Patents

Literature

294 results about "Cr element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-toughness ultrafine-grained high-entropy alloy and preparation method thereof

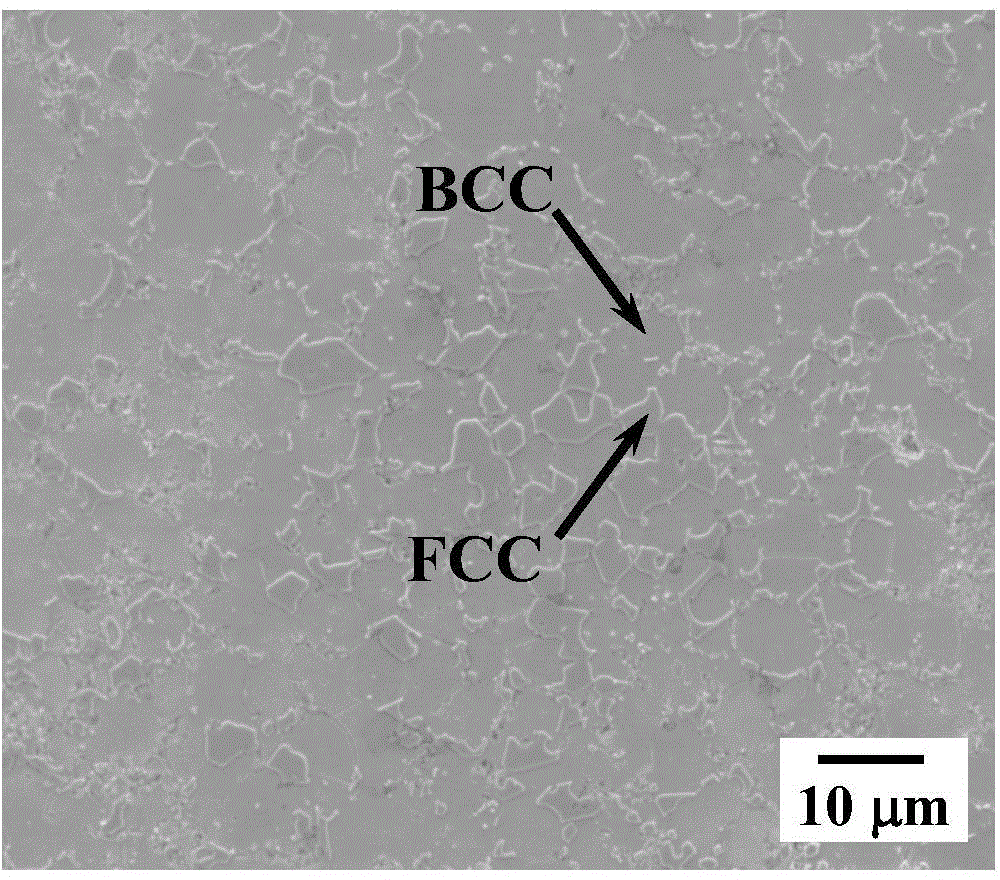

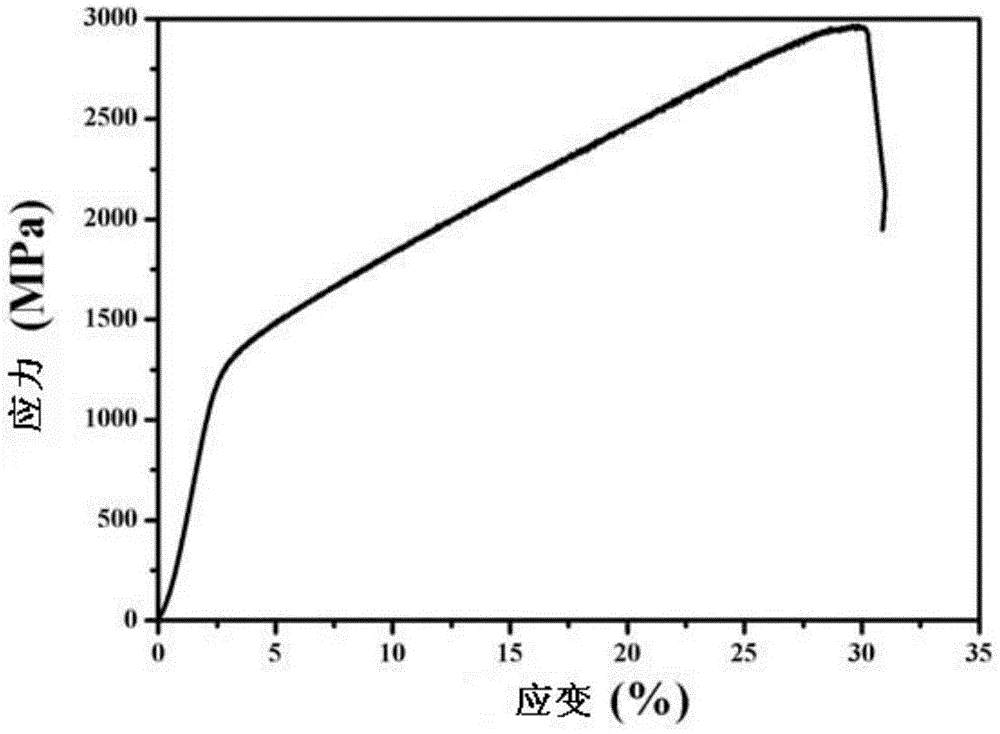

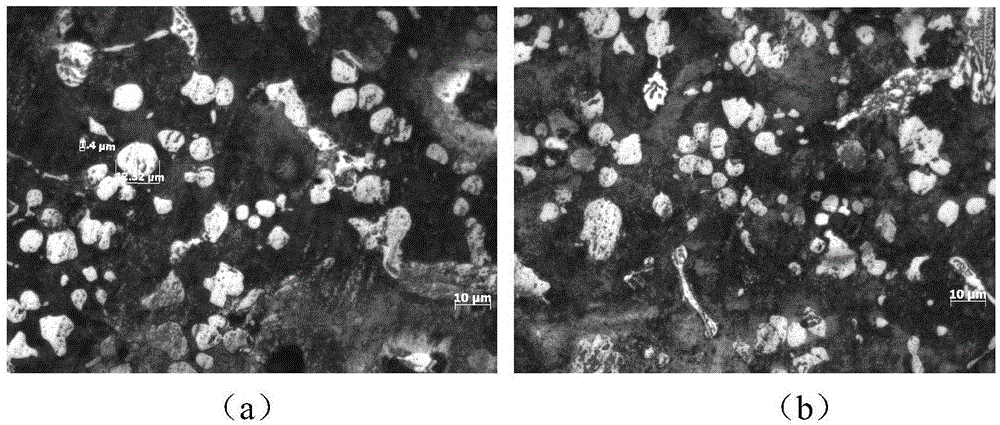

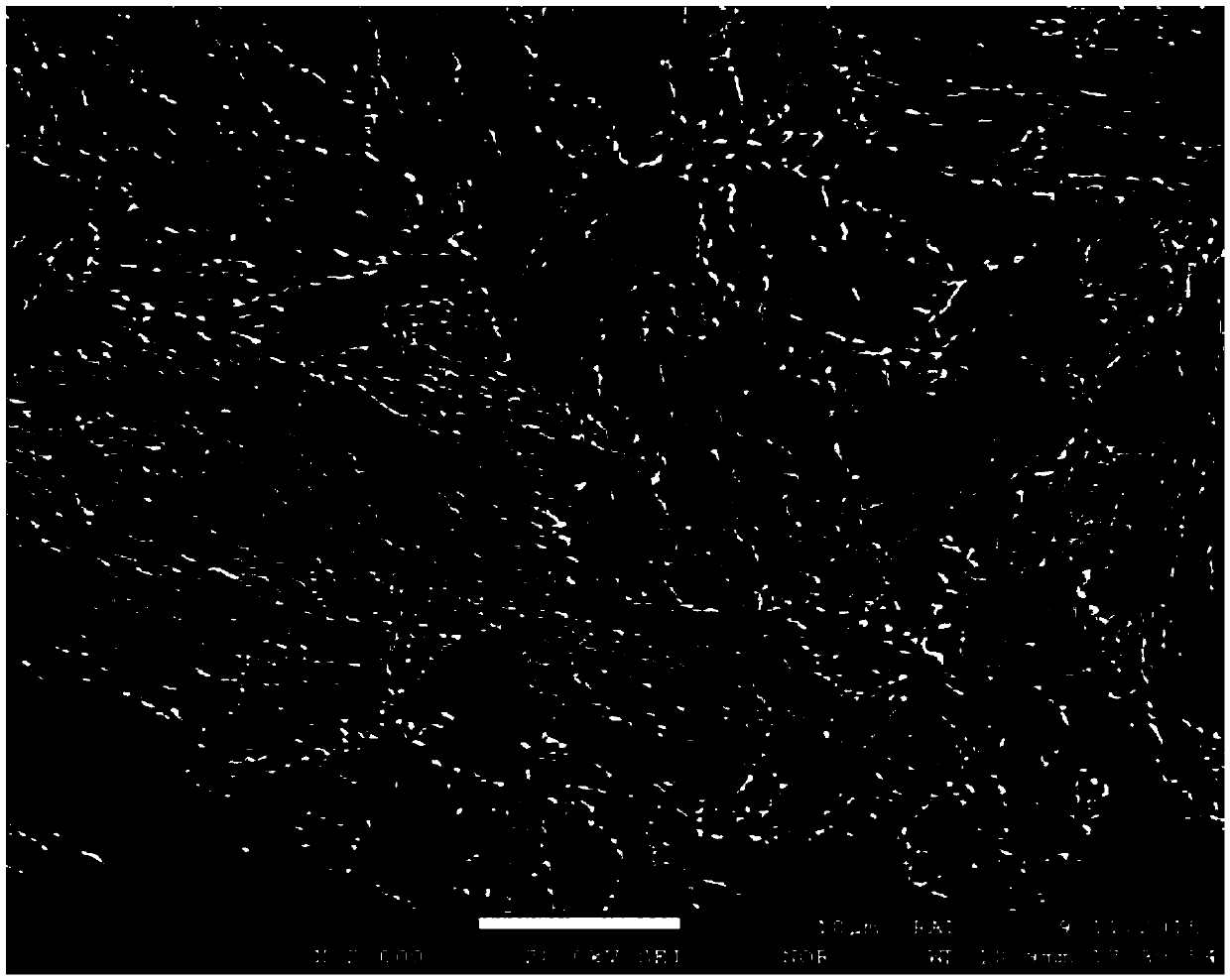

The invention belongs to the technical field of alloy material, and discloses a high-strength high-toughness ultrafine-grained high-entropy alloy and a preparation method thereof. The high-strength high-toughness ultrafine-grained high-entropy alloy is composed of the following elements according to the atomic percentage: 20%-25% of Ni, 18%-20% of Fe, 18%-22% of Co, 18%-20% of Cr, and 20%-24% of Al; the microstructure takes a body-centered cubic disordered solid solution phase rich in Ni and Al elements as a matrix phase, and takes a face-centered cubic disordered solid solution phase rich in Fe and Cr elements as a reinforcing phase. The preparation method of the alloy comprises the steps: elemental powders with the atomic percentages are subjected to powder mixing and high-energy ball milling to prepare an amorphous composite powder, and the amorphous composite powder is sintered to obtain the high-strength high-toughness ultrafine-grained high-entropy alloy. The prepared high-entropy alloy has the advantages of large size and good comprehensive mechanical properties, and can be used in the fields of aeronautics and astronautics, military industry, electrons, instruments and apparatuses and the like.

Owner:SOUTH CHINA UNIV OF TECH

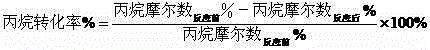

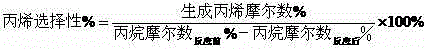

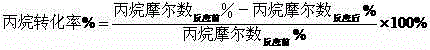

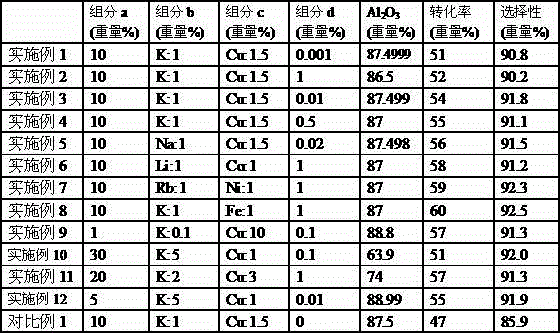

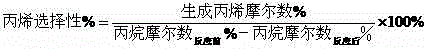

Catalyst for dehydrogenating light alkane

The invention relates to a catalyst for dehydrogenating light alkane in order to mainly solve the problem of relatively-low activity of a dehydrogenating catalyst prepared in the prior art. The problem is better solved through the technical scheme that the catalyst for dehydrogenating light alkane comprises the following components in parts by weight: 1-30 parts of a Cr element or an oxide of the Cr element (a), 0.1-5 parts of alkali metal oxides or alkaline earth metal oxides (b), 0.001-1 part of the group VA elements selected from a periodic table of elements or oxides of the group VA elements (c), 0.001-1 part of the group IIIA elements selected from the periodic table of elements or oxides of the group IIIA elements (d), and 54-99 parts of Al2O3 or SiO2 (e). The catalyst can be used for industrial production of light olefin prepared by dehydrogenating light alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

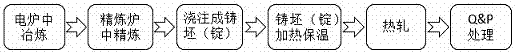

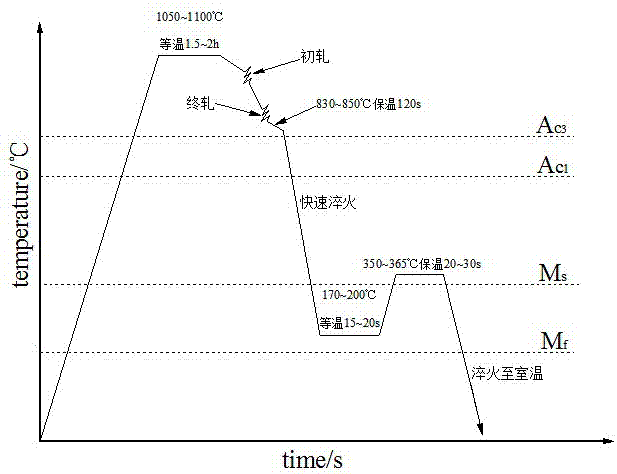

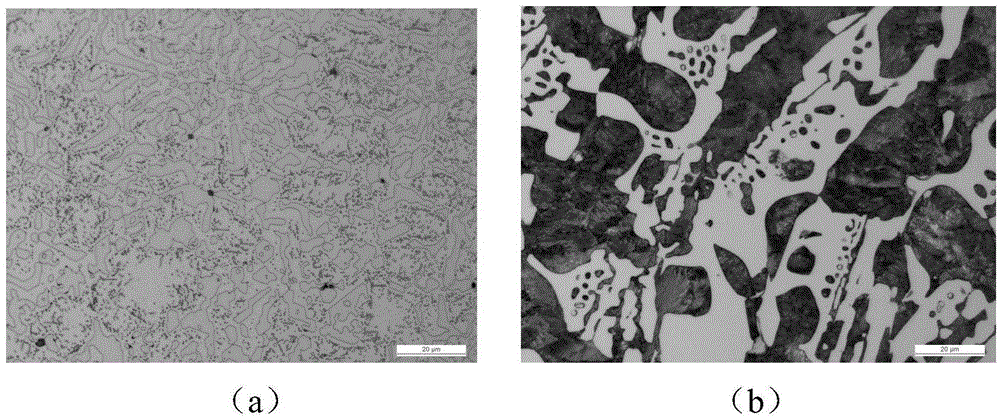

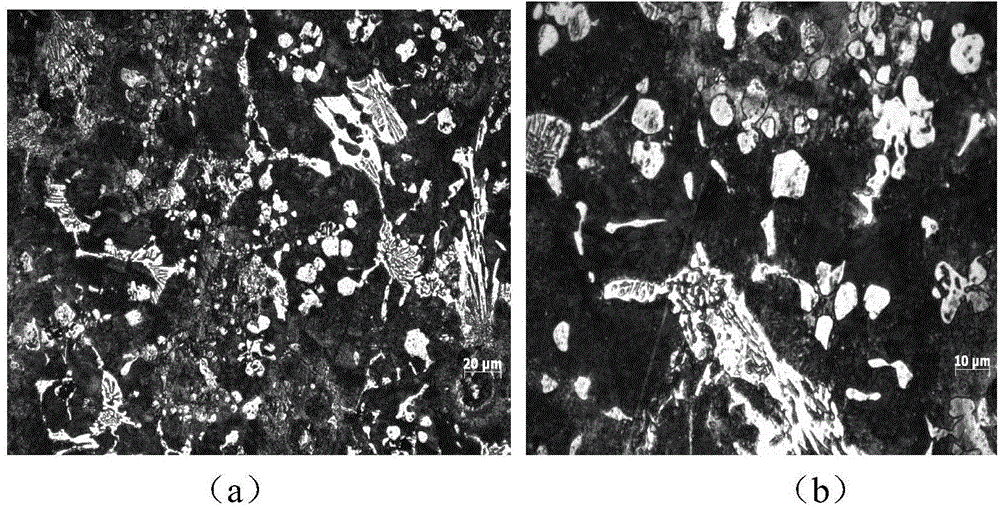

High-strength hot-rolled Q and P steel and manufacturing method thereof

The invention discloses a high-strength hot-rolled Q and P steel and a manufacturing method thereof. The high-strength hot-rolled Q and P steel contains the chemical components in percentage by weight: 0.20-0.50% of C, 0.8-2.0% of Si, 1.5-3.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.02-0.08% of Al, less than or equal to 0.006% of N, 0.005-0.015% of Ti, 0.5-1.5% of Cr and the balance of Fe and unavoidable impurities. On the basis of the traditional C-Mn steel components, the content of Si is increased to inhibit the separation of a cementite, a trace of Ti is added to control the size of an austenite grain during heating, so that fine lath martensite is obtained during quenching; and a certain quantity of Cr element is added to improve the hardenability of a steel plate and delay the conversion from a residual austenite to a bainite at a distribution stage, so that the high-strength hot-rolled wear-resistant steel is manufactured at low cost, and the steel has the tensile strength of greater than 1500MPa and favorable elongation of greater than 10% and is excellent in strength and plasticity matching.

