Method for recovering tail gas of propane oxidation preparation of acrylic acid

A technology of acrylic acid and oxidation method, which is applied in the chemical industry, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems affecting the economic benefits of enterprises, low propane conversion rate, environmental problems, etc., and achieves life extension, less investment, Reduce the effect of being able to shout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

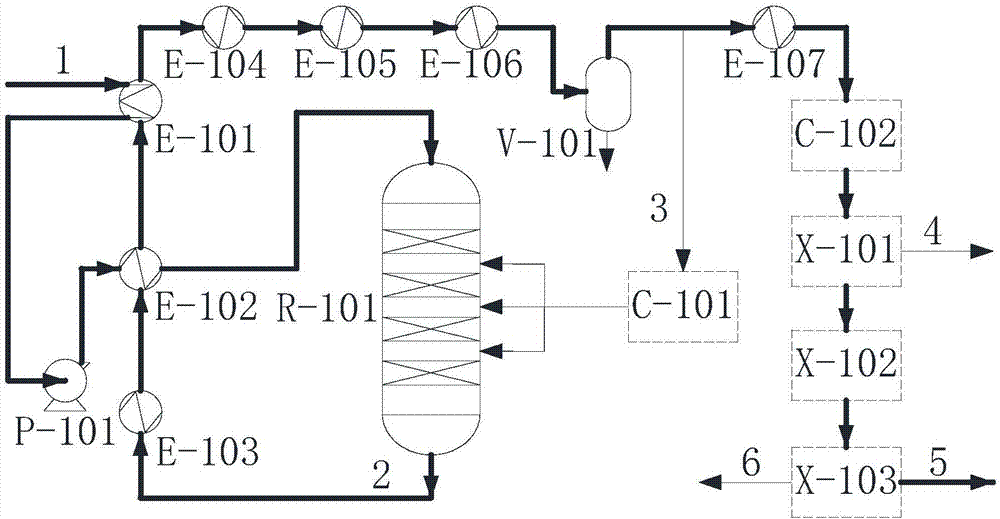

[0057] In this example, propane oxidation to prepare acrylic acid tail gas recovery device and process flow are as follows figure 1 shown. During operation, the temperature of the raw material tail gas of stream 1 is 80°C, the pressure is 115kPaA, and the flow rate is 57538Nm 3 / h, the molar composition is nitrogen 49.86%, carbon monoxide 0.89%, oxygen 4.83%, carbon dioxide 0.59%, propylene 0.18%, propane 6.57%, water 37.03%, acrylic acid 0.001%, acetone 0.049%; raw material tail gas enters the tail gas preheater first I E-101 is preheated to 90°C to prevent liquid water from being precipitated by subsequent pressurization; the preheated exhaust gas enters the exhaust gas blower P-101 to pressurize to 160kPaA; then it is preheated to 250°C by the exhaust gas preheater IIE-102 , into the oxidation reactor R-101.

[0058] The oxidation reactor R-101 adopts a fixed bed reactor, and the catalyst is a supported noble metal catalyst. The catalyst particle diameter is 3-4mm, the bu...

