Recovery method and application of retired lithium ion battery electrode material

A lithium-ion battery and electrode material technology, which is applied in the field of decommissioned lithium-ion battery electrode material recovery, can solve the problems of high energy consumption, high temperature environment, and large amount of acid used in fire recovery, so as to reduce the process and environment of recycling and reuse. The effect of less pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

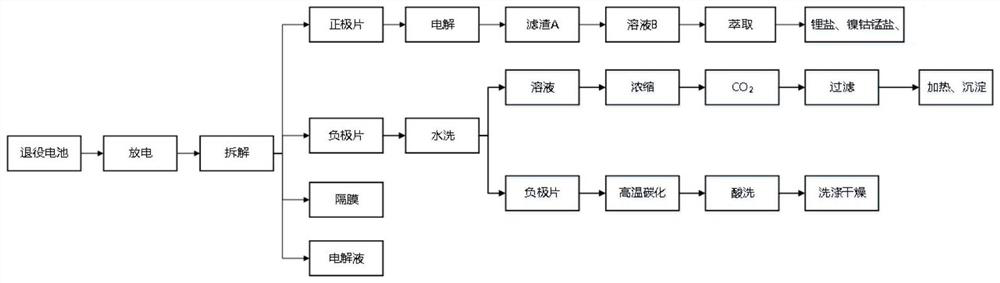

[0028] A method for recycling electrode materials of decommissioned lithium-ion batteries, refer to figure 1 , the specific process is:

[0029] (1) Disassemble the power battery unit (nickel-cobalt-manganese ternary battery) after deep discharge, sort out the positive and negative electrode sheets, use the positive electrode sheet and the metal Pt electrode as the cathode and anode respectively, and mix 0.5mol / L of oxalic acid was used as electrolyte, electrolyzed at 1.2V voltage, and the resulting precipitate was filtered to obtain solution A and filter residue A, then filter residue A was acid-washed with hydrochloric acid, filtered again to obtain solution B and filter residue B, and then an extractant was used P204 extracts and purifies solution B, then alkalizes to form nickel-cobalt-manganese salt mixed hydroxide, and adds sodium carbonate to solution A to prepare lithium carbonate precipitation to obtain lithium salt;

[0030] (2) Rinse the negative electrode sheet w...

Embodiment 2

[0035] A method for recycling electrode materials of decommissioned lithium ion batteries, the specific process is as follows:

[0036] (1) Disassemble the battery cell (nickel-cobalt-manganese ternary battery) after deep discharge, sort out the positive and negative electrode sheets, use the positive electrode sheet and the metal Pt electrode as the cathode and anode respectively, 0.1mol / L oxalic acid For electrolyte, electrolyze under 1.2V voltage, filter the resulting precipitation to obtain solution A and filter residue A, then pickle filter residue A with hydrochloric acid, filter again to obtain solution B and filter residue B, then use extractant P204 to the solution. B is extracted and purified, then alkalized to form nickel-cobalt-manganese salt mixed hydroxide, and sodium carbonate is added to solution A to prepare lithium carbonate precipitation to obtain lithium salt;

[0037] (2) Rinse the negative electrode sheet with a large amount of water, heat and concentrate...

Embodiment 3

[0042] A method for recycling electrode materials of decommissioned lithium ion batteries, the specific process is as follows:

[0043] (1) Disassemble the battery cell (nickel-cobalt-manganese ternary battery) after deep discharge, sort out the positive and negative electrode sheets, and use the positive electrode sheet and metal Pt electrode as the cathode and anode respectively, 0.2mol / L phosphoric acid For electrolyte, electrolyze under 1.5V voltage, filter the resulting precipitation to obtain solution A and filter residue A, then pickle filter residue A with hydrochloric acid, filter again to obtain solution B and filter residue B, then use extractant P204 to the solution. B is extracted and purified, then alkalized to form nickel-cobalt-manganese salt mixed hydroxide, filtered to obtain filtrate C, and sodium carbonate is added to the filtered filtrate to prepare lithium carbonate precipitation to obtain lithium salt;

[0044] (2) Rinse the negative electrode sheet with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com