Patents

Literature

182results about How to "Reduce coating cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilic coat solution applied to surface of medicinal instrument and preparation method thereof

InactiveCN101812265AReduce solvent usageReduce harmLiquid surface applicatorsPolyurea/polyurethane coatingsSolventLubrication

The invention discloses hydrophilic coat solution applied to the surface of a medicinal instrument, which comprises modified polyurethane dispersing liquid serving as matrix polymer, hydrophilic polymer and reaction activity crosslinking agent. A preparation method for the hydrophilic coat solution comprises the following steps: (1) dissolving the hydrophilic polymer in water uniformly to form hydrophilic polymer solution, and stirring the solution uniformly; (2) dissolving the matrix polymer in the water uniformly, adding the matrix polymer solution into the hydrophilic polymer solution prepared in the step (1), and stirring the solution uniformly; and (3) adding the reaction activity crosslinking agent into the solution, and stirring the solution uniformly. The aqueous system-based hydrophilic coat solution reduces the used amount of a solvent, and reduces harm to an environment and an operator; the preparation method is simple and easy to operate, and can be applied to the surfaces of multiple medicinal instruments, improve the surface lubricating property of the medicinal instrument, reduce the friction coefficient and improve the effect of lubrication action; and the coating method is a one-step method, avoids processes of plasma pretreatment and the like for materials, is simple and can reduce the cost of the coat.

Owner:SINO MEDICAL SCI TECH INC

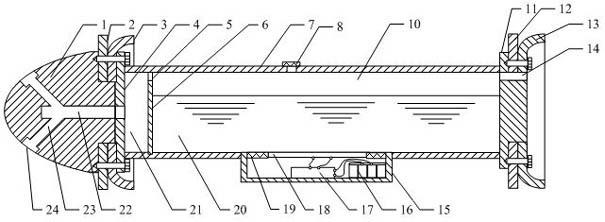

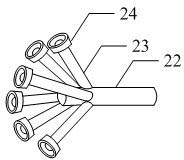

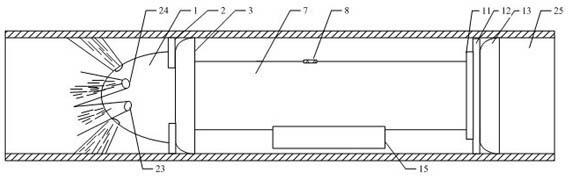

Natural gas pipe corrosion inhibitor coating device

InactiveCN102601010AReduce consumptionOvercome the disadvantage of not being able to cover the entire pipe circumferenceLiquid surface applicatorsLiquid spraying apparatusEngineeringMoisture

The invention discloses a natural gas pipe corrosion inhibitor coating device, and particularly relates to a device for coating a corrosion inhibitor on a high-sulphur moisture collection and delivery pipe. The natural gas pipe corrosion inhibitor coating device comprises an atomizing head and a tubular body, a main atomizing channel, a secondary atomizing channel and atomizing nozzles of the secondary atomizing channel are arranged in the atomizing head, and the secondary atomizing channel is communicated with the main atomizing channel; a front cover plate and a rear cover plate are respectively arranged at the front end and the rear end of the tubular body, a center hole which is communicated with the main atomizing channel is arranged on the front cover plate, a gas leading through hole is arranged on the upper portion of the rear cover plate, a partition board is disposed in the tubular body, an air vent is arranged at the top of the partition board, the tubular body is divided into a liquid storage chamber and a pre-mixing chamber, a corrosion inhibitor filling opening is arranged on the upper side of the liquid storage chamber, and an ultrasonic atomizing chamber is arranged on the lower side of the liquid storage chamber; a guiding disc and a sealing cup are mounted between the atomizing head and the front cover plate of the tubular body and are connected via bolts; and another guiding disc and another sealing cup are mounted on the rear cover plate via bolts. The corrosion inhibitor is sprayed to the periphery of the pipe via the multiple atomizing nozzles, the shortcoming that a traditional coating device cannot coat the total periphery of a pipe is overcome, consumption of the corrosion inhibitor is reduced, and coating cost is lowered.

Owner:CHINA PETROCHEMICAL CORP +1

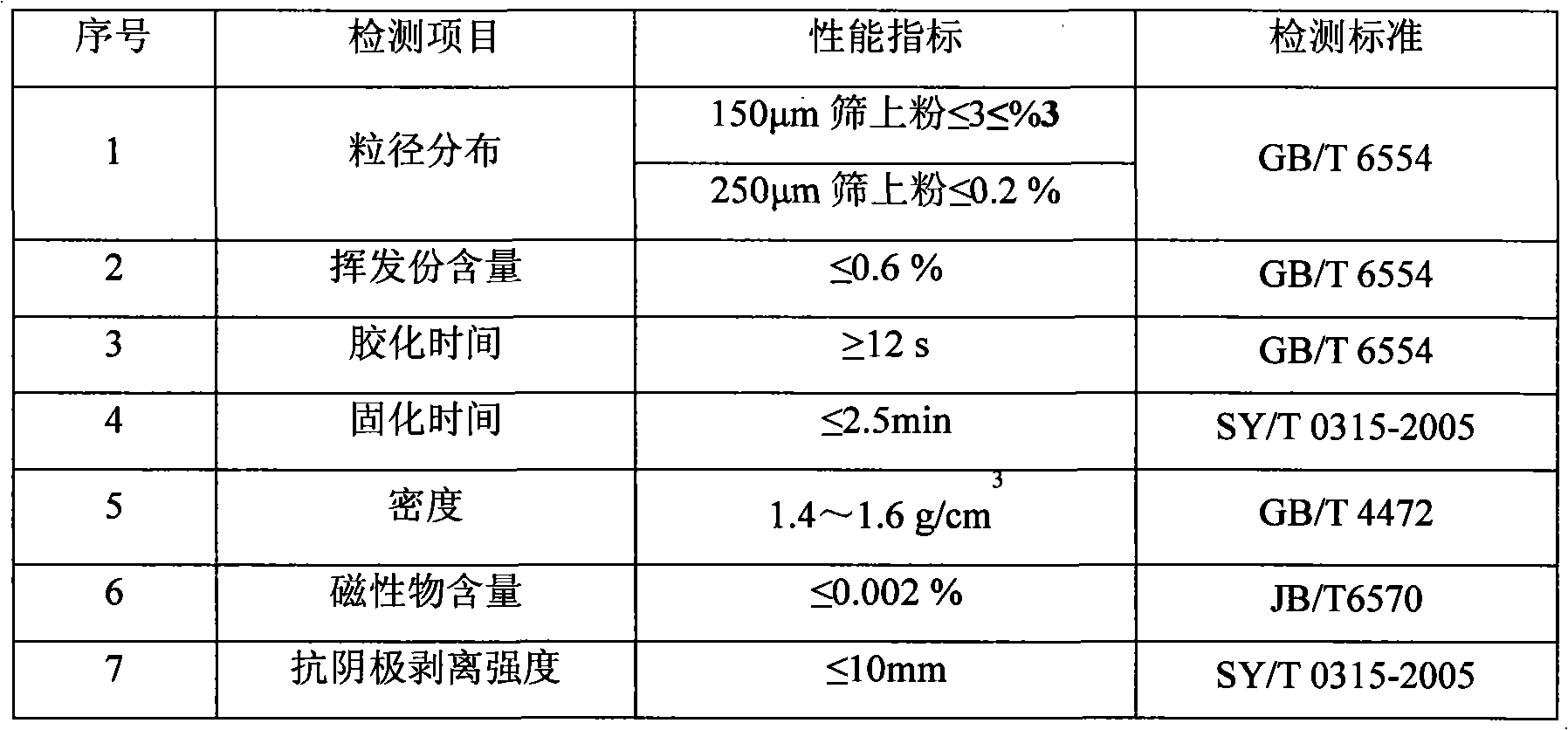

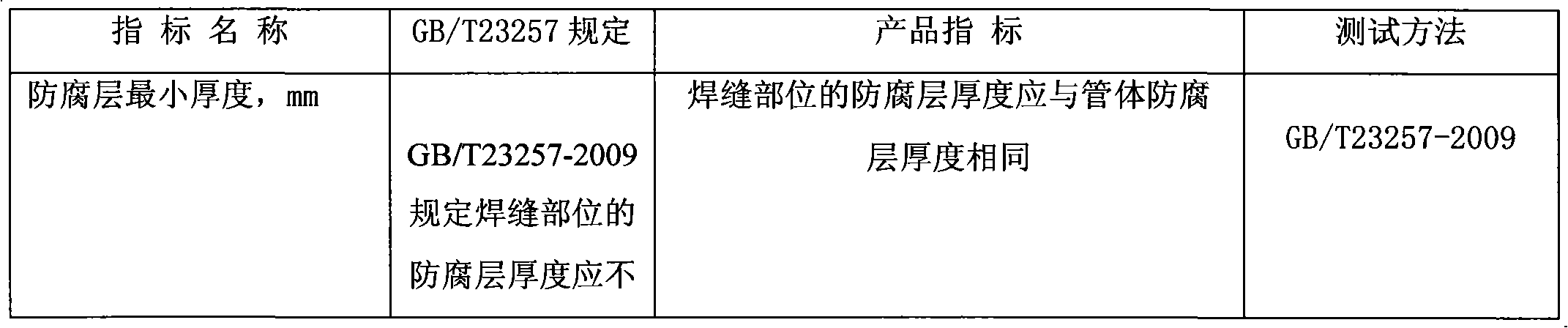

Composite polyethylene (PE) powder thermally sprayed anticorrosion coating for petroleum and natural gas pipe

InactiveCN102052543AImprove corrosion resistanceImprove cathodic protection resistanceCorrosion preventionAnti-corrosive paintsPetroleumPolymer gel

The invention provides a PE powder thermally sprayed anticorrosion coating for a petroleum and natural gas pipe, which is a blended interface anticorrosion coating formed on the inner or outer wall of the petroleum and natural gas pipe by thermally spraying low-temperature setting epoxy powder (PBE), holt melt polymer gel (AD) and modified polyethylene (PE) / propenepolymer (PP) powder on the inner or outer wall of the petroleum and natural gas pipe in turn. The anticorrosion coating has an ultrahigh stripping strength for the petroleum and natural gas pipe, overcomes the AD / PE intra-layer separation of the conventional 3PE anticorrosion technology, and improves the anticorrosion performance of the pipe; and the anticorrosion layer eliminates a cathode shielding area, improves cathode protection resistance, reduces drawbacks of 'edge turning' at a weld joint part and effectively reduces coating cost due to a one-time spraying process.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

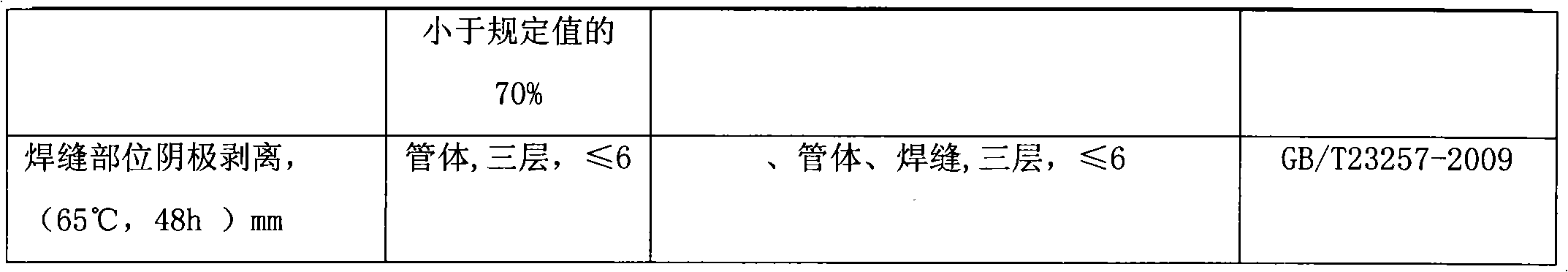

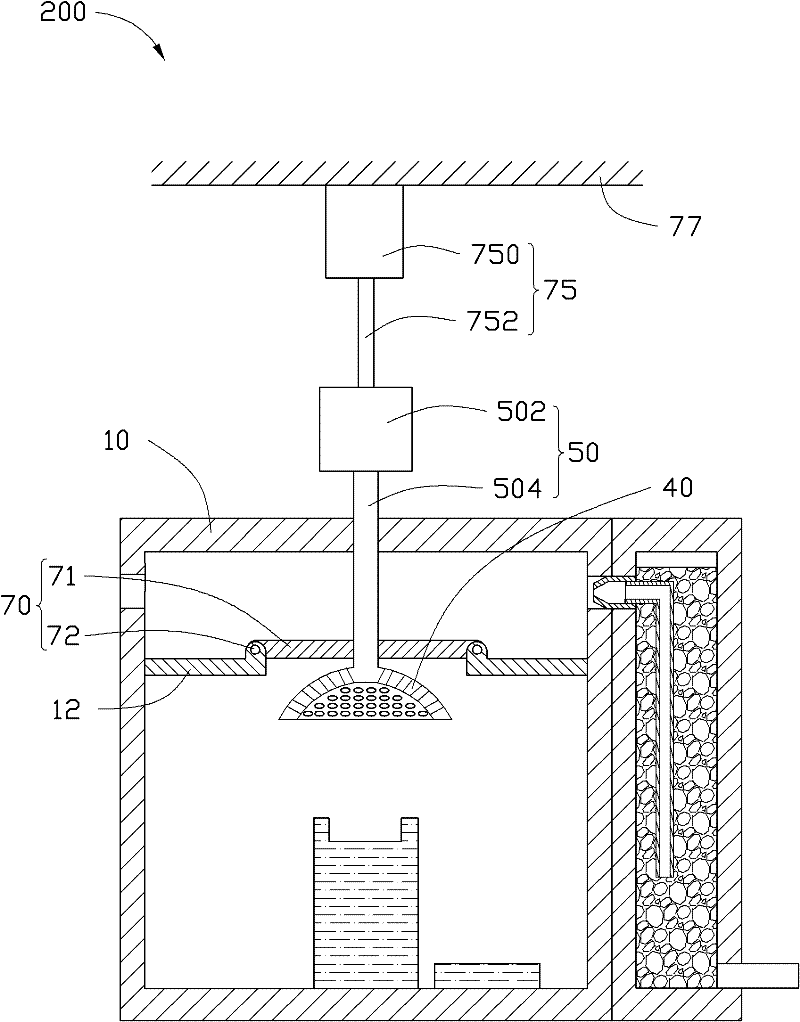

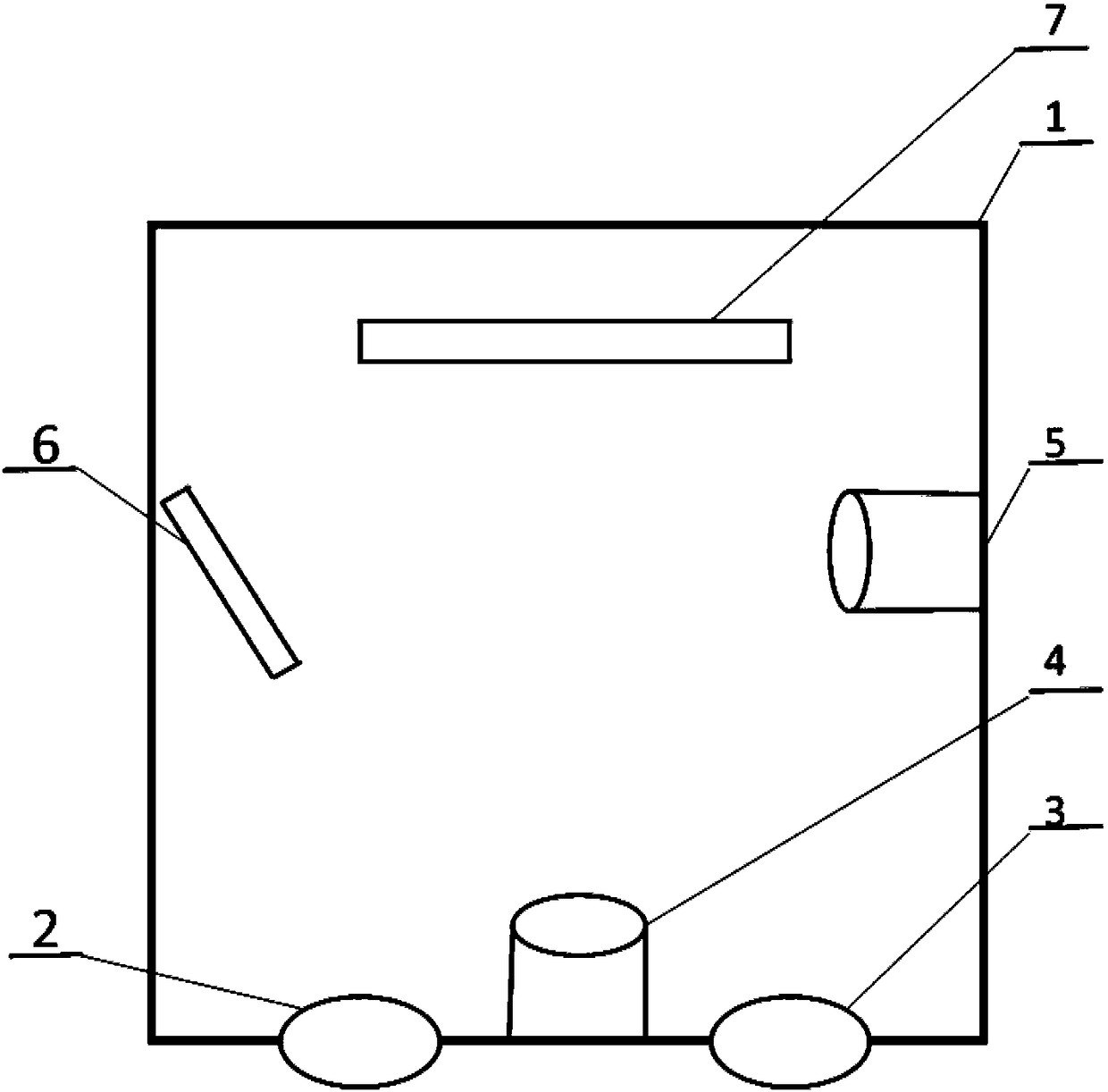

Coating system

InactiveCN102234762AOmit shipping actionAvoid pollutionLiquid surface applicatorsVacuum evaporation coatingCoating systemEngineering

The invention discloses a coating system, which comprises a cavity, a coating umbrella frame and a rotation driving component, wherein the coating umbrella frame is used for accommodating a plurality of substrates to be coated; the rotation driving component is connected to the coating umbrella frame, and is used for driving the coating umbrella frame to rotate in the cavity; and the cavity comprises a clapboard which separates the cavity into a coating cavity and a paint spraying cavity which are separated from each other. The coating system also comprises a lifting driving component, a solvent storage chamber and an injection device, wherein the lifting driving component drives the rotation driving component to lift, so that the coating umbrella frame lifts in the coating cavity and the paint spraying cavity; the solvent storage chamber is used for storing a coating solvent, and is communicated with the paint spraying cavity; and the injection device is arranged in the solvent storage chamber and is connected to the paint spraying cavity, so that the coating solvent in the solvent storage chamber is injected to the substrates to be coated. The coating system can evaporate the substrates to be coated and also can inject a coating to the substrates to be coated.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

