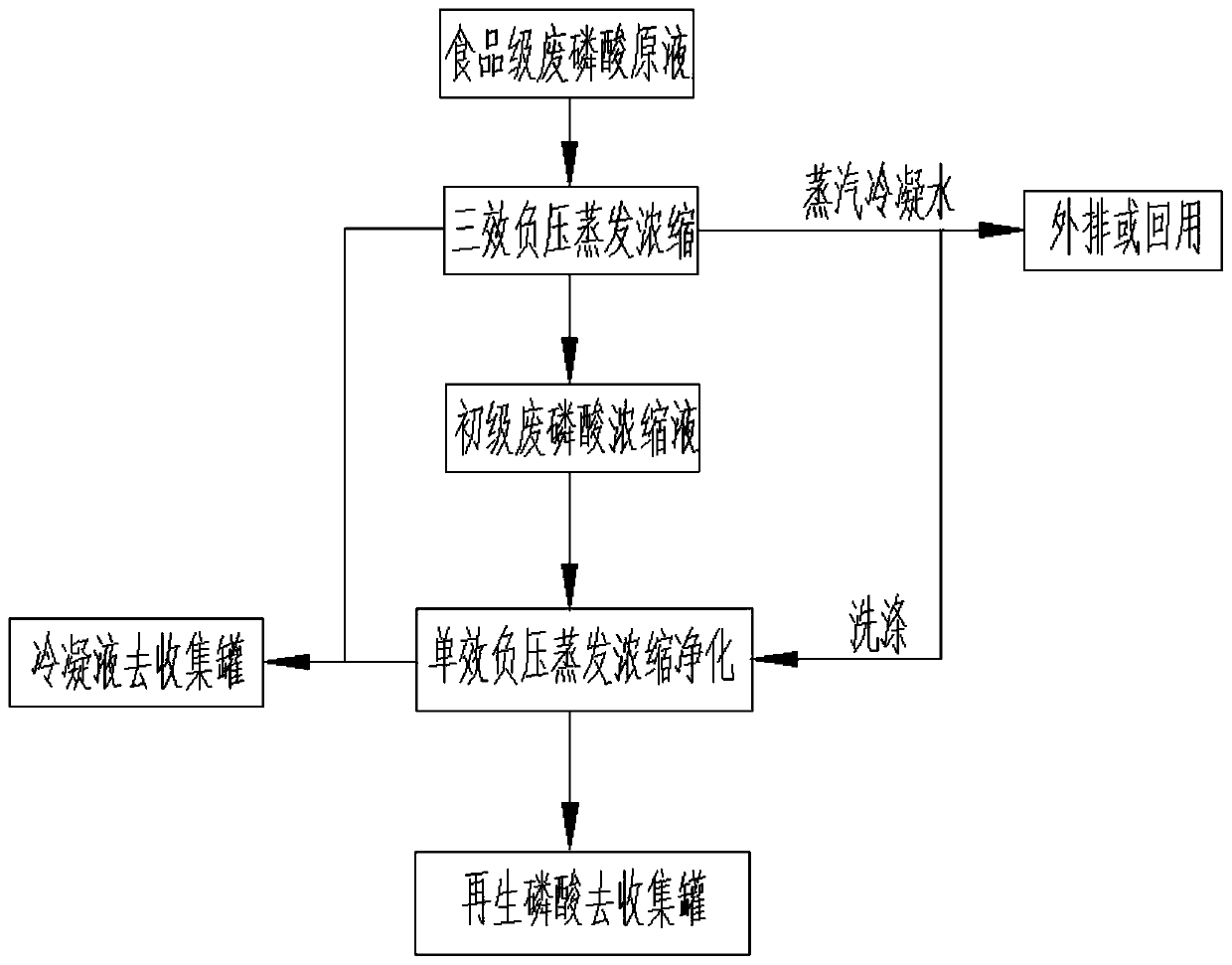

[0046] Such as figure 1 As shown, the present invention is a two-stage negative pressure evaporation concentration purification treatment process for food-grade waste phosphoric acid, comprising the following steps:

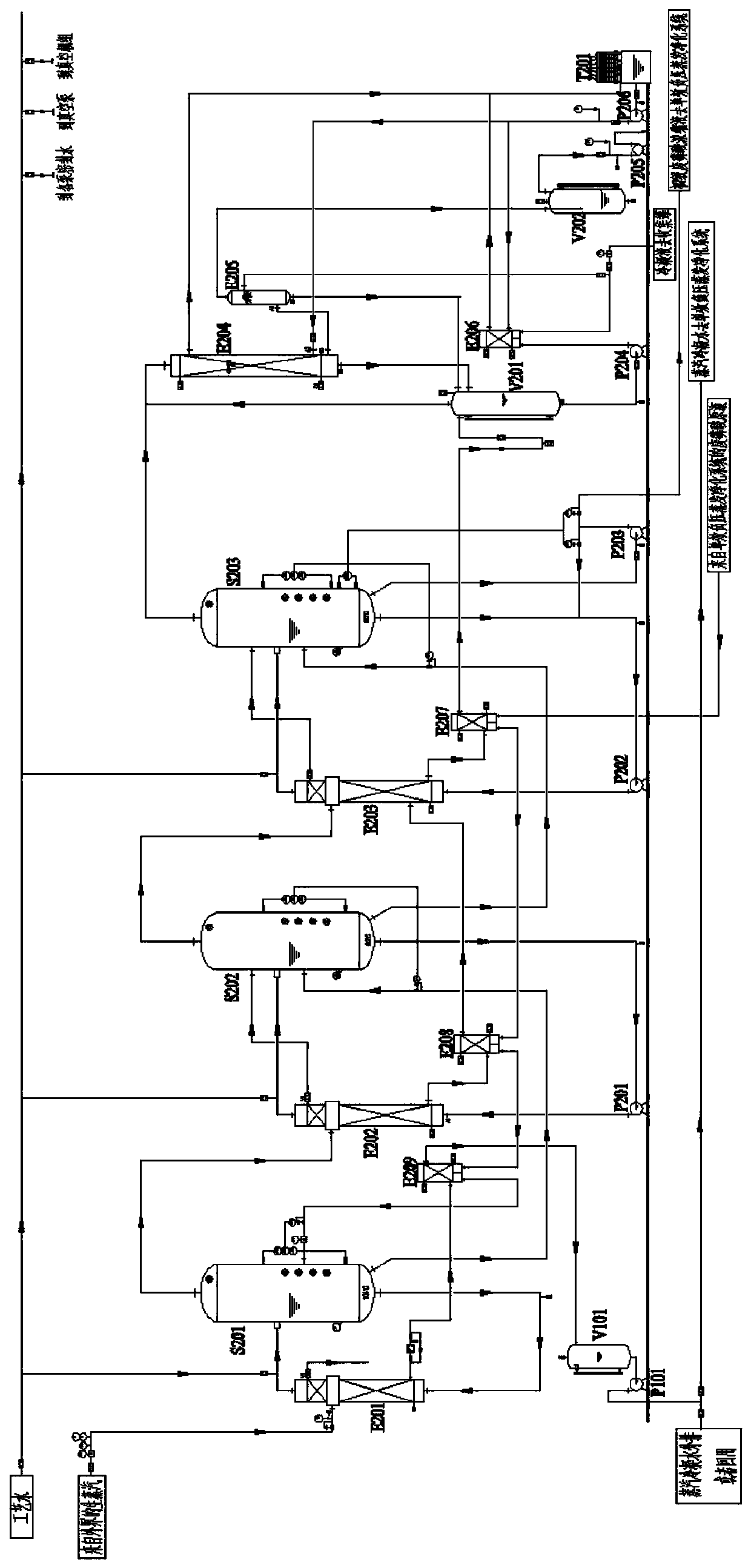

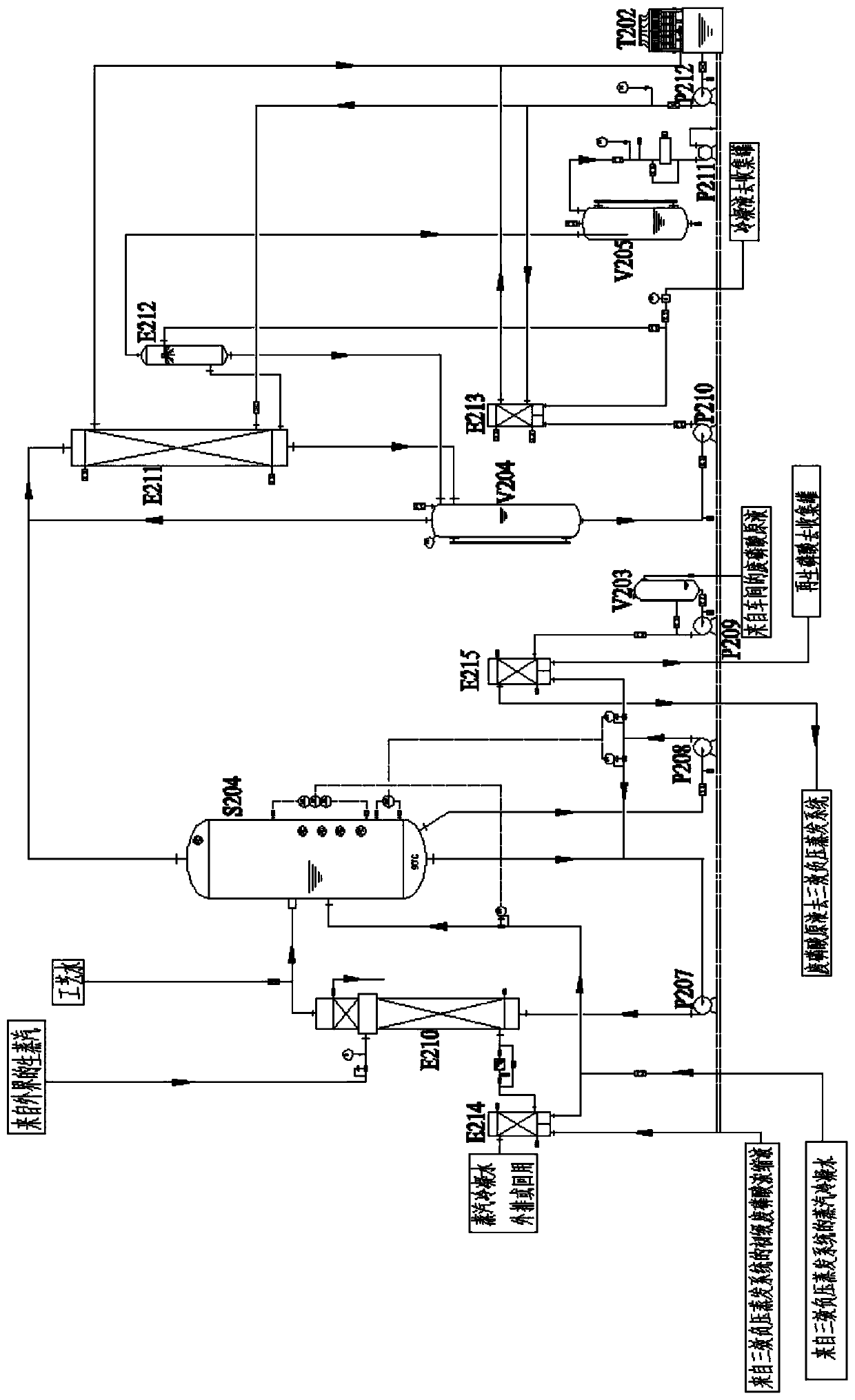

[0047] S1: Three-effect negative pressure evaporation: Under negative pressure conditions, the waste phosphoric acid stock solution from the workshop is preheated and injected into the three-effect negative pressure evaporation system. In the three-effect negative pressure evaporation system, raw steam from the outside Saturated steam is provided in the evaporation unit, the secondary steam generated by the first-effect evaporation unit enters the second-effect evaporation unit, the secondary steam generated by the second-effect evaporation unit enters the third-effect evaporation unit, and the secondary steam generated by the three-effect evaporation unit After cooling, dilute acid is recovered; in the three-effect negative pressure evaporation system, the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com