Patents

Literature

163results about How to "Lower ohmic resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

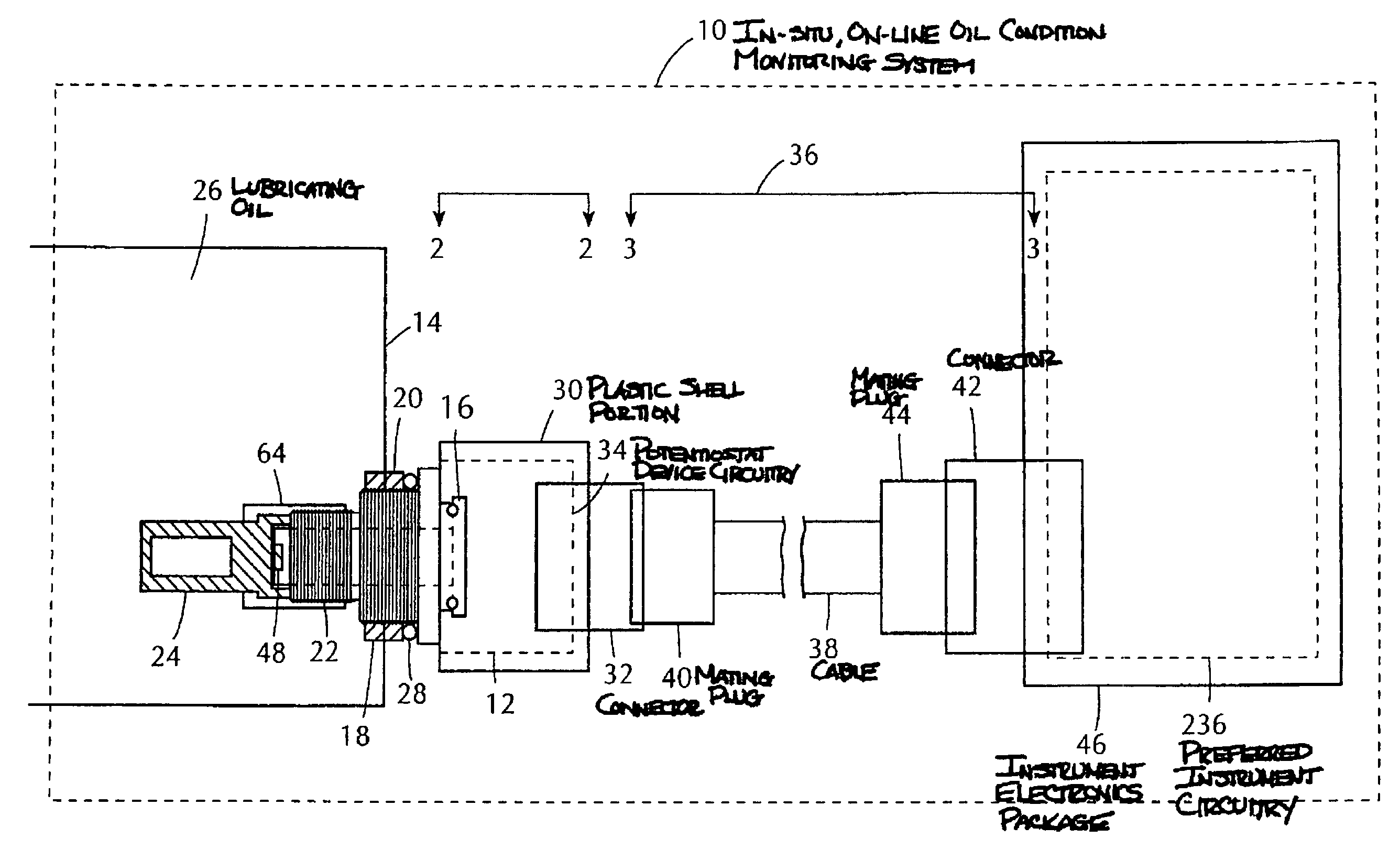

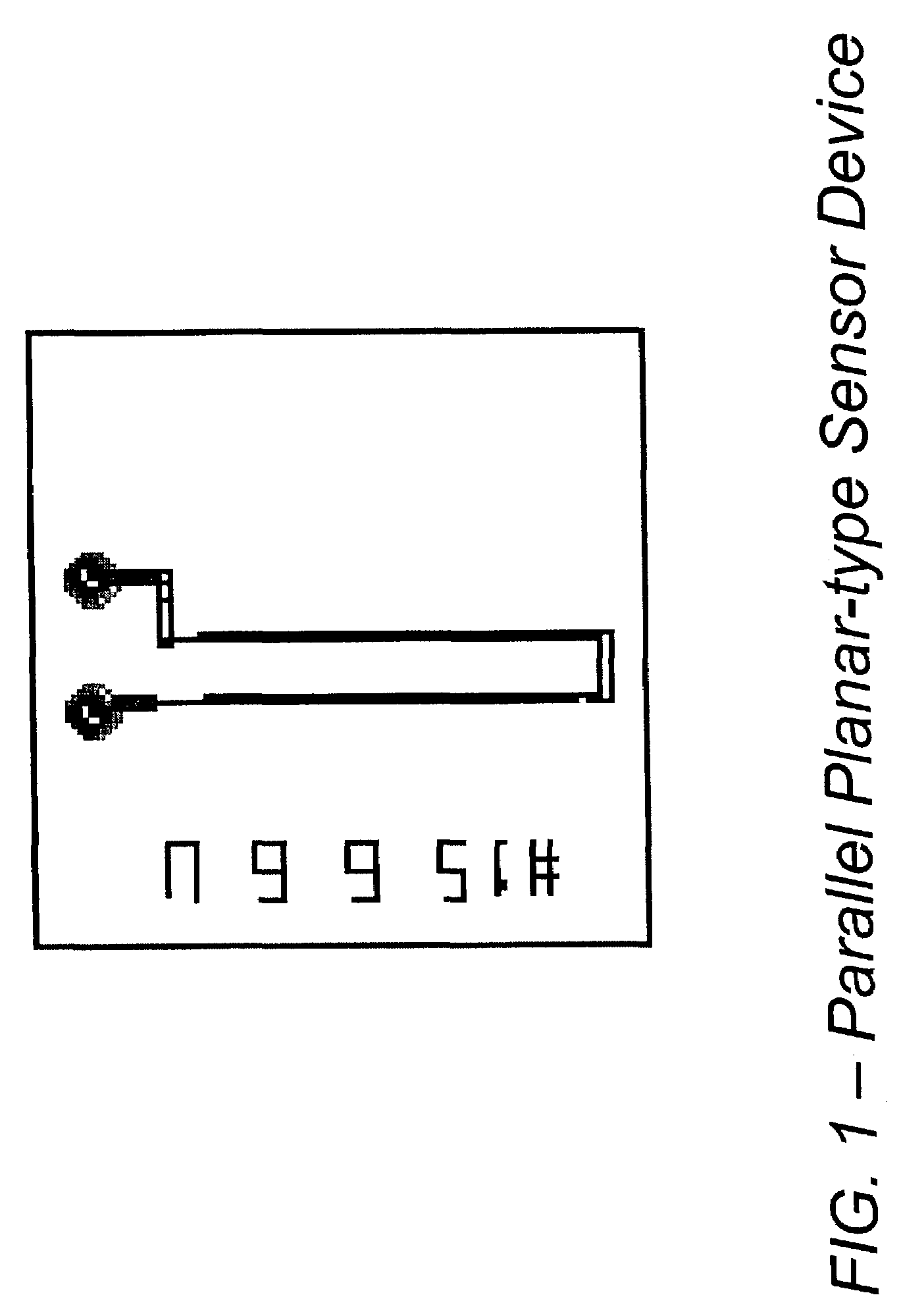

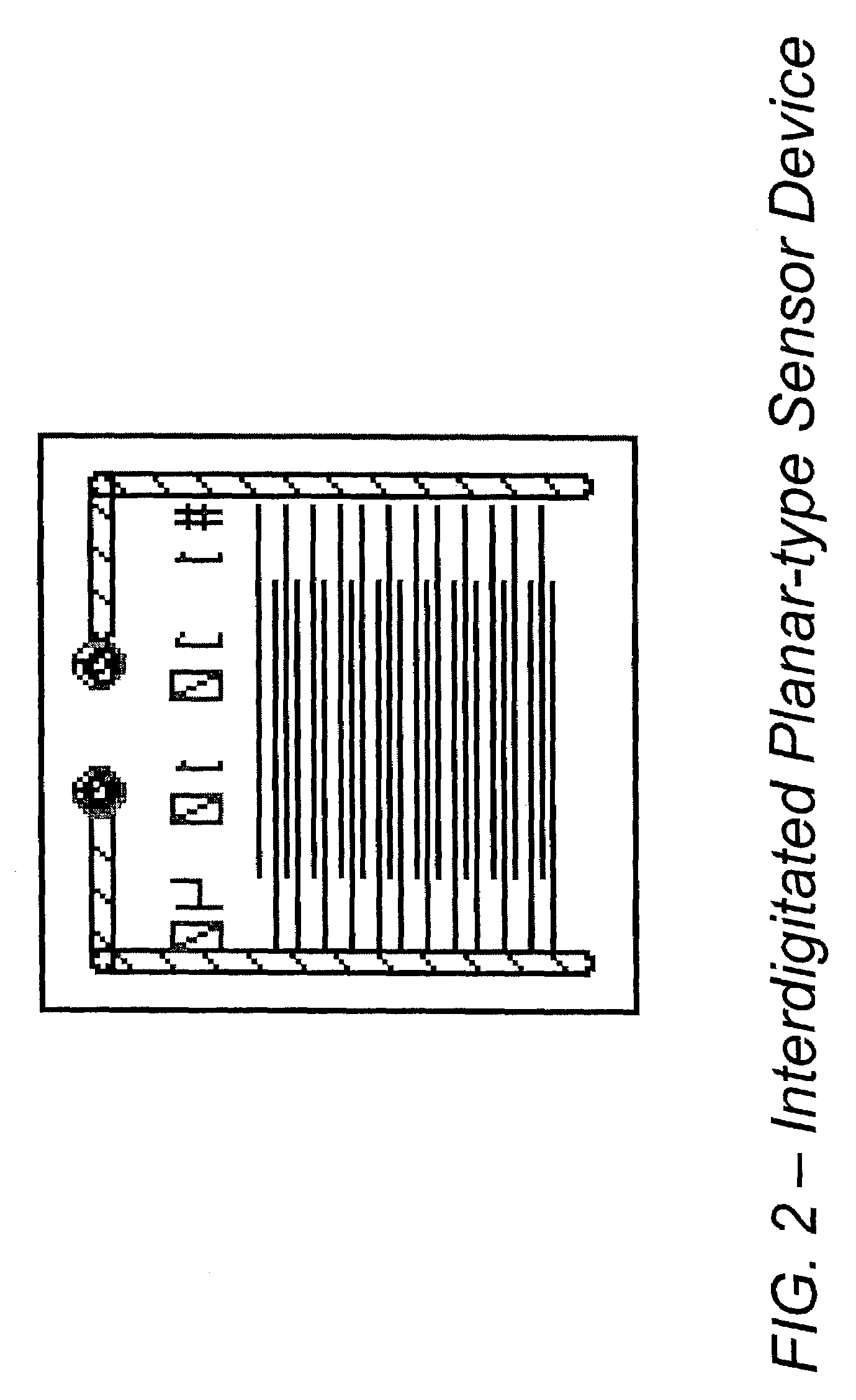

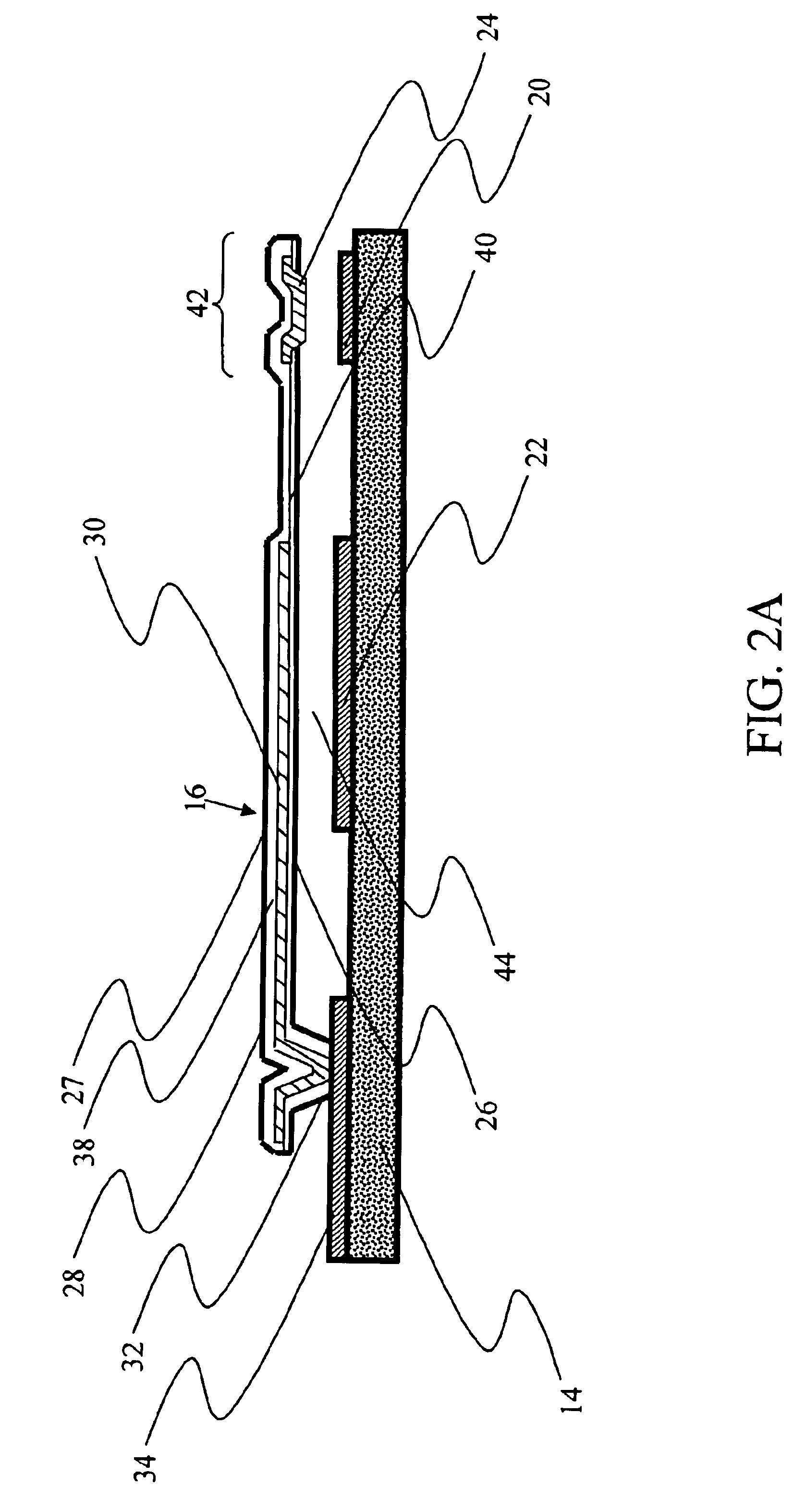

On-line oil condition sensor system for rotating and reciprocating machinery

InactiveUS7043402B2Improve performanceRepeatabilityFlow propertiesMachines/enginesElectrochemistryElectrode Contact

