Lithium salt and graphene composite material as well as preparation method and application thereof

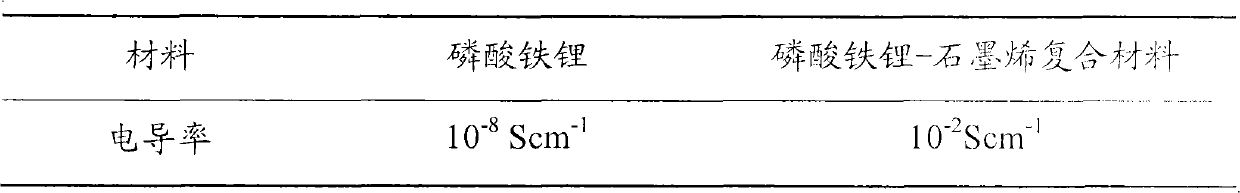

A composite material and graphene technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, electrolytic capacitors, etc., can solve the problems of reduced reversible capacity, reduced area, limited conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Further, the embodiment of the present invention provides the preparation method of the lithium salt-graphene composite material, including the following process steps:

[0025] Preparation of graphite oxide system: oxidize natural flake graphite, potassium permanganate and concentrated sulfuric acid to obtain graphite oxide, and then dissolve it in water;

[0026] Preparation of lithium salt and graphite oxide mixed system: it is prepared by mixing lithium salt and graphite oxide system;

[0027] Formation of mixed powder of lithium salt and graphite oxide: heat the mixed system of lithium salt and graphite oxide to remove water, and pulverize;

[0028] Reductive crystallization: the lithium salt and graphite mixed powder are subjected to reduction reaction and crystallization at 200-1000° C. for 2-24 hours in a reducing atmosphere to obtain the lithium salt-graphene composite material.

[0029] In the above-mentioned preparation steps of the graphite oxide system, th...

Embodiment 1

[0036] Preparation of lithium salt-graphene composites

[0037] (1) Preparation of lithium salt precursor: 1mol of LiH 2 PO 4 and 1mol of FeSO 4 ·7H 2 O was dissolved in deionized water to form a uniformly dispersed mixture, and a solution of 0.5 mol / L LiOH was added dropwise to the mixture under stirring to obtain a pale gray precipitate, which was washed with water and filtered.

[0038] (2) Preparation of graphite oxide system: the preparation method of graphene oxide is according to the improved hummers method, (J.Am.Chem.Soc., 1958,80 (6), 1339-1339, Preparation of GraphiticOxide), about 10g Natural flake graphite, 30g of potassium permanganate and 230ml of concentrated sulfuric acid are mixed and oxidized at a temperature lower than 100°C for 2 hours, then the reactant is washed with water and filtered to obtain graphite oxide, which is then dissolved in a small amount of water. Prepare graphite oxide system containing 0.01mol / L graphite oxide;

[0039] (3) Preparat...

Embodiment 2

[0045] Preparation of lithium salt-graphene composites

[0046] (1) Preparation of lithium salt precursor: 0.3moL of LiH 2 PO 4 , 0.7moL of LiCoO 2 and 1moL of FeSO 4 ·7H 2 O was dissolved in deionized water to form a uniformly dispersed mixture, and a 0.5 mol / L LiOH solution was added dropwise to the mixture under stirring to obtain a pale gray precipitate, which was washed with water and filtered.

[0047] (2) Preparation of graphite oxide system: the preparation method of graphene oxide is to obtain graphite oxide according to the improved hummers method in Example 1, and then dissolve it in a small amount of water to prepare the graphite oxide system containing graphite oxide as 10mol / L;

[0048] (3) Preparation of lithium salt and graphite oxide mixed system: mix lithium salt and graphite oxide with the graphite oxide system in a mass ratio of 99:1, and stir vigorously;

[0049] (4) Preparation of lithium salt and graphite oxide mixed powder: heating and evaporating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com