Patents

Literature

64results about How to "Reduce recycling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering positive pole material of Li-ion battery

InactiveCN101212074AImprove recycling efficiencyShorten production timeSolid waste disposalWaste accumulators reclaimingOrganic solventAlcohol

The invention relates to a method for recycling anode material of a lithium ion battery, which includes the processes: organic solvent is used for soaking anode plates of the battery so as to separate the anode material from a current collector; the current collector is taken out and filtered to obtain anode active substances; the anode active substances are parched. The organic solvent is the mixed solvent of the N, N - dimethylformamide and liquid alcohol and / or liquid ketone. By adopting the mixed solvent, the invention greatly promotes the recycling efficiency of the anode material; in the method of the invention, the recycling rate of the anode material is higher by over 20 per cent compared with the prior art in the situation of adopting different used organic solvent but other same conditions; besides, by adopting the method provided by the invention, the needed production time is greatly shortened and the production efficiency is promoted.

Owner:SHANGHAI BYD

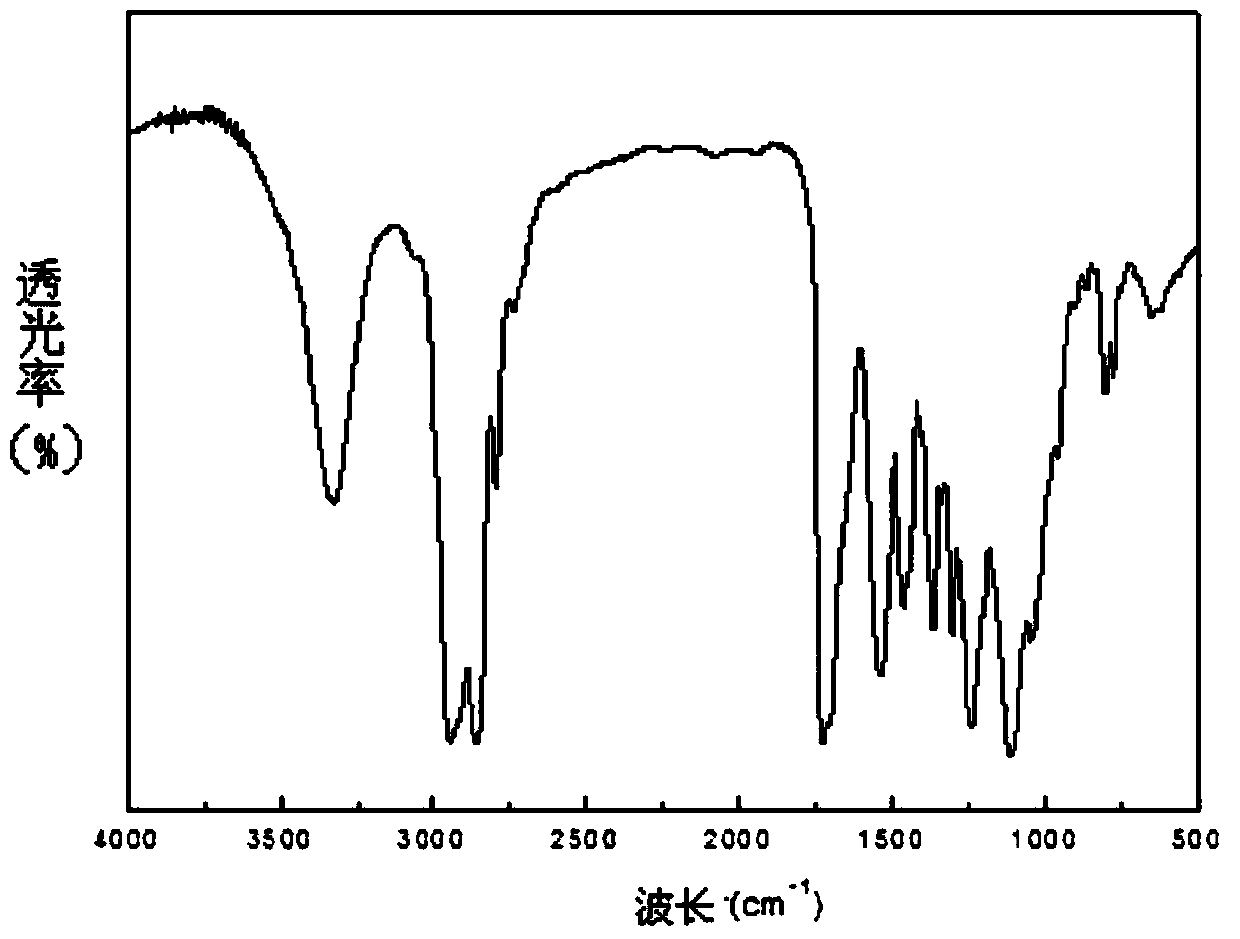

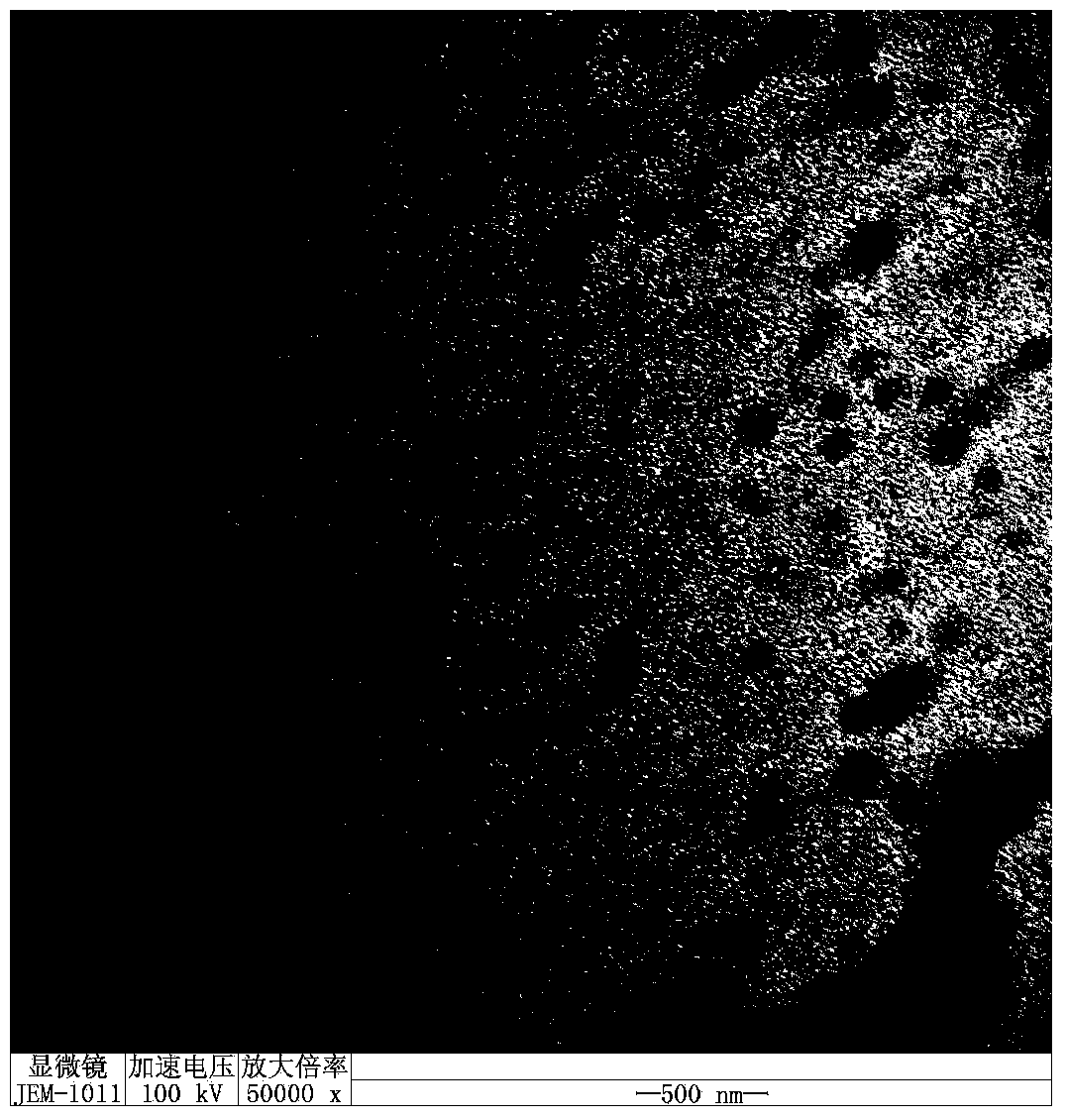

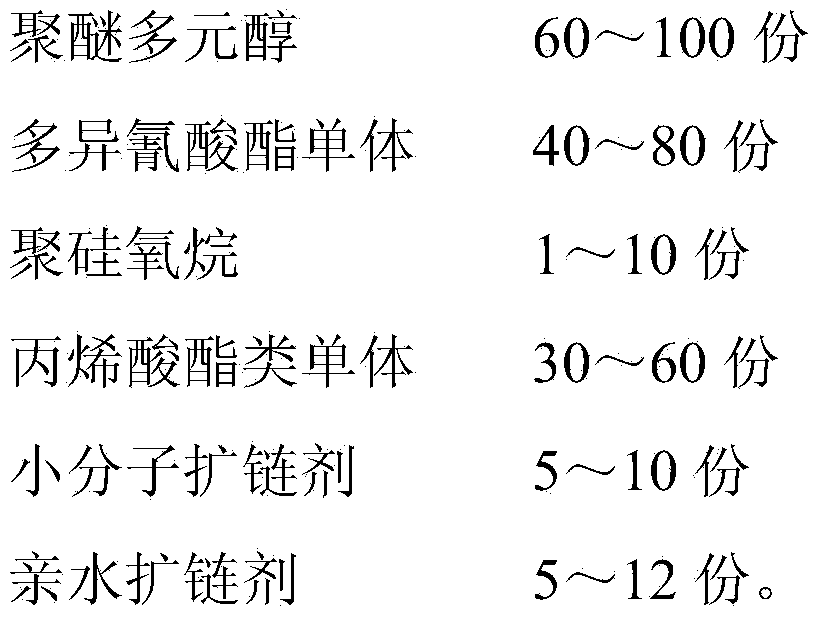

Waterborne polyurethane-acrylic emulsion as well as preparation method and application thereof

The invention provides waterborne polyurethane-acrylic emulsion as well as a preparation method and application thereof, belonging to the field of leather auxiliaries. The emulsion comprises 60-100 parts of polyether polyols, 40-80 parts of polyisocyanate monomers, 1-10 parts of polysiloxane, 30-60 parts of acrylic monomers, 5-10 parts of small molecule chain extenders and 5-12 parts of hydrophilic chain extenders by weight. The invention also provides the preparation method of the waterborne polyurethane-acrylic emulsion. The preparation method comprises the steps of stepwise polymerizing the polyisocyanate monomers, polyether polyols, hydrophilic chain extenders and organic silicon in proportion to prepare a prepolymer, synthesizing anionic waterborne polyurethane emulsion by a self-emulsification method, adding the acrylic monomers and continuing polymerization, thus preparing the dual-modified waterborne polyurethane emulsion. After a film is formed by coating the emulsion, the tensile strength is not less than 20MPa and the elongation is not less than 600%. The waterborne polyurethane-acrylic emulsion has good surface properties and excellent overall properties.

Owner:CHANGCHUN UNIV OF TECH

Preparation method of bifunctional hollow fibrous membrane with strong acidic catalysis and pervaporation

ActiveCN102327743AImprove conversion rateFewer separation stepsSemi-permeable membranesOrganic compound preparationFiberDip-coating

The invention relates to a preparation method of a bifunctional hollow fibrous membrane with strong acidic catalysis and pervaporation. The preparation method comprises the following steps: 1, preparing hollow fibrous basilemmas of a high molecular material and an inorganic material; 2, preparing an aqueous solution of polyvinyl alcohol (PVA); 3, dip-coating the aqueous solution of the PVA and anaqueous solution of PVA-GA (polyvinyl alcohol-glutaraldehyde) on the hollow fibrous basilemmas, carrying out surface crosslinking, and drying at room temperature to prepare a hollow fibrous pervaporation membrane; 4, placing a perfluorinated sulfonic acid (PFSA) resin in an aqueous solution of a lower boiling alcohol solvent, and heating for dissolving; 5, adding the PVA and an inorganic nanomaterial to the aqueous solution of the alcohol solvent containing the PFSA, or adding the PVA, the inorganic nanomaterial, GA and an acid catalyst to prepare a catalyst coating liquid; and 6, dip-coatingthe catalyst coating liquid on the hollow fibrous prevaporization membrane, and drying at room temperature to prepare the hollow fibrous membrane with the dual functions. The preparation method of the present invention has the advantages of simple preparation technology, no complex equipment requirement, and convenient and fast operation.

Owner:EAST CHINA UNIV OF SCI & TECH

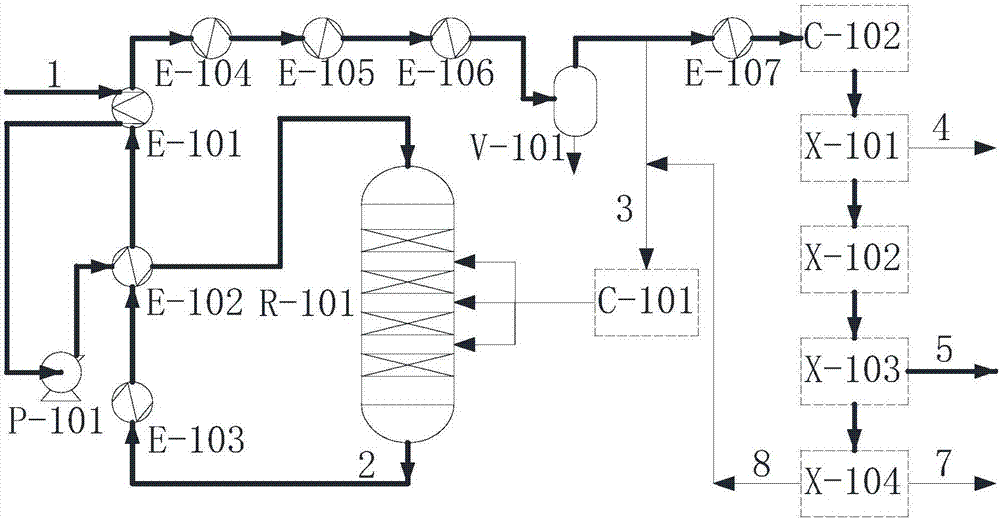

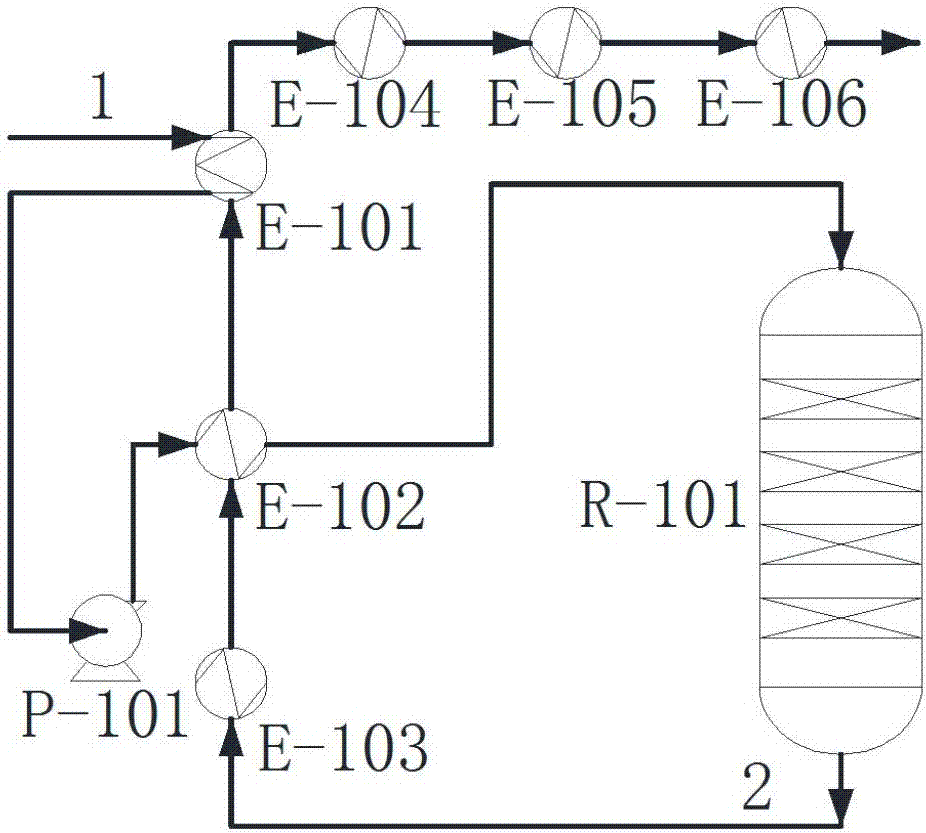

Technical method for associated producing carbonic allyl ester, methyl carbonate, and propylene glycol

InactiveCN101092365AReduce cakingEliminate the safety hazard of overpressureProductsReagentsMethyl carbonatePropanediol

This invention discloses a process for combined production of propylene carbonate, dimethyl carbonate and propylene glycol. The method utilizes propylene oxide, CO2 and methanol as the raw materials, and adopts two-step reaction to produce propylene carbonate, dimethyl carbonate and propylene glycol. The method avoids propylene carbonate refinery process; catalyst recovery process and propylene carbonate storage apparatus. The method utilizes a novel thin film evaporator to separate and refine crude propylene carbonate and catalyst, and thus increase the separation precision and productivity. The method utilizes a set of platform framework and a DCS control chamber to realze continuous operation of the whole process, and is stable and reliable. The produced propylene carbonate, dimethyl carbonate and propylene glycol can reach pharmaceutical grade purity.

