Chassis armored coating and preparation method thereof

An armor and coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., to achieve the effects of good weather resistance, good adhesion and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

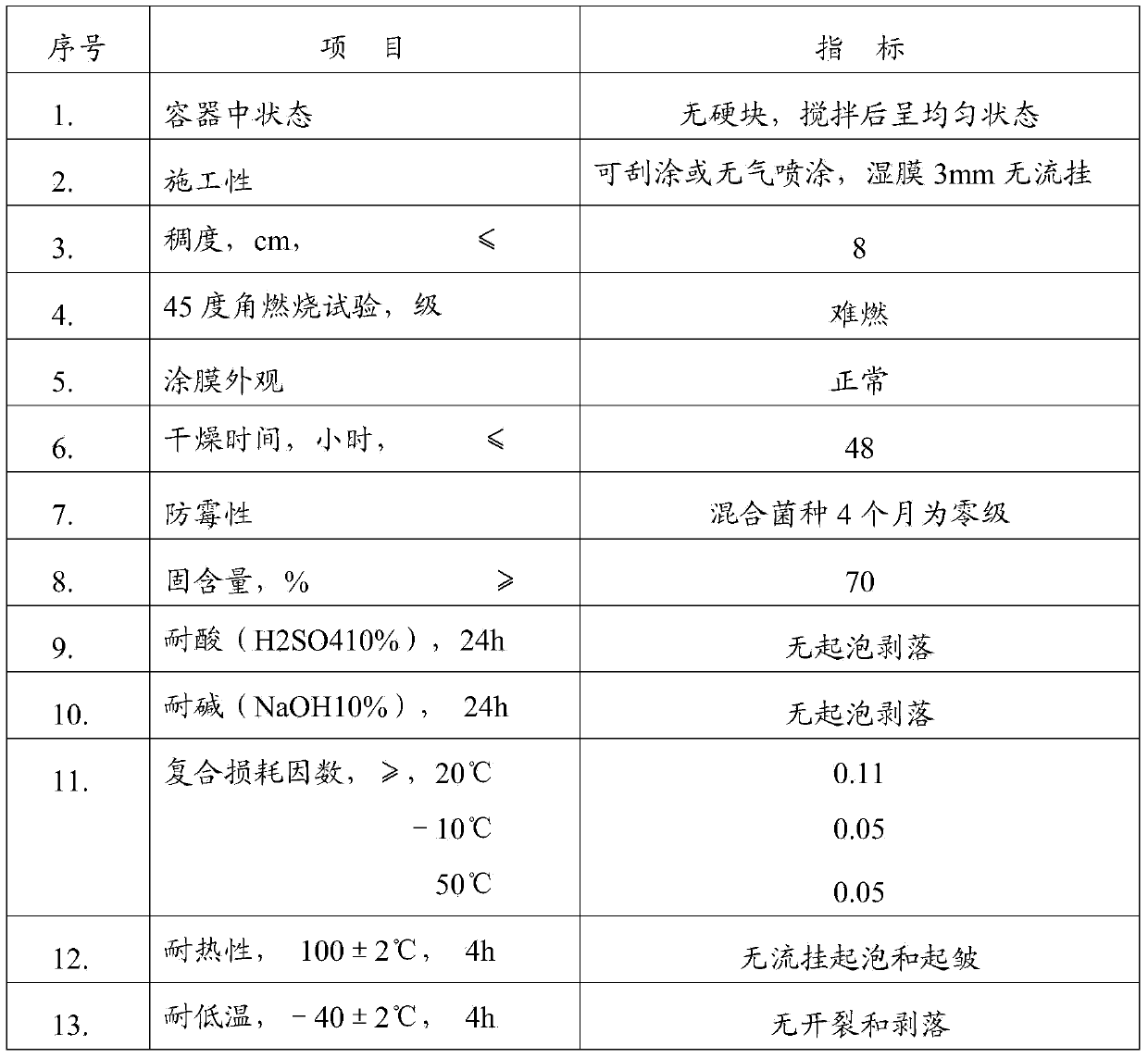

[0033] The preparation technology in the embodiment of the present invention is as follows:

[0034] (1) Preparation of aqueous mixture:

[0035] At room temperature, mix water-based emulsion, 1 / 2 of water, 1 / 2 of defoamer, all antifreeze, wetting agent, dispersant, preservative, antifungal agent, flame retardant, and rust inhibitor according to weight Mix evenly, then add thixotropic agent and paint film anti-cracking agent in turn and stir evenly to obtain an aqueous mixed solution.

[0036] 2) Filler addition and paint mixing:

[0037] Add all functional fillers, film-forming aids, and 1 / 2 defoamer to the above-mentioned aqueous mixture according to the weight ratio, stir and mix at a high speed, then add the remaining 1 / 2 of water, and finally add an appropriate amount of thickener Adjust viscosity. Among them, the order of antifreeze, flame retardant, and rust inhibitor can be interchanged, otherwise it will cause demulsification and gel phenomenon.

Embodiment 1

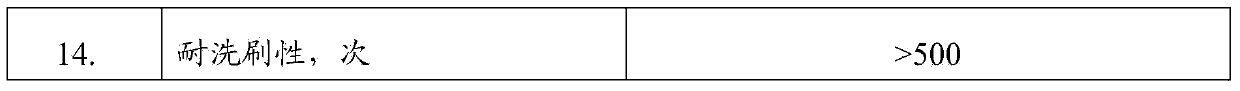

[0040] A kind of chassis armor coating of the present embodiment, with aqueous emulsion as main agent; With expanded perlite, expanded vermiculite, talcum powder, kaolin, calcium carbonate, flaky mica powder, hollow microspheres as functional filler; Silicon is used as a thixotropic agent; wood fiber is used as an anti-cracking agent for the paint film; and an appropriate amount of halogen-free environmentally friendly flame retardant aluminum hydroxide, dispersant, wetting agent, anti-corrosion and anti-mold agent, rust inhibitor, flame retardant, etc. are added Various additives for water-based coatings, the main components are proportioned according to the following weight ratio: 30 parts of water-based pure acrylic emulsion; 15 parts of mica powder, 10 parts of hollow glass microspheres, 10 parts of kaolin, 10 parts of calcium carbonate; 1.0 parts of thixotropic 0.5 parts of anti-cracking agent; 5 parts of halogen-free environmentally friendly flame retardant; 5 parts of co...

Embodiment 2

[0050]A kind of chassis armor coating of the present embodiment, with aqueous emulsion as main agent; With expanded perlite, expanded vermiculite, talcum powder, kaolin, calcium carbonate, flaky mica powder, hollow microspheres as functional filler; Silicon is used as a thixotropic agent; wood fiber is used as an anti-cracking agent for the paint film; and an appropriate amount of halogen-free environmentally friendly flame retardant aluminum hydroxide, dispersant, wetting agent, anti-corrosion and anti-mold agent, rust inhibitor, flame retardant, etc. are added Various additives for water-based coatings, the main components are proportioned according to the following weight ratio: 20 parts of water-based pure acrylic emulsion, 20 parts of styrene-acrylic emulsion; 10 parts of mica powder, 5 parts of hollow glass microspheres, 10 parts of expanded perlite, 10 parts 0.5 parts of thixotropic agent; 0.8 parts of anti-cracking agent; 10 parts of halogen-free environmental protectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com