Owner:BAOSHAN IRON & STEEL CO LTD

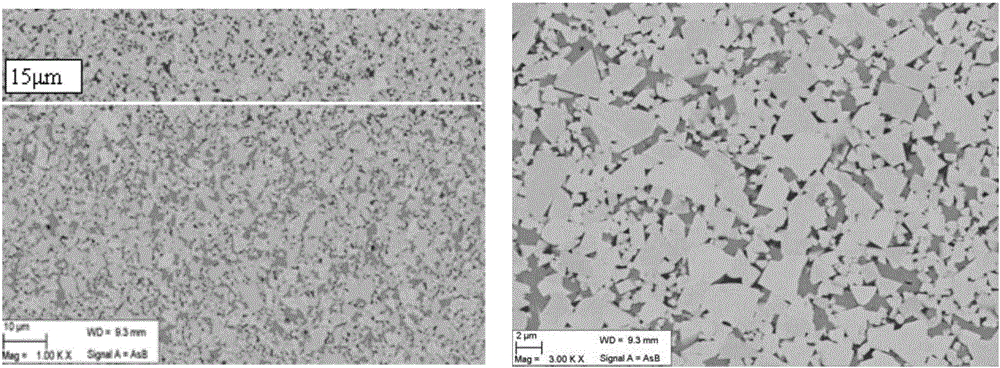

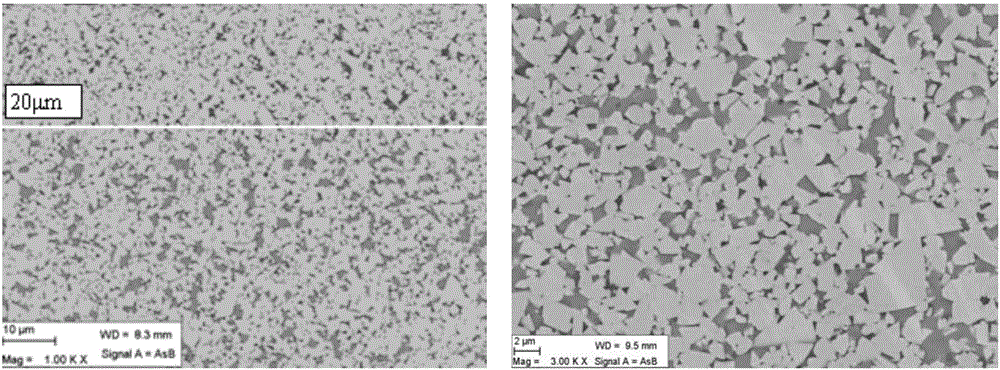

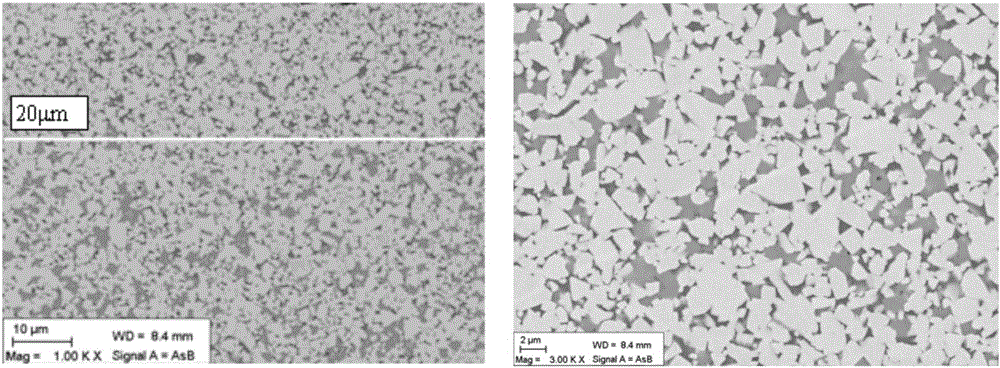

Non-oriented high-silicon electrical steel ribbon and its making method

InactiveCN103060701ASolve the characteristics of poor processing performanceImprove magnetismElectrical steelUltimate tensile strength

The invention relates to a non-oriented high-silicon electrical steel ribbon and its making method, and belongs to the fields of the metallurgical technology and the material science. The chemical components of the ribbon comprise 4.5-7.0wt% of Si, 2.0-5.0wt% of Cr, 0.06-1.0wt% of Al, 0.3-0.8wt% of Mn, 0.005wt% or less of N, 0.004wt% or less of S, 0.02wt% or less of P, 0.003wt% or less of O, 0.005wt% or less of C, and the balance Fe, and the thickness of the ribbon is 0.35-0.5mm. The making method comprises the following steps: smelting non-oriented high-silicon steel in a vacuum smelting furnace; carrying out double-roller ribbon roll-casting at a casting temperature of 1420-1460DEG C to the ribbon thickness of 1.0-1.5mm; carrying out hot rolling of the ribbon at 800-1100DEG C to the hot rolled ribbon thickness of 0.8-1.0mm; pickling, and preheating the ribbon, and carrying out warm rolling at 400-700DEG C; and annealing. The addition of the Cr element in the high-silicon electrical steel ribbon obviously improves the processing performance of the high-silicon steel ribbon, the iron loss value is same to the iron losses of present high-silicon steel products, and the magnetic induction intensity is above 0.03T higher than that of the present products. The making method has the advantages of simple technology, low energy consumption, high yield, and excellent product magnetic property.

Owner:NORTHEASTERN UNIV

Hard alloy blade and preparation method thereof

ActiveCN105950937AHigh hardnessImprove high temperature performanceTurning toolsTi elementTungsten carbide

The invention discloses a hard alloy blade and a preparation method thereof. The hard alloy blade comprises a hard alloy blade basal body and a coating layer; the hard alloy blade basal body uses Co as a binding phase, and uses tungsten carbide and a titanium-contained cubic-phase compound as a hard phase; the solid solution is performed for a W element and a Cr element in the binding phase; the mass fraction of the W element in the binding phase is 2-10 wt.%; the mass fraction of the Cr element in the binding phase is 1-10 wt.%; the titanium-contained cubic-phase compound is a carbon-nitrogen compound containing one or two in a Ta element and a Nb element and a Ti element; and the grain distribution of tungsten carbide has a double-peak structure. The preparation method comprises batching, powder preparation by mixing, molding by pressing, sintering and preparation of a coating layer. The hard alloy blade has the advantages of high hardness, toughness and strength and excellent and stable cutting performance, and is high in generality, suitable for various processing fields, simple in preparation method and low in cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Metal support half-cell of solid oxide fuel cell and preparation method thereof

ActiveCN103928693AAvoid direct contactReduce interdiffusionCell electrodesSolid electrolyte fuel cellsFuel cellsMixed oxide

The invention discloses a metal support half-cell of a solid oxide fuel cell and a preparation method thereof. The half-cell comprises a porous metal supporting layer thick membrane, a porous cermet gradient transition layer film, a porous anode layer and a compact electrolyte layer film from down to up. The porous gradient transition layer composed of a mixed oxide and a oxide with a fluorite structuring can avoid the direct contact of the porous metal supporting layer and the porous anode layer, and the mutual diffusion of Fe / Cr elements in the metal supporting layer and Ni element in the porous anode layer can be reduced under high temperature sintering condition. The mixed oxide is reduced to an alloy under the work condition of the cell; a high anode active material is formed at a side interface of the anode, a high conductivity composite material which takes the alloy as a main phase is formed on the side interface of a metal support body, so that higher conductivity is presented, ohmic resistance is reduced, electrocatalytic activity is not reduced, long-term stability for operation of the cell can be ensured, and good combination of the porous metal supporting layer and the porous anode layer can be simultaneously realized.

Owner:中弗(无锡)新能源有限公司

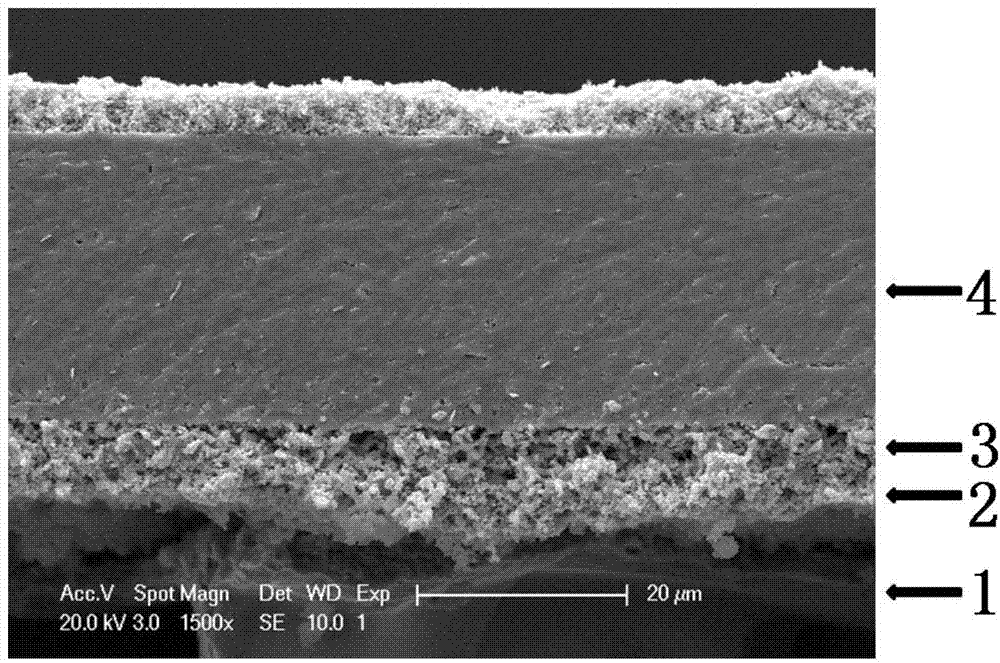

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

Manufacturing method of steel

The invention provides a manufacturing method of steel, comprising the following steps: smelting the molten steel to ensure that the content of P in the molten steel is less than or equal to 0.035%, the content of S is less than or equal to 0.015% and the content of V is less than or equal to 0.15%; then adding Cu element and Ni element to the molten steel to ensure that the content of Cu in the molten steel is 0.20-0.60% and the content of Ni is 0.15-0.55%; tapping to a steel ladle when the content of C in the molten steel is below 0.05%; adding physical mixture of lime and fluorite and predeoxidizing agent to the steel ladle in the tapping process to ensure that the content of S in the molten steel is less than or equal to 0.012%; adding Cr element, Si element and Mn element to the molten steel to ensure that the content of Si in the molten steel is 0.25-0.60%, the content of Mn is 0.80-1.60% and the content of Cr is 0.20-0.80%; feeding Al simple substance to the molten steel to carry out final deoxidation; heating the molten steel in the condition of argon blowing to lead the steel slag to melt; then adding Al simple substance to the steel ladle to ensure that the content of S in the molten steel is less than or equal to 0.010%; and then adding C element to the molten steel to ensure that the content of C in the molten steel is 0.08-0.16%; feeding Al simple substance and alloy containing Ti, V and N to the molten steel to control that the content of acid-soluble aluminium in the molten steel is 0.025-0.040%, the content of Ti is 0.005-0.015%, the content of V is 0.08-0.15% and the content of N is 0.010-0.020%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

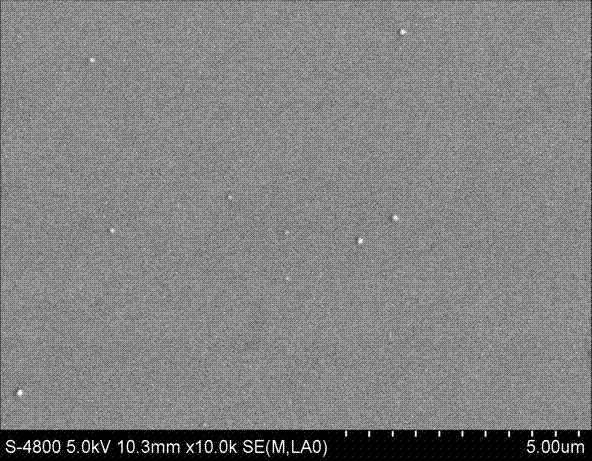

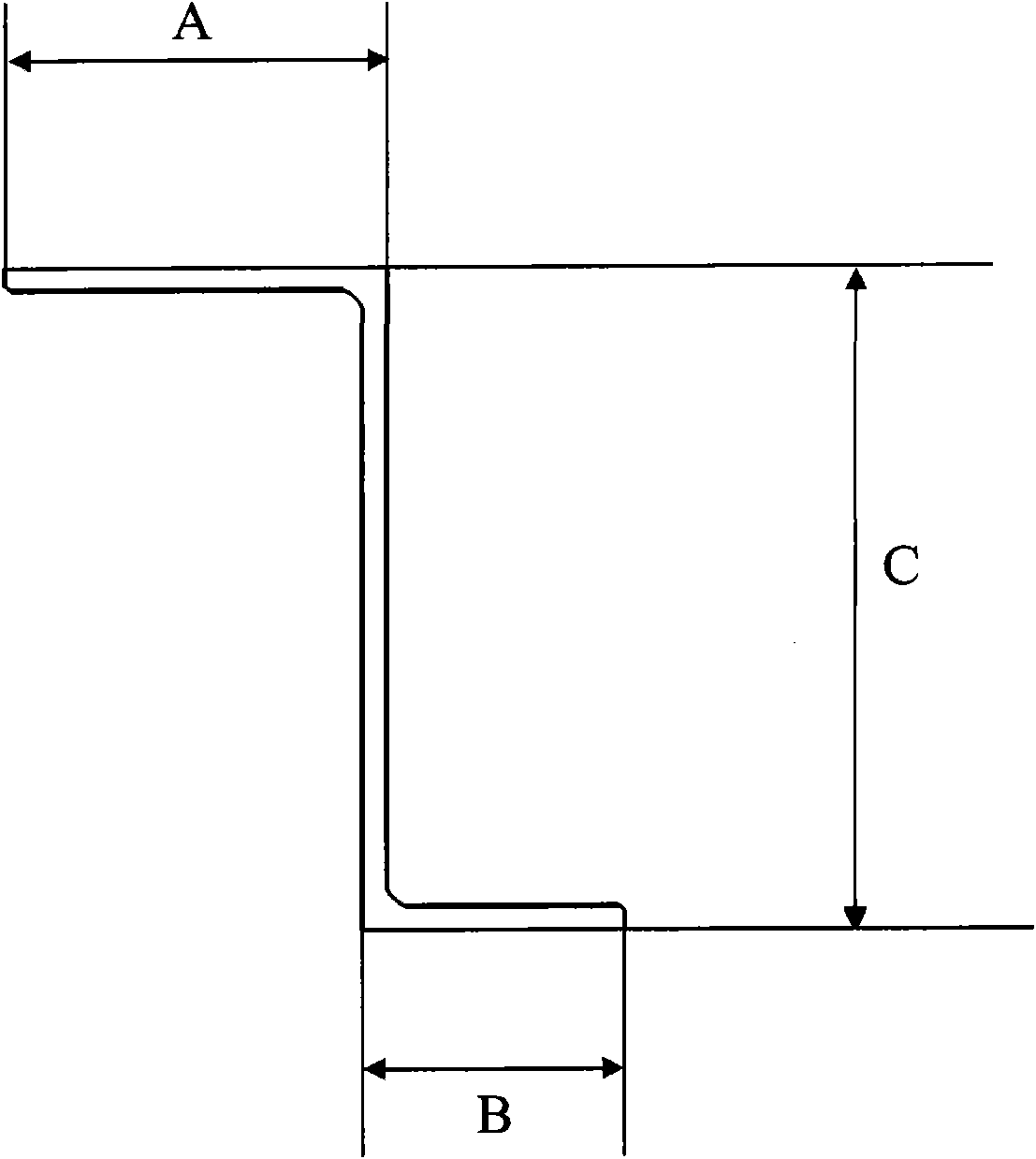

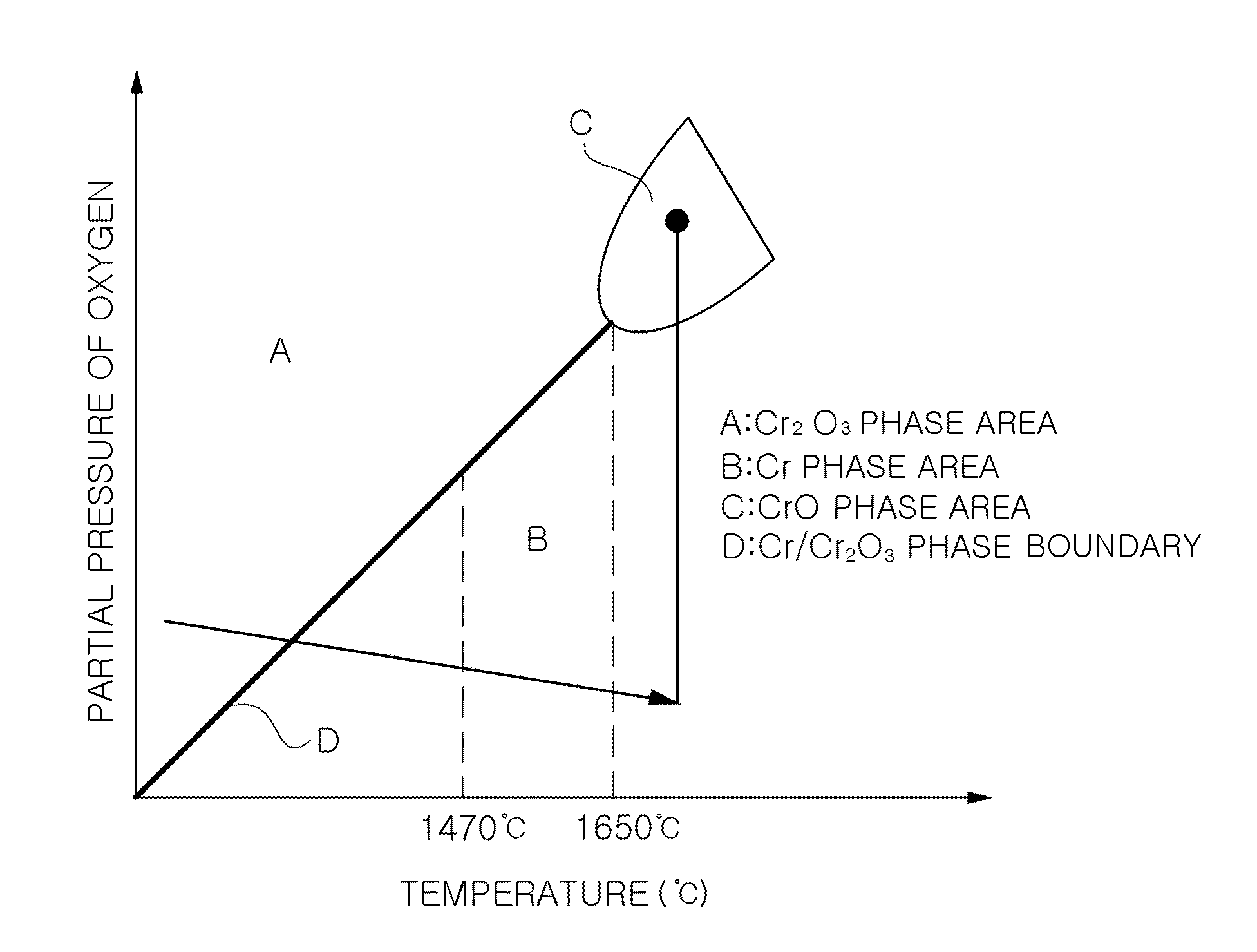

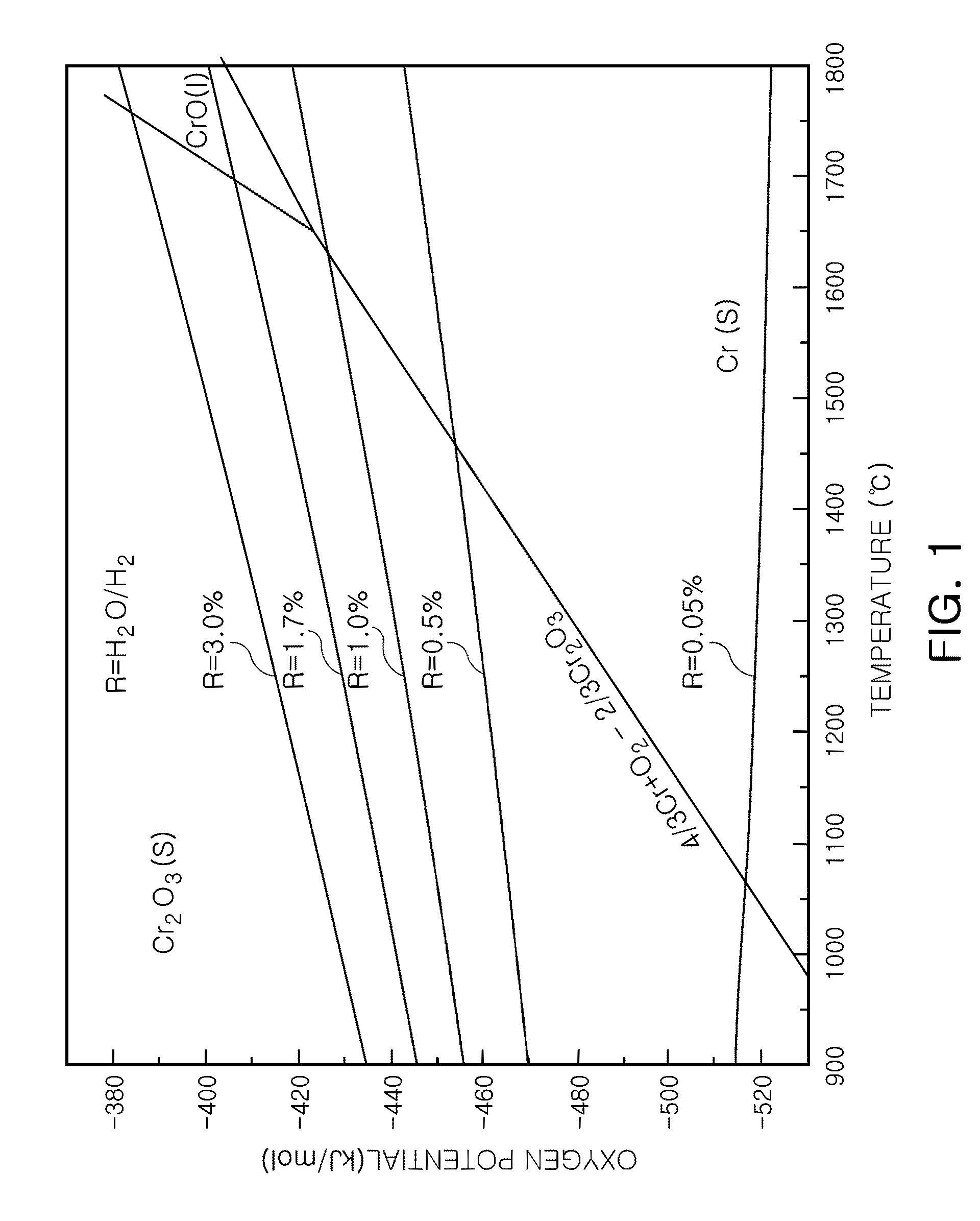

Method of producing large-grained nuclear fuel pellet by controlling chrome cation solubility in uo2 lattice