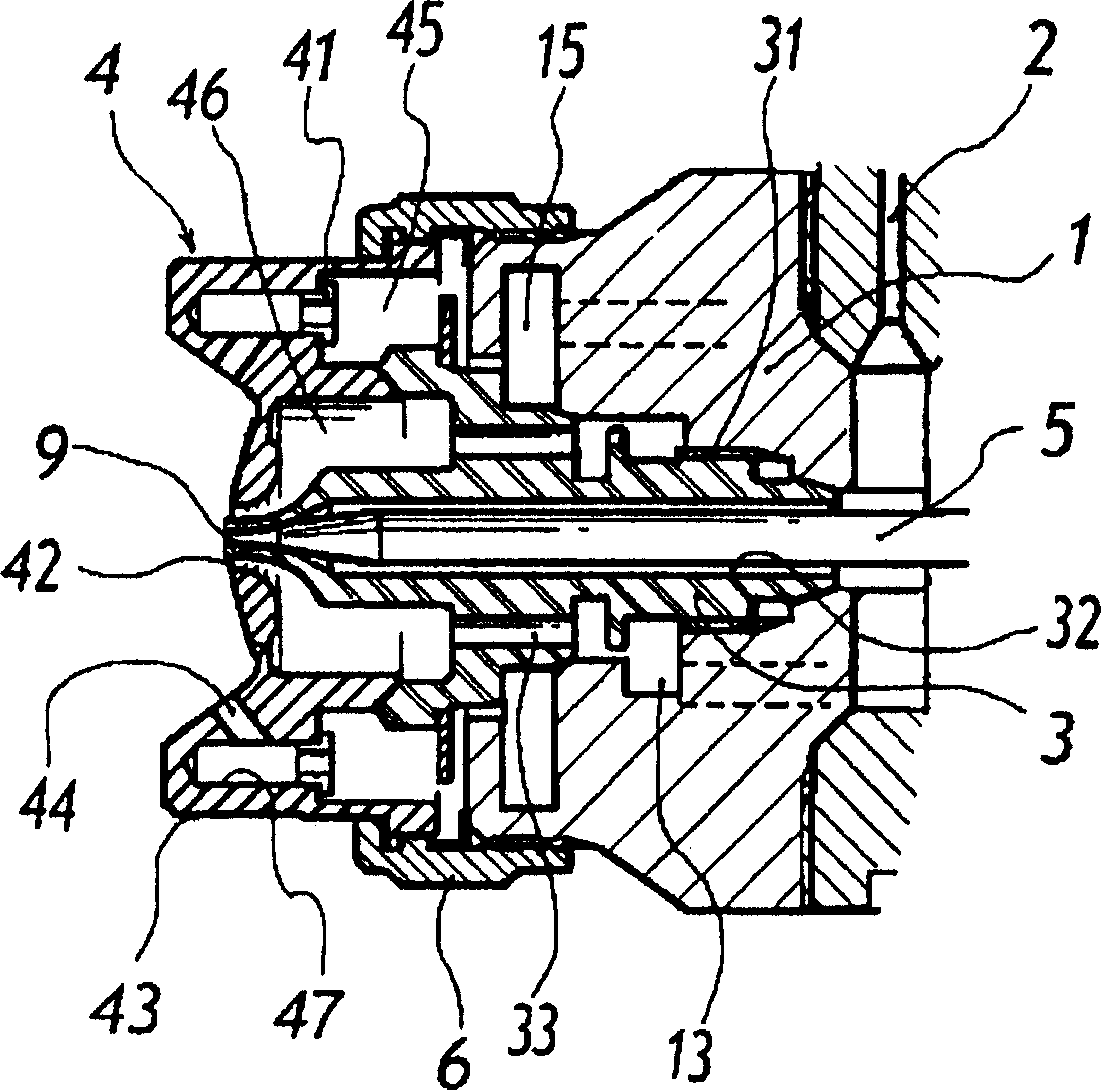

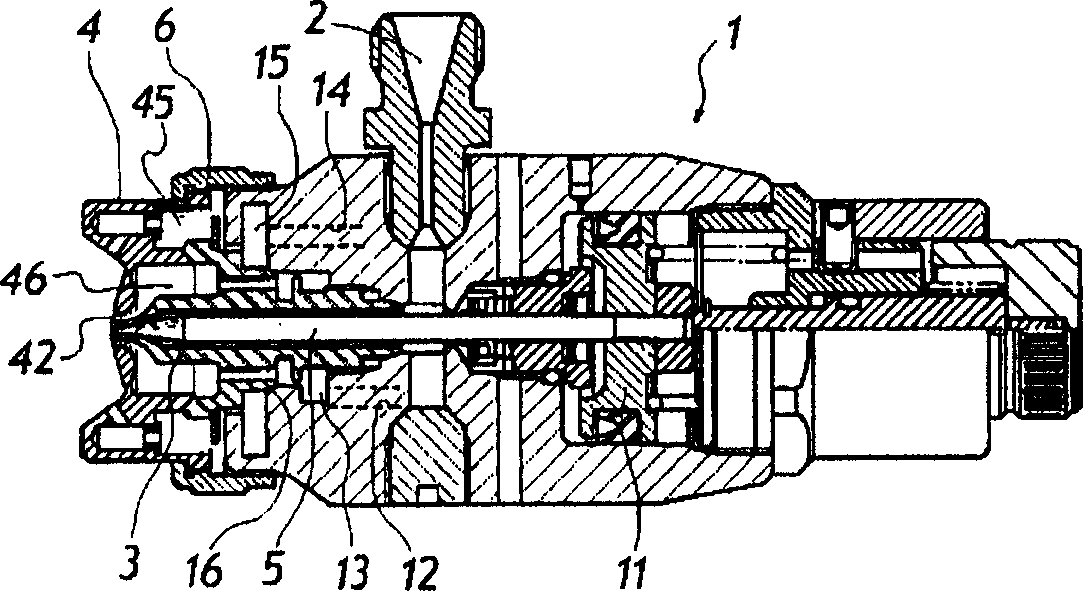

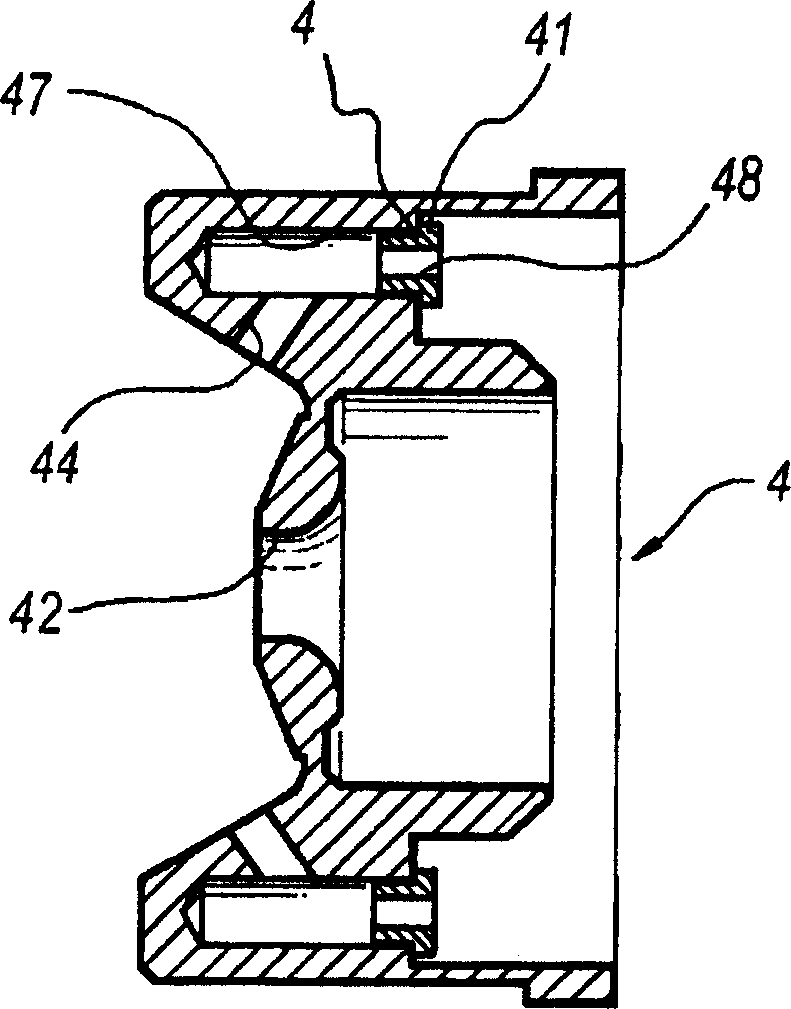

Air atomization air cover for spray gun

ActiveCN1899704AIncrease air velocityReduce speed lossSpray nozzlesLiquid spraying apparatusCoatingCompressed air

The invention provides an atomization apparatus capable of lessening the unevenness of the entire patterned region at the time of spraying and accordingly making the coating thickness distribution uniform in the coated face and easily forming a smooth coating free from disorder of the coating face in an air atomizing spray gun. The air cap is to be used in an air spray gun for atomization with compressed air and has a center air port composing a circular air port in the outer peripheral part of a center coating material jetting port, a pair of corner parts formed symmetrically in the outside of the center air port, and side air ports for forming spraying patterns by jetting air through the corner parts. In the air cap, the surface area of inlet parts of vertical holes formed in the respective corner parts and communicating with the side air ports is made smaller than the surface area of the side air ports. To make the inlet surface area narrower than the vertical hole surface area by narrowing the flow channel surface area, a bush is fitted or caulking is carried out in the circumference of the vertical hole inlets.

Owner:ANEST IWATA CORP

Adhesive formulation and creping methods using same

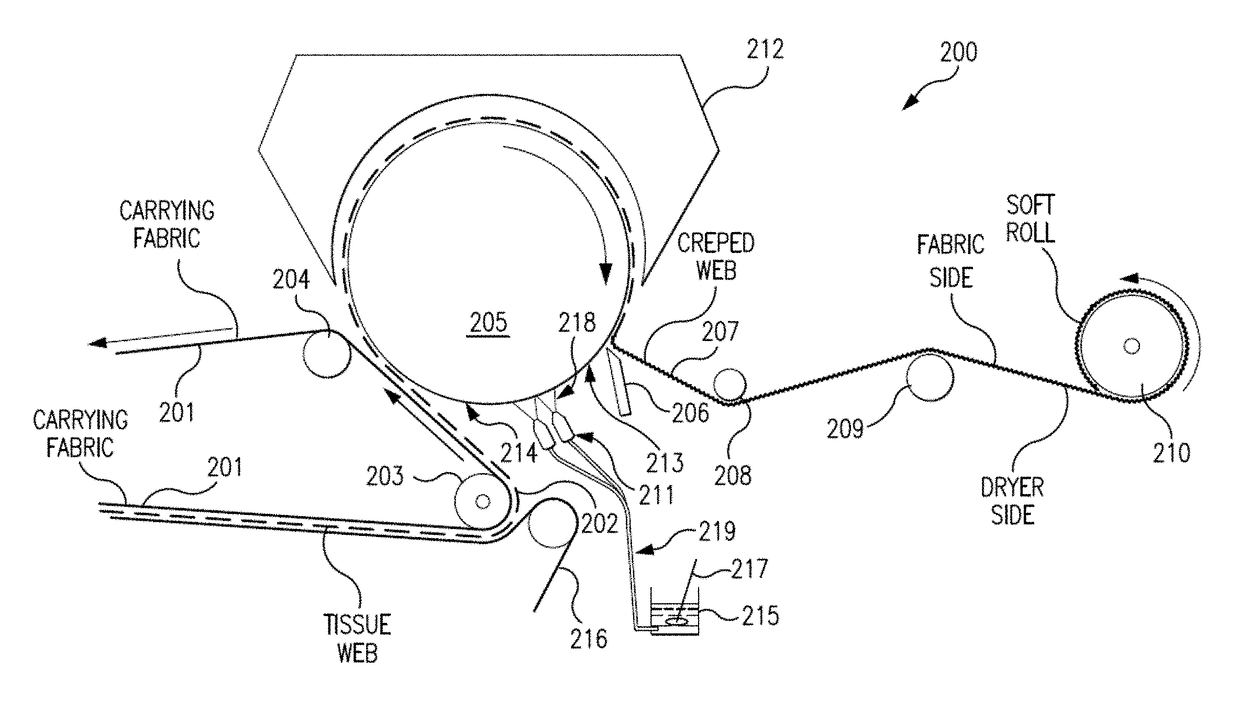

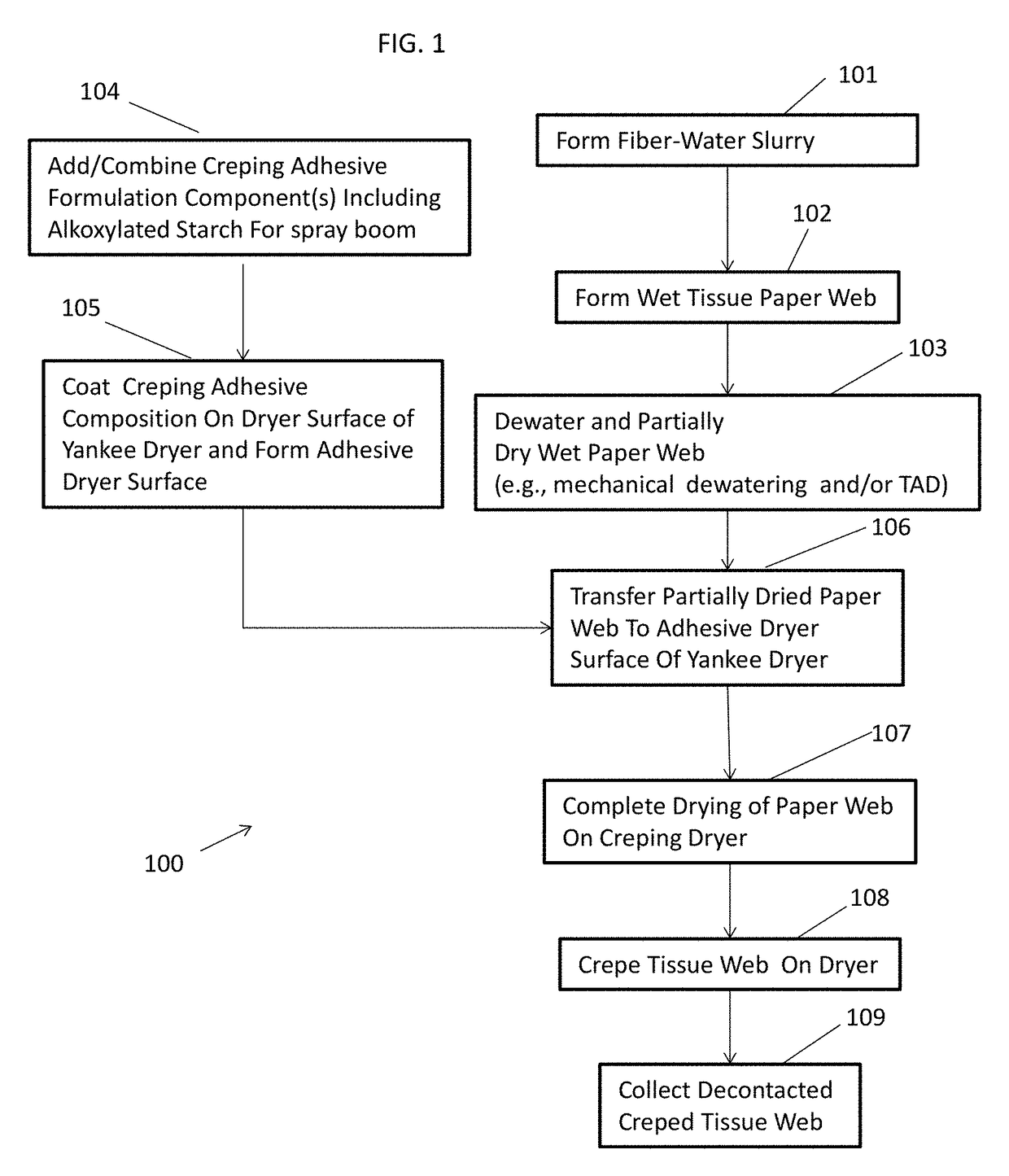

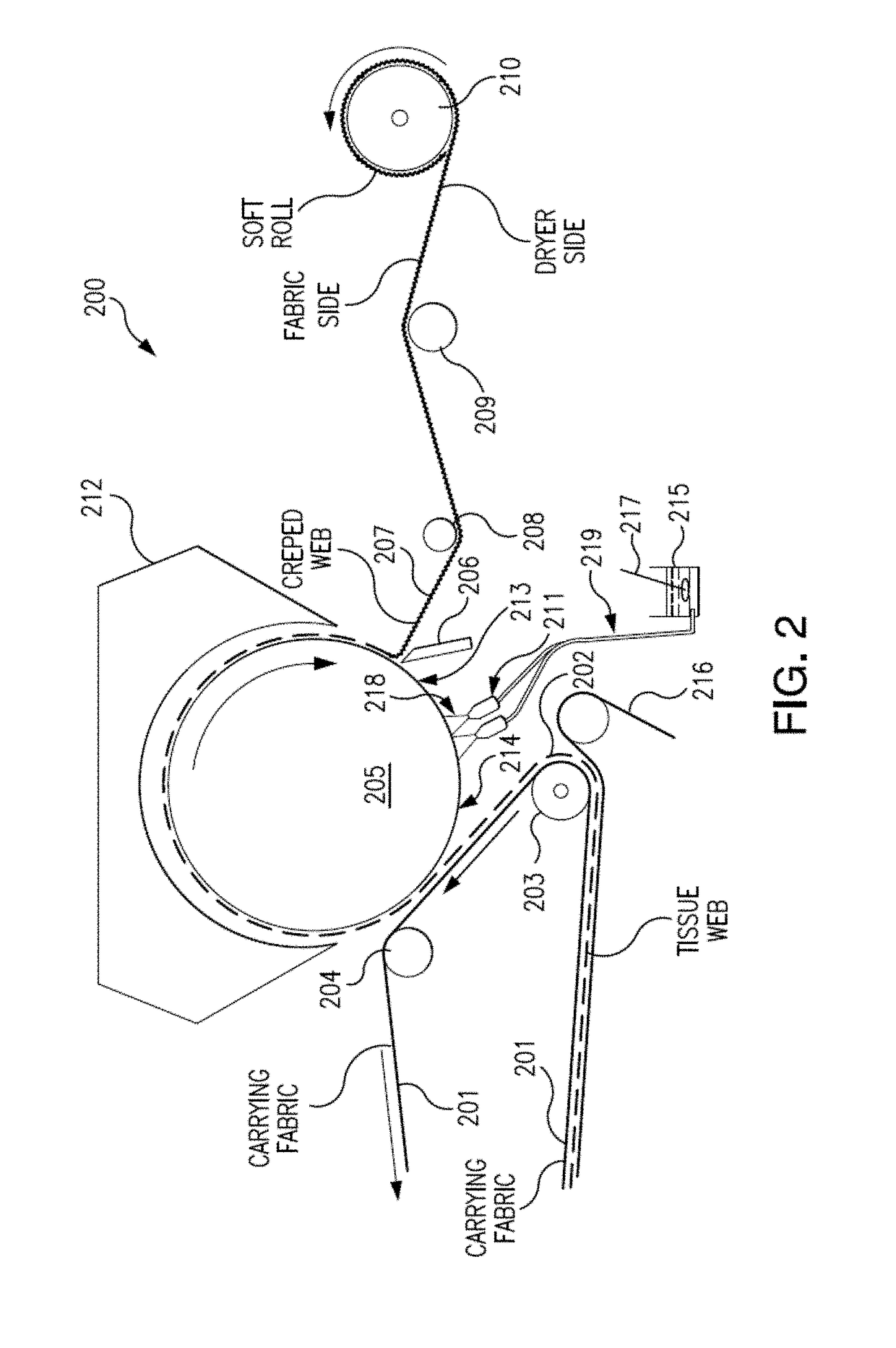

ActiveUS9976259B2High solid contentHigh temperature resistanceNon-macromolecular adhesive additivesCreping adhesives additionMedicineCoating