Owner:SHANDONG SHIDA SHENGHUA CHEM GROUP

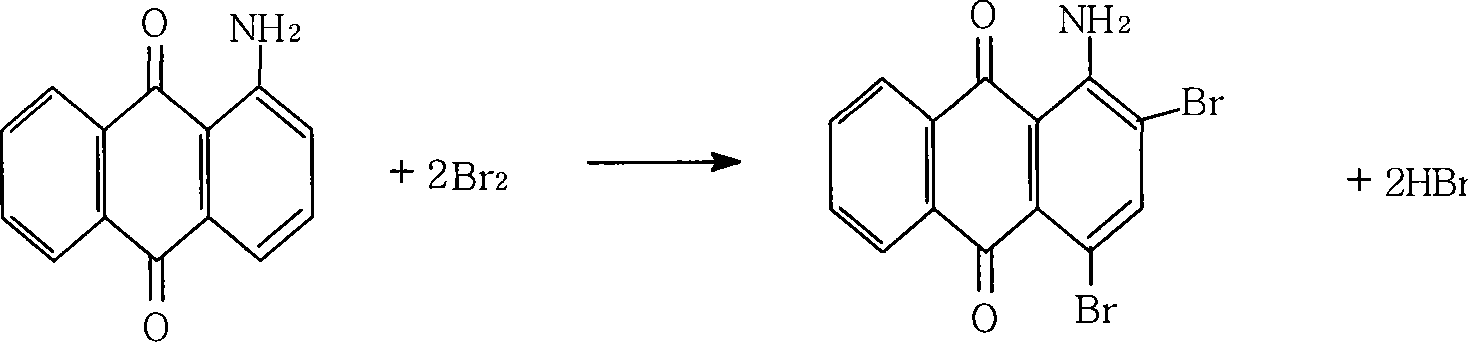

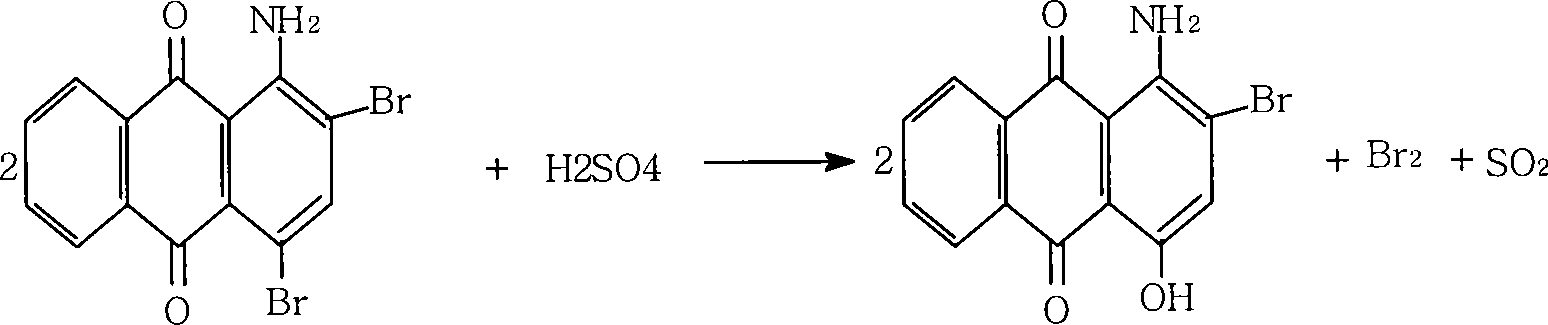

Method for preparing disperse red 60

ActiveCN101182390AReduce unit consumptionEnergy savingAmino-hydroxy-anthraquinone dyesQuinonePhenols

A method for preparing disperse red 60, which belongs to the technical field of manufacturing chemical dyes and chemicals, and uses 1-aminoanthraquinone as a raw material to obtain 1-amino-2-bromo-4-hydroxyanthracene through bromination and hydrolysis in a sulfuric acid medium Quinone, characterized in that 1-amino-2-bromo-4-hydroxyanthraquinone undergoes condensation reaction in the presence of treated mother liquor water, phenol, and acid-binding agent to obtain Disperse Red 60; said treated mother liquor water is 1-amino- After the condensation reaction of 2-bromo-4-hydroxyanthraquinone, the condensation mother liquid water obtained by filtering is adjusted to acidity by adding acid, and acidified by adding sulfate or hydrochloride, and standing for more than half an hour, the upper layer is containing phenol and The solution of disperse red 60 dissolved in phenol, after adding alkali to adjust the pH to 6-9, is the treated mother liquor water, and the addition amount is 20% by weight of 1-amino-2-bromo-4-hydroxyanthraquinone ~200%. The invention can effectively reduce the unit consumption of phenol, increase product yield, reduce production cost and reduce environmental pollution.

Owner:浙江长征化工有限公司

Method for recycling mixed alkali liquor in indigo production

InactiveCN103554995ASave waterReduce recycling processOrganic dyesCarbonate preparationMother liquorSludge

The invention relates to a method for recycling mixed alkali liquor in indigo production, and the method comprises the following steps: feeding indigo into a filter press so as to be filter-pressed after an oxidation process, concentrating a filter-pressing filtrate to obtain caustic sludge, and feeding a filter-pressing concentrated liquor into a reaction still; washing the indigo filter-pressed in the step (1), adding the caustic sludge of the step (1) into washing water, warming and stirring until the caustic sludge is completely dissolved, naturally cooling to room temperature, filtering, concentrating the filtrate as a concentrated alkali liquor, and then feeding the concentrated alkali liquor into the reaction still; washing filter residue by using saturated Na2CO3, filtering to obtain a Na2CO3 solid, concentrating the filtrate as the concentrated alkali liquor, and then feeding the concentrated alkali liquor into the reaction still, introducing CO2 into the reaction still, stopping introducing CO2 when the reaction temperature is at 60-70 DEG C, cooling to room temperature, stirring for 1-2 hours, crystallizing, filtering to obtain mother liquor and crude product Na2CO3, concentrating the filtrate as the concentrated alkali liquor, and then feeding the concentrated alkali liquor into the reaction still in the step (3). By adopting the method of circularly recycling, the filter-pressed filtrate, the washing water and the KOH in the caustic sludge are effectively recycled.

Owner:JIANGSU TAIFENG CHEM

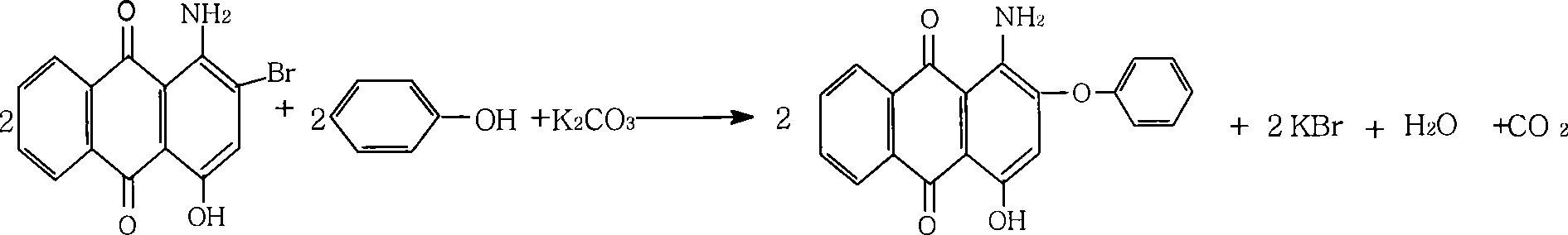

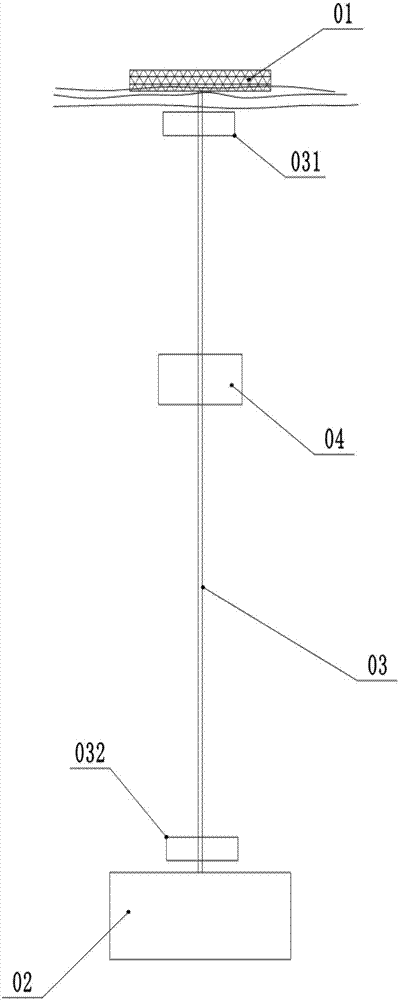

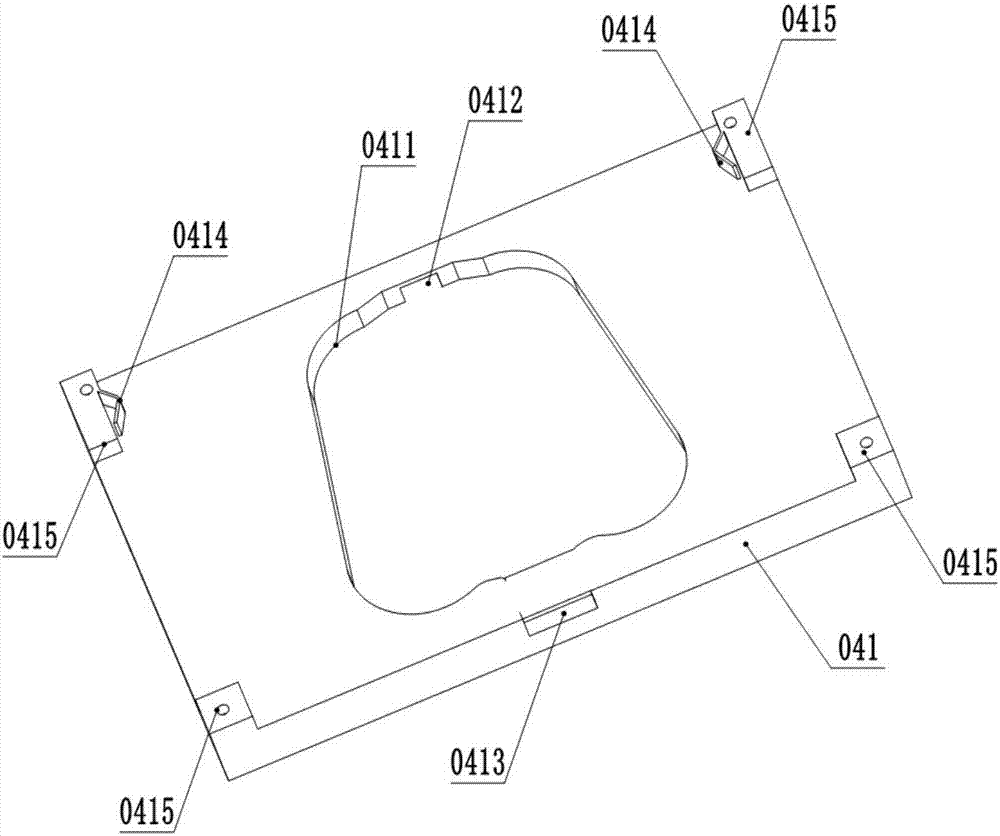

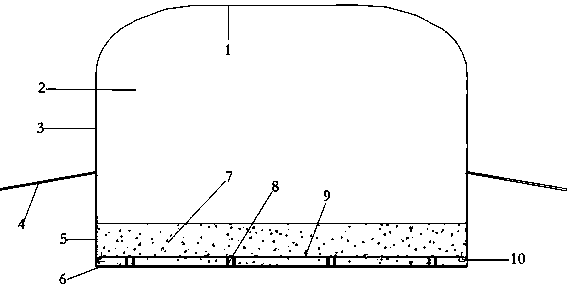

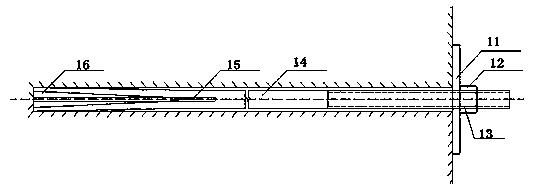

Underwater carrying device and marine detection device

ActiveCN107490367AReduce deliveryReduce recycling processWaterborne vesselsOpen water surveyMarine engineeringUnderwater

The invention provides an underwater carrying device and a marine detection device and relates to the technical field of ocean detection equipment. The underwater carrying device comprises a floating body, a counterweight body, a rope and a carrying unit, wherein one end of the rope is fixed on the floating body and the other end of the rope is fixed on the counterweight body; the carrying unit is connected onto the rope; the carrying unit comprises a bracket body, an upward floating body and at least two first sliding bodies. The carrying unit can move up and down along the rope under the driving of waves. By adopting the underwater carrying device provided by the invention, the technical problems of a working method for observing layers with different depths of the ocean by adopting detection equipment in the prior that that launching and recycling procedures of observation equipment are complicated, risks are high and the labor cost and the equipment cost are high are relieved.

Owner:舟山水全科技有限公司 +1

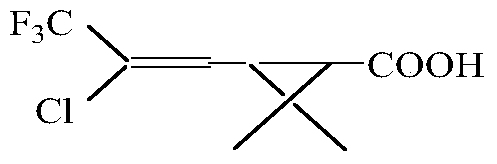

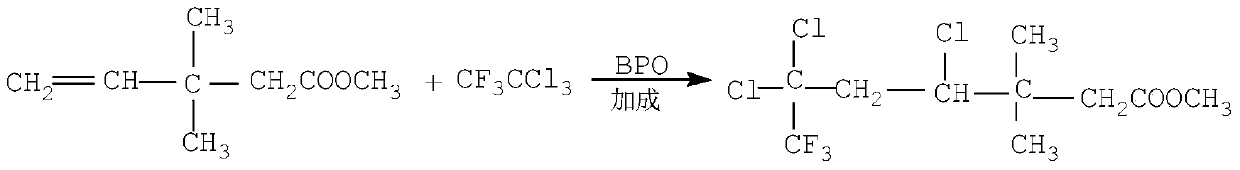

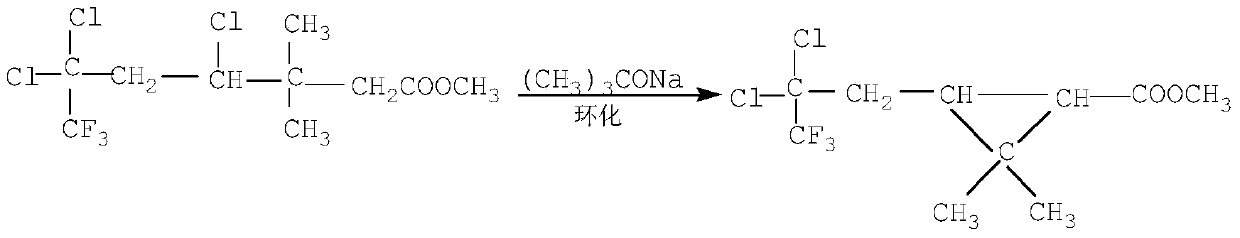

Continuous production method for trifluoro monochloro chrysanthemic acid

InactiveCN105503582ABest production methodQuality improvementOxygen-containing compound preparationOrganic compound preparation4-pentenoic acidChrysanthemic acid

The invention discloses a continuous production method for trifluoro monochloro chrysanthemic acid. The method includes the steps of (1) performing an addition reaction to prepare 3,3-dimethyl-4,6,6-trichloro-7,7,7-trifluoro heptylic acid ester with 3,3-dimethyl-4-pentenoic acid methyl ester and trifluorotrichloroethane as initial raw materials; (2) performing a cyclization reaction with sodium tert-butoxide to generate cis(trans)-3-(2,2-dichloro-3,3,3-trifluoropropyl)-2,2-dimethyl cyclocarboxylate; and (3) performing a saponification reaction to prepare 3-(2-chloro-3,3,3-trifluoro-propylene-1-yl)-2,2-dimethylcyclopropane carboxylic acid, namely, the trifluoro monochloro chrysanthemic acid. In the invention, continuous control is employed in the production method, so that the method is simple in process, is high in equipment utilization, is high in yield and stable in quality of products, is low in production cost and has a wide application prospect.