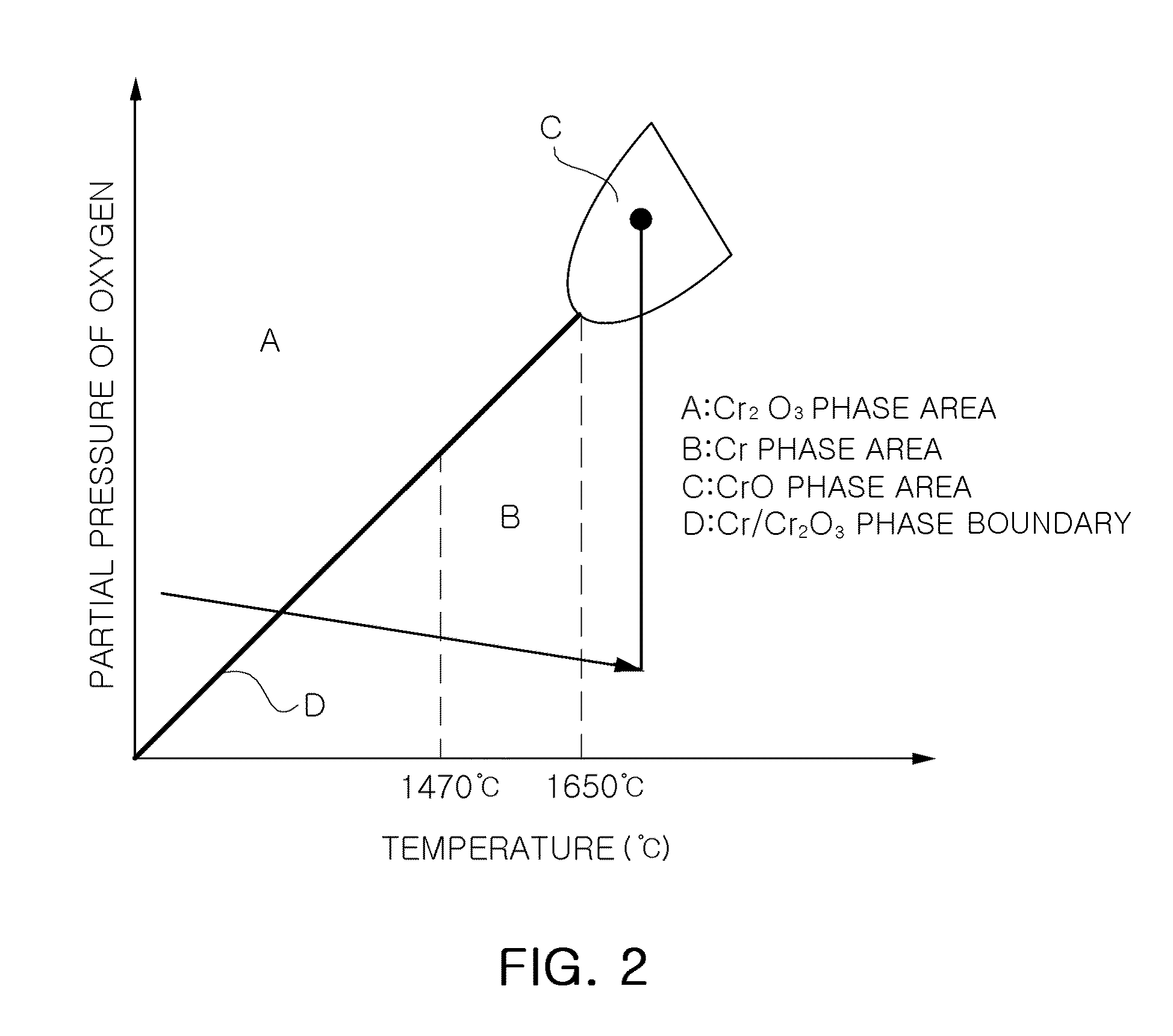

In a method of producing large-grained nuclear fuel pellet, Cr-compound contained in an uranium oxide green pellet is reduced to Cr phase at 1,470° C. or below and maintained to the Cr phase, and the uranium oxide green pellet containing the Cr-compound is then sintered at 1,650° C.-1,800° C. in a gas atmosphere of oxygen potential at which Cr element in the uranium oxide green pellet becomes liquid phase.

Owner:KOREA ATOMIC ENERGY RES INST +1

Environment friendly no-chromium conversion treating solution

InactiveCN1986883ACreate pollutionImprove corrosion resistanceMetallic material coating processesRedoxTitanium

The environment friendly no-chromium conversion treating solution consists of titanium salt in 1-25 g / l, complexing agent in 12-30 g / l, silicate in 5-15 g / l, redox agent in 10-25 g / l, additive in 3- 6.5 g / l and deionized water for the rest. The treating solution contains no Cr element, is suitable for chemical conversion treatment of galvanizing coating and zinc alloy product, and produces no environmental pollution. When the treating solution is used in chemical conversion treatment of galvanizing coating and zinc alloy product, white film, blue film or film in other color may be obtained.

Owner:BEIHANG UNIV

Low-alloy high-intensity high-toughness steel and production method of low-alloy high-intensity high-toughness steel

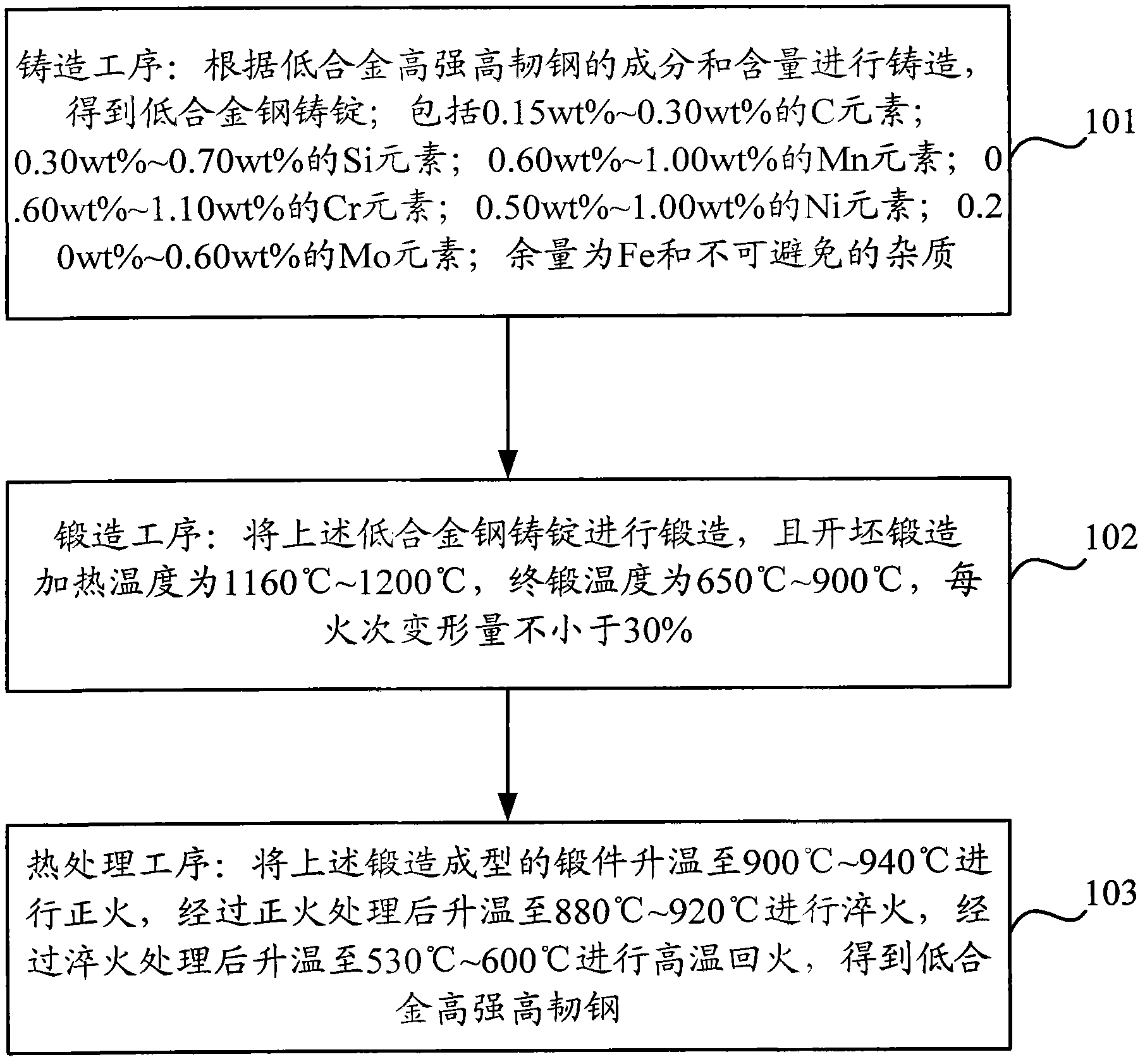

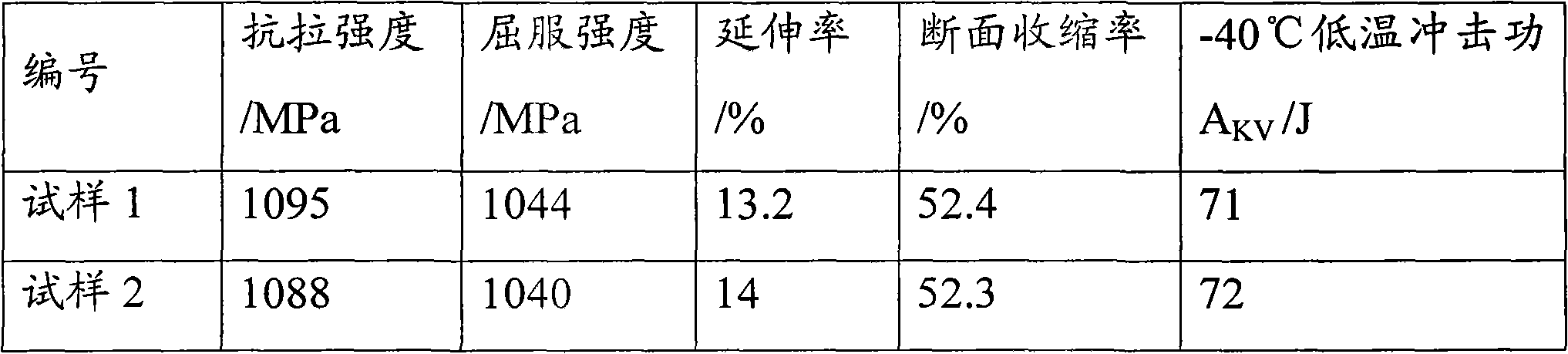

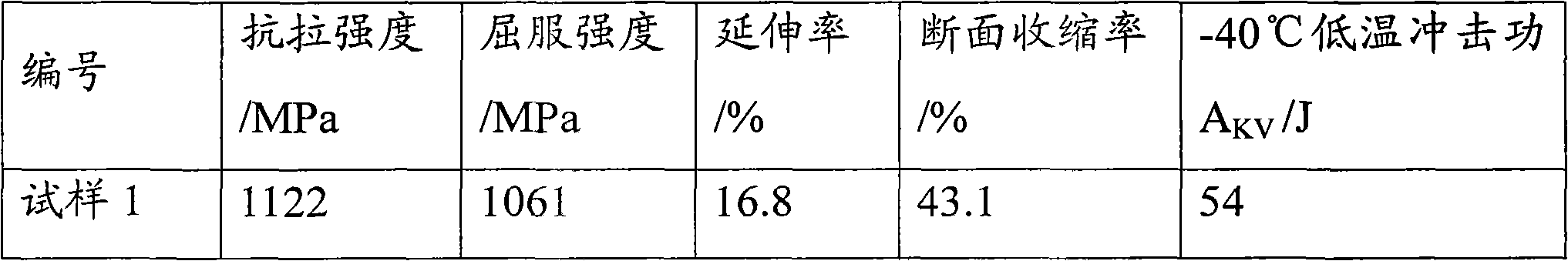

The invention discloses low-alloy high-intensity high-toughness steel and a production method of low-alloy high-intensity high-toughness steel. The method comprises the following work procedures of: the casting work procedure: the casting is carried out according to the following ingredients and contents to obtain low-alloy steel cast ingots: 0.15 to 0.30 weight percent of C elements, 0.30 to 0.70 weight percent of Si elements, 0.60 to 1.00 weight percent of Mn elements, 0.60 to 1.10 weight percent of Cr elements, 0.50 to 1.00 weight percent of Ni elements, 0.20 to 0.60 weight percent of Mo elements and the balance Fe and unavoidable impurities; the forging work procedure: the low-alloy steel cast ingots are forged, in addition, the blank opening forging heating temperature is 1160 DEG C to 1200 DEG C, the final forging temperature is 650 DEG C to 900 DEG C, and the deformation in each firing time is not smaller than 30 percent; and the heat treatment work procedure: the temperature of the forged and formed forgings is raised to 900 to 940 DEG C to be subjected to normalizing, the temperature is raised to 880 to 920 DEG C for carrying out quenching after the normalizing treatment, the temperature is raised to 530 to 600 DEG C for carrying out high-temperature tempering after the quenching treatment, and the low-alloy high-intensity high-toughness steel is obtained. In the embodiment of the invention, the low-alloy high-intensity high-toughness steel has high intensity and high toughness.