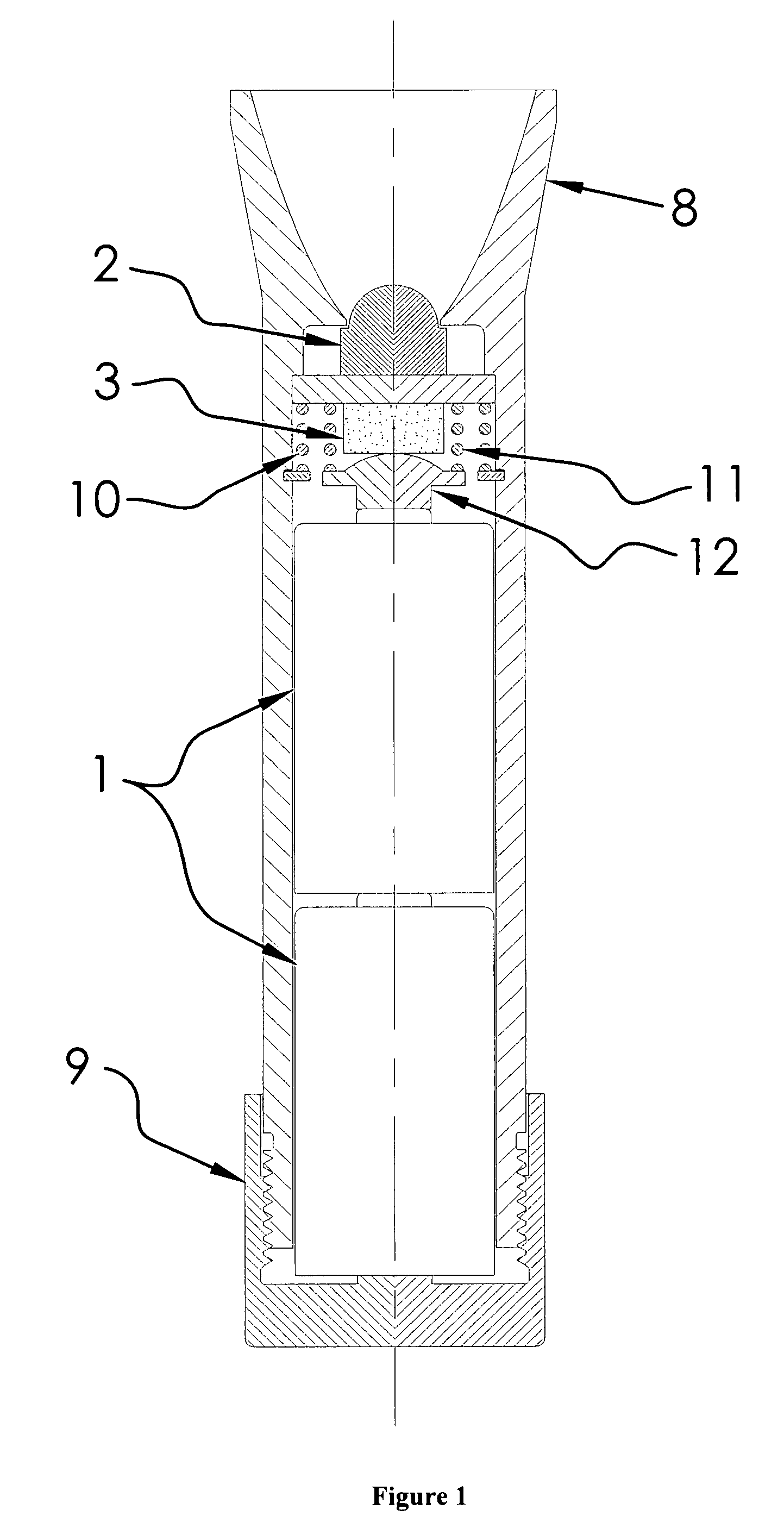

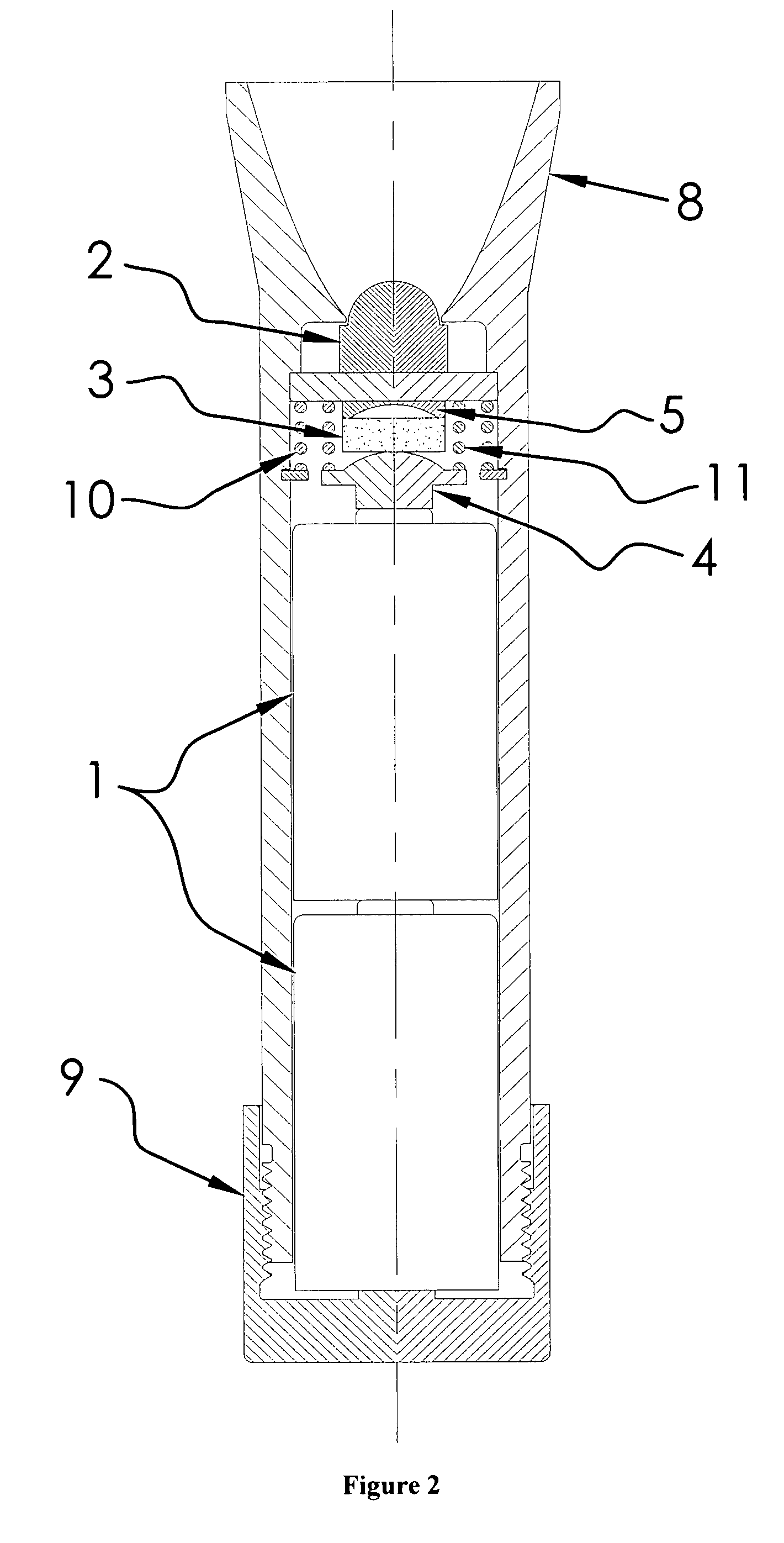

An on-line sensing system and method for monitoring in real-time thermal-oxidative breakdown, water contamination, and / or fuel dilution conditions in operational engine lubricating oils. The method of the invention includes an electrochemical impedance analysis technique specific to the particular oil to be monitored. Sensing devices having of at least two electrodes are configured for direct installation in an existing access port, or drain port, of a lubricating oil reservoir. An AC voltage waveform is applied to the sensing device (preferably less than 100 Hz) to produce voltage and current responses between the appropriate electrodes contacting the oil. The magnitude impedance |Z| and phase angle components of the complex impedance are used to characterize the quality and / or condition of the engine oil under test. The system also provides an electrical indication indicative of the percentage remaining useful life of the oil.

