Patents

Literature

319 results about "Enone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

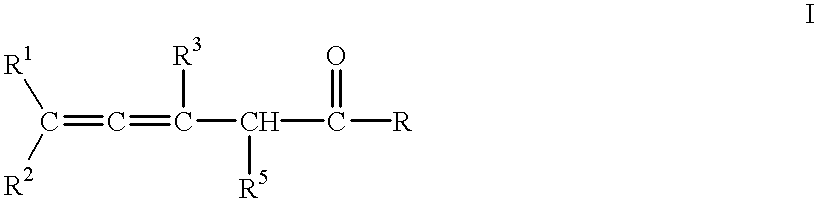

An enone, also called an α,β-unsaturated carbonyl, is a type of organic compound consisting of an alkene conjugated to a ketone. The simplest enone is methyl vinyl ketone (butenone) or CH₂=CHCOCH₃. An enal is the corresponding α,β-unsaturated aldehyde, an example being acrolein (CH₂=CHCHO).

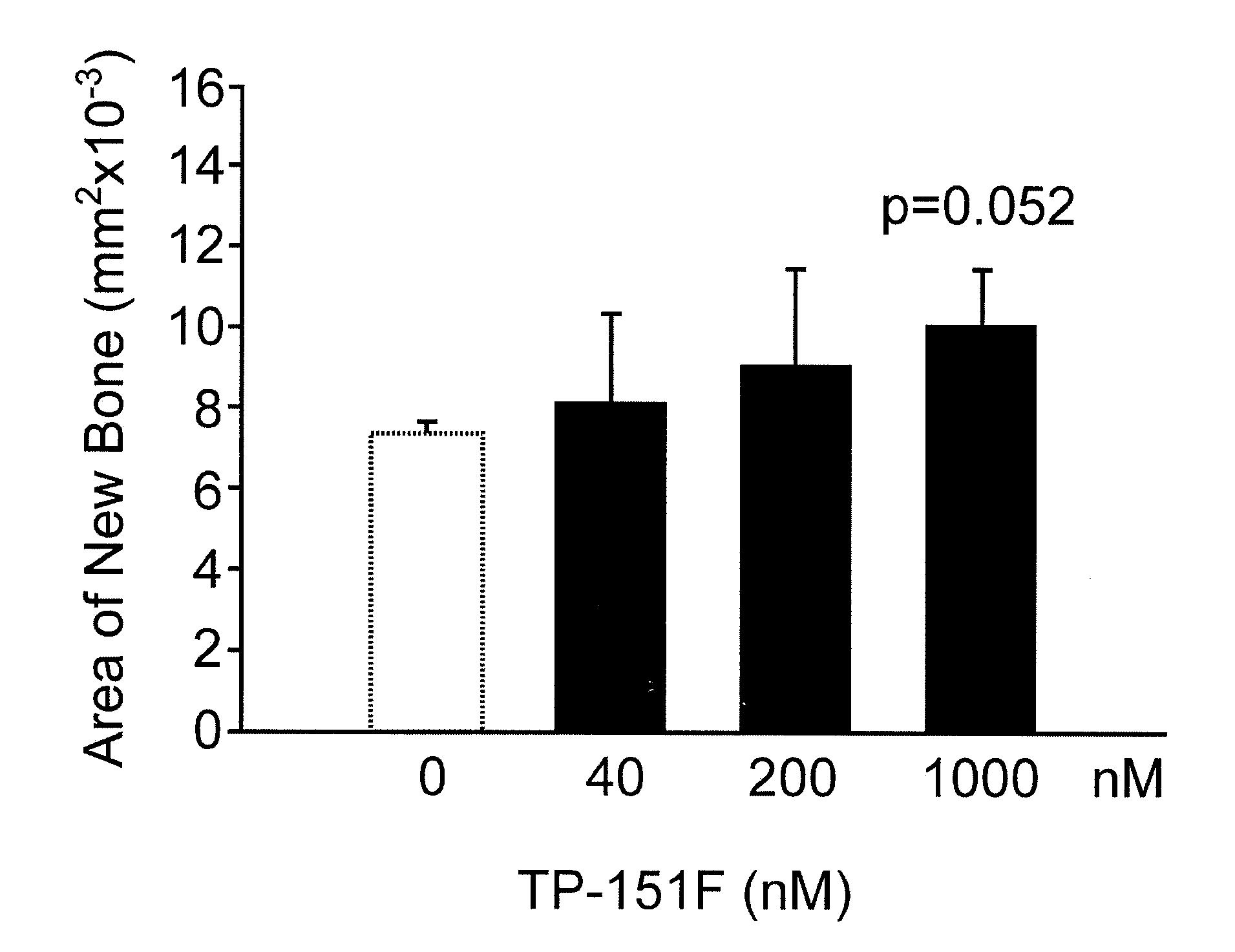

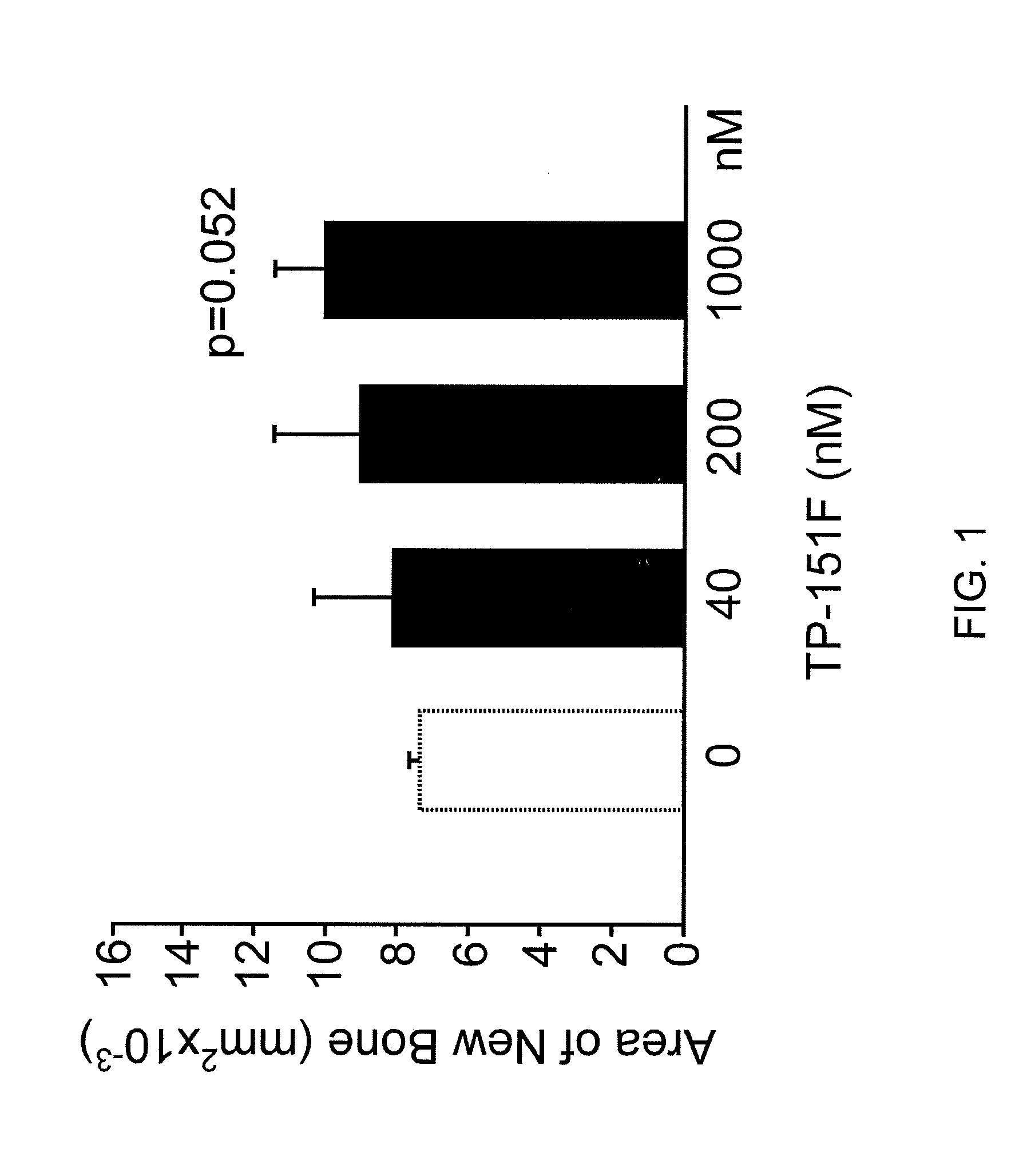

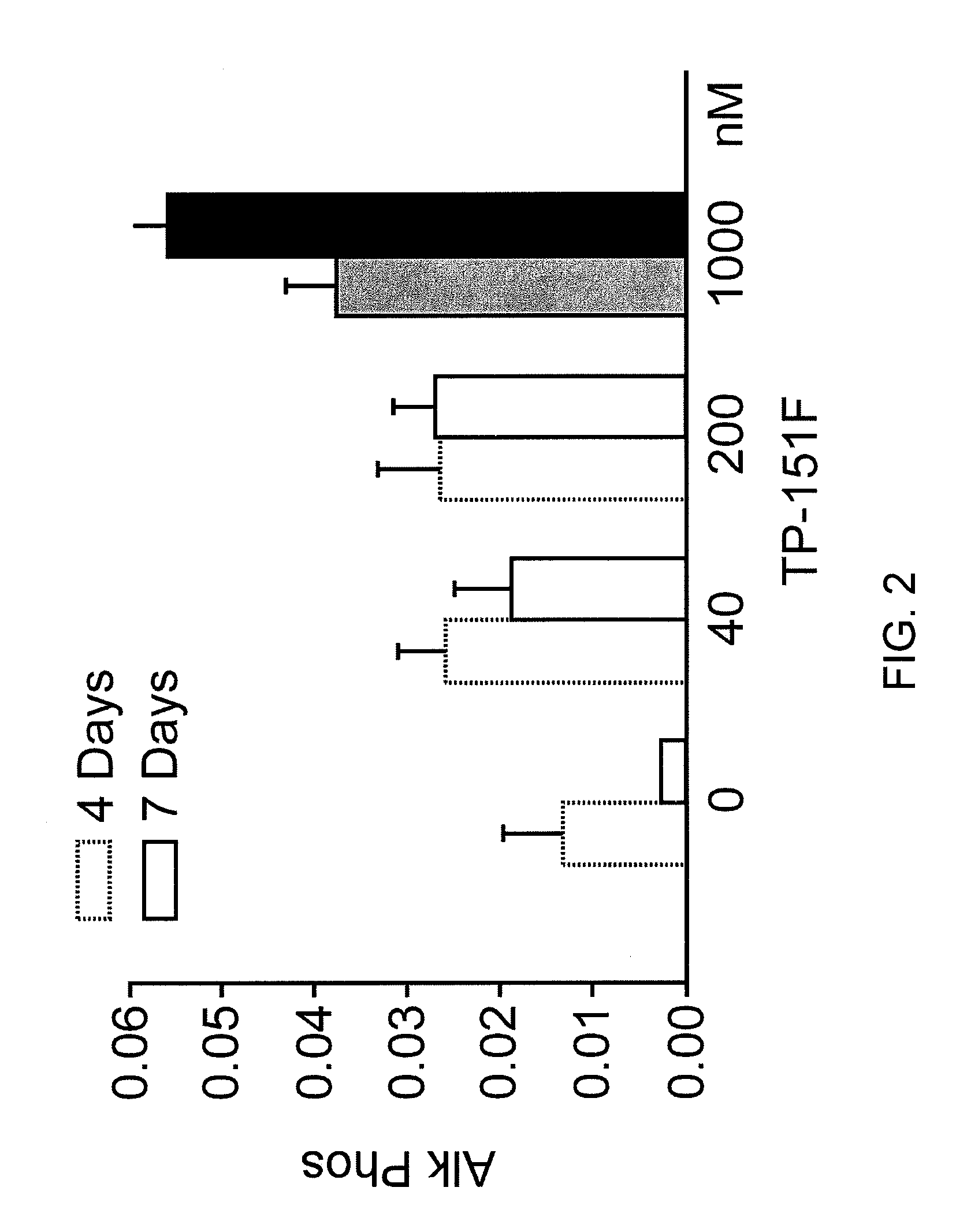

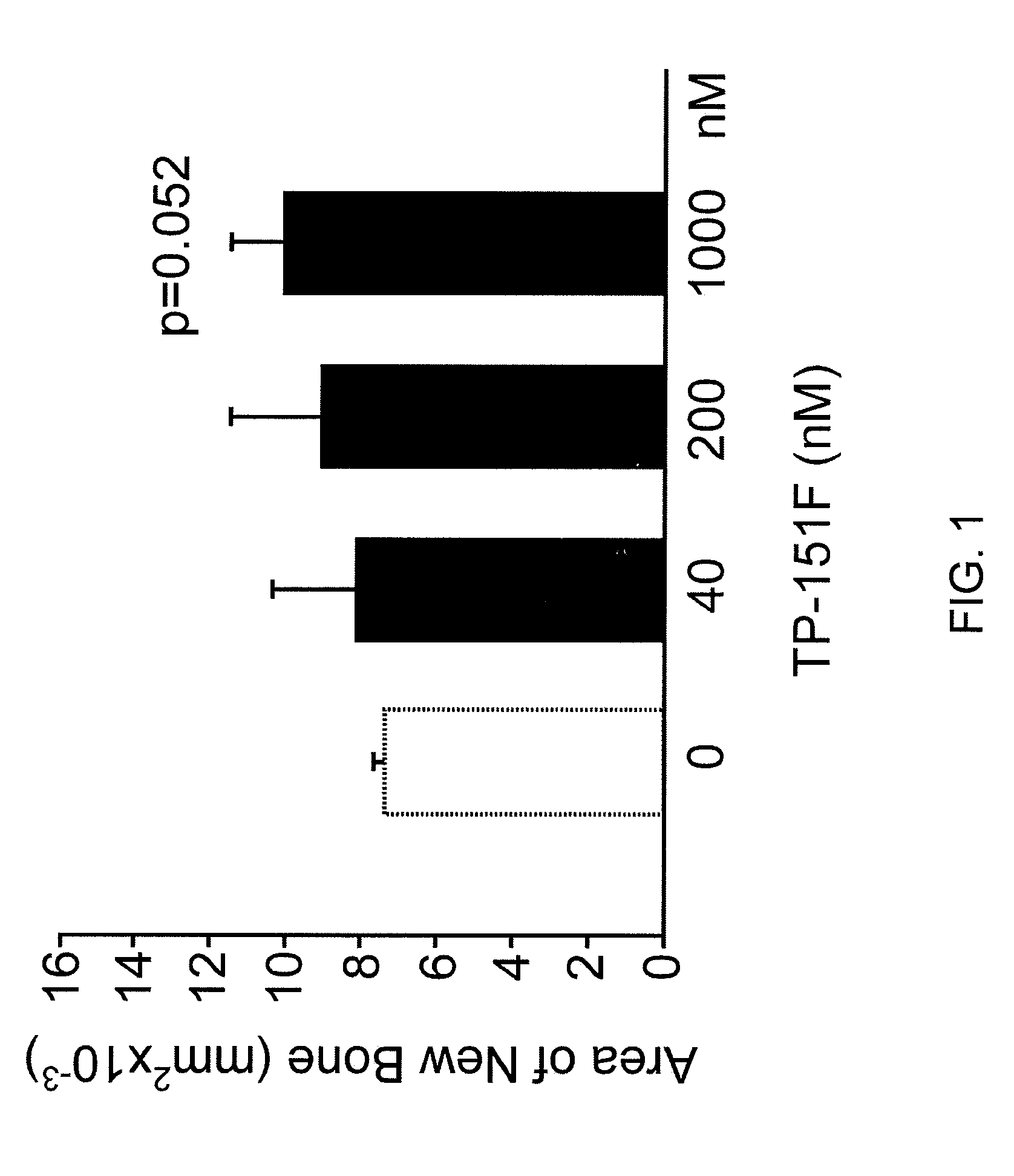

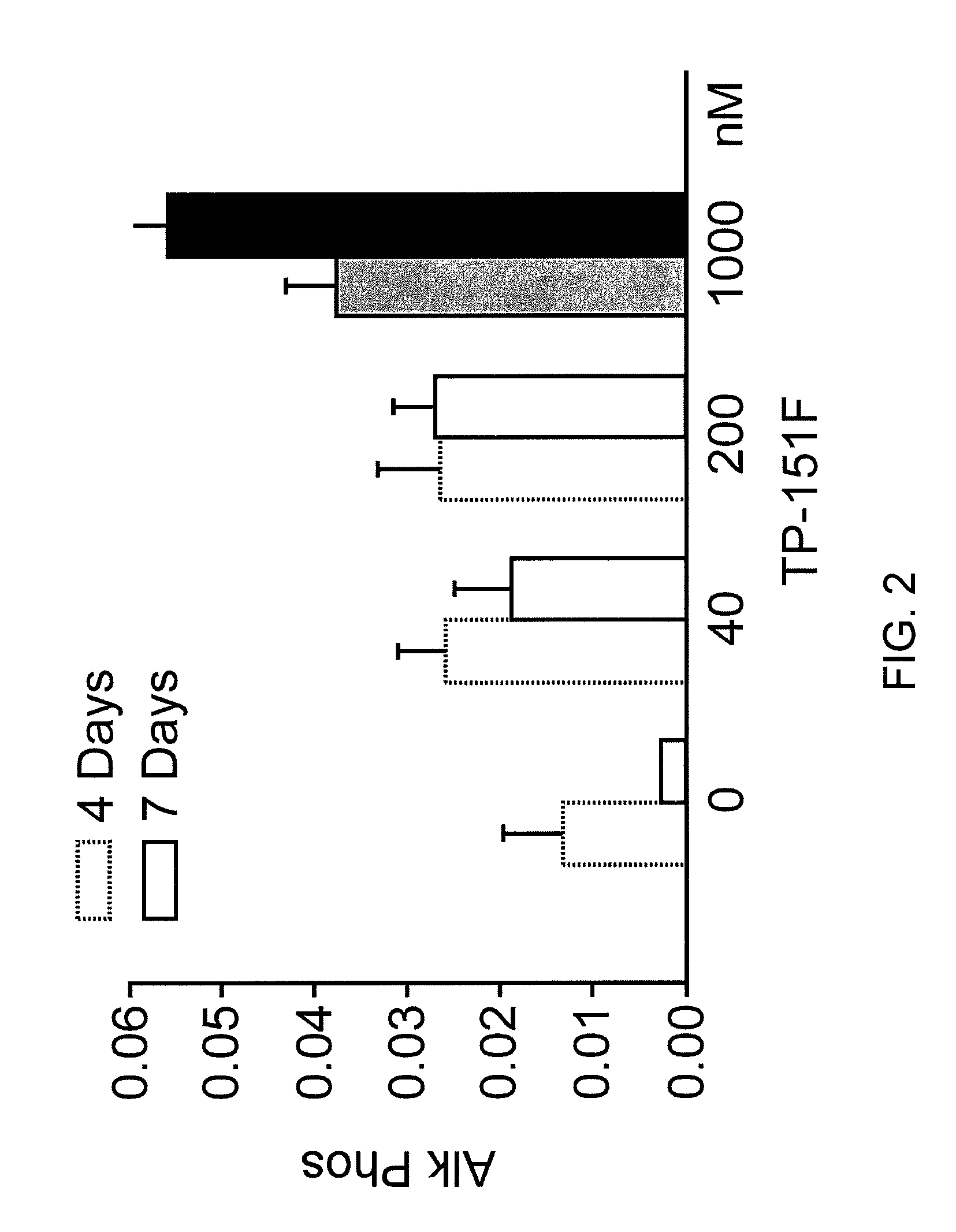

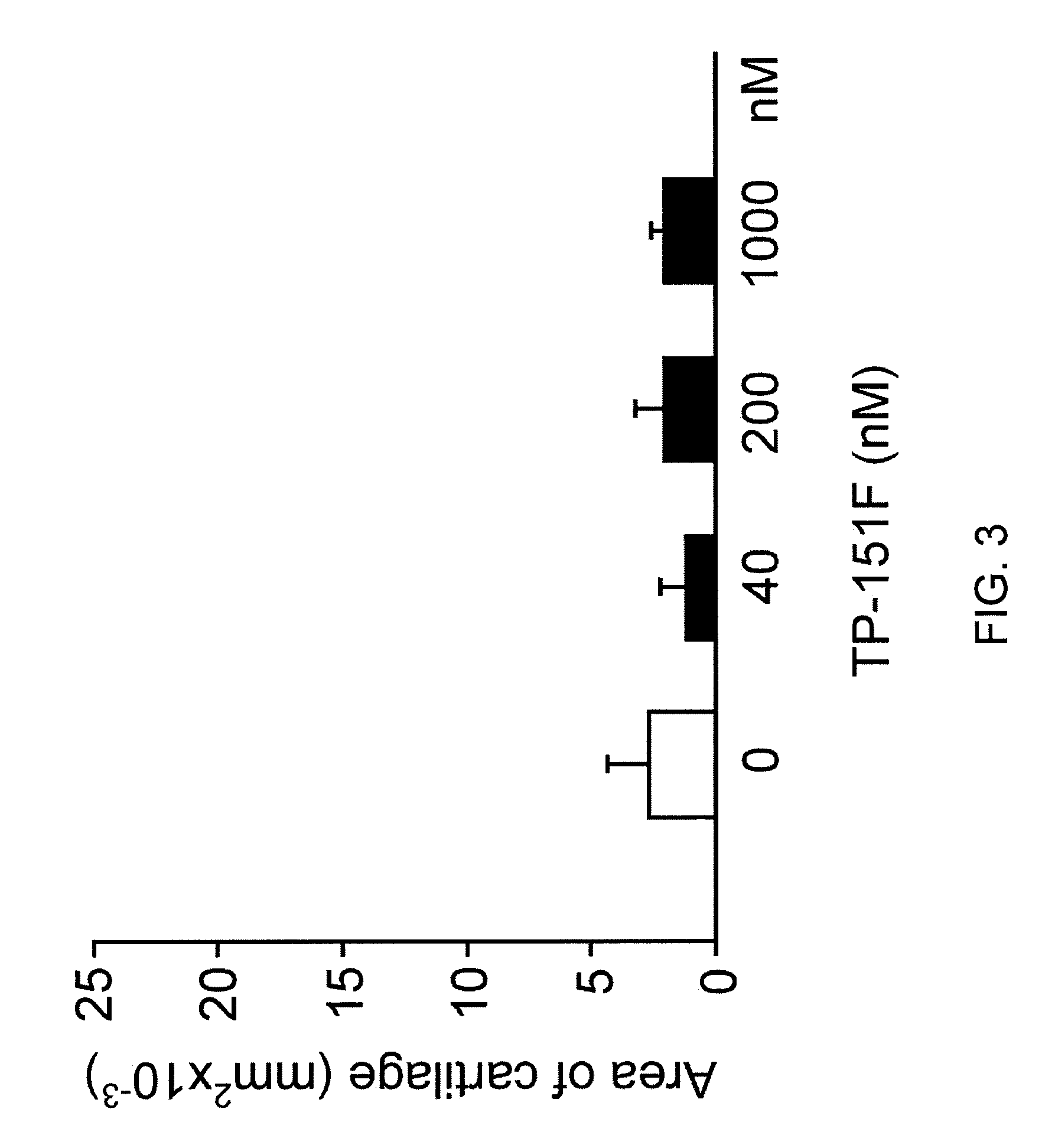

Synthetic triterpenoids and tricyclic-bis-enones for use in stimulating bone and cartilage growth

The present invention concerns methods for stimulating the growth and repair of bone and cartilage using synthetic triterpenoids and tricyclic-bis-enones. Examples of suitable triterpenoids include CDDO, CDDO-Me, CDDO-Im, and CDDO-Ethylamide. Examples of tricyclic-bis-enones include TBE-31 and TBE-34.