Owner:SANY GRP

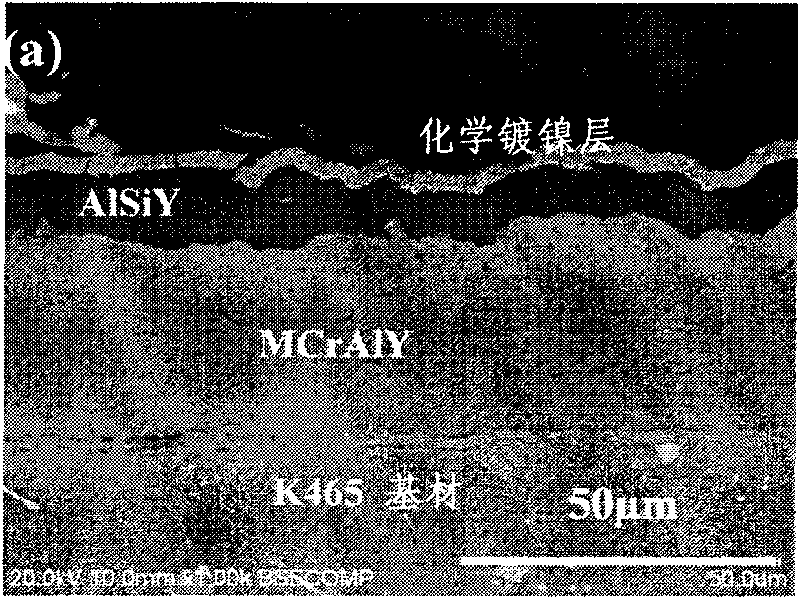

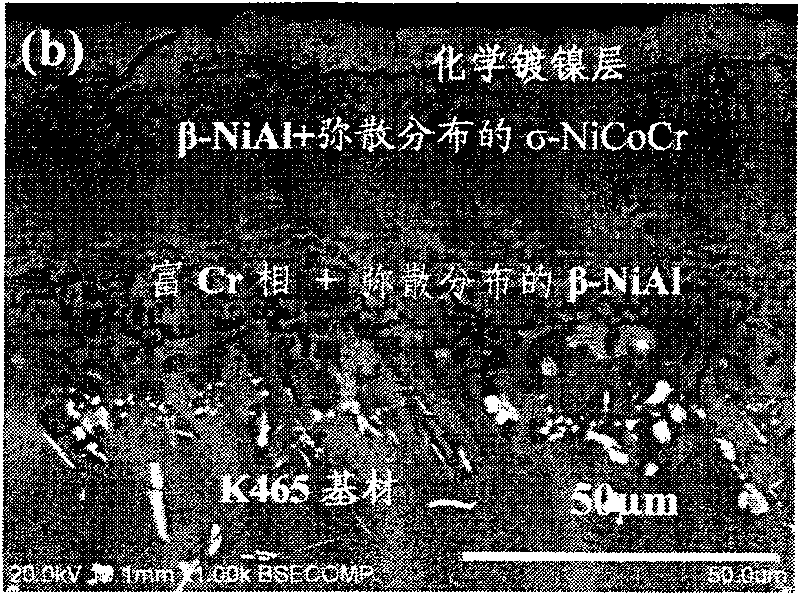

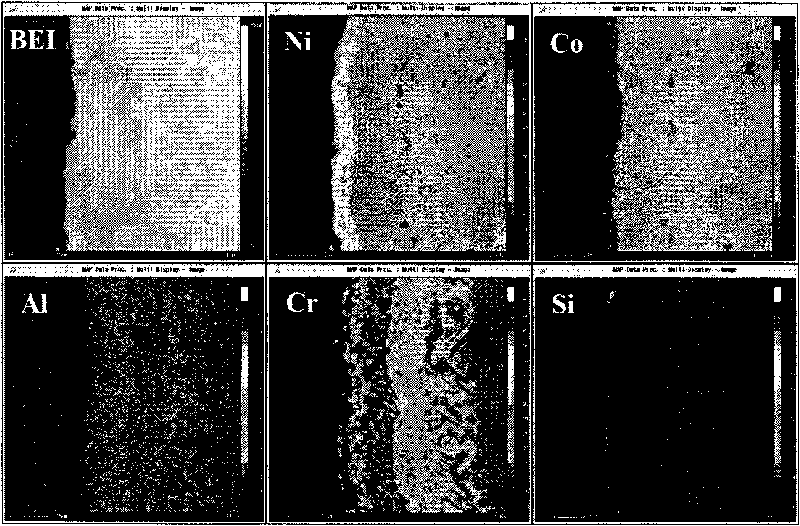

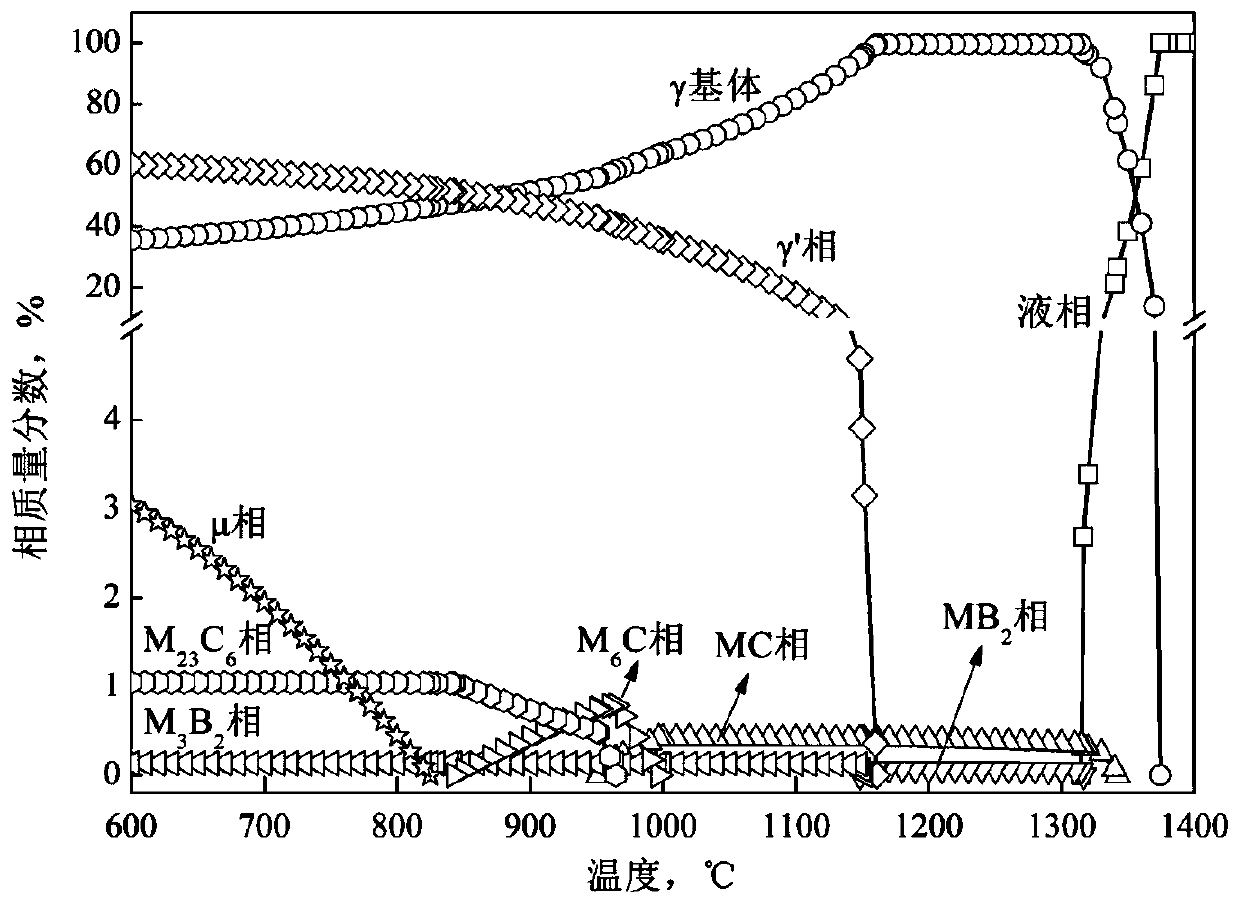

MCrAlY+AlSiY composite coating and preparation technique thereof

InactiveCN101724301AExtended service lifeIncrease contentFireproof paintsVacuum evaporation coatingSurface layerSuperalloy

The invention relates to high-temperature protective coating technology, in particular to an MCrAlY+AlSiY composite coating and a preparation technique thereof. A MCrAlY composite coating, which is rich in Al on an outer layer and rich in Cr on an inner layer and is distributed in a gradient form, is formed by depositing an AlSiY coating on a MCrAlY coating and by using a vacuum diffusion annealing method. The concentration of Al elements on the surface layer of the composite coating is 18 to 22 weight percent, and the concentration of Cr elements on the inner layer is 28 to 45 weight percent. The MCrAlY composite coating, which is rich in Al on the outer layer and rich in Cr on the inner layer and is distributed in a gradient form, is prepared by combination of arc ion plating deposition and the vacuum diffusion annealing. Compared with the existing conventional MCrAlY high-temperature protective coating, the MCrAlY+AlSiY composite coating of the invention effectively improves an A1 storage phase content and Si content in the surface layer of the coating; and the layer rich in Cr is formed on the inner layer of the coating, so the high temperature oxidation resistance and hot-corrosion resistance of the coating are improved, and the service life of the coating can be effectively prolonged. The composite coating and a preparation method thereof are suitable for protecting Ni-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

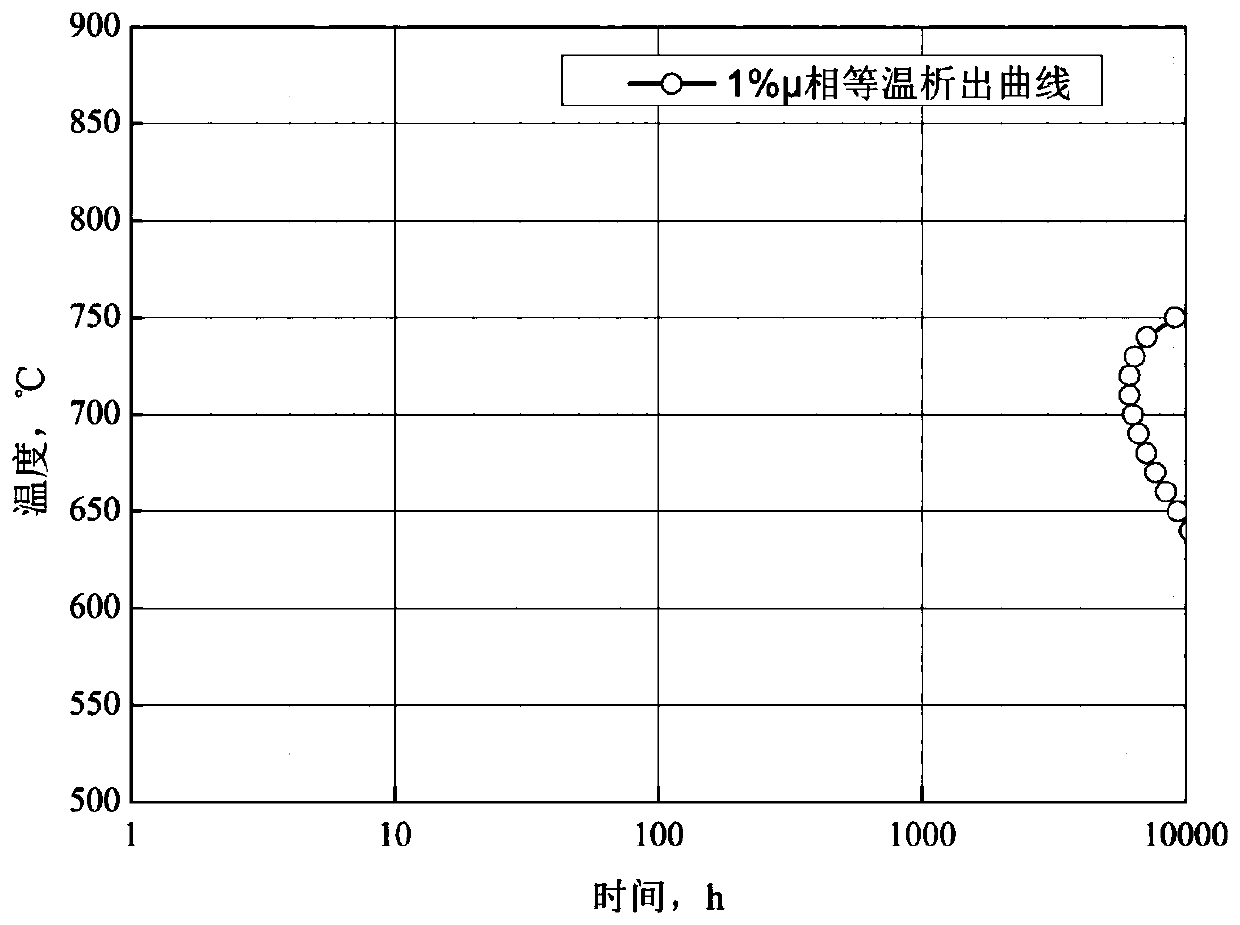

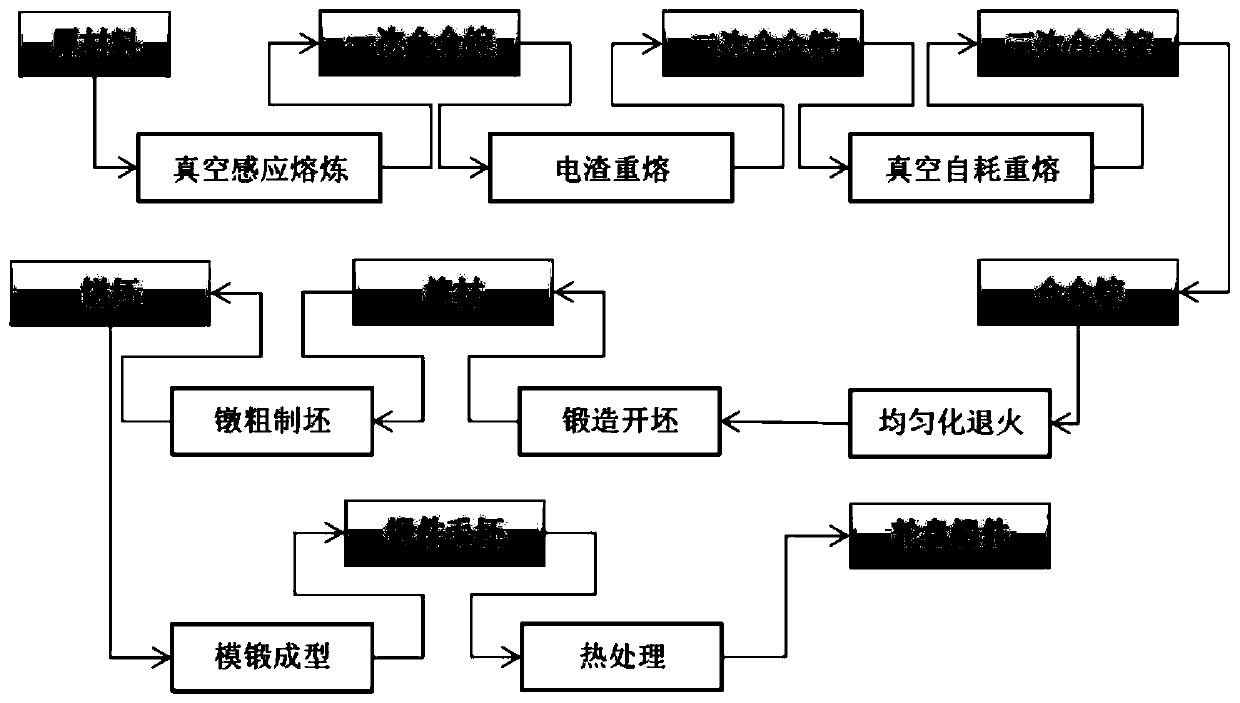

Nickel-based deformed superalloy with high aluminum content and preparation method thereof

ActiveCN111187946AGood mechanical propertiesSatisfied with service stabilityMetal-working apparatusSolid solution strengtheningSuperalloy

The invention provides a nickel-based deformed superalloy with high aluminum content and a preparation method thereof. A traditional Ni-Co-Cr component serves as a matrix element, the content of the alloy element is increased, particularly, the content of a solid solution strengthening phase gamma'phase forming element Al is increased, the content of a strengthening phase gamma'phase is increasedto 55%-65%, and the temperature bearing capacity of the alloy is effectively improved. A proper amount of Nb element is added into the alloy, so that the stability of a gamma'phase can be improved, the casting-forging process performance is further improved, the long-time structure stability of the alloy at 850 DEG C can be improved by reducing the addition of Cr element, and the surface stabilityloss caused by the reduction of the Cr element can be compensated by the high-content Al element. Meanwhile, a duplex technology or a triple technology is adopted for preparing and machining an alloyraw material, the obtained nickel-based deformed superalloy solves the problem that no high-performance wheel disc forge piece material capable of being used at 850 DEG C for a long time exists at present, and the nickel-based deformed superalloy particularly has excellent tensile strength and yield strength and long service life at 850 DEG C.

Owner:BEIJING CISRI GAONA TECH +1

Hot rolling multiphase steel and production method thereof

The invention provides a hot rolling multiphase steel, which is produced by employing a billet-heating furnace-rough rolling-finish rolling-reeling process flow, and the obtained hot rolling multiphase steel contains the following chemical components by mass: 0.07-0.10% of C, 0.50-1.00% of Si, 0.90-1.50% of Mn, no more than 0.02% of P, no more than 0.004% of S, no more than 0.05% of Al, 0.0005-0.0010% of B, no more than 0.0050% of N, 0.060-0.150% of Ti, and the rest of Fe and inevitable impurities. The invention provides the hot rolling multiphase steel, and in the condition that the production technology cost is not changed, the B element can replace the Cr element in the hot rolling multiphase steel, thereby reducing alloy cost; the intensity and plasticity of the obtained hot rolling multiphase steel are matched well.

Owner:SHOUGANG CORPORATION

6-series railway vehicle suspension arm aluminum profile and preparation method thereof

ActiveCN104073698AFine Stable MicrostructureHomogeneous dispersion stateChemical compositionMaterials science

The invention discloses a 6-series railway vehicle suspension arm aluminum profile which contains the following metal substances in percentage by mass: 0.6-0.7% of Si, less than 0.15% of Fe, 0.5-0.7% of Mg, 0.02-0.25% of Mn, less than 0.01% of Cu, 0.1-0.25% of Cr, less than 0.05% of Zn, 0.03-0.06% of Ti and the balance of Al. The invention also discloses a preparation method of the 6-series railway vehicle suspension arm aluminum profile. The 6-series railway vehicle suspension arm aluminum profile has optimized chemical components as compared with the aluminum profile in the prior art, the Mn element content is enhanced to 0.2%, and the Cr element content is enhanced to 0.12%; the Mn can be utilized to enhance the recrystallization temperature characteristic and inhibit the crystal grains from growing, thereby refining the crystal grains of the profile and enhancing the microstructure of the material (grain refinement); and the optimized aluminum profile has the advantages of high tensile strength, high yield strength and high elongation percentage.