Owner:LIANYUNGANG CCA CHEM CO LTD

Method for synthesizing rubber vulcanization accelerator NS (N-tertiary butyl-2-benzothiazole sulfenamide) through two-step method by taking hydrogen peroxide as oxidant

InactiveCN102838562ASimple processReduce recycling processOrganic chemistrySulfuric acidHydrogen peroxide

The invention discloses a method for synthesizing rubber vulcanization accelerator NS (N-tertiary butyl-2-benzothiazole sulfenamide) through a two-step method by taking hydrogen peroxide as an oxidant. The method comprises the following steps of: (1) weighing 80 g of 98 percent sulfuric acid, preparing 20 percent of sulfuric acid, adding in a reaction kettle with 60 g of tert-butylamine, fully reacting the sulfuric acid with the tert-butylamine under the conditions of 40 DEG C and rotation speed of 600 rpm and dropwise adding 105 ml of M-Na salt with density of 1.5 g / ml to produce M-tert-butylamine salt; and (2) adding 360 ml of oxidant hydrogen peroxide with mass content of 12.0-18.0 percent according to a flow speed of 3 ml / min, wherein the dropwise adding time is 2.0 hours, and performing suction filtration, washing, filtration and drying after reaction to obtain the rubber vulcanization accelerator NS product. The method has the advantages of simple process, use of the environment-friendly hydrogen peroxide as the oxidant, easiness in industrialization, proper amount of the used tert-butylamine, capability of saving acidification, spin-drying and drying steps of an M workshop, high yield of synthesized NS and high quality.

Owner:KEMAI CHEM

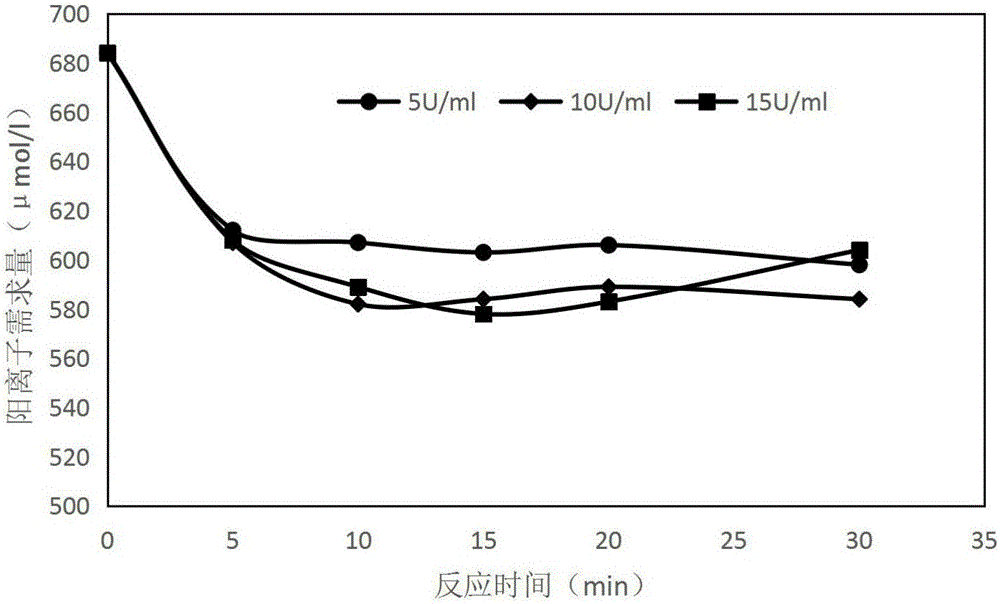

Preparation method of immobilized enzyme used for processing papermaking white water

InactiveCN106277349AReduce demandCause interferenceWater contaminantsWaste water treatment from plant processingFiberFiltration

The invention relates to a preparation method of an immobilized enzyme used for processing papermaking white water. The method comprises the following steps: (1) dissolving cationic polyacrylamide (CPAM) in water to prepare a solution; (2) adding pulp fibers in the prepared CPAM solution for adsorption to make the concentration of pulp to be 0.1-0.8%, performing stirring for 30-60 min, and performing filtration and washing; and (3) adding the prepared fiber carrier in a pectase solution with the concentration of 0.1-0.25% for adsorption, and performing filtration and washing. The prepared immobilized enzyme is high in enzymatic activity, the quantity demand of cations in white water can be reduced, and the cost for processing white water for an industry is reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

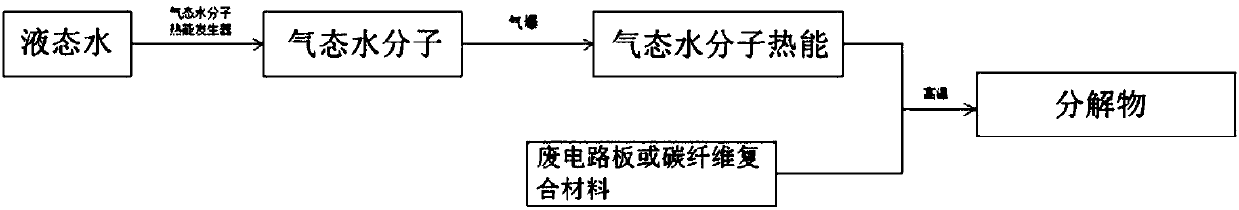

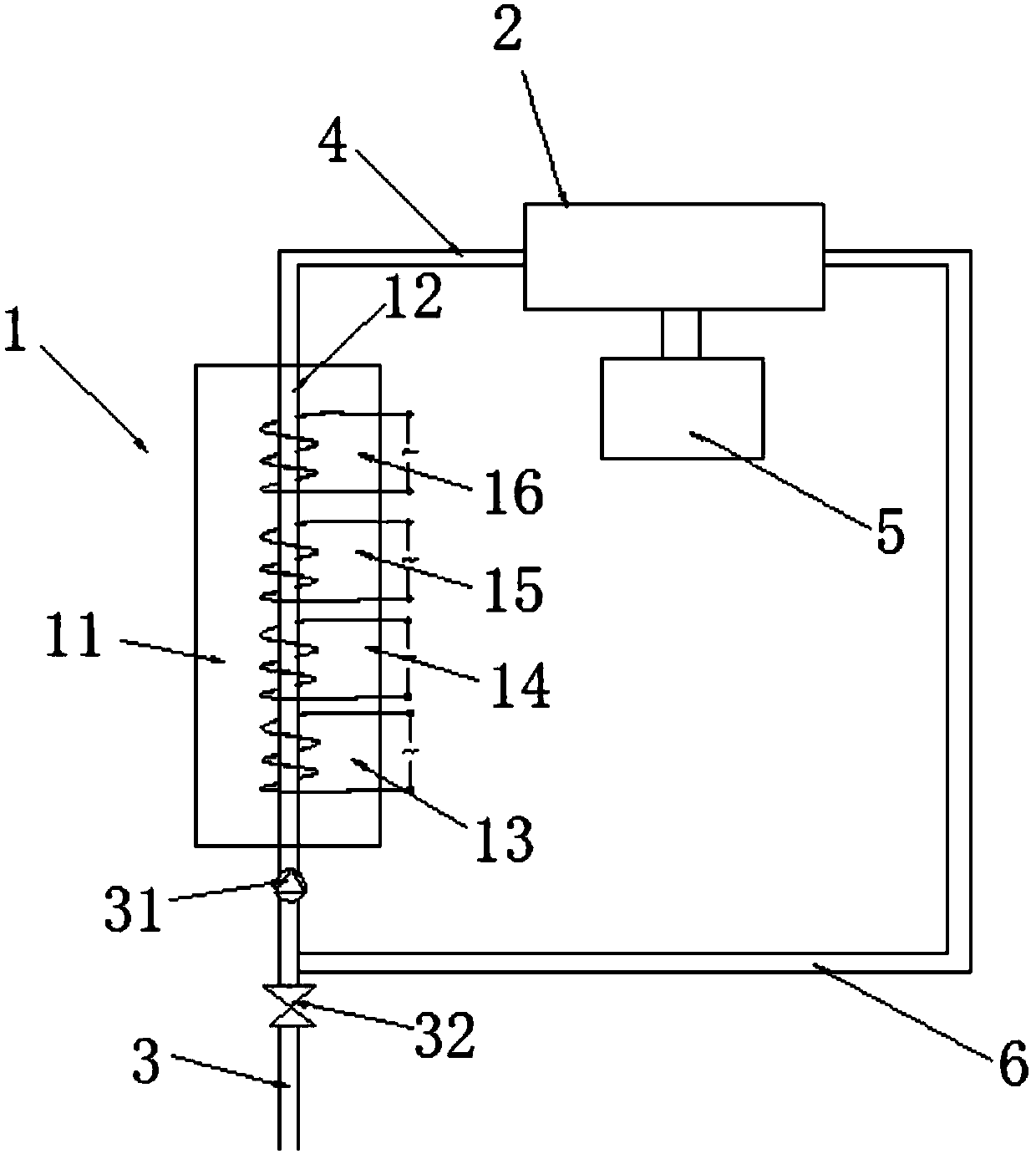

Method and device for treating waste circuit boards or carbon fiber composite materials

PendingCN107695080AHigh purityCause secondary pollutionTransportation and packagingSolid waste disposalFiberLiquid water

The invention provides a method for treating waste circuit boards or carbon fiber composite materials. According to the method, the recycled waste circuit boards or carbon fiber composite materials are placed into a closed space; liquid water is heated to gas-state water molecules, high-temperature gas-state water molecule heat energy is formed, the gas-state water molecules are utilized as heat transmission media, and the heat transmission efficiency is high; meanwhile, the gas-state water molecules are continuously introduced into the closed space in which the waste circuit boards or carbonfiber composite materials are loaded through a gas output pipeline, firstly, the gas-state water molecules discharge air in the closed space so that the closed space with an oxygen-free environment can be formed, then organic matter in the waste circuit boards or carbon fiber composite materials is heated and decomposed under the high-temperature effect of the gas-state water molecules, and carbonblack, carbon fiber, water, carbon dioxide, carbon monoxide and other impurity tail gas are generated; and the carbon black, the carbon fiber or metal material copper plates in the circuit boards arecollected, and the tail gas is introduced into a gas purifier to be vented after being cooled through a heat exchanger along with the gas-state water molecules.

Owner:GUANGZHOU BAOSHI WIRELESS POWER SUPPLYING TECH CO LTD

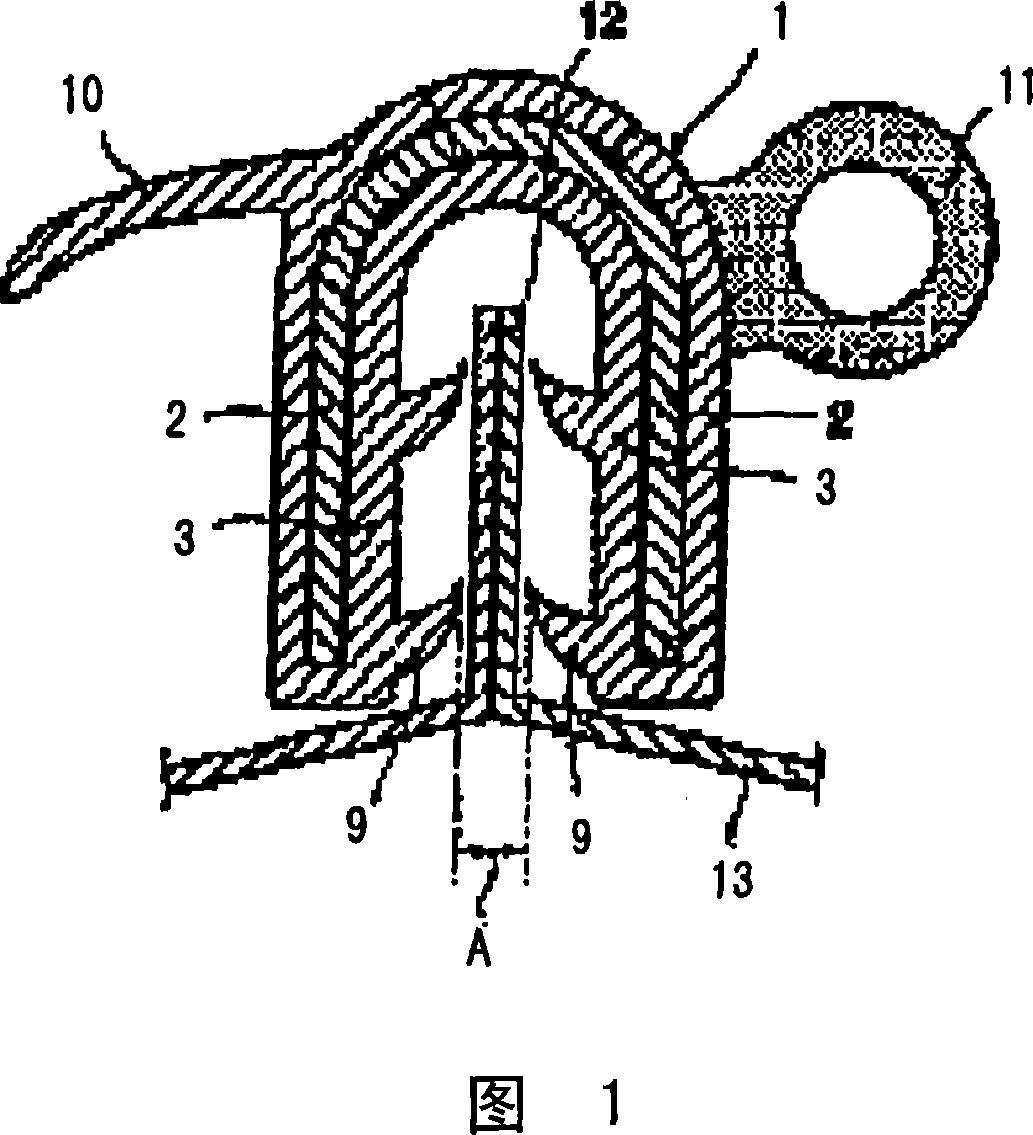

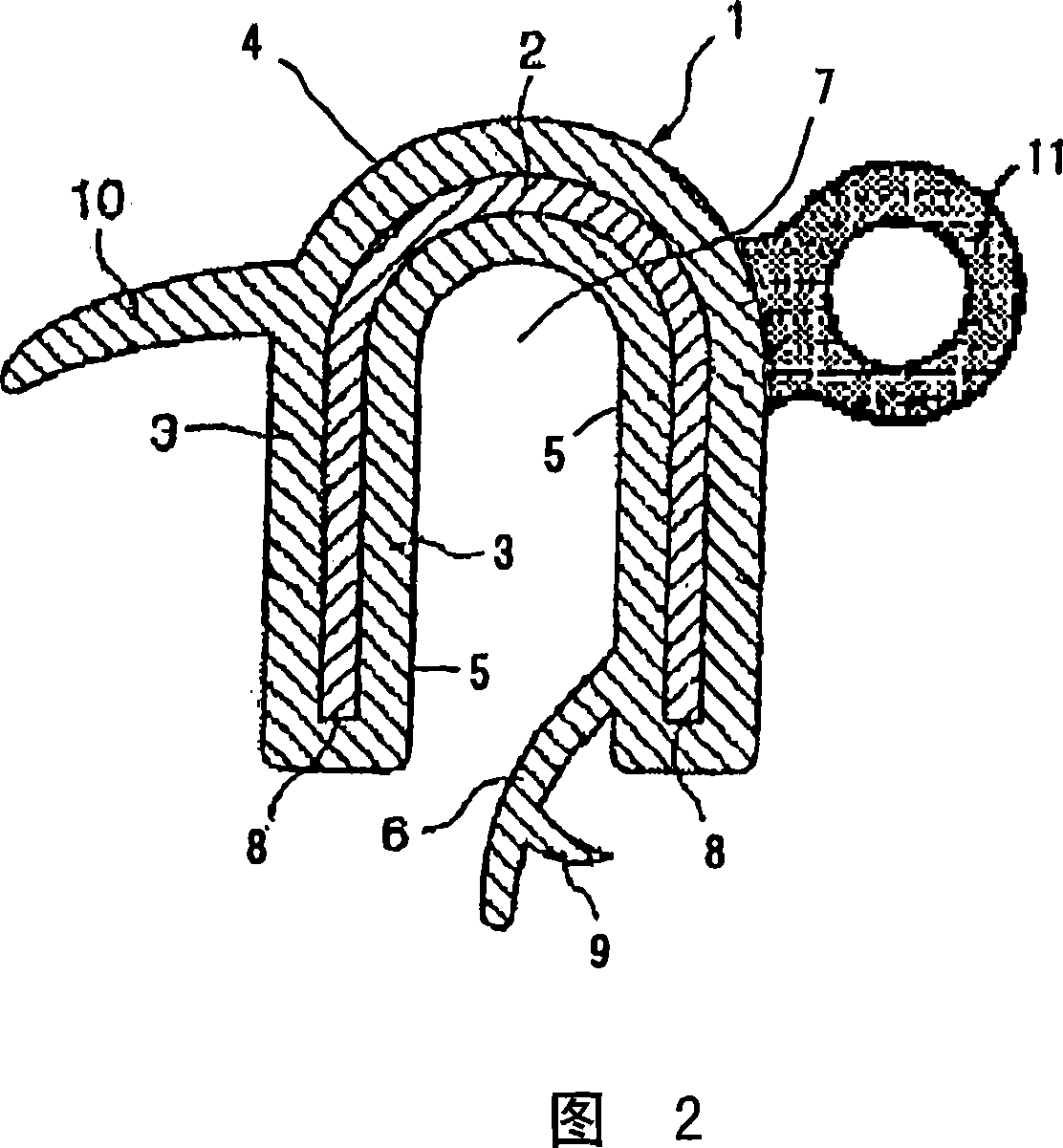

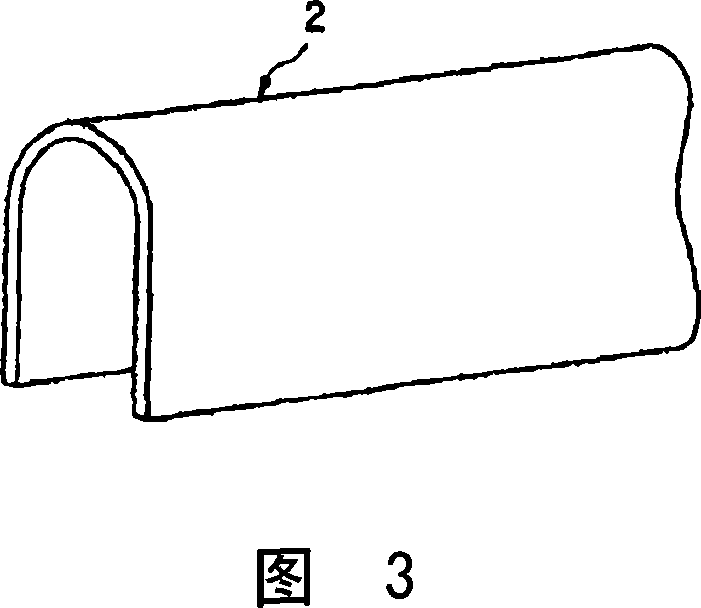

Extrusion molded article for automobiles

ActiveCN101049726AEasy to squeeze outFully flexibleEngine sealsVehicle sealing arrangementsThermoplastic elastomerEngineering