Owner:BUCKMAN LAB INT INC

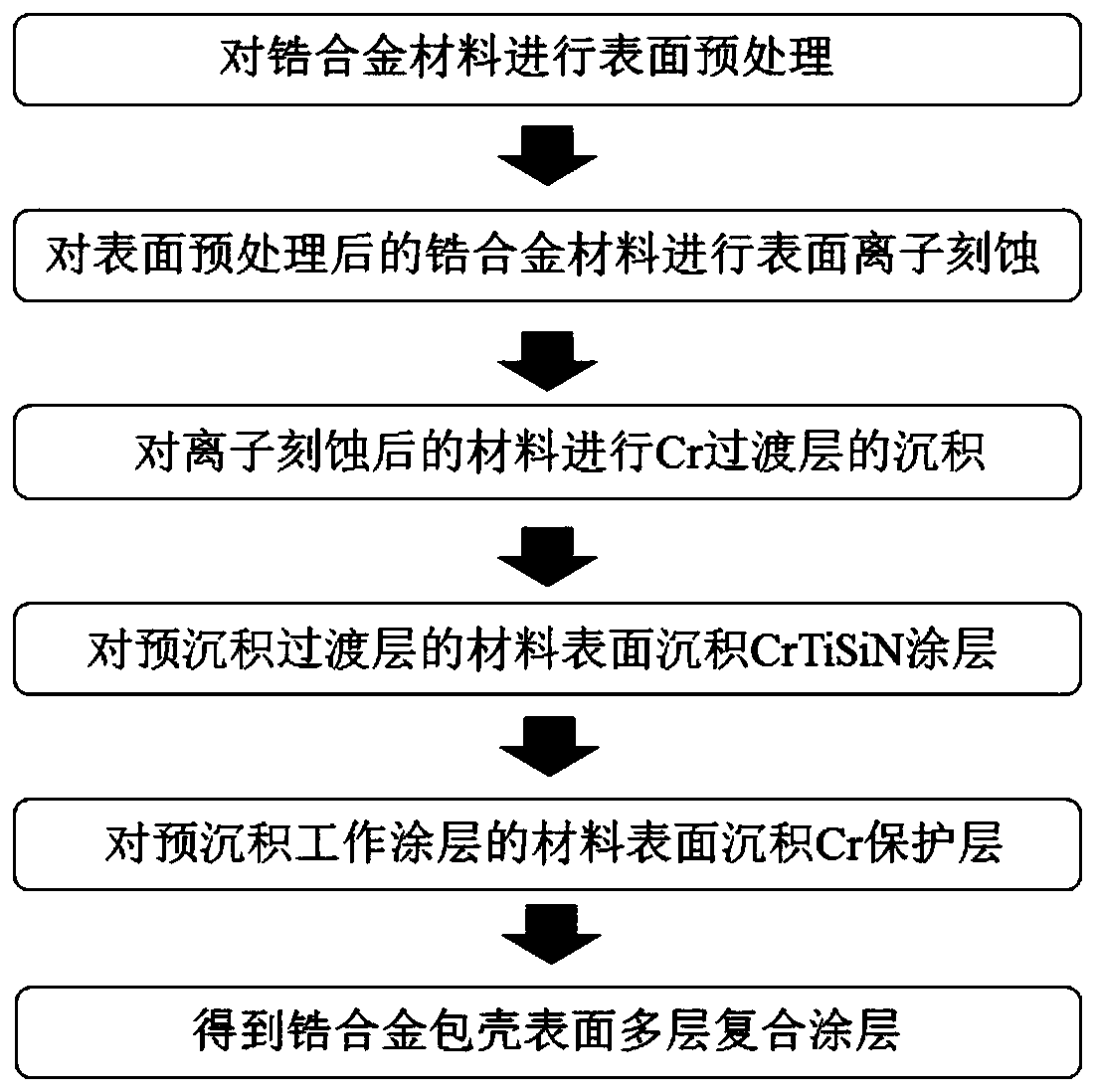

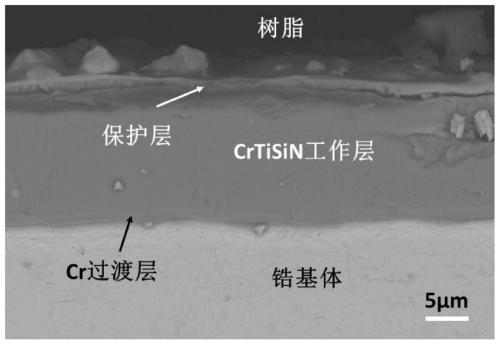

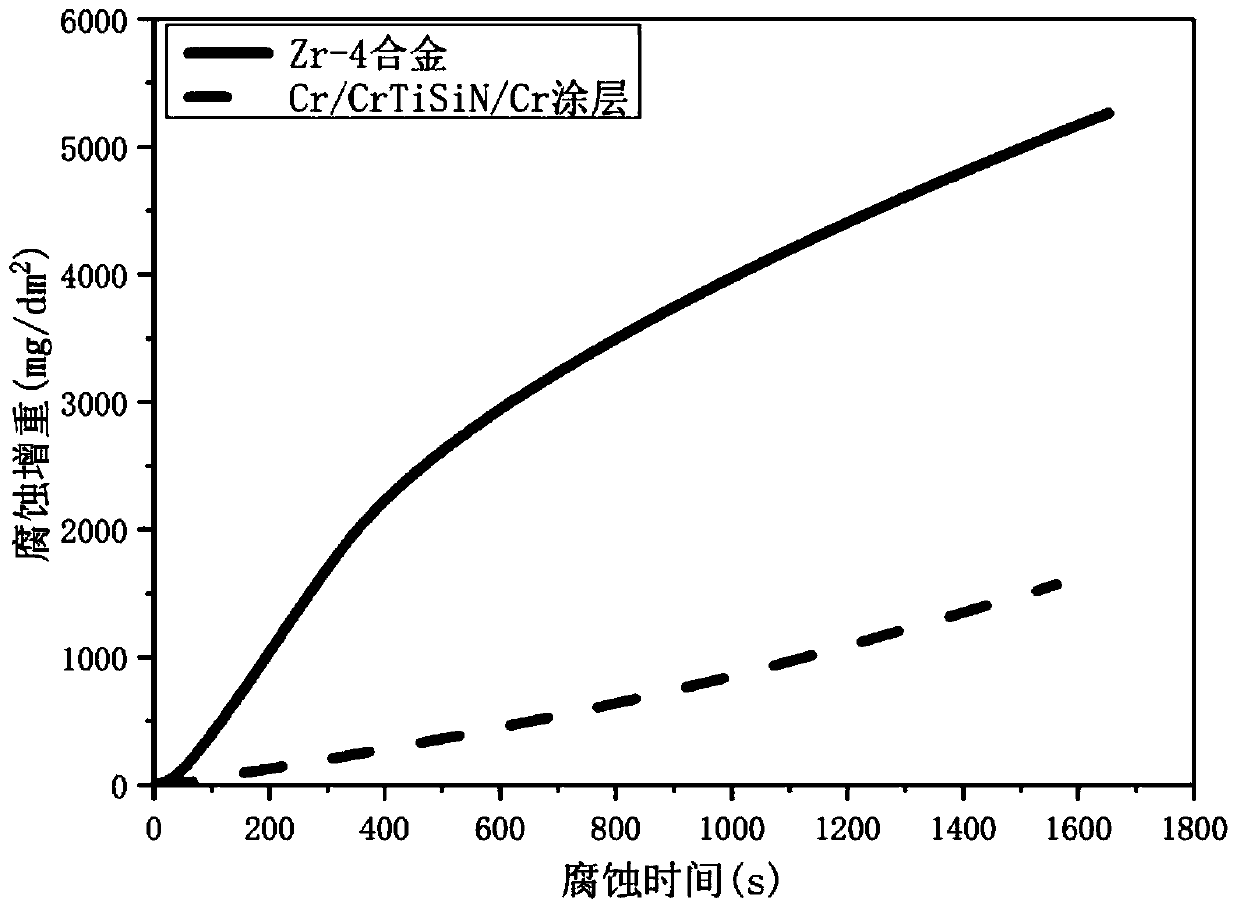

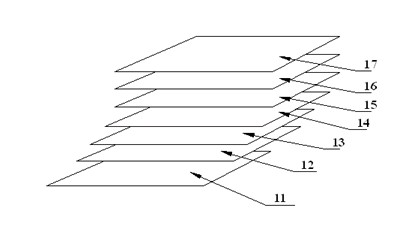

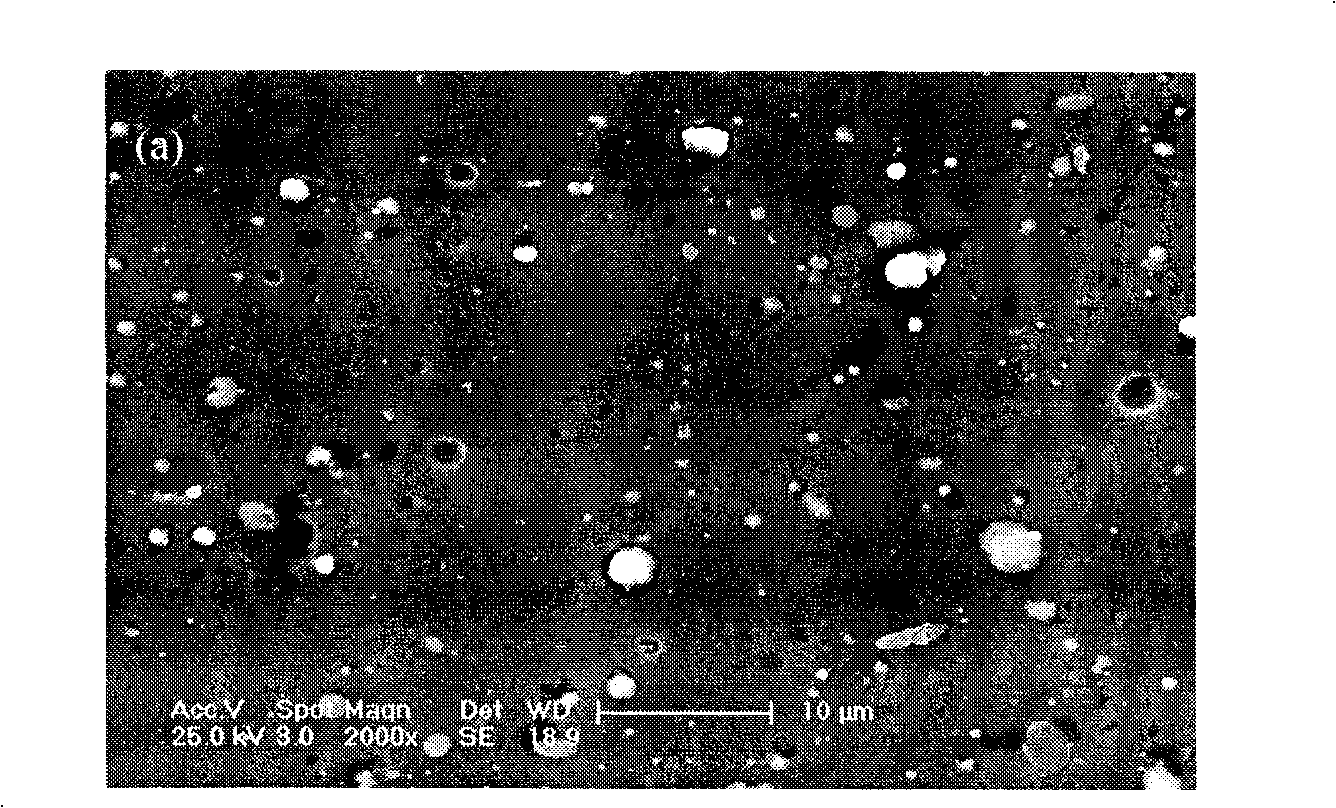

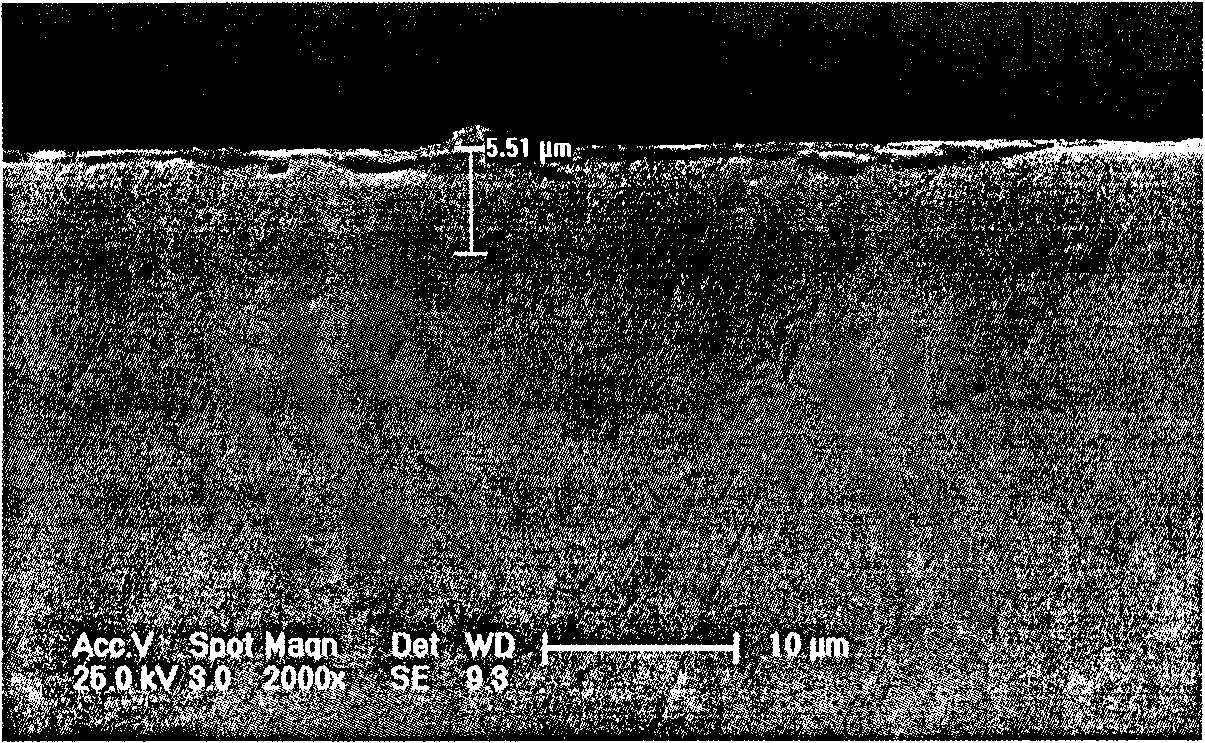

Multilayer composite coating of zirconium alloy cladding surface, and preparation method thereof

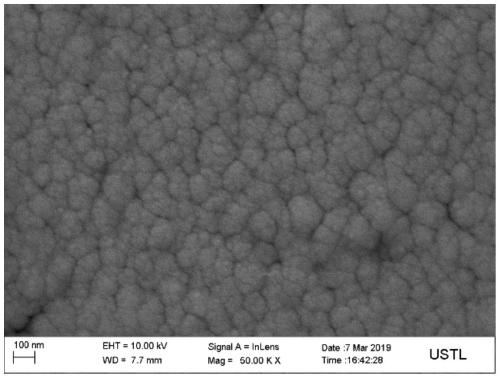

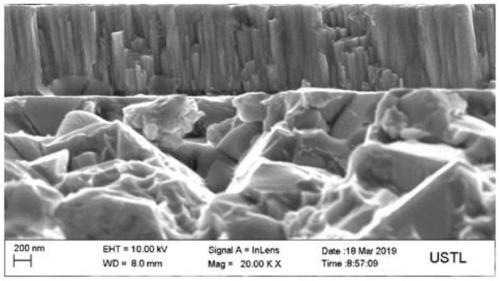

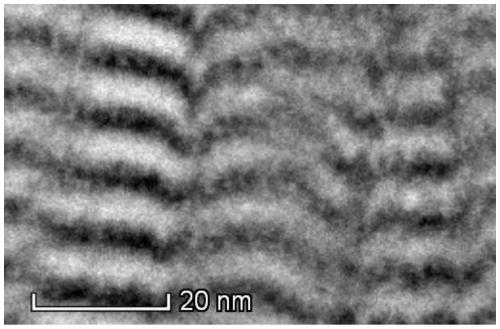

ActiveCN111172503AImprove economyUniform thicknessVacuum evaporation coatingSputtering coatingFrettingNitrogen gas

The invention discloses a multilayer composite coating of a zirconium alloy cladding surface, and a preparation method thereof. According to the method, a multi-arc ion plating technology is adopted,and zirconium alloy materials are used as a base; high purity nitrogen is used as reaction gas, and high purity argon is used as protective gas; the vacuum degree, arc current, temperature, depositiontime, gas flow and other parameters of a vacuum chamber are regulated; and a three-layer composite coating, using Cr as a transition layer, a CrTiSiN as a working coating and Cr as a protective coating, are formed on the surface of the zirconium alloy materials through deposition. The coating is uniform and compact, and the binding force between the coating and the zirconium alloy base is strong;the cladding integrity is ensured, and generation of hydrogen is inhibited; and hydrogen explosion is avoided. The coating is extremely high in hardness, and the friction resistance of zirconium alloy can be improved effectively; the a cladding pipe is prevented from being failed due to fretting wear, and the safety and accident tolerance of a reactor are improved.

Owner:XI AN JIAOTONG UNIV

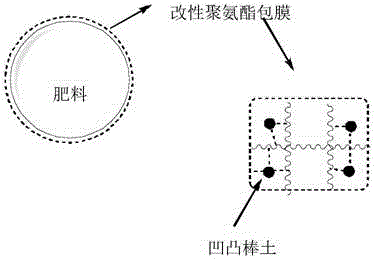

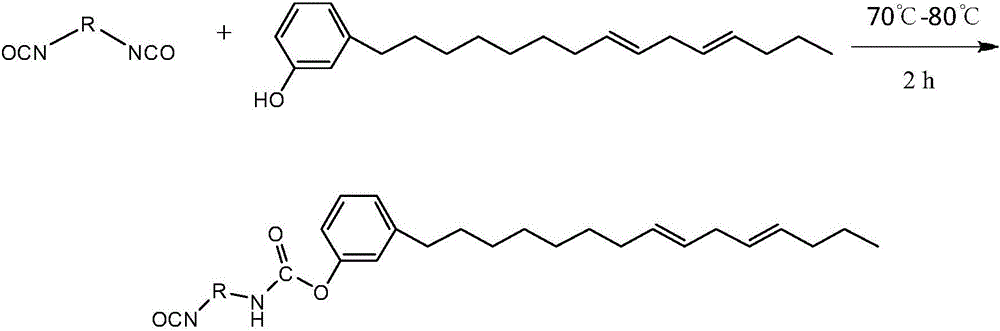

Composite modified polyurethane coating slurry, controlled release fertilizer and preparation method of controlled release fertilizer

ActiveCN106800472AWide variety of sourcesGood adhesionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersControlled releaseAlcohol

The invention discloses composite modified polyurethane coating slurry, a controlled release fertilizer and a preparation method of the controlled release fertilizer. The preparation method of the polyurethane coating controlled release fertilizer comprises the following steps: (1) vegetable oil polyhydric alcohol and attapulgite are uniformly mixed at a preset ratio to obtain an A component; (2) polymethylene polyphenyl isocyanate and cardanol with a mole ratio of 10-15% react for 1-3h at 70-80 DEG C to obtain a B component; (3) the A component and the B component are uniformly mixed in proportion to obtain vegetable oil based attapulgite hybridized composite modified polyurethane coating slurry; (4) a to-be-coated granular fertilizer is preheated; (5) the composite modified polyurethane coating slurry is sprayed on the surface of the preheated granular fertilizer; (6) the vegetable oil based polyurethane coating slurry is repeatedly sprayed for 3-6 times after the vegetable oil based polyurethane coating slurry is solidified to obtain the vegetable oil based attapulgite hybridized composite modified polyurethane coating controlled release fertilizer.

Owner:上海永通生态工程股份有限公司

Dampproof mildew-resistant paint for bamboo and wood

InactiveCN1569997AGood water and moisture resistanceGood film forming performanceRosin coatingsMINERAL WAXParaffin wax

The invention discloses a dampproof mildew-resistant paint for bamboo and wood, which comprises (by weight portion) common resin 50-60 parts, mineral wax 35-45 parts, China wood oil 5-15 parts, and 0.1-0.25 part of curing agent of copper oxide, lead monoxide can also be added.

Owner:刘傲雄

Composition for preparing monolayer antiseptic polyethylene powder coating and method for preparing composition

InactiveCN102676018AImprove mechanical propertiesImprove adhesionAnti-corrosive paintsPowdery paintsLinear low-density polyethylenePolymer science

A composition for preparing monolayer antiseptic polyethylene powder coating is made of, by weight, 25-60 parts of melt grafting copolymer of linear low-density polyethylene and functional monomer, 25-60 parts of high-density polyethylene, 5-25 parts of ethylene and vinyl acetate copolymer, 1-5 parts of carbon black, 0.05-0.3 part of antioxidant and 0.05-0.3 part of light stabilizer, wherein the functional monomer can be maleic anhydride, acrylic acid, maleic acid or methyl maleic acid. The components are well mixed and then fed into a double-screw extruder for melt extrusion at the temperature ranging from 190 DEG C to 230 DEG C to obtain the composition for preparing the monolayer antiseptic polyethylene powder coating. The composition for preparing the monolayer antiseptic polyethylene powder coating has fine mechanical property and highly adhesive to metal, the tensile strength ranges from 15MPa to 28MPa, and the peel strength ranges from 6N / mm to 15N / mm. The invention further discloses a method for preparing the composition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultraviolet cured gloss oil for paper

The invention provides ultraviolet cured gloss oil for paper and belongs to the field of the gloss oil for paper. The gloss oil comprises a prepolymer, an active thinning agent, a photoinitiator, a chain transfer agent and a polymerization inhibitor, the contents of the components by weight percentage are: the prepolymer accounts for 20-80%, the active thinning agent accounts for 10-40%, the photoinitiator accounts for 1-10%, and the chain transfer agent and the polymerization inhibitor account for 0.5-5%. Through the selection of a formulation monomer, the gloss oil improves the film-forming speed of resins and a uniform film layer is formed after the gloss oil is coated and is not absorbed by a fibrous layer immediately. The gloss oil has low rate of shrinkage and cannot cause the deformation retraction of the paper after film formation so that the stiffness of the paper is maintained well.

Owner:BEIJING COMENS NEW MATERIALS

Comprehensive depositing and coating device and comprehensive coating method

ActiveCN108342699AImprove performanceAvoid multiple drawsVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention relates to a comprehensive depositing and coating device and a comprehensive coating method integrating electron beam evaporation, ion beam assistance and ion beam sputtering. The devicecomprises a comprehensive depositing system formed by a left electronic gun crucible, a right electronic gun crucible, an ion source auxiliary source, an ion source main source, a sputtering target material and a fixture plate. According to the comprehensive depositing and coating device and the comprehensive coating method provided by the invention, the advantages of an electron beam evaporationand deposition technology, an ion beam assistance deposition technology and an ion beam sputtering deposition technology are combined, so that the quality of a coating can be improved, the coating efficiency can be improved, and the coating cost is reduced.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

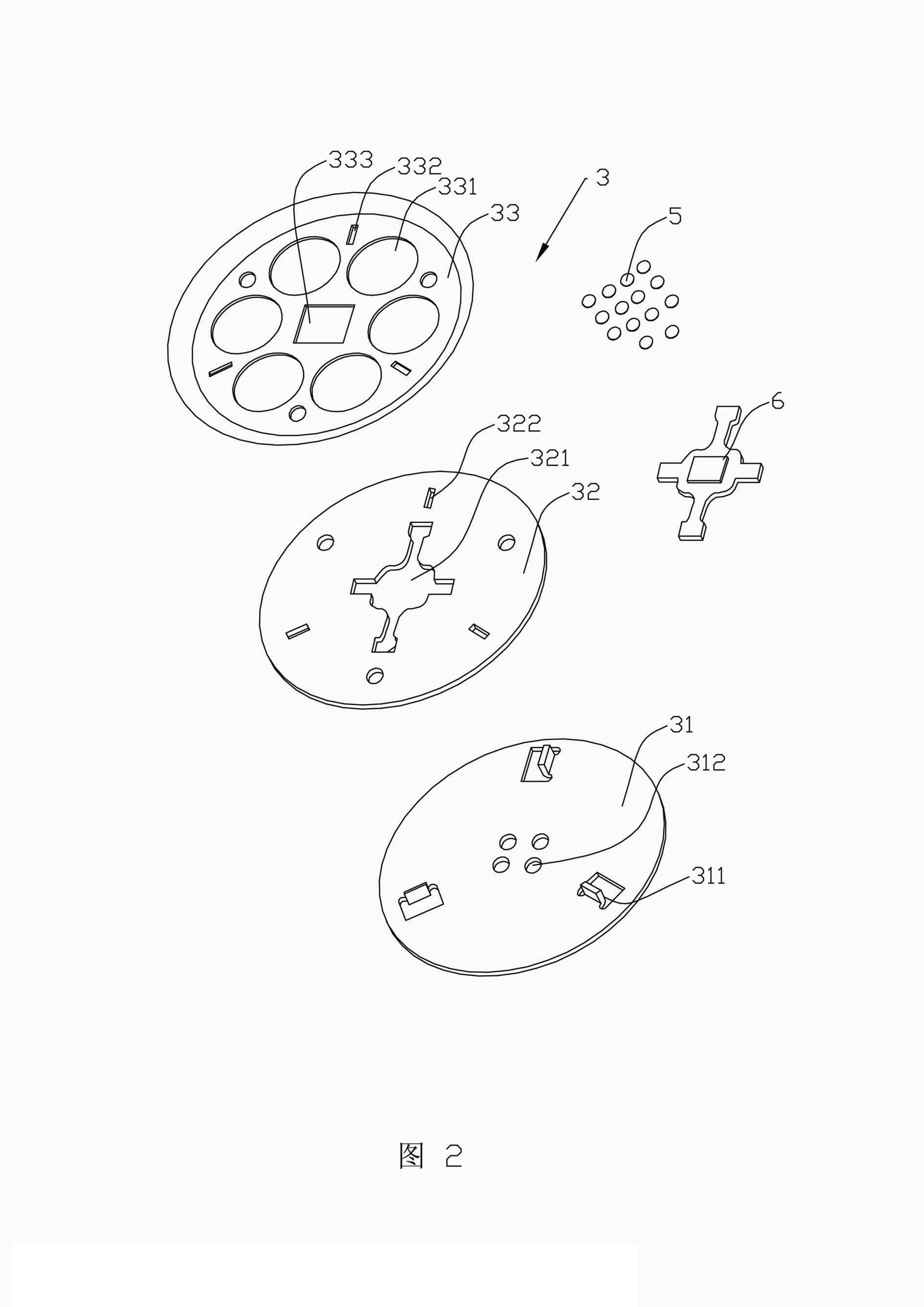

Street lamp adopting LED light source

InactiveCN102109134AGuaranteed flatnessFixed flatPoint-like light sourceLighting heating/cooling arrangementsEngineeringControl circuit

A street lamp adopting an LED light source comprises a lamp housing, a reflecting shade, a light-emitting port, a light-transmittable shade and an LED light source module, wherein the reflecting shade is arranged in the lamp housing; the light-emitting port is arranged on the lamp housing; the light-transmittable shade is arranged at the light-emitting port; the LED light source module is fixed in the reflecting shade, and comprises a first stamping sheet metal, a second stamping sheet metal, a third stamping sheet metal, a plurality of LED chips and a control circuit board; the LED chips are arranged on the second stamping sheet metal; the control circuit board is connected with the LED chips; the second stamping sheet metal is provided with a mounting port used for fixing the control circuit board; a plurality of openings for limiting an area with point fluorescent powder glue are formed on the third stamping sheet metal; the LED chips are stuck on the second stamping sheet metal in positions corresponding to the openings; and the first stamping sheet metal, the second stamping sheet metal and the third stamping sheet metal are fixed with one another through a connecting mechanism. The street lamp adopting the LED light source has the advantages of good heat dissipation performance, low cost and long service life.

