Integrally recyclable full-PET material foam sandwich panel and production process thereof

A foam sandwich panel and production process technology, applied in the field of new composite materials, can solve the problems of wasting resources, non-recyclable, easy to pollute the environment, etc., and achieve the effects of saving production costs, reducing recycling costs, and reducing recycling processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The production process of the integrally recyclable full PET material foam sandwich panel of the present invention comprises the following steps:

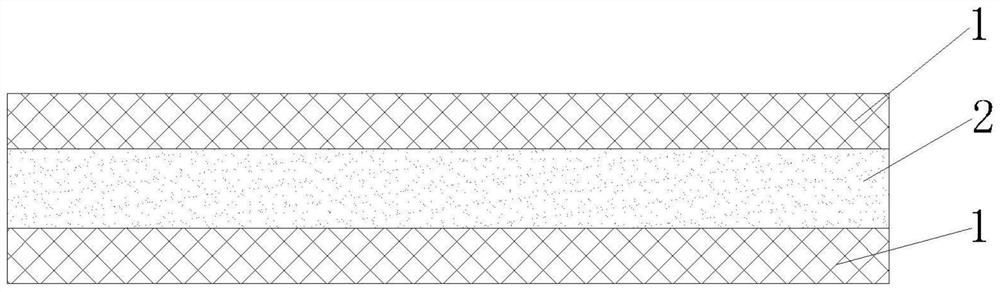

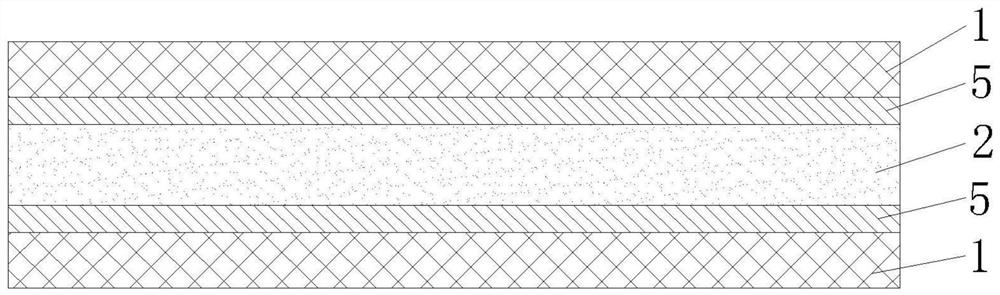

[0047] 1) Set the density to 60kg / m 3 The PET foam core 2 is cut into 5mm thick and prepared with a grammage of 440g / m 2 PET fiber surface layer 1;

[0048] 2) The PET fiber surface layer 1, the PET foam core 2 and the PET fiber surface layer 1 are sequentially stacked and heated through the continuous heating device 6, the heating temperature is 180-200°C, and the feeding speed is 2m / min;

[0049] 3) The heated PET material is pre-compressed by the compacting device 7, applying a pressure of 0.1Mpa, and cooling by the cooling device 8 at the same time, so that the two-layer PET fiber surface layer 1 and the PET foam core 2 are bonded and then cooled;

[0050] 4) The bonded PET material is cut by the cutting device 9 to make a semi-finished sandwich panel.

[0051] After heating the semi-finished sandwich panel to 180°C, ...

Embodiment 2

[0053] The production process of the integrally recyclable full PET material foam sandwich panel of the present invention comprises the following steps:

[0054] 1) Set the density to 105kg / m 3 The PET foam core 2 is cut into 4mm thick and prepared with a grammage of 400g / m 2 PET fiber surface layer 1;

[0055] 2) The PET fiber surface layer 1, the PET foam core 2 and the PET fiber surface layer 1 are sequentially stacked and heated through the continuous heating device 6, the heating temperature is 180-200°C, and the feeding speed is 2m / min;

[0056] 3) The heated PET material is pre-compressed by the compacting device 7, applying a pressure of 0.1Mpa, and cooling by the cooling device 8 at the same time, so that the two-layer PET fiber surface layer 1 and the PET foam core 2 are bonded and then cooled;

[0057] 4) The bonded PET material is cut by the cutting device 9 to make a semi-finished sandwich panel.

[0058] After heating the semi-finished sandwich panel to 180°C,...

Embodiment 3

[0060] The production process of the integrally recyclable full PET material foam sandwich panel of the present invention comprises the following steps:

[0061] 1) Set the density to 105kg / m 3 The PET foam core 2 is cut into 4mm thick and prepared with a grammage of 600g / m 2 PET fiber surface layer 1;

[0062] 2) The PET fiber surface layer 1, the PET foam core 2 and the PET fiber surface layer 1 are sequentially stacked and heated through the continuous heating device 6, the heating temperature is 180-200°C, and the feeding speed is 2m / min;

[0063] 3) The heated PET material is pre-compressed by the compacting device 7, applying a pressure of 0.1Mpa, and cooling by the cooling device 8 at the same time, so that the two-layer PET fiber surface layer 1 and the PET foam core 2 are bonded and then cooled;

[0064] 4) The bonded PET material is cut by the cutting device 9 to make a semi-finished sandwich panel.

[0065] After heating the semi-finished sandwich panel to 180°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com