Owner:OSTEOSCREEN +2

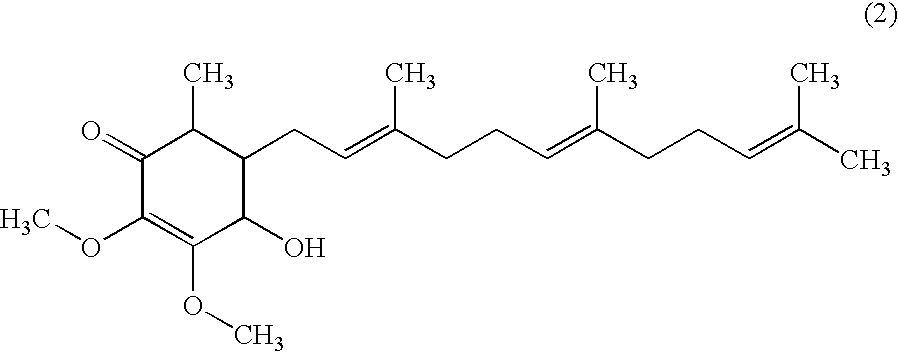

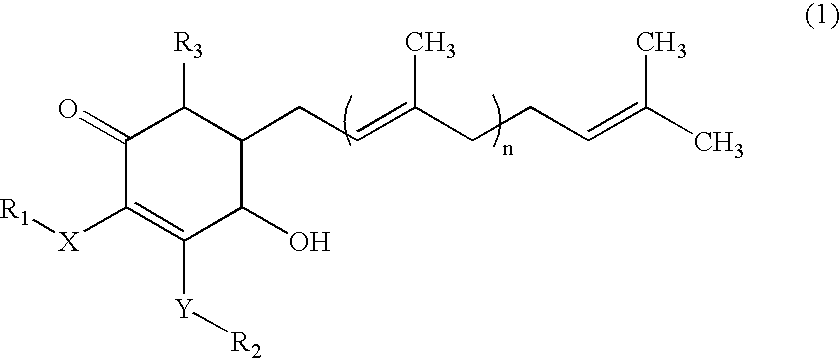

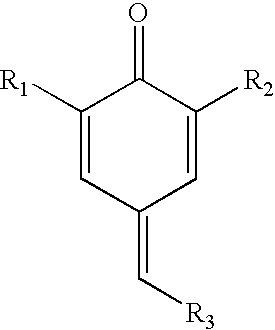

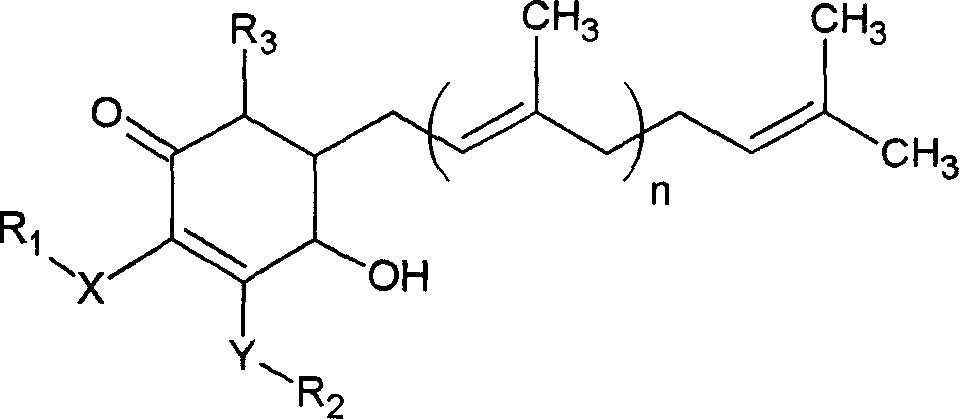

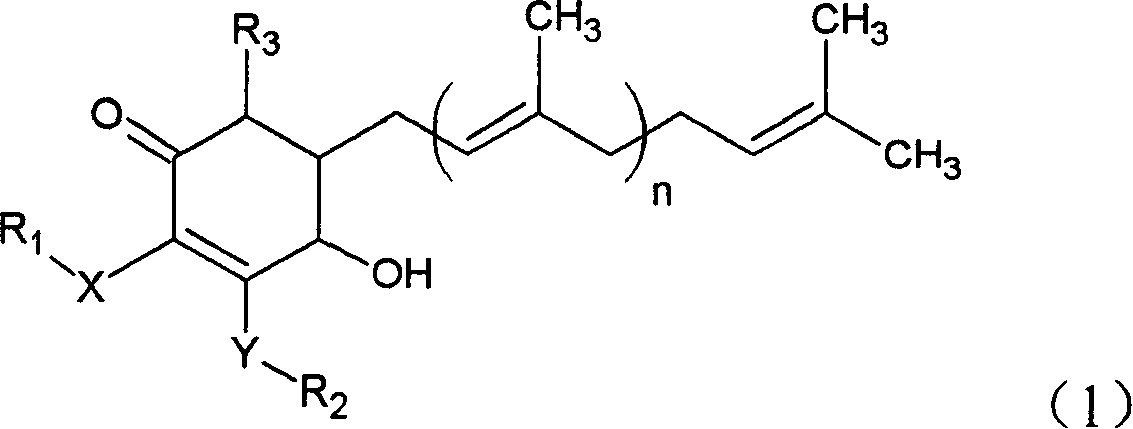

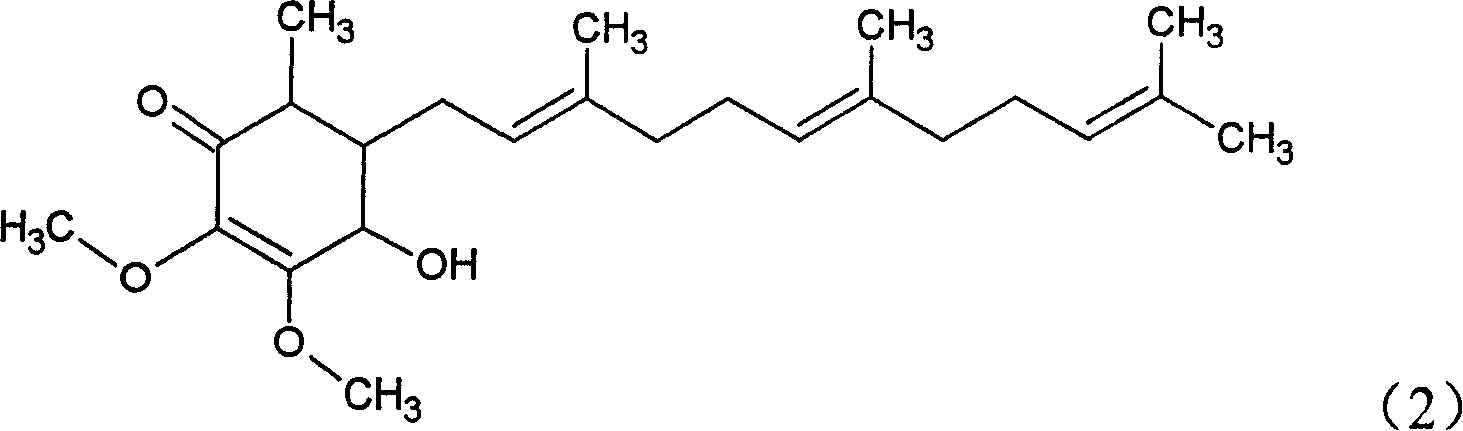

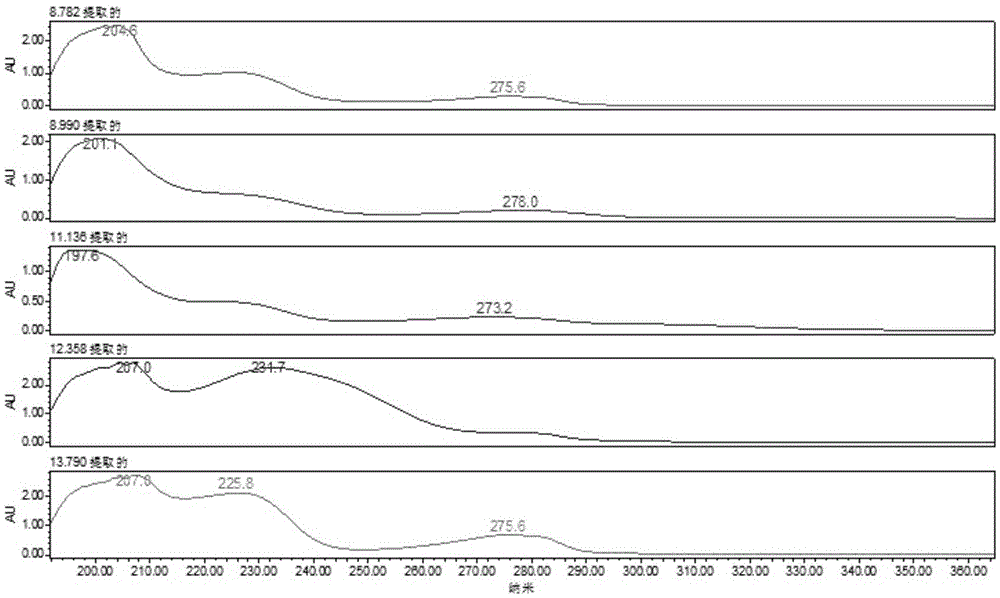

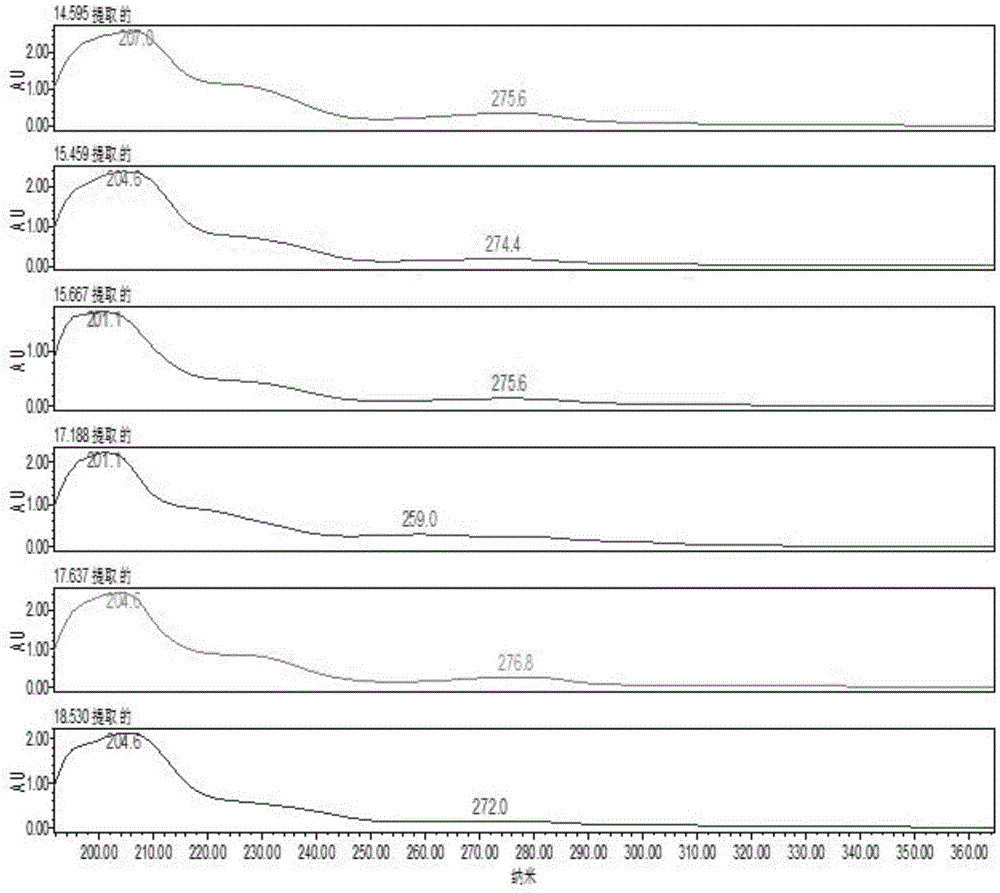

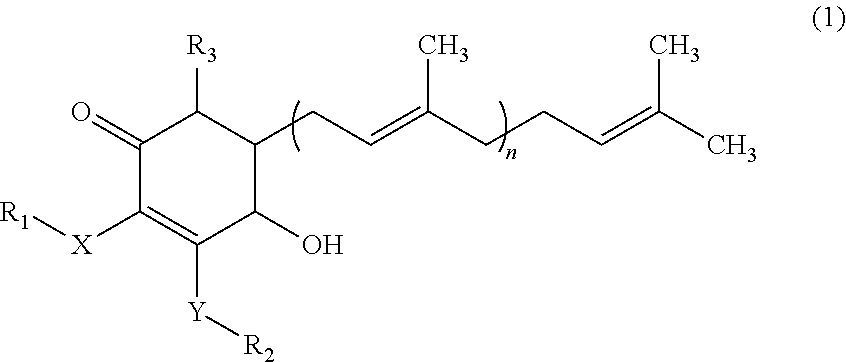

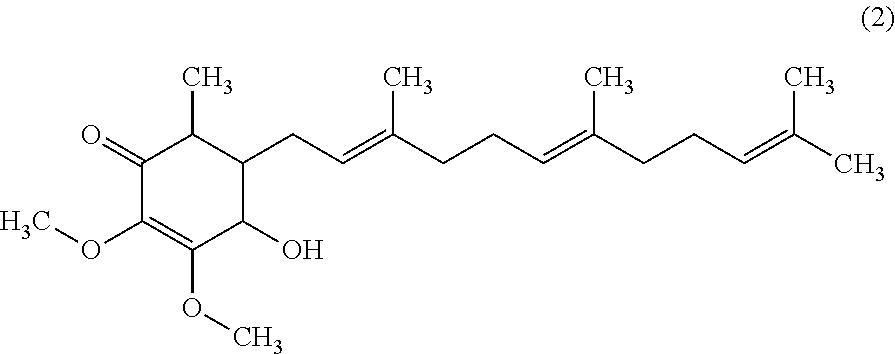

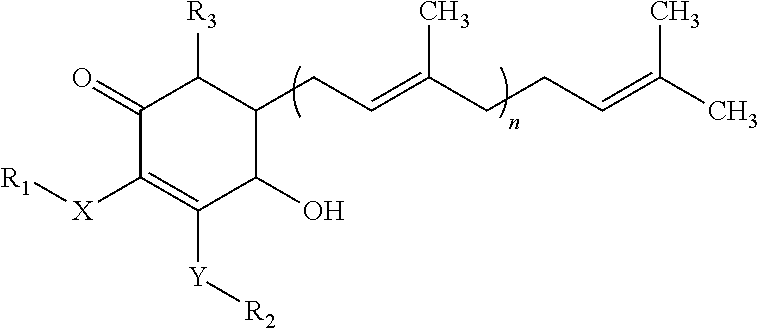

Cyclohexenone compounds from Antrodia camphorata and application thereof

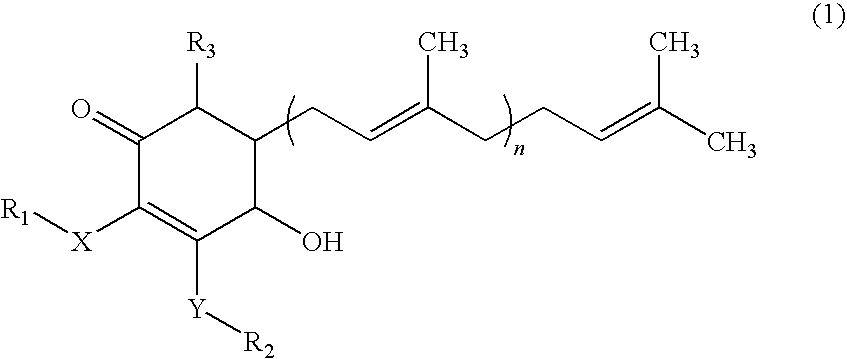

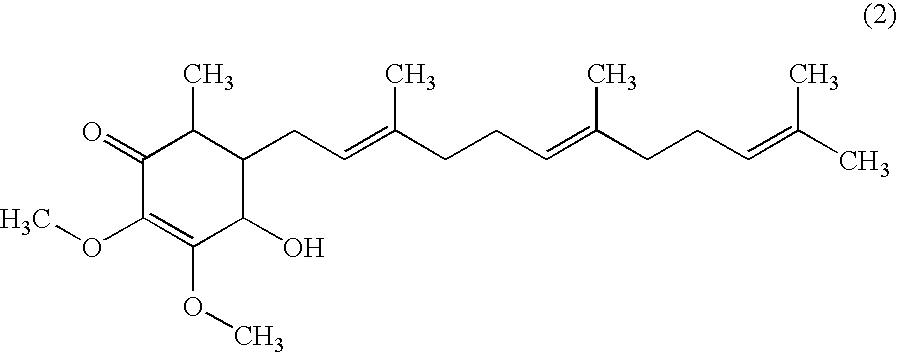

The present invention relates to a novel compound and its uses, which is an extract isolated and purified from Antrodia camphorate, in particular to 4-hydroxy-2,3 -dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone, and its use in tumor growth inhibition. The compound of the invention, which has never been discovered in Antrodia camphorate, can be applied in inhibiting the growth of cancer cells, such as breast cancer, hepatic cancer and prostate cancer; and be used as a pharmaceutical composition to inhibit the tumor growth; or further be applied in prevention of heart and blood vessel disease or dietary supplements for health needs through its antioxidant activity.

Owner:GOLDEN BIOTECH

Synthetic triterpenoids and tricyclic-bis-enones for use in stimulating bone and cartilage growth

The present invention concerns methods for stimulating the growth and repair of bone and cartilage using synthetic triterpenoids and tricyclic-bis-enones. Examples of suitable triterpenoids include CDDO, CDDO-Me, CDDO-Im, and CDDO-Ethylamide. Examples of tricyclic-bis-enones include TBE-31 and TBE-34.

Owner:OSTEOSCREEN +2

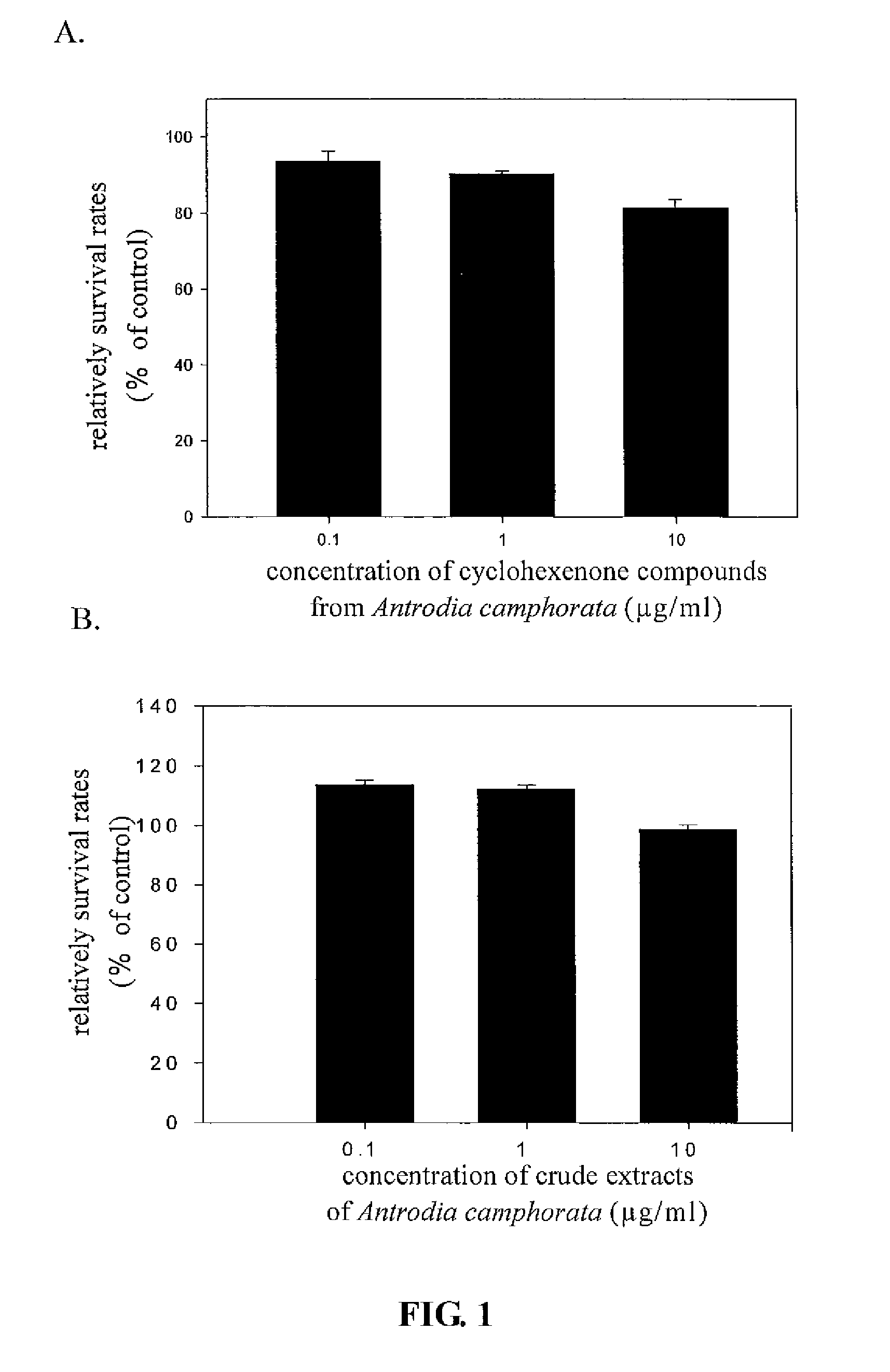

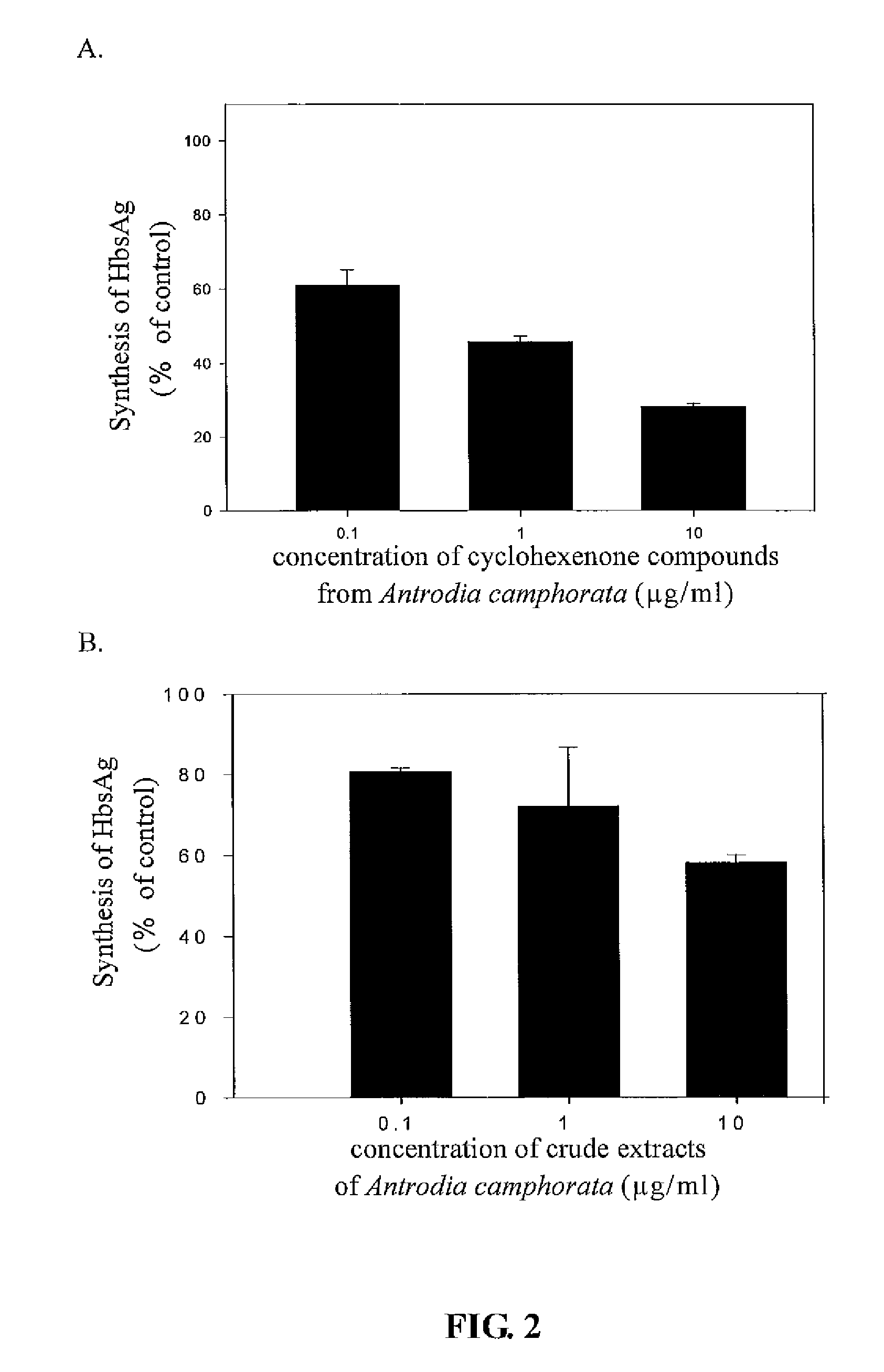

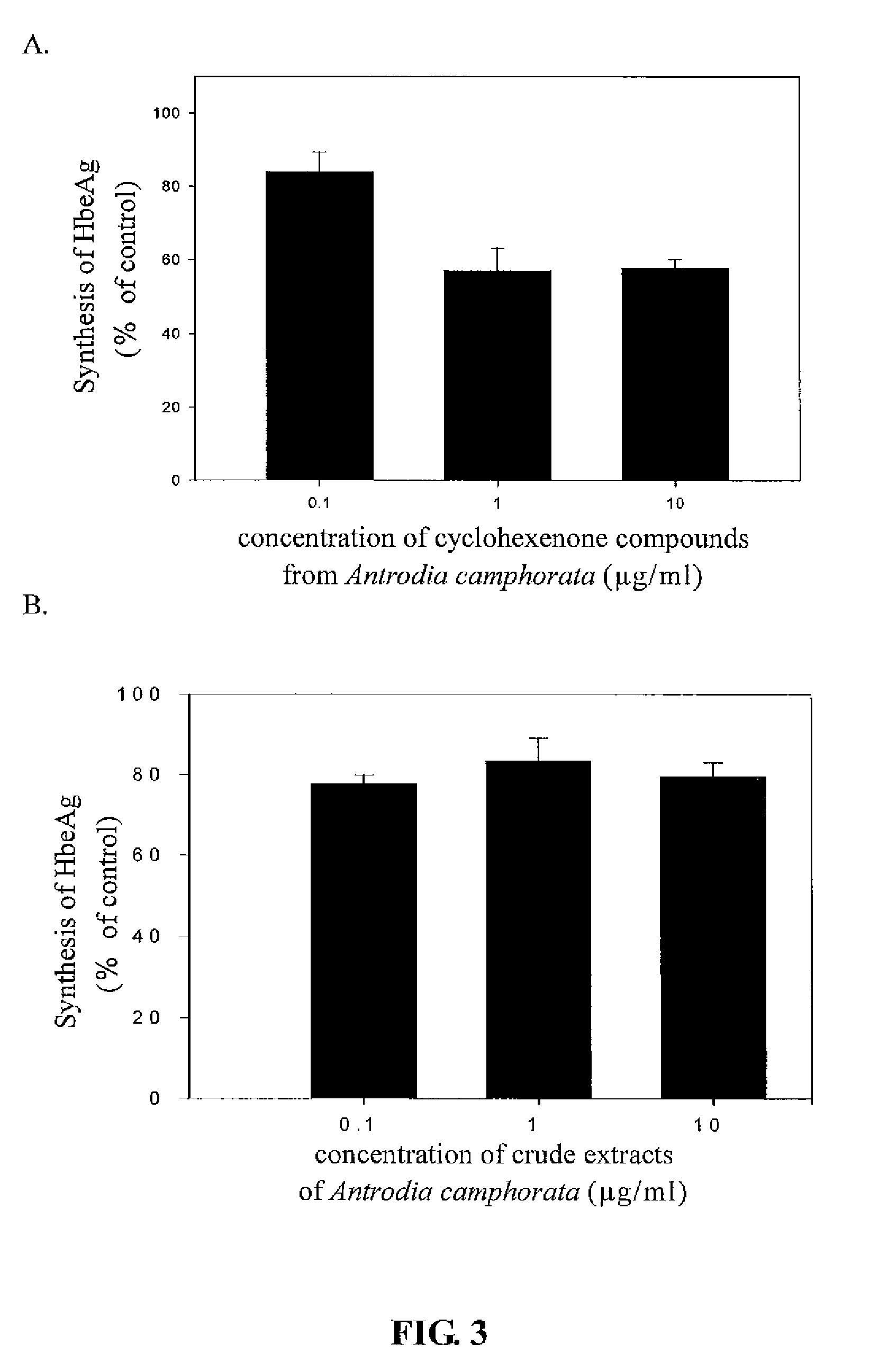

Inhibition of Hepatitis B virus by cyclohexenone compounds from Antrodia camphorata

ActiveUS7411003B1Good treatment effectAvoid survival rateBiocideOrganic chemistryHepatoma cell lineCyclohexenone

The present invention relates to a compound of Antrodia camphorata used to inhibit HBV, in particular to an extract, 4-hydroxy-2,3-dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone which is isolated from Antrodia camphorata, and its use in inhibiting HBV effectively. The cyclohexenone compound according to the present invention showed cytotoxicity on HBV-secreting human hepatoma cell line HepG2 2.2.15, decreased synthesis of HBV particles, further inhibited synthesis of HbsAg and HbeAg effectively to achieve the goal of HBV inhibition.