An extrusion molded article for automobiles, having a body portion (1) and a hollow sealing portion (11), where the body portion (1) comprises a core (2) made of a resin having a U-shaped cross-section extending in a longitudinal direction and a covering layer (3) surrounding and covering the core partly or entirely, and the hollow sealing portion (11) is bonded integrally with an outer surface (4) of the body portion, characterized in that the covering layer (3) is made of a thermoplastic elastomer composition having a tensile elongation at break of at least 350% , as determined according to JIS K6251, and a change in 100% modulus of at most 40%, wherein the change in 100% modulus = [(100% modulus at 23 DEG C - 100 % modulus at 80 DEG C) / 100 % modulus at 23 DEG C ] x 100, and the 100 % modulus is a stress at 100% elongation, as determined according to JIS K6251, and the hollow sealing portion (11) is made of a thermoplastic elastomer composition having a tensile elongation at break of at least 250%, as determined according to JIS K6251, and a compression set of 35% or less, as determined at 25% compression, 70 DEG C, 200 hours.

Owner:RIKEN TECHNOS CORP

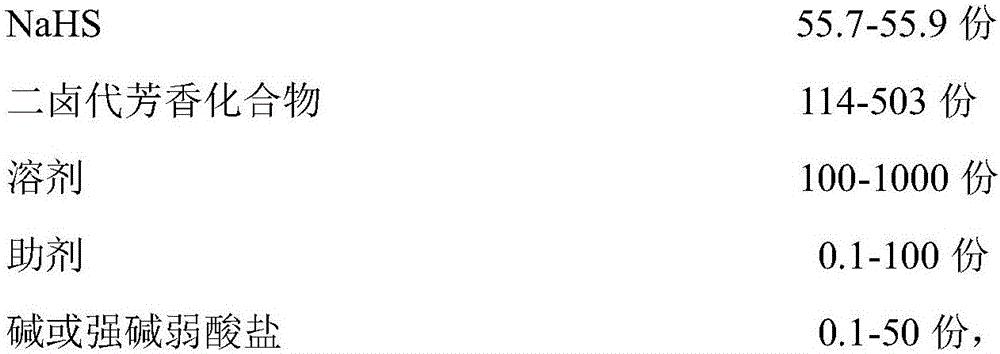

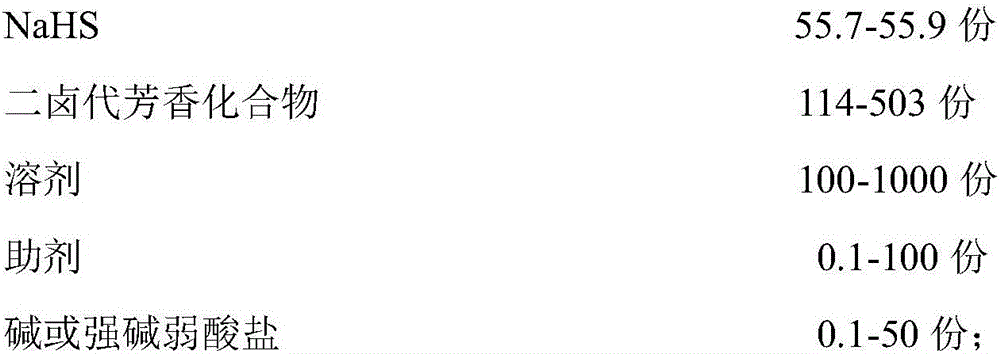

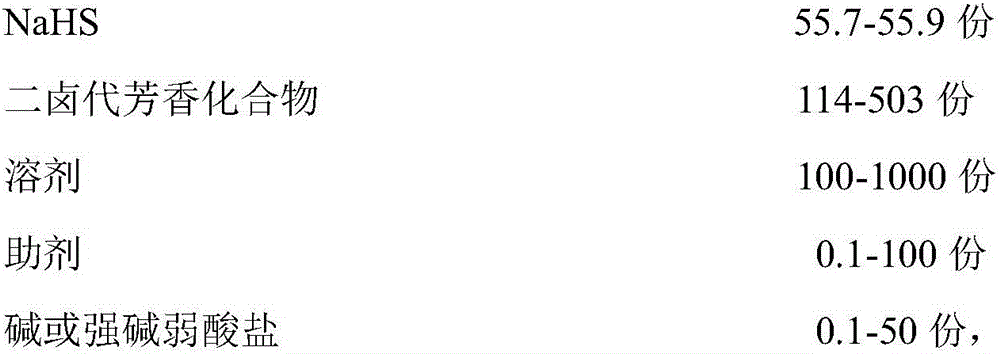

High-brightness polyarylene sulfide with narrow particle size distribution and preparation method of polyarylene sulfide

The invention relates to high-brightness and low-cost polyarylene sulfide with narrow particle size distribution and a preparation method of polyarylene sulfide and belongs to the field of polymer synthesis. The high-brightness polyarylene sulfide with narrow particle size distribution is prepared from components of raw materials in parts by weight as follows: 55.75-55.9 parts of NaHS, 114-503 parts of dihalogenated aromatic compounds, 100-1,000 parts of a solvent, 0.1-100 parts of an aid and 0.1-50 parts of alkali or strong alkali and weak acid salt, wherein the aid is at least two of lithium salt, zinc salt, sodium salt, magnesium salt and calcium salt. The high-brightness polyarylene sulfide having narrow particle size distribution and suitable for industrial production is provided and is characterized in that high-brightness polyarylene sulfide is prepared from the raw materials including sodium hydrosulfide and dihalogenated aromatic compounds under coordination of the specific aid through a solution condensation polymerization reaction and has narrow particle size distribution and high brightness.

Owner:SICHUAN UNIV

Method for extracting vanadium from vanadium slag

ActiveCN109402380AReduce recycling processAdd lessProcess efficiency improvementSlagSodium carbonate

The invention relates to a method for extracting vanadium from vanadium slag. The method includes mixing vanadium slag, sodium carbonate and sodium vanadate, then roasting the obtained mixture to obtain a roasted clinker, leaching the roasted clinker and conducting solid-liquid separation to obtain a vanadium-containing leaching solution. The mixture of the sodium vanadate and the sodium carbonateis utilized to roasting the vanadium slag to extract the vanadium, the conversion rate of the vanadium by sodium salt roasting of the vanadium slag is improved, and the vanadium conversion rate can reach 92% or above, 5-10% higher than the prior art. In addition, the sodium vanadate in an intermediate product produced by the vanadium slag sub-molten salt method is added to achieve full utilization of the intermediate product sodium vanadate produced by the vanadium slag sub-molten salt method, and the sodium vanadate recovery procedure is reduced. At the same time, the addition amount of thesodium carbonate in the sodium salt roasting is reduced, the raw material cost is reduced, and good economic benefits and application prospects are achieved.

Owner:HEBEI IRON AND STEEL

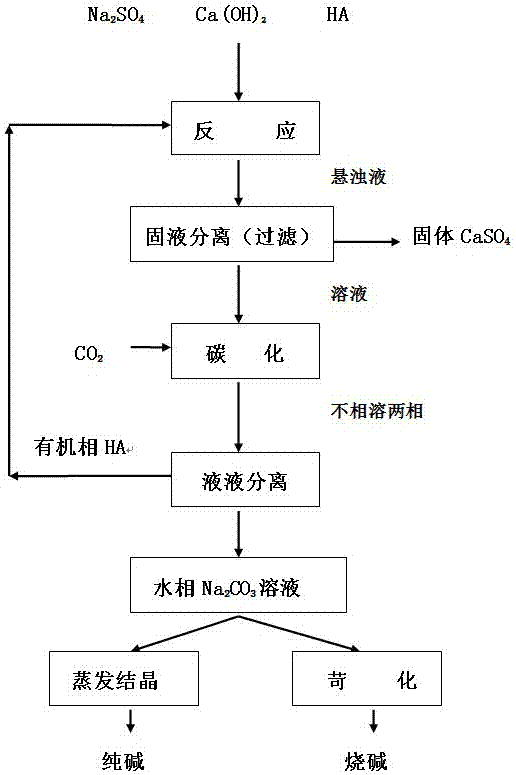

Method for preparing sodium carbonate and sodium hydroxide by mirabilite liquid circulation

InactiveCN107986299ASimple recycling processReduce recycling processAlkali metal hydroxidesAlkali metal carbonatesCarbonizationPotassium hydroxide

The invention discloses a method for preparing sodium carbonate and sodium hydroxide by mirabilite liquid circulation. The method comprises the following steps: (1) the raw materials including 0.9-1.1parts by weight of mirabilite, 0.5-0.8 parts by weight of quicklime, 2.0-3.0 parts by weight of cresol and 4.0-4.5 parts by weight of water are mixed, uniformly stirred and subjected to a reaction under ordinary pressure for 0.5-1 h at 20-70 DEG C; (2) reaction slurry is filtered, a filtrate is a cresol-containing sodium salt solution, and a precipitate is calcium sulfate; (3) CO2 is introduced into the cresol-containing sodium salt solution, carbonization is stopped when pressure of CO2 is 0.05-0.25 MPa, carbonization temperature is 20-30 DEG C and pH of the solution is 10, the solution is layered, the upper layer is cresol, and the lower layer is a sodium carbonate solution with concentration being 10%-12%; (4) the sodium carbonate solution is evaporated and concentrated to be crystalized, sodium carbonate is prepared, or the sodium carbonate solution is causticized with calcium hydroxide for preparation of sodium hydroxide. Local mirabilite resources and different intermediate species are used, the production process and the intermediate species recovery process are simplified, the recovery flow and equipment are reduced, the reaction conditions are mild and easy to control, and energy consumption is low.

Owner:新疆昌吉职业技术学院

Graphite material for heat exchanger and preparation method of graphite material

Provided is a graphite material for a heat exchanger. The graphite material is mainly prepared by mixing pitch meso-carbon microbeads, a petroleum coke stage material and modified pitch, wherein the petroleum coke stage material is needle petroleum coke subjected to secondary coking or third-time coking. A preparation method comprises the steps that the petroleum coke and modified pitch slurry are subjected to mixing kneading and rolling and flaking under vacuum condition, cooling and smashing are conducted in sequence, the smashed materials are subjected to mixing, standing, isostatic press molding, calcining and smashing, and the petroleum coke stage material is obtained; the petroleum coke stage material and the pitch meso-carbon microbeads are subjected to mixing kneading, the modified pitch is added and rolled to be flakes, cooling and smashing are conducted in sequence, the smashed materials are subject to mixing, standing, isostatic press molding, calcining carbonization treatment and graphitization treatment, and the graphite material for the heat exchanger is obtained. According to the graphite material for the heat exchanger, the needle petroleum coke subjected to secondary coking or third-time coking is used for the first time, toughness and self-lubrication of graphite are enhanced, the processing efficiency of graphite machinery is improved, and thermal conductivity of graphite pieces can be increased.

Owner:HUNAN CHANGYU NEW CARBON MATERIALS

Method for synthesizing rubber vulcanization accelerator CZ

The invention discloses a method for synthesizing a rubber vulcanization accelerator CZ. In the method, hydrogen peroxide and sulfuric acid are mixed to serve as an oxidant, and an M-Na salt and cyclohexylamine serve as raw materials. The method is characterized by comprising the following steps of preparing the oxidant according to the molar ratio of sulfuric acid to hydrogen peroxide to water being 1: 2.05-2.3:7; adding cyclohexylamine into a reaction kettle, dripping the M-Na salt at a flow velocity of 1.5-2.5 millimole / min at the temperature of 30-60 DEG C under the condition that the rotating speed is 600-1200 revolutions per minute, and simultaneously dripping 0.15 mol of oxidant, wherein the molar ratio of cyclohexylamine to the M-Na salt is 1:1, the dripping speed and amount of the oxidant are based on the molar ratio of sulfuric acid in the oxidant to the M-Na salt of 1:2, and the dripping time is 2-3 hours; after the reaction is finished, performing suction filtration, washing, filtering and drying to obtain the rubber vulcanization accelerator CZ. The purity of the accelerator CZ is 98.5 percent, the yield is 97 percent, and the method is simple in process and easy for industrial production.

Owner:KEMAI CHEM

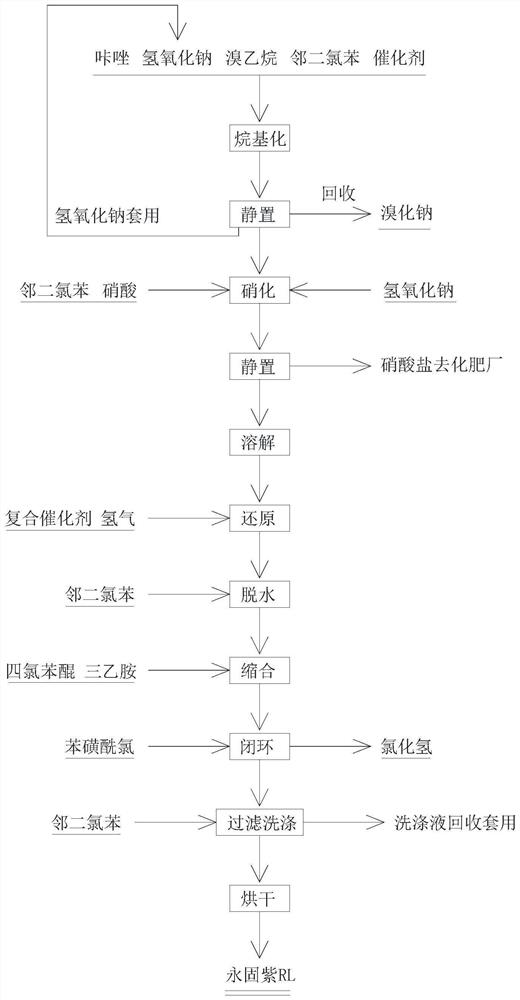

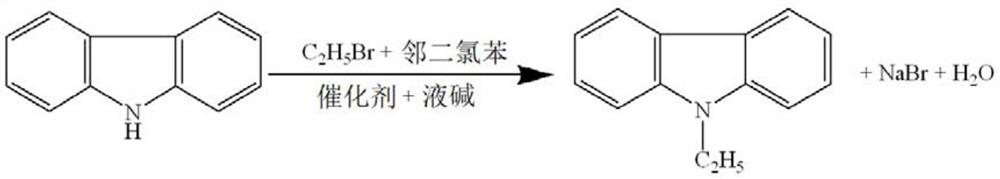

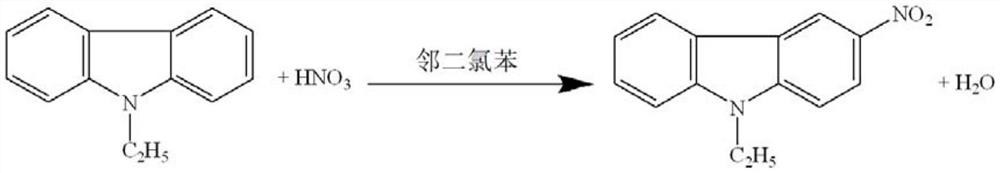

One-pot process for synthesizing permanent violet RL

ActiveCN112724700AToxicRaise the reaction temperatureBisoxazinesChemical recyclingReaction temperatureNitration

The invention discloses a process for synthesizing permanent violet RL by a one-pot method. The process comprises the following steps: S1, alkylation; S2, nitrification; S3, reduction; and S4, condensation ring-closing. Compared with the prior art, the production process disclosed by the invention is mainly improved in alkylation, nitrification and reduction procedures, so that the operation time is greatly shortened, raw materials are saved, wastes are reduced, the labor intensity is low, a large amount of manpower and equipment energy are saved, and the intermediate procedure is simplified. According to the invention, o-dichlorobenzene is used as a solvent, so that a condenser can use common circulating water due to the boiling point of o-dichlorobenzene so as to save energy, the reaction temperature can be increased so as to shorten the reaction time, and after the reaction is finished, direct standing for layering is performed without distilling the solvent, and the next step is performed.