Owner:PHILLIPS INTPROP

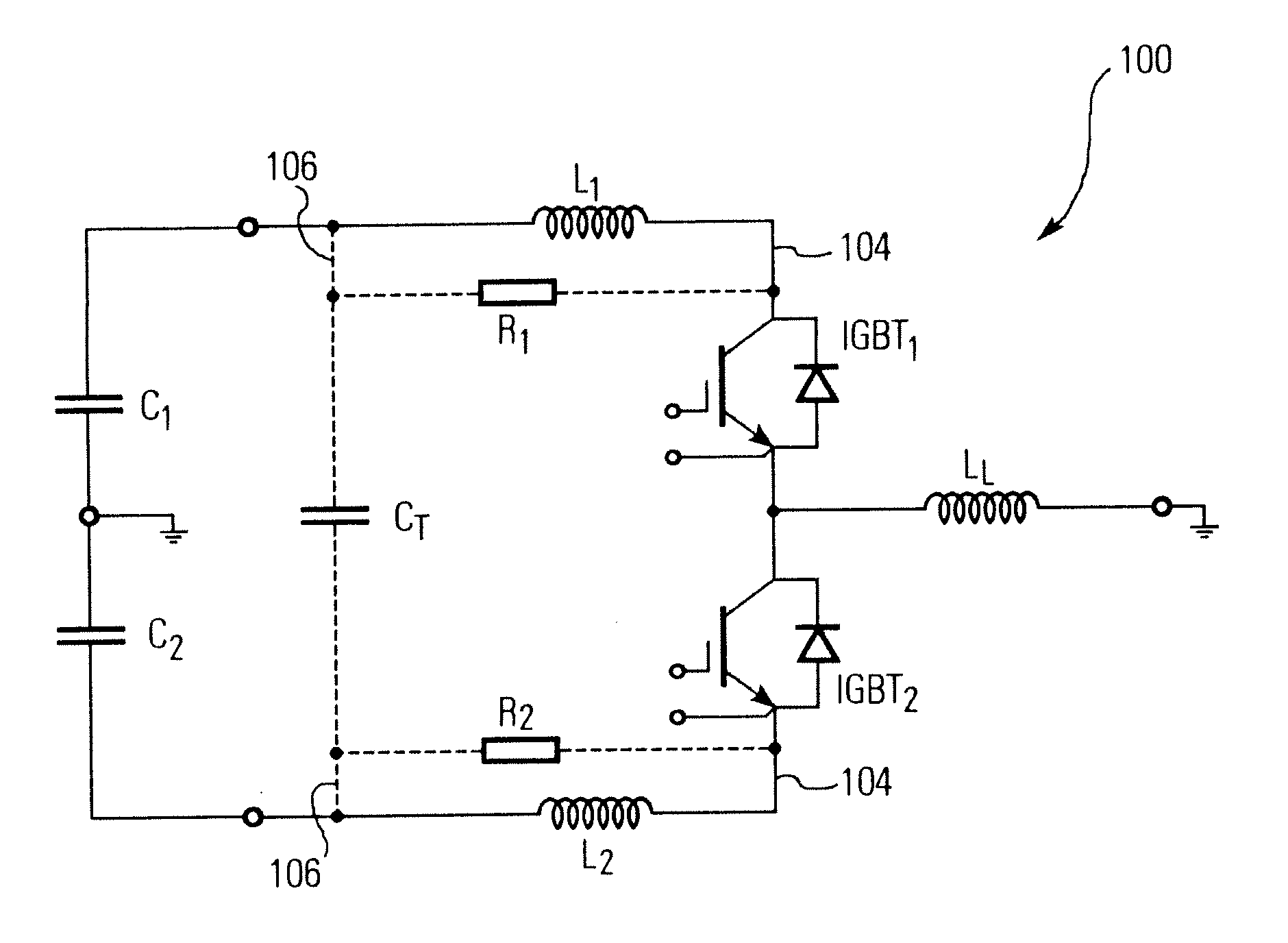

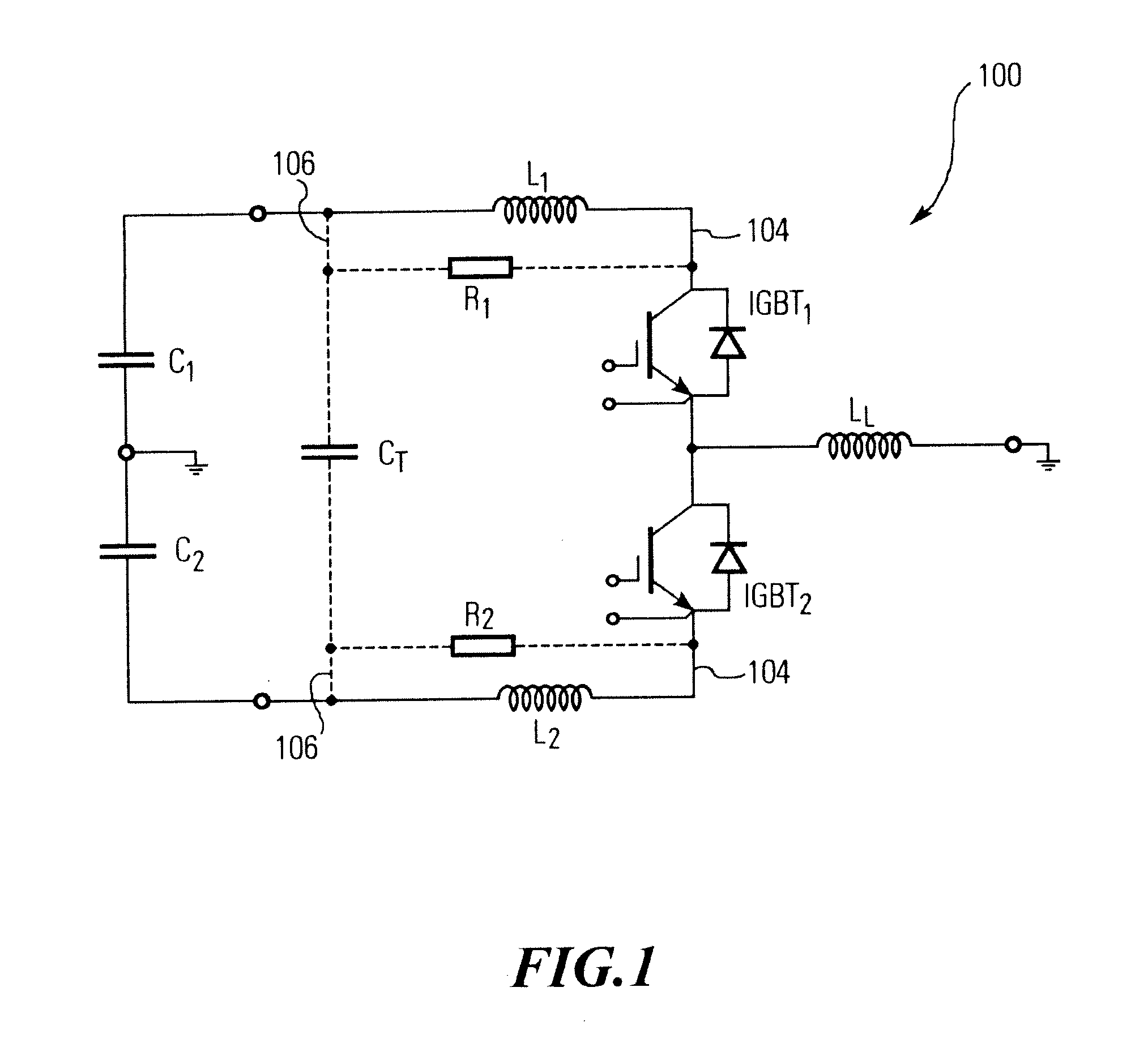

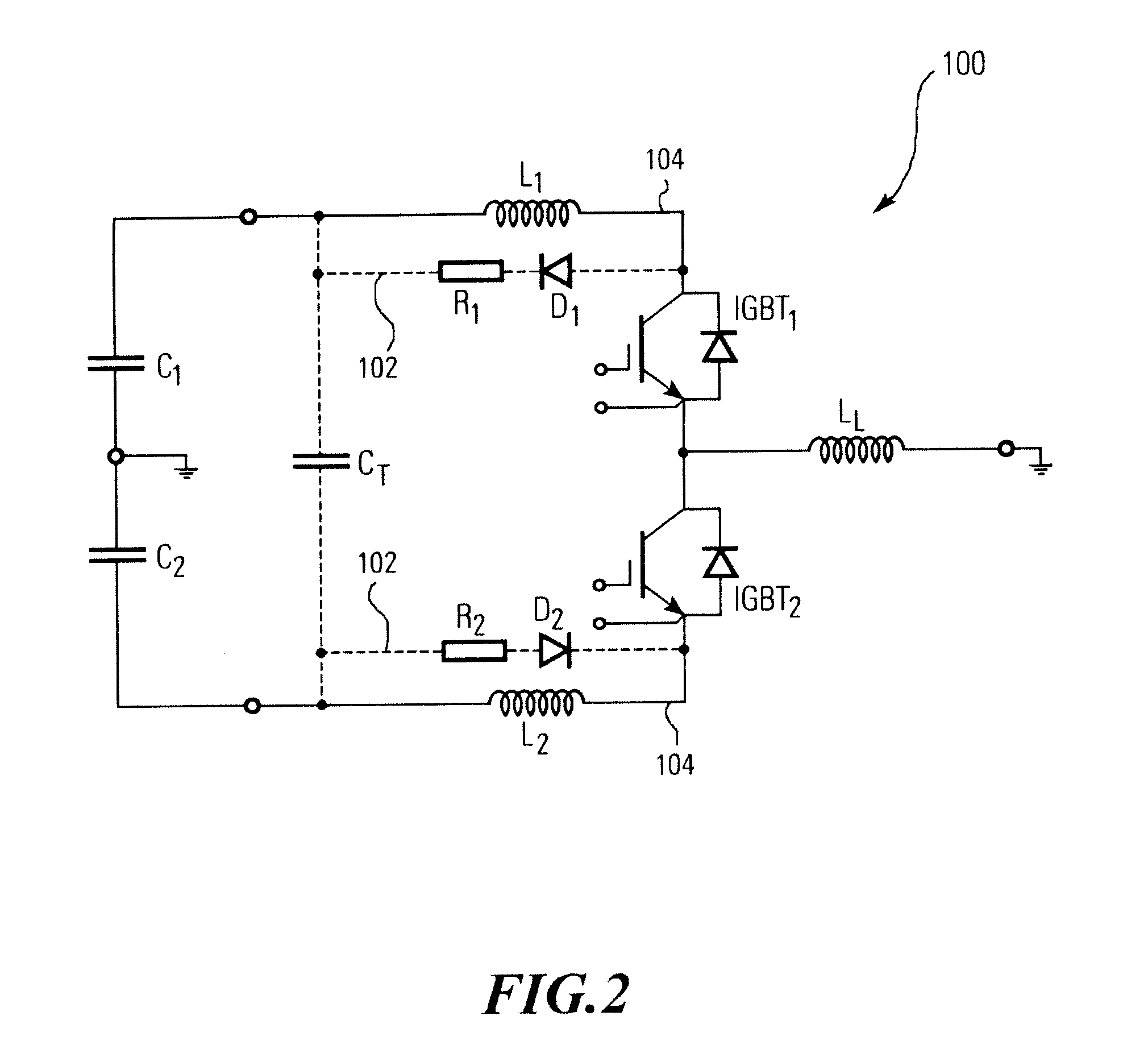

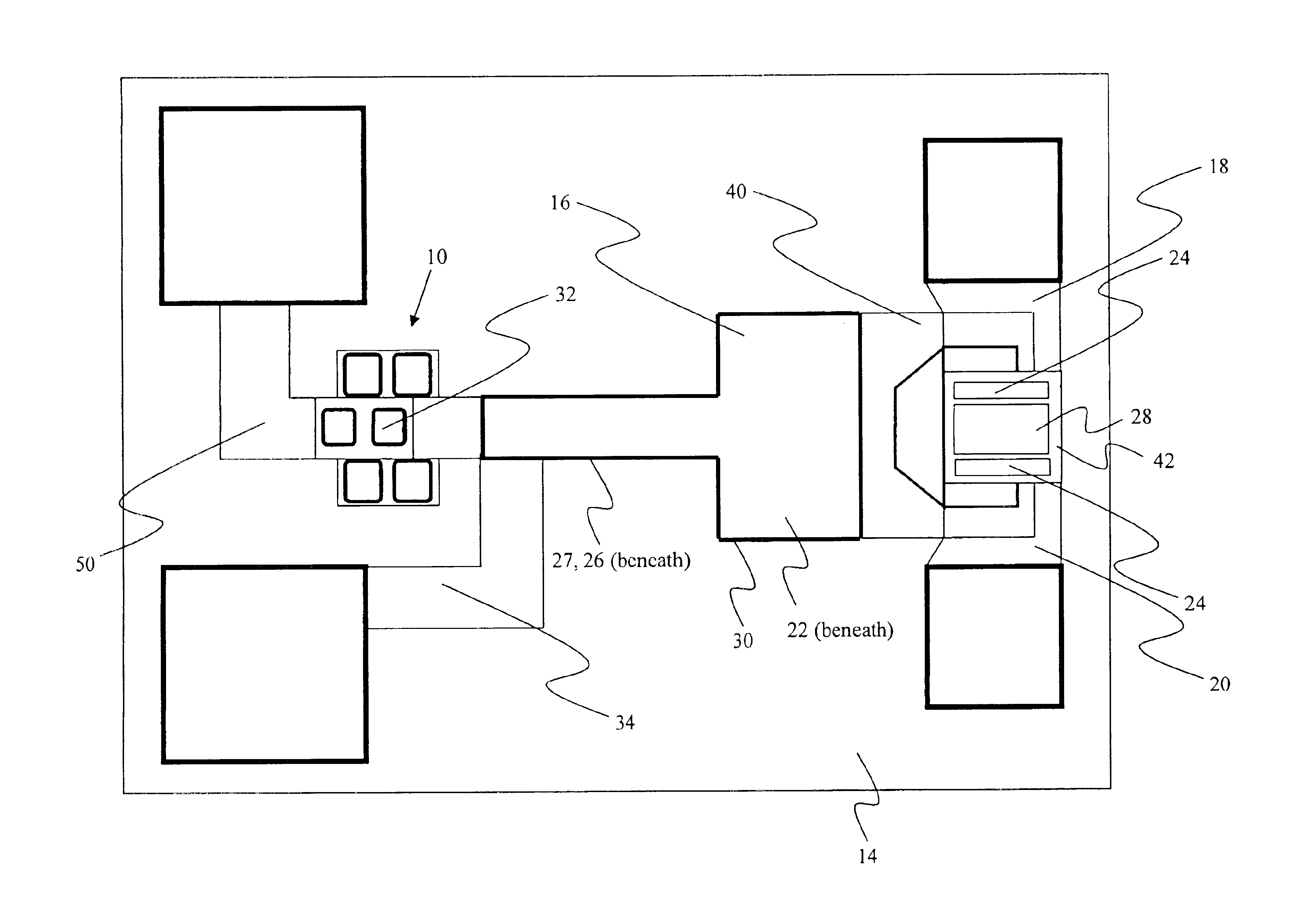

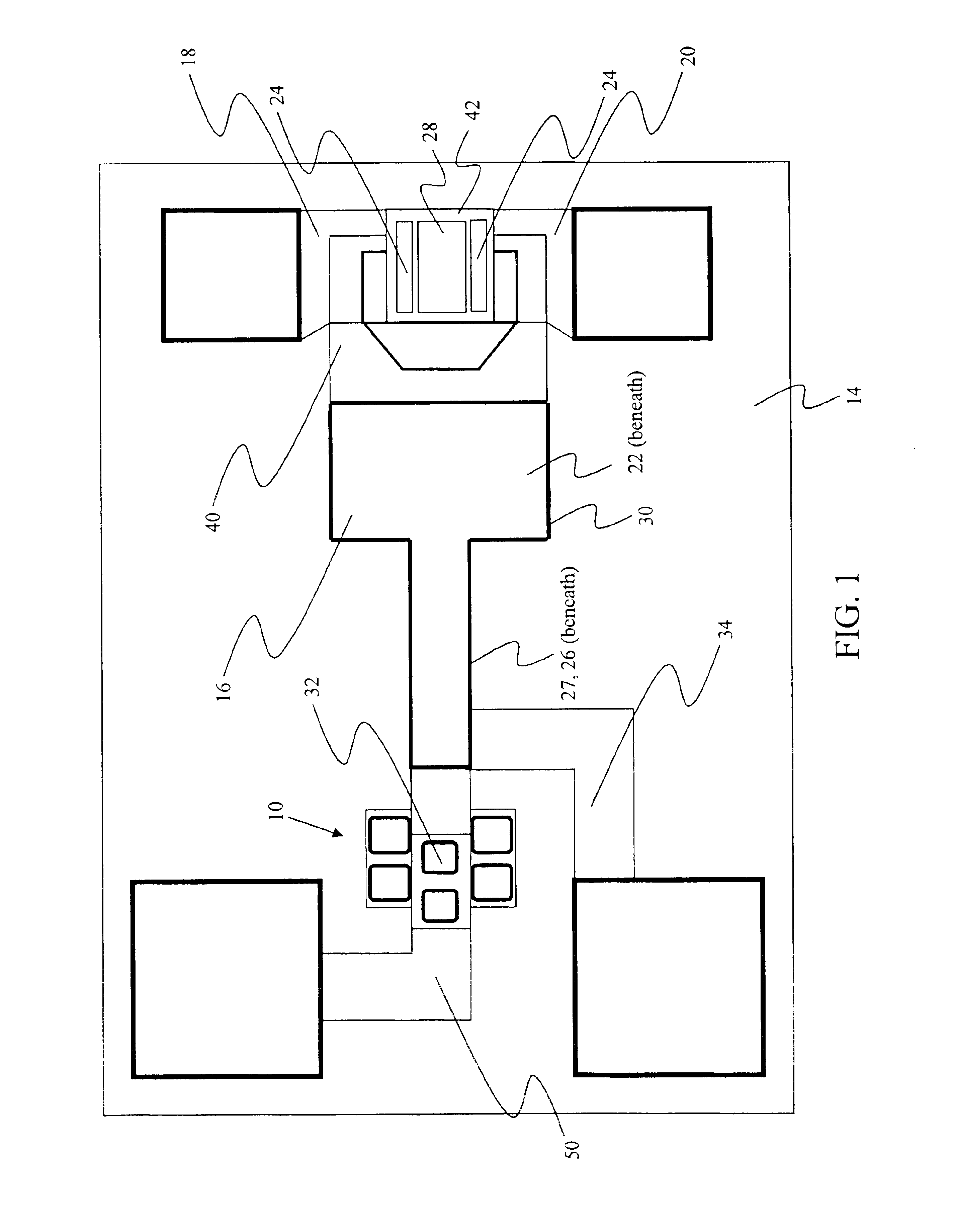

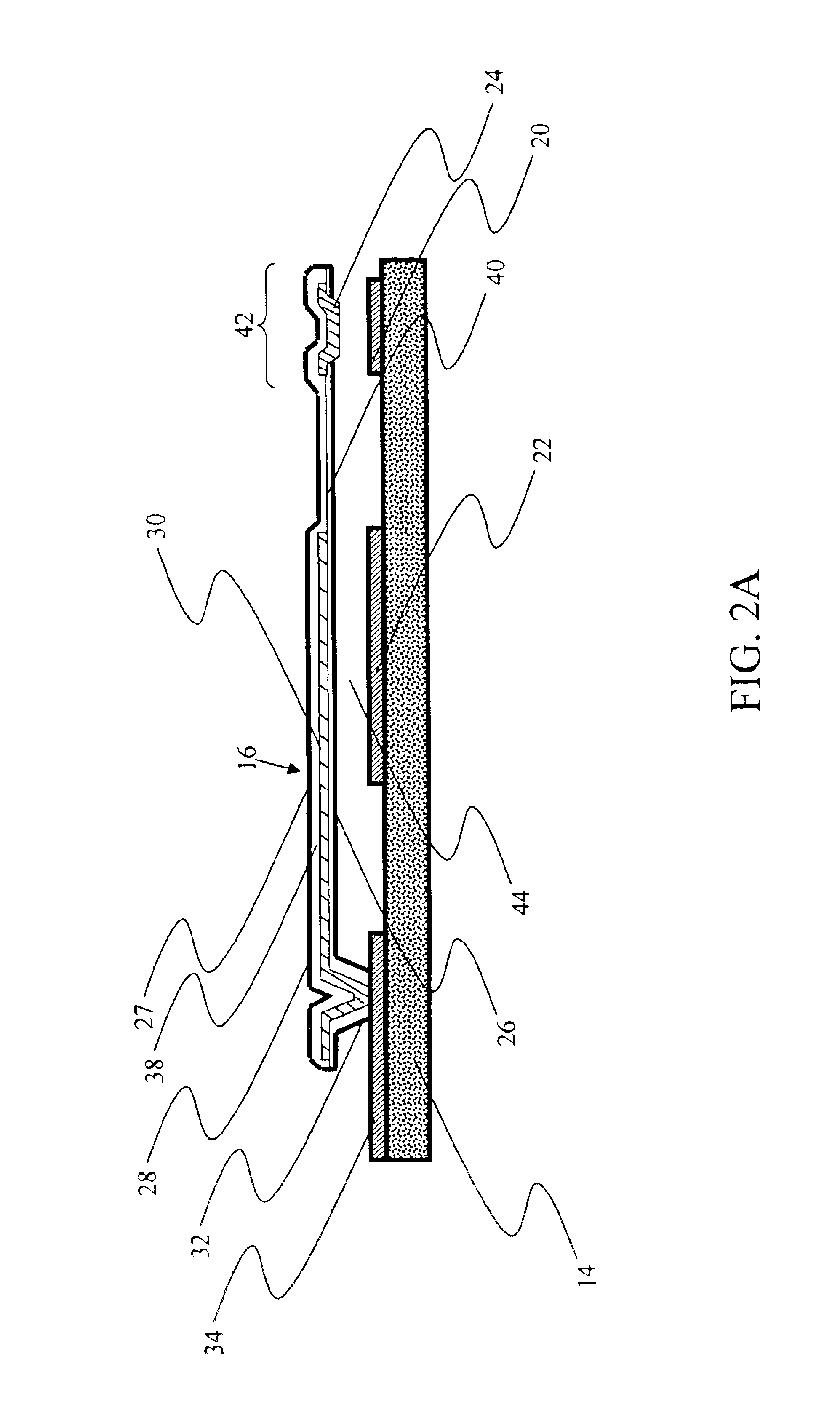

