Method for preparing high-thermal conductivity graphite radiating fins

A technology of high thermal conductivity graphite and graphite heat sink, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of low mechanical strength, short service life and unfavorable processing of graphite heat sink, so as to achieve the convenience of subsequent processing and use, and the service life Longer, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

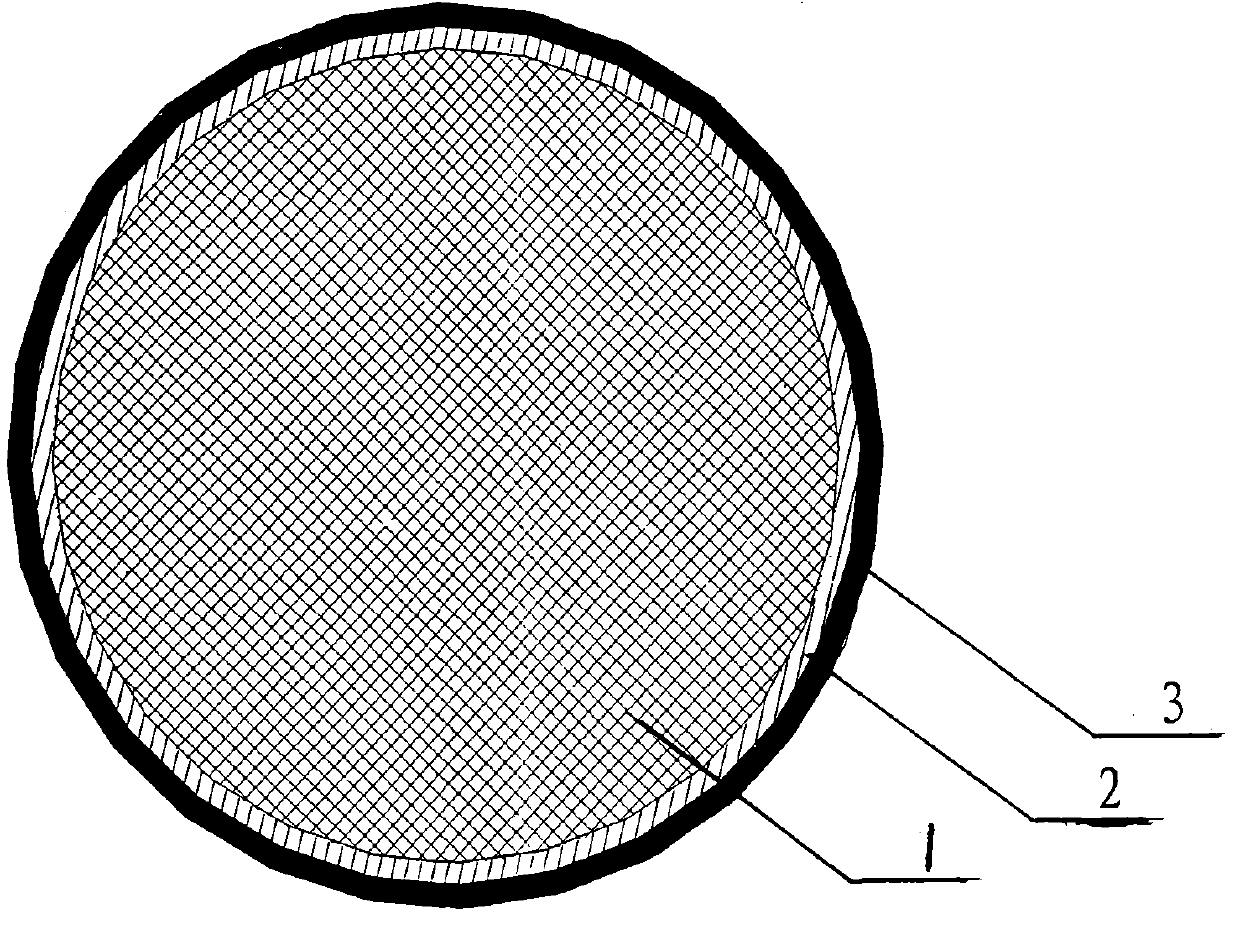

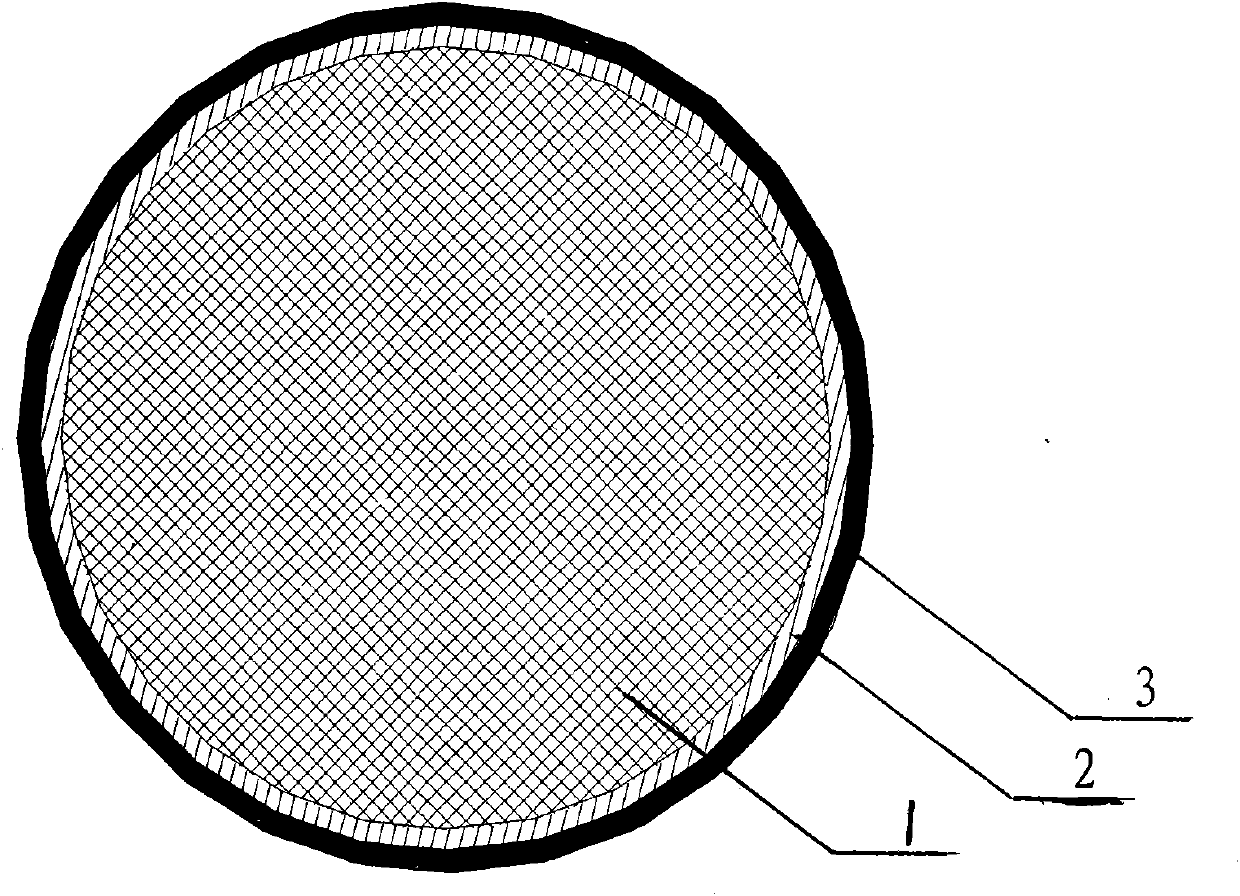

Image

Examples

Embodiment 1

[0028] b. Then wash the treated graphite powder with water at room temperature to pH=6.5;

[0029] c. Put the washed graphite powder into a graphite expansion furnace for high-temperature expansion. The temperature of the graphite expansion furnace expands at a high temperature of 800 ° C for 20 hours, and then slowly cools to room temperature;

[0030] d. get the carbon black that the particle diameter is 0.5 μ m- is the composite particle of graphite powder, according to graphite powder: after the mass parts proportioning of carbon black=8: 1 is mixed, make density by flexible graphite coiled material production equipment: 0.5g / cm 3 , Thickness of 5mm graphite heat sink.

[0031] Example 2:

Embodiment 2

[0033] b. Then wash the treated graphite powder with water at normal temperature to pH=5;

[0034] c. Put the washed graphite powder into a graphite expansion furnace for high-temperature expansion. The temperature of the graphite expansion furnace expands at a high temperature of 1000 ° C for 3 hours, and then slowly cools to room temperature;

[0035] d. get the carbon black that particle diameter is 200 μ m to be the composite particle of graphite powder, after graphite powder: carbon black=2: 1 mass portion proportioning mixes, it is 1.5g to make density by flexible graphite coiled material production equipment / cm 3 , Thickness of 0.05mm graphite heat sink.

[0036] Example 3:

Embodiment 3

[0038] b. Then wash the treated graphite powder with water at room temperature to pH=6.0;

[0039] c. Put the washed graphite powder into the graphite expansion furnace for high-temperature expansion. The temperature of the graphite expansion furnace expands at a high temperature of 900 ° C for 10 hours, and then slowly cools to room temperature;

[0040] d. get the carbon black that particle diameter is 100 μ m and be the composite particle of graphite powder, according to graphite powder: carbon black=5: 1 mass part proportioning after orientation arrangement, make density by flexible graphite coiled material production equipment: 1.2g / cm 3 , Thickness of 3.0mm graphite heat sink.

[0041] Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com