Owner:GOLDEN BIOTECH

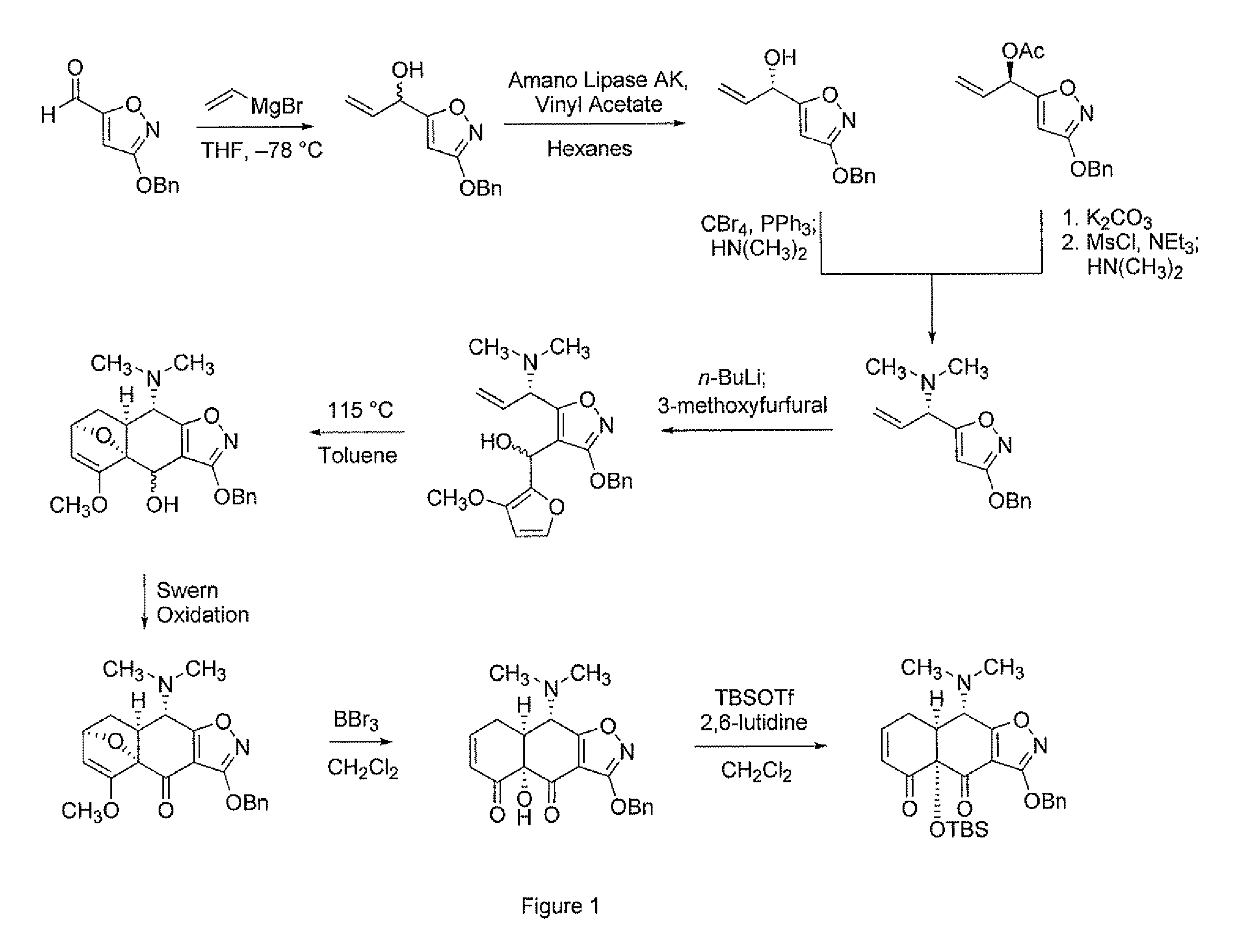

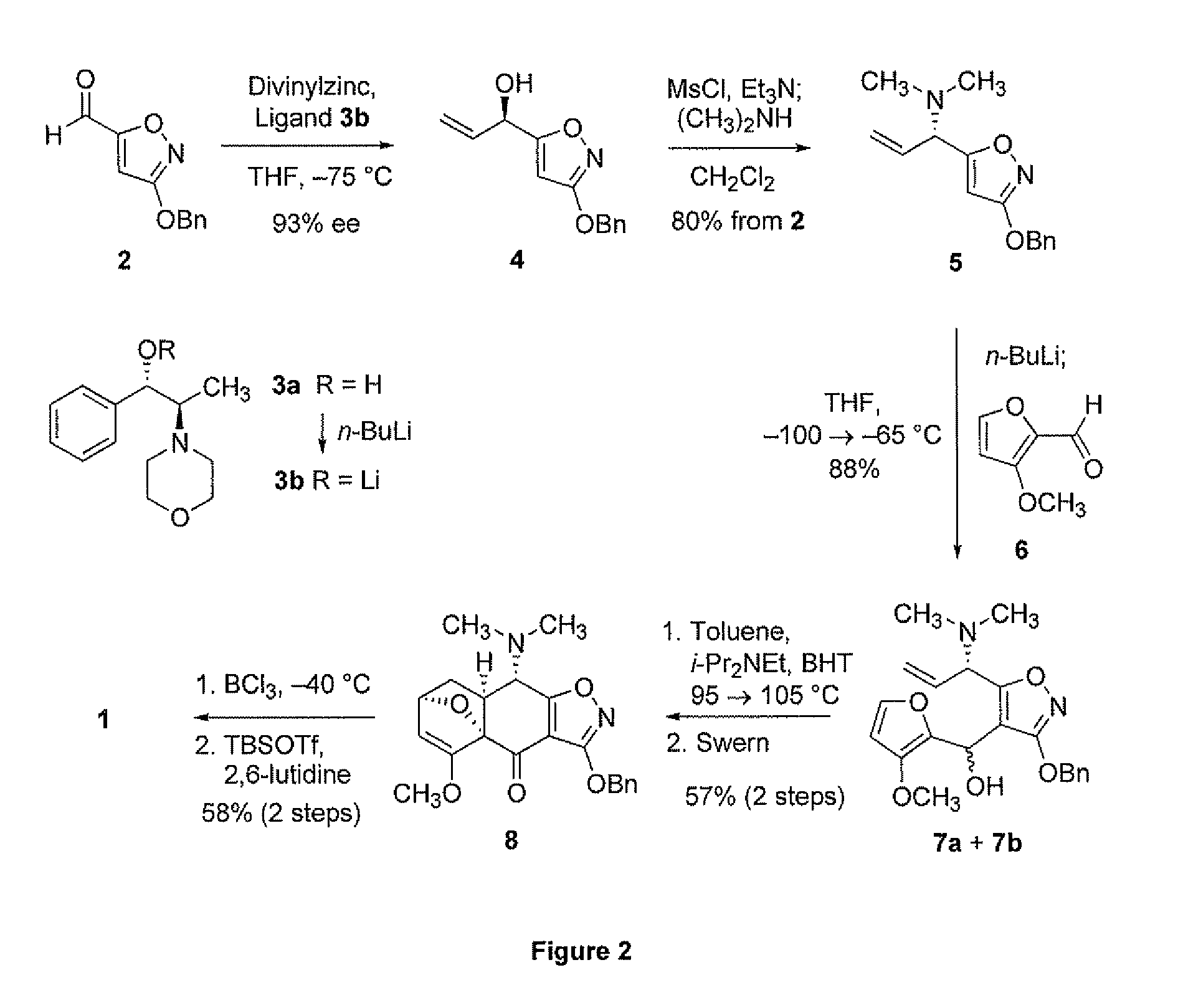

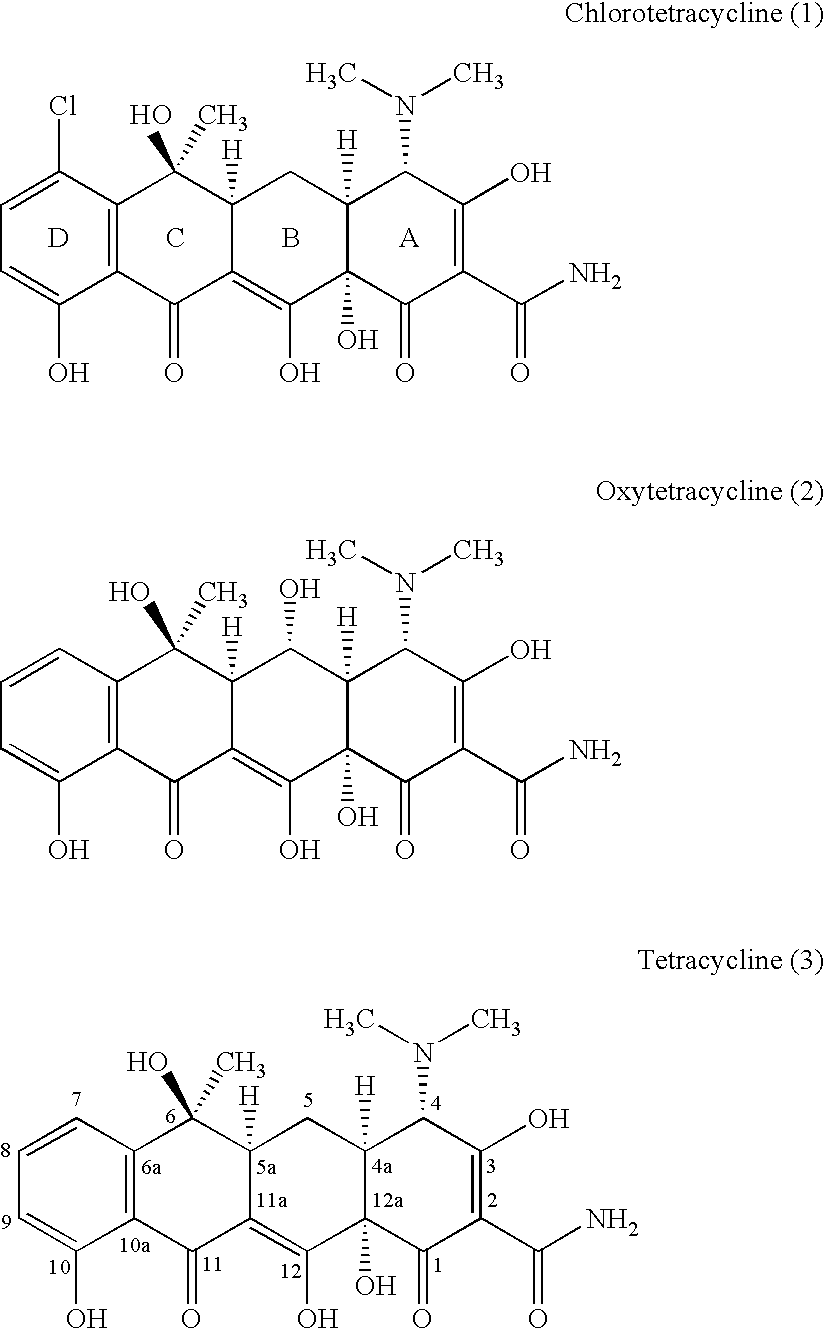

Synthesis of enone intermediate

ActiveUS7763735B2High yieldVersatility and efficiencyGroup 4/14 element organic compoundsBiological bodyAntibiotic Y

The tetracycline class of antibiotics has played a major role in the treatment of infectious diseases for the past 50 years. However, the increased use of the tetracyclines in human and veterinary medicine has led to resistance among many organisms previously susceptible to tetracycline antibiotics. The recent development of a modular synthesis of tetracycline analogs through a chiral enone intermediate has allowed for the efficient synthesis of novel tetracycline analogs never prepared before. The present invention provides a more efficient route for preparing the enone intermediate.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

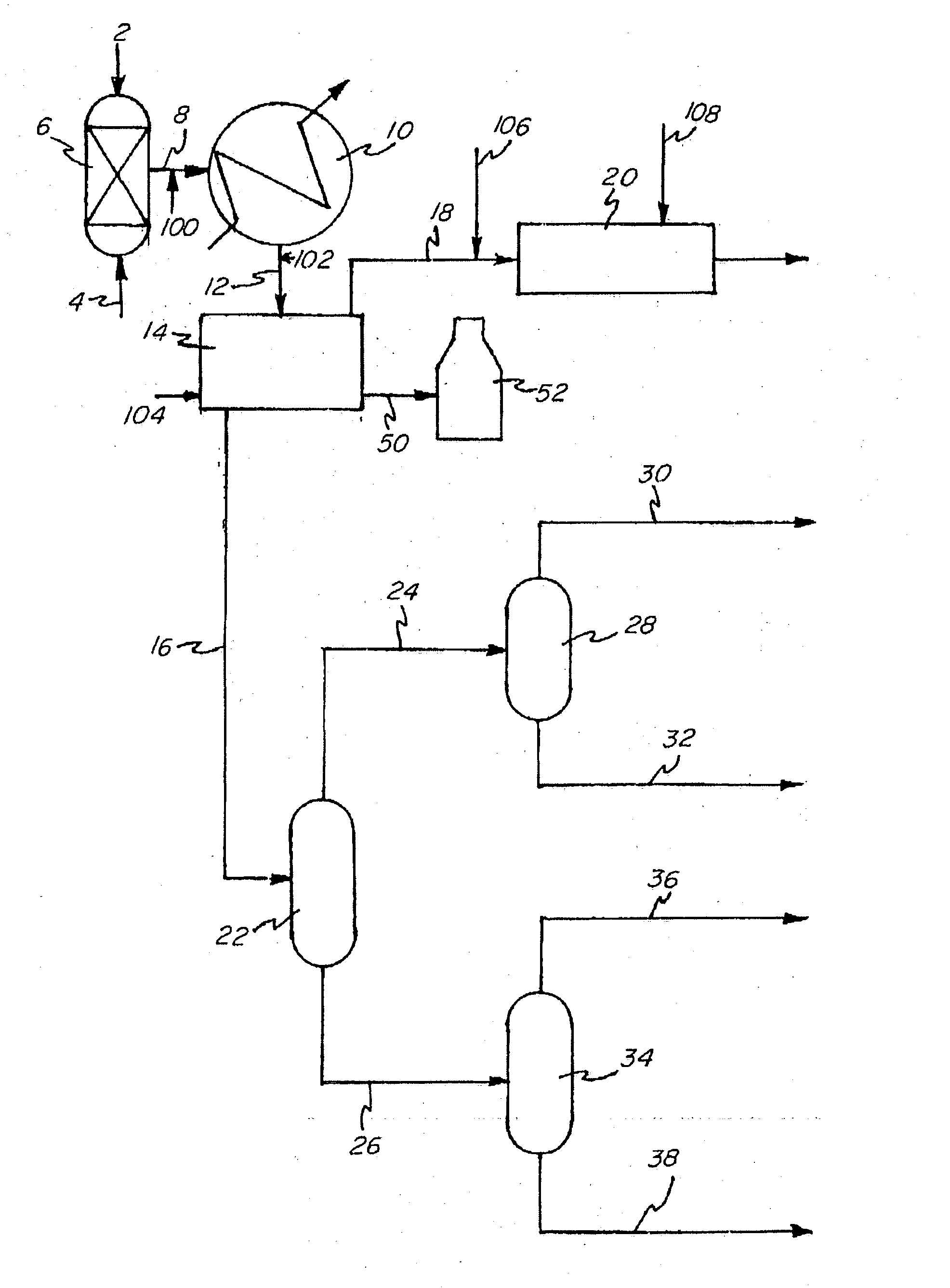

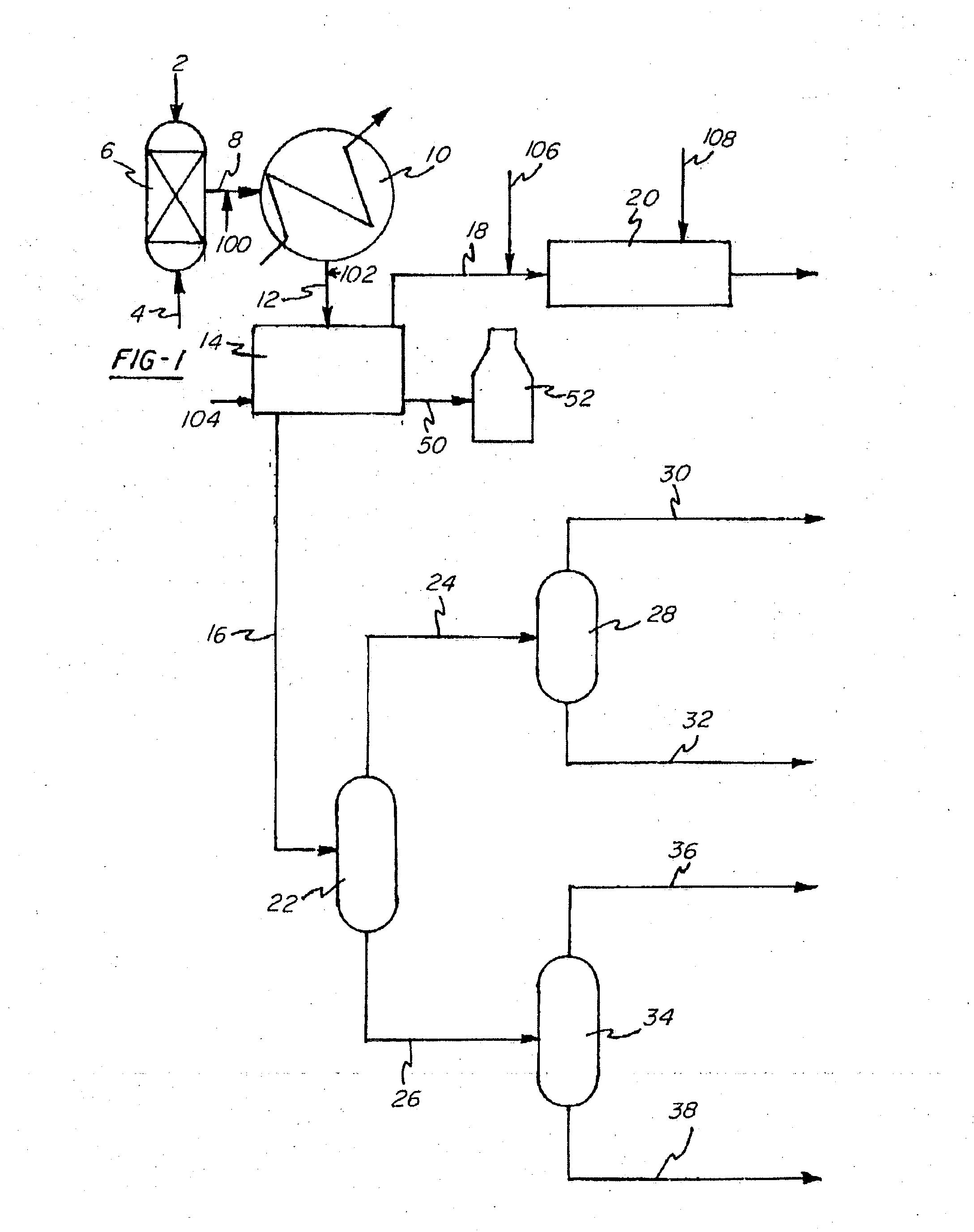

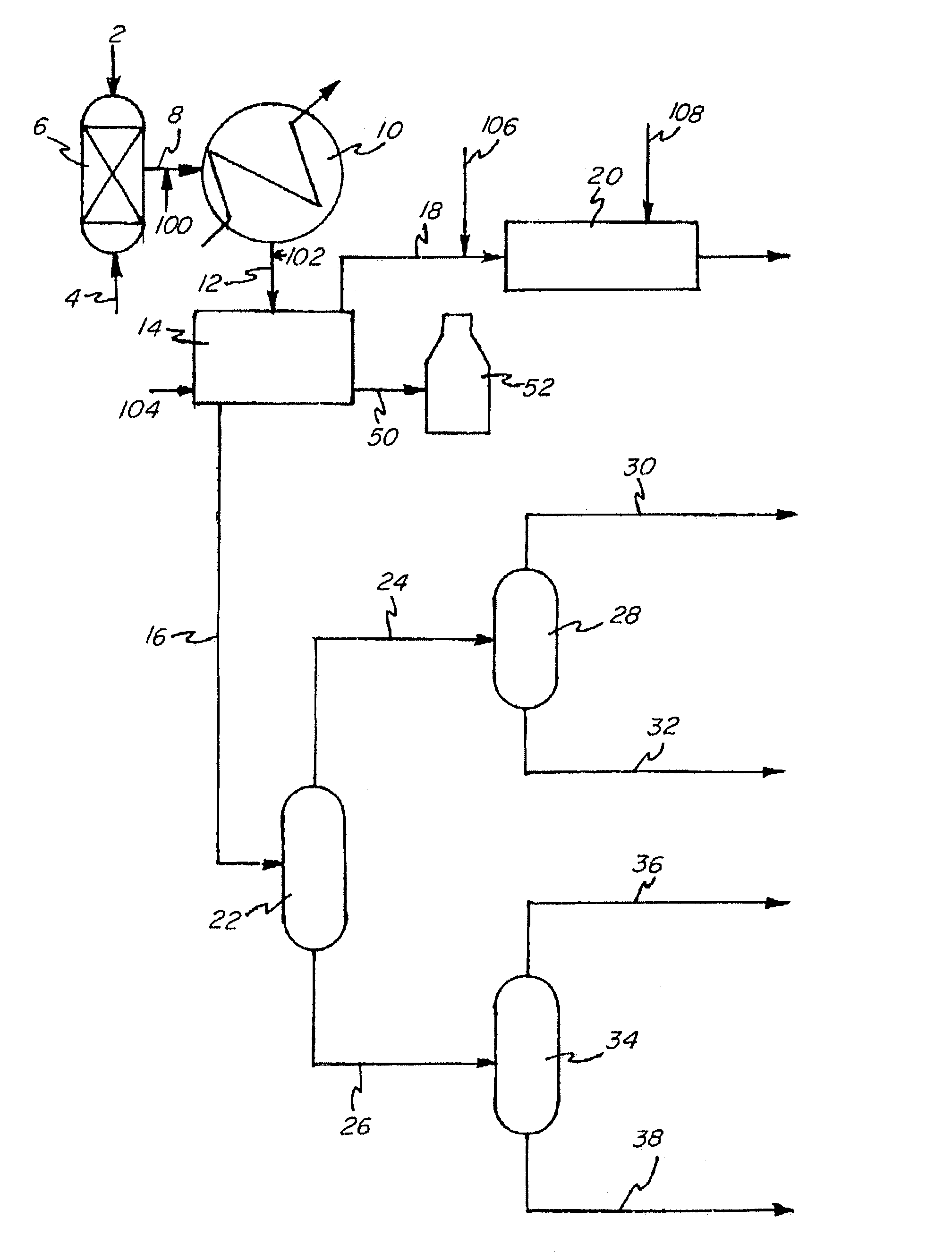

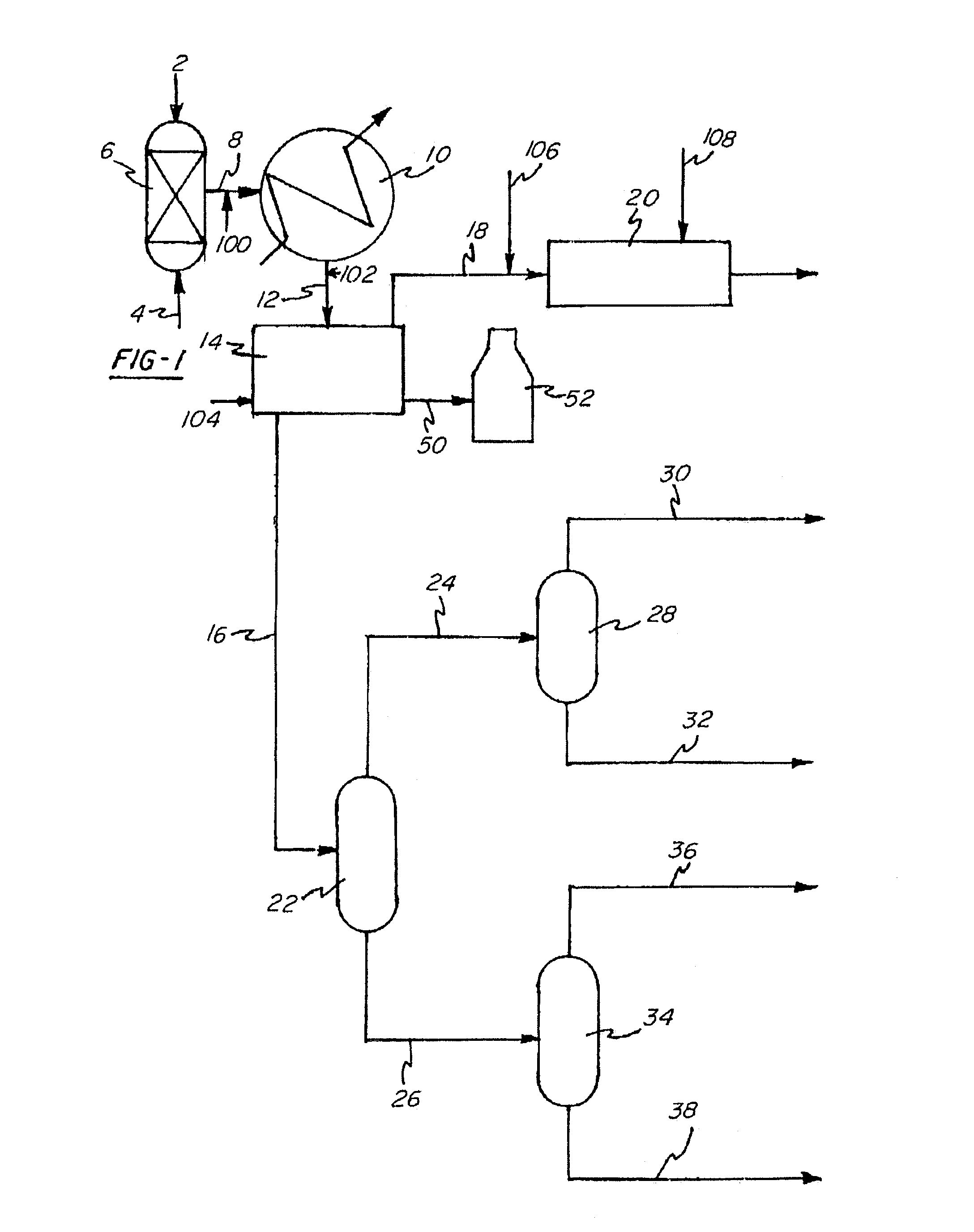

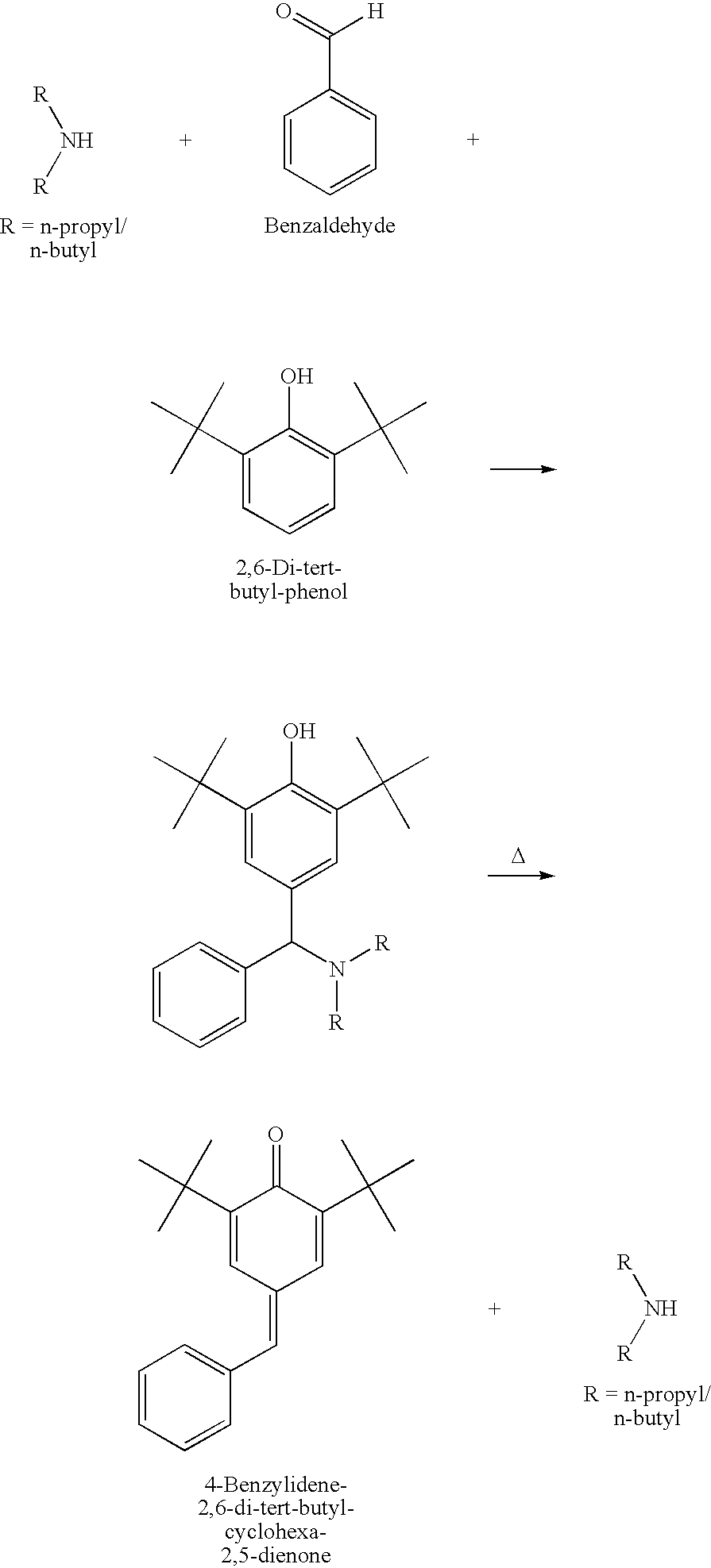

Polymerization inhibitor for styrene dehydrogenation units

ActiveUS20050027150A1Hydrocarbon purification/separationIsotope separationQuinone methideDehydrogenation

Quinone methide derivatives such as 4-benzylidene-2,6-di-tert-butyl-cyclohexa-2,5 dienone are used to inhibit styrene monomer polymerization in the dehydrogenator portion of a styrene monomer production system. The inhibitor contacts the dehydrogenation effluent and does not partition in substantial amounts to the aqueous phase that is separated in the phase separator.