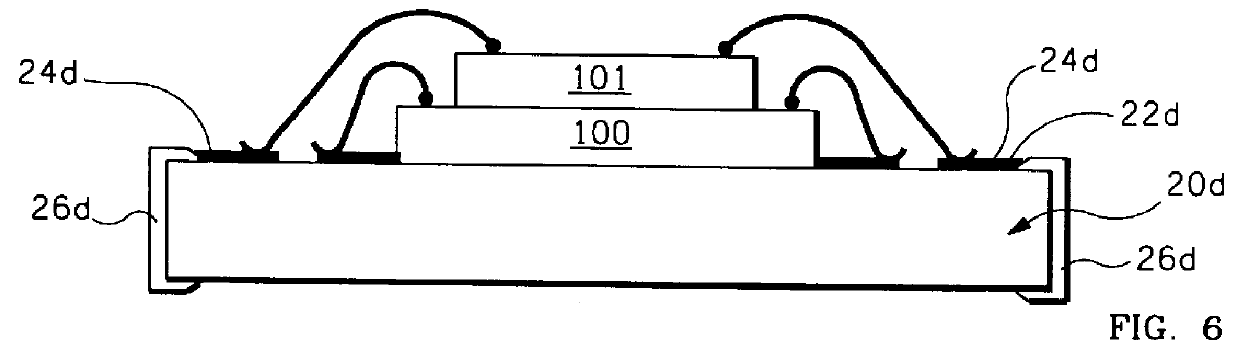

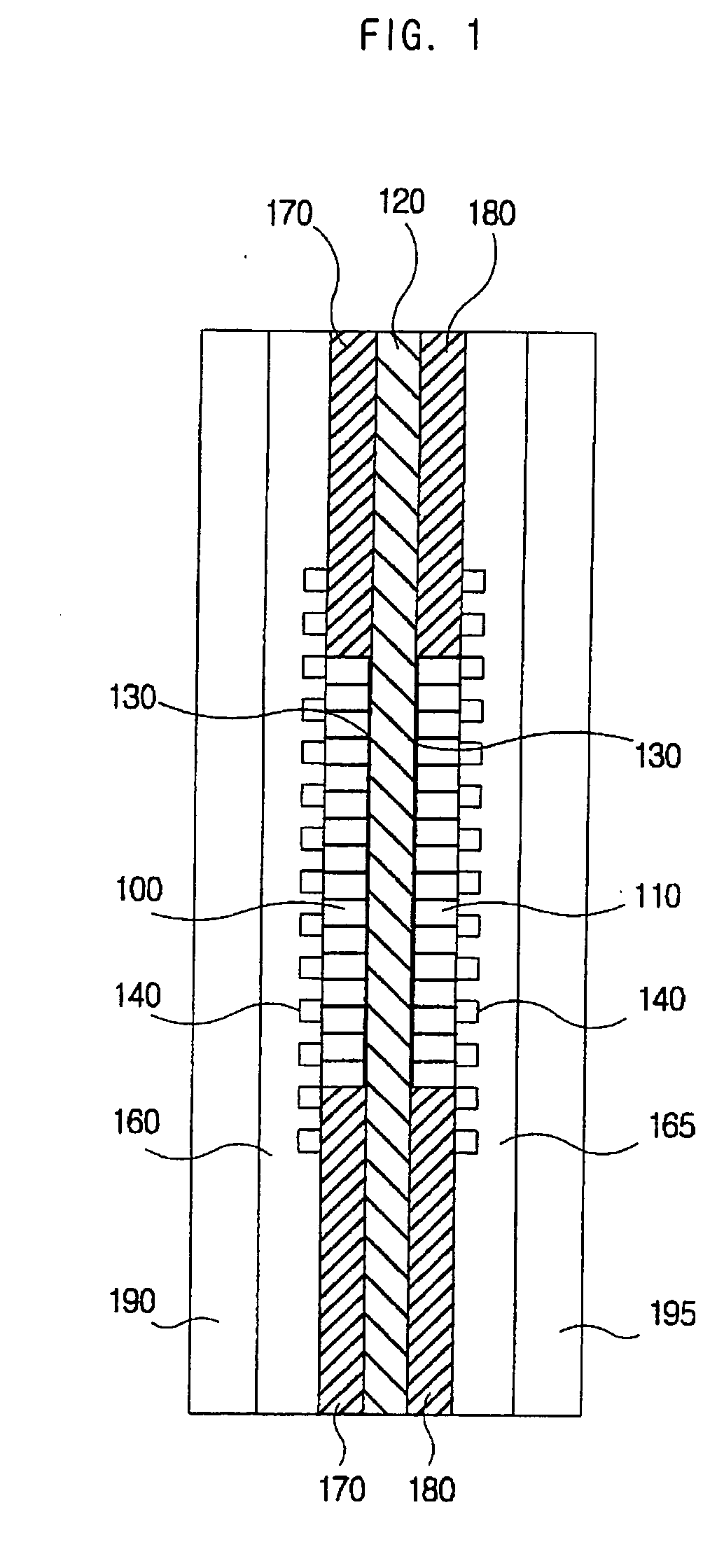

Power module with additional transient current path and power module system

InactiveUS20100328833A1Easily assembleReduce assemblyConversion constructional detailsSemiconductor/solid-state device detailsOhmContinuous current