example 2

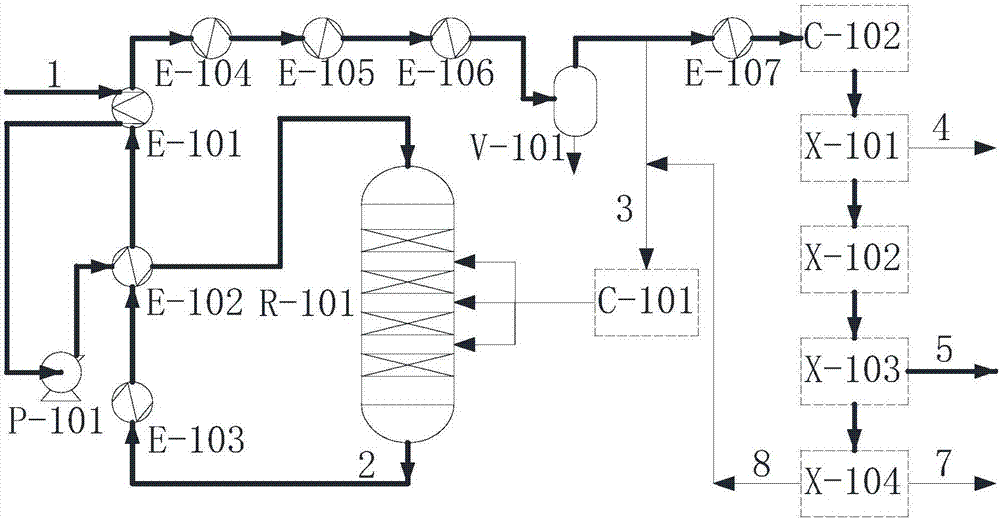

[0064] In this example, propane oxidation to prepare acrylic acid tail gas recovery device and process flow are as follows figure 2 As shown. During operation, the tail gas temperature of stream 1 raw material is 80°C, the pressure is 115kPaA, and the flow rate is 57538Nm 3 / h, the molar composition is nitrogen 49.86%, carbon monoxide 0.89%, oxygen 4.83%, carbon dioxide 0.59%, propylene 0.18%, propane 6.57%, water 37.03%, acrylic acid 0.001%, acetone 0.049%; raw material tail gas enters the tail gas preheater first I E-101 is preheated to 90°C to prevent liquid water from being precipitated by subsequent pressurization; the preheated exhaust gas enters the exhaust gas blower P-101 to pressurize to 160kPaA; then it is preheated to 250°C by the exhaust gas preheater IIE-102 , into the oxidation reactor R-101.

[0065] The oxidation reactor R-101 adopts a fixed bed reactor, and the catalyst is a supported noble metal catalyst. The catalyst particle diameter is 3-4mm, the bulk d...

example 3

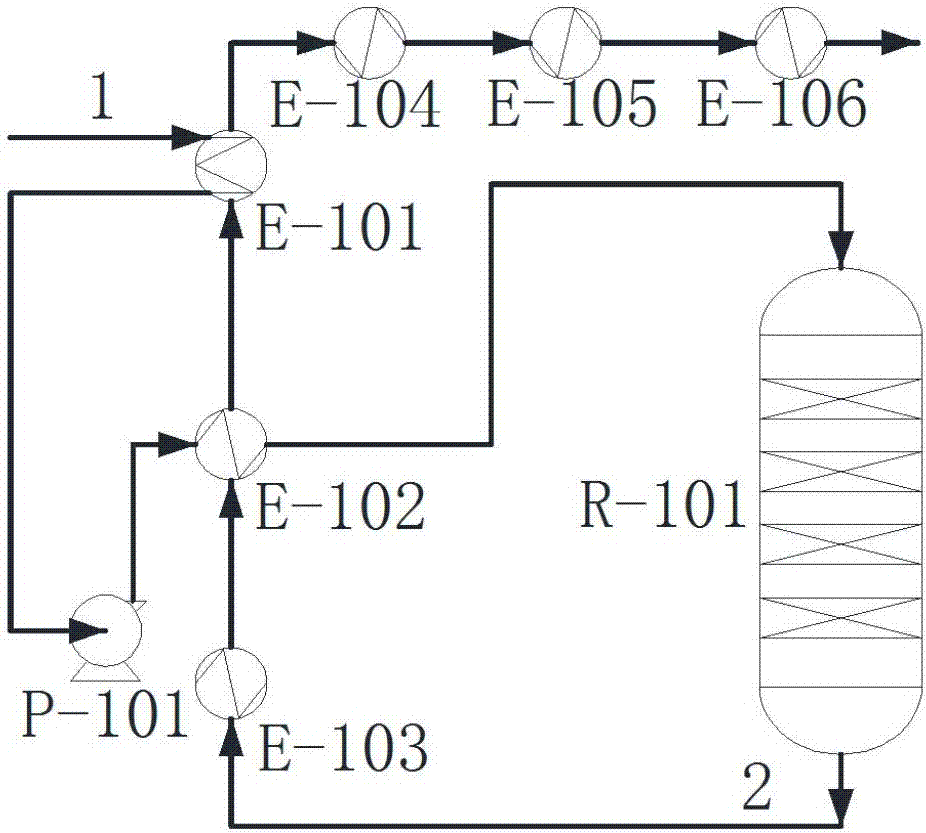

[0071] In this example, propane oxidation to prepare acrylic acid tail gas recovery device and process flow are as follows image 3 shown. During operation, the temperature of the raw material tail gas of stream 1 is 80°C, the pressure is 115kPaA, and the flow rate is 57538Nm 3 / h, the molar composition is nitrogen 49.86%, carbon monoxide 0.89%, oxygen 4.83%, carbon dioxide 0.59%, propylene 0.18%, propane 6.57%, water 37.03%, acrylic acid 0.001%, acetone 0.049%; raw material tail gas enters tail gas preheater first I E-101 is preheated to 90°C to prevent liquid water from being precipitated by subsequent pressurization; the preheated exhaust gas enters the exhaust blower P-101 to pressurize to 160kPaA; then it is preheated to 180°C by the exhaust gas preheater IIE-102 , into the oxidation reactor R-101.

[0072] The oxidation reactor R-101 adopts a fixed bed reactor, and the catalyst is a supported noble metal catalyst. The catalyst particle diameter is 3-4mm, the bulk densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com