Owner:内蒙古彩晶新材料科技有限公司

Artificial false bottom and manufacturing method

PendingCN110541729AHigh strengthReduce mix rateMaterial fill-upAnchoring boltsEconomic benefitsEngineering

The invention discloses an artificial false bottom. The artificial false bottom is built in a roadway and comprises an artificial false bottom body and a fixing part, wherein one end of the fixing part is inserted into a side plate of the roadway, and the other end of the fixing part is connected with the artificial false bottom body through a connecting piece; the artificial false bottom body ispositioned on a bottom plate of the roadway, and a reinforcing mesh is arranged in the artificial false bottom body. The artificial false bottom can replace a top-bottom ore column in the mining process, so that the top-bottom ore column does not need to be reserved in the mining process, the top-bottom ore column does not need to be recovered in the later period, and as a result, the recovery process is saved; the artificial false bottom is made of high-grade concrete, so that the strength of the artificial false bottom is high, the mixing rate of waste rocks in the process of recovering thetop-bottom ore column is low, the mineral separation recovery rate is high, and the economic benefit is good; in addition, reinforcing steel bars and anchor rods are connected with the side plate of the roadway, so that the safety is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

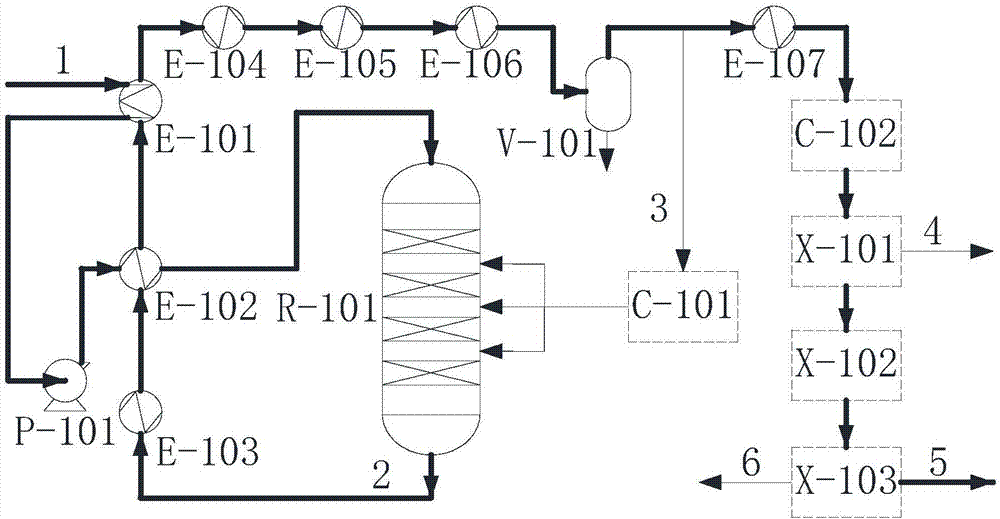

Method for recovering tail gas of propane oxidation preparation of acrylic acid

ActiveCN107162895AAchieving zero emissionsAchieve coolingNitrogen purification/separationOrganic compound preparationGas phaseCatalytic oxidation

The invention provides a method for recovering tail gas of propane oxidation preparation of acrylic acid and belongs to the technical field of acrylic acid tail gas treatment. The method comprises preheating and pressurizing tail gas, feeding the tail gas into an oxidation reactor, carrying out oxidation, orderly treating the reaction tail gas through a steam generator, a tail gas preheater II, a tail gas preheater I, a boiler water preheater and a desalted water preheater, recovering heat, treating the tail gas through a cooler and a gas-liquid separator, returning a part of the gas phase as recycling gas to the oxidation reactor, wherein the recycling gas is used as quenching gas, cooling and pressurizing the other part of the gas phase through a water cooler, carrying out decarburization and drying, feeding the dried gas into a cryogenic separation device, carrying out cryogenic separation to obtain a product containing greater than or equal to 99.9% of propane and fully discharging cryogenic tail gas. Through a catalytic oxidation method, oxygen and volatile organic matters in the tail gas are removed, propane, carbon dioxide and nitrogen gas are recovered and zero emission of the exhaust gas is realized. The method has the advantages of low investment in the process, low wastes, low pollutant discharge and good economic benefits, and provides guarantee for the large-scale industrialization of propane oxidation preparation of acrylic acid.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

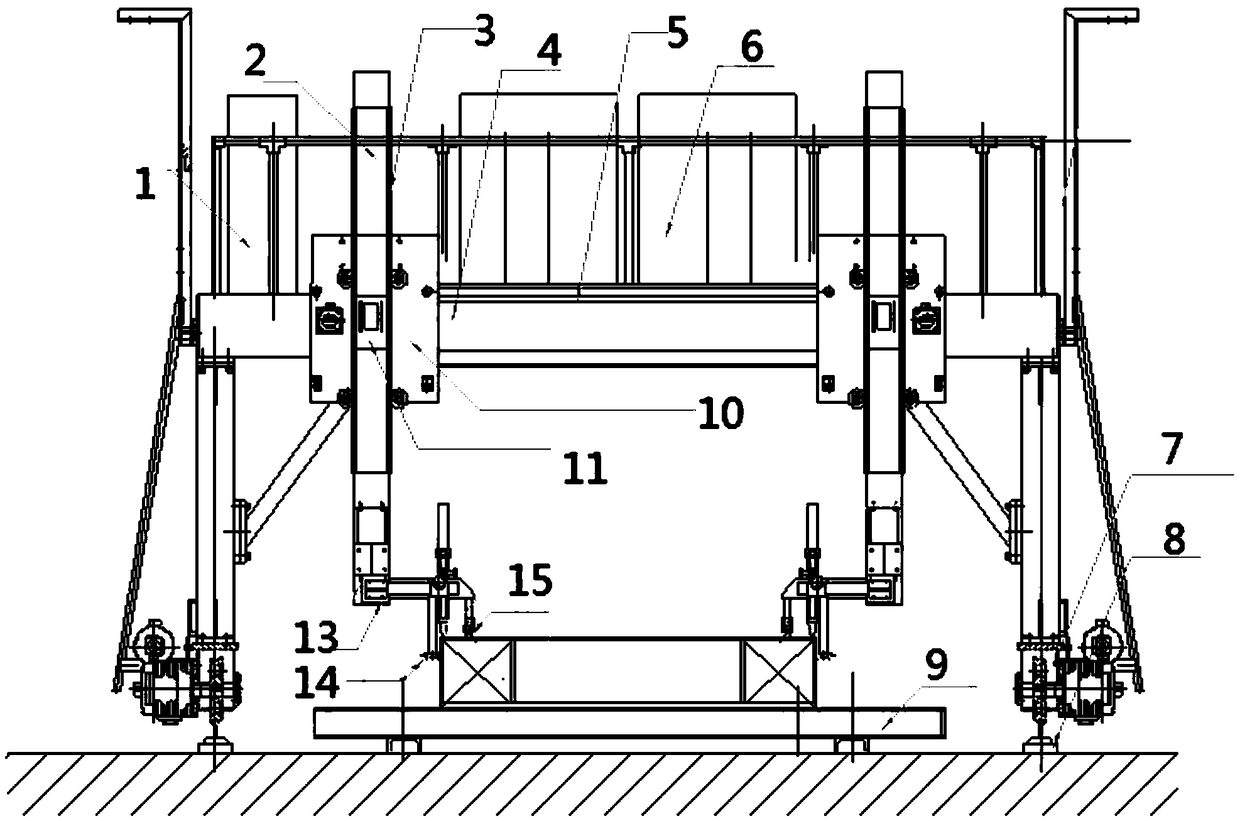

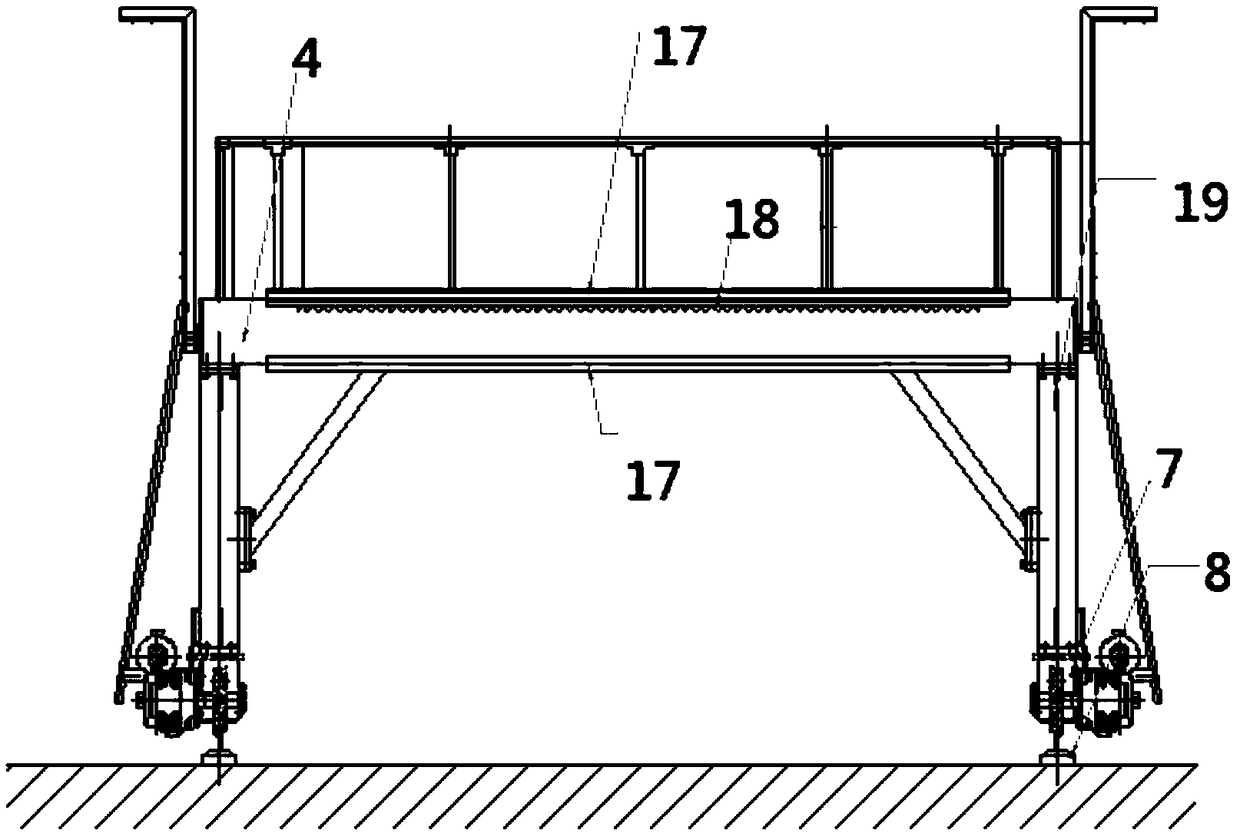

Gantry welding machine

PendingCN109434245AImprove welding efficiencyImprove welding qualityElectrode supporting devicesWelding accessoriesEngineeringSlide plate

Disclosed is a gantry welding machine. The gantry welding machine comprises a gantry, transverse sliding plate mechanisms, lifting column mechanisms, an electric controller and a welding device. The two transverse sliding plate mechanisms are arranged on the gantry and are provided with the lifting column mechanisms correspondingly. The lower ends of the two lifting column mechanisms are providedwith welding mechanisms correspondingly. The two welding mechanisms are oppositely arranged. The transverse sliding plate mechanisms and the lifting column mechanisms are connected to and controlled to move by the electric controller.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

