Glass mould pressing coating, preparation method thereof, application of the coating and mould

A coating and molding technology, used in glass pressing, glass manufacturing equipment, glass die-casting equipment, etc., can solve the problems of short service life, serious carbon film, adhesion of nitride coatings, etc., and achieve excellent and good anti-adhesion properties. The effect of anti-oxidation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

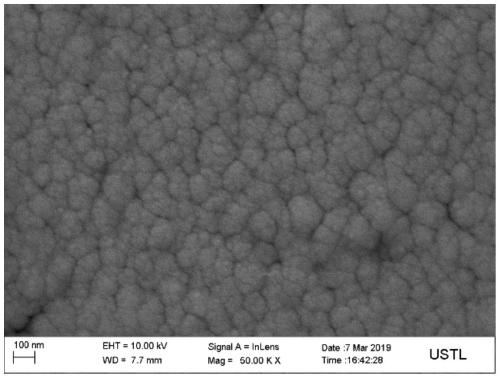

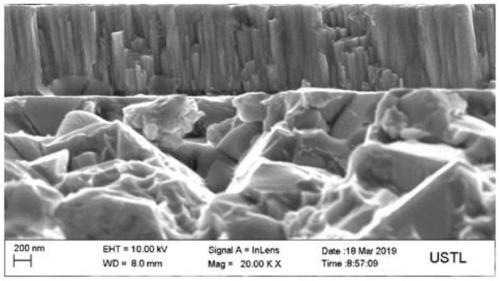

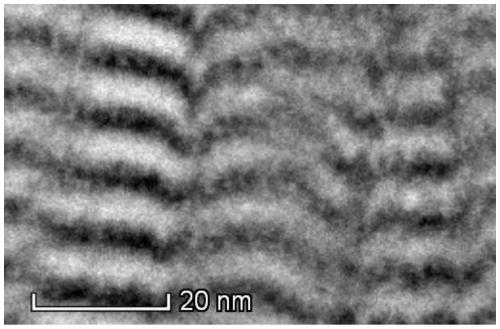

[0049] A kind of glass molding coating, including Cr transition layer, Cr x W y N (1-x-y) layer and diffuse distribution in Cr x W y N (1-x-y)Pt nanoparticles within the layer. In this embodiment, the surface roughness of the glass molded coating is 3.47 nm; the content of each element in the glass molded coating is: the atomic content of Cr element is 19.8 at.%, the atomic content of W element is 28.7 at.%, N The atomic content of the element is 46.9 at.%, the atomic content of the Pt element is 4.6 at.%, and the Pt nanoparticles are dispersed in the nitride matrix with a columnar crystal structure; the thickness of the Cr transition layer is 100nm, and the thickness of the CrWN-Pt layer It is 1010nm, the hardness is 20.41GPa, and the elastic modulus is 365.7 GPa.

[0050] The glass molded coating in this embodiment was prepared by using a plasma-enhanced magnetron sputtering system and the following method. Among them, the plasma-enhanced magnetron sputtering system i...

Embodiment 2

[0065] A kind of glass molding coating, comprises Cr transition layer, Cr x W y N (1-x-y) layer and diffuse distribution in Cr x W y N (1-x-y) Pt nanoparticles and Ir nanoparticles in the layer.

[0066] In the present embodiment, the surface roughness of the glass molded coating is 5.741nm; the content of each element in the glass molded coating is: the atomic content of Cr element is 22.3 at.%, the atomic content of W element is 27.96 at.%, N The atomic content of the element is 44.72 at.%, the atomic content of the Pt element is 3.5 at.%, and the atomic content of the Ir element is 1.52 at.%, and the Pt nanoparticles and Ir nanoparticles are dispersed in the nitride with a columnar crystal structure. In the matrix; the thickness of the Cr transition layer of the glass molded coating is 111nm, the thickness of the CrWN-PtIr layer is 932 nm, the hardness is 18.27GPa, and the elastic modulus is 342.1 GPa.

[0067] The glass molded coating in this embodiment was prepared ...

Embodiment 3

[0081] Example 3: The coating is deposited on a silicon wafer, and the surface roughness of the coating deposited on the silicon wafer is measured using an atomic force microscope (AFM). The measurement area is 10x10 μm, and the results show that the surface roughness of the coating is 1.6- 2.3nm.

[0082] To sum up: the hardness of the coating prepared in the embodiment of the present invention can reach 18.27-24.32GPa, the modulus of elasticity can reach 280-413GPa, and the surface roughness of the coating can reach 2-11.73nm. Not only has good oxidation resistance, but also has excellent anti-adhesion properties, which can effectively inhibit the adhesion reaction between the glass body and the mold; through scanning electron microscope observation, the cross-section of the glass molded coating of the present invention is a columnar crystal growth structure with a fine structure. The matrix is tightly bonded, and the crystal grains doped on the surface of the coating are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com