Owner:厦门宝晨照明科技有限公司

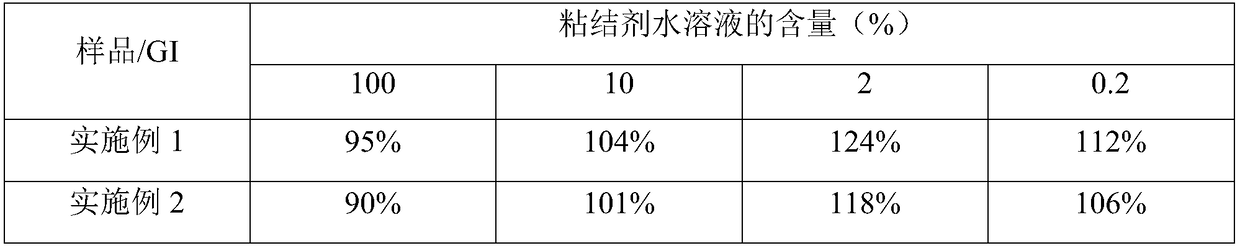

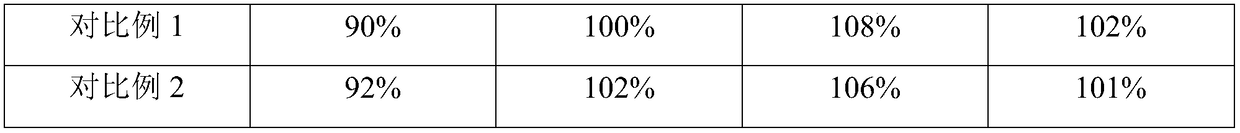

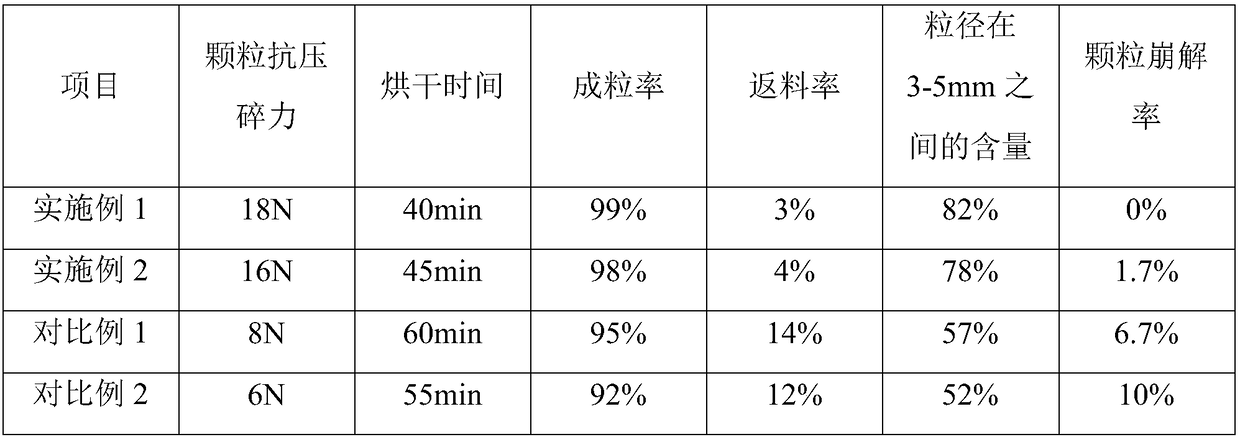

Functional sustained or controlled release fertilizer core based on bio-based adhesive and preparation method thereof

ActiveCN108516899AReduce dependencePromote degradationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCross-linkControl release

The invention discloses a functional sustained or controlled release fertilizer core based on a bio-based adhesive and a preparation method thereof. The bio-based adhesive is prepared through the steps that a biomass material is subjected to a liquidation reaction, bio-based polyalcohol is prepared, and the bio-based polyalcohol, a chain extender, a cross-linking agent and a curing agent are pre-mixed. The bio-based adhesive is prepared from regenerative biomass resources, dependence on petrification-based raw materials is reduced, good degradability is achieved, and meanwhile the bio-based adhesive is high in adhesive performance, good in heat resistance, high in water resistance, easy to spray and easy to dry. The functional sustained or controlled release fertilizer core prepared basedon the bio-based adhesive is high in granulation rate, large in particle strength, excellent in moisture absorption resistance, high in impact resistance, good in roundness, good in storage and transport performance and especially suitable for a coated sustained or controlled release fertilizer production process, the material fluidifying performance can be improved, the specific area of the fertilizer core is reduced, and the coating cost of controlled-release fertilizer is greatly reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

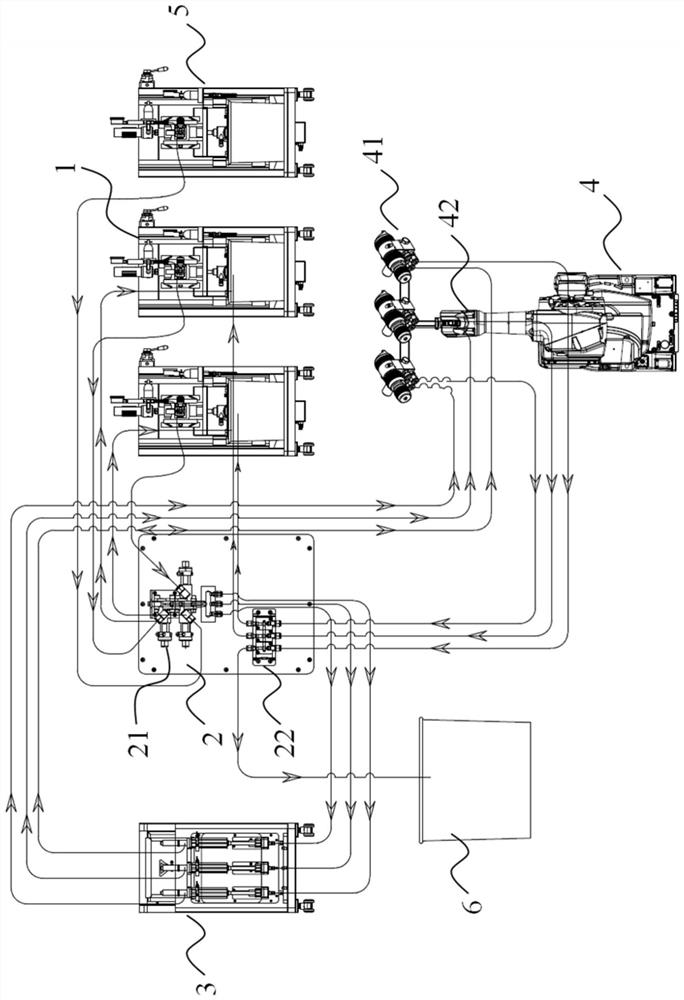

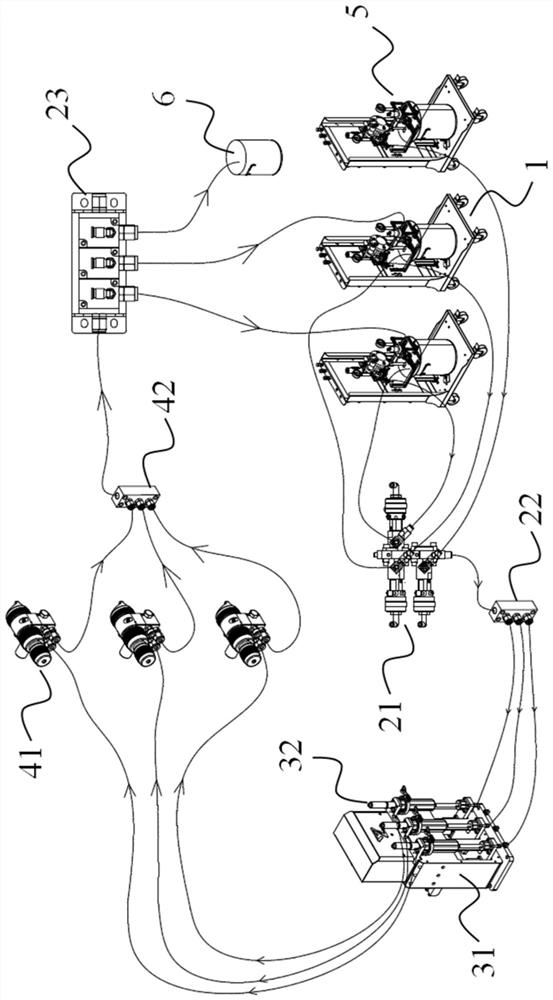

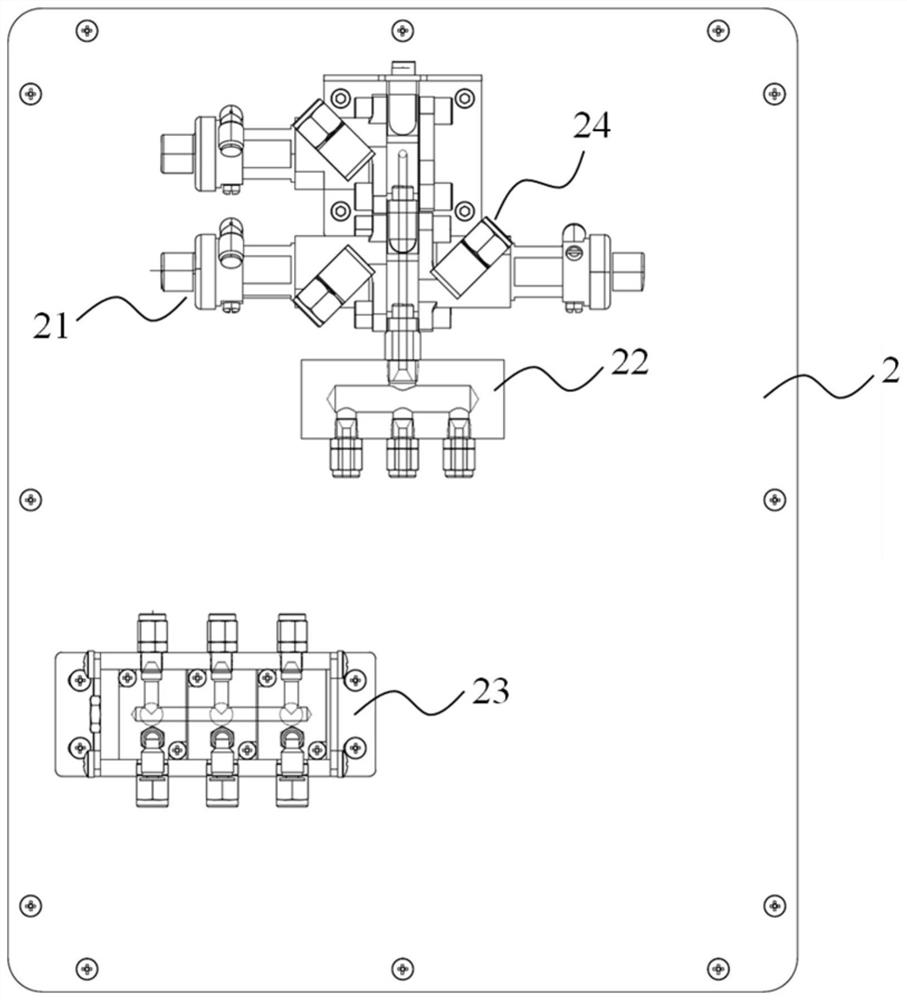

Fluid pipeline paint supply system and method capable of automatically changing color, metering and spraying

PendingCN111921734AAvoid defectsReduce coating costLiquid spraying apparatusChange colorControl engineering

The invention relates to a fluid pipeline paint supply system capable of automatically changing color, metering and spraying and a corresponding paint supply method. The fluid pipeline paint supply system comprises multiple paint supply systems, a fluid disc assembly, a metering cylinder module, a spraying robot module, a feed pipe, and a return pipe; the fluid disc assembly comprises a color change valve, a color change valve manifold, and a fluid valve set manifold; the metering cylinder module comprises a metering cylinder body and multiple plunger pumps; the metering cylinder body synchronously drives the multiple plunger pumps to complete feed and discharge actions; the spraying robot module comprises multiple spray guns and a spray gun manifold; and multiple paint supply systems, thecolor change valve, the color change valve manifold, multiple plunger pumps, multiple spray guns, the spray gun manifold and multiple paint supply systems are sequentially connected by means of the feed pipe and the return pipe. The whole flow channel and related valve sets are redesigned and arranged to form closed-loop spraying, so that the paint cost is lowered, the spraying quality is improved, and the defect of spraying breakage caused by air generated in a pipeline due to higher speed during plunging is overcome.

Owner:SHENZHEN YUANTONG ROBOT AUTOMATION CO LTD

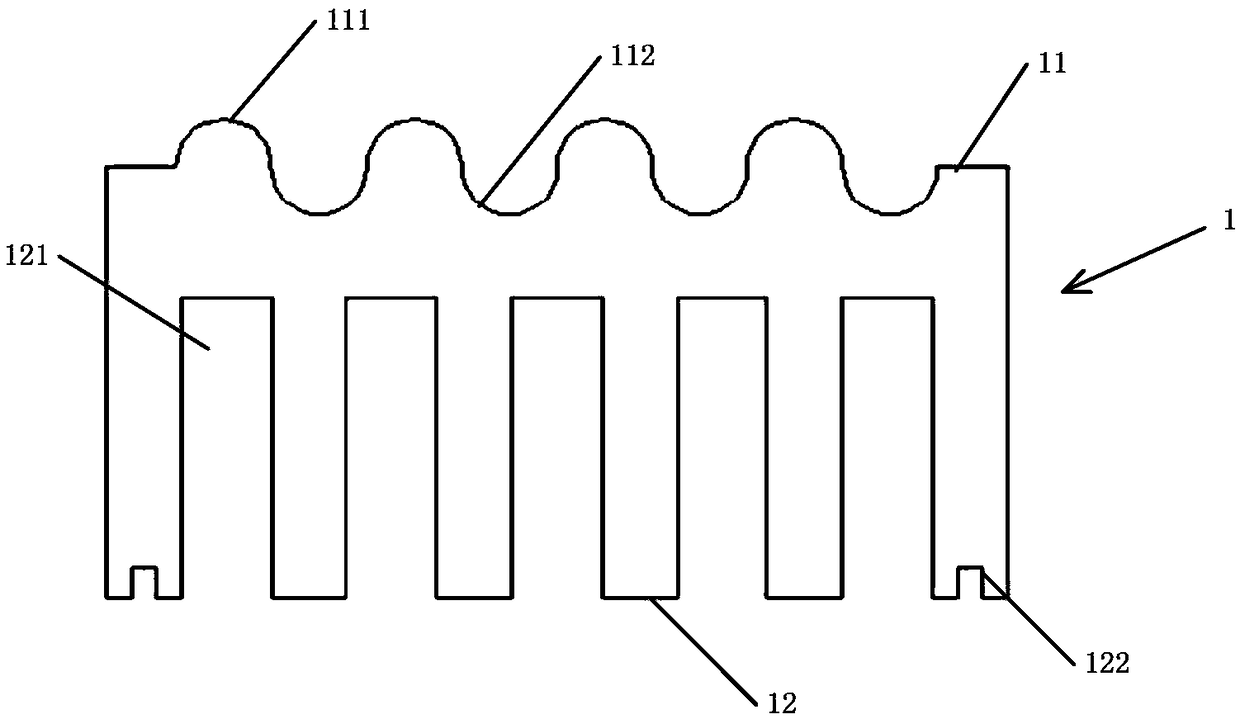

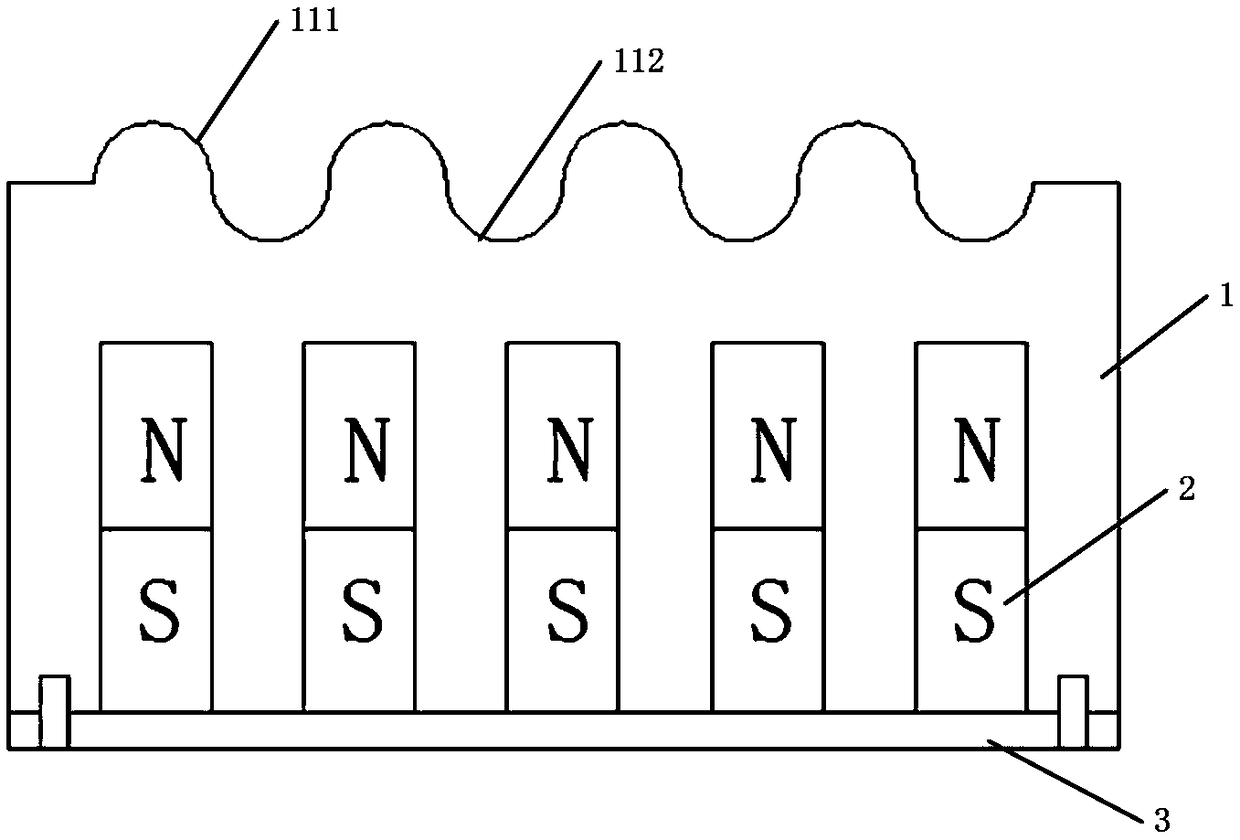

Anti-adhesion plate and manufacturing method thereof

ActiveCN109023267AExtended service lifeReduce maintenance costsVacuum evaporation coatingSputtering coatingEngineeringParticle generation

The invention discloses an anti-adhesion plate. The anti-adhesion plate comprises a plate body, a plurality of magnets and a rear cover. The anti-adhesion face of the plate body is provided with a plurality of protrusions and grooves formed around the protrusions. A plurality of mounting grooves are formed in the back side of the anti-adhesion plate, and permanent magnets or electromagnets are assembled in the mounting grooves. The anti-adhesion plate has the beneficial effects that a magnetic field with certain intensity is added into the anti-adhesion plate to increase the moving distance ofplasma, so that sputtered atoms stay on the surface of the anti-adhesion plate after hitting against argon ions repeatedly, the sputtered atoms adhere to the surface of the anti-adhesion plate more uniformly, the membranous compactness is better, the service life of the anti-adhesion plate is prolonged, particle generation is restrained, and accordingly, the coating cost is reduced, and the maintenance cost of the anti-adhesion plate is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