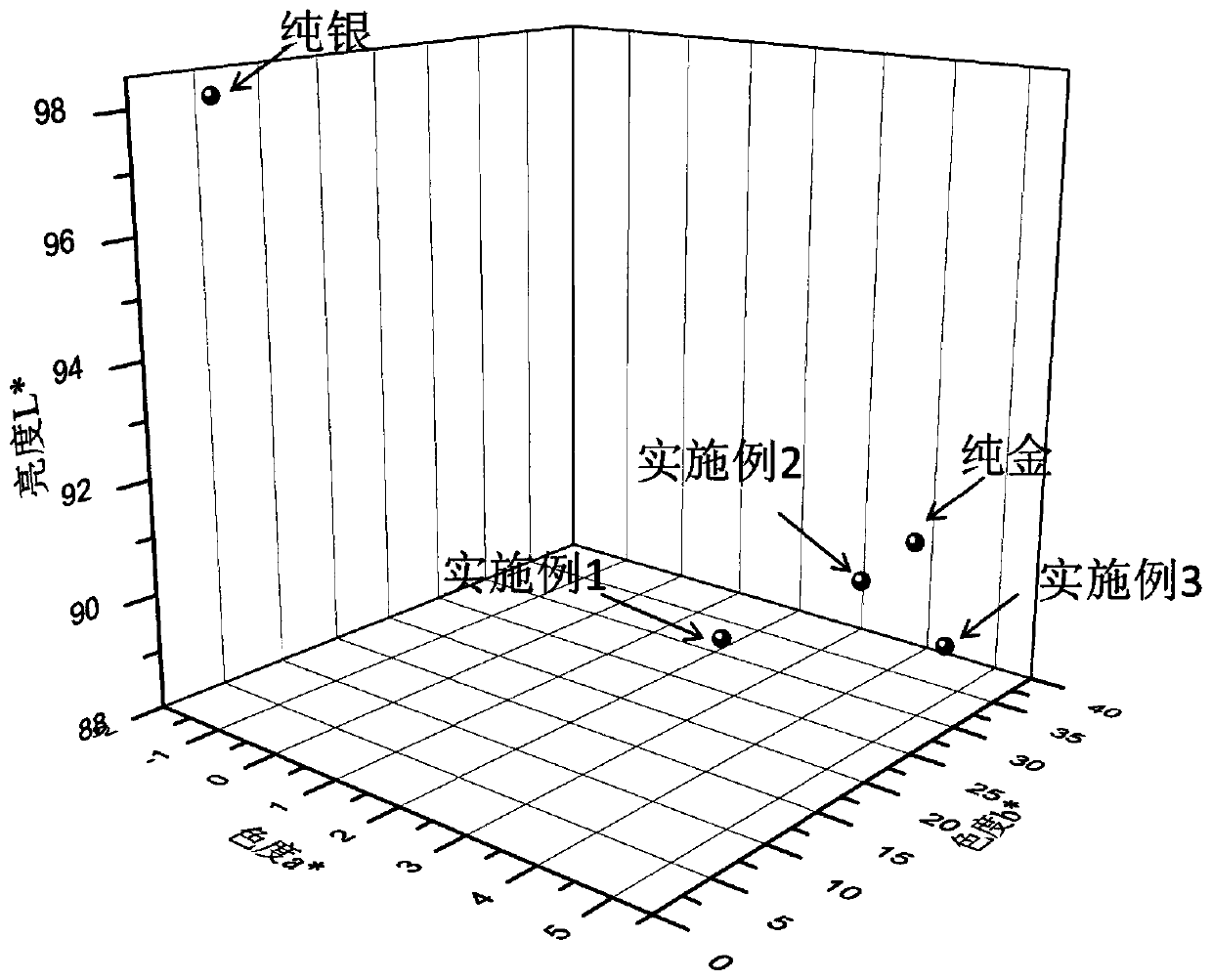

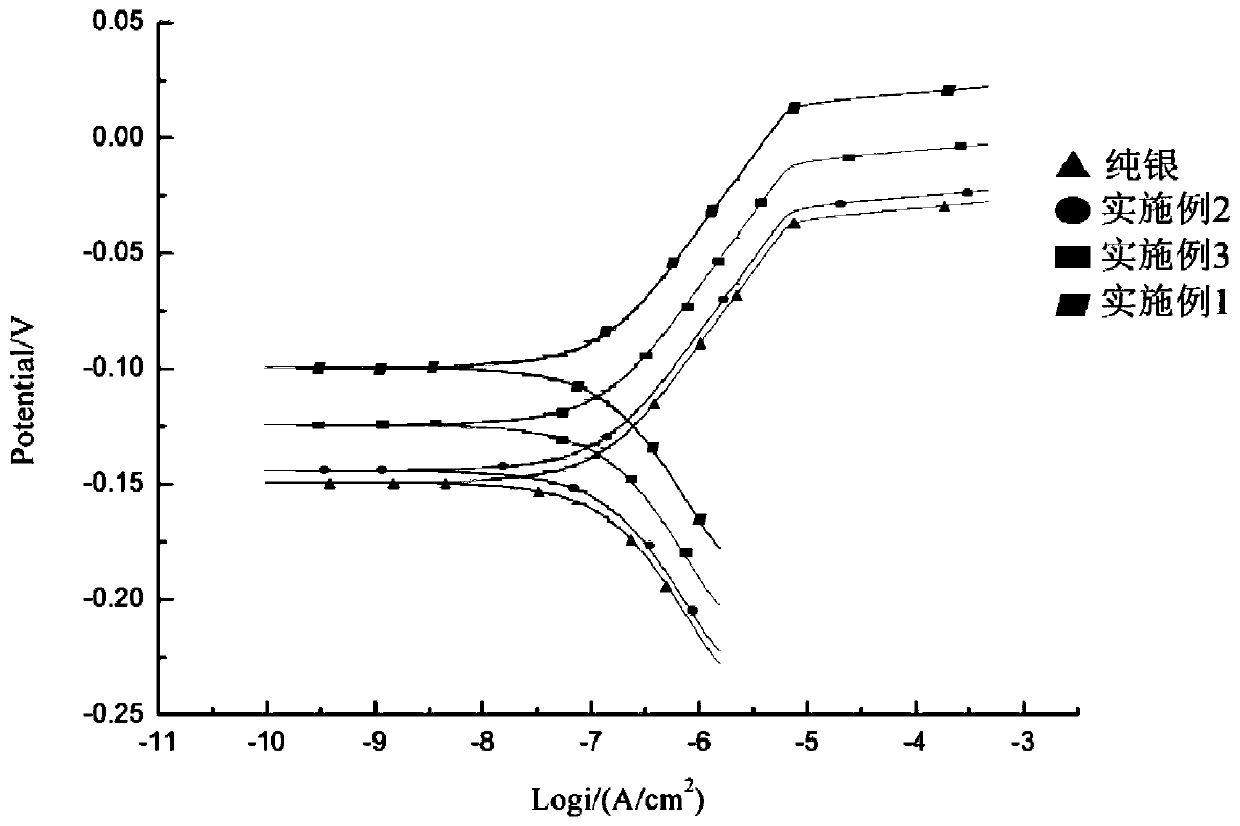

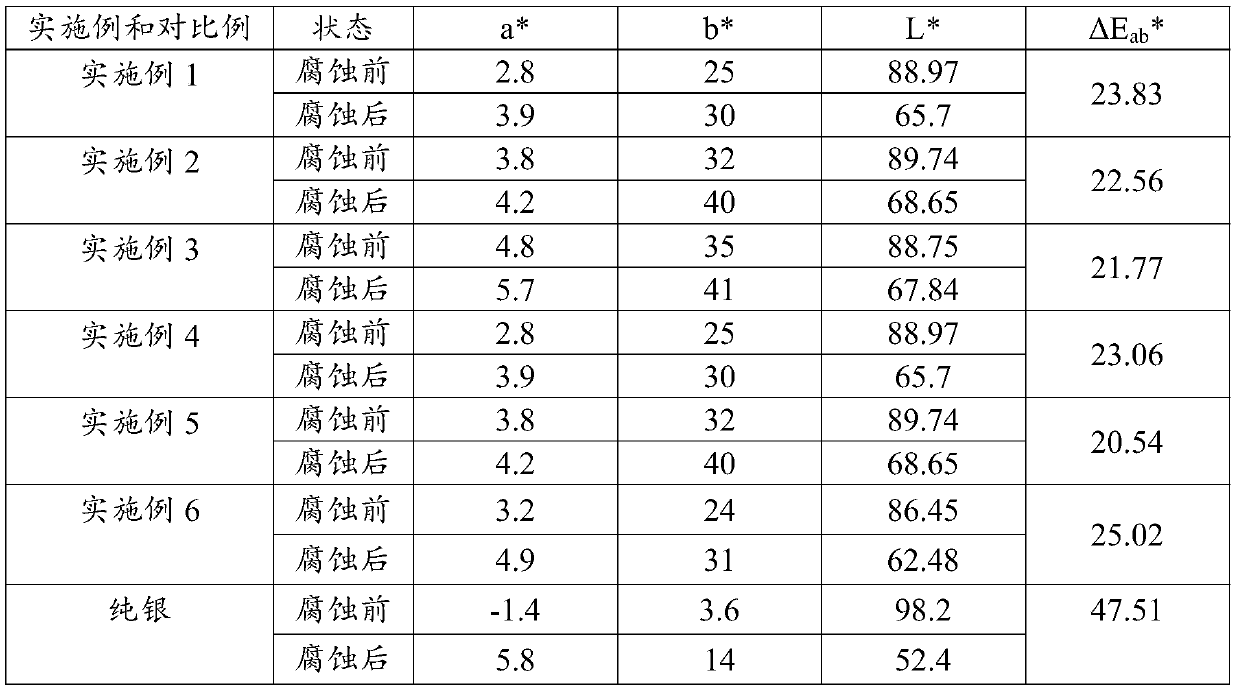

Silver alloy, silver alloy ornament and preparation method of silver alloy ornament

InactiveCN111378862AGood resistance to vulcanization and discolorationAccelerated corrosionJewelleryRare-earth elementSulfidation

The invention relates to the field of sliver alloy ornaments, in particular to a silver alloy, a silver alloy ornament and a preparation method of the silver alloy ornament. The silver alloy comprises, by weight, 10-40 parts of Ag, 30-72 parts of Cu, 9-40 parts of Zn, 0.01-3 parts of Sn, 0.2-3.6 parts of Al, 0.02-1 part of Si, 0.1-1 part of Ni, and 0.01-0.1 part of rare earth elements. The sliveralloy ornament prepared from the silver alloy has the same color and luster as 18K-22K yellow silver ornaments and has good anti-sulfurized discoloration performance and excellent sweat corrosion resistance.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

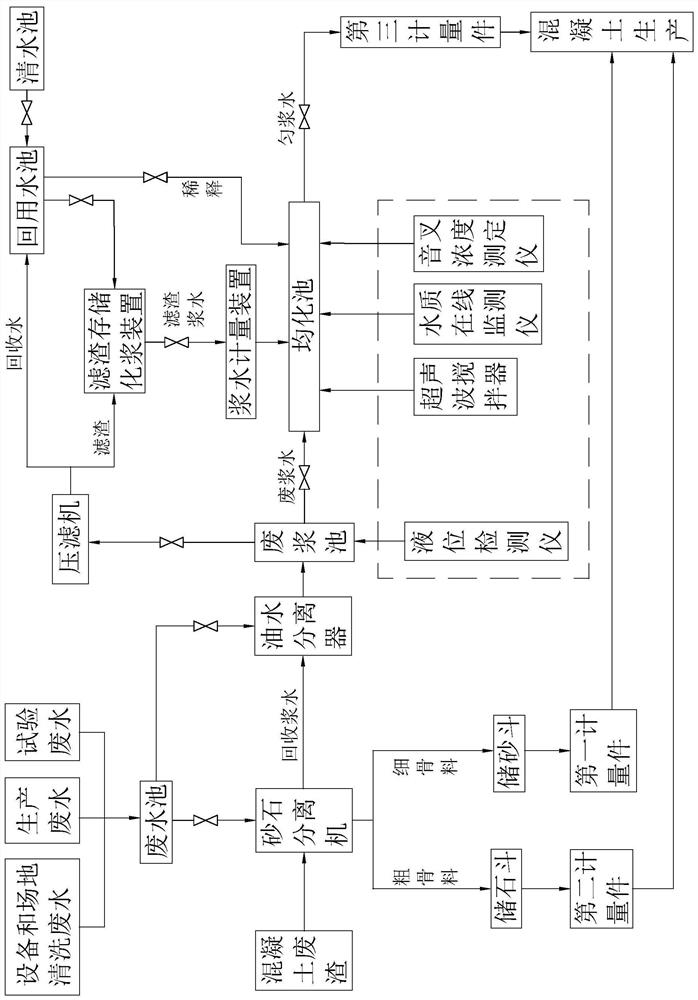

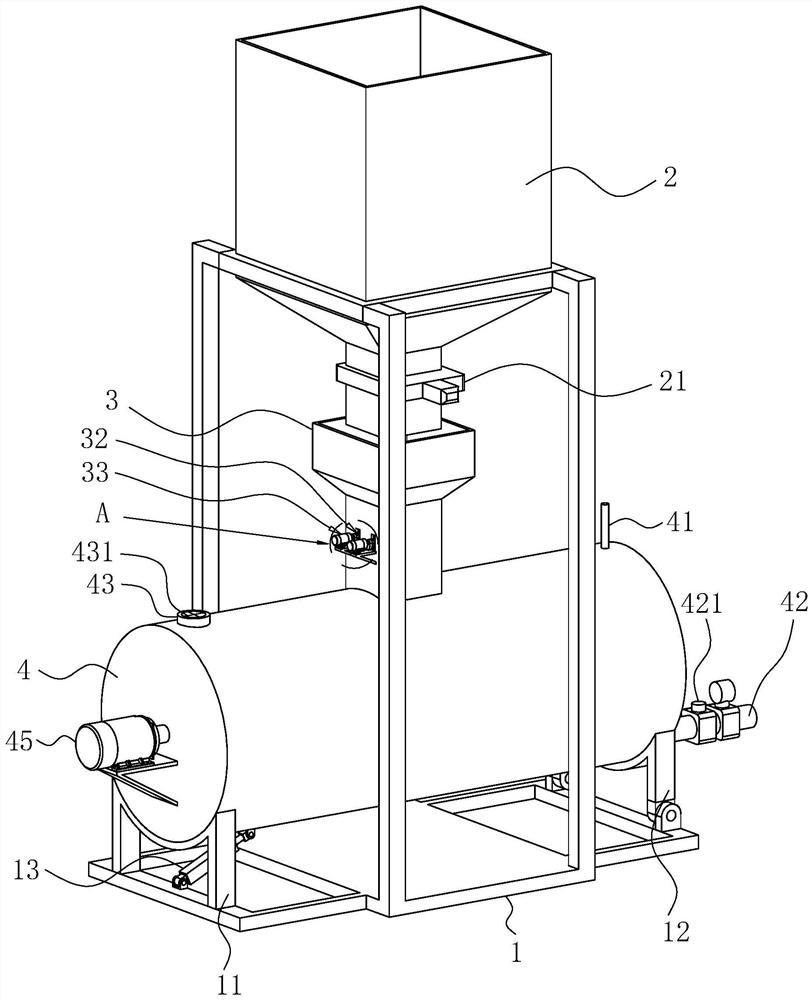

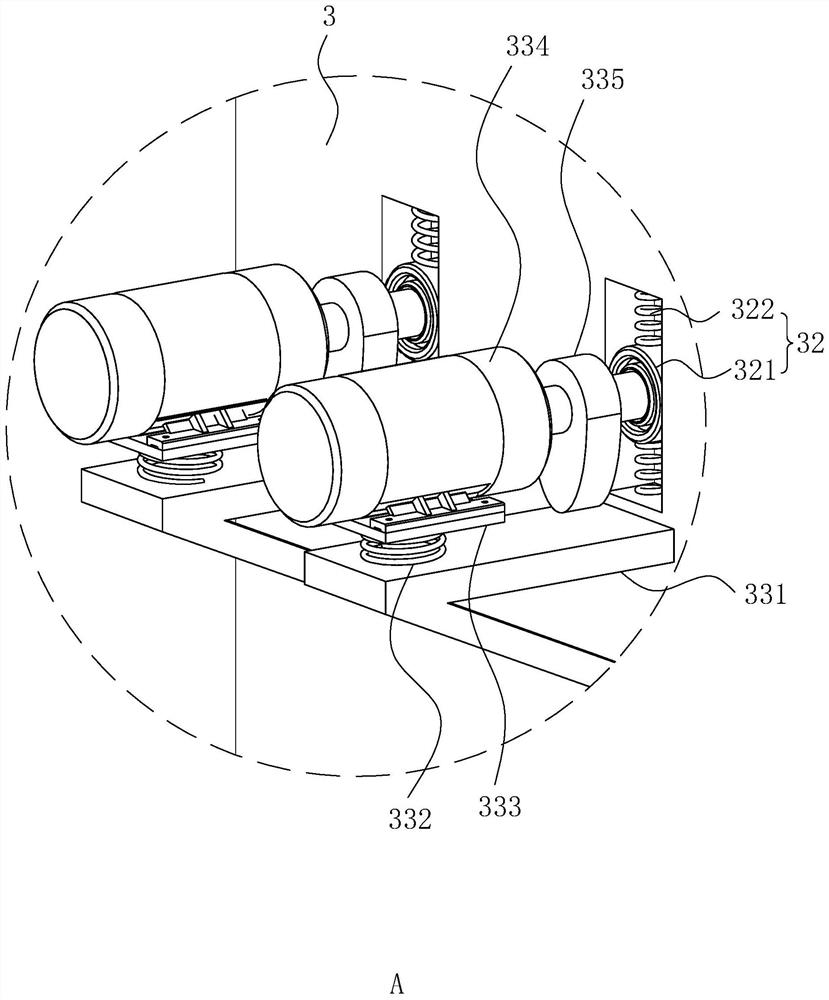

Recycling process and recycling system for wastewater and waste residues in concrete mixing plant

ActiveCN112387000AChange the three-stage precipitation treatment modeReduce recycling processFatty/oily/floating substances removal devicesTransportation and packagingWastewaterSlurry

The invention relates to the field of building material recycling, in particular to a recycling process and system for wastewater and waste residues in a concrete mixing plant. The recycling process comprises the following steps: separating concrete waste residues to obtain coarse aggregate, fine aggregate and recycled slurry water, and subjecting the obtained coarse aggregate and fine aggregate to concrete production; removing oil from the obtained recycled slurry water and and the wastewater of the concrete mixing plant, and carrying out collecting and storing to obtain waste slurry water; stirring the obtained waste slurry water to obtain homogenate water, and carrying out filter pressing treatment on the waste slurry water which cannot be recycled in time to obtain filter residues andrecycled water; and carrying out concentration monitoring and pH value monitoring on the obtained homogenate water, and applying the homogenate water with qualified monitoring values to concrete production. The recycling system comprises a gravel separation unit, a waste slurry water collecting and monitoring unit, a waste slurry water control unit, a recycling unit and a control unit. The processand the system have the effect of fully recycling the wastewater and the waste residues of the concrete mixing plant.

Owner:中建西部建设北方有限公司

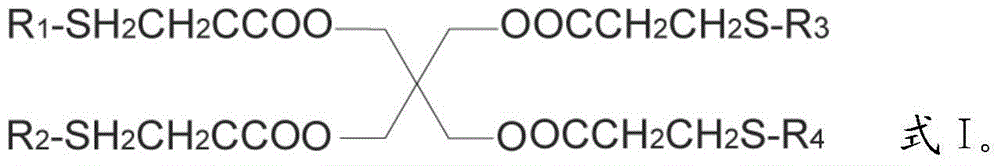

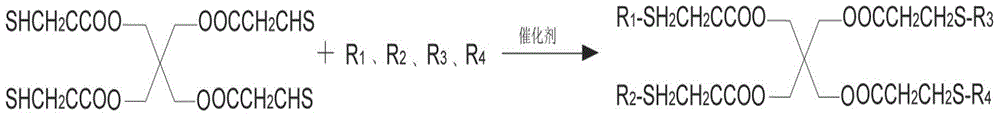

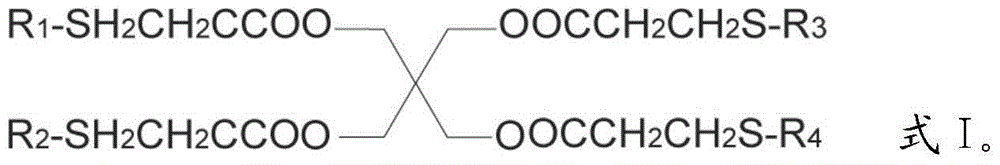

Preparation method for pentaerythritol tetra (3-R-alkyl thiopropionic acid)

InactiveCN104529845AImprove structural activityReduce recycling processSulfide preparationSolventChemistry

The invention relate to a preparation method for pentaerythritol tetra (3-R-alkyl thiopropionic acid), and belongs to the technical field of antioxidant preparation. The preparation method includes the steps of firstly, adding pentraerythritol tetra (3-mercaptopropionate) and alkaline catalysts into a reactor, and then dropping or slowly injecting alkene R1, alkene R2, alkene R3 and alkene R4 to conduct the addition reaction; secondly, adding neutralizer after the addition reaction is completed, evaporating the redundant alkene R1, the redundant alkene R2, the redundant alkene R3, the redundant alkene R4 and the pentraerythritol tetra (3-mercaptopropionate) which does not participate in the reaction through a rectifying tower after the reaction mixture is precisely filtered, and conducting fractionation to obtain pentaerythritol tetra (3-R-alkyl thiopropionic acid). In the reaction process of the method, no solvent is used, the solvent recycle procedure is omitted, cost is reduced, and the method is more environmentally friendly. In addition, products are separated through rectifying in the postprocessing process, production is more environmentally friendly due to the fact that no solvent is used, the yield is higher than that of an ordinary crystallization centrifugal process, and quality is good.