Owner:龙口市丛林铝材有限公司

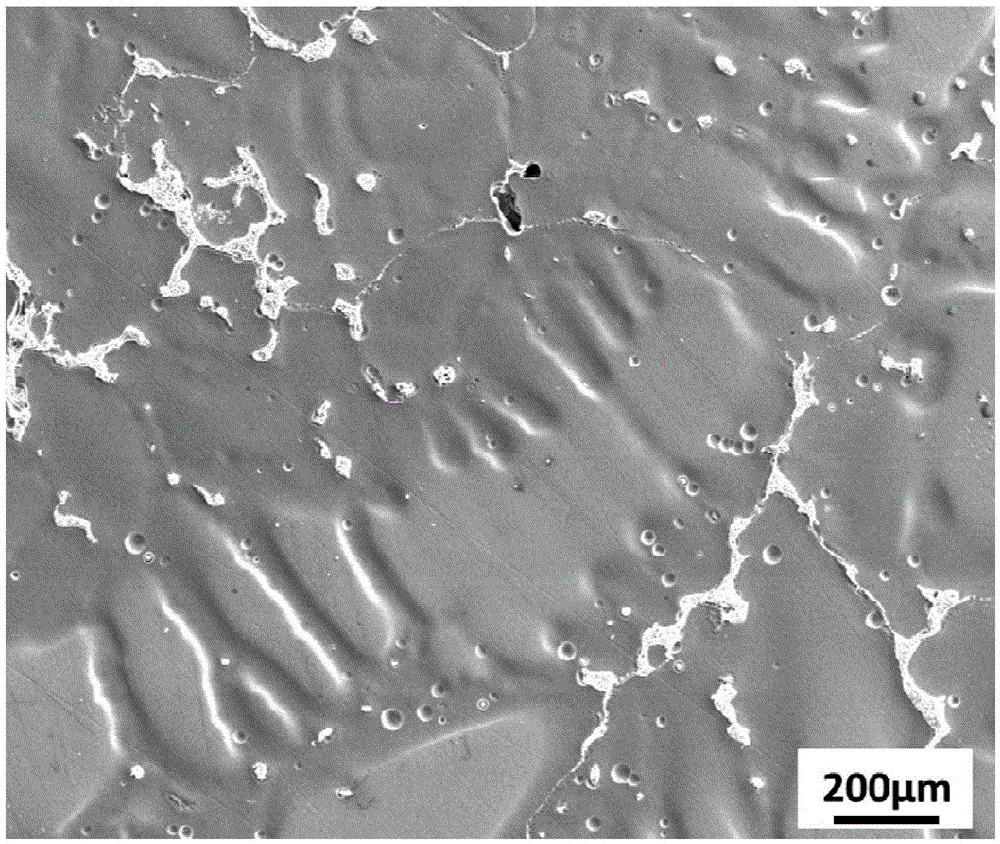

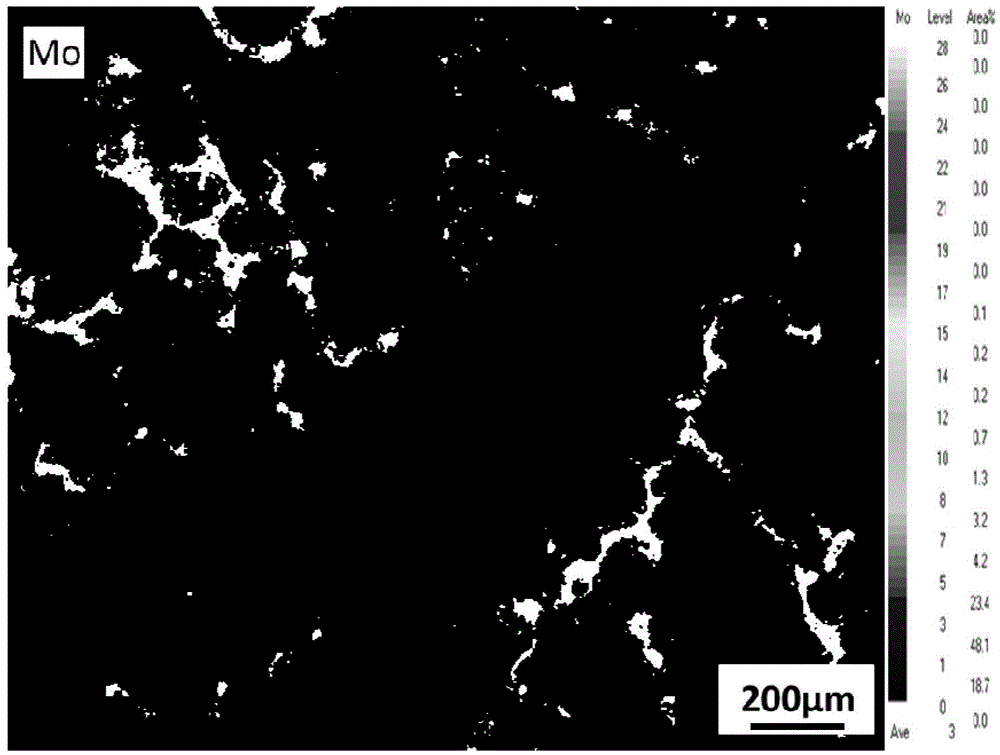

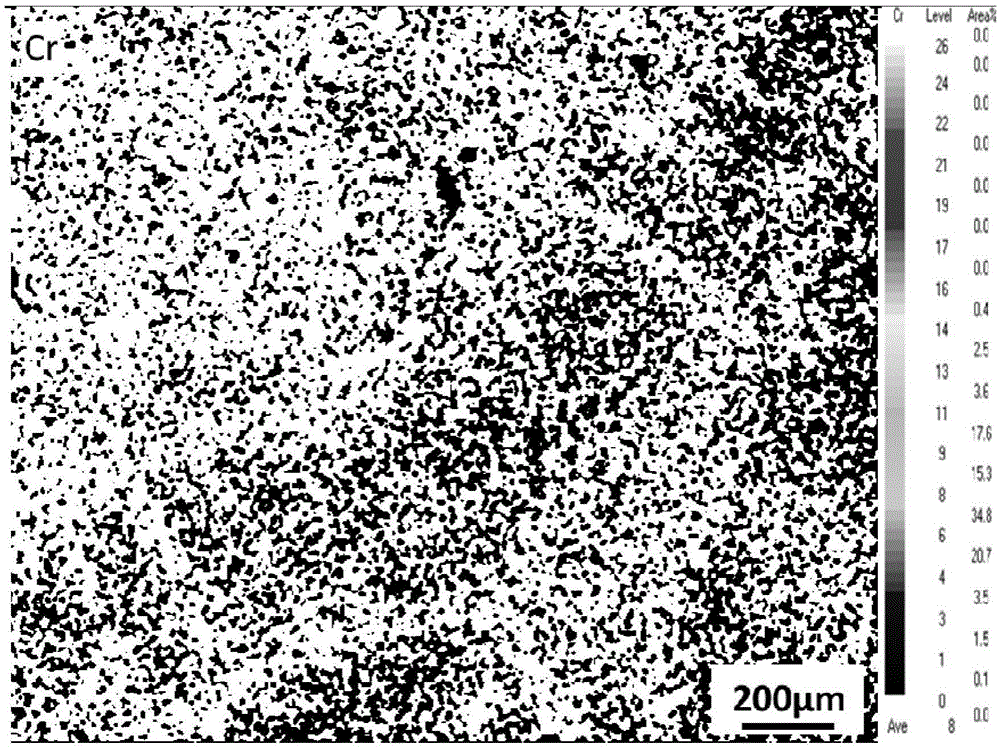

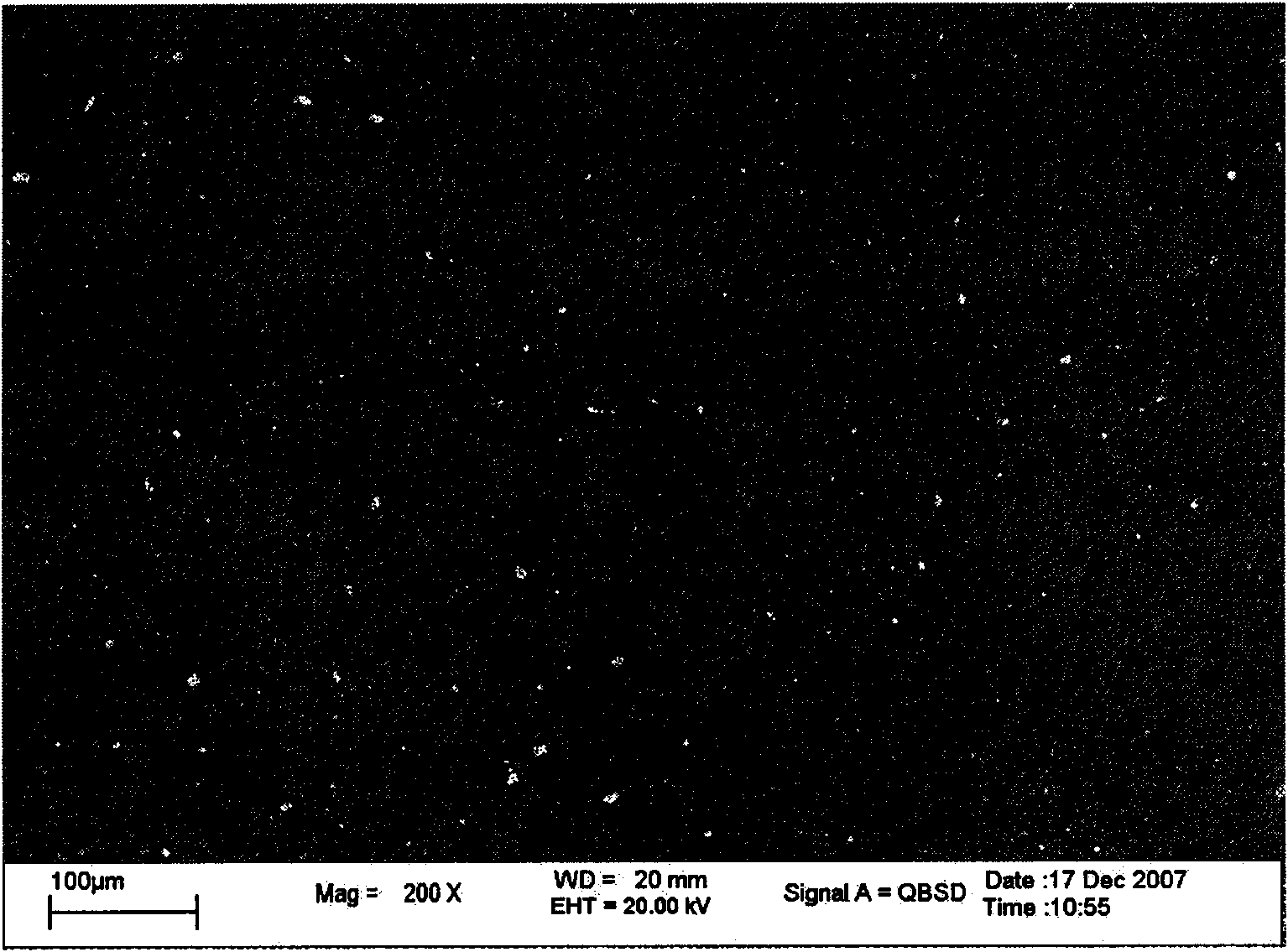

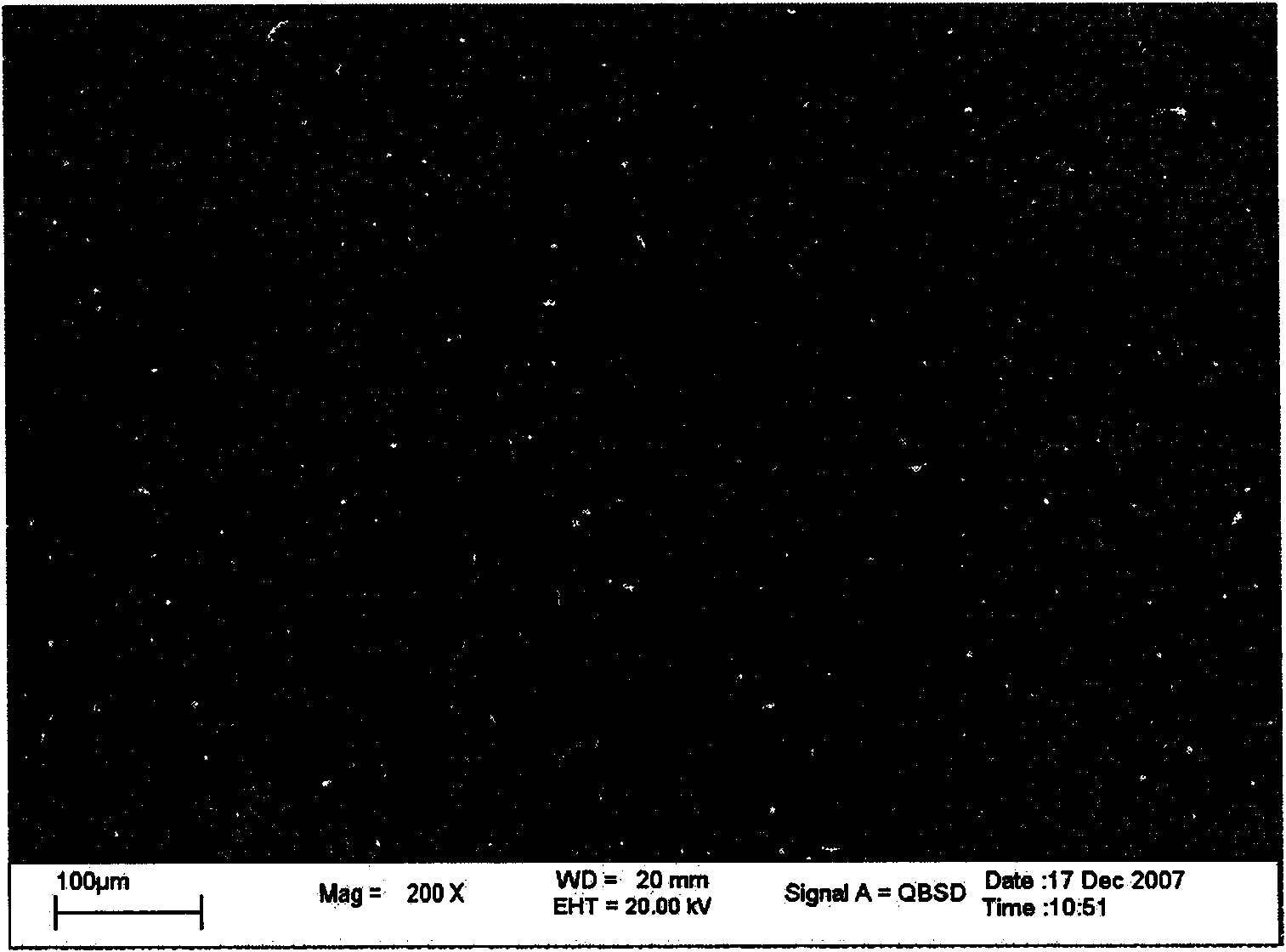

Cast-rolling method for restraining Cr element and Mo element of super-austenitic stainless steel from center segregation

The invention discloses a cast-rolling method for restraining a Cr element and a Mo element of super-austenitic stainless steel from center segregation and belongs to the technical field of manufacturing of the super-austenitic stainless steel. The method includes the steps that (1) raw materials are weighed according to the composition proportion of the super-austenitic stainless steel, and the raw materials are subjected to heat preservation at the temperature ranging from 150 DEG C to 250 DEG C for 100 minutes to 150 minutes; (2) the raw materials are sorted and placed into a vacuum induction melting furnace step by step to obtain molten steel by being smelted; and (3) the molten steel is poured into a dual-roll thin strip cast-rolling machine for cast rolling under shielding of high-purity nitrogen, and a thin super-austenitic stainless steel strip 2.0-3.0 mm thick is obtained, wherein the pouring temperature ranges from 1450 DEG C to 1550 DEG C, the cast-rolling speed ranges from 10 m / min to 40 m / min, and the cast-rolling force ranges from 30 kN to 70 kN. According to the manufactured thin super-austenitic stainless steel strip, center segregation of the Cr element and the Mo element is restrained, and on the premise of maintaining the plasticity, the yield strength is improved by 5%-10% compared with that of traditional strip steel of the same specification as the thin super-austenitic stainless steel strip. Meanwhile, the cast-rolling method reduces energy consumption and production cost, improves the utilization rate of materials and reduces environmental pollution.

Owner:NORTHEASTERN UNIV

Heat treatment method for improving strength and conductivity of copper alloy of Cu-Cr series

InactiveCN101565803ASmall sizeIncrease the number ofHeat treatment process controlContact lineElectron

The invention pertains to the field of heat treatment of nonferrous metal and relates to a heat treatment technique for improving the strength and conductivity of copper alloy of Cu-Cr series. The alloy is used as lead frame materials, electrified railway contact lines and the like in the electronic industry. The invention adopts a secondary ageing heat treatment technique with two stages, which comprises the following steps: copper alloy containing supersaturation precipitated phase element Cr after solution treatment is first aged at lower temperature for a long time for leading the precipitated phase to be in a fine and dispersed distribution and the precipitation to be relatively sufficient, and laying a foundation for obtaining high strength; then the ageing temperature is properly increased to improve the diffusion velocity of atoms, thus leading the Cr elements in the residual solution in the Cu matrix to be further precipitated; as the precipitated phase exists, part of the newly precipitated Cr is precipitated on the existing Cr particles; the existing dispersed distribution of Cr is retained at the lower temperature, and the other part of Cr is also precipitated, thereby forming more dispersion-distributed nanometer particles, greatly improving the strength of the alloy, and simultaneously purifying the copper matrix and improving the conductivity.

Owner:UNIV OF SCI & TECH BEIJING

High-strength and high-toughness metastable beta titanium alloy and preparation method thereof

ActiveCN112251632AHigh yield strengthLow costTemperature control deviceMetal rolling arrangementsMo elementSolid solution strengthening

The invention discloses a high-strength and high-toughness metastable beta titanium alloy and a preparation method thereof. The Ti-Al-Mo-V-Cr-Zr metastable beta titanium alloy comprises the componentsof, in percentage by weight, 4.5%-5.5% of Al, 6.5%-9.0% of Mo, 1%-4% of V, 1.5%-4% of Cr, 1%-2.5% of Zr and the balance Ti and other inevitable impurities. According to the high-strength and high-toughness metastable beta titanium alloy and the preparation method thereof, after an alloy is subjected to smelting, hot rolling and heat treatment, good matching of strength and plasticity can be obtained; according to the high-strength and high-toughness metastable beta titanium alloy and the preparation method thereof, the content of the V element is further reduced to about 3.5%, and the cheap Cr element is added so that the cost can be reduced to a certain extent; meanwhile, a certain amount of the Cr and Mo elements are added to reinforce a beta matrix, so that the solid solution strengthening effect of the multi-component alloy is improved; and according to the high-strength and high-toughness metastable beta titanium alloy and the preparation method thereof, the yield strength of thealloy is improved to 1518 MPa, meanwhile, and the alloy also has the total elongation at break of 5.3%, so that the requirements of a new generation of high-strength and high-toughness titanium alloyare met.

Owner:XI AN JIAOTONG UNIV

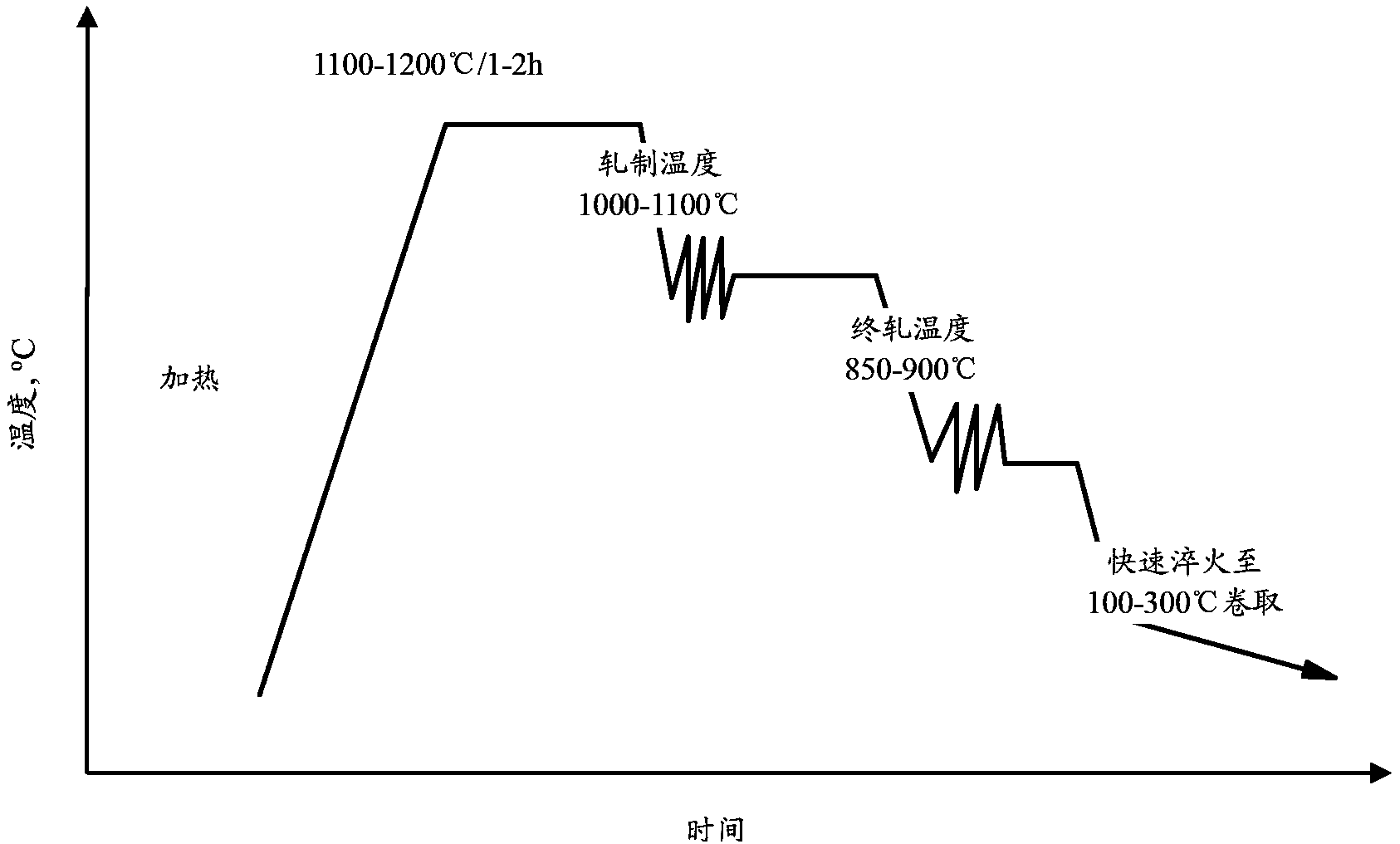

Component design and production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel

The invention relates to component design and a production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel. The 1500 MPa-grade low-carbon and medium-manganese copper-contained steel comprises the following chemical components in percentage by mass: 0.20-0.23% of C, 0.5-0.8% of Si, 3.5-4.0% of Mn, 1.2-2.0% of Al, 0.5-1.0% of Cr, 0.6-1.0% of Cu, 0.2-0.5% of Ni, 0.003-0.012% of N, 0.00051-0.003% of B, and the balance of Fe and inevitable impurities. One part of alloy elements are added based on traditional TRIP steel to largely increase the content of manganese to reach the medium-manganese range; when Al is used for replacing the Si elements, a proper amount of Si elements are retained, so that the Al and Si elements are matched for use; and a certain quantity of precipitation-hardened Cu elements are added to match with a proper amount of Ni elements for use to eliminate the hot brittle phenomenon caused by Cu in hot working. In addition, few Cr elements are added; a proper amount of N elements are added to match with the Al elements for use; through matching between hot rolling and hot partition processes, a martensite+residual austenite+separated second-phase particle structure with ultrahigh strength and excellent plasticity is obtained; and the tensile strength exceeds 1500 MPa.