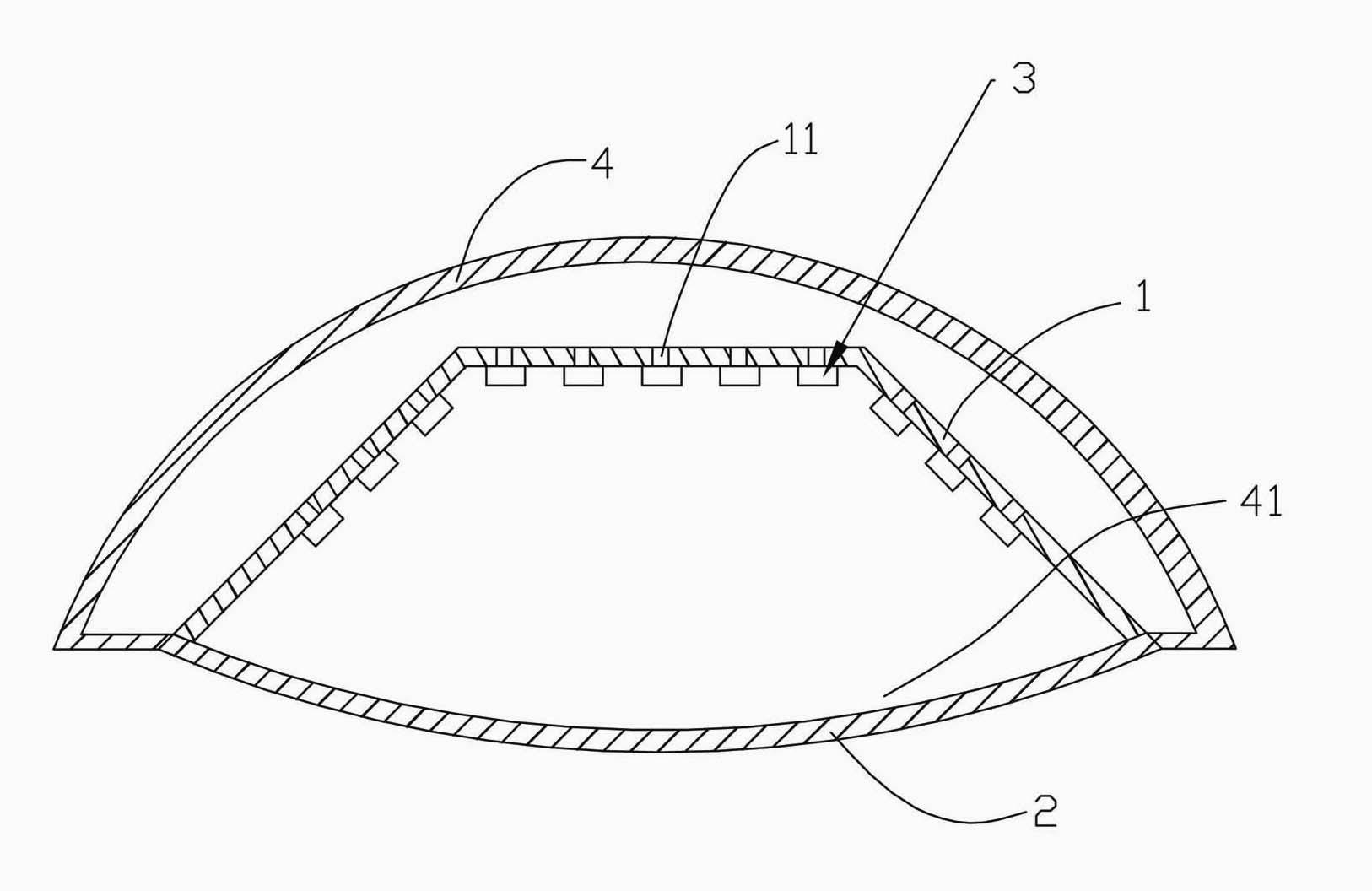

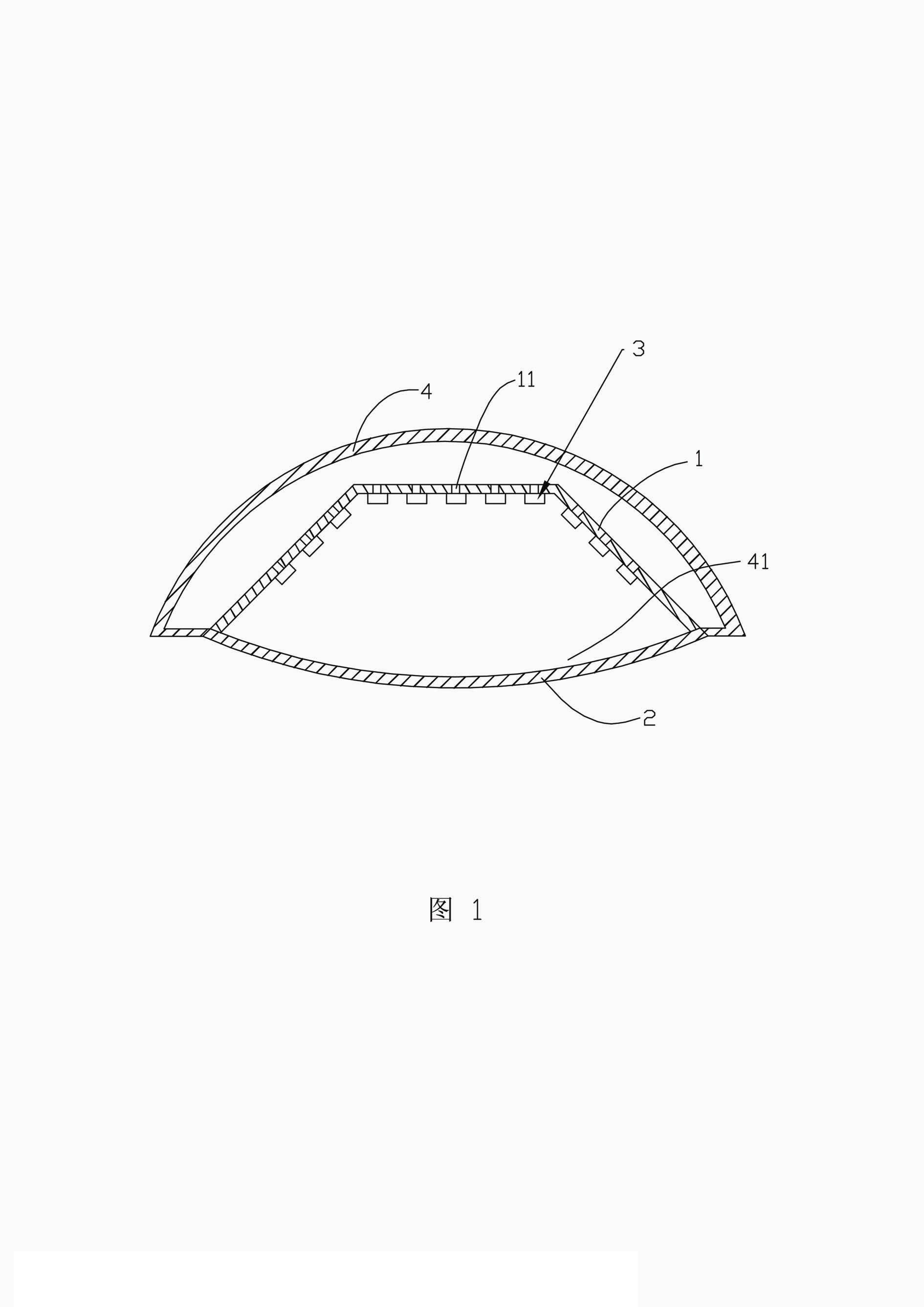

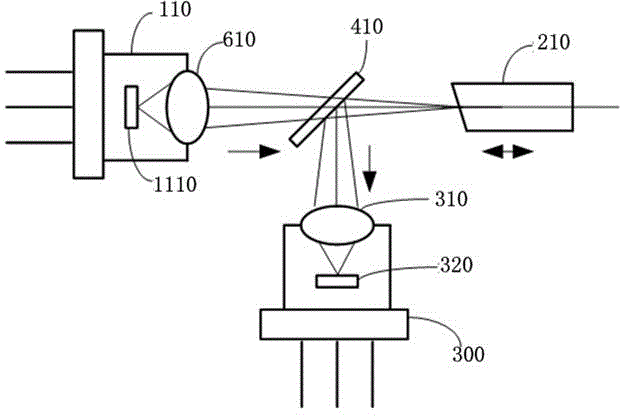

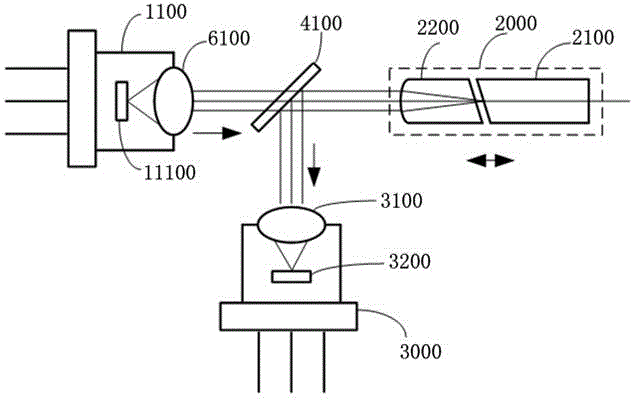

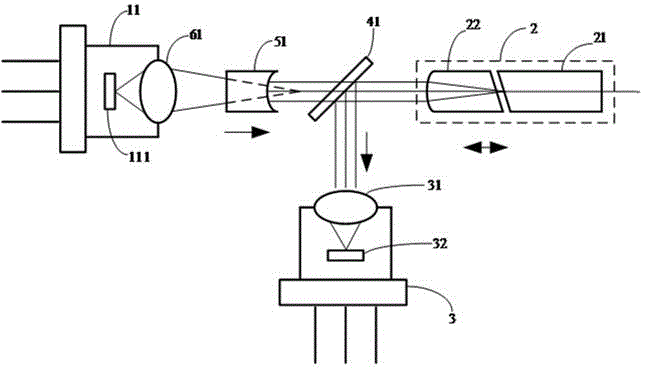

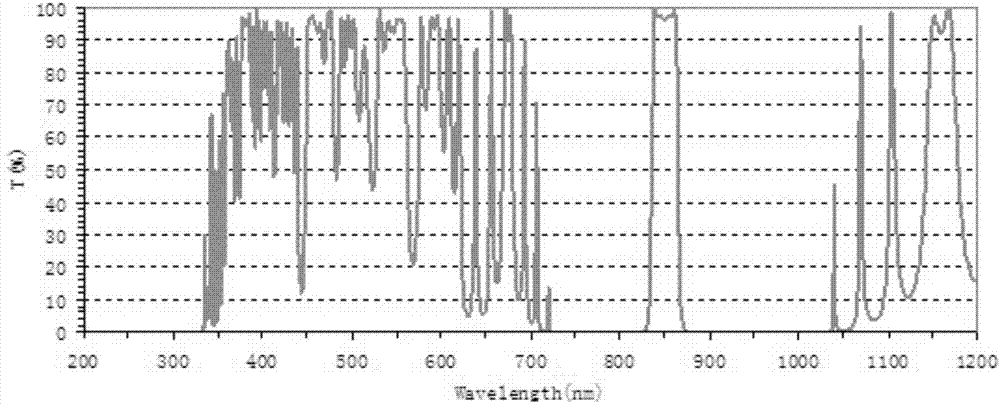

Multi-wavelength component for fiber optic communication

InactiveCN104808299AEasy to debugIncrease brightnessCoupling light guidesFiber-optic communicationLength wave

The invention discloses a multi-wavelength component for the fiber optic communication. The component is used for multi-wavelength laser coupling for single optical fiber transceiving communication and comprises an emitting portion, a receiving portion, an optical coupling portion and an optical fiber terminal. The optical fiber terminal is provided with a straightening portion used for straightening the laser; the emitting portion comprises more than one emitting terminal comprising laser chips generating laser and straightening lens groups; the wavelengths of laser generated by the laser chips of the emitting terminals are different; the straightening lens groups are located in the light emitting ports of the emitting terminals, and the laser generated by the laser chips is concentrated through the straightening lens groups before emitting to the optical coupling portion through the light emitting ports. An optical path component is optimized, the brightness and parallelism of laser emitted through the emitting portion can be guaranteed well, the optical path component is easy to package and adjust, and the multi-wavelength laser coupling capability of an optical coupling component can be improved.

Owner:RISING ELECTRO OPTICS LTD

Stable water-based coating for rusted surface

The present invention provides a stable water-based coating for rusted surfaces which is non-toxic, harmless, non-radioactive, low in coating cost, suitable for metal surfaces having rust, solid oxide skin or old paint film, and has good rust-preventing effect for metal surfaces free of rust. The rust-preventing coating can be used for large metal structures where surface treatments are difficult to carry out, such as bridges, traffic barriers, large machinery, metal doors and windows, etc.

Owner:王娟

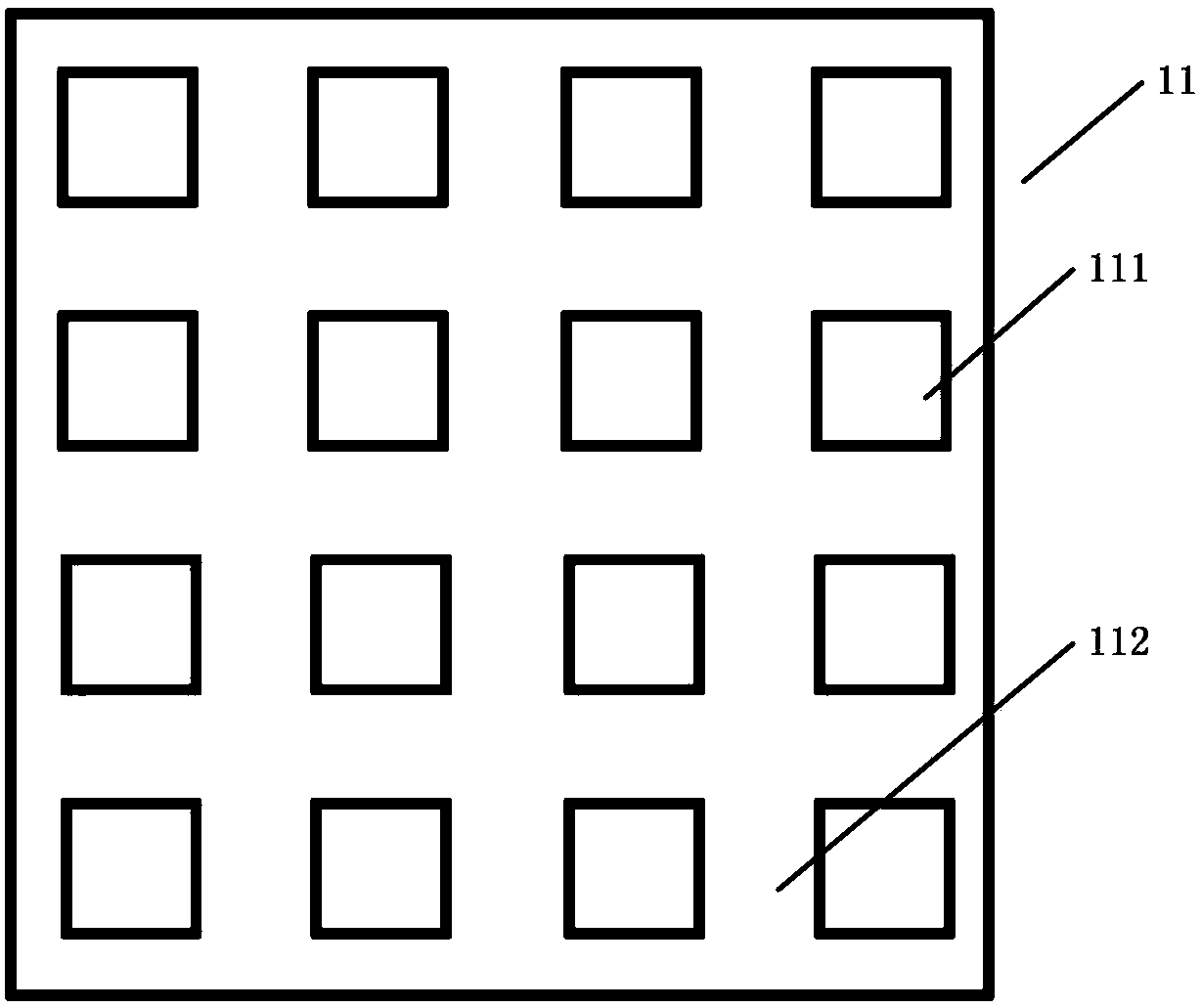

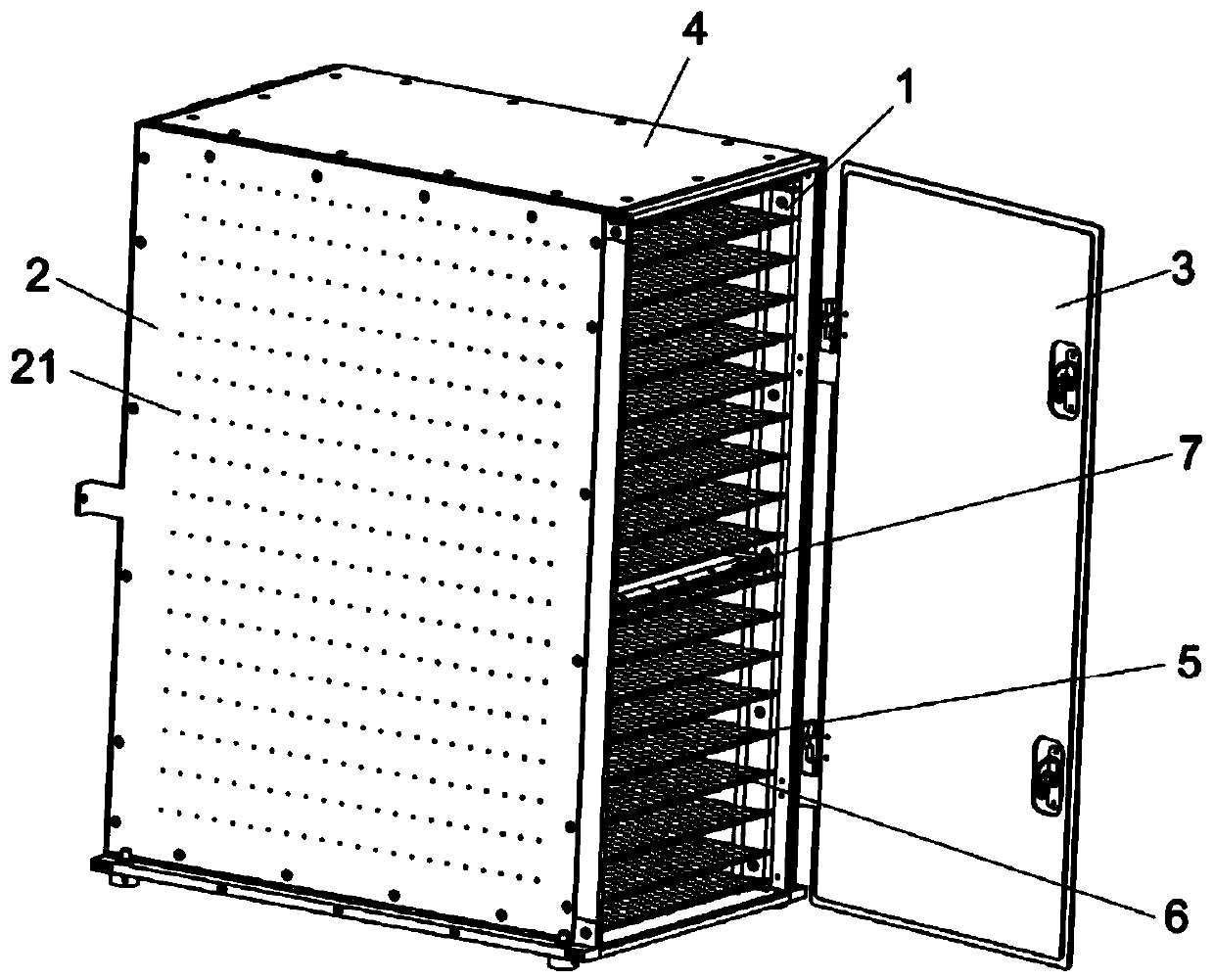

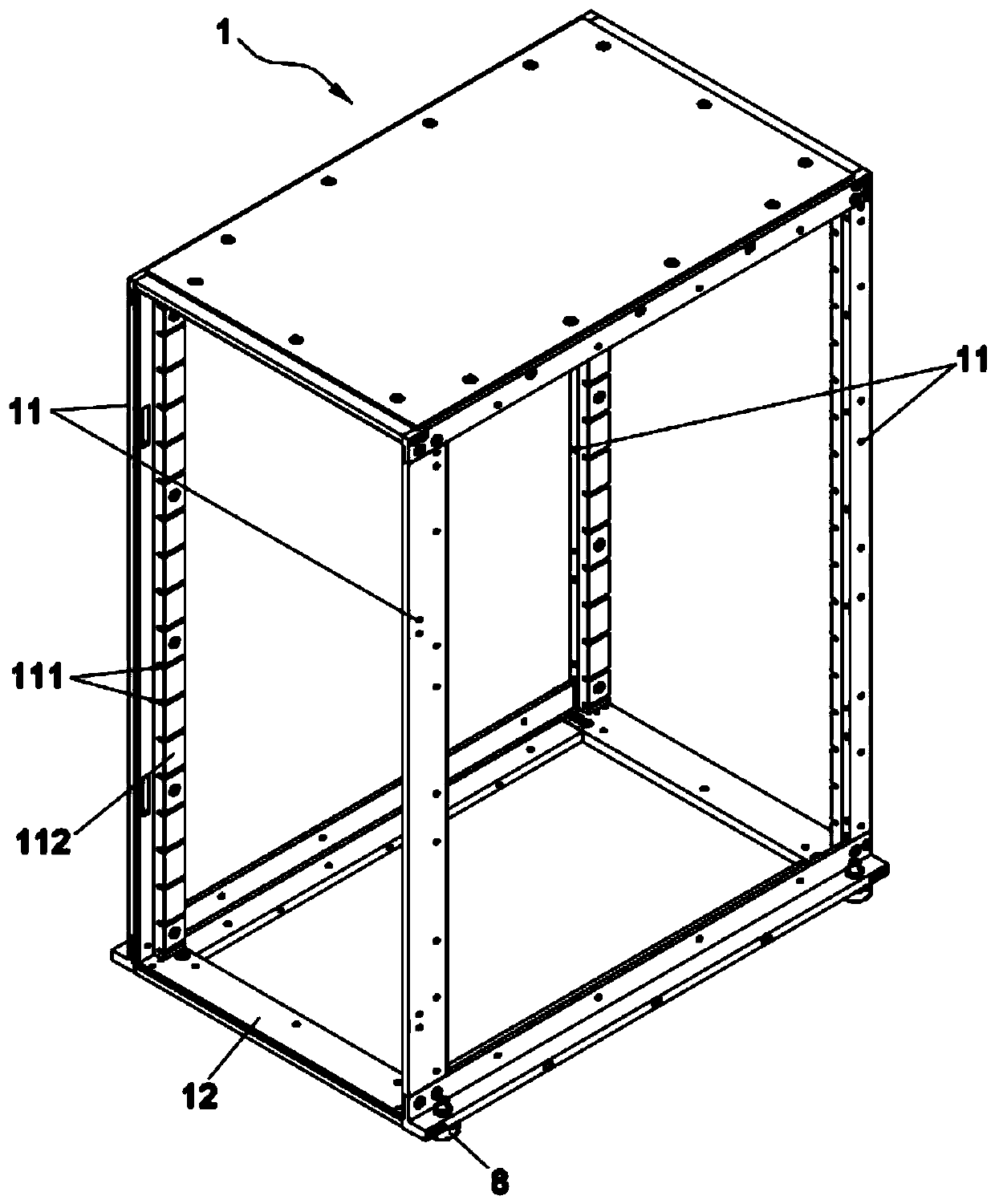

Workpiece rack and coating system

ActiveCN111349910AAvoid the phenomenon of large difference in thicknessImprove space utilizationChemical vapor deposition coatingCoating systemEngineering

The invention belongs to the technical field of coating, and specifically discloses a workpiece rack and a coating system. The workpiece rack includes a frame, a front baffle, two side plates, a radio-frequency electrode plate and a grounding electrode plate; the two side plates and the front baffle are enclosed together to form an accommodating cavity with an opening facing away from the front baffle, and through holes on the side plates communicate with the accommodating cavity; each electrode plate is arranged in the accommodating cavity, and is alternately connected to the frame at intervals along the height direction of the frame. The coating system includes a reaction chamber; the workpiece rack is arranged in the reaction chamber; and the workpiece rack is detachably connected to the reaction chamber through a common electrode plate. In the workpiece rack and the coating system provided by the invention, the electric field uniformity is improved; the coating uniformity and coating efficiency can be improved without additional devices; and the coating cost is reduced.