Owner:北京极易控股集团有限公司

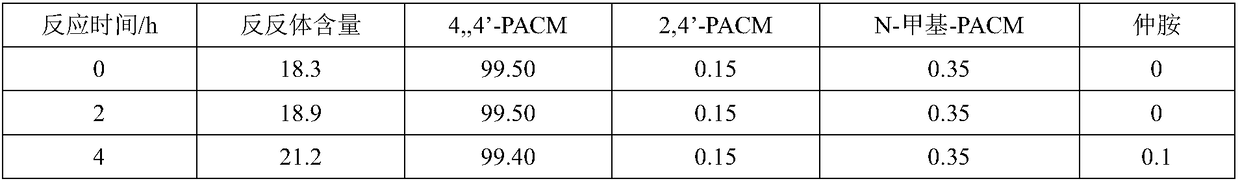

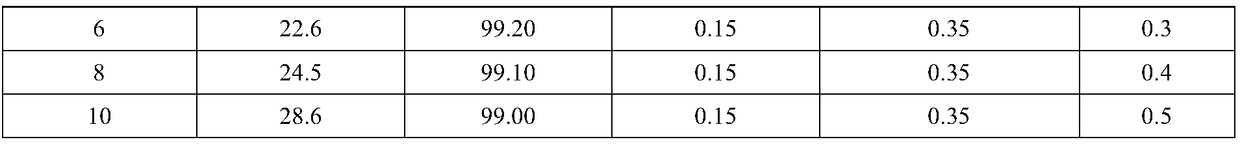

Preparation method of high-anomer 4,4'-diaminodicyclohexylmethane

ActiveCN108516939ASimple production processReduce usageAmino compound purification/separationOrganic chemistry methodsIsomerizationSolvent free

The invention discloses a preparation method of high-anomer 4,4'-diaminodicyclohexylmethane. The content of anomer (PACM50) in the prepared product is 45-55 wt%. The preparation method comprises the following steps: performing a modification reaction on a raw material low-anomer 4,4'-diaminodicyclohexylmethane at 100-110 DEG C under the action of a catalyst and a modifier, raising the temperatureto 120-250 DEG C, and performing an isomerization reaction to prepare the high-anomer 4,4'-diaminodicyclohexylmethane. The method allows the PACM20 conversion rate to reach 99-100% and the PACM50 yield to reach 98-99%. The method has the advantages of realization of a high-temperature catalysis reaction under solvent-free and low-pressure nitrogen conditions without high-pressure nitrogen, simplicity in operation, safety, environmental protection, and suitableness for industrial production.

Owner:WANHUA CHEM GRP CO LTD

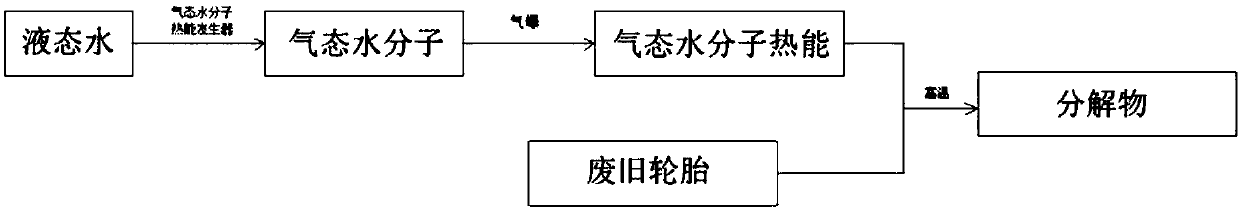

Method and device for treating waste tires

The invention provides a method for treating waste tires. The method includes the steps: placing recycled waste tires into closed space; heating liquid water to gaseous water molecules to obtain gaseous water molecule heat energy with a high heat enthalpy value; continuously leading the gaseous water molecules into the closed space filled with the waste tires through an air outlet pipeline, discharging the air in the closed space by the gaseous water molecules to form a closed space without oxygen environments, and heating and decomposing the waste tires under the high-temperature action of the gaseous water molecules to generate tar, alkane gas, water, carbon dioxide, carbonic oxide, foreign gas and solid substances such as carbon black and steel wires; recycling waste heat of gas-liquidmixture generated by pyrolysis by a heat exchanger, performing oil-liquid separation on the gas-liquid mixture, purifying tail gas by the aid of a gas purifier, and discharging the purified tail gas;collecting and recycling the cooled solid substances such as the carbon black and the steel wires in a classified manner.

Owner:GUANGZHOU BAOSHI WIRELESS POWER SUPPLYING TECH CO LTD

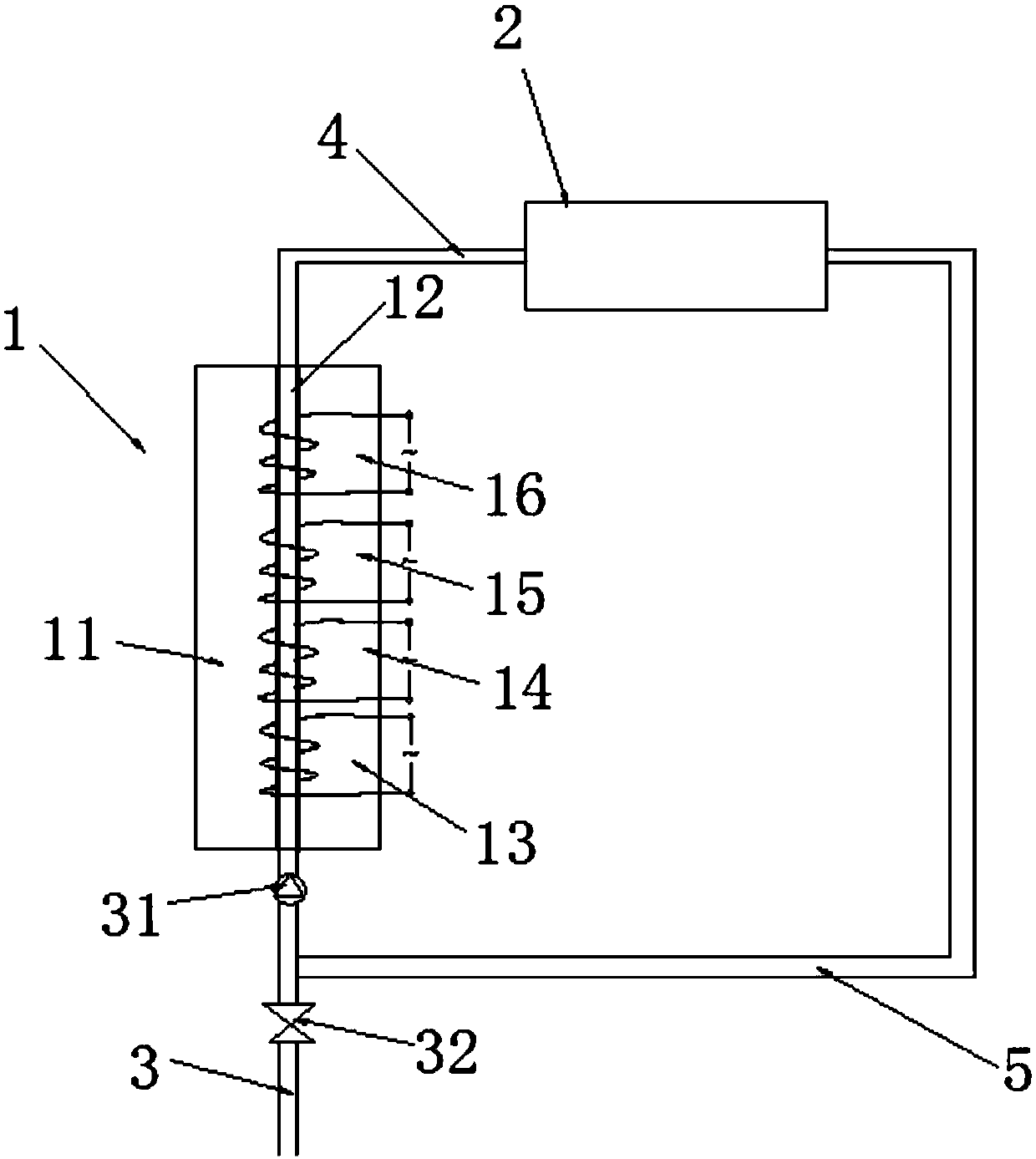

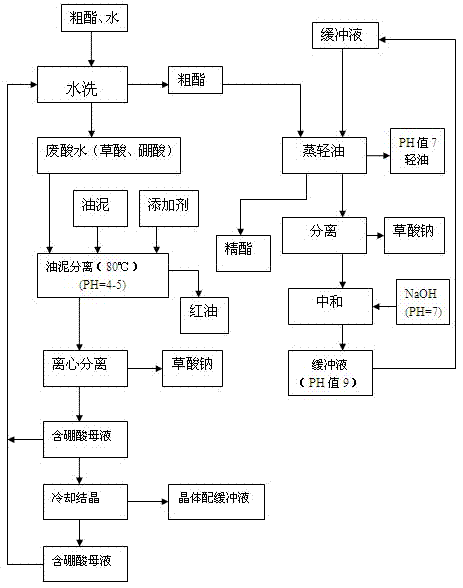

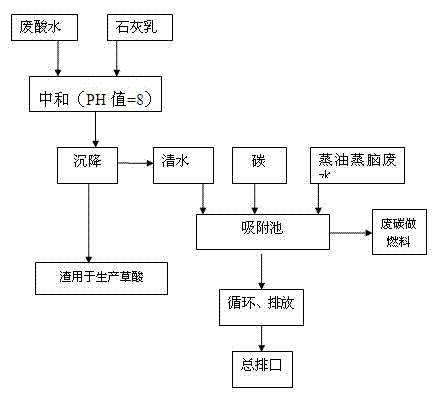

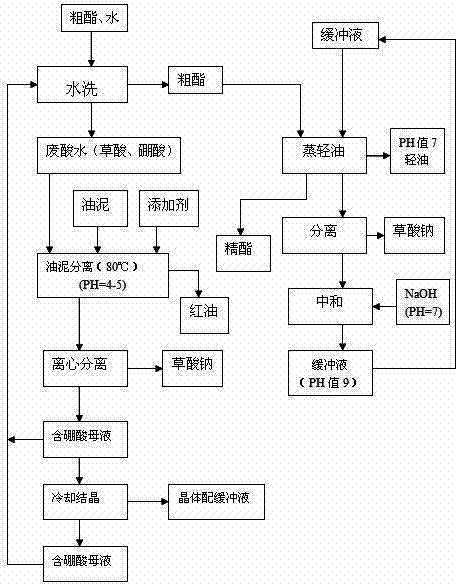

Postprocessing method for synthetic borneol

ActiveCN102584577AIncrease concentrationAdjust affinityPreparation from carboxylic acid saltsSolid fuelsSurface-active agentsNonionic surfactant

A postprocessing method for synthetic borneol comprises the steps of preparing the raw materials of synthetic borneol to obtain raw ester according to a conventional production method, then washing the ester by water, postprocessing the washed ester through a light oil steaming method, mixing the waste water (including oxalic acid and boric acid) obtained by washing the raw ester and oil mud generated by postprocessing refined ester obtained by steaming the light oil, adding non-ionic surface active agent to be taken as a demulsifying agent, conducting oil-mud separation to obtain red oil, and postprocessing the waste water after the oil-mud separation so as to achieve the purposes of recycling and discharging after reaching the standard. If the boric acid content is too high, part of boric acid crystals can be separated out by cooling and crystallizing, so that mother liquor containing boric acid achieves the demanded index and then returns to be taken as a water source for washing the raw ester; and the boric acid crystals can return to be taken as the water source for washing the raw ester through a prepared buffer solution.

