Preparation method of aqueous slurry for lithium ion battery

A lithium-ion battery, water-based slurry technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor conductivity of lithium iron phosphate, poor slurry stability, difficult slurry screening, etc., to reduce coating cost, material cost savings, the effect of reducing the solvent recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a kind of preparation method of lithium-ion battery aqueous slurry, comprising the following steps:

[0025] Step 1, mix the binder and deionized water according to a given ratio and add it to the container, stir and mix for the first time and disperse for the first time to prepare a mixed slurry; the binder is an acrylic shell binder glue liquid. Wherein, the binder and deionized water can be mixed in a given weight ratio.

[0026] Step 2, adding a conductive agent to the mixed slurry in a given proportion and mixing, and then performing a second stirring and mixing and a second dispersion to prepare a conductive slurry; wherein, the conductive agent can be added to the mixed slurry in a weight ratio Mixing in the mixed slurry, for example, adding the conductive agent into the mixed slurry in proportion by weight (0.3-3%) and mixing.

[0027] Step 3, adding lithium-ion battery positive electrode materials to the conductive paste to form...

Embodiment 1

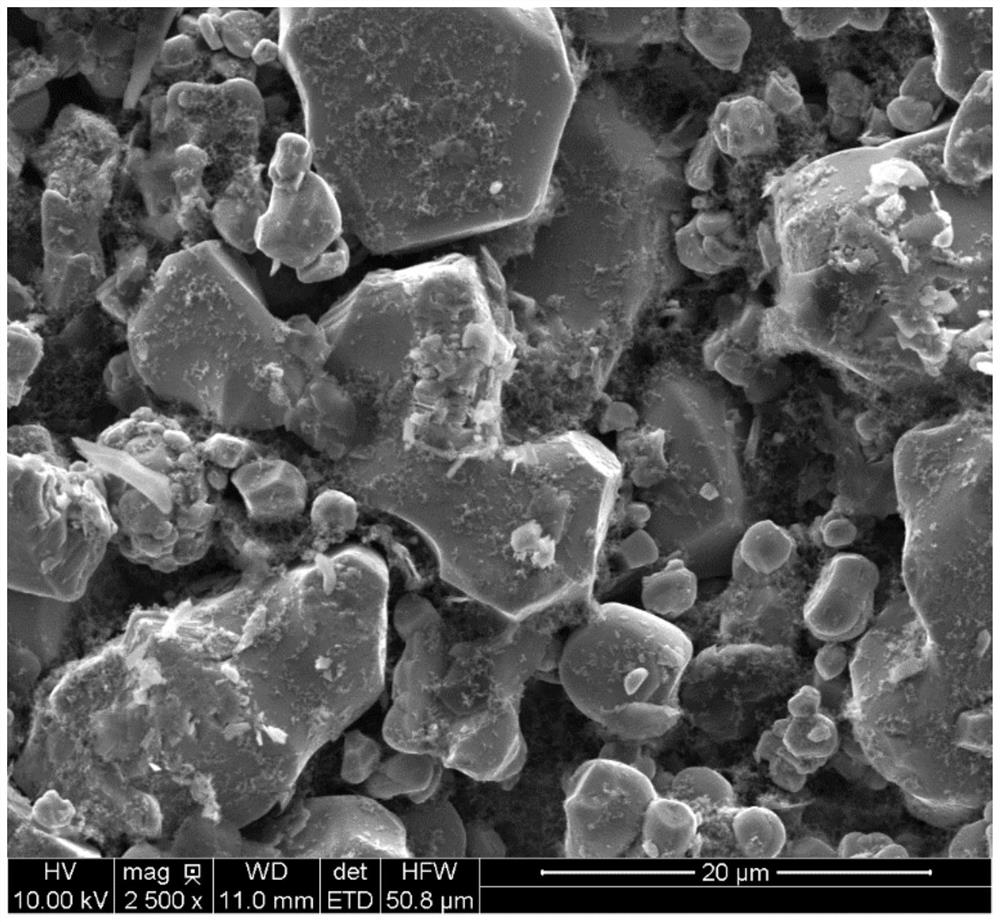

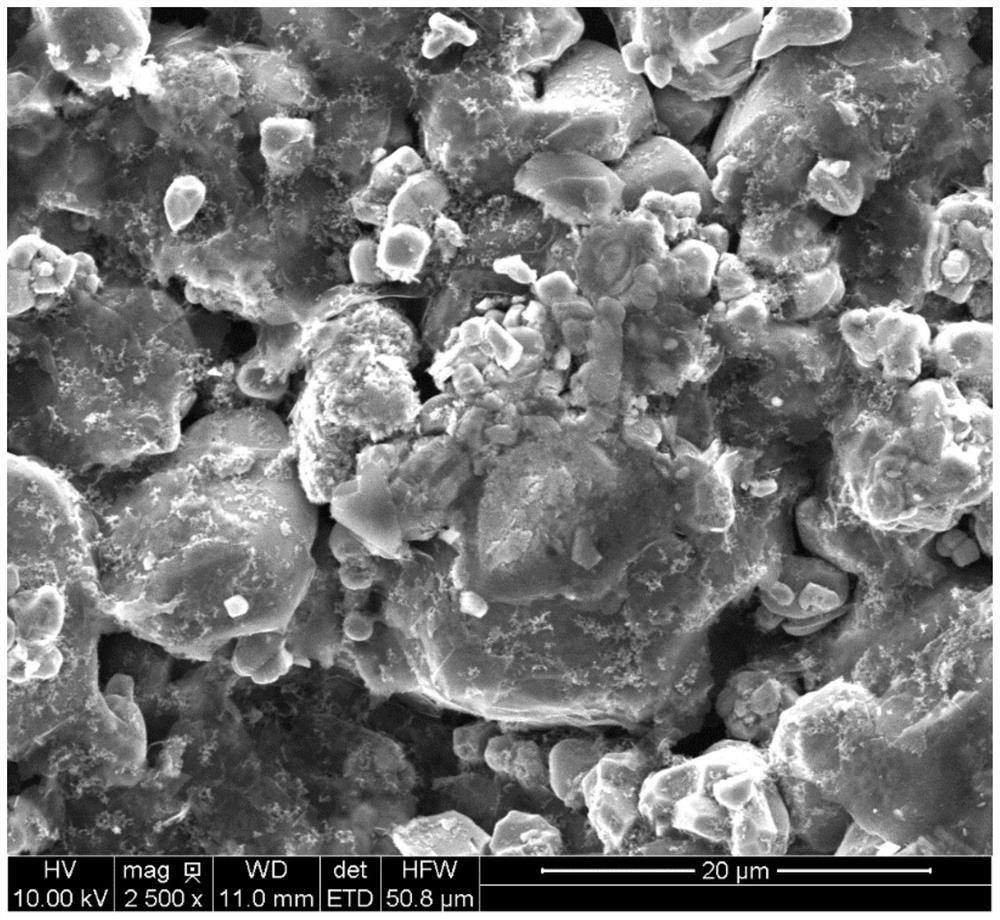

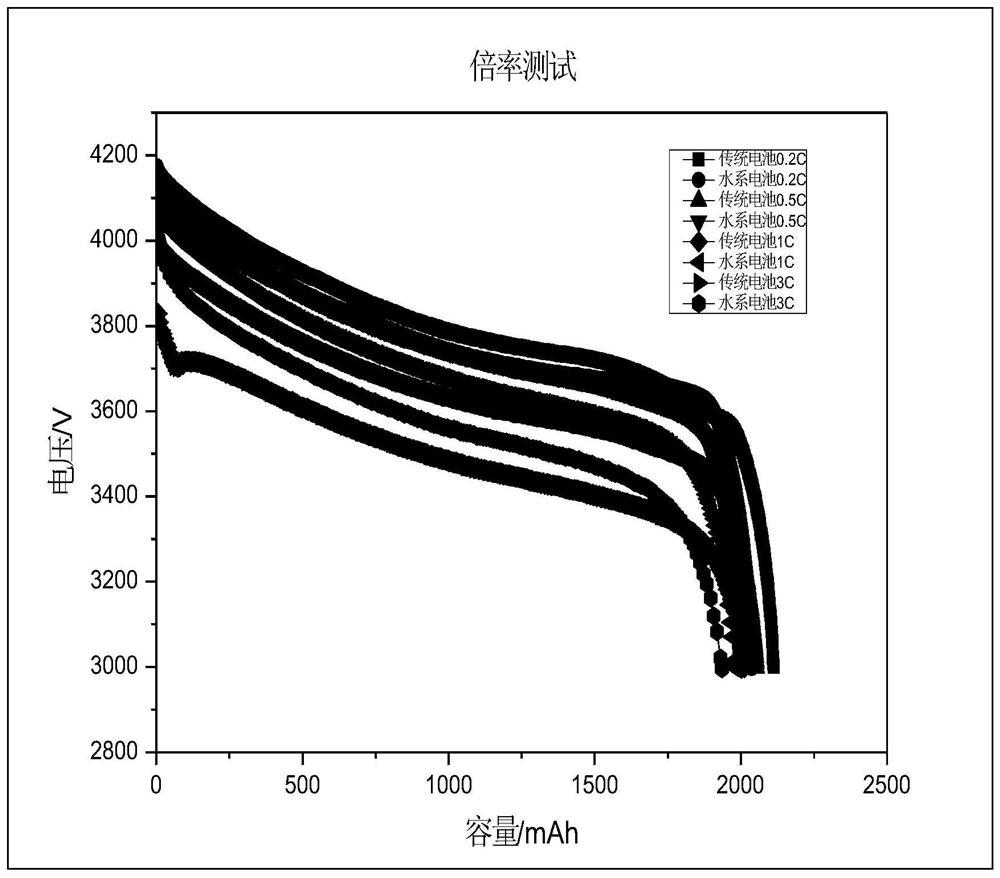

[0037] Example 1 as image 3 , Figure 4 As shown, according to production requirements, the prepared acrylic shell adhesive glue is added to a cleaned mixing tank, and the mixing equipment is a double planetary mixing equipment. Add an appropriate amount of deionized water, rotate at 20-30r / min, rotate at 2500-4000r / min, stir for 30-90min to prepare the glue with a solid content of 3-9%, add graphene conductive agent (conductive agent includes: graphene, CNTs slurry Material, SP, phosphorus flake graphite (such as KS-6), single-walled carbon tube slurry, and one or more of them are compounded, and then 20-30r / min revolution, 2500-5000r / min high-speed dispersion for 60-120min; Prepare conductive paste;

[0038]The active substance lithium iron phosphate is added, and the high-rate lithium cobalt oxide slurry formula is as follows: lithium iron phosphate: graphene: acrylic glue: chitosan: PVP: H2O = 95.2:1:1.8:1.0:46. Revolution 25~45r / min, rotation 3000~7000r / min, control t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com