Owner:BL TECH INC +1

Liver protection compounds of the cyclohexenone type from Antrodia camphorata

InactiveUS7456225B1Shorten the progressLower Level RequirementsBiocideOrganic chemistryCyclohexenoneAspartate carbamoyltransferase

The present invention relates to a compound of Antrodia camphorata used for liver protection, in particular to an extract, 4-hydroxy-2,3-dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone which is isolated from Antrodia camphorata. The cyclohexenone compound according to the invention helps to alleviate liver injury and fibrosis induced by chemicals and reduces the levels of alanine aminotransferase (ALT) and aspartate aminotransferase (AST). By increasing the contents of glutathione peroxidase (GSHPx) and catalase (CAT), cyclohexenone further decreases the liver damage and the oxidative pressure caused by free radicals, enhances the antioxidant ability and achieves the purposed of liver protection.

Owner:GOLDEN BIOTECH

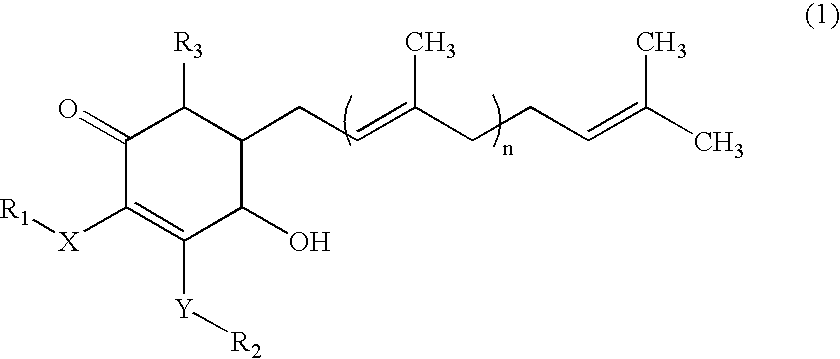

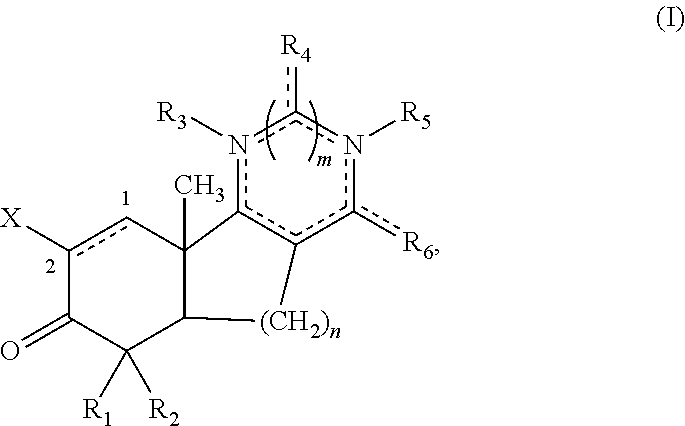

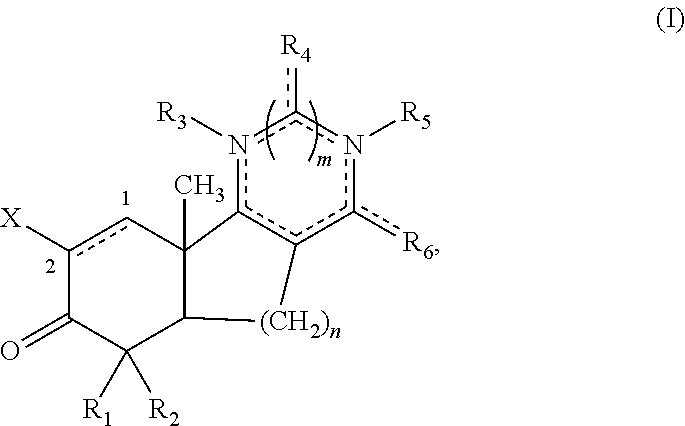

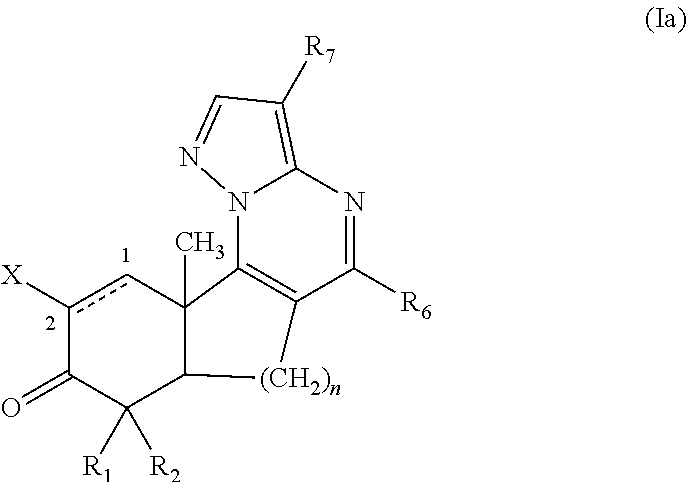

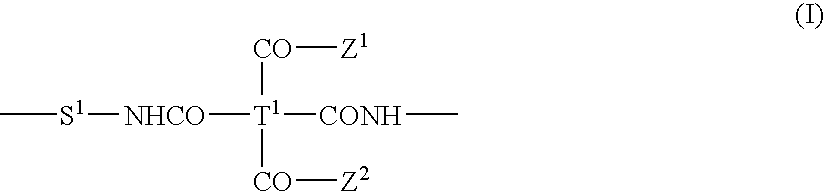

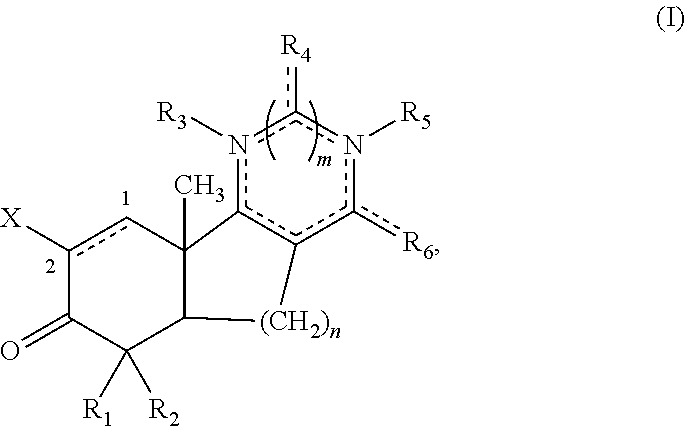

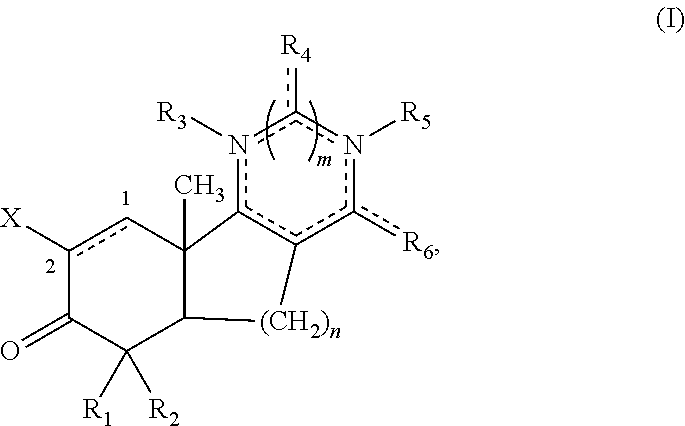

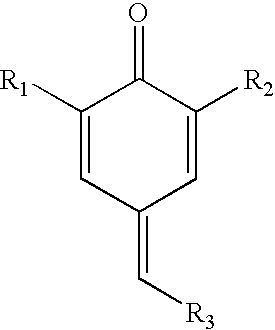

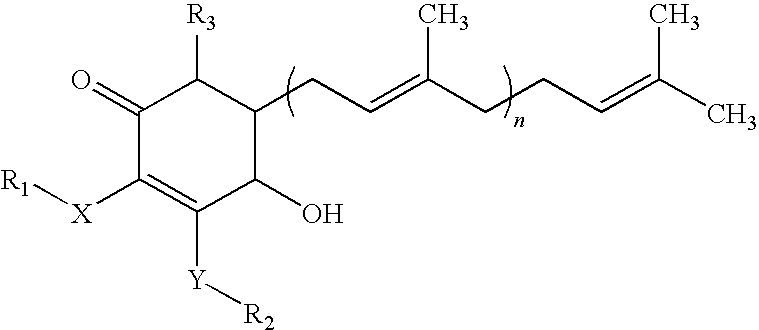

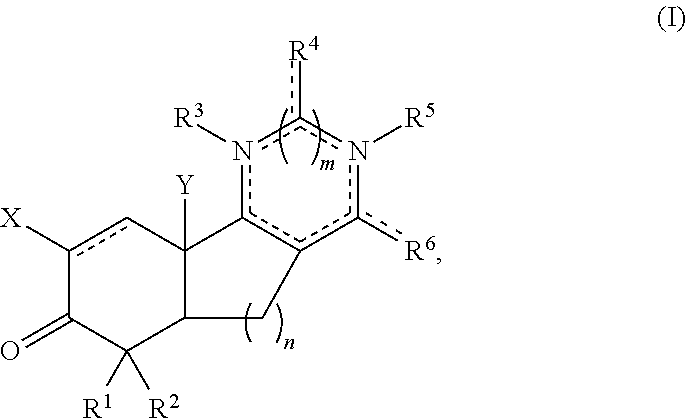

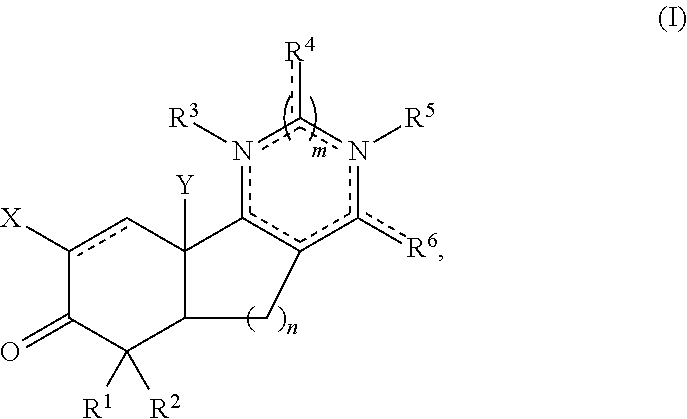

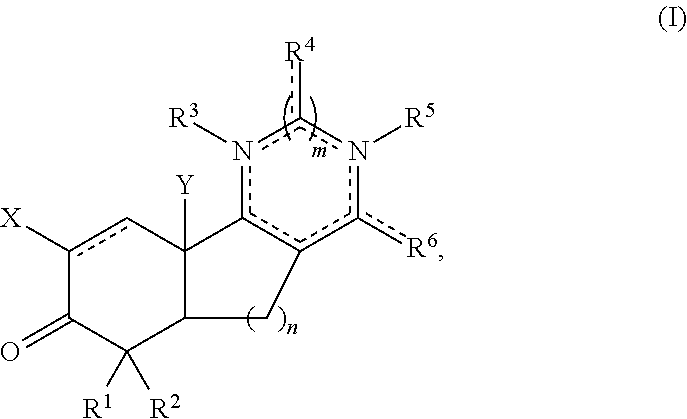

Pyrazolyl and pyrimidinyl tricyclic enones as antioxidant inflammation modulators

Disclosed herein are novel antioxidant inflammation modulators, including those of the formula:wherein the variables are defined herein. Also provided are pharmaceutical compositions, kits and articles of manufacture comprising such compounds. Methods and intermediates useful for making the compounds, and methods of using the compounds and compositions thereof are also provided.

Owner:REATA PHARMA INC

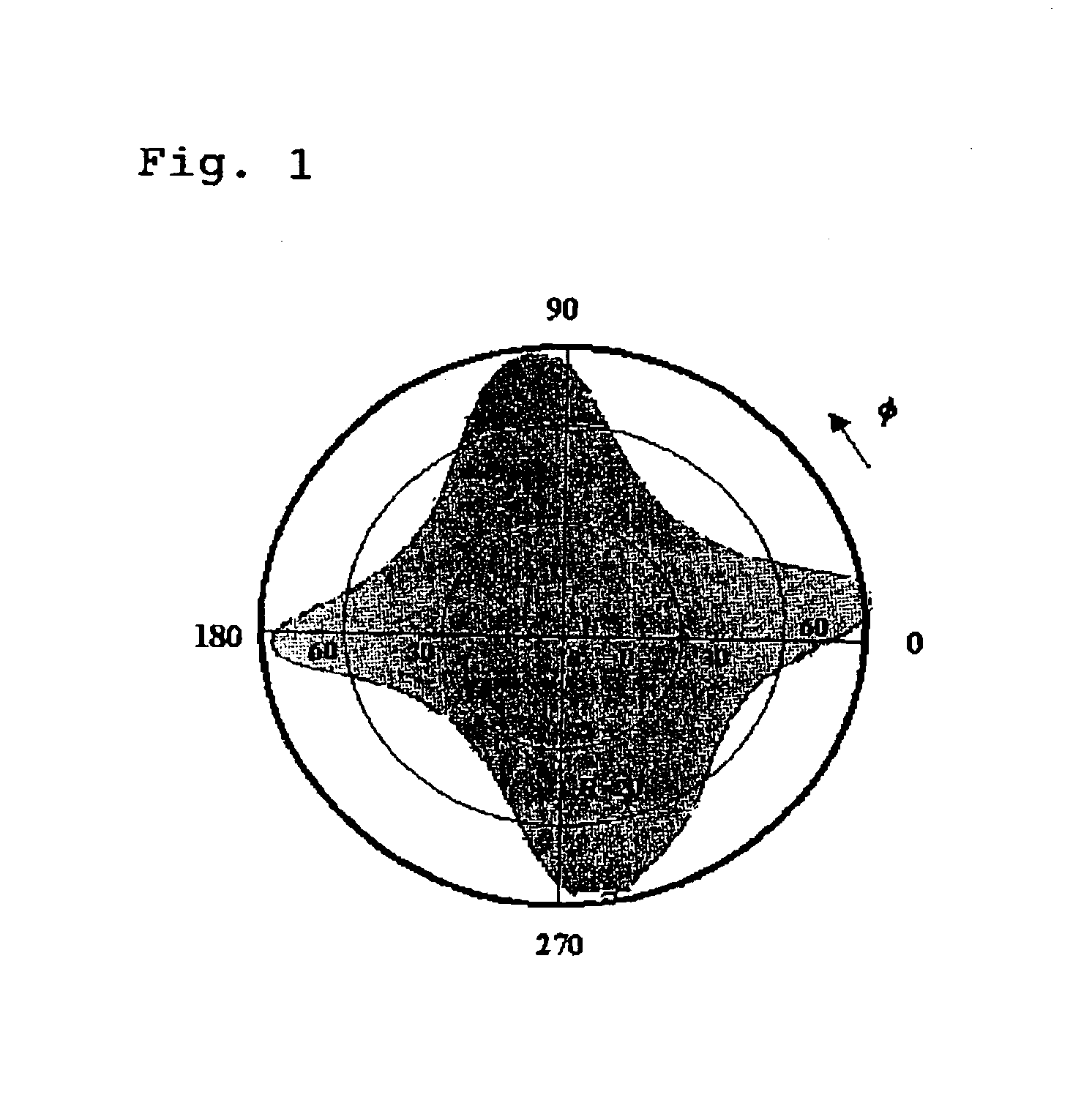

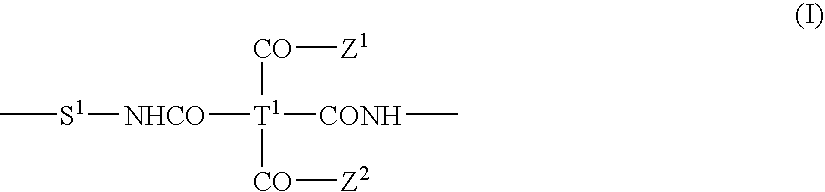

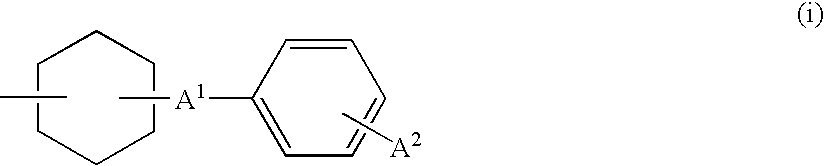

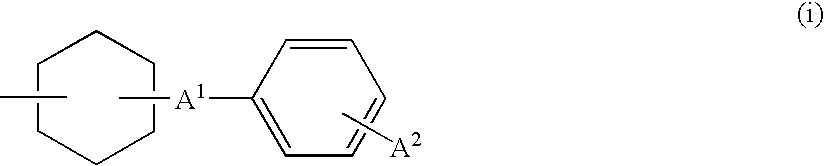

Liquid crystal aligning agent, method of forming a liquid crystal alignment film and liquid crystal display element

InactiveUS6887534B2Improve thermal stabilityImprove featuresLiquid crystal compositionsThin material handlingLiquid-crystal displaySide chain

Owner:JSR CORPORATIOON

Cyclohexenone extract of antrodia camphorata

ActiveCN101225066AHas antioxidant activityAvoid mutationOrganic active ingredientsOrganic compound preparationCyclohexenoneProstate cancer

The invention discloses a new compound and the usage, in particular to a 4-hydroxy-2, 3- dimethoxy -6-methyl-5 (3, 7, 11- trimethyl-2, 6, 10-dodecatrien) -2- cyclohexenone (4-hydroxy- 2, 3-dimethoxy -6- methy-5 (3, 7, 11-trimethyl -dodeca-2, 6, 10- trienyl) -cyclohex-2-enone) separated from antrodia camphorate extract and the application in inhibiting the growth of tumor cell. The new compound is firstly seen in antrodia camphorate. The 4-hydroxy-2, 3- dimethoxy -6-methyl-5 (3, 7, 11- trimethyl-2, 6, 10-dodecatrien) -2- cyclohexenone (4-hydroxy- 2, 3-dimethoxy -6- methy-5 (3, 7, 11-trimethyl -dodeca-2, 6, 10- trienyl) -cyclohex-2-enone) separated from antrodia camphorate extract and the application in inhibiting the growth of tumor cell has the advantages of inhibiting the growth of breast cancer, liver cancer and prostate cancer tumor cell, being a component of drug combination inhibiting the growth of the tumor cell at the same time or further being applied in preventing cardiovascular disease or being added into healthy food by right of antioxidant activity.

Owner:GOLDEN BIOTECH

Liquid crystal aligning agent, method of forming a liquid crystal alignment film and liquid crystal display element

InactiveUS20040009310A1Improve thermal stabilityImprove featuresLiquid crystal compositionsThin material handlingLiquid-crystal displaySide chain

A liquid crystal aligning agent which can provide liquid crystal aligning capability through exposure to polarized radiation without rubbing and which is used to form a liquid crystal alignment film, a method of forming a liquid crystal alignment film, and a liquid crystal display element having this liquid crystal alignment film. An alignment film is formed from a liquid crystal aligning agent containing a polymer having a polyamic acid ester structure with a conjugated enone structure in the side chain and applying radiation to it from a predetermined direction. Thereby, a liquid crystal display element having high thermal stability in the alignment of liquid crystals and excellent display characteristics can be manufactured.

Owner:JSR CORPORATIOON

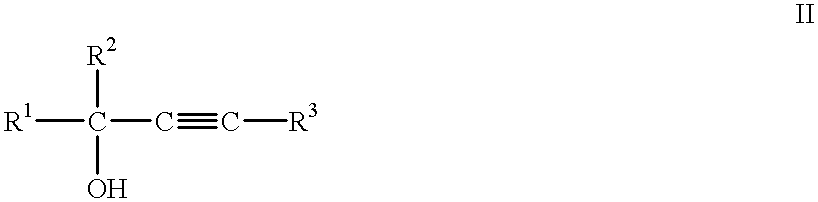

Process for the preparation of unsaturated 4,5-allene ketones, 3,5-diene ketones and the corresponding saturated ketones

InactiveUS6380437B1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsKetonePropargyl

Process for the preparation of unsaturated 4,5-allene ketones by reaction of tertiary propargyl alcohols with alkenyl alkyl ethers or ketals in the presence of aliphatic sulfonic acids or sulfonic acid salts.