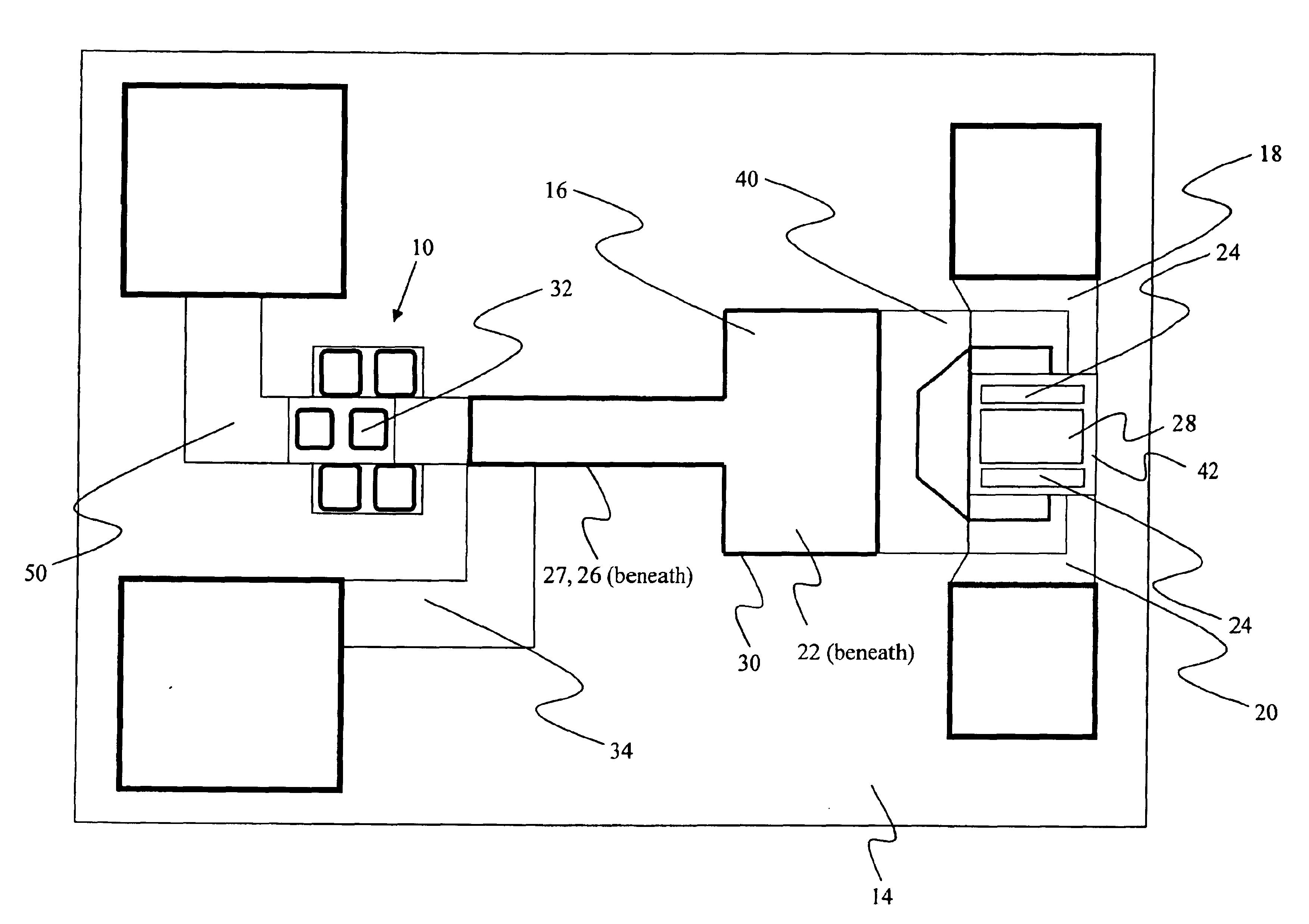

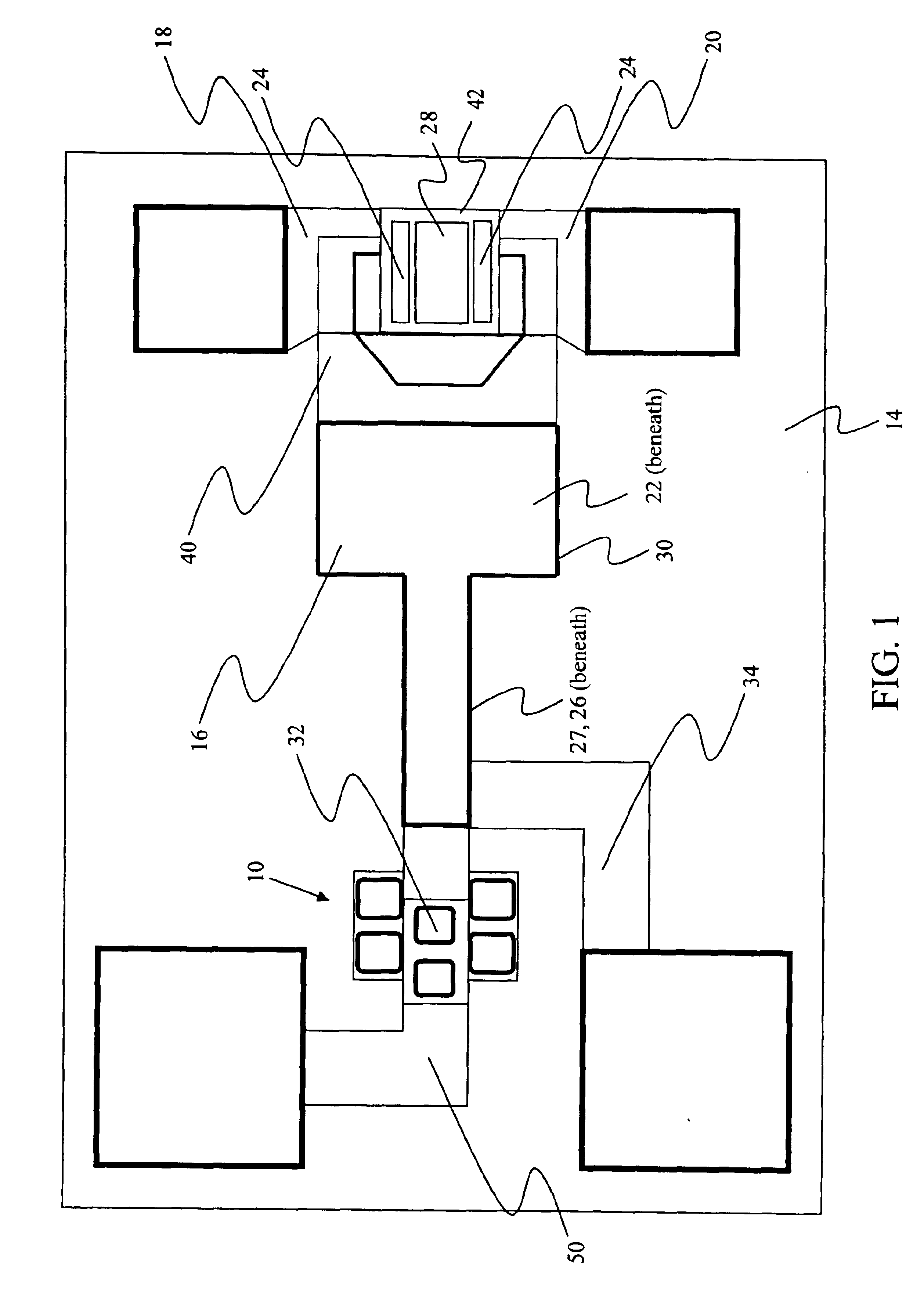

The present invention relates to power modules for controlling an input current to provide an output current, in particular, to such a power module (100) comprising at least one semiconductor switch for controlling the input current and a circuit substrate. The circuit substrate (108, 110) has at least one input terminal for being connected to an input voltage and at least one output terminal for outputting the output voltage. The input terminal and the output terminal are connected to each other via a main current path (104) that is controlled by the semiconductor switch. Said power module further comprises at least one transient current path (102) with extremely low inductivity for carrying a transient current during a switching operation of the semiconductor switch. The main path for the continuous current has a low ohmic resistance, but does not have to be designed to have a specifically low inductance.

Owner:VINCOTECH HLDG R L

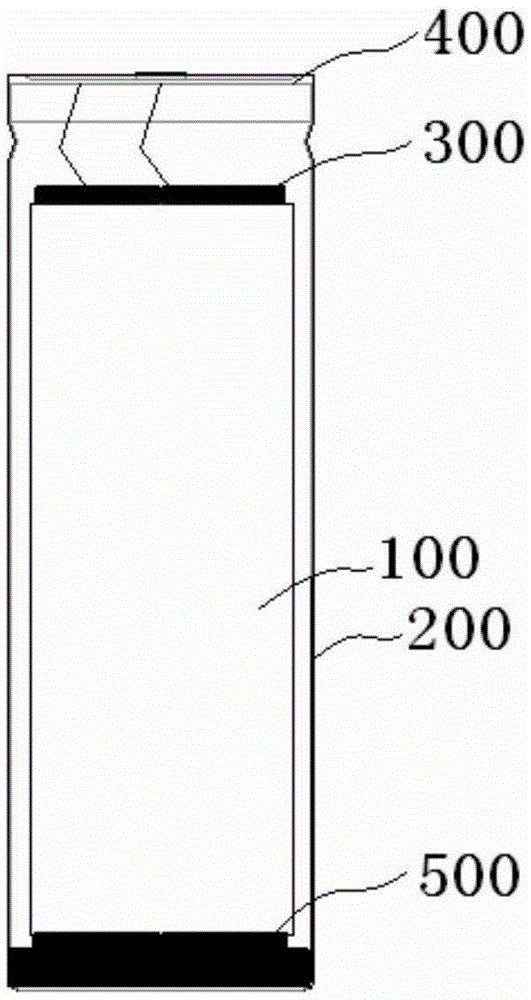

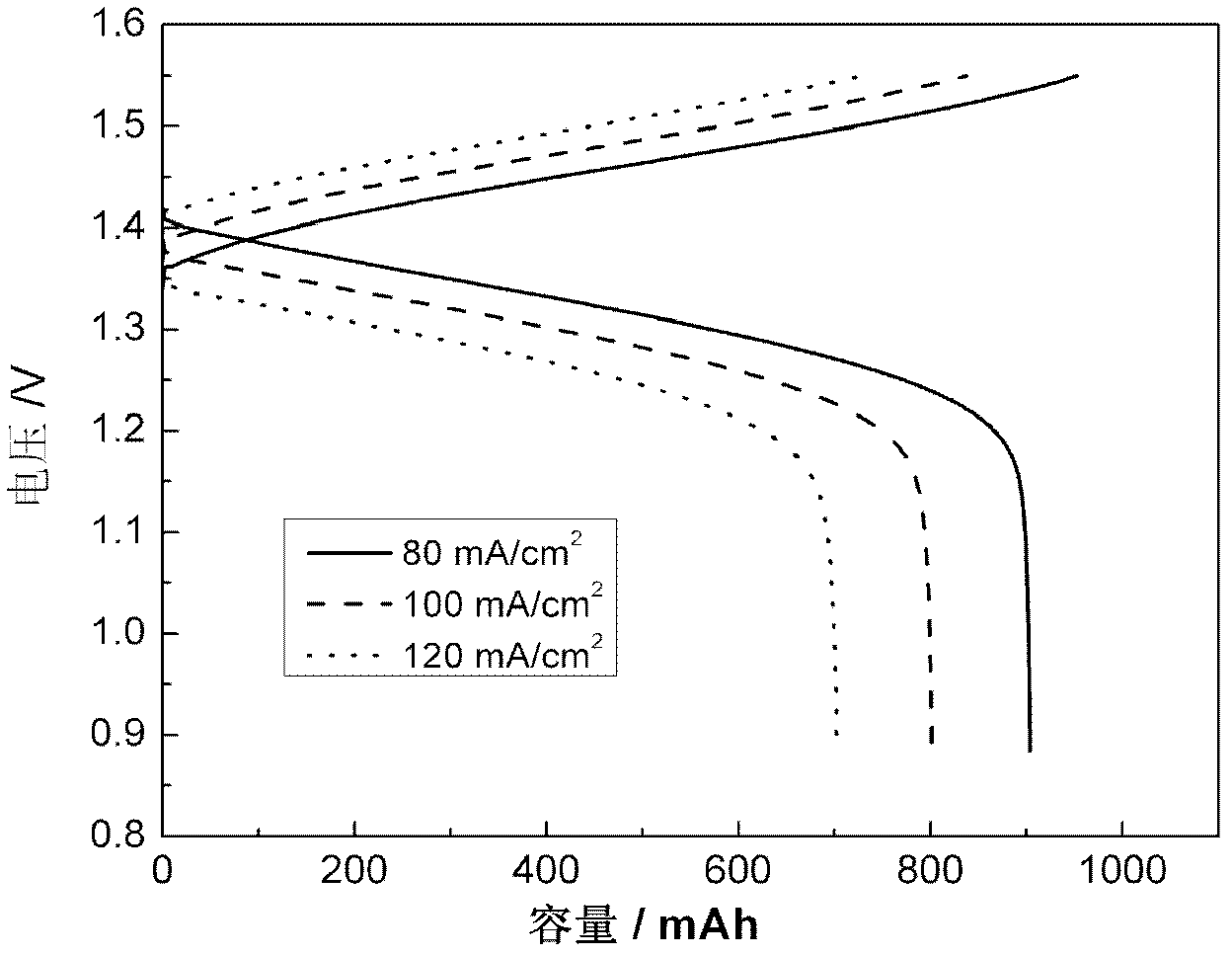

Super-wide-temperature-range nickel-hydrogen battery and manufacturing method therefor

ActiveCN105390755AImprove conductivityLower ohmic resistanceCell seperators/membranes/diaphragms/spacersFinal product manufacturePotassiumNickel electrode

The invention discloses a super-wide-temperature-range nickel-hydrogen battery. The battery comprises an iron shell as well as a nickel electrode, a hydrogen electrode, a diaphragm and an electrolyte solution mounted in the iron shell, wherein the nickel electrode takes foam nickel as a substrate material; the space in foam nickel is filled with a positive electrode active substance Ni(OH)2, a conductive agent, an additive and a binder; the hydrogen electrode takes a porous nickel-plated steel belt, a copper net or foam nickel as a substrate material; the porous nickel-plated steel belt, the copper net or foam nickel is coated with a negative electrode active substance, namely, hydrogen storage alloy powder, the conductive agent, the additive or the binder; and the electrolyte solution is a mixture of a potassium-rich alkaline aqueous solution and sodium tungstate or tungstic acid crystals. The invention furthermore discloses a manufacturing method for the super-wide-temperature-range nickel-hydrogen battery. According to the super-wide-temperature-range nickel-hydrogen battery disclosed by the invention, the ratio of 0.2C discharge capacity to normal-temperature capacity maximally can reach 70-80% in an environment with the temperature of -45 DEG C; and the ratio of 0.2C discharge capacity to normal-temperature capacity of the nickel hydrogen battery maximally can reach 85-95% in an environment with the temperature of 70 DEG C. Moreover, the manufacturing method is simple and suitable for large-scale production.