Owner:SHANDONG JIANZHU UNIV

High-vanadium wear-resistant alloy material and production technique thereof

InactiveCN104946964AIncrease the amount of participationIncrease in the number of particlesWear resistantMaterials science

The invention relates to the field of wear-resistant materials, particularly a high-vanadium wear-resistant alloy material and a production technique thereof. The high-vanadium wear-resistant alloy material is composed of the following components in percentage by mass: 2.7-3.5% of C, 7.5-8.5% of V, 0.5-1.5% of Si, 0.8-1.5% of Mn, 2.0-3.5% of Cr, 1.0-2.5% of Mo, 1.0-2.0% of Ti, at most 0.04% of S, at most 0.04% of P and the balance of iron. The V is used instead of the Cr element in the high-chromium cast iron to generate the high-hardness VC carbide particles in the iron base. 1.0-2.0% of Ti element is added into the iron to generate a (V,Ti)C eutectic carbide in the iron. Since the workpiece generally has a certain thickness, certain amounts of chromium (Cr) element and molybdenum (Mo) element are added as hardenability-enhancing elements. The Ti element can be easily combined with the sulfur element to generate the hazardous compound Ti2S, and therefore, the sulfur and phosphorus elements are respectively strictly controlled to at most 0.04% according to the requirements.

Owner:曾松盛

Preparation method of 7Ni steel plate for liquefied natural gas storage tank

The invention discloses a preparation method of a 7Ni steel plate for a liquefied natural gas storage tank and belongs to the field of alloy steel manufacturing. The preparation method comprises the following steps: (1), smelting according to components of the 7Ni steel plate; (2), after heat preservation knobbling, carrying out hot rolling: rough rolling and finish rolling; and (3), cooling the hot rolled plate to a temperature of 20 to 300 DEG C at a super fast speed, then rising the temperature and keeping the temperature, and carrying out water cooling or air cooling to reach a room temperature so as to obtained a finished product, or carrying out air cooling to the hot rolled plate to reach a temperature of 660 to 700 DEG C, then quenching after heat preservation, rising the temperature and keeping the temperature, and then carrying out water cooling or air cooling to reach a room temperature, so as to obtained the finished product. The preparation method of the 7Ni steel plate for the liquefied natural gas storage tank has the beneficial effects as follows: (1), except for four elements such as C, Si, Mn and Ni in the components, only a small quantity of Cr element is added, stable control to components is facilitated, and the alloy cost is lowered; and (2), the TMCP technology is adopted, the hot rolling process is reasonably designed, the organization is detailed, and the low-temperature toughness and intensity of steel are improved; (3), after finally rolling, carrying out on-line quenching and tempering or air cooling to two-phase region heat preservation quenching and tempering, the heat processing time is short, and the product rhythm is compact.

Owner:NORTHEASTERN UNIV LIAONING

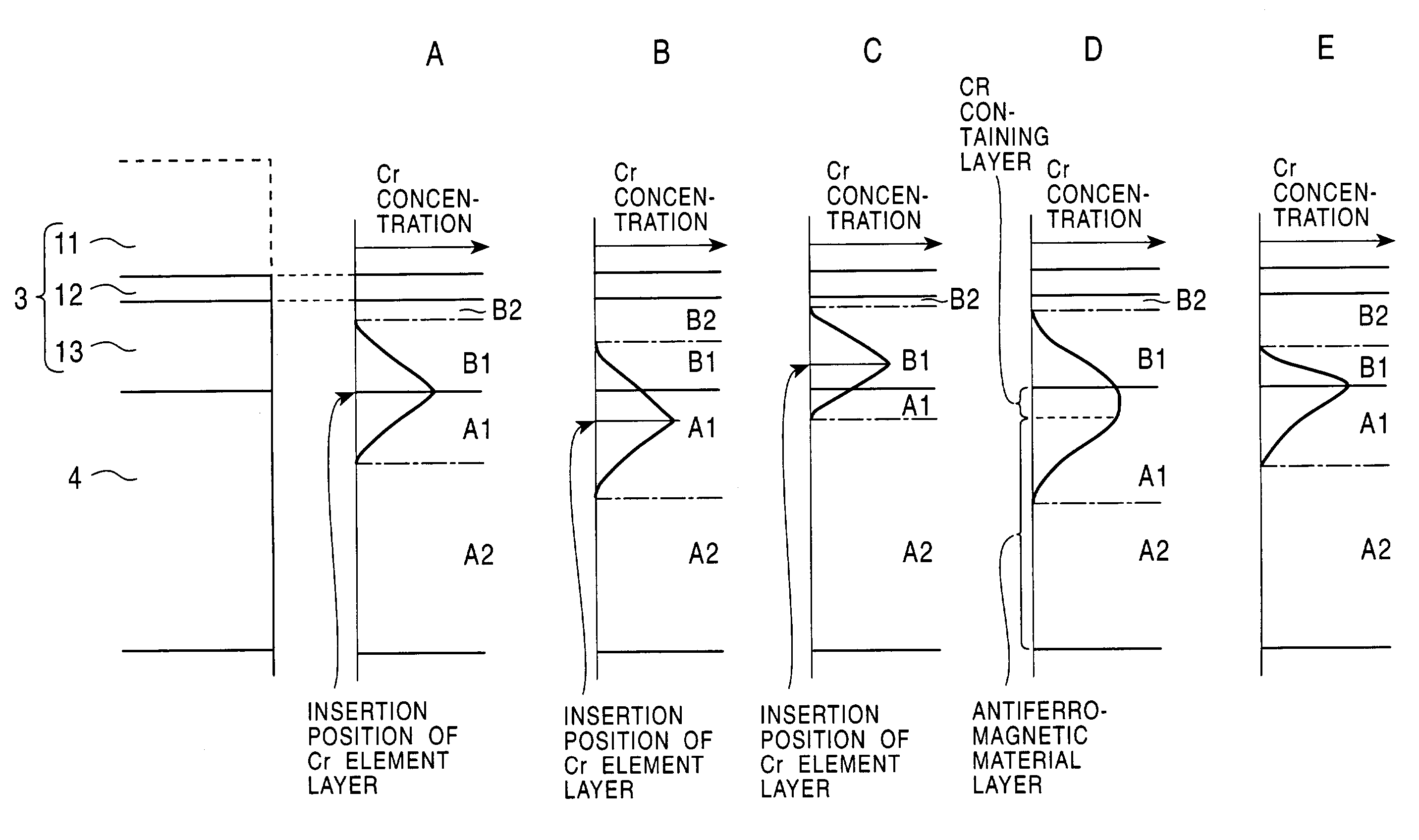

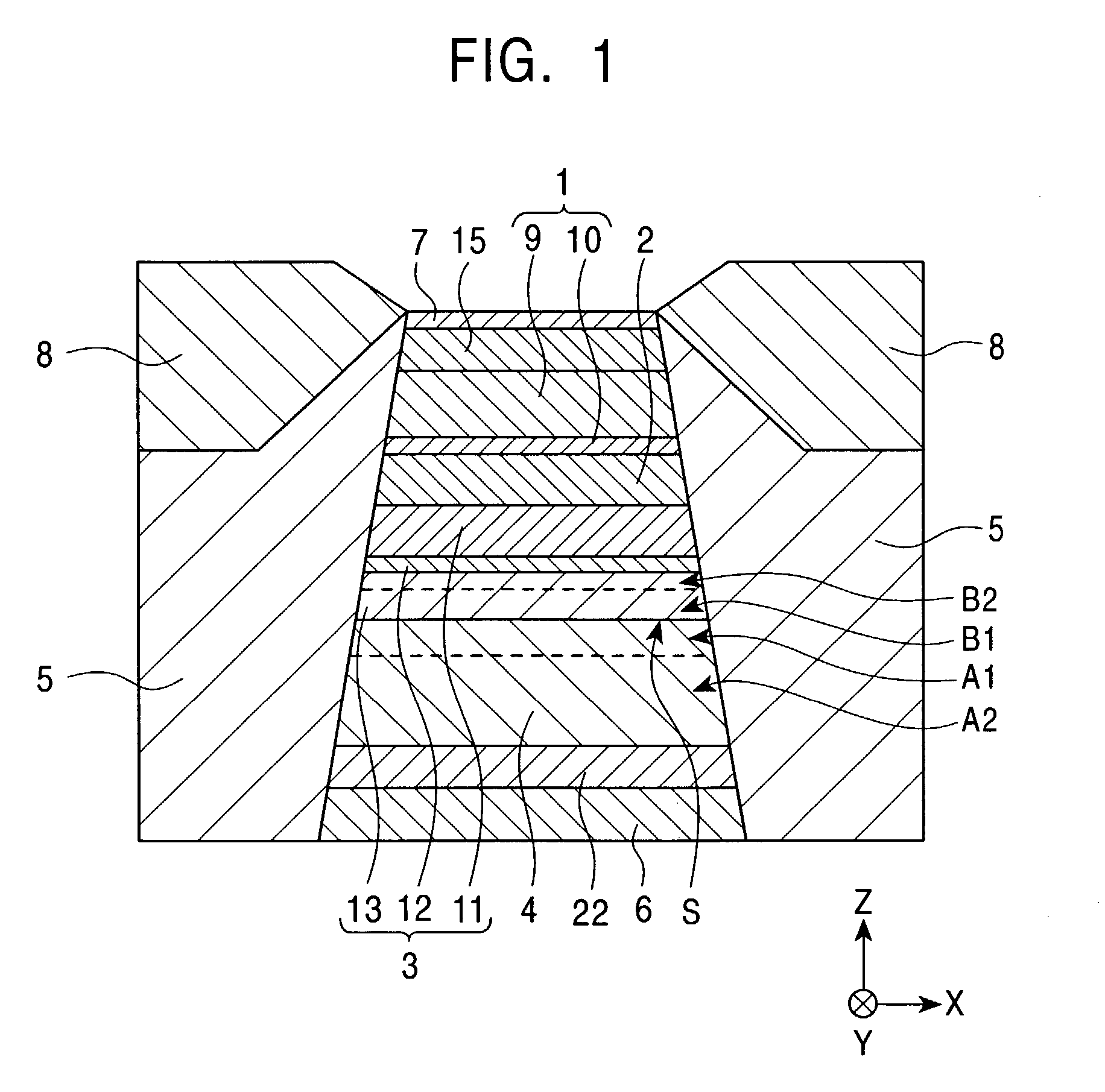

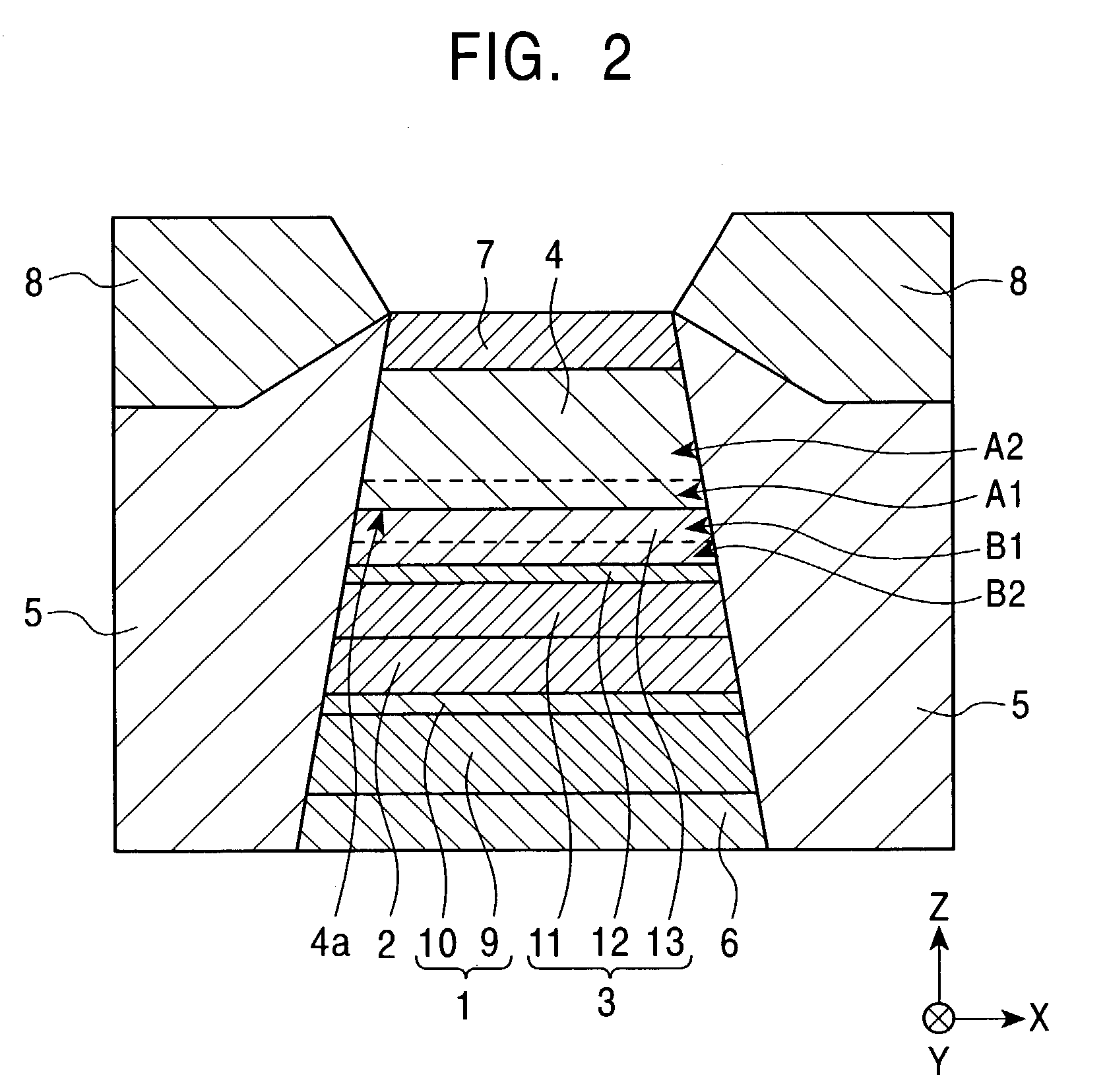

Exchange coupling film, magnetic detecting element using the exchange coupling film, and method of making same

InactiveUS7063904B2Additional exchangePin being securedNanomagnetismMagnetic measurementsExchange biasCr element

Each of an antiferromagnetic layer and a pinned magnetic layer has a region containing a Cr element, thereby increasing an exchange coupling magnetic field (Hex) produced between the antiferromagnetic layer and the pinned magnetic layer. Therefore, the exchange coupling magnetic field produced between the antiferromagnetic layer and the pinned magnetic layer can be increased, and a coupling magnetic field due to RKKY interaction can also be increased, thereby increasing a one-directional exchange bias magnetic field (Hex*) in the pinned magnetic layer as compared with a conventional exchange coupling film.

Owner:ALPS ALPINE CO LTD

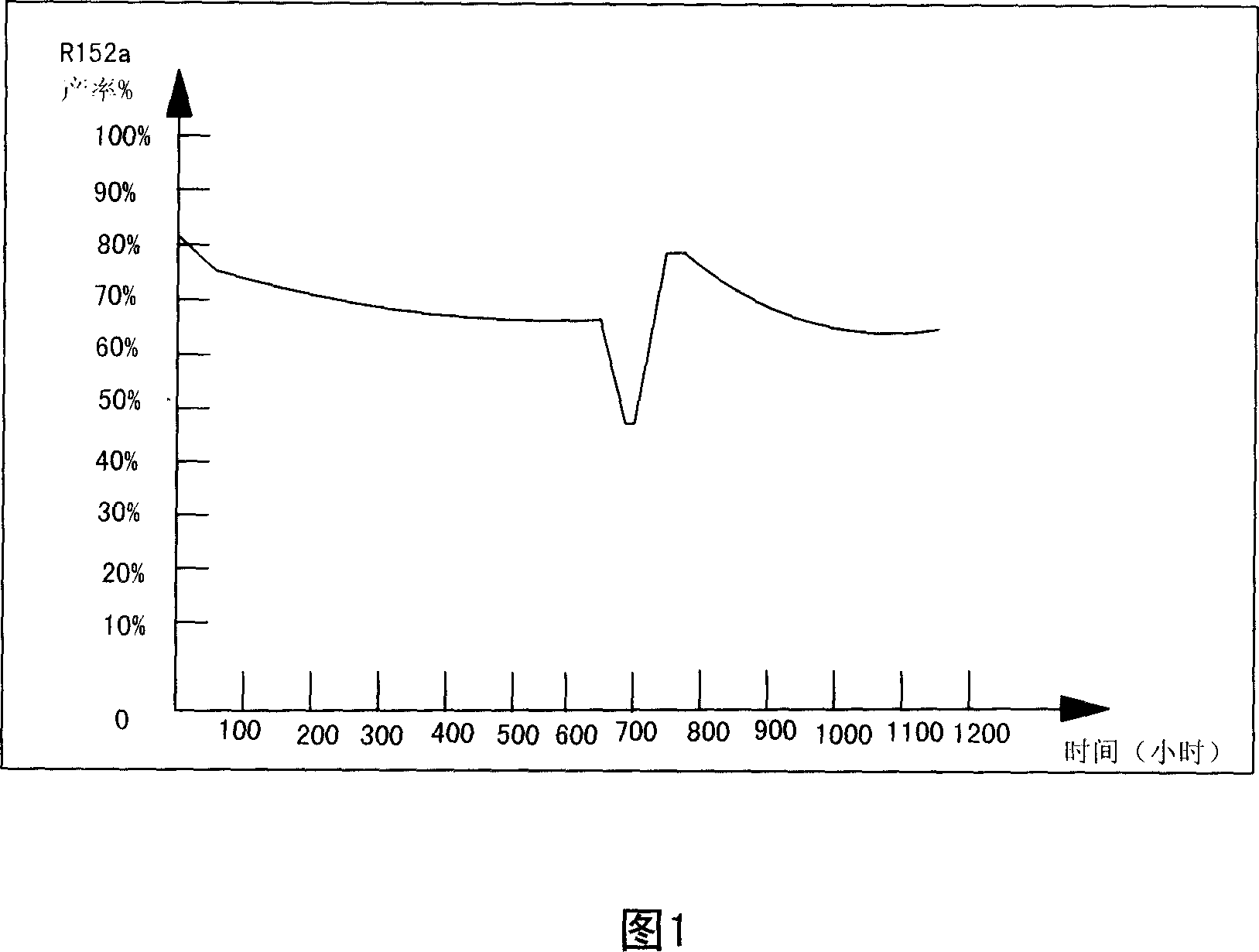

Catalyst for 1,1-difluoroethane producing vapor process

ActiveCN1931431AHigh activityImprove stabilityPhysical/chemical process catalystsPreparation by halogen replacementReaction temperatureHigh activity

The catalyst for preparing 1, 1-difluoroethane includes Cr element and one or two other metal elements of Co, Mn, Zn, Fe, Mg, Al and Ni in the molar ratio of 1 to 0.001-0.6, as well as F element and O element. The Cr base catalyst has less environmental pollution, high activity, high stability, long service life, no tendency of polymerizing 1, 1-difluoroethane, great contact area, fast reaction, high space time yield and easy regeneration. When the reaction is controlled in 150-200 deg.c, the reaction pressure has no influence on the variety of the reaction products, and the reaction products have less side products. The catalyst is prepared through a simple co-precipitation process.