Owner:DEGUSSA AG

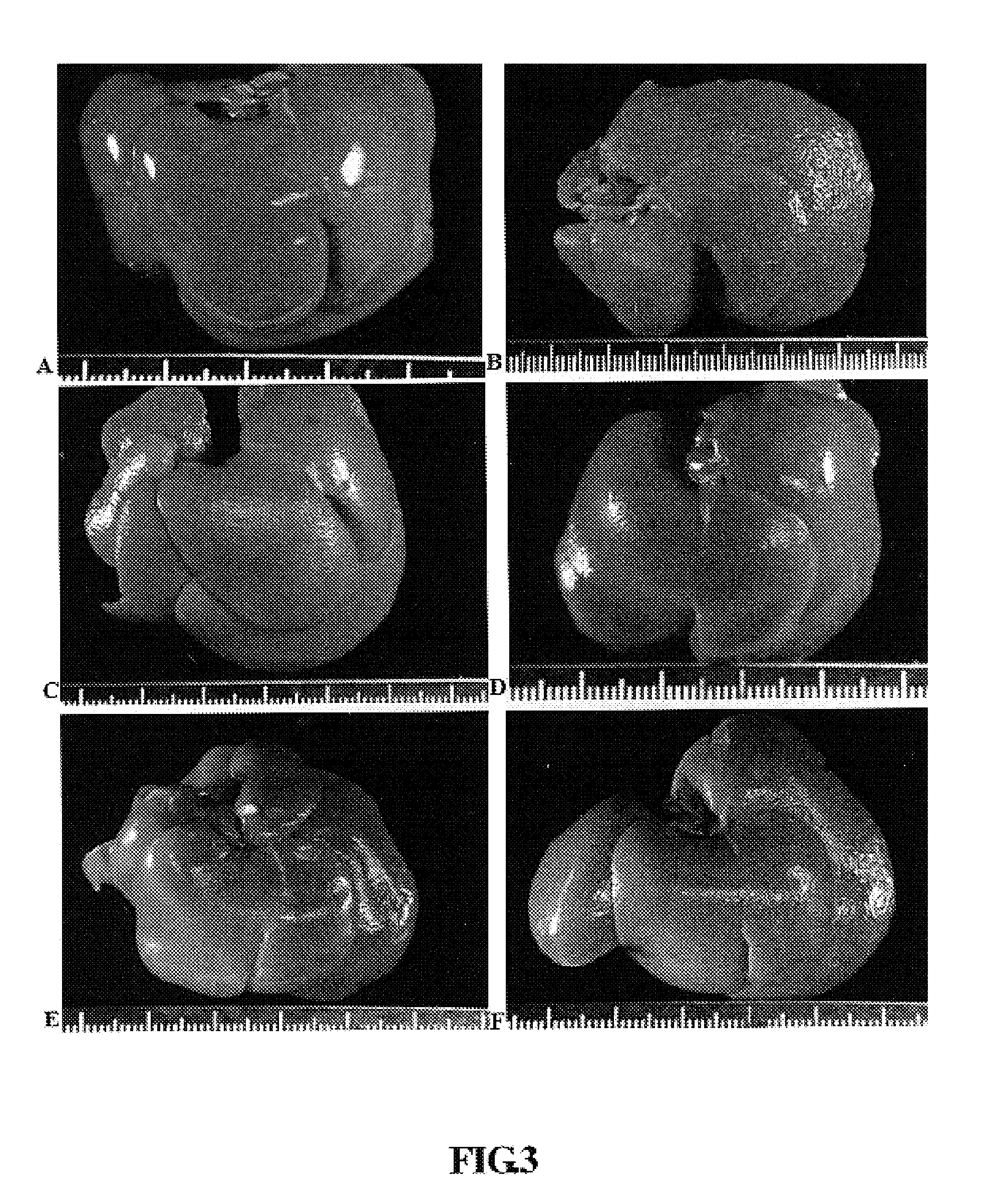

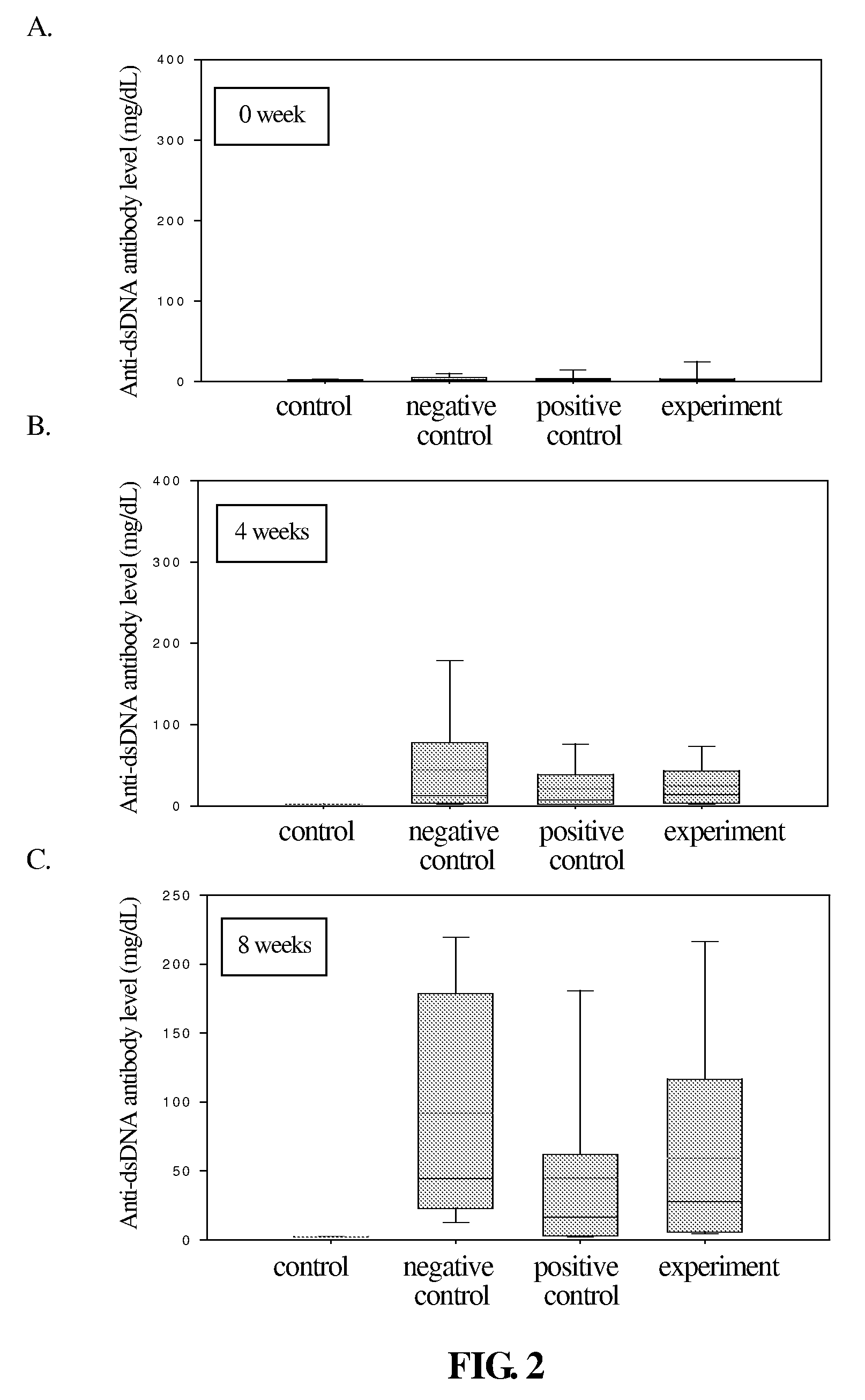

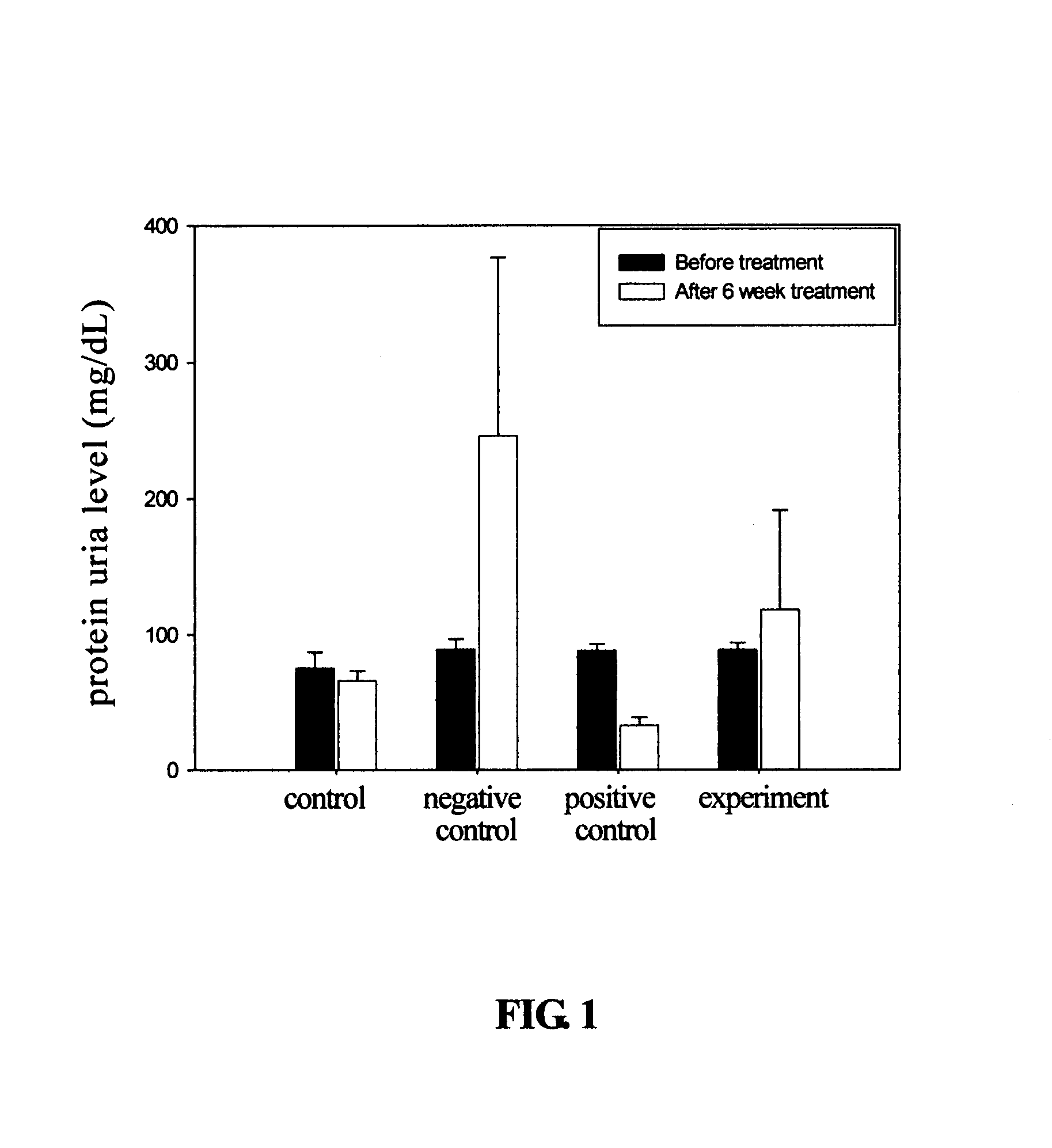

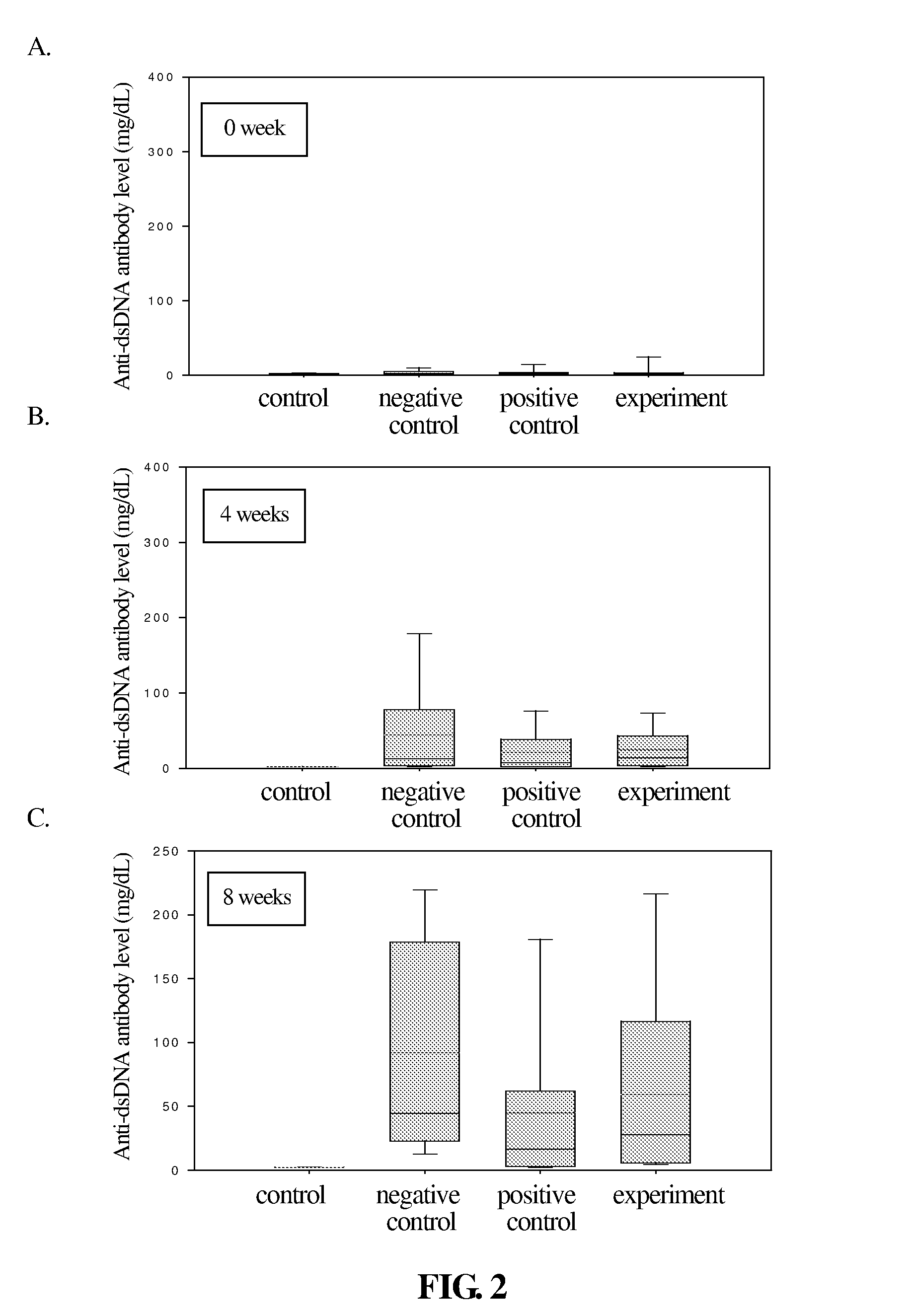

Cyclohexenone compounds from antrodia camphorata to treat autoimmune diseases

ActiveUS20080312334A1Avoid complicationsAvoid side effectsBiocideOrganic chemistryDiseaseImmunologic disorders

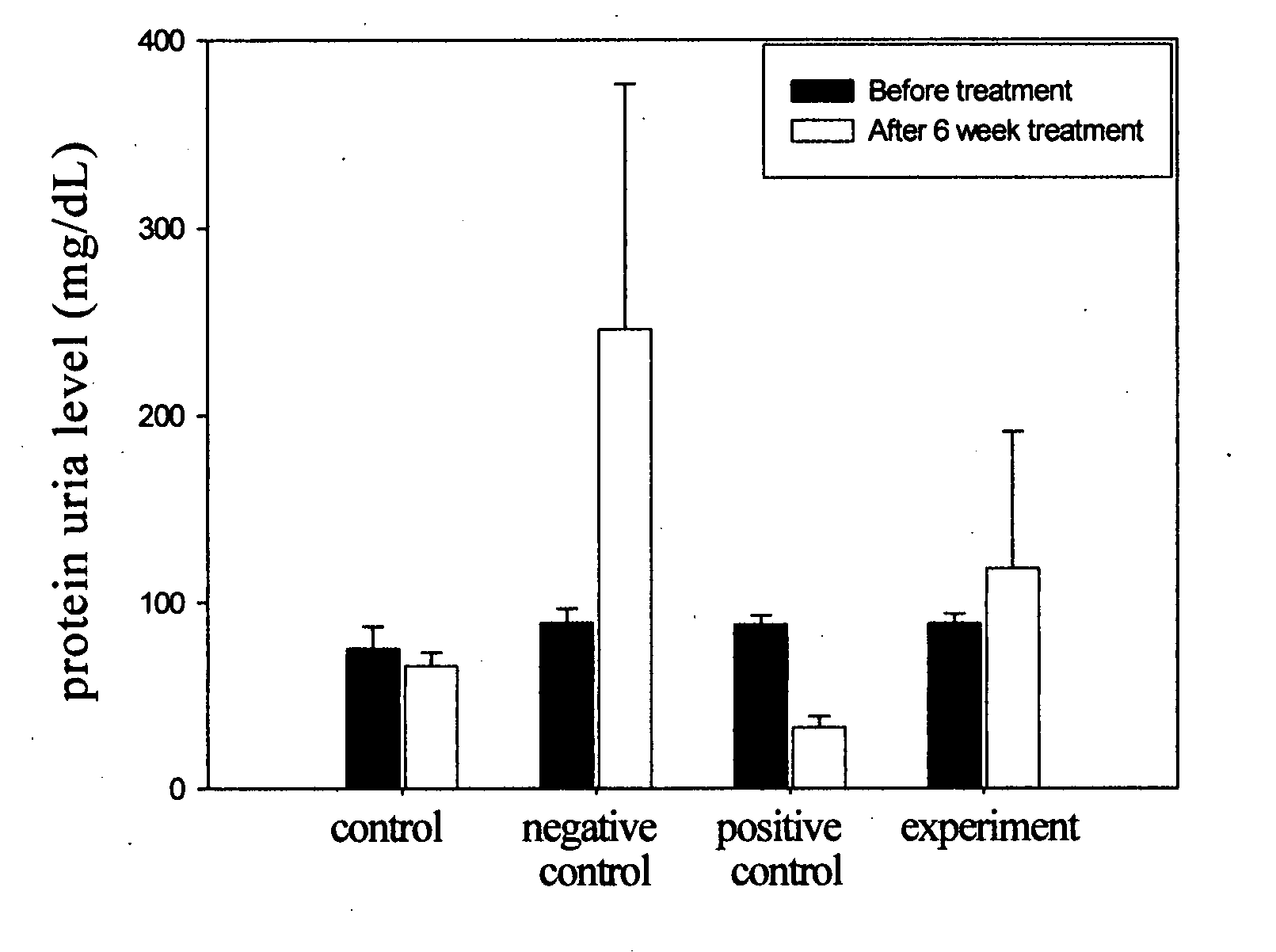

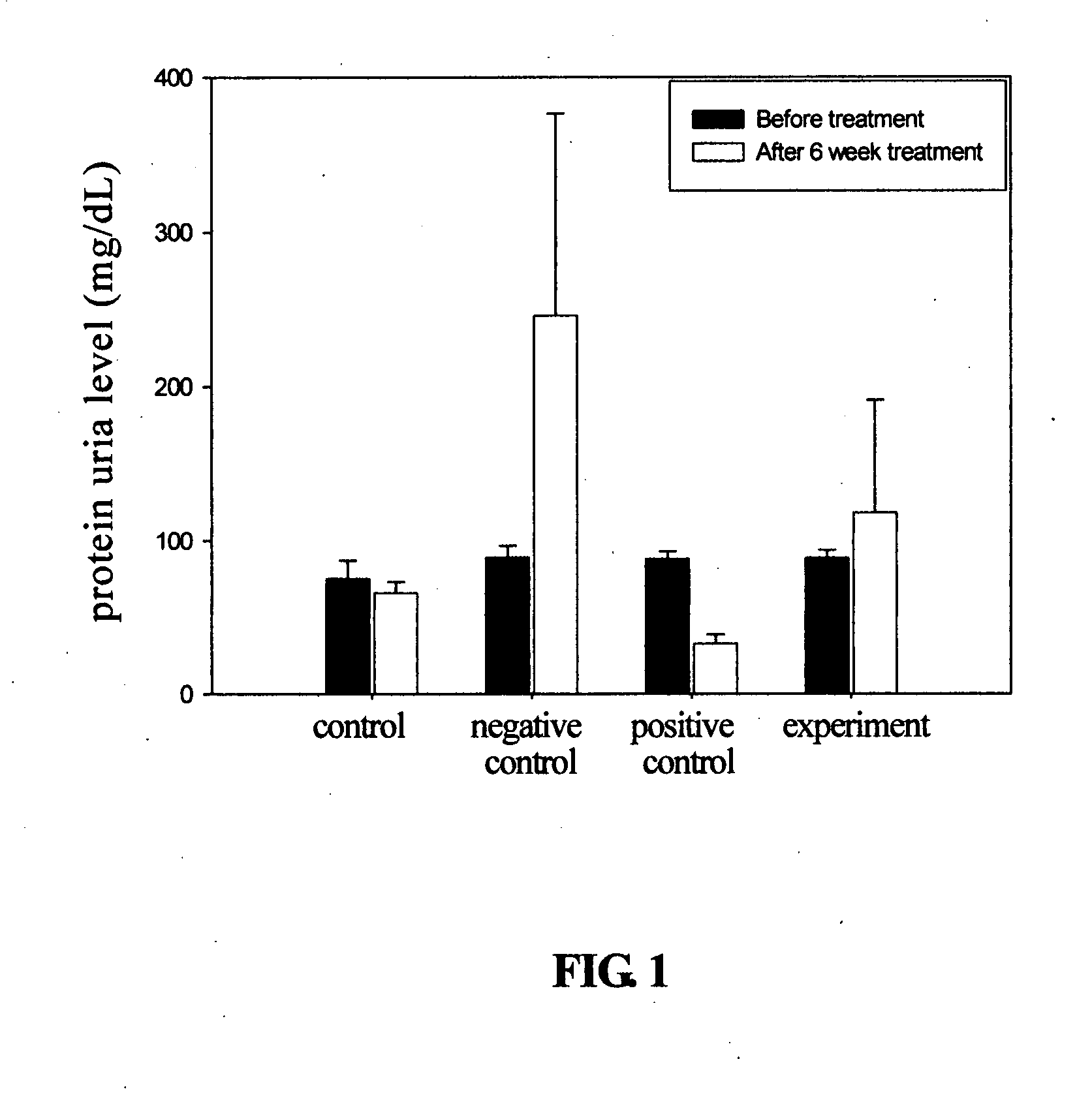

The present invention relates to a compound of Antrodia camphorata used to treat autoimmune diseases, in particular to an extract, 4-hydroxy-2,3-dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone, isolated from Antrodia camphorata, and its use in alleviating symptoms of autoimmune diseases such as systemic lupus erythematosus (SLE). The cyclohexenone compound according to the present invention helps to decrease proteinuria levels and antinuclear antibody titers in SLE mammals in order to alleviate kidney inflammation and disease, as well as the self-damage caused by antinuclear antibodies. The purpose for prevention and treatment of autoimmune diseases and kidney diseases by the natural, side-effect free substance can then be accomplished.

Owner:GOLDEN BIOTECH

Pyrazolyl and pyrimidinyl tricyclic enones as antioxidant inflammation modulators

Disclosed herein are novel antioxidant inflammation modulators, including those of the formula:wherein the variables are defined herein. Also provided are pharmaceutical compositions, kits and articles of manufacture comprising such compounds. Methods and intermediates useful for making the compounds, and methods of using the compounds and compositions thereof are also provided.

Owner:REATA PHARMA INC

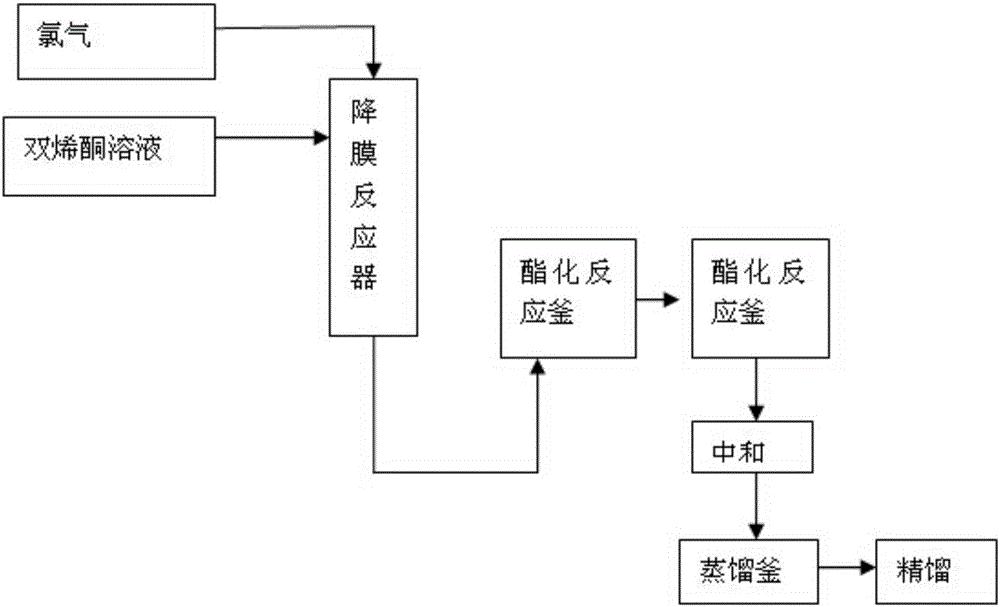

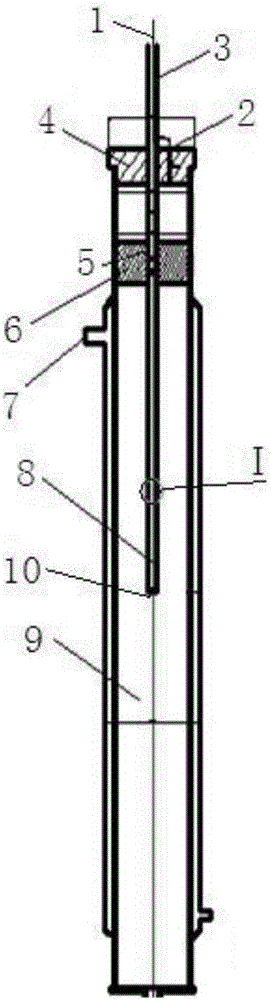

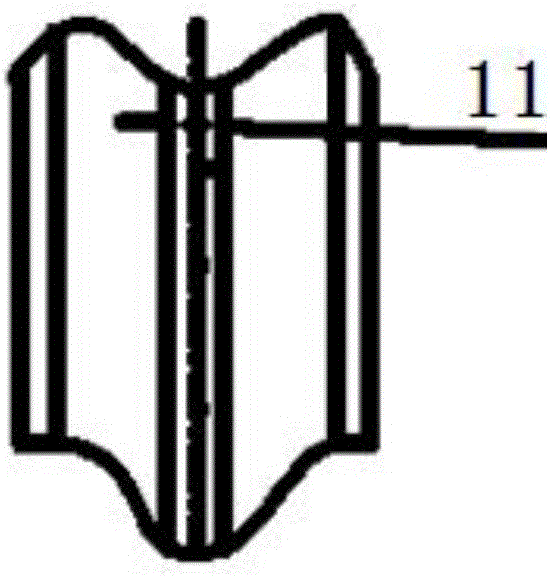

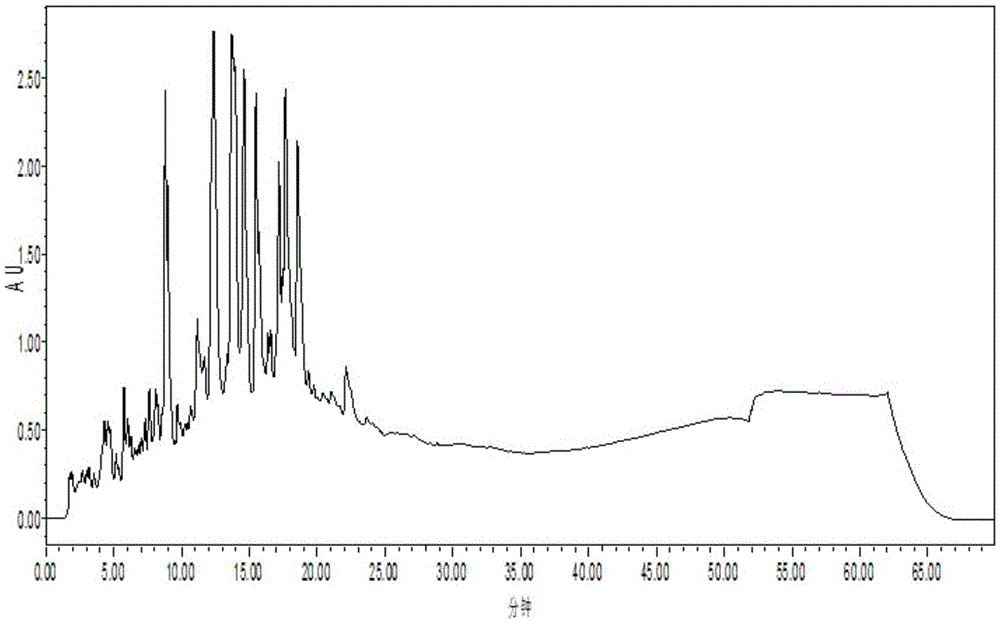

Method for continuously synthesizing ethyl 4-chloroacetoacetates

ActiveCN105693509AReduce volumeIncrease the effective cooling areaPreparation from carboxylic acid halidesCarboxylic acid halides preparationSolventEthyl Chloride

The invention relates to a method for continuously synthesizing ethyl 4-chloroacetoacetates. The method comprises the following steps: pumping a cooled diketene solution into a falling film reactor through a metering pump, and enabling the cooled diketene solution to uniformly form a film through a distributor, and flow into the reactor from a tower top; meanwhile, controlling the flow of chlorine gas through a gas flow meter; introducing the chlorine gas into the reactor through a gas distributor; carrying out a reaction on the diketene and the chlorine gas on the surface of the falling film reactor; after the reaction is finished, enabling reaction liquid to flow out from a tower bottom and enter an esterification reaction kettle; pumping in different alcohols and overflowing into a next esterification reaction kettle to continually react; absorbing hydrogen chloride gas, which is generated in a reaction process, with water; after the reaction is finished, washing with water and neutralizing to remove the residual hydrogen chloride; distilling an organic phase to recycle a solvent and excessive alcohol raw materials to obtain a crude product; rectifying the crude product to obtain an ethyl 4-chloroacetoacetates product. With the adoption of the method, reaction time can be shortened, energy consumption is reduced, polychlorides are controlled, reaction selectivity is improved, rectification is relatively easy, and yield and purity of the product are improved.

