Metal support half-cell of solid oxide fuel cell and preparation method thereof

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cell parts, fuel cells, etc., can solve the problems of cumbersome battery preparation process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

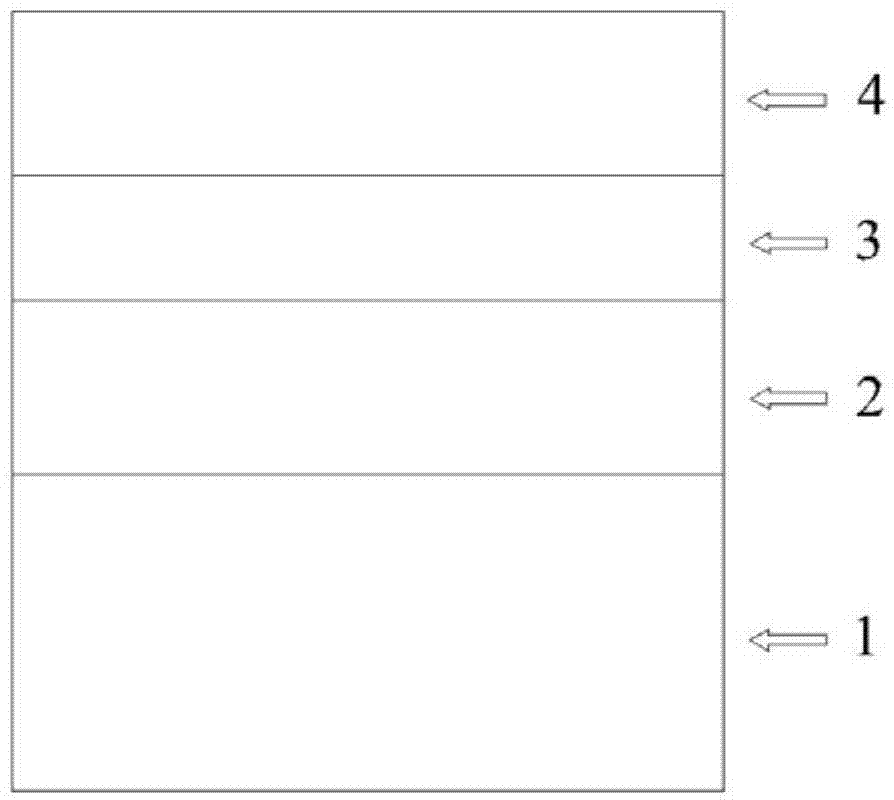

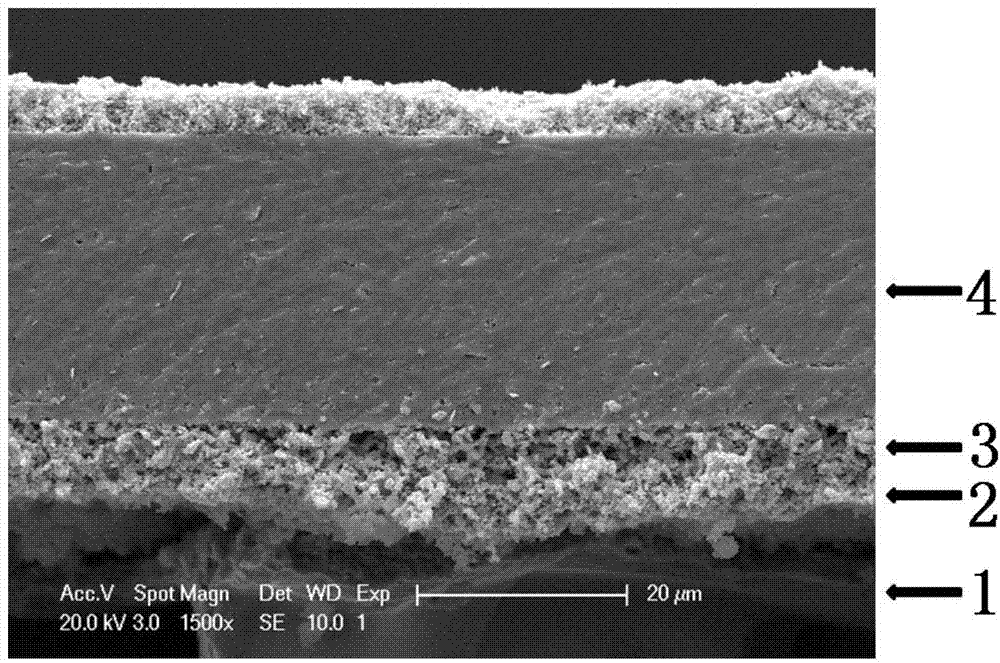

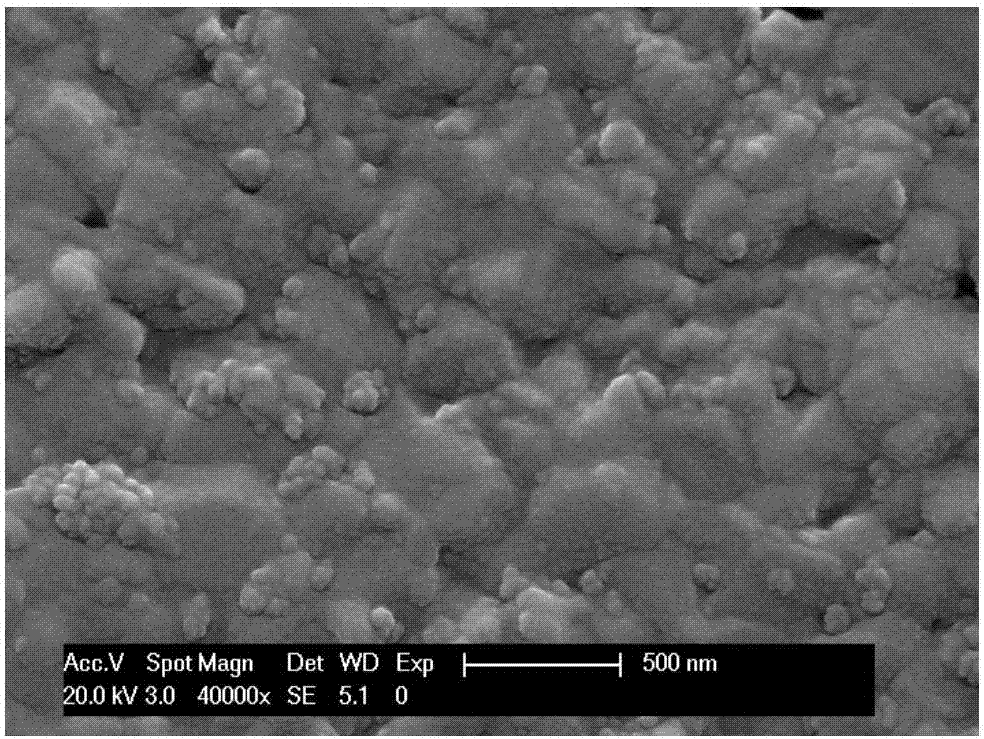

[0056] This embodiment relates to a metal-supported half-cell of a solid oxide fuel cell; the metal-supported half-cell has a structure such as figure 1 As shown, it includes a porous metal support layer thick film 1 , a porous metal ceramic gradient transition layer film 2 , a porous anode layer film 3 and a dense electrolyte layer film 4 , which are sequentially arranged from bottom to top. Its preparation process comprises the following steps:

[0057] A. Preparation of thick film green body of porous metal support layer and thin film green body of dense electrolyte layer;

[0058] Disperse 90 grams of stainless steel AM-1 (the composition is shown in Table 1) powder, 10 grams of raw powder pore-forming agent, 82 grams of methyl ethyl ketone and ethanol mixed solvent and 2 grams of triethyl phosphate in a weight ratio of 2:1 respectively. The agent was ball milled at 300 rpm for 8 hours with a planetary ball mill and mixed well. 12 grams of polyvinyl butyral binder, 6 gra...

Embodiment 2

[0069] The preparation of the metal-supported half-cell of the solid oxide fuel cell involved in this embodiment is as follows:

[0070] A. Preparation of thick film green body of porous metal support layer and thin film green body of dense electrolyte layer;