Owner:SHANDONG DONGYUE CHEM

Catalyst for dehydrogenating light alkane and application of catalyst

The invention relates to a catalyst for dehydrogenating light alkane and application of the catalyst in order to mainly solve the problem of relatively-low activity of a dehydrogenating catalyst prepared in the prior art. The problem is better solved through the technical scheme that the catalyst for dehydrogenating light alkane comprises the following components in parts by weight: 1-30 parts of a Cr element or an oxide of the Cr element (a), 0.1-5 parts of Li, Na, K and Rb elements or oxides of the Li, Na, K and Rb elements (b), 0.1-10 parts of Cu, Co, Ni and Fe elements or oxides of the Cu, Co, Ni and Fe elements (c), 0.001-1 part of a Ga element or an oxide of the Ga element (d), and 54-99 parts of Al2O3 (e). The catalyst can be used for industrial production of light olefin prepared by dehydrogenating light alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

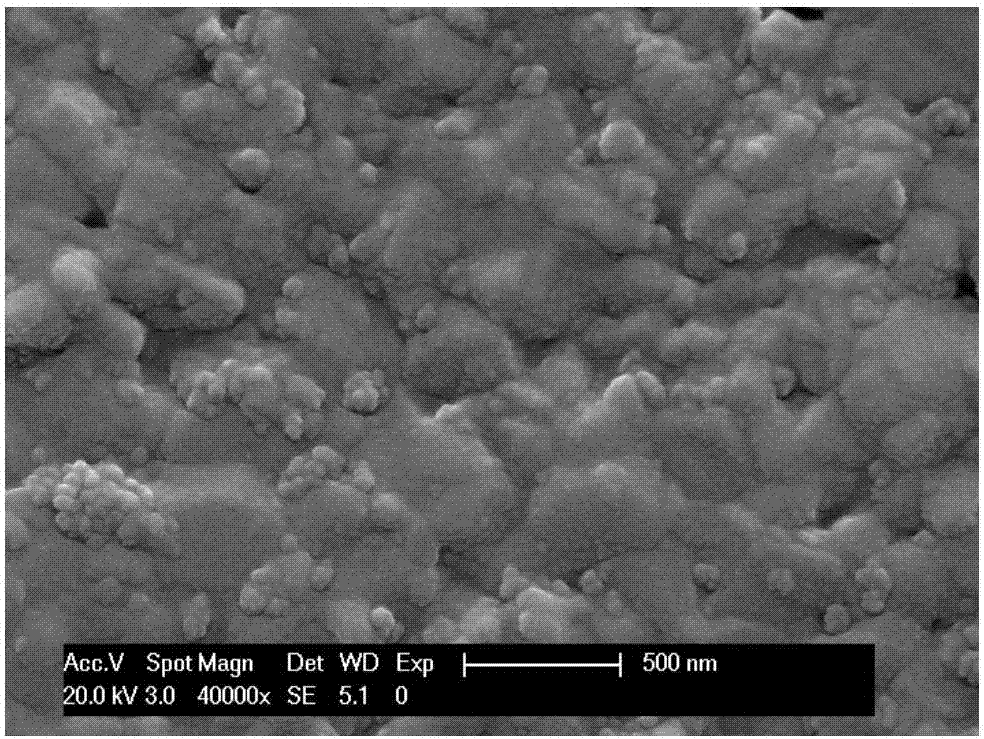

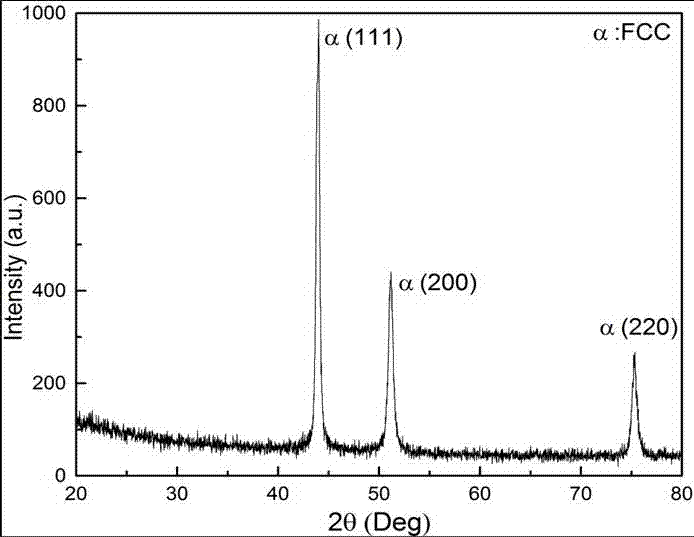

Cr-doped Ge2Sb2Te5 phase change material, phase change memory unit and preparation method

InactiveCN105047816AImprove thermal stabilityLow write operation currentElectrical apparatusVacuum evaporation coatingHigh resistanceExternal energy

The invention provides a Cr-doped Ge2Sb2Te5 phase change material, a phase change memory unit and a preparation method. The ingredient general formula of the Cr-doped Ge2Sb2Te5 phase change material is CrxGe2Sb2Te5, wherein x is an atomic ratio of the Cr element, and x is more than 0.5 and less than 1.5. Cr doping in Ge2Sb2Te5 is carried out, Cr is a kind of metal with an extremely high melting point, heat stability of a phase change material can be raised, Cr can form bonds with Ge, Sb and Te, so segregation is avoided effectively. Under action of external energy, the Cr-doped Ge2Sb2Te5 phase change material can achieve reversible conversion between high resistance state and low resistance state, and the resistance value ratio of the high resistance state to the low resistance state can reach about two orders of magnitudes. When the phase change material is employed as a memory media of a phase change memory, the phase change memory unit has advantages of fast phase change speed, low write operation current and the like, and high temperature data retentivity and reliability of the device are raised greatly. The phase change memory employing the phase change memory unit structure has advantages of high speed, low power consumption, good data retentivity and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

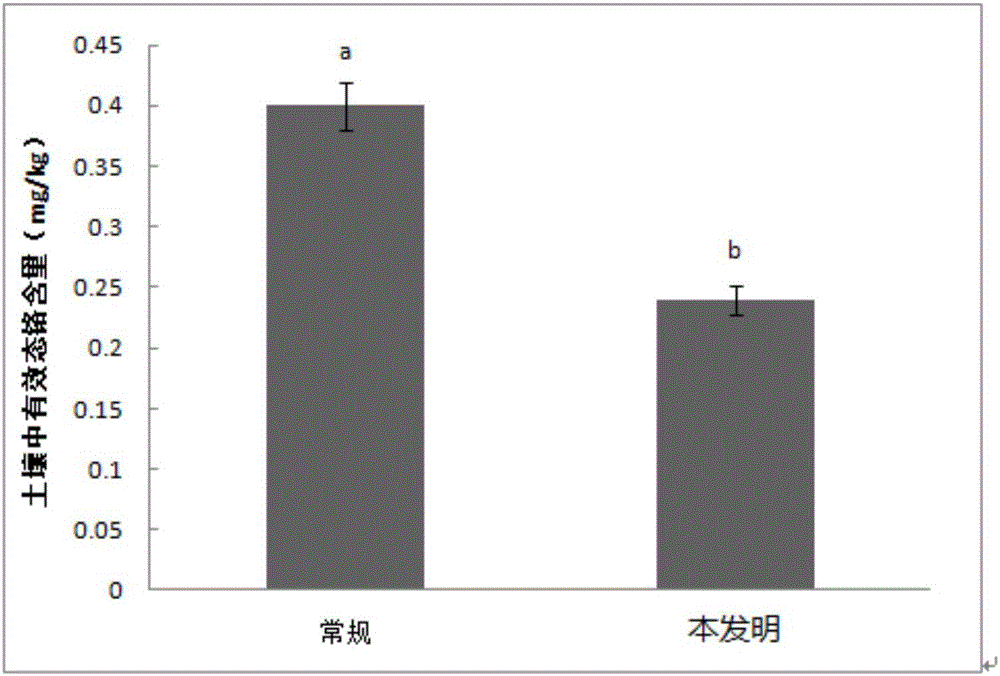

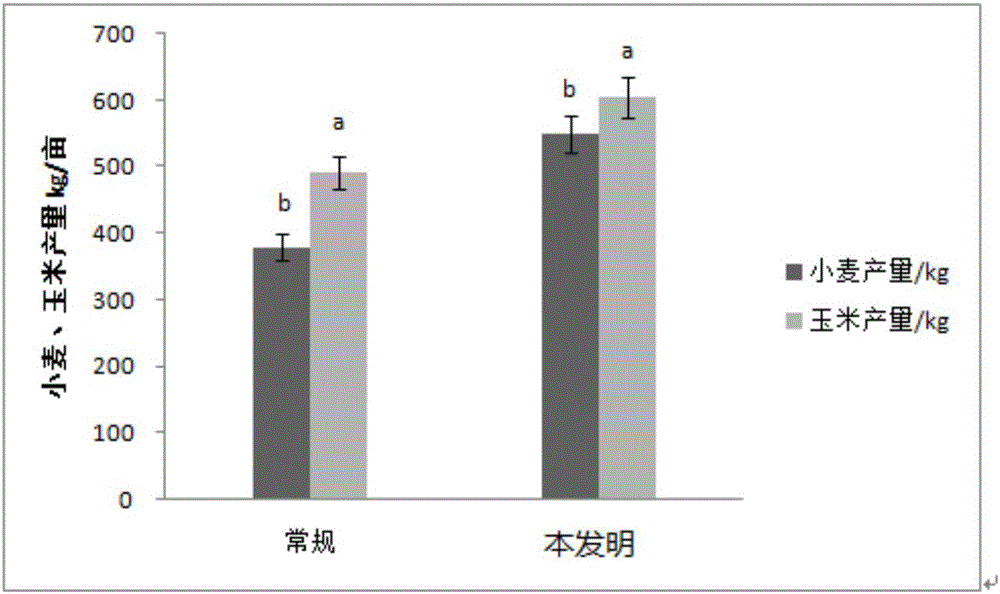

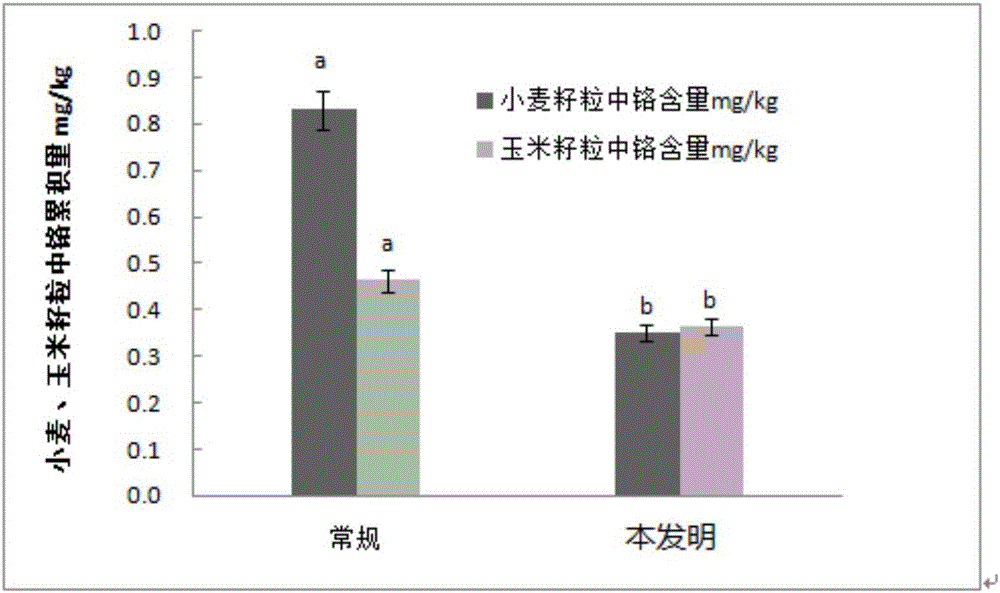

Farmland chromium pollution remediation method under planting production condition

InactiveCN105750323AReduce the effective contentLow compliance costContaminated soil reclamationGrowing seasonBiology

The invention relates to a farmland chromium pollution remediation method under a planting production condition. The farmland chromium pollution remediation method comprises the following steps: performing crop rotation of wheat and corn on soil to be treated according to growth seasons, and applying an organic fertilizer at least before seeding of wheat and corn, wherein a heavy metal passivator consists of the following components in percentage by weight: 64-75% of ferrous sulfate, 0.2-1% of compound bacteria and 0-35% of aluminum oxide; the organic fertilizer is one or a combination of two of wormcast, commercial organic fertilizers and cow dung. The passivation remediation technique provided by the invention is relatively low in remediation cost, normal planting and production of cereal crops are not affected, moreover, a bio-availability passivation effect on the Cr element can be achieved, and the condition requirements on heavy metal polluted soil remediation can be relatively well met. As ferrous sulfate and the active compound bacteria are induced to have oxidation reduction with Cr in the soil, Cr can be transformed to be trivalent from hexavalent, and CrO2- and Cr3+ compound precipitate can be formed.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

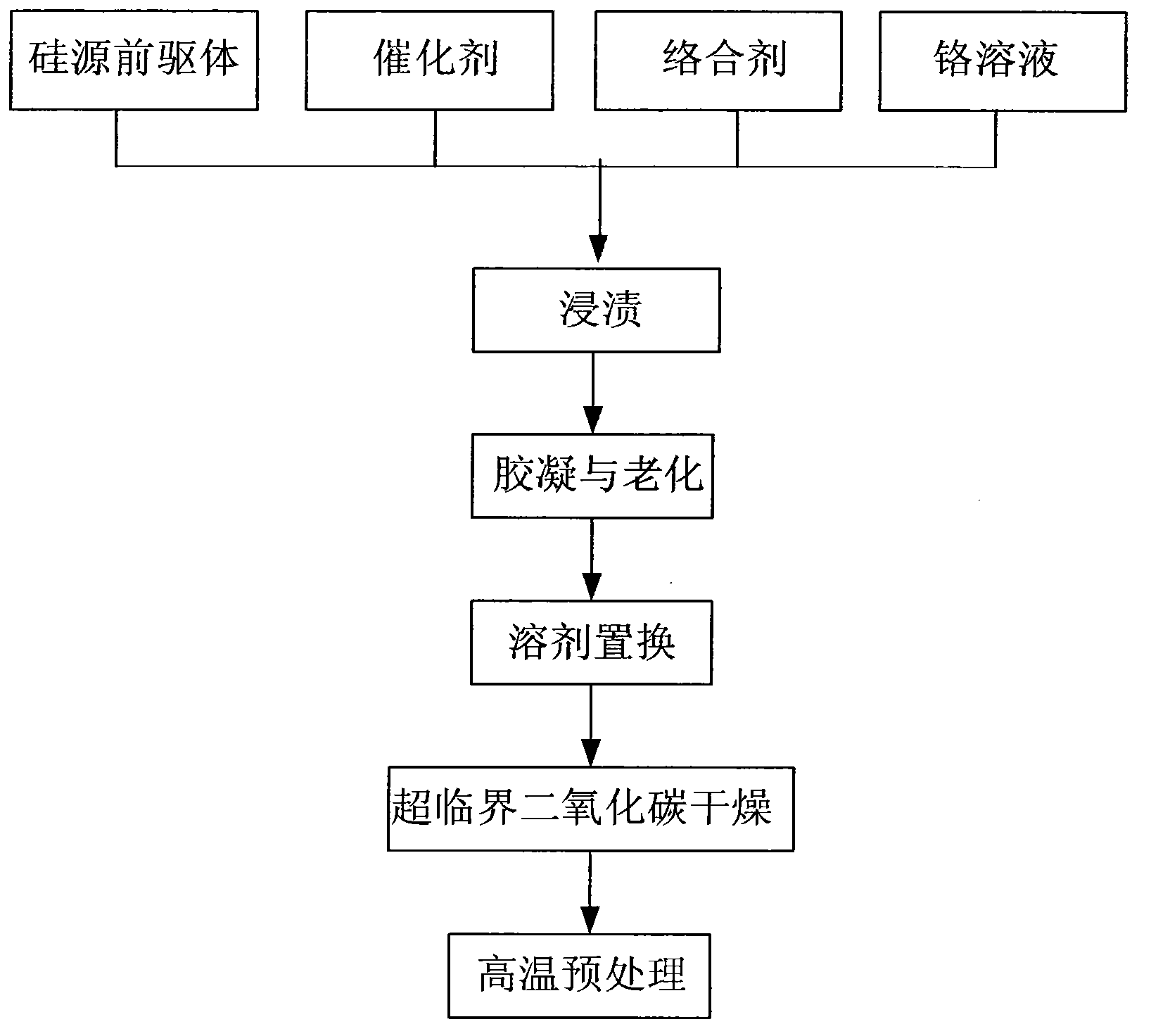

Cr2O3 doped silicon dioxide aerogel material and preparation method thereof

The invention provides a Cr2O3 doped silicon dioxide aerogel material and a preparation method thereof. The preparation method of the Cr2O3 doped silicon dioxide aerogel material comprises the following steps: taking a silicon source as a precursor, adopting an inorganic compound containing the Cr element and an organic compound as doping ions, mixing the compounds with a solvent, a complexing agent and a catalyst to form a composite sol, conducting impregnation technology to be compounded with reinforced fibers, carrying out gelatinizing, ageing, solvent replacement, supercritical carbon dioxide drying, high-temperature pretreatment and other technologies to obtain the product. The preparation method disclosed by the invention is to conduct metal Cr doping and modification on the aerogel through a complexing-gelatinizing method, skillfully combine the complexing reaction with the gelatinizing reaction to increase the complexing force of the metal Cr doping ions in the gel system, effectively restrain the phenomenon that the Cr is not uniform in distribution as the Cr ions are migrated during the follow-up treatment process of the gel, so that the diffusion effect of the complexing-gelatinizing method is uniform and stable, and the complexing-gelatinizing method is better than the in-situ doping method. The aerogel obtained by the complexing-gelatinizing method is treated in advance at high temperature, so as to enable the internal reaction to be conducted thoroughly under high-temperature action, then transform the aerogel to be the Cr2O3 doped stable aerogel structure, and facilitate the pore structure and the heat-insulating property to be stable.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