Owner:山东德澳精细化学品有限公司

Preparation method of terpenoid and lignan substances in eucommia ulmoides bark or eucommia ulmoides leaves and application of terpenoid and lignan substances in preparation of senile dementia treatment drug

The invention relates to a preparation method of terpenoid and lignan substances in eucommia ulmoides bark or eucommia ulmoides leaves and an application of the terpenoid and lignan substances in preparation of senile dementia and AD (Alzheimer disease) treatment drugs or healthcare food. The prepared terpenoid substance in the eucommia ulmoides bark or the eucommia ulmoides leaves is one or more of 1-deoxy-delta4,5-eucommiol, 2,3-dyhydroxyl-delta4,5-eucommiol, 5-hydroxyl-3,4-dihydroxymethyl-2-hydroxyethyl-cyclohex- 1-enone-2'-O-beta-D-glucopyranoside), (6R, 7E, 9R)-megastigma-4,7-dien-3-one-9-O-[beta-D-xylopyranos-yl-(1'-6')-beta-D-glucopyranoside, (6S, 7E, 9R)-megastigma-4,7-dien-3-one-9-O-[beta-D-xylopyranos-yl-(1'-6')-beta-D-glucopyranoside] and the like. The prepared lignan substance in the eucommia ulmoides bark or the eucommia ulmoides leaves is one or more of pinoresinol-4,4'-O-beta-D-bis(glucopyranoside), 8-hydroxyl-pinoresinol-4'-O-beta-D-glucopyranoside, lariciresinol-4,4'-O-beta-D- bis(glucopyranoside) and the like. The terpenoid and lignan substances have common or similar structural units such as eucommiol, megastigmane sesquiterpene, bisepoxylignans, single-epoxy lignans and the like, thereby having the similar treatment effect in a human body.

Owner:张忠立

Inhibition of the Survival of Ovarian Cancer by Cyclohexenone Compounds from Antrodia Camphorata

InactiveUS20110060058A1Enhance cancer therapeutic effectPromote growthBiocideKetone active ingredientsCyclohexenoneOvarian cancer cells

The present invention relates to a novel application of a compound. The compound 4-hydroxy-2,3-dimethoxy-6-methyl-5-(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone of the invention is isolated and purified from the extracts of Antrodia camphorata, which can be applied for inhibiting the survival of ovarian cancer cells and be used as a pharmaceutical composition to inhibit the ovarian tumor growth.

Owner:GOLDEN BIOTECH

Cyclohexenone compounds from Antrodia camphorata to treat autoimmune diseases

ActiveUS7501454B2Lower Level RequirementsDelay progressBiocideOrganic chemistryImmunologic disordersCyclohexenone

The present invention relates to a compound of Antrodia camphorata used to treat autoimmune diseases, in particular to an extract, 4-hydroxy-2,3-dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone, isolated from Antrodia camphorata, and its use in alleviating symptoms of autoimmune diseases such as systemic lupus erythematosus (SLE). The cyclohexenone compound according to the present invention helps to decrease proteinuria levels and antinuclear antibody titers in SLE mammals in order to alleviate kidney inflammation and disease, as well as the self-damage caused by antinuclear antibodies. The purpose for prevention and treatment of autoimmune diseases and kidney diseases by the natural, side-effect free substance can then be accomplished.

Owner:GOLDEN BIOTECH

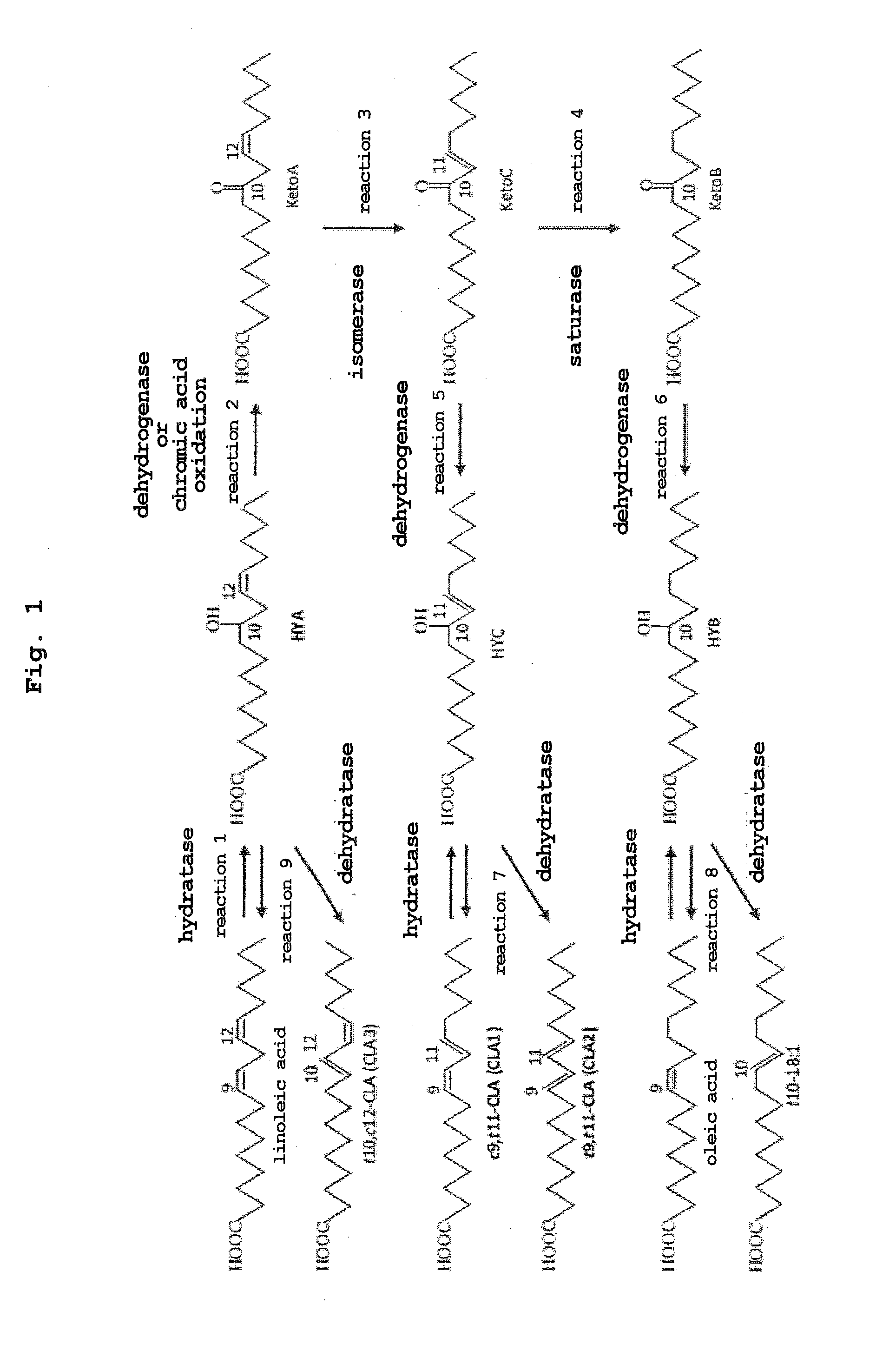

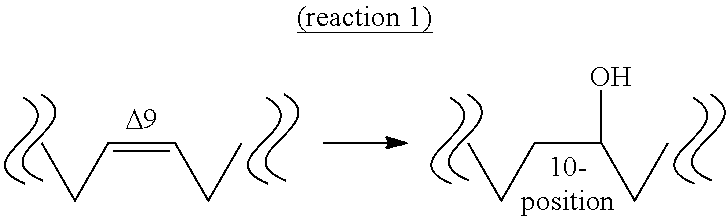

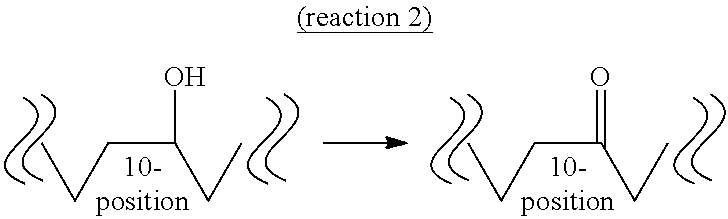

Method for producing oxo fatty acid and rare fatty acid

ActiveUS20150125911A1Efficient productionEfficient conversionMicroorganismsMicroorganism based processesLactic acid bacteriumIsomerase

The present invention provides a production method of oxo fatty acid, as well as rare fatty acids such as conjugated fatty acid, hydroxylated fatty acid, partially saturated fatty acid and the like, which uses 4 kinds of enzymes (fatty acid-hydratase, hydroxylated fatty acid-dehydrogenase, oxo fatty acid-isomerase, oxo fatty acid-enone reductase) derived from Lactobacillus plantarum including lactic acid bacteria and the like. Furthermore, the present invention also provides a more efficient production method of oxo fatty acid and the like, which partly uses a chemical oxidation reaction in combination.

Owner:NOSTER INC +1

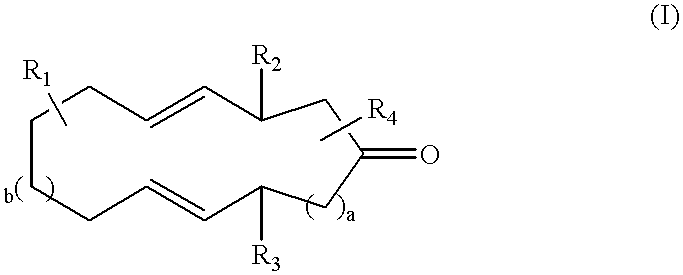

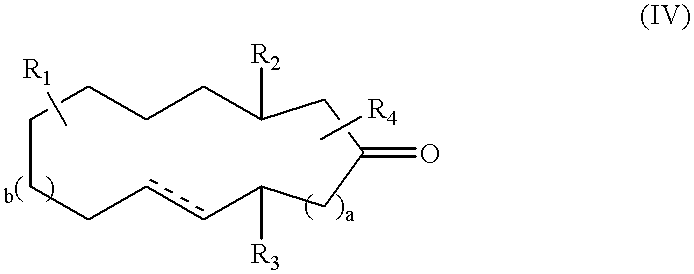

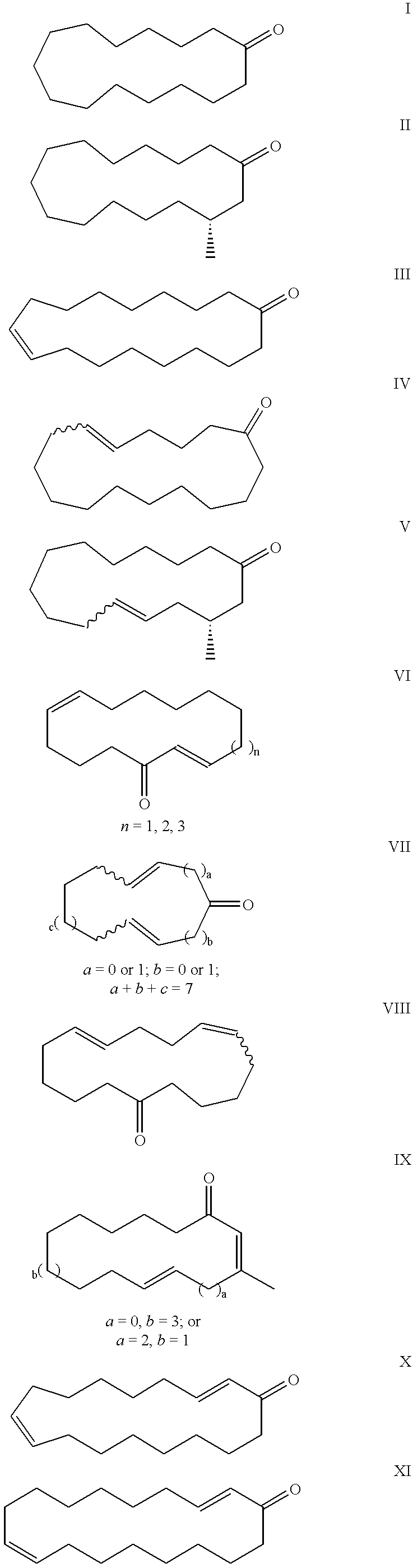

Macrocyclic ketones as fragrance materials and methods for making same

Novel macrocyclic diene ketone compounds useful as fragrance materials are described having the following general formula (I):where R1, R2, R3 and R4 are each either a hydrogen atom or a C1 to C4 alkyl, a is the integer 1 or 2 and b is an integer in a range from 1 to 6. Novel pathways are described for synthesizing these macrocyclic diene ketones, as well as saturated and mono-unsaturated macrocyclic ketones having the following general formula (IV):where R1, R2, R3 and R4 are each independently a hydrogen atom or a C1 to C4 alkyl, a is the integer 1 or 2 and b is an integer in a range from 1 to 6.