[0071] 85 grams of stainless steel AM-1 powder, 15 grams of raw powder pore-forming agent, 90 grams of butanone and ethanol mixed solvent and 3 grams of triethanolamine dispersant in a weight ratio of 2:1 were ball-milled with a planetary ball mill at 300 rpm. Mix for 8 hours. 13 grams of polyvinyl butyral binder, 7 grams of dibutyl phthalate and 7 grams of polyethylene glycol 200 mixed plasticizer were added to the above-mentioned ball milled slurry. ball mill at 300 rpm for another 16 hours to mix well. 85 grams of ScCeSZ powder, 70 grams of methyl ethyl ketone and ethanol mixed solvent and 4 grams of triethanolamine dispersant in a weight ratio of 2:1 were respectively mixed with a planetary ball mill at 300 rpm fo...

Embodiment 3

[0079] The preparation of the metal-supported half-cell of the solid oxide fuel cell involved in this embodiment is as follows:

[0080] A. Preparation of thick film green body of porous metal support layer and thin film green body of dense electrolyte layer;

[0081] 80 grams of stainless steel AM-1 powder, 20 grams of raw powder pore-forming agent, 100 grams of methyl ethyl ketone and ethanol mixed solvent and 4 grams of disc-80 dispersant in a weight ratio of 2:1 were mixed with a planetary ball mill at 300 rpm. Rotate ball mill for 8 hours and mix well. 14 grams of polyvinyl butyral binder, 8 grams of dibutyl phthalate and 8 grams of polyethylene glycol 200 mixed plasticizer were added to the above-mentioned ball-milled slurry. ball mill at 300 rpm for another 16 hours to mix well. 90 grams of SSZ powder, 80 grams of methyl ethyl ketone and ethanol mixed solvent and 6 grams of disc-80 dispersant in a weight ratio of 2:1 were respectively mixed with a planetary ball mill ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com