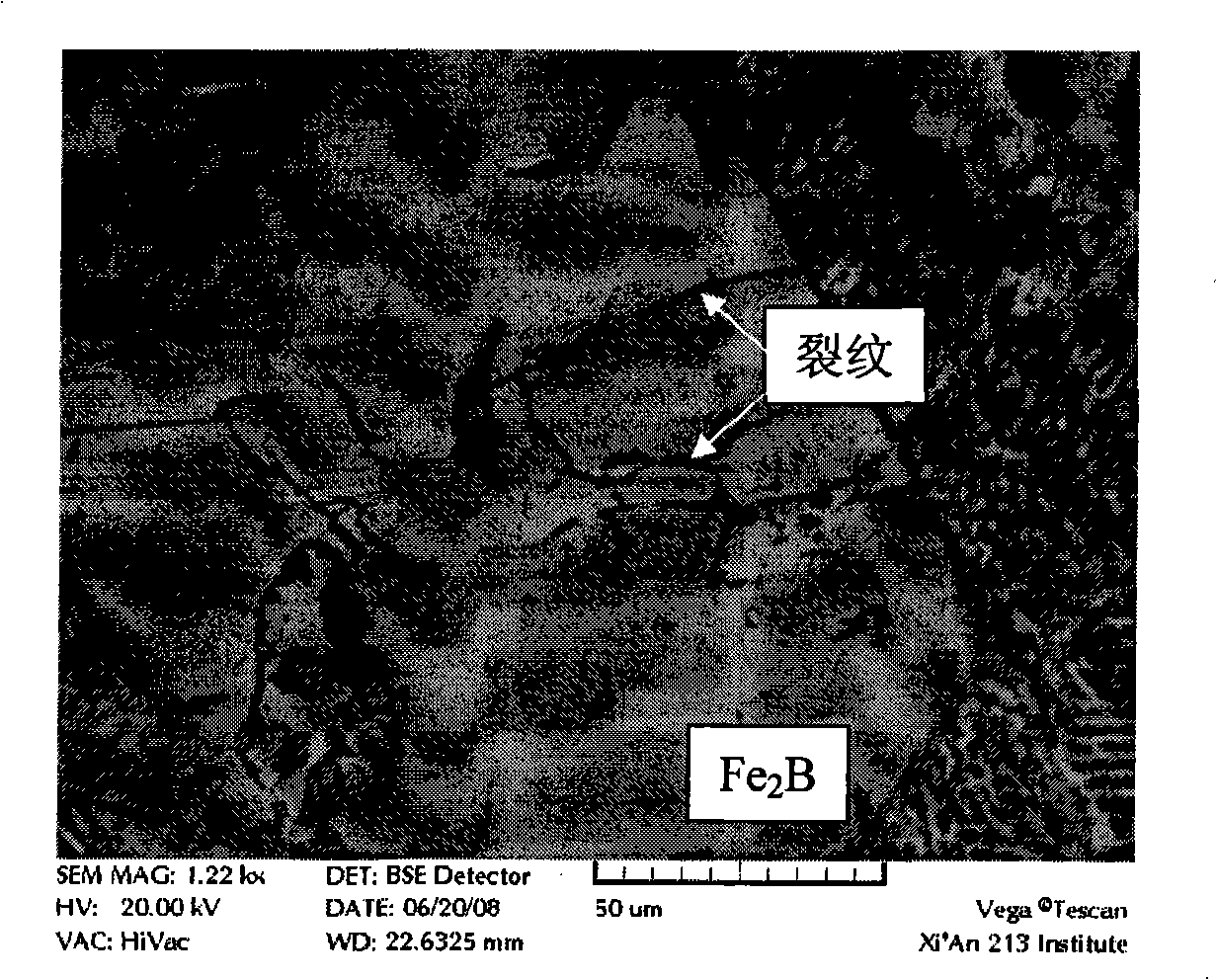

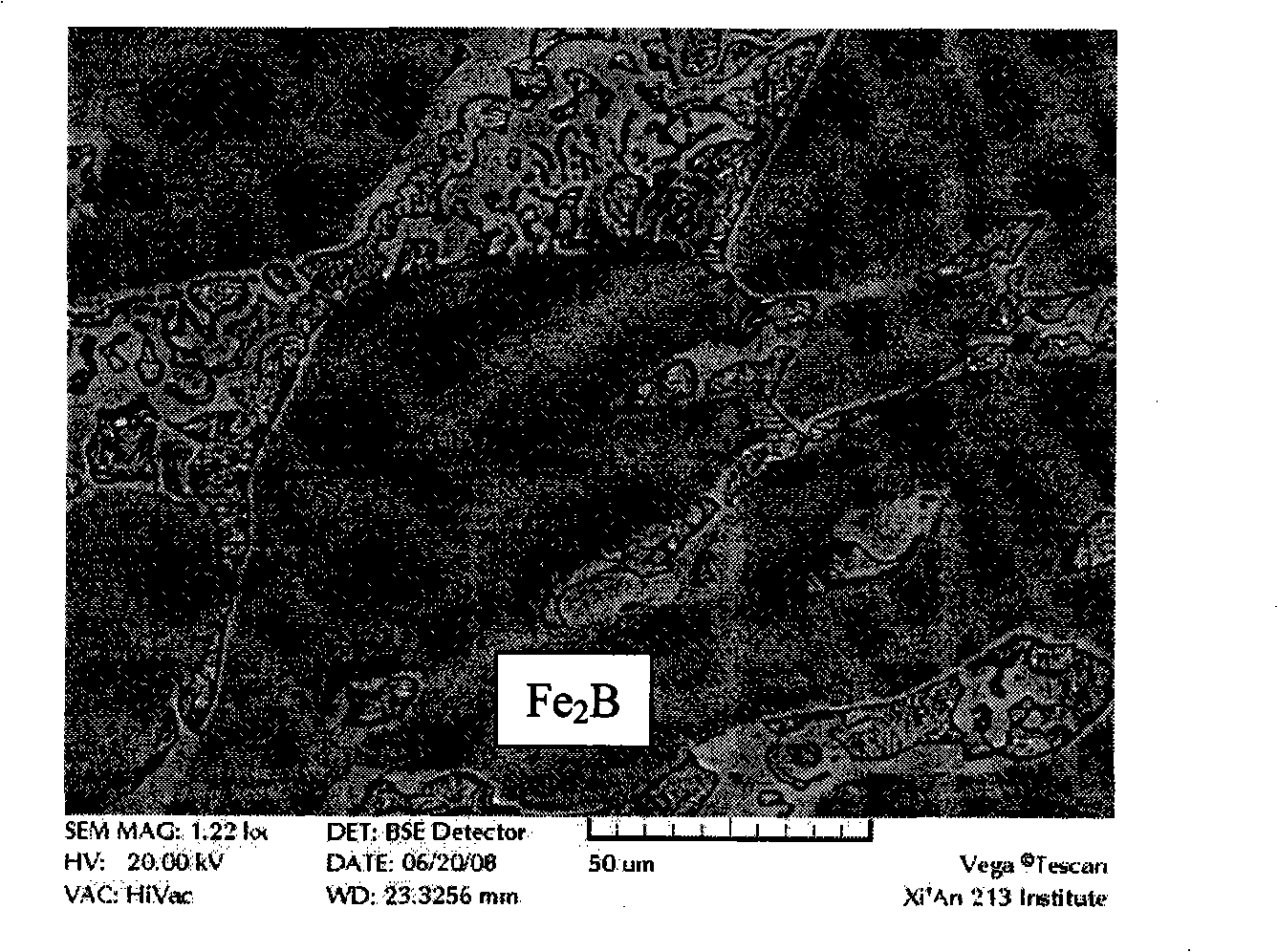

Toughening processing method of hard phase Fe2B in iron boron wear-resistant alloy

The invention relates to the ferroboron wearproof cast alloy field and discloses a method for toughening a hard phase Fe2B in the ferroboron cast wearproof alloy. The method comprises the following steps that: firstly, the ingredients of the ferroboron cast wearproof alloy are determined and comprises scrap steel, silicoferrite, ferromanganese and ferroboron; based on the total weight of the ingredients of the ferroboron cast wearproof alloy, ferrochromium, ferromolybdenum and the ingredients of the ferroboron cast wearproof alloy are respectively calculated and weighed according to 0.5 to 10 percent of Cr element and 0 to 4.0 percent of Mo element; then the ferroboron is taken out for standby; the other ingredients of the ferroboron cast wearproof alloy are added into a furnace for smelting in turn; after the ingredients are melted down, aluminum wire which accounts for 0.01 percent of the molten iron weight is adopted for deoxidation; the ferrochromium and ferromolybdenum are added into the furnace and melted down; finally, a ferroboron block is added into the furnace and melted down; after the molten iron is melted down and kept stand, slag are removed and the mixed materials are molded, thereby completing the toughening.

Owner:XI AN JIAOTONG UNIV

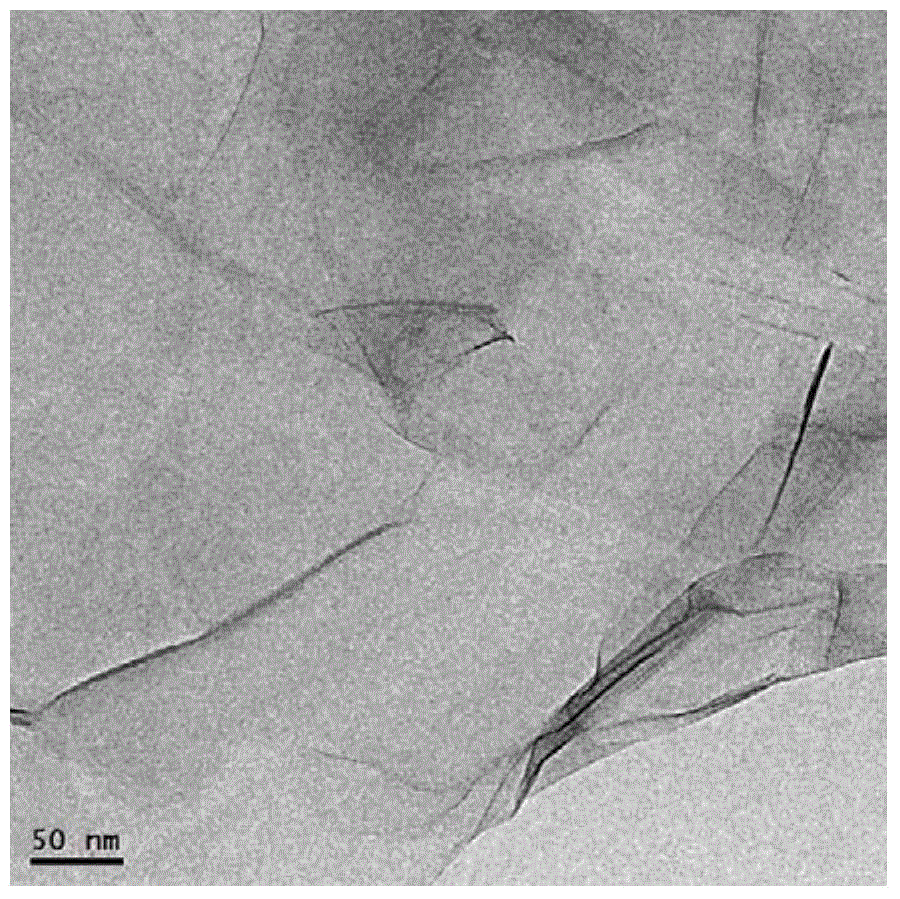

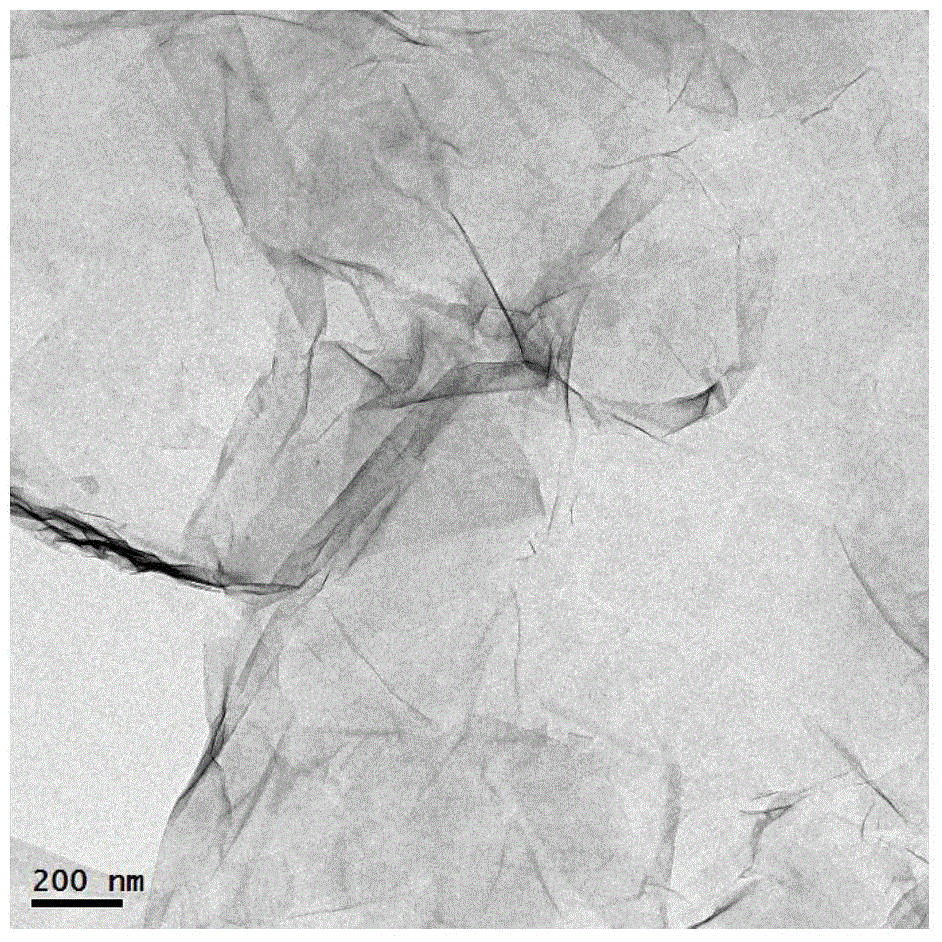

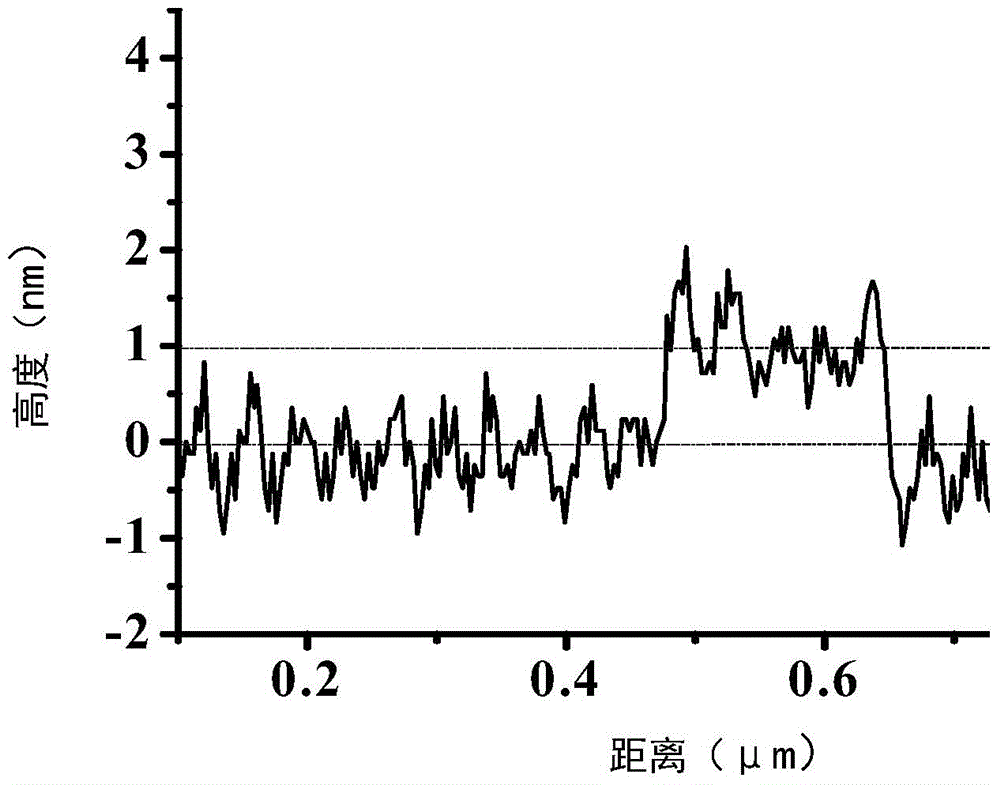

Two-dimensional titanate nanometer material and preparation method thereof

ActiveCN105800676AIncrease surface areaNot easy to curlMaterial nanotechnologyPhysical/chemical process catalystsOrganic groupUltraviolet lights

The invention discloses a two-dimensional titanate nanometer material and a preparation method thereof. The two-dimensional titanate nanometer material comprises a modified protonated titanate film which comprises organic groups and a doped Cr element. Through the doped Cr element which facilitates to broadening absorption bandwidth of the two-dimensional titanate nanometer material, the two-dimensional titanate nanometer material can absorb ultraviolet light and visible light, and greatly improves efficiencies of light absorption and photoelectric conversion, thereby improving photocatalytic efficiency. Meanwhile, through doping of the organic groups which are relatively large molecules and are used as a balance medium of nanometer sheets, the prepared two-dimensional titanate nanometer material is not easy to curl and has relatively-stable two-dimensional structure and relatively-large surface area, thereby further improving photocatalytic efficiency.

Owner:BYD CO LTD

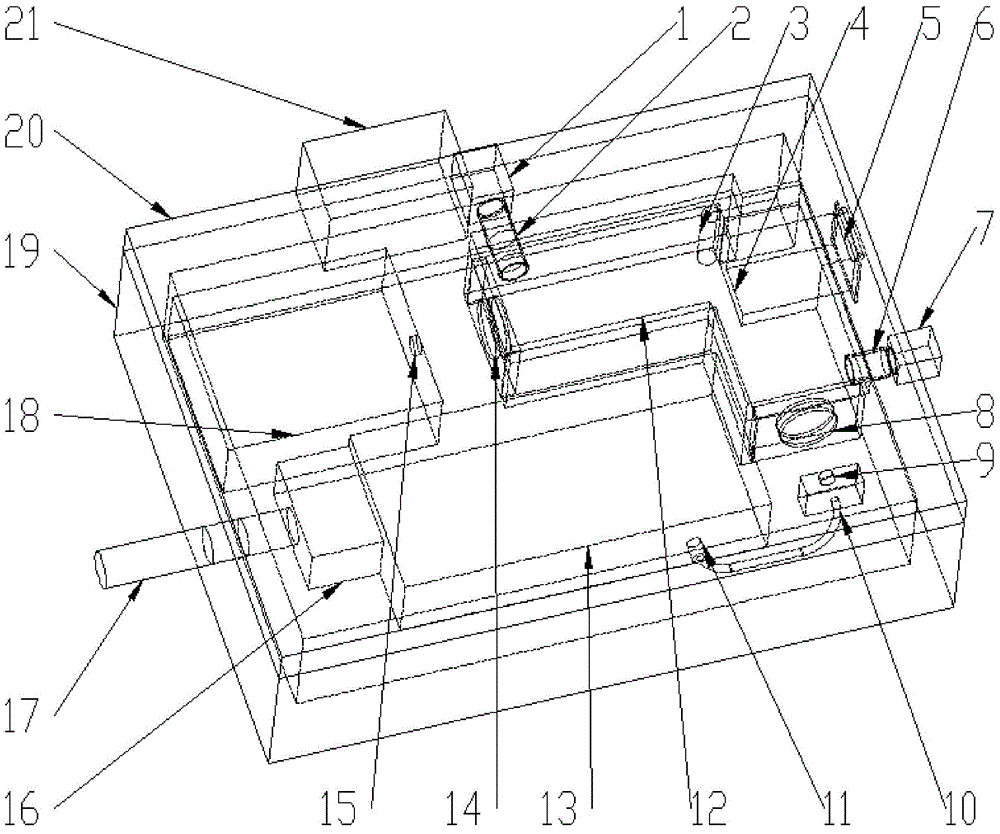

Device for detecting the content of heavy metal Cr element in soil by laser-induced breakdown spectroscopy

InactiveCN105181679AQuick checkSimple structureAnalysis by thermal excitationLaser-induced breakdown spectroscopyOptical fiber probe

The invention discloses a device for detecting the content of heavy metal Cr element in soil by laser-induced breakdown spectroscopy, which comprises an electromagnetic valve A, an air inlet tube, a temperature and air pressure sensor, a soil sample carrier, a feed inlet, an air outlet tube, an electromagnetic valve B, a fused quartz lens A, an optical fiber probe, an optical fiber, an optical fiber connector, a closed laser induction chamber, a spectrometer, a fused quartz lens B, a laser head, an ICCD (Intensified Charge Coupled Device) detector, an external connection cable, a femtosecond laser, a bottom shell, a cover plate and a miniature air conditioner. The laser head, the fused quartz lens B and the soil carrier on the femtosecond laser are located on the shame horizontal straight line, the centers of the soil carrier, the fused quartz lens A and the optical fiber probe are located on the same longitudinal straight line, both ends of the optical fibers are connected with the optical fiber probe and the optical fiber connector, and the ICCD detector, the left side of which is connected with the external connection cable, is mounted on the left side of the spectrometer.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com