Owner:龙鳞(深圳)新材料科技有限公司

Novel overlapping integral capacitor touch screen and manufacturing method thereof

InactiveCN102637102AImprove transmittanceImprove reliabilityInput/output processes for data processingCapacitanceIndium

The invention discloses a novel overlapping integral capacitor touch screen and a manufacturing method thereof. The novel overlapping integral capacitor touch screen comprises a transparent substrate, as well as a silicon dioxide layer, a niobium pentoxide layer, a dark resin layer, an ITO (Indium Tin Oxides) electrode, a metal electrode and an insulating layer which are overlapped on the transparent substrate successively; the silicon dioxide layer covers the whole plane of the glass; the niobium pentoxide layer covers the whole plane of the silicon dioxide layer; the ITO electrode is a guide electrode in the horizontal direction or the vertical direction and is provided with a regular pattern structure; the ITO electrode is formed by an ITO guide electrode 1 and an ITO guide electrode 2; the ITO guide electrode 1 and the ITO guide electrode 2 are both arranged on one same plane but are independent and insulated mutually, and are designed in an interlacing manner. According to the touch screen, the guide mode of the overlapping structure of the capacitor touch screen is design reasonably; the transmissivity of the capacitor touch screen is improved effectively; the visuality of the ITO pattern is reduced; and the reliability of the touch screen is further improved.

Owner:SHENZHEN BAOMING TECH

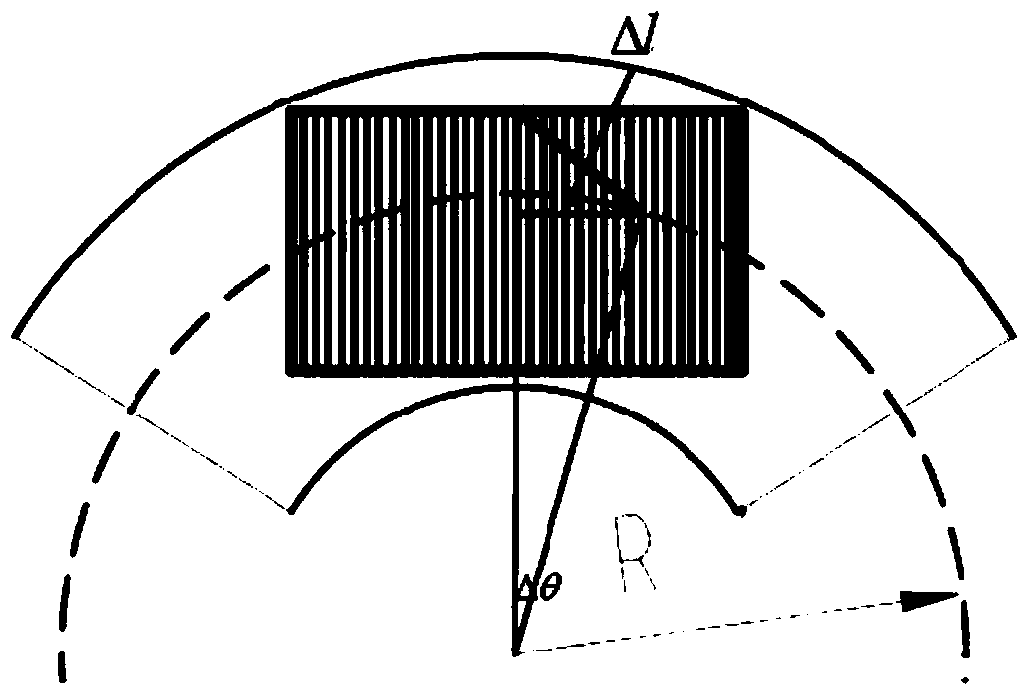

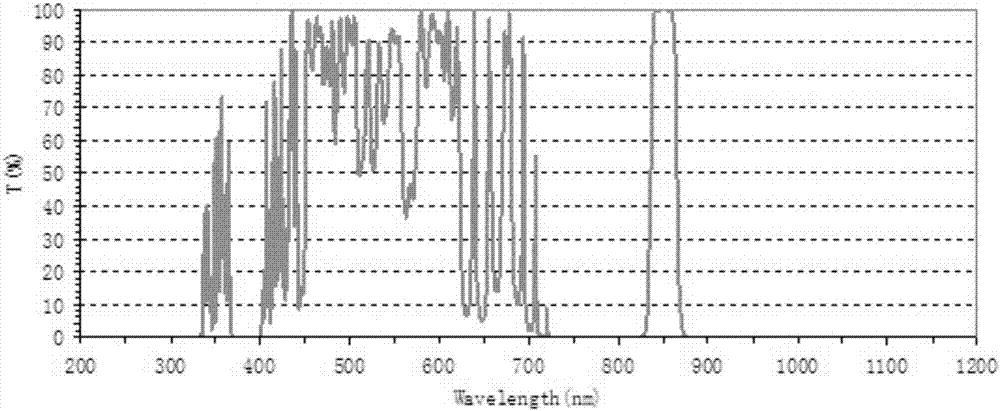

Broadband infrared scanning beam split device and calibrating method

InactiveCN104266756AReduce difficultyReduce coating costRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsBroadbandScanning beam

The invention provides a broadband infrared scanning beam split device and a calibrating method. The device comprises an LVF, a clamp, a drive motor, a photoelectric switch, a zero position opening, an external pressing ring and an internal pressing ring. The drive motor drives the clamp with a gradual optical filter to conduct rotating scanning test, the internal pressing ring and the external pressing ring of the clamp press the non-working region of the LVF to conduct fixing, assembly is simple and firm, and the high-speed rotating scanning test can be achieved. Compared with a CVF, by the adoption of the scheme, the coating technology difficulty and coating cost are lowered greatly, and through a corresponding wavelength calibrating algorithm, continuous test of broadband infrared radiation can be achieved.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

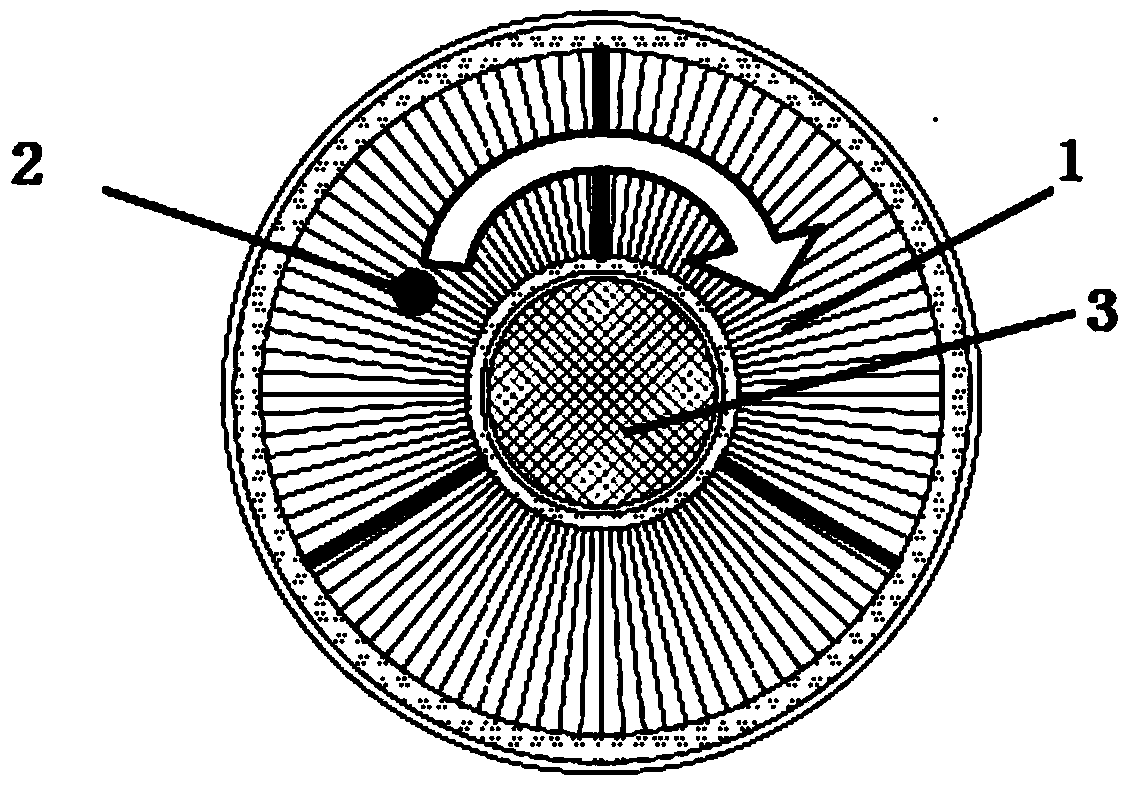

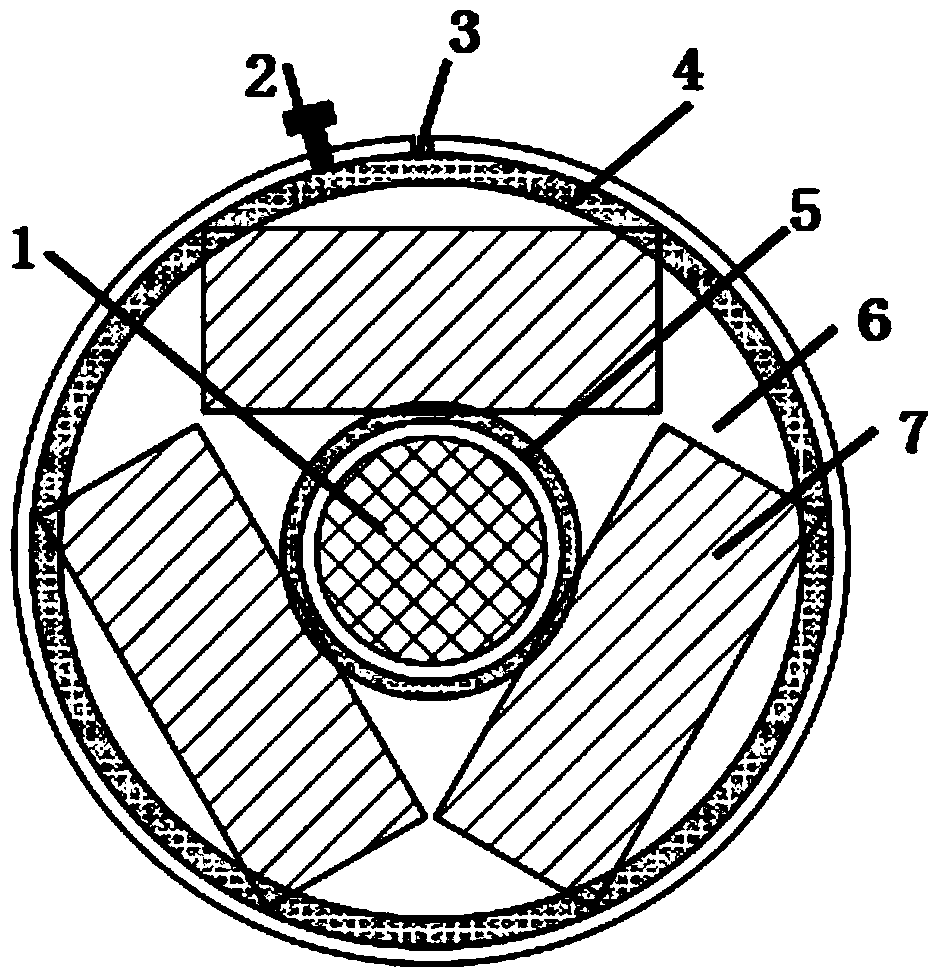

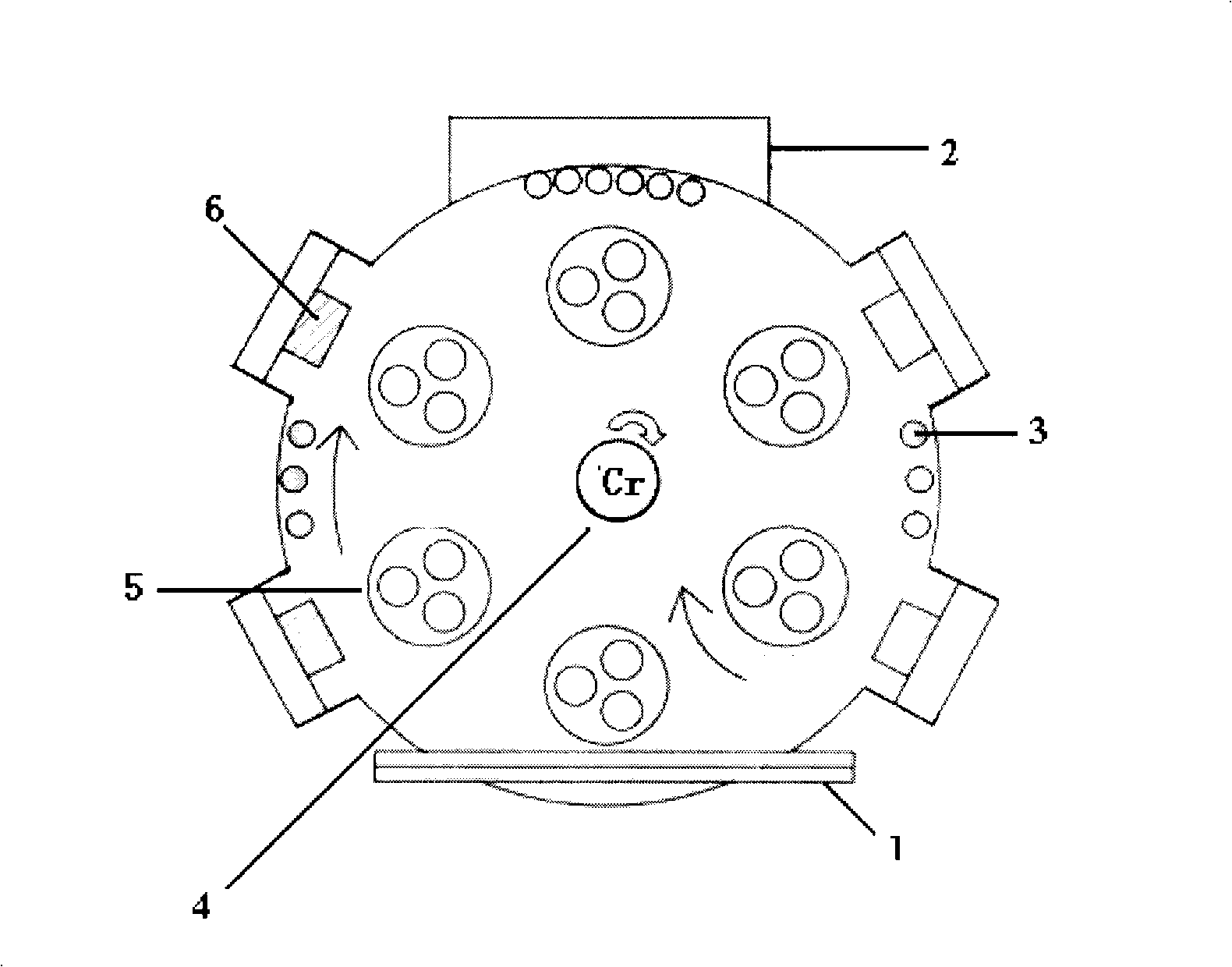

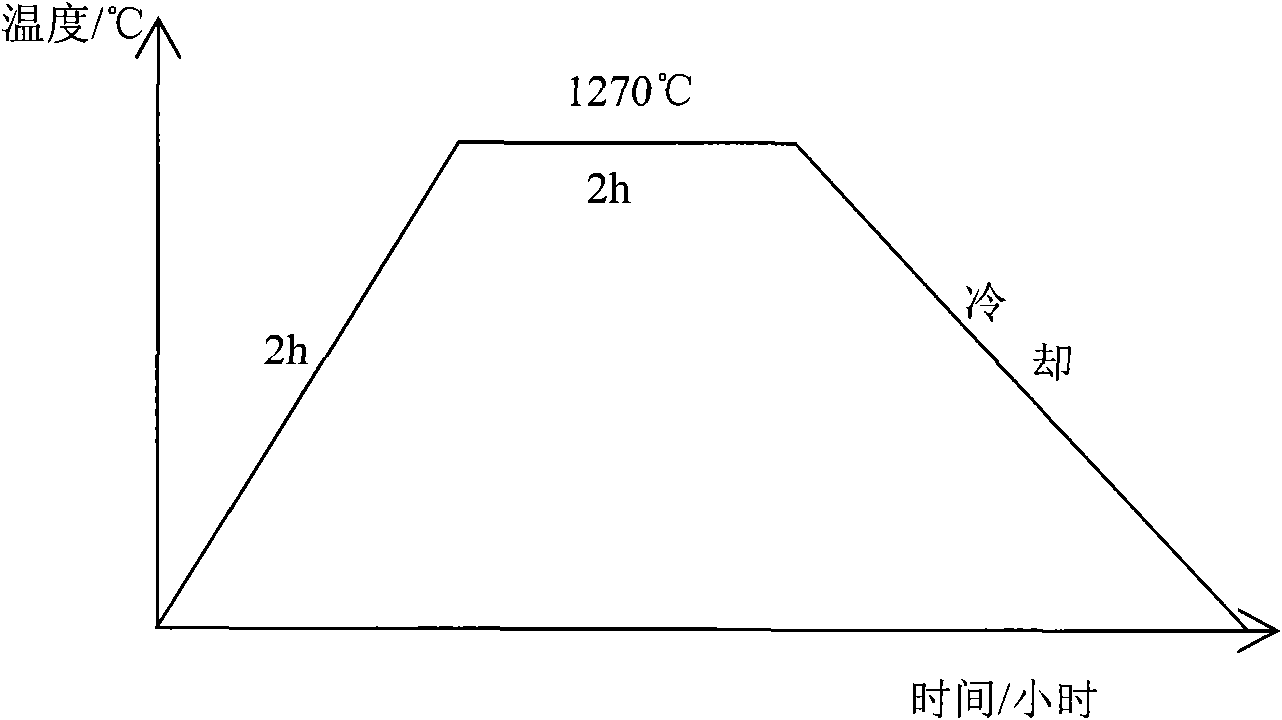

Quick solid-ceramic coating ion plating apparatus

InactiveCN101403101AImprove uniformityAdjustable temperatureVacuum evaporation coatingSputtering coatingVacuum pumpingCeramic coating

The invention discloses a rapid hard ceramic coating ion plating device which comprises a vacuum chamber formed by a furnace wall, one side of which is provided with a furnace door, and the vacuum chamber is provided with a vacuum pumping port. The interior of the vacuum chamber is provided with round electric arc targets and a high-power cylindrical rotary electric arc target, wherein, the round electric arc targets are divided into 2N rows, N is more than or equal to 1, the round electric arc targets are uniformly distributed on the furnace wall, the high-power cylindrical rotary electric arc target is arranged at the centre of the vacuum chamber, and the space between the round electric arc targets and the central high-power cylindrical electric arc target is an ion plating deposition area, and work supports are distributed in the ion plating deposition area. The device fully utilizes the high ionization rate of the electric arc ion plating technology, greatly improves the deposition efficiency of the ceramic coating and overcomes the defects in the prior art that expensive ion sources need to be added so as to improve adhesive force, etc. The device has the advantages of high film plating efficiency, low film plating cost, convenient operation, and the like. The device can meet the demand of over-thick ceramic coating in industry and has good application prospect in industrial production.