Owner:HENGYANG BST POWER

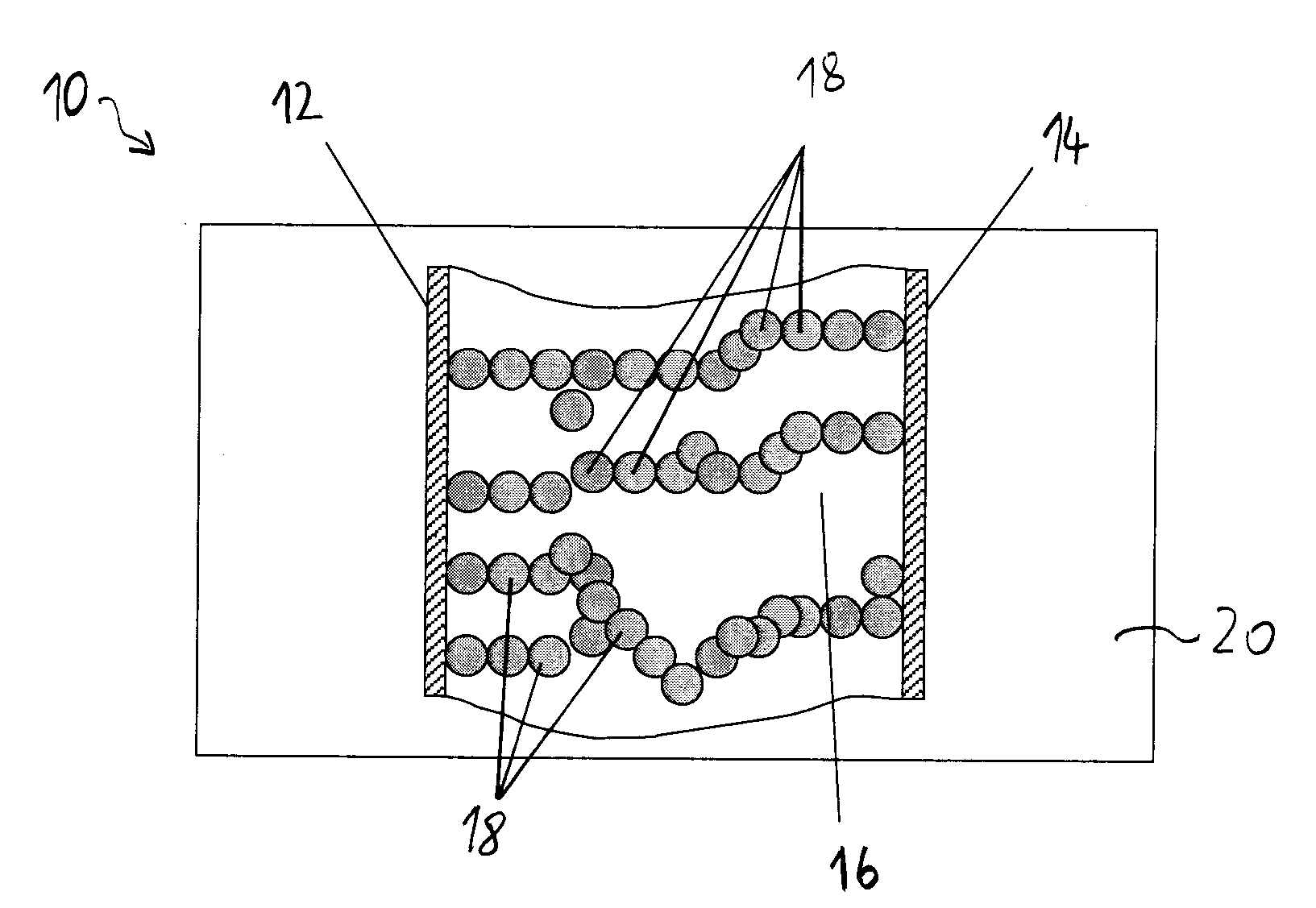

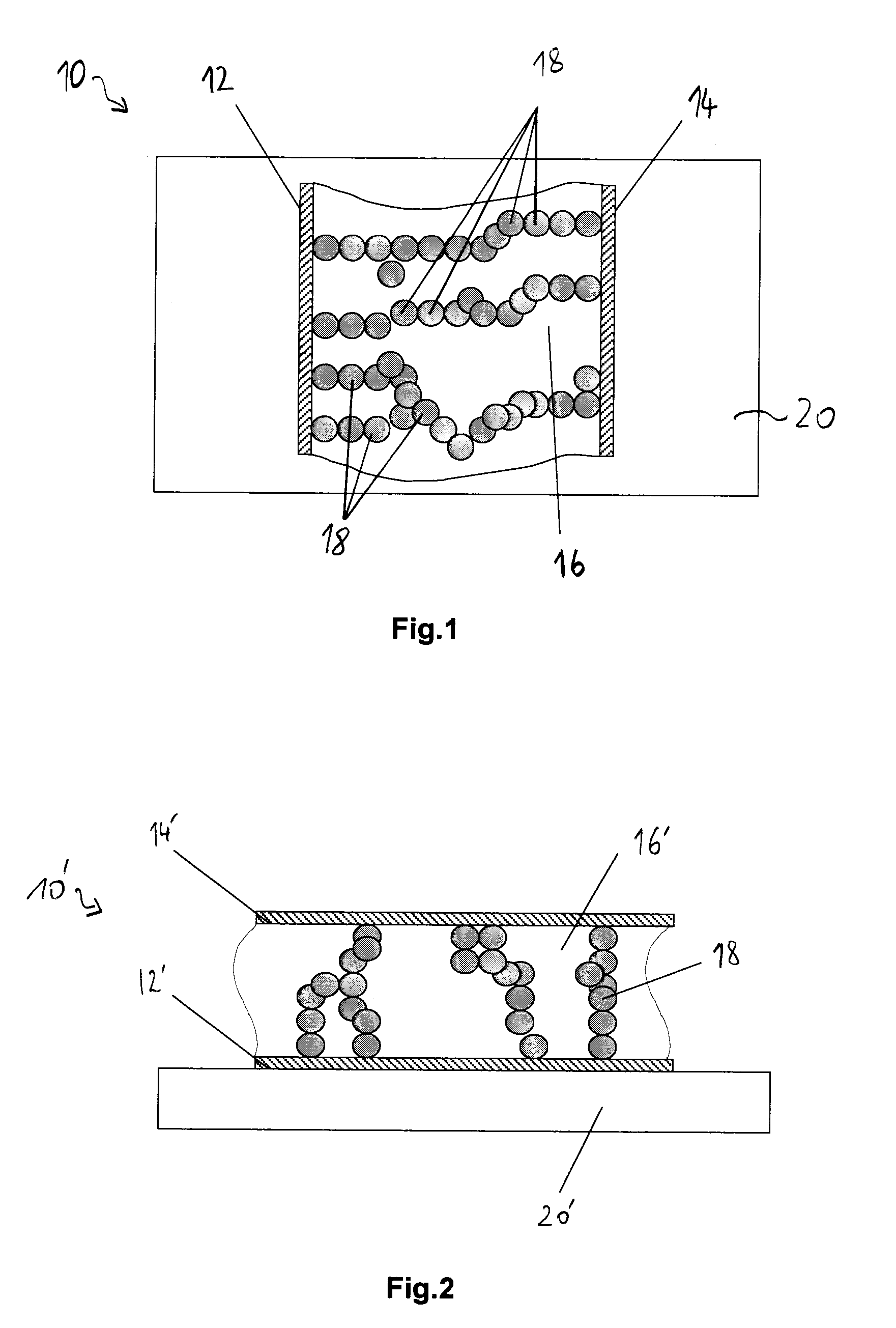

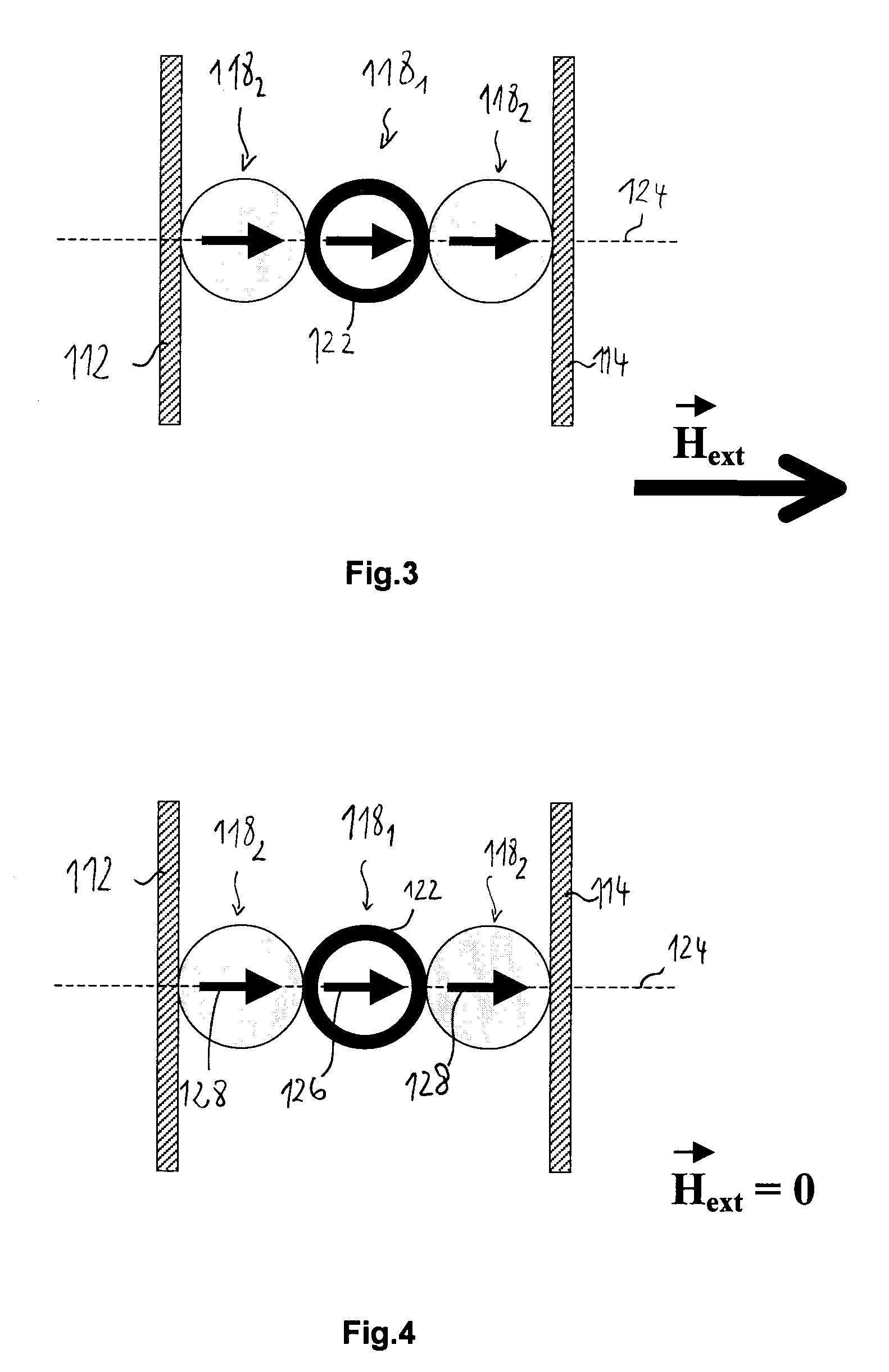

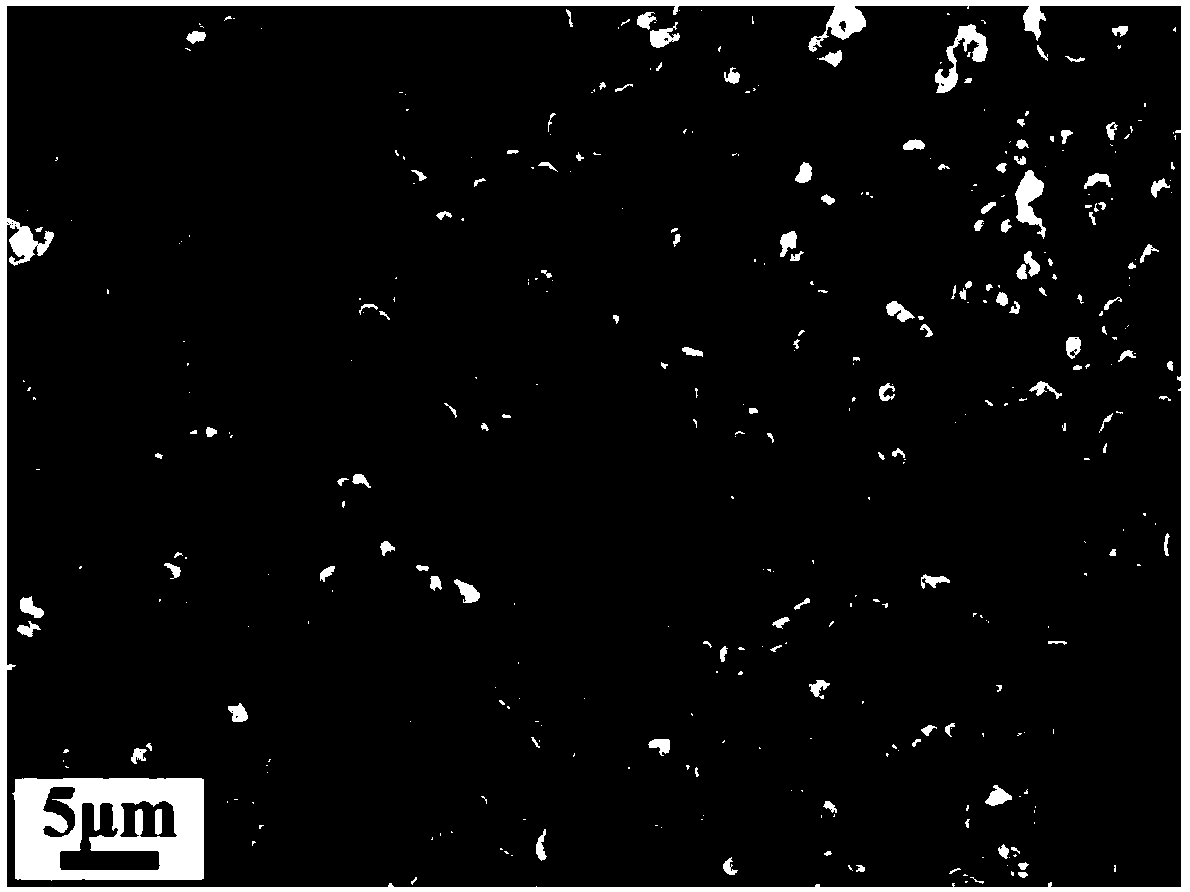

Magnetic Field Sensing Element

InactiveUS20090001983A1Easy to controlMaintain good propertiesSpark gapsMagnetic-field-controlled resistorsMagnetite NanoparticlesTunnel junction

A magnetic field sensing element includes a pair of electrodes; a dielectric polymer layer separating the electrodes; and a network of magnetic nanoparticles in the insulating layer forming a current flow path between the electrodes; where the network of magnetic nanoparticles includes at least one magnetic tunnel junction involving two neighbouring nanoparticles of different coercivity.