Owner:TAKASAGO INTERNATIONAL CORPORATION +1

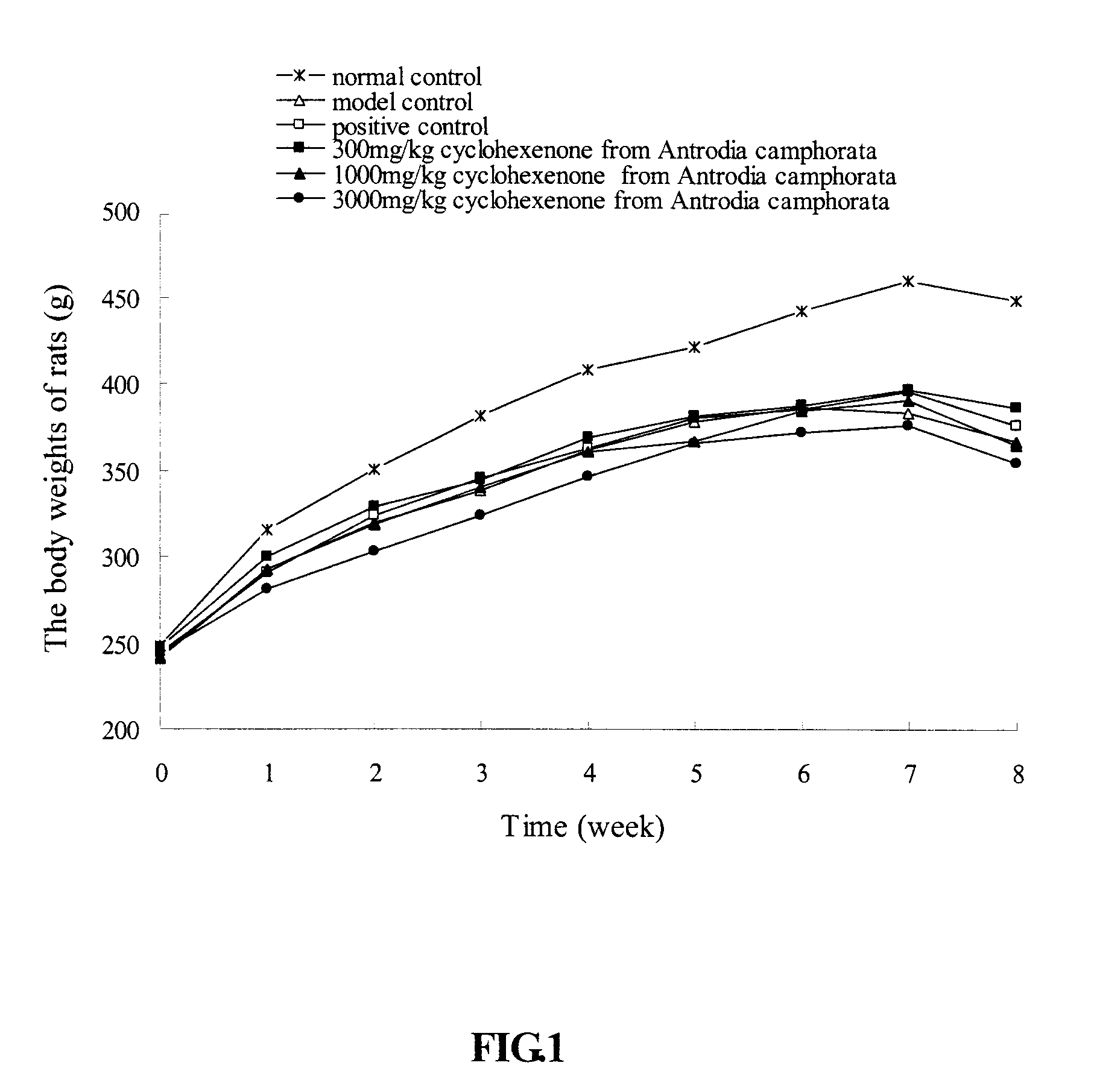

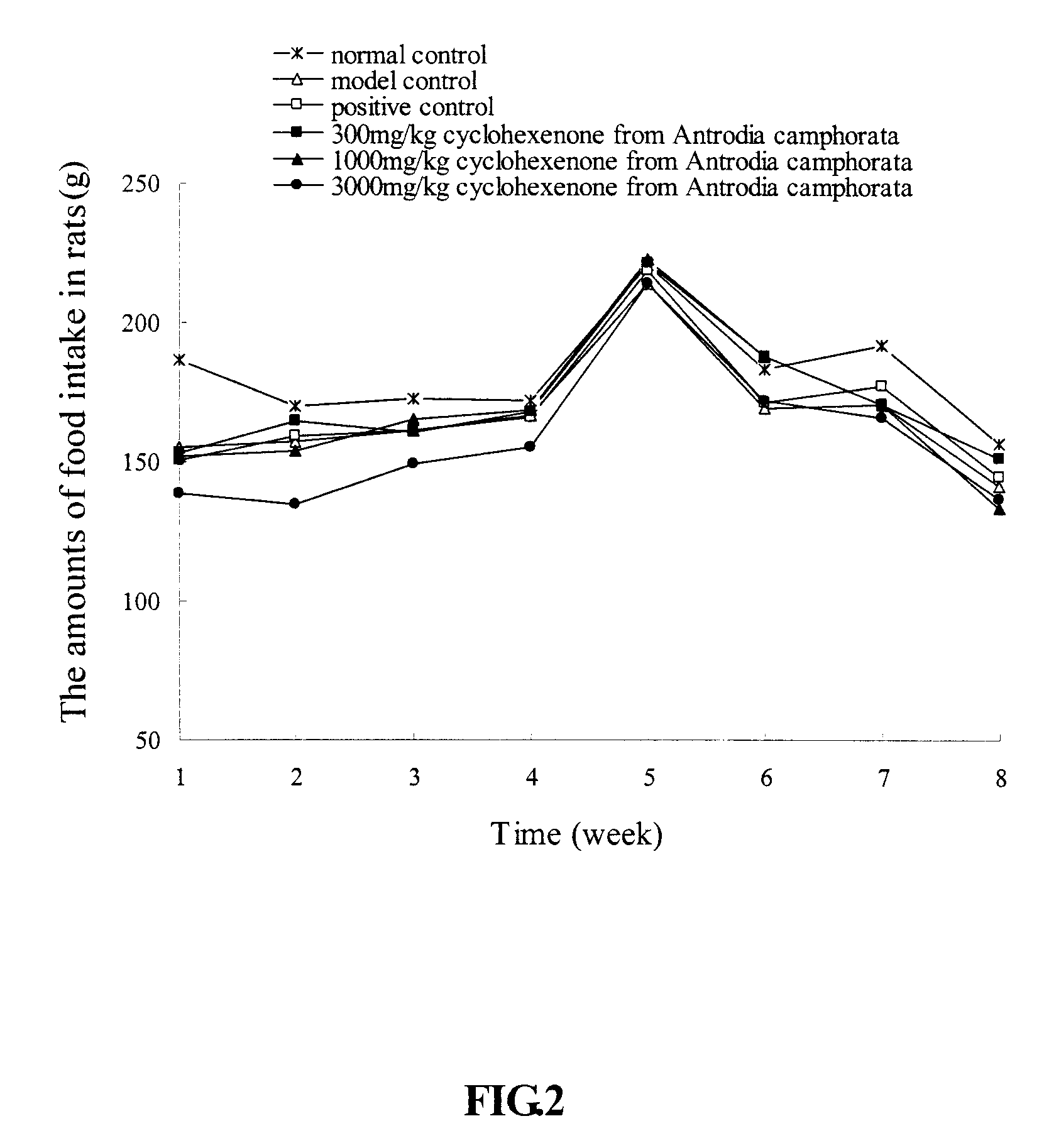

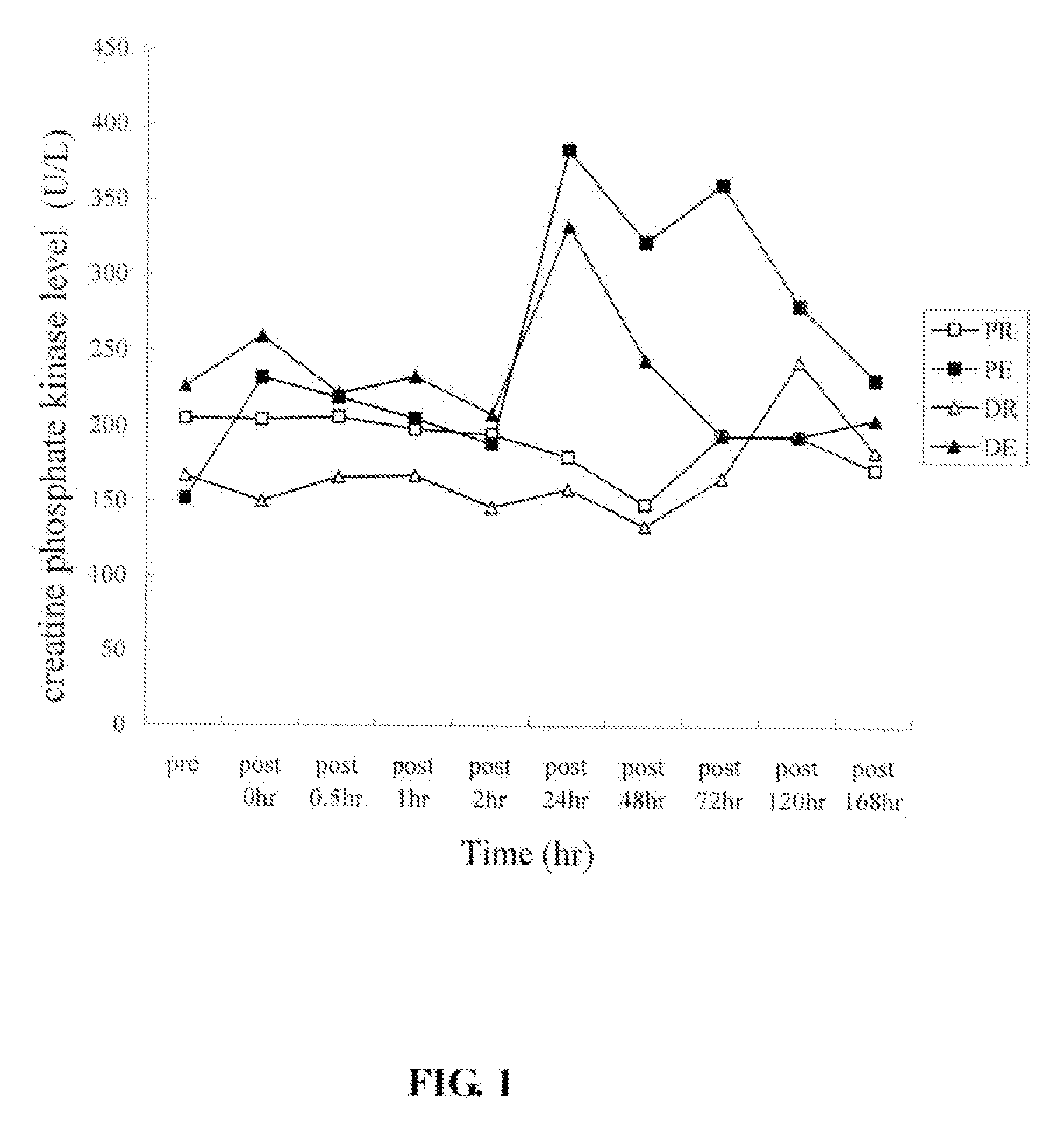

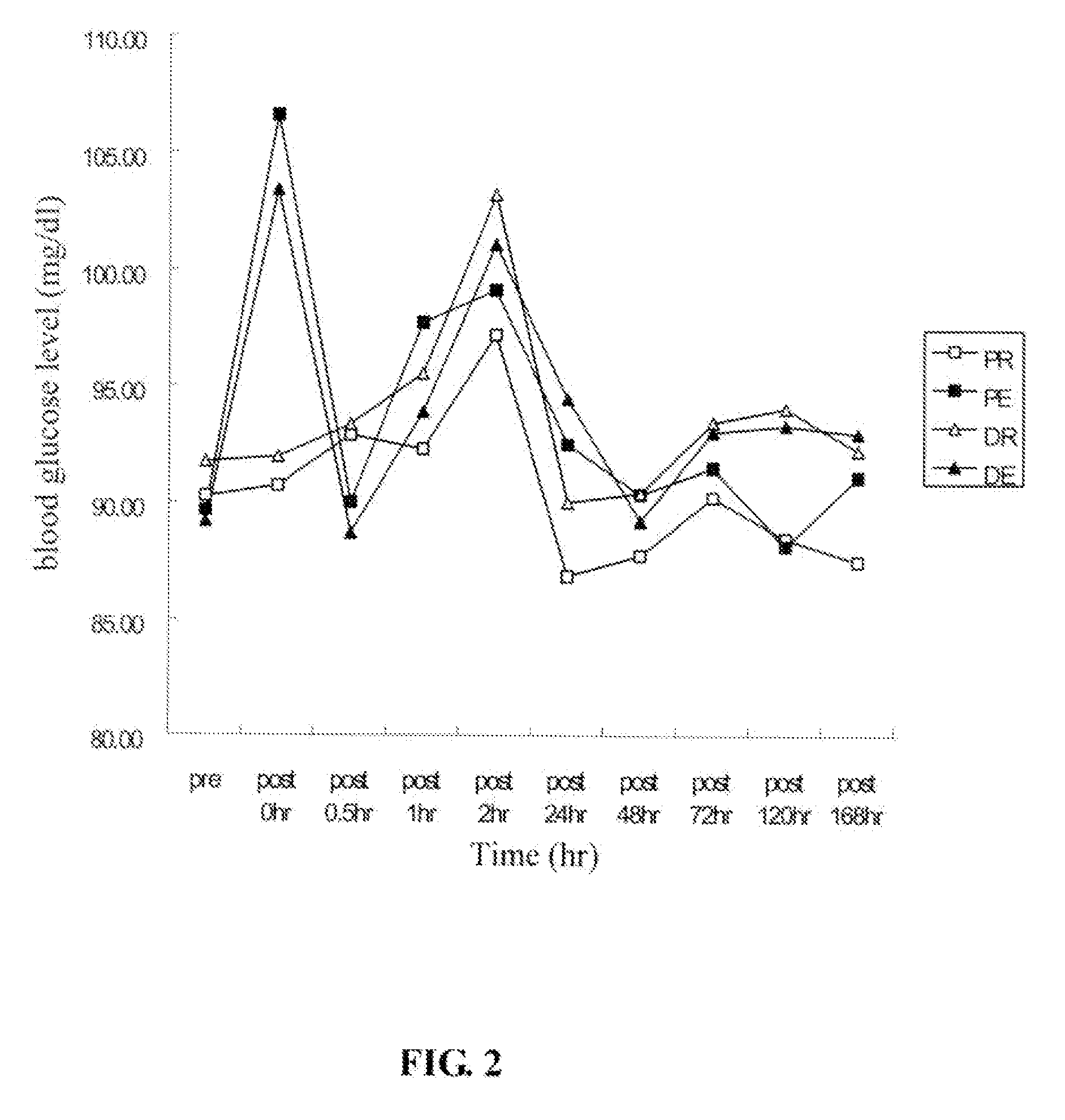

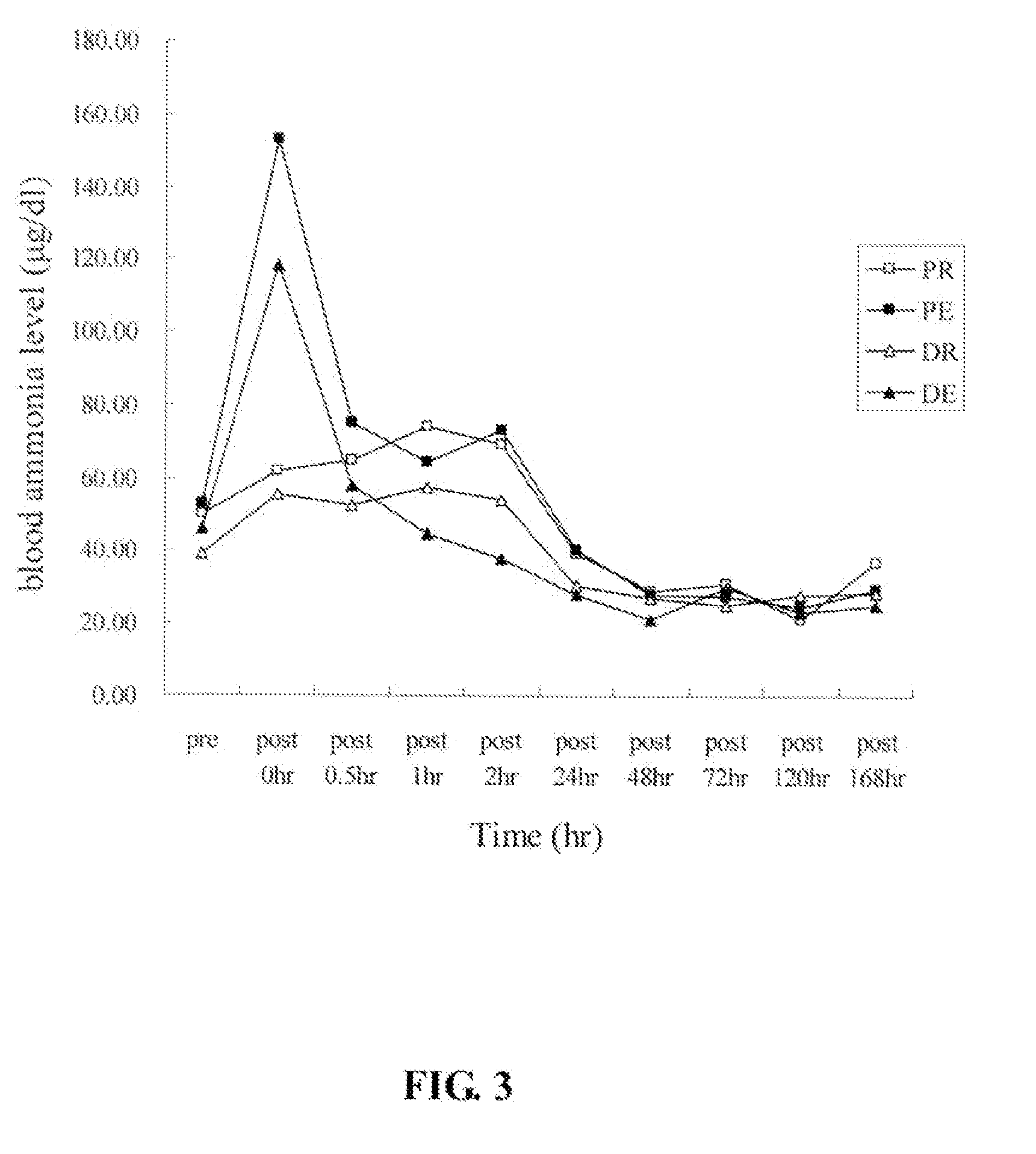

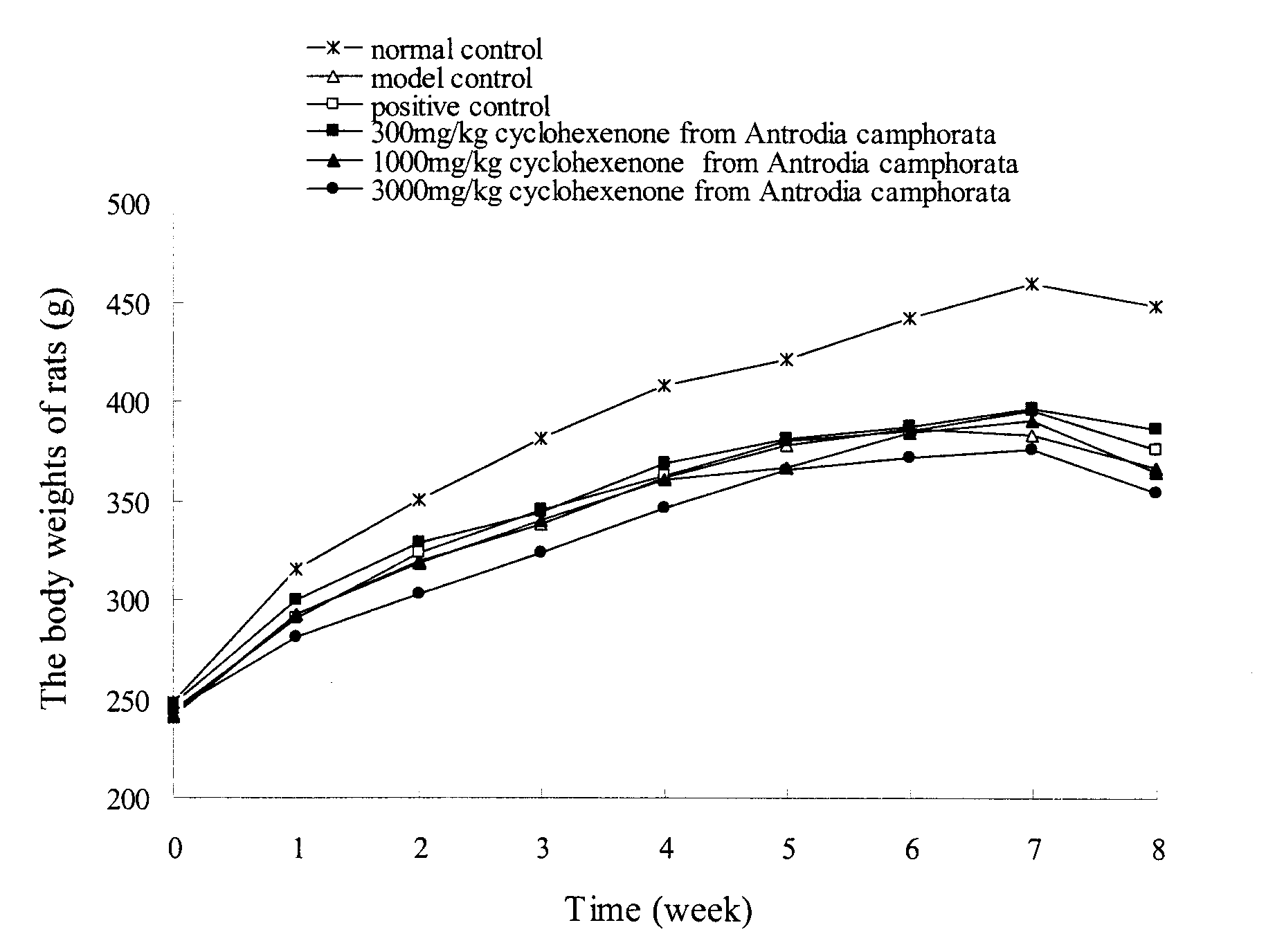

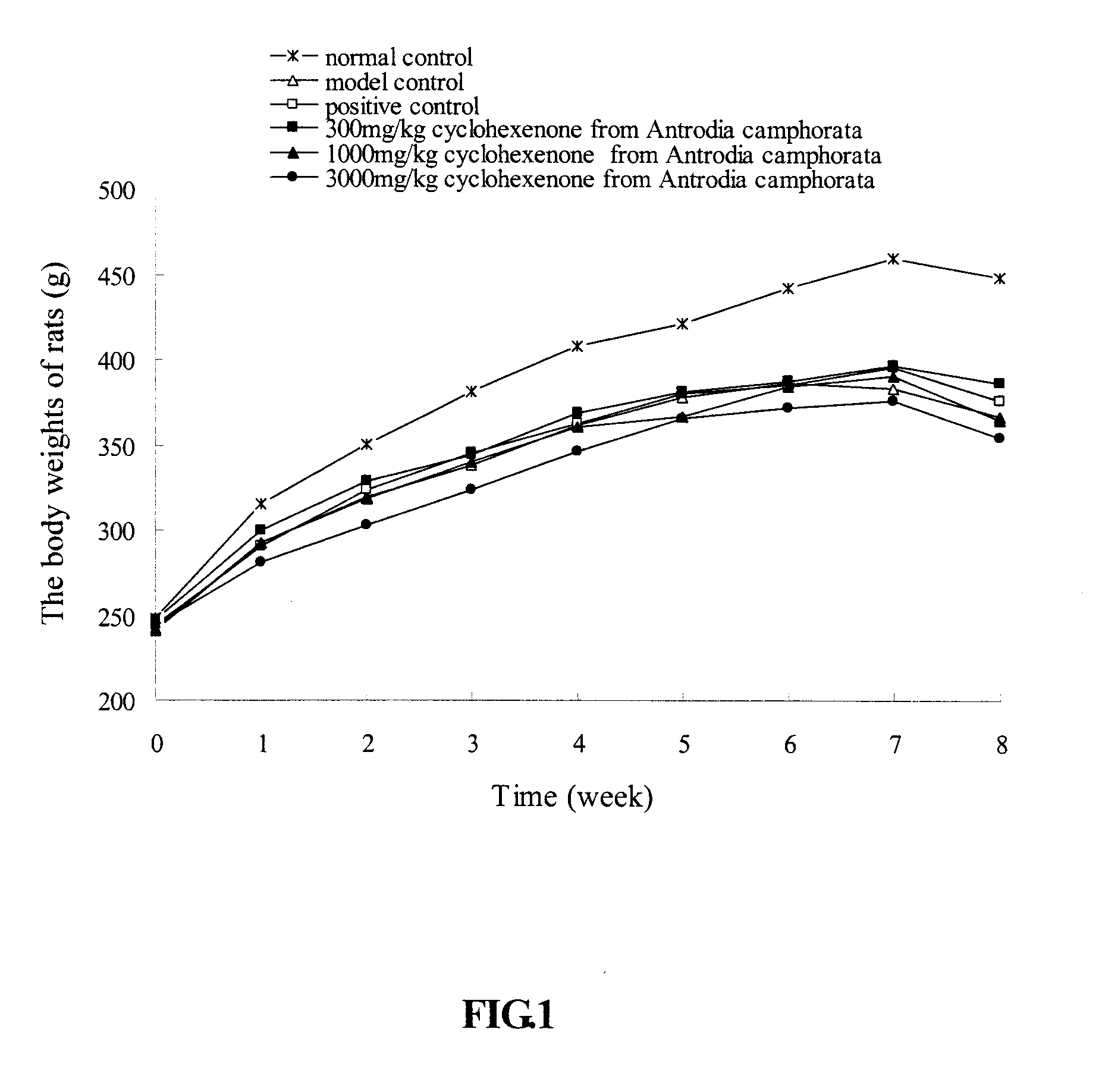

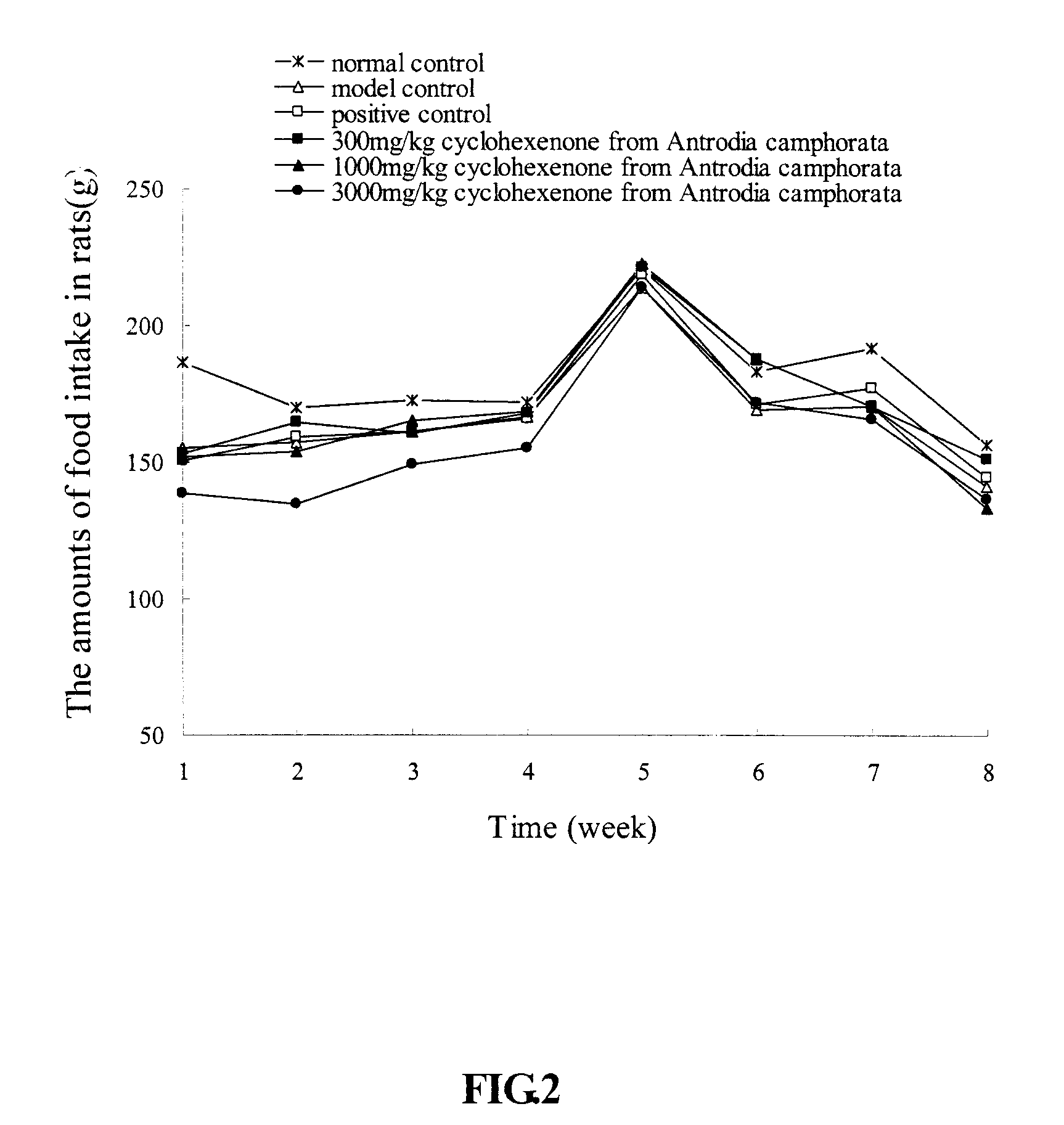

Anti-fatigue cyclohexenone compounds from antrodia camphorata

InactiveUS7468392B1Facilitate creating phosphate kinase (CPK)Eliminate the muscle cell impairmentBiocideOrganic chemistryCyclohexenoneBlood ammonia

The present invention relates to a compound of Antrodia camphorata used to delay physiological fatigue, in particular to a extract isolated from Antrodia camphorata, 4-hydroxy-2,3-dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6-10-trienyl)-cyclohex-2-enone, and its use in delaying fatigue. Immediate supplementation of the compound according to the invention after high intensity exhausted exercise at 80% VO2max can promote the metabolism of creatine phosphate kinase and blood ammonia in human bodies, be beneficial to their recovery, further achieves the function in delaying physiological fatigue.

Owner:GOLDEN BIOTECH

Polymerization inhibitor for styrene dehydrogenation units

ActiveUS7128826B2Thermal non-catalytic crackingDistillation purification/separationQuinone methideDehydrogenation

Quinone methide derivatives such as 4-benzylidene-2,6-di-tert-butyl-cyclohexa-2,5 dienone are used to inhibit styrene monomer polymerization in the dehydrogenator portion of a styrene monomer production system. The inhibitor contacts the dehydrogenation effluent and does not partition in substantial amounts to the aqueous phase that is separated in the phase separator.

Owner:BL TECH INC +1

Inhibition of the Survival of Pancreatic Cancer by Cyclohexenone Compounds from Antrodia Camphorata

ActiveUS20110009494A1Enhance cancer therapeutic effectPromote growthBiocideOrganic chemistryPancreas tumorsCyclohexenone

The present invention relates to a novel application of a compound. The compound 4-hydroxy-2,3-dimethoxy-6-methyl-5-(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone of the invention is isolated and purified from the extracts of Antrodia camphorata, which can be applied for inhibiting the survival of pancreatic cancer cells and be used as a pharmaceutical composition to inhibit the pancreatic tumor growth.

Owner:GOLDEN BIOTECH

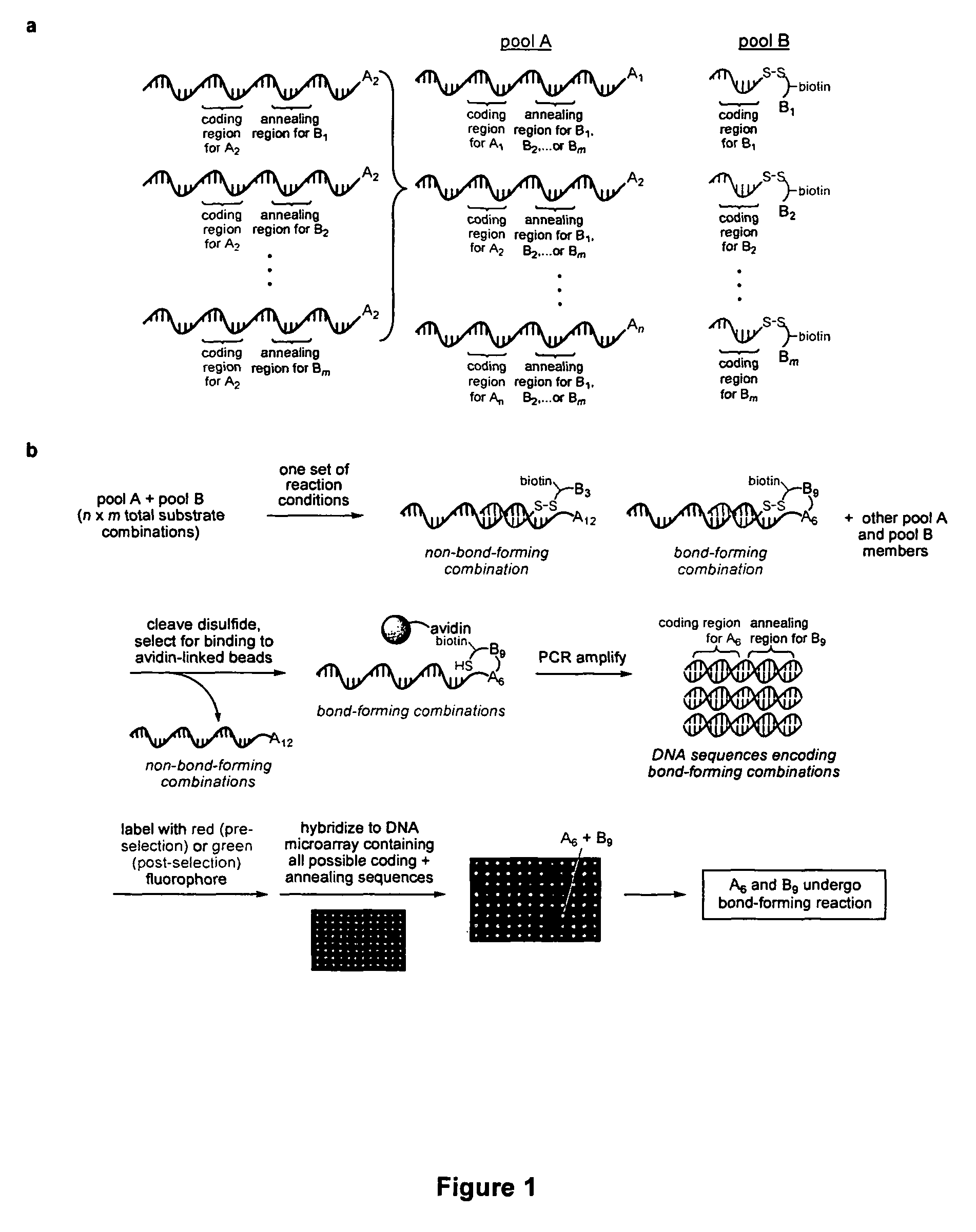

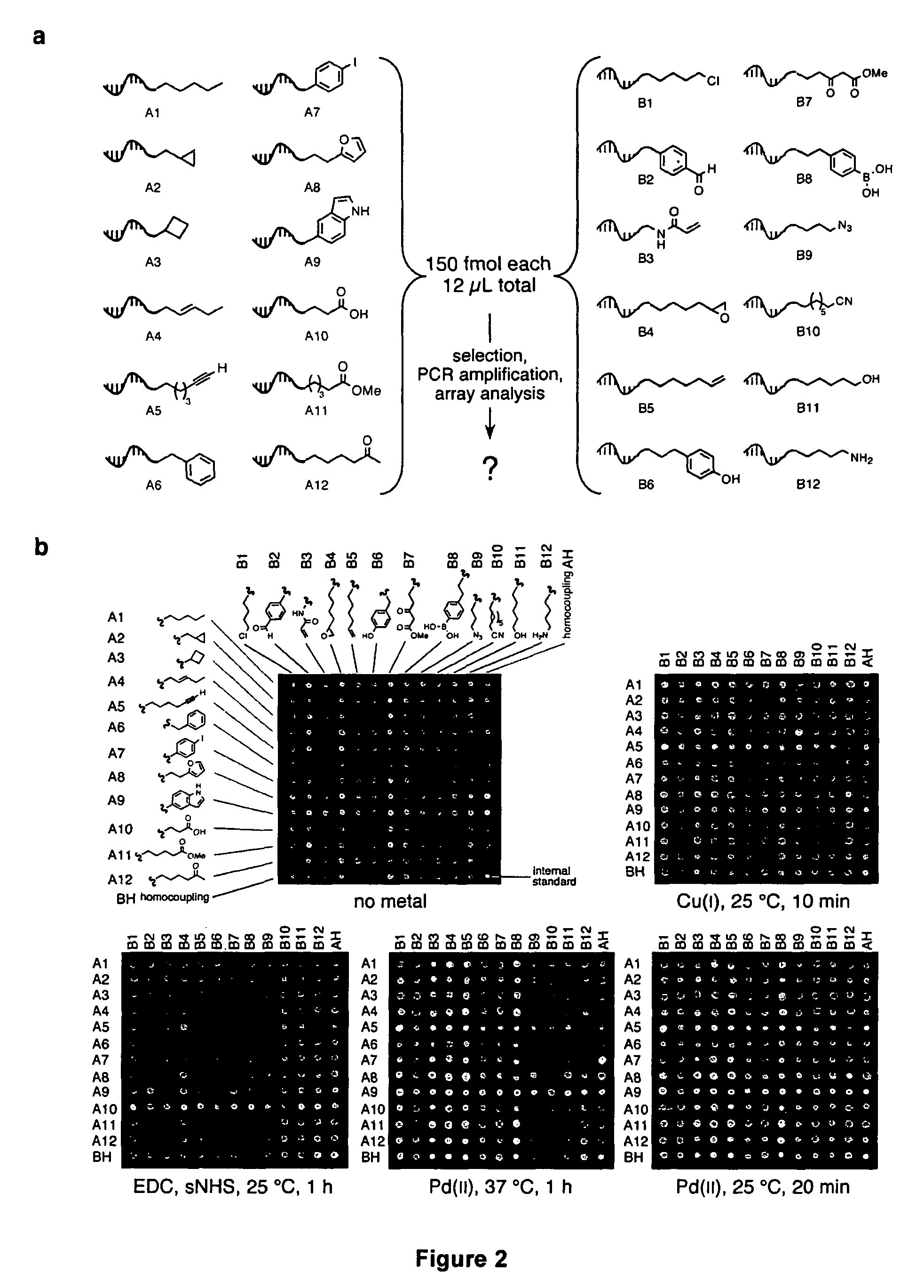

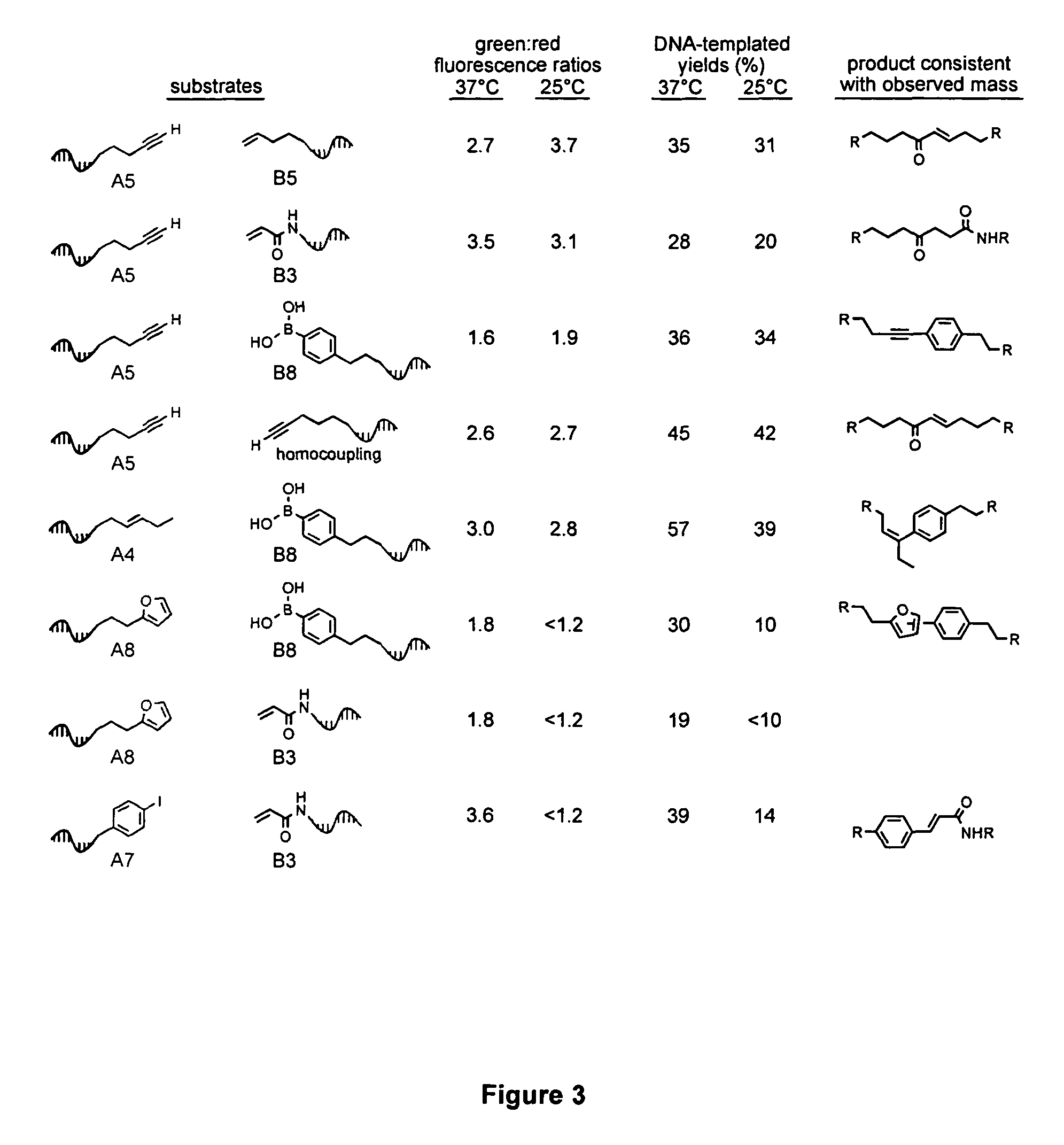

Palladium-catalyzed carbon-carbon bond forming reactions

ActiveUS7851658B2Organic compound preparationCarboxylic acid amides preparationCarbon–carbon bondAlkyne

A novel palladium-mediated carbon-carbon bond forming reaction has been discovered using DNA-templated chemistry. The inventive reaction involves the palladium-mediated coupling of a terminal alkyne with an alkene to form an enone. A catalytic amount of palladium may be used in the reaction if an oxidant is present. The reactions is also compatible with a variety of organic solvent as well as aqueous solution. Both intermolecular and intramolecular reactions have been demonstrated. This novel carbon-carbon bond forming reaction is particularly useful in the synthesis of macrocycles. Kits, reagents, catalysts, solvents, oxidants, salts, acids, instructions, and other materials useful in the practice of the inventive reaction are also provided.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Liver protection compounds of the cyclohexenone type from antrodia camphorata

InactiveUS20080312335A1Shorten the progressLower Level RequirementsBiocideOrganic chemistryCyclohexenoneAspartate carbamoyltransferase

The present invention relates to a compound of Antrodia camphorata used for liver protection, in particular to an extract, 4-hydroxy-2,3-dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone which is isolated from Antrodia camphorate. The cyclohexenone compound according to the invention helps to alleviate liver injury and fibrosis induced by chemicals and reduces the levels of alanine aminotransferase (ALT) and aspartate aminotransferase (AST). By increasing the contents of glutathione peroxidase (GSHPX) and catalase (CAT), cyclohexenone further decreases the liver damage and the oxidative pressure caused by free radicals, enhances the antioxidant ability and achieves the purposed of liver protection.