Owner:WUHAN UNIV

Preparation method of temperature-resistant and erosion-resistant coating for walling of flue

InactiveCN101096460AImprove heat resistanceImprove acid resistanceFireproof paintsAlkali metal silicate coatingsSilanesPhosphate

The invention discloses a high temperature-resistant and corrosion resistant paint making method of flue inwall, which comprises the following steps: blending 100g potassium silicate solution, 2.5g polymethyl triethoxy silane, 0.2g carbon element and 1.7g calcium aluminate evenly; blending 7g silicon phosphate, 11g scale shaped glass, 4.5g hydrated silica and 1g chromic potassium sulfate evenly; blending two composite liquids evenly to coat on the cement board; heating to obtain the coating with thickness at 400pm to resist 350 deg. c and diluted sulfur acid.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Glass mould pressing coating, preparation method thereof, application of the coating and mould

InactiveCN110482852ANo sheddingFine grainVacuum evaporation coatingSputtering coatingSurface roughnessOxidation resistant

The invention provides a glass mould pressing coating, a preparation method thereof, application of the coating and a mould. The coating comprises a nitride layer and nano precious metal particles dispersed in the nitride layer, and the surface roughness of the coating is 2-12 nm. The preparation method comprises the following steps: cleaning a to-be-deposited substrate and a target material in aninert gas protective atmosphere environment; in a mixed environment atmosphere of nitrogen and inert gas, depositing a Cr transition layer, the nitride layer and the nanometer precious metal particles on the surface of the to-be-deposited substrate by adopting a high-purity W target, a high-purity Cr target and a precious metal inlaid Cr target. The prepared coating not only has good oxidation resistance, but also is quite excellent in anti-adhesion property, can effectively inhibit adhesion reaction between a glass body and a mould, can be applied to the precision mold pressing mould, and can also be applied to a high-temperature resistant material, an anti-oxidation material and an anti-adhesion material.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND +2

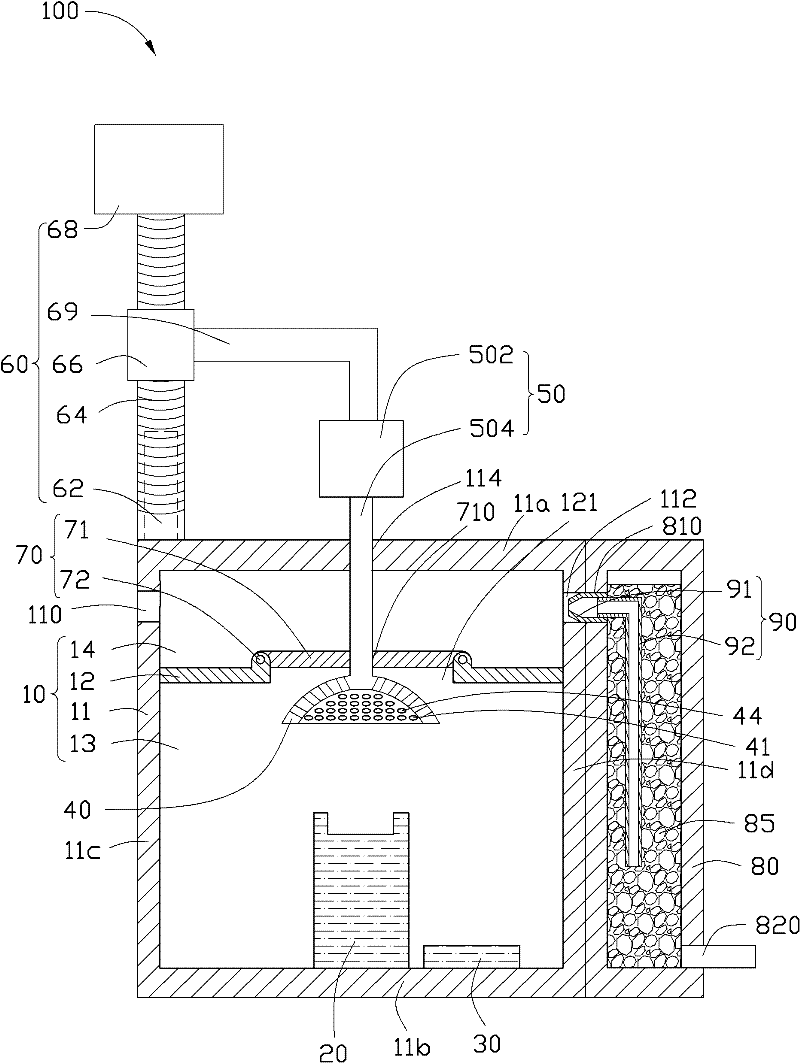

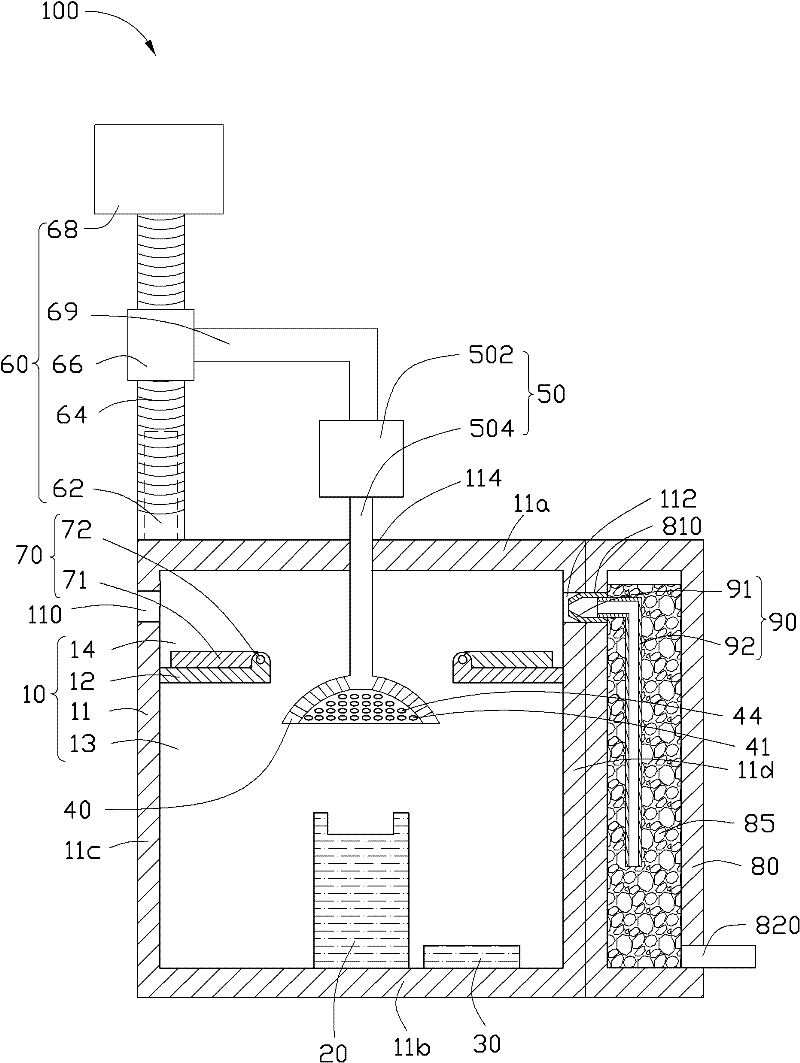

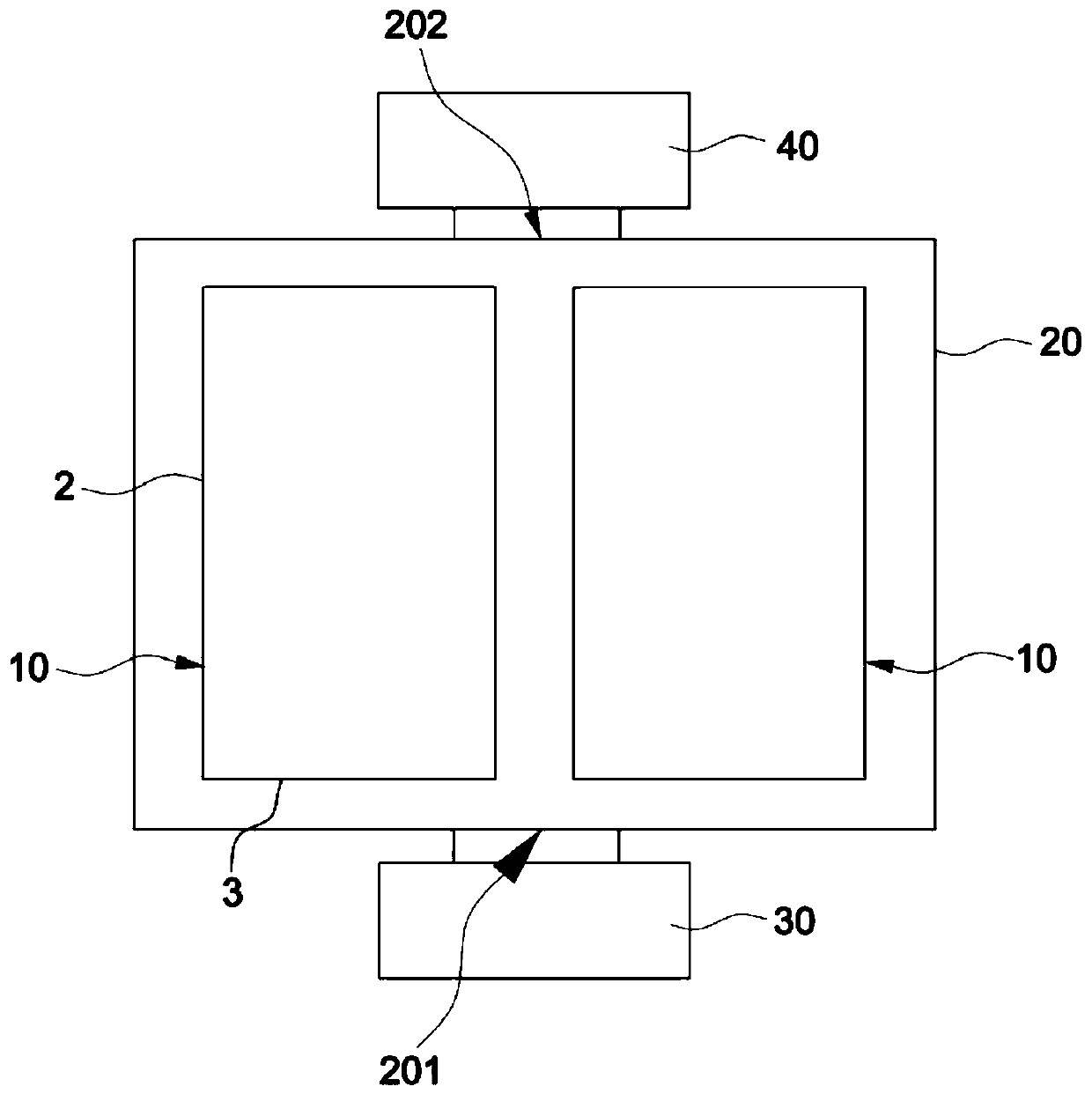

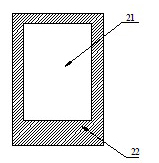

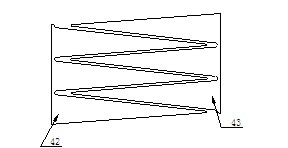

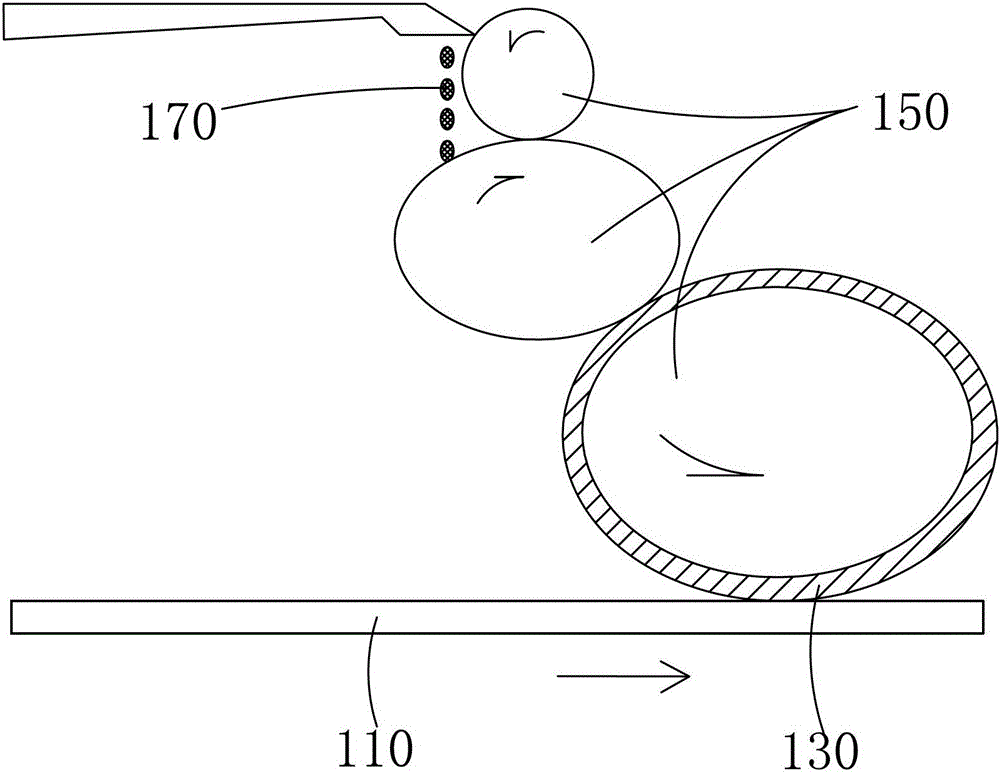

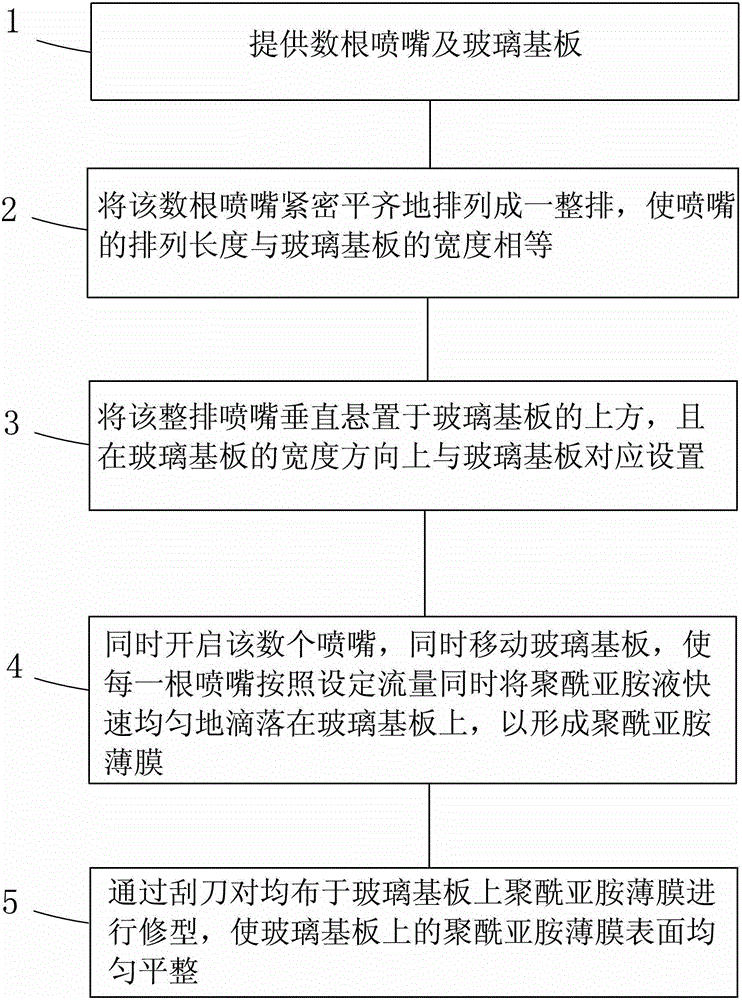

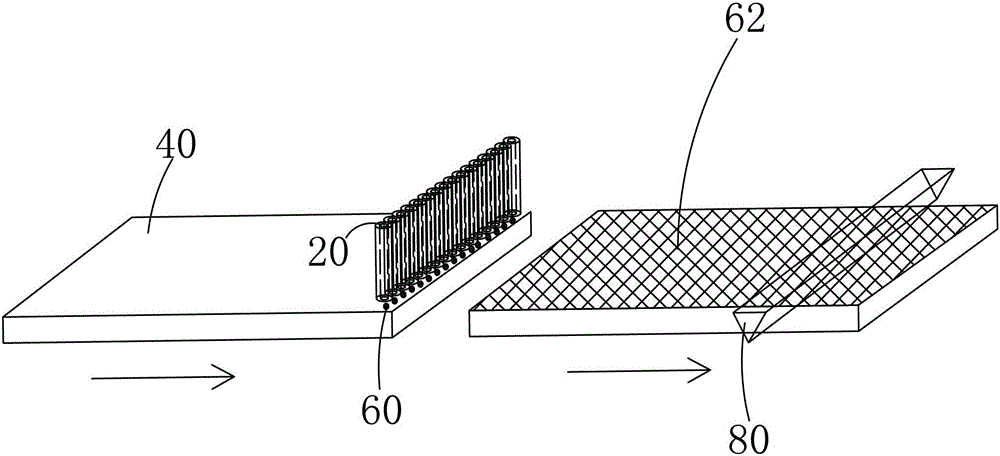

Polyimide coating method of liquid crystal display panel

A method for coating polyimide on a liquid crystal display panel, comprising the following steps: step 1, providing a plurality of nozzles (20) and a glass substrate (40); step 2, arranging the plurality of nozzles (20) close and flush in a row, and ensuring that the arrangement length of the nozzles (20) equals to the width of the glass substrate (40); step 3, vertically suspending the entire row of nozzles (20) above the glass substrate (40), the nozzles being disposed corresponding to the glass substrate (40) in the width direction of the glass substrate (40); step 4, simultaneously opening the plurality of nozzles (20) to enable each nozzle (20) to simultaneously, quickly, and uniformly drip polyimide liquid (60) at a preset flow rate while moving the glass substrate (40), such that the polyimide liquid (60) is uniformly coated on the glass substrate (40) to form a polyimide film (62); and step 5, smoothening the polyimide film (62) uniformly coated on the glass substrate (40) via a scraper (80), so that the surface of the polyimide film (62) on the glass substrate (40) is uniform and level. The method for coating polyimide on a liquid crystal display panel simplifies the coating processes and device, and reduces production time and coating cost, and improves the coating effect.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