Owner:IEE INT ELECTRONICS & ENG SA

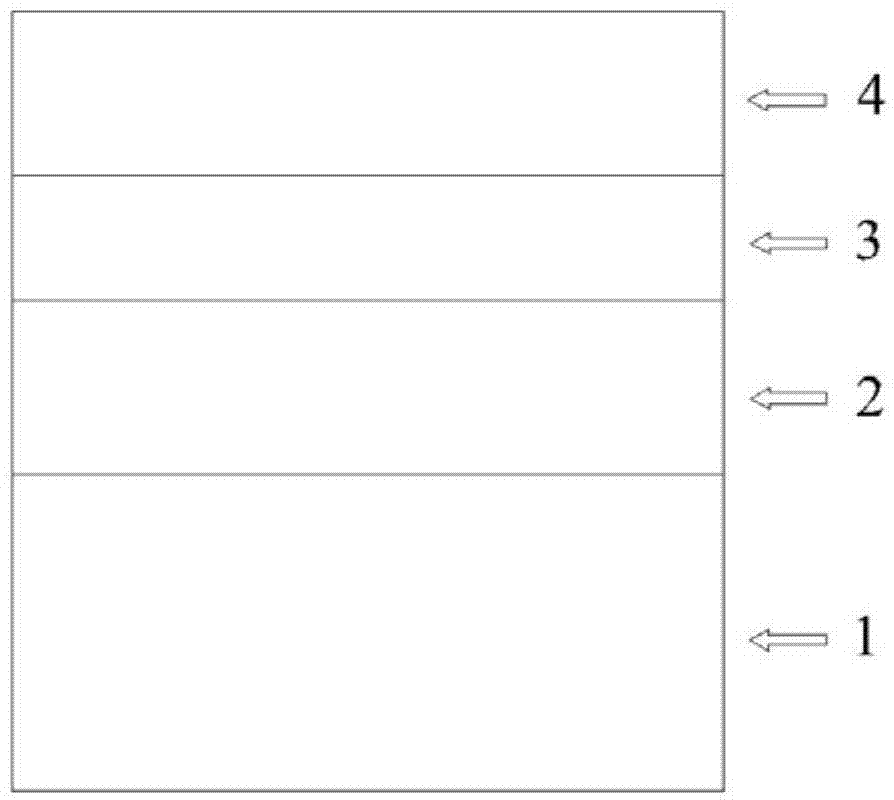

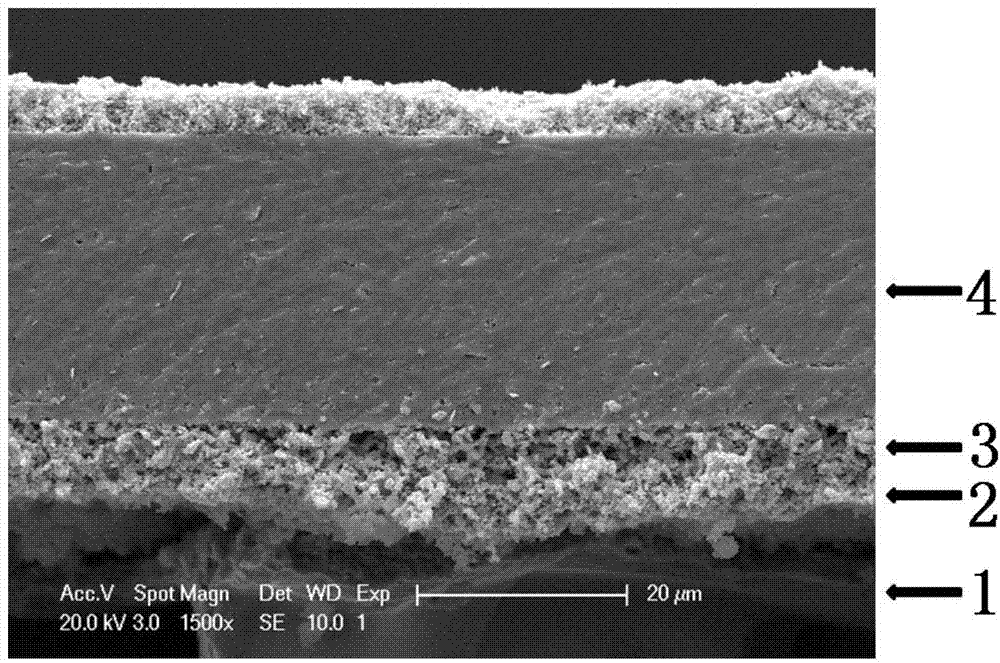

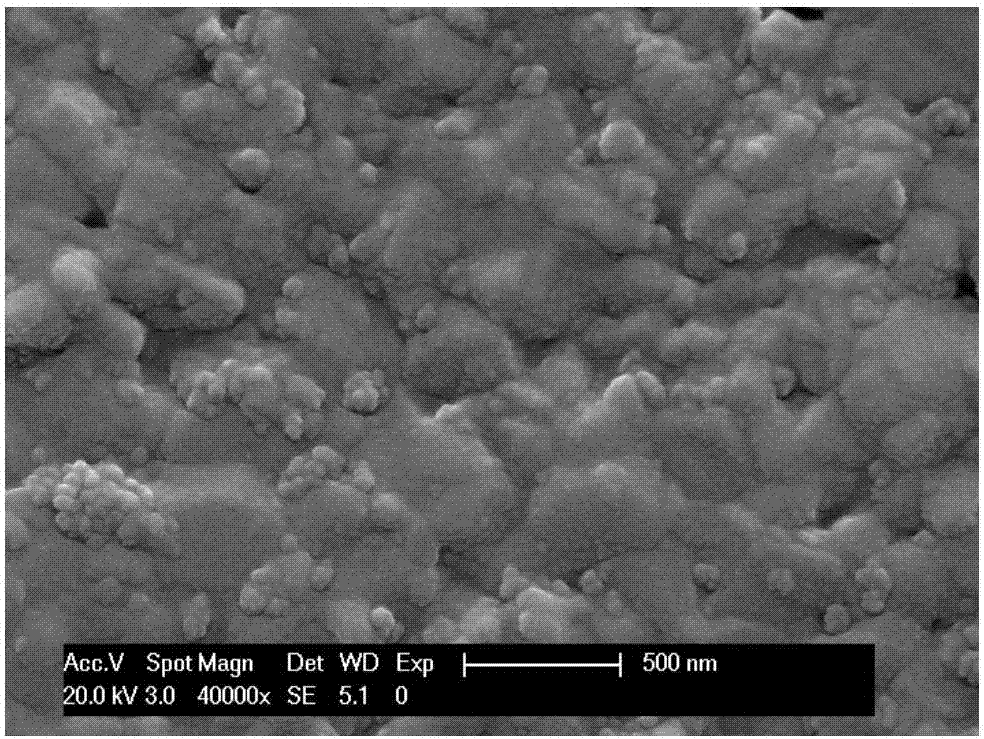

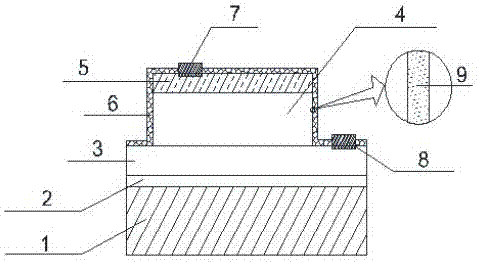

Metal support half-cell of solid oxide fuel cell and preparation method thereof

ActiveCN103928693AAvoid direct contactReduce interdiffusionCell electrodesSolid electrolyte fuel cellsFuel cellsMixed oxide

The invention discloses a metal support half-cell of a solid oxide fuel cell and a preparation method thereof. The half-cell comprises a porous metal supporting layer thick membrane, a porous cermet gradient transition layer film, a porous anode layer and a compact electrolyte layer film from down to up. The porous gradient transition layer composed of a mixed oxide and a oxide with a fluorite structuring can avoid the direct contact of the porous metal supporting layer and the porous anode layer, and the mutual diffusion of Fe / Cr elements in the metal supporting layer and Ni element in the porous anode layer can be reduced under high temperature sintering condition. The mixed oxide is reduced to an alloy under the work condition of the cell; a high anode active material is formed at a side interface of the anode, a high conductivity composite material which takes the alloy as a main phase is formed on the side interface of a metal support body, so that higher conductivity is presented, ohmic resistance is reduced, electrocatalytic activity is not reduced, long-term stability for operation of the cell can be ensured, and good combination of the porous metal supporting layer and the porous anode layer can be simultaneously realized.

Owner:中弗(无锡)新能源有限公司

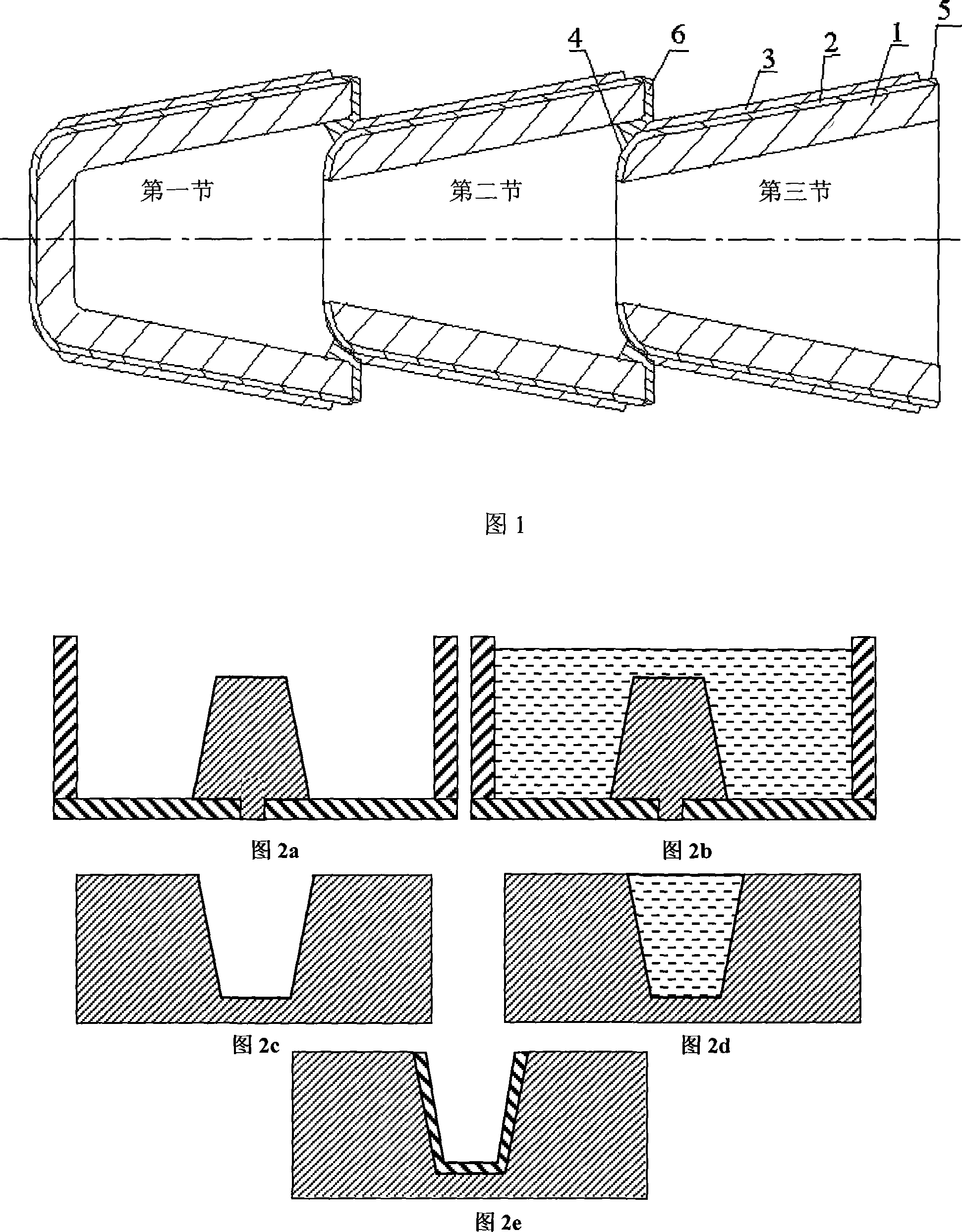

Preparation method of anode supporter of tube-type solid-oxide fuel battery

InactiveCN101162779ALower ohmic resistanceImprove output characteristicsFuel cells groupingFinal product manufactureGypsumSizing

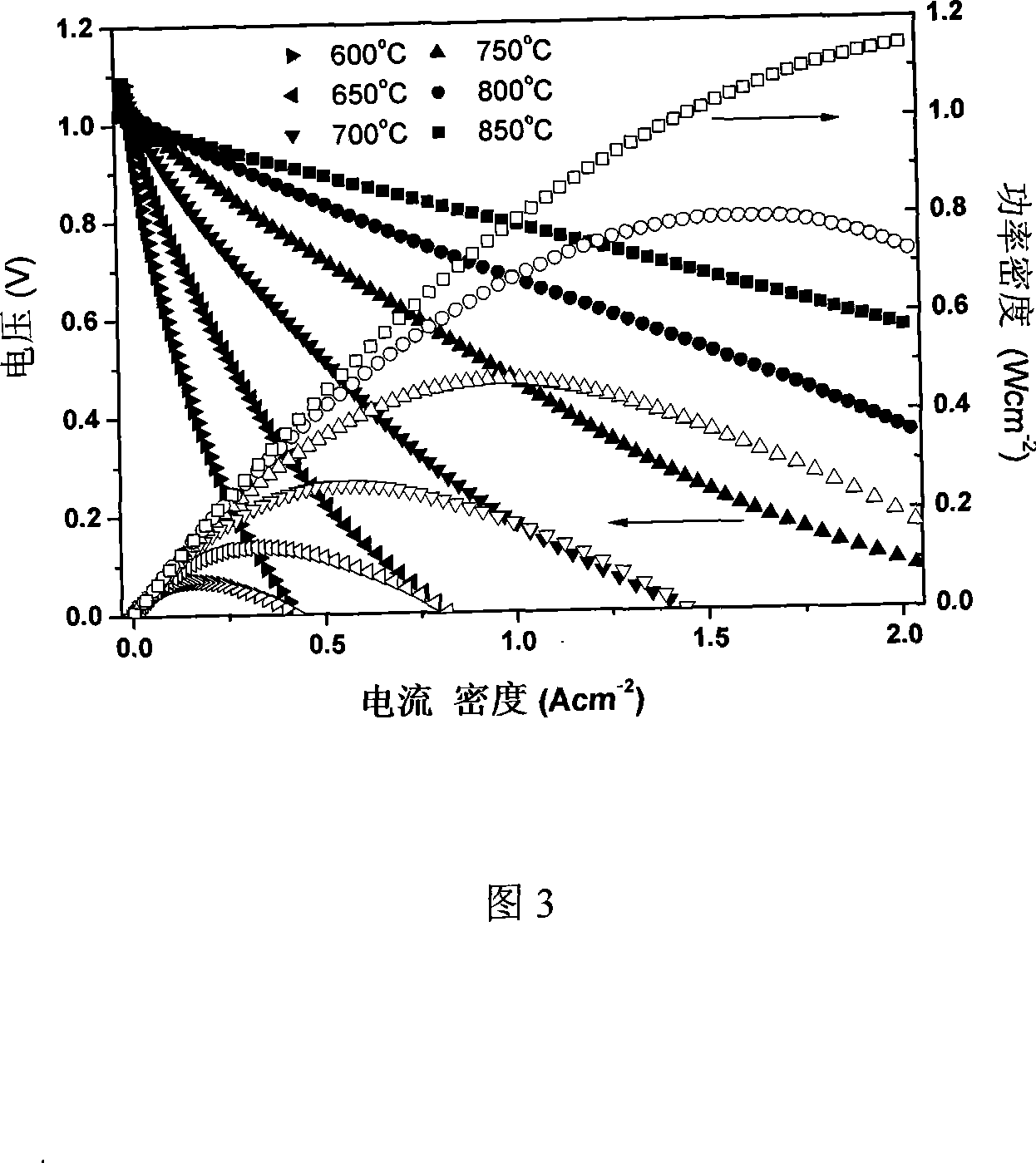

The present invention discloses a preparation method of a tube-type solid oxide fuel cell anode support body. The method comprises the preparation of a gypsum mold and the anode support body gained by injecting anode sizing agent to the gypsum mold; anode powders are gained through uniformly mixing NiO powders and YSZ powders with equal quality; water is added to the anode powders; anode injecting sizing agent is gained by planetary type ball milling; acacia as dispersant is added to the anode injecting sizing agent; the prepared anode injecting sizing agent is injected to the cavum of the gypsum mold and an anode layer is formed in the cavum of the gypsum mold; the anode tube is taken out and is presintered for 1 hour to 3 hours in the temperature between 800 DEG C and 1250 DEG C. The method can prepare anode support tubes with different shapes by changing the shape of the gypsum mold and can prepare NiO-YSZ compound anode support tubes. On the basis of the anode support tube prepared by the method of the invention, electrolytical membrane and the cathode are prepared on the anode support tube, and the battery has good output performance in a middle temperature zone (600 DEG C to 800 DEG C).

Owner:SOUTH CHINA UNIV OF TECH

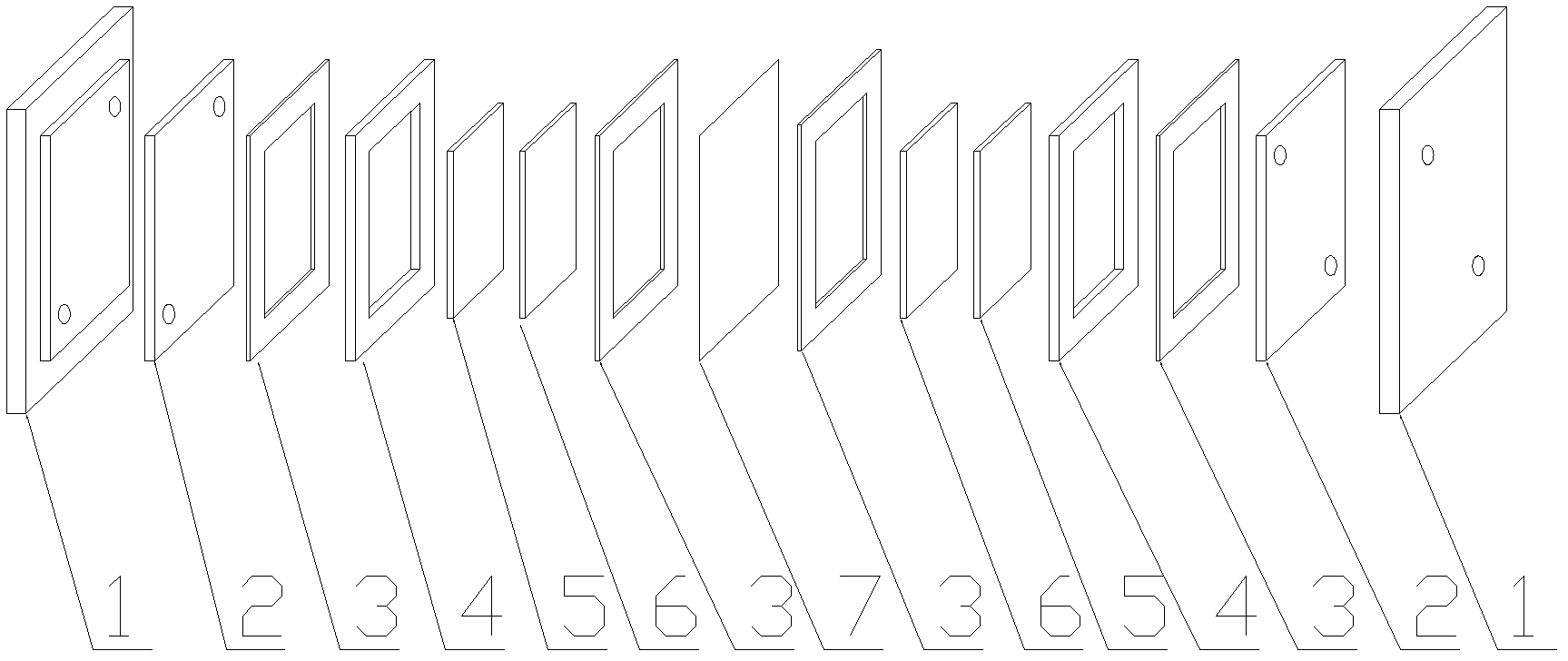

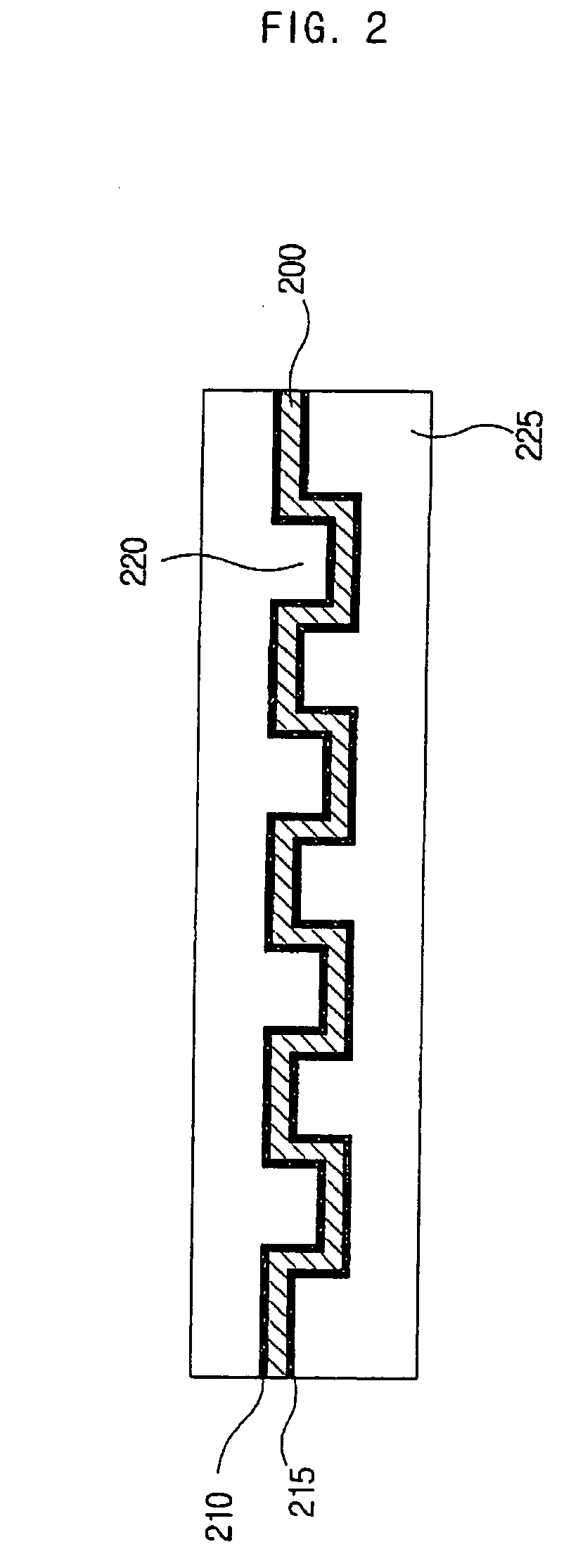

Solid oxide fuel cell positive electrode-electrolyte-negative electrode

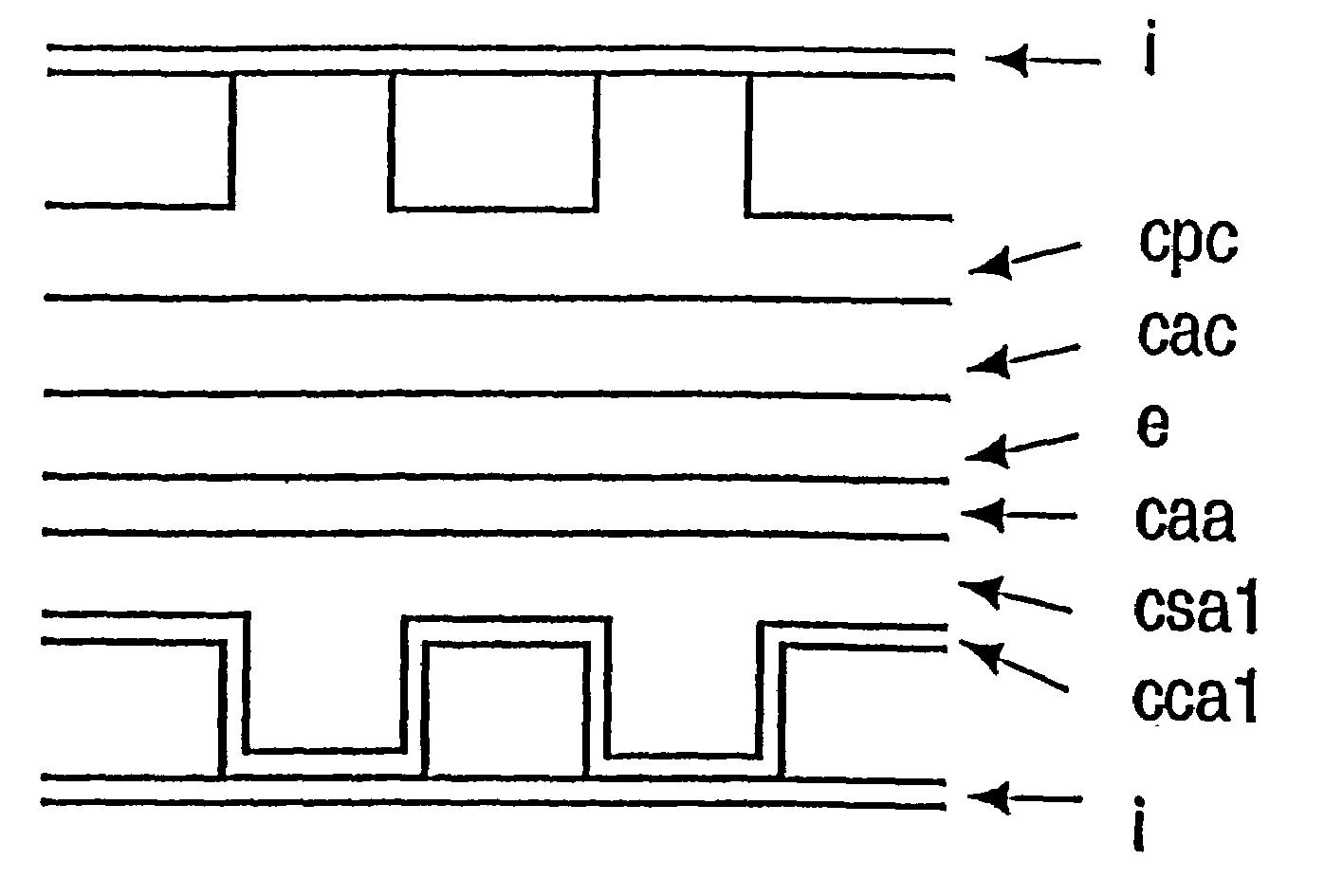

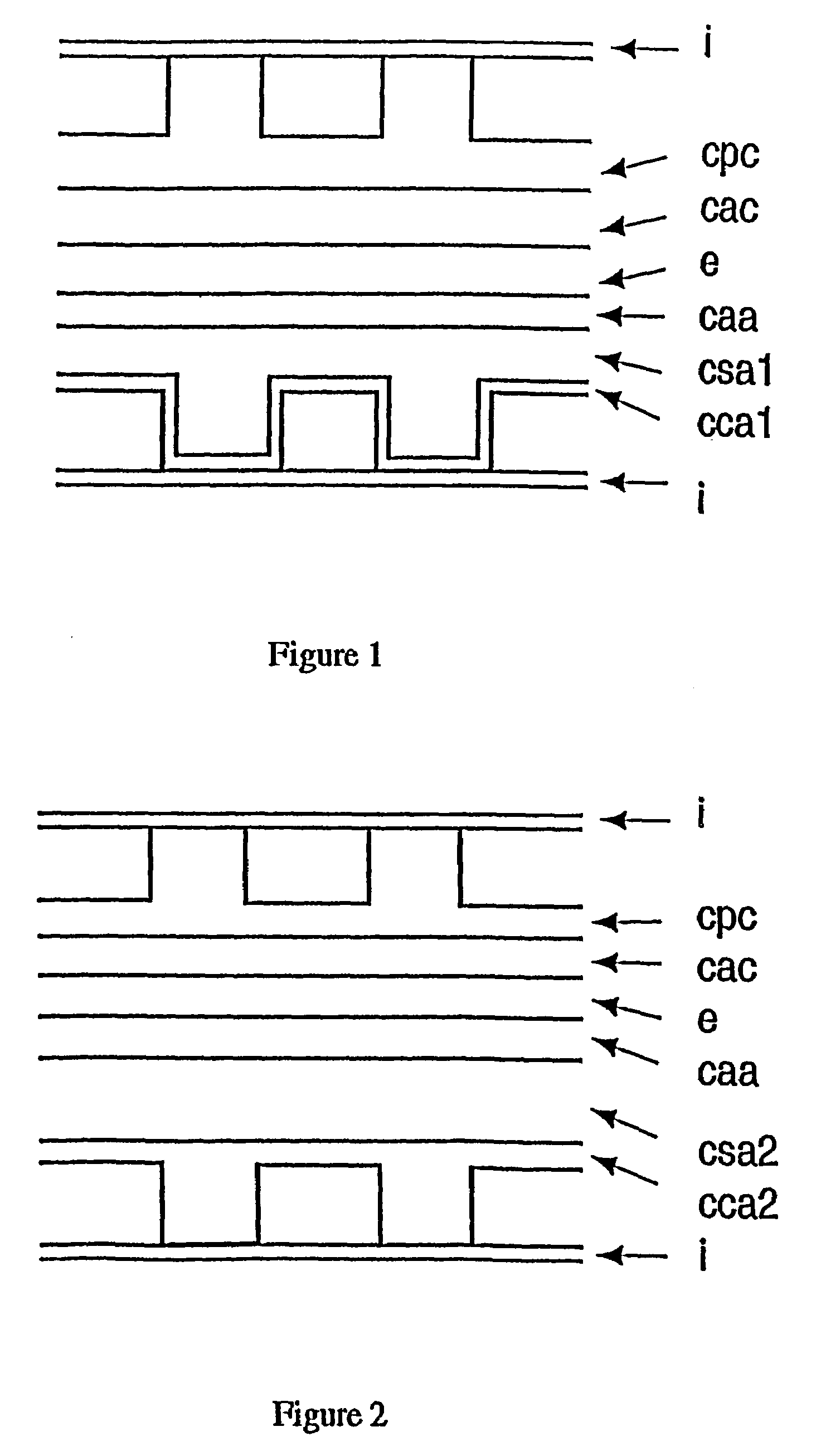