Owner:GOLDEN BIOTECH

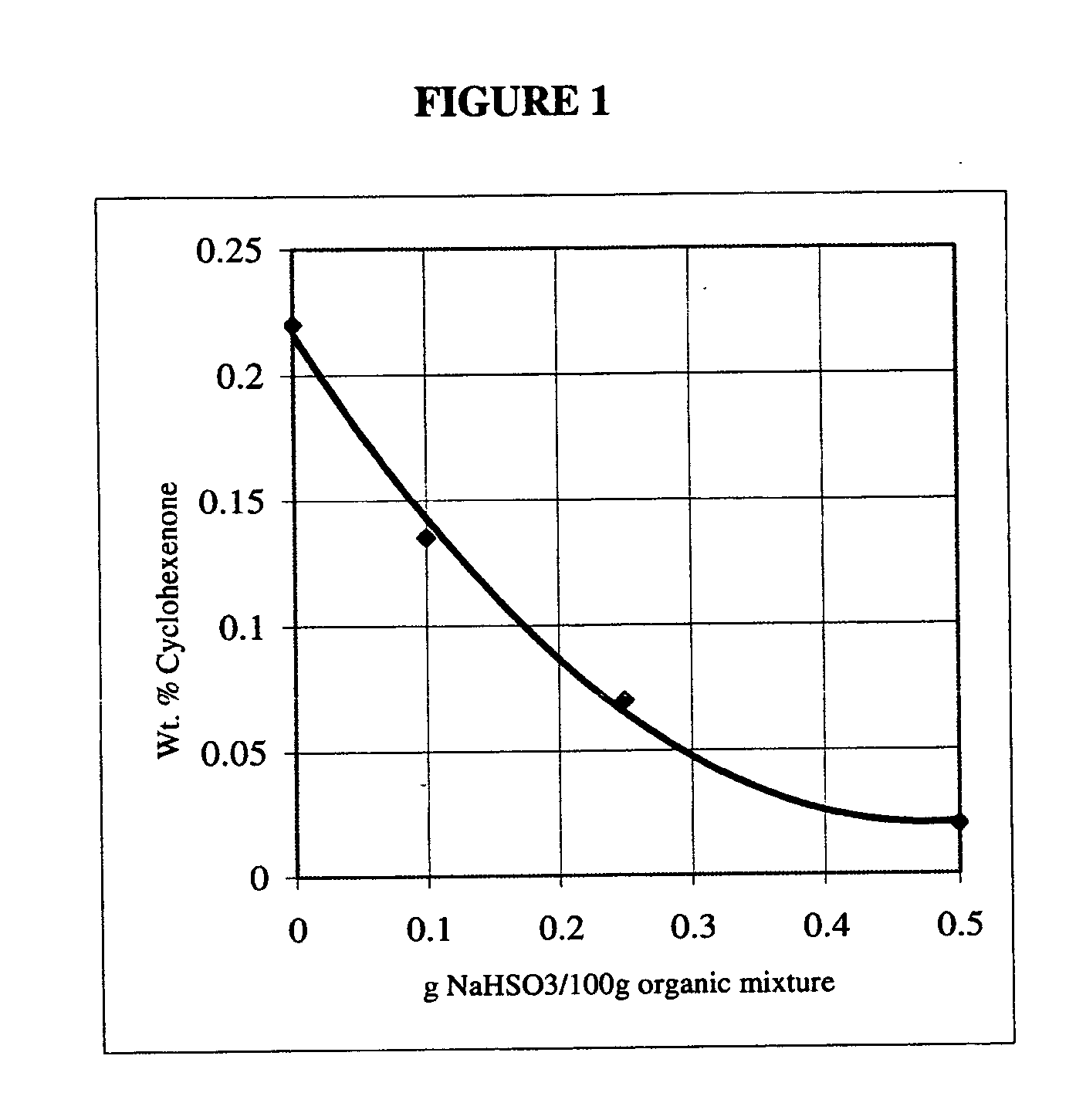

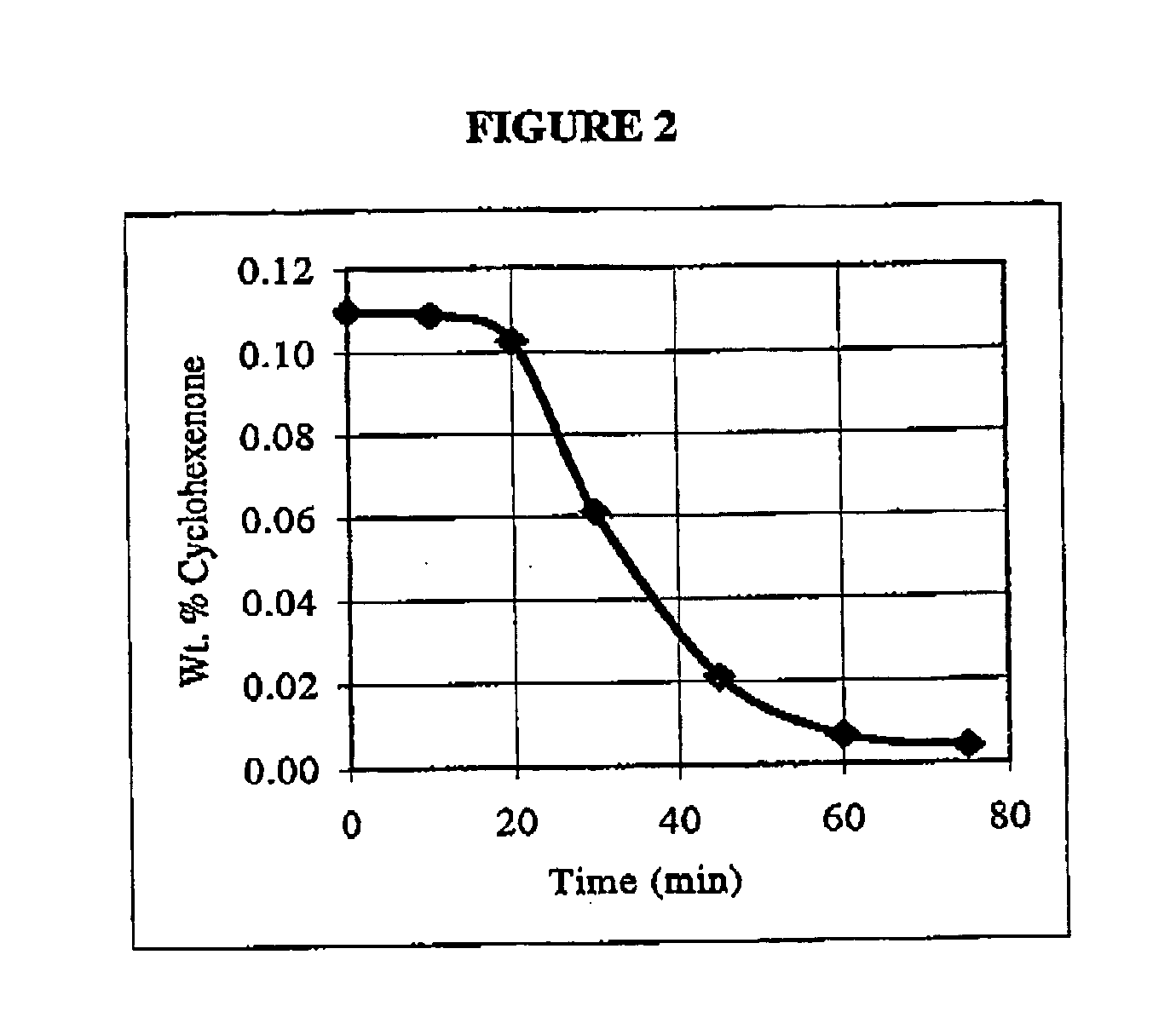

Method for reducing cyclohexenone content of a cyclohexenone-containing organic mixture

InactiveUS20060211890A1Reduce decreaseOrganic compound preparationPreparation by dehydrogenationCyclohexenoneMetal hydroxide

A method for reducing the concentration of cyclohexenone in a cyclohexenone containing organic mixture is disclosed. The method includes contacting an organic mixture comprising cyclohexenone with an effective amount of at least one of sulfurous acid, a salt of sulfurous acid, an alkali hydroxide, or a mixture of two or more of these compounds.

Owner:INVISTA NORTH AMERICA R L

Process for the production of quinone methide

InactiveUS20080132726A1Reduction potential eliminationAvoid economic wasteOrganic compound preparationCarbonyl compound preparation by condensationQuinone methideTert butyl

Owner:GENERAL ELECTRIC CO

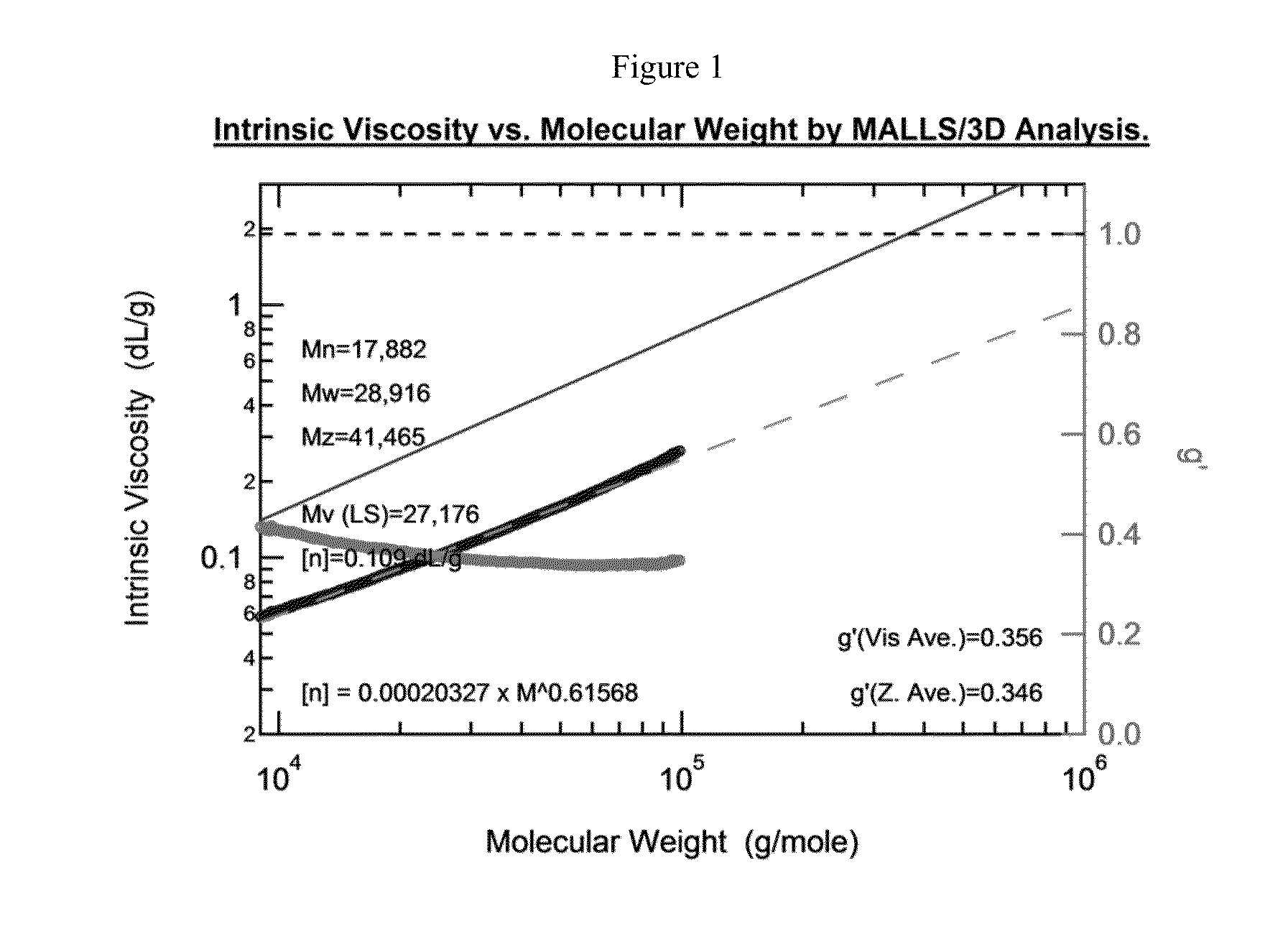

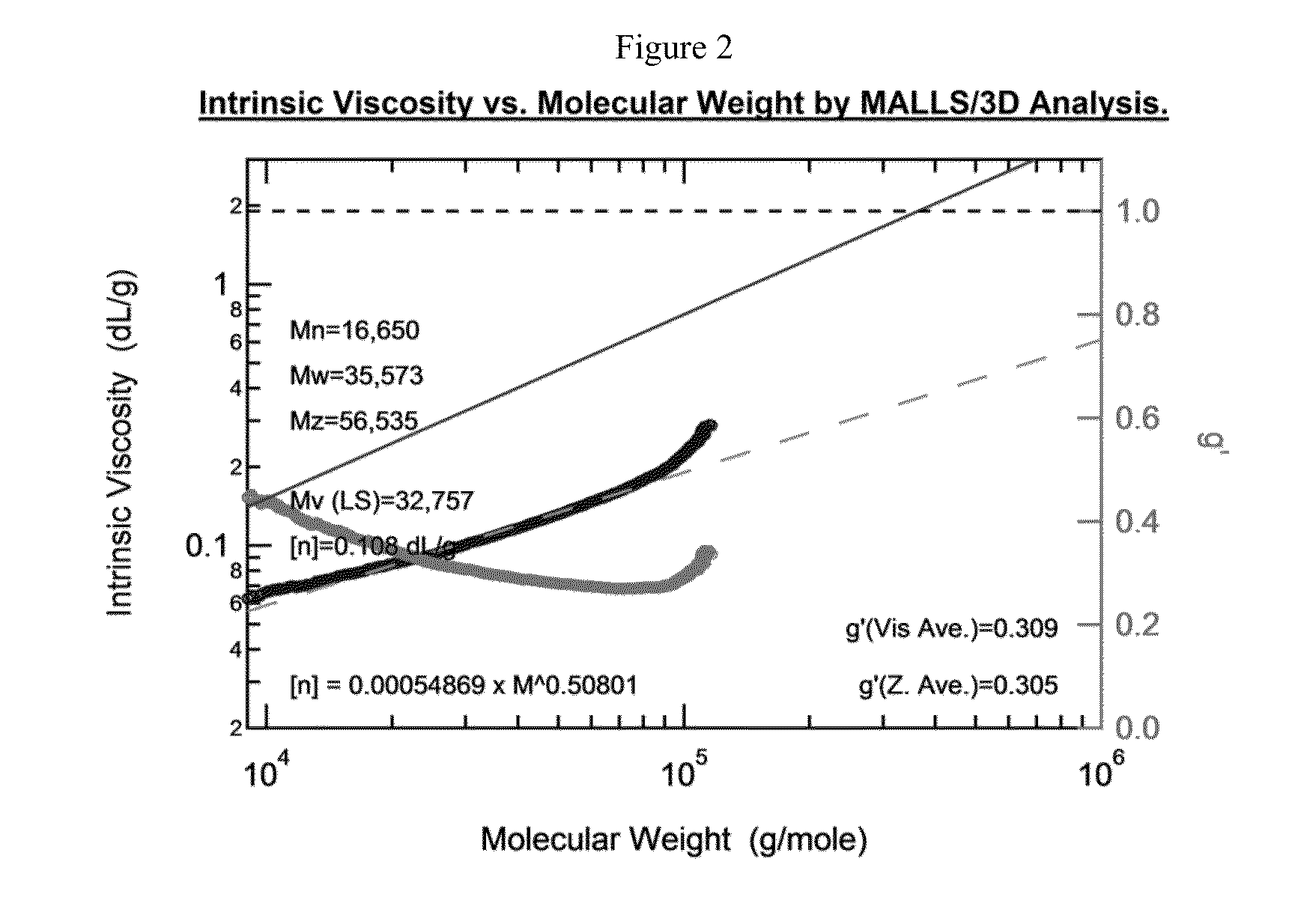

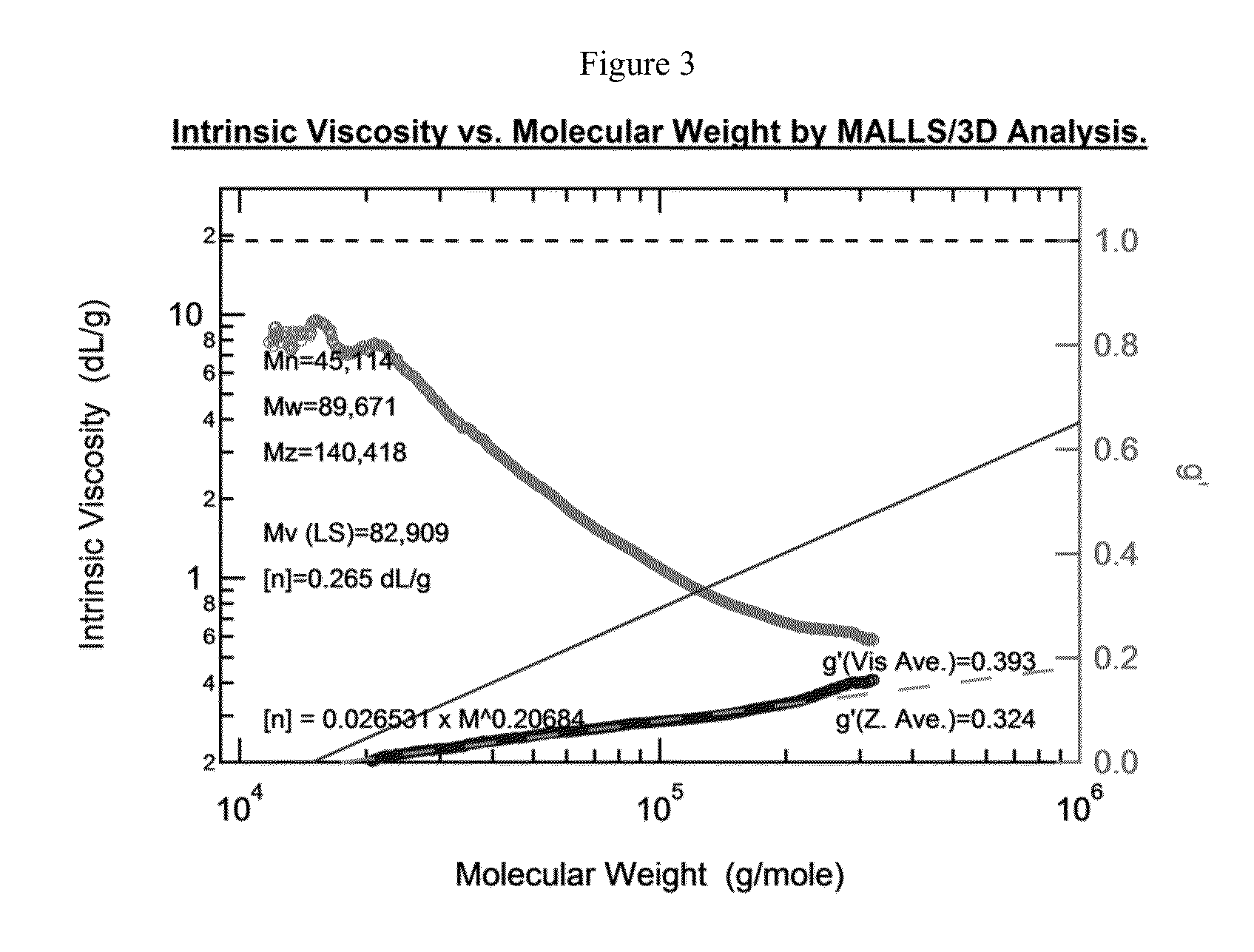

Preparation of Bottlebrush Polymers via Ring-Opening Metathesis Polymerization

This invention relates to a reaction product obtained by ring-opening metathesis polymerization of norbornene ketones functionalized with the residual portion of a vinyl terminated macromonomer.

Owner:EXXONMOBIL CHEM PAT INC

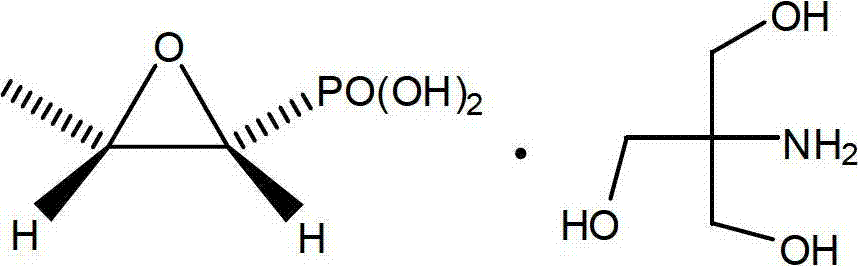

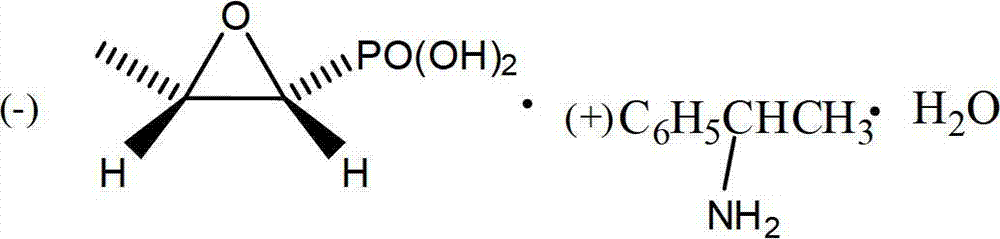

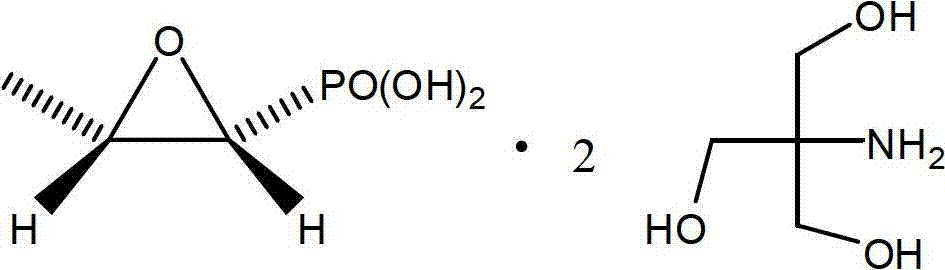

Preparation method of fosfomycin amine salt

ActiveCN102807586ALow costReduce energy consumptionGroup 5/15 element organic compoundsOrganic solventIon exchange

The invention discloses a preparation method of fosfomycin amine salt, which comprises the following steps of: in organic solvent, enabling fosfomycin phenylethylamine salt to react with isocyanate, isothiocyanate, ketene, dipolymer of isocyanate, dipolymer of isothiocyanate or dipolymer of ketene, and tromethamine; or in the organic solvent, enabling fosfomycin bistromethamine to react with isocyanate, isothiocyanate, ketene, dipolymer of isocyanate, dipolymer of isothiocyanate or dipolymer of ketene. The preparation method provided by the invention has the advantages that the fosfomycin amine salt can be prepared in one step only, a low-temperature ion exchange column is not required, the yield is high, the cost is low, the waste gas, waste water and waste residue are less, the reaction conditions are moderate, the energy consumption is low, the operation is convenient to conduct and the method is suitable for industrial production.

Owner:NORTHEAST PHARMA GRP

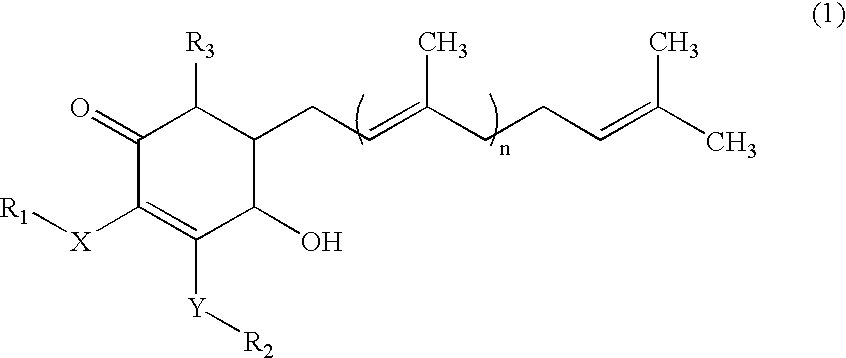

Aryl and arylalkyl substituted pyrazolyl and pyrimidinyl tricyclic enones as antioxidant inflammation modulators

The present application relates to: (a) compounds of Formula (I):and salts thereof, wherein R1, R2, R3, R4, R5, R6, m, n, X and Y are as defined in the specification; (b) compositions comprising such compounds and salts; and (c) methods of use of such compounds, salts, and compositions, particularly use for the treatment and prevention of diseases such as those associated with oxidative stress and inflammation.

Owner:REATA PHARMA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com