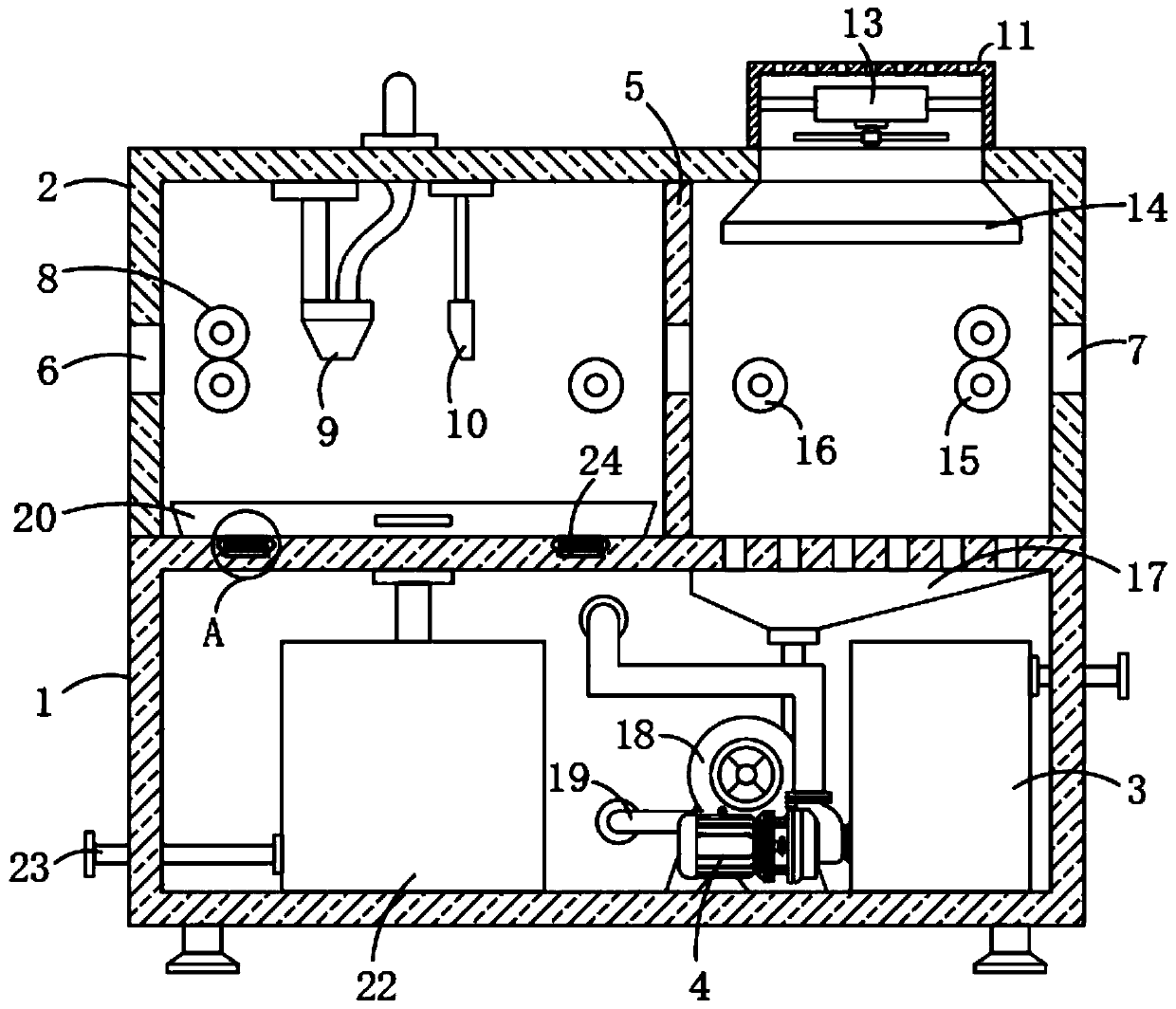

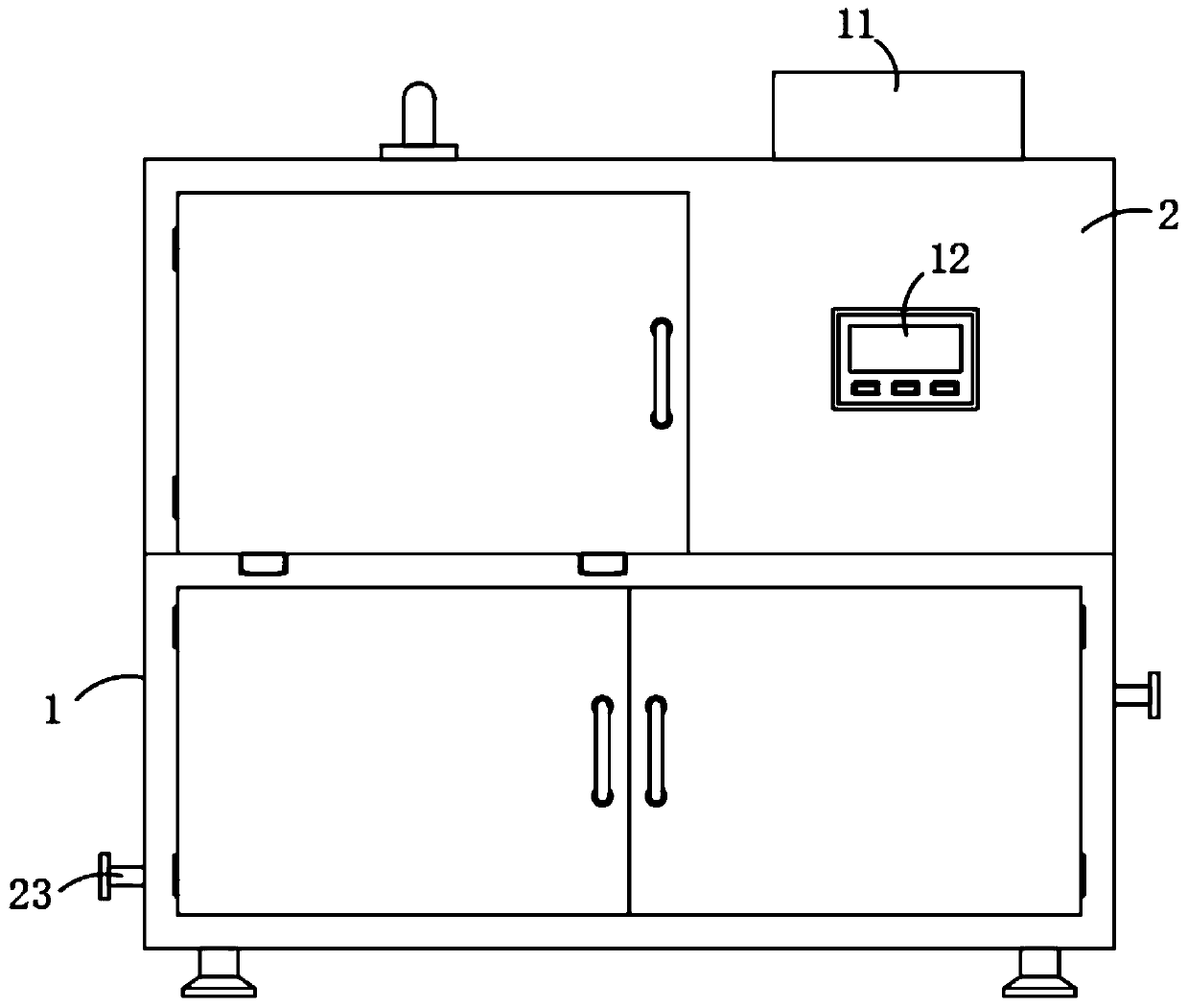

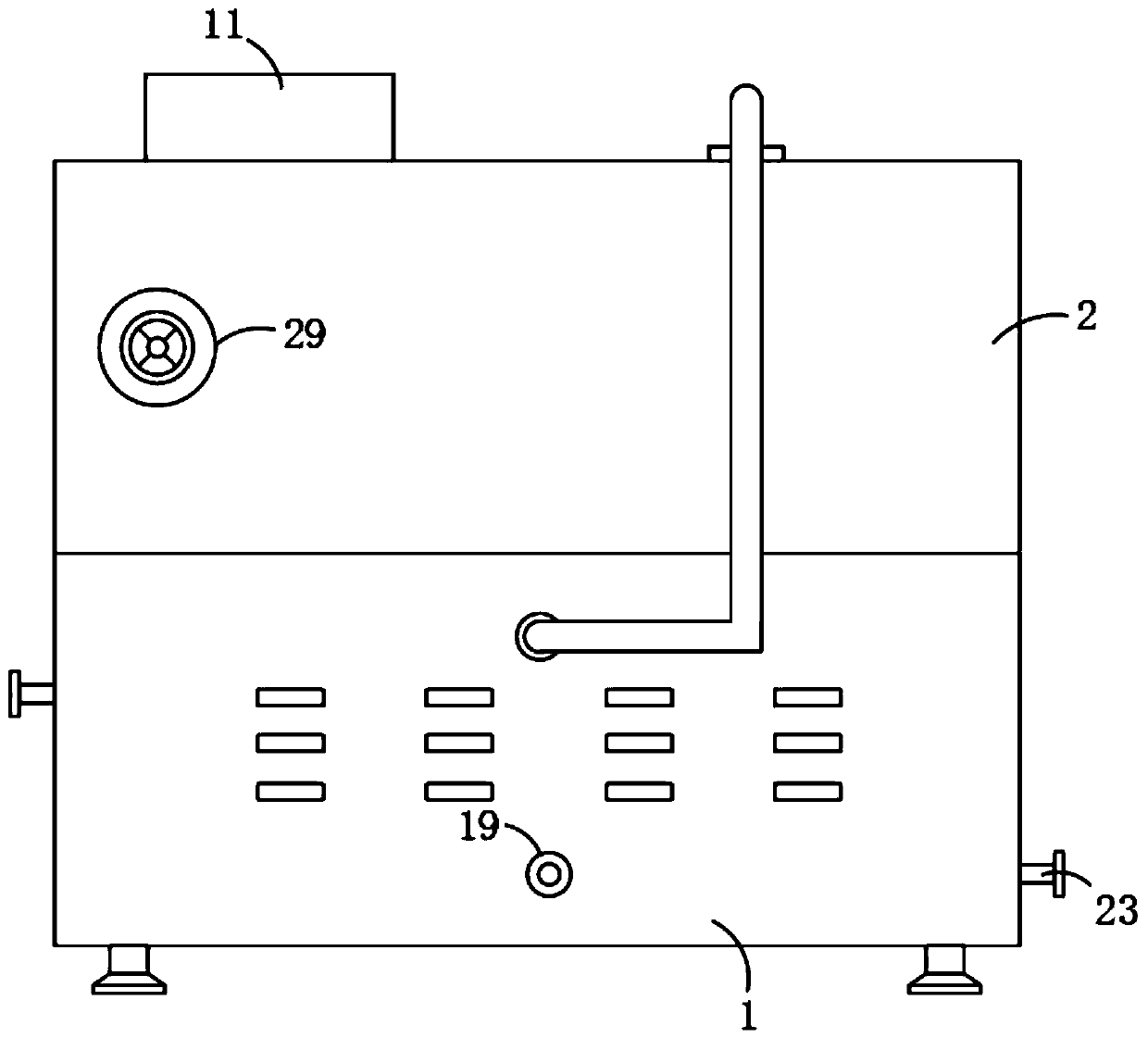

Slurry coating device for medical dressing production

InactiveCN111589640AAchieve dryingImprove drying efficiencyPretreated surfacesCoatingsSlurry coatingInfusion pump

The invention discloses a slurry coating device for medical dressing production, and relates to the technical field of medical dressing production. The slurry coating device for medical dressing production comprises a machine body, a coating box is mounted on the top of the machine body, a liquid storage box and an infusion pump which is in pipeline connection with the liquid storage box are fixedly mounted on one side in the machine body, a partition board with through holes is mounted in the coating box, the interior of the coating box is divided by the partition board into a coating cavityand a drying cavity, through a hot air fan and an exhaust fan, slurry on dressing can be dried, the slurry can be rapidly dried, the slurry drying efficiency is effectively improved, dressing conveying is facilitated, the device is integrated with coating and drying, the dressing production procedure is simplified, drying by the subsequent procedure is not needed, the dressing production efficiency is greatly improved, and the dressing production benefits can be increased.

Owner:ZHEJIANG WELLONG MEDICAL TECH CO LTD

Heat-curable magnetic epoxy resin powder and inductor packaging method thereof

InactiveCN106010124AReduce wasteStorage time exceededTransformers/inductances casingsEncapsulation/impregnationEpoxyFerrite powder

The invention discloses a heat-curable magnetic epoxy resin powder coating and an inductor packaging method thereof. The heat-curable magnetic epoxy resin powder coating is characterized by containing the following substances in percentage by weight: 30 to 50 percent of epoxy resin, 20 to 50 percent of soft magnetic ferrite powder, 10 to 20 percent of a composite curing agent, 5 to 8 percent of a filler and 3 to 8 percent of an assistant. The method comprises the following steps: proportionally mixing the epoxy resin, the soft magnetic ferrite powder, the composite curing agent, the filler and the assistant, performing uniform stirring by virtue of stirring equipment, preparing a flaky dry material, crushing the flaky dry material, impregnating a preheated inductor in obtained powder by virtue of fluidized coating equipment, and performing baking, cooling and packaging. The heat-curable magnetic epoxy resin powder coating and the inductor packaging method thereof have the advantages that the powder has high flowability under the driving of airflow, so that packaging is facilitated without adhesion; the material cost is reduced, and the prepared coating can be easily stored for long; the production efficiency can be improved, the coating can be kept uniform, and the product is stable in inductance and small in error change; the inductance can be increased, the coating can be endowed with an electromagnetic shielding function, and flux leakage is avoided; the saturation resistance of current is improved; the heat-curable magnetic epoxy resin powder coating and the inductor packaging method thereof are applied to improvement of packaging of a vertical plug-in inductor and a packaging material.

Owner:王强

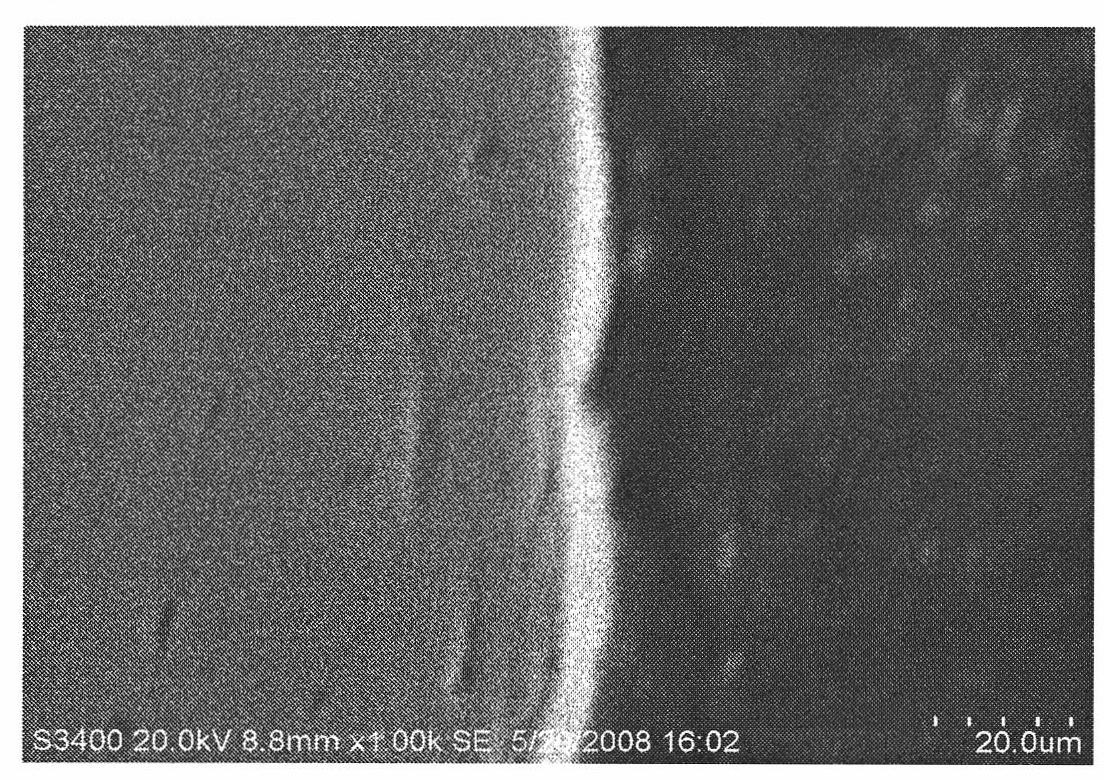

Preparation method of titanium carbide-based multi-ceramic coating

InactiveCN101798696AChange uniformityChange efficiencySurface reaction electrolytic coatingElectrochemical responseKerosene

The invention discloses a preparation method of a titanium carbide-based multi-ceramic coating, which comprises the following steps: 1) putting a powdered agglomerate metal electrode and a workpiece electrode into kerosene; 2) connecting the anode of a pulse power source with the powdered agglomerate metal electrode, and connecting the cathode of the pulse power source with the workpiece electrode; and 3) switching on the pulse power source to enable Ti and other metal Me ions released by discharging of the powdered agglomerate metal electrode in liquid-phase media to carry out electrochemical reaction with C ions ionized from the kerosene under the action of plasma to synthesize the titanium carbide-based multi-ceramic coating, and depositing the titanium carbide-based multi-ceramic coating on the surface of the workpiece electrode, wherein the powdered agglomerate metal electrode is prepared by carrying out compression molding on the powder in which the weight ratio of Ti to Me is 70-90:30-10 and then carrying out high-temperature sintering in a vacuum sintering furnace, wherein Me is Al, W or Zr. The invention has the advantages of uneven components of a strengthened layer, high process stability, no need of large film coating devices, no need of vacuumization, and low film coating cost.

Owner:GUANGDONG UNIV OF TECH

Narrowband optical filter and film plating method thereof

InactiveCN107193071AGuaranteed image qualityReduce distortionOptical elementsRefractive indexLength wave

The invention discloses a coating process for a narrow-band filter, which comprises the following steps: coating a main membrane stack on one side of a blank glass substrate, so that the main membrane stack and the blank glass substrate form an equivalent base. The equivalent refractive index of the equivalent substrate at the center wavelength is equal to the refractive index of the blank glass substrate; the first sub-film stack is coated on one side of the equivalent substrate, and the second sub-film stack is coated on the other side of the equivalent substrate. Two membrane stacks. The invention can prevent the thickness of the secondary film layer from being too thick compared with that of the main film layer, so that the stress on both sides of the substrate is basically balanced, the deformation of the substrate is reduced, and the imaging quality is guaranteed.

Owner:上海兆九光电技术有限公司

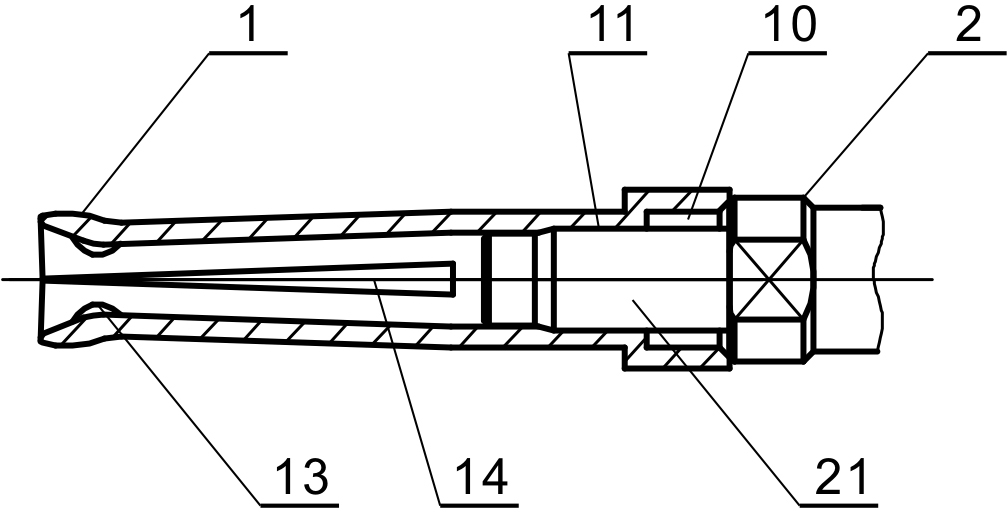

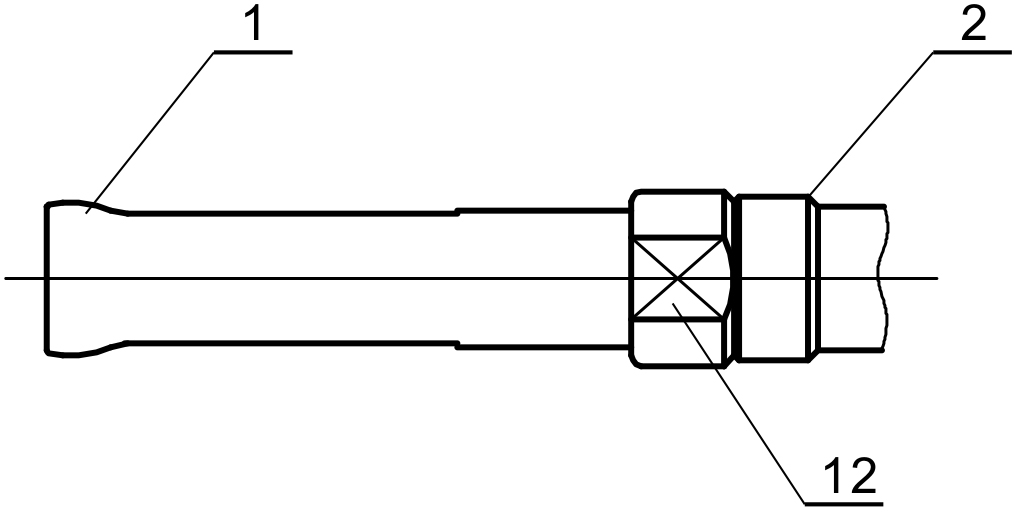

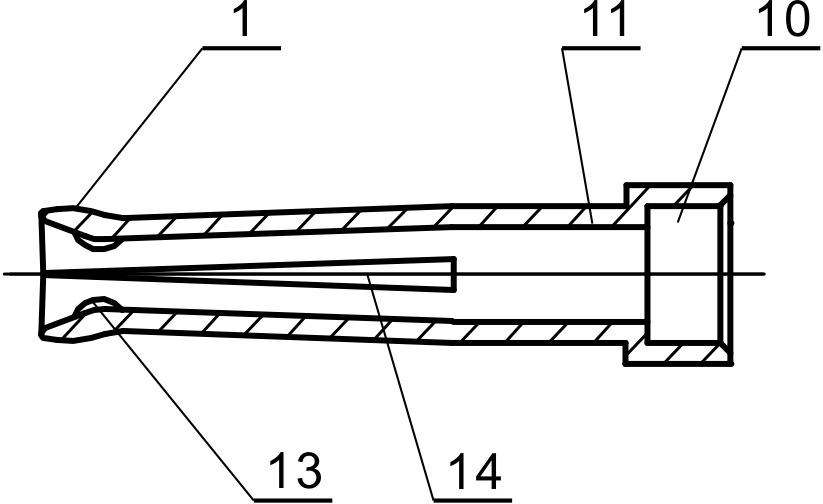

Combined female contact element

InactiveCN102623828AIncrease elasticityImprove fatigue resistanceCoupling contact membersInterference fitContact element

The invention discloses a combined female contact element, which comprises a head part and a tail end. The head part is a cylinder body, and a step hole, an assembly hole, a nick and a flange are arranged on the head part, wherein the nick is deformed to be wedged. A cylindrical head is arranged at the tail end. The cylindrical head of the tail end penetrates through the step hole of the head part, is spliced with the assembly hole, and is in interference fit with the assembly hole. An integrated contact element is divided into a contact element head part and a contact element tail end, the contact element head part is designed and manufactured in a standard way, the contact element tail end is in interference fit with the contact element head part through a standard cylindrical head, and the nick is axially reserved in the head part, so that the elastic performance and anti-fatigue performance of the contact element head part are improved, and the aims of interface standardization of a contact element of a connector, improvement in connection reliability and remarkable reduction in coating cost are fulfilled.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com