Owner:WUZHOU HUANGPU CHEM PHARM CO LTD

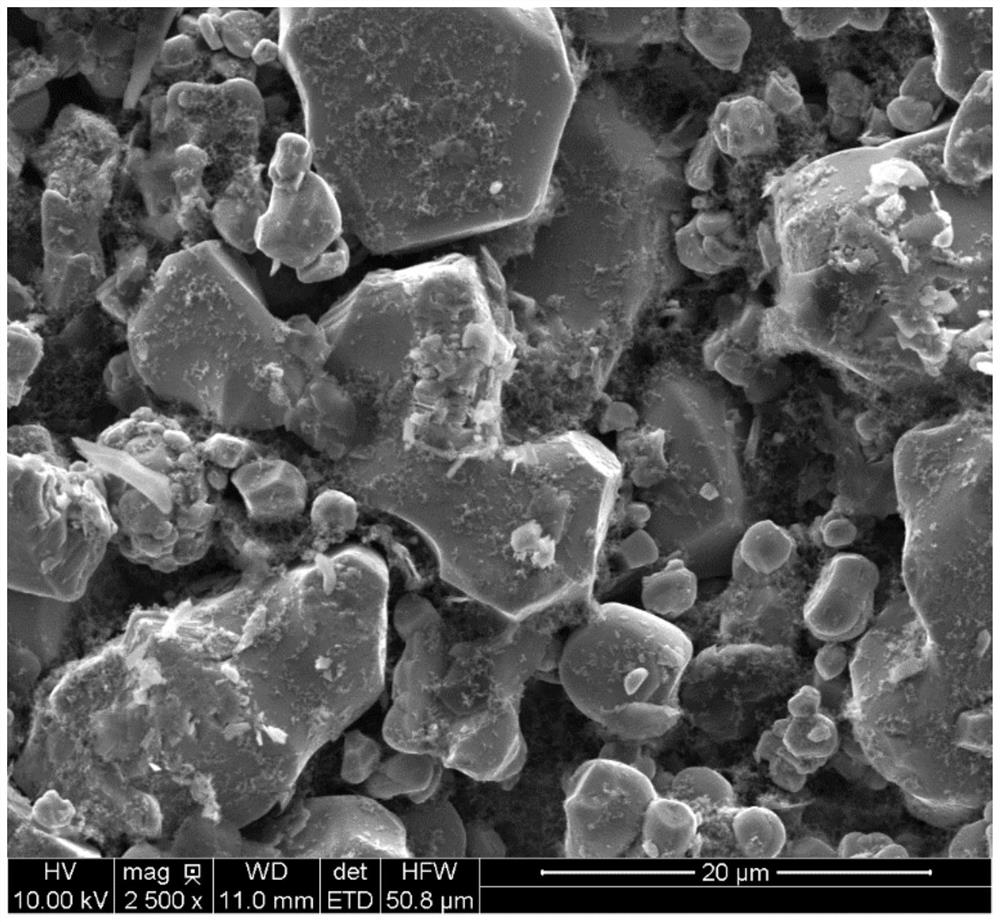

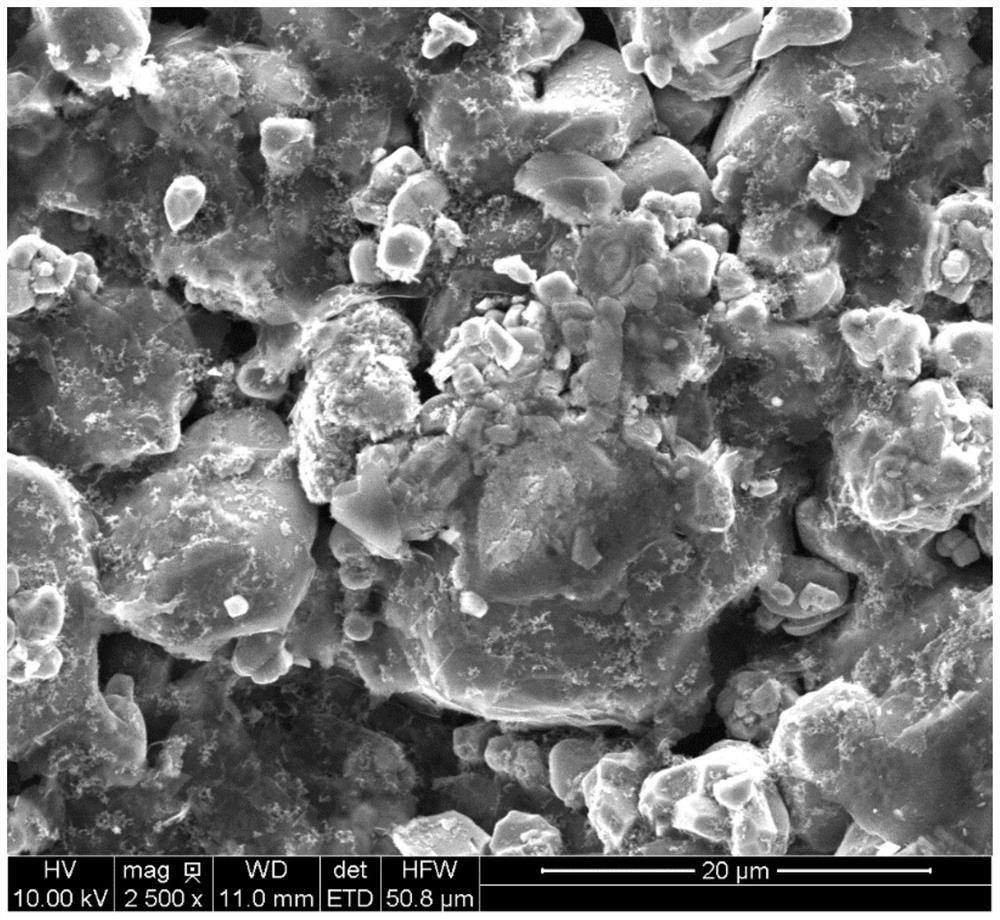

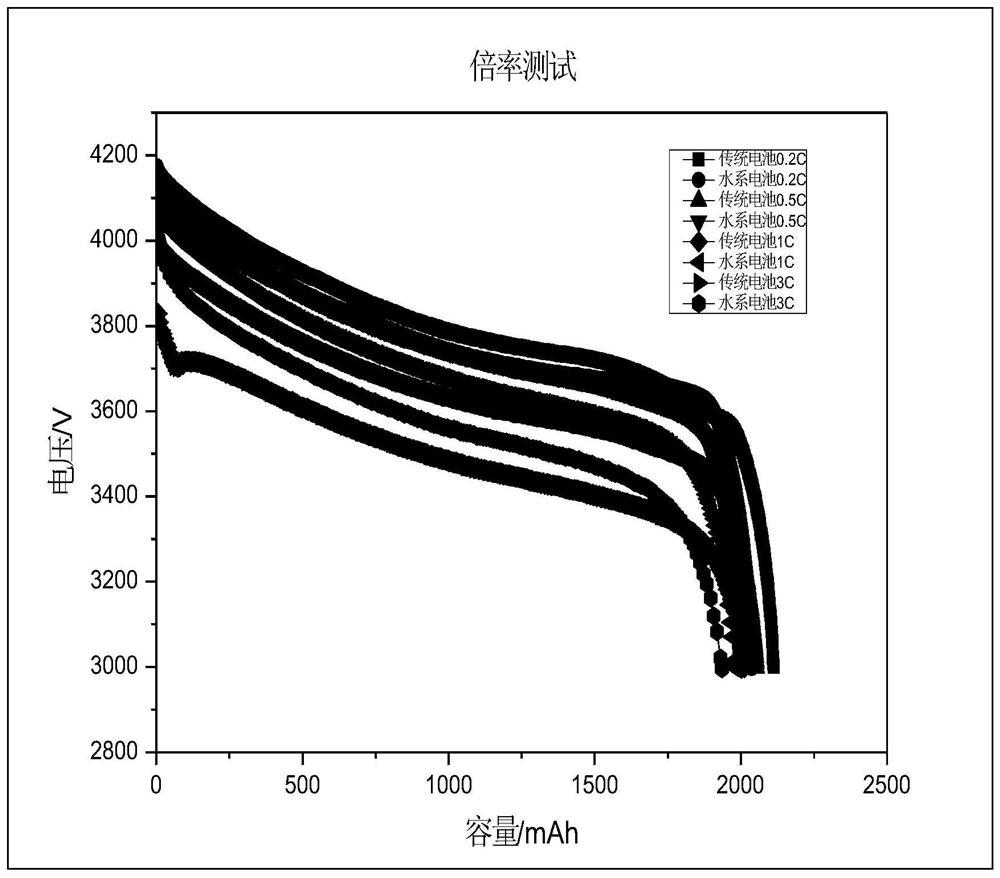

Preparation method of aqueous slurry for lithium ion battery

PendingCN114300677AReduce recycling processManufacturing friendlyCell electrodesPhysical chemistryOrganosolv

The invention discloses a lithium ion battery aqueous slurry preparation method, which comprises: 1, mixing a binder and deionized water according to a given ratio, stirring for the first time, and dispersing for the first time to prepare a mixed slurry; step 2, adding a conductive agent into the mixed slurry according to a given proportion, mixing, and carrying out second stirring and second dispersion to prepare conductive slurry; and 3, adding a lithium ion battery positive electrode material into the conductive slurry to form a mixture, carrying out third stirring and third dispersion on the mixture, controlling the solid content and viscosity of the conductive slurry, and adding a modifier and an additive to obtain the lithium ion battery aqueous slurry. The environment pollution risk of an organic solvent is eliminated, the solvent recovery process is reduced, the slurry preparation and post-process coating cost can be greatly reduced, and the NMP material cost, the solvent recovery equipment and the manufacturing cost are saved.

Owner:深圳市首通新能源科技有限公司

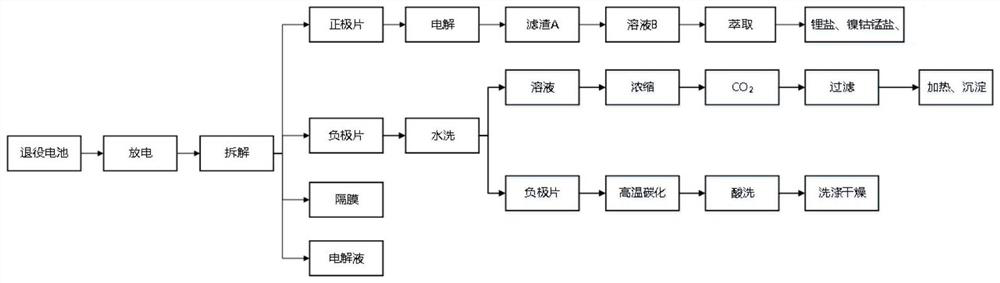

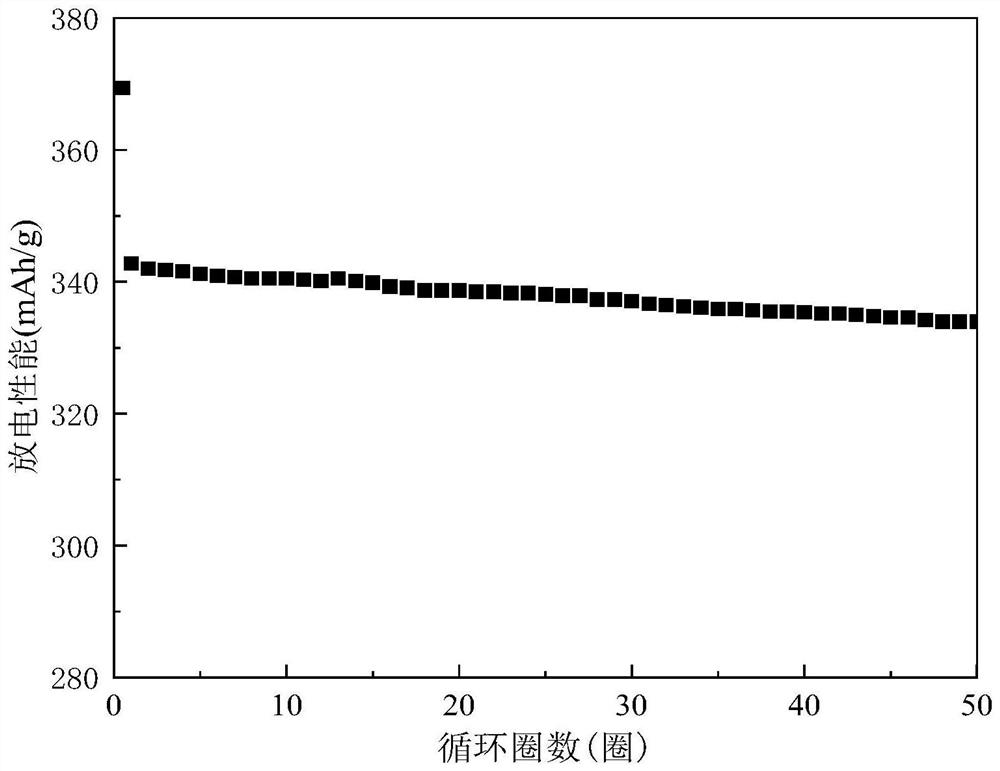

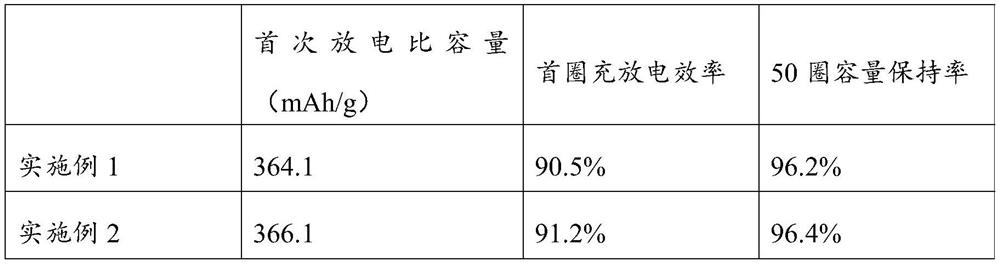

Recovery method and application of retired lithium ion battery electrode material

PendingCN114388922AAchieve recyclingAvoid lostWaste accumulators reclaimingBattery recyclingElectrical batteryLithium carbonate

The invention discloses a retired lithium ion battery electrode material recycling method and application thereof. The retired lithium ion battery electrode material recycling method comprises the steps that a retired lithium ion battery is disassembled, a negative plate is separated out, the negative plate is washed or soaked with water or acid, a lithium-containing solution and a lithium-removed negative plate are obtained, the lithium-containing solution is subjected to precipitation treatment, and lithium carbonate is obtained; and carrying out low-temperature calcination on the lithium-removed negative electrode plate in a vacuum or inert atmosphere to melt the binder, and then carrying out high-temperature calcination to carbonize the binder to obtain the carbon-coated graphite material. According to the method, the lithium resource in the SEI film of the graphite negative electrode is recycled, the SEI film in the negative electrode plate is washed or soaked, so that lithium ions enter the solution, the lithium resource is recycled, the negative electrode plate is calcined step by step, the binder PVDF is melted and coated on the surface of the graphite, and then the PVDF is pyrolyzed and carbonized at high temperature, so that the lithium resource is recycled. The in-situ carbon-coated recycled graphite material is formed, and the modified graphite can still be used as an electrode material to realize reutilization.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

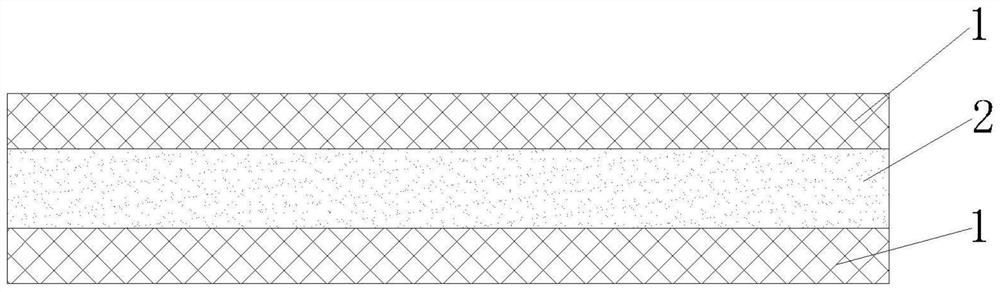

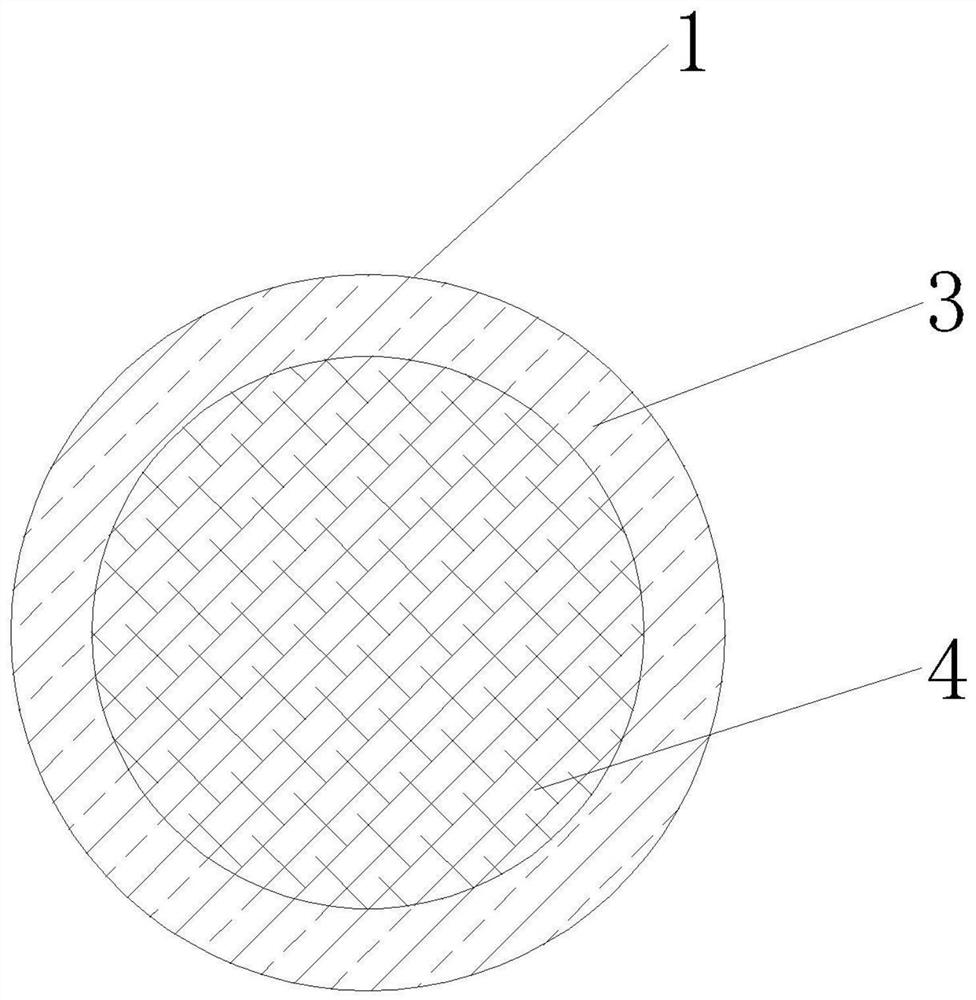

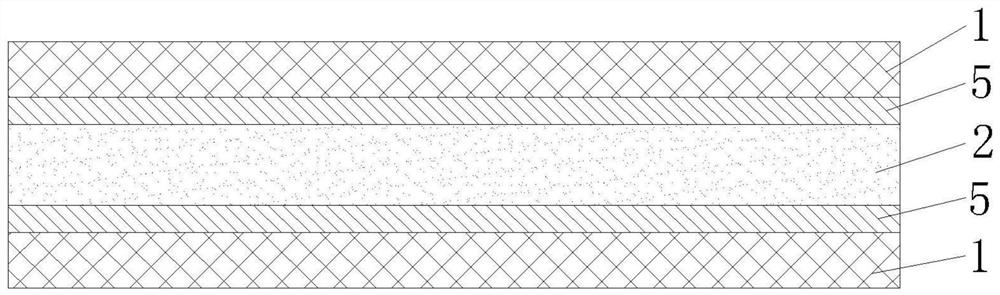

Integrally recyclable full-PET material foam sandwich panel and production process thereof

PendingCN112406208AAchieve material unityReduce pollutionSynthetic resin layered productsFlat articlesFiberPolymer science

The invention discloses an integrally recyclable full-PET material foam sandwich panel and a production process thereof. The integrally recyclable full-PET material foam sandwich panel comprises two PET fiber surface layers and a PET foam core, the two PET fiber surface layers are compounded on the upper side and the lower side of the PET foam core, and each PET fiber surface layer comprises low-melting-point PET fibers and common PET fibers; the PET fiber surface layer is formed by combining low-melting-point PET fibers and common PET fibers in a sheath-core structure or in a mixed mode. Theinvention has the following beneficial effects: the material does not contain other reinforced fiber materials, realizes material singleness, can be integrally crushed and recovered without separatingthe surface layer from the core layer during scrapping, reduces environmental pollution and recovery processes, and reduces recovery cost; moreover, the low-melting-point PET fiber is melted at a lowtemperature while the common PET fiber still holds a physical structure, so that since the cooled low-melting-point PET fiber is used as an adhesive film and has good adhesive strength, use of otheradhesive materials is avoided, light weight is facilitated, the cost is saved, and the efficiency is improved.

Owner:戴铂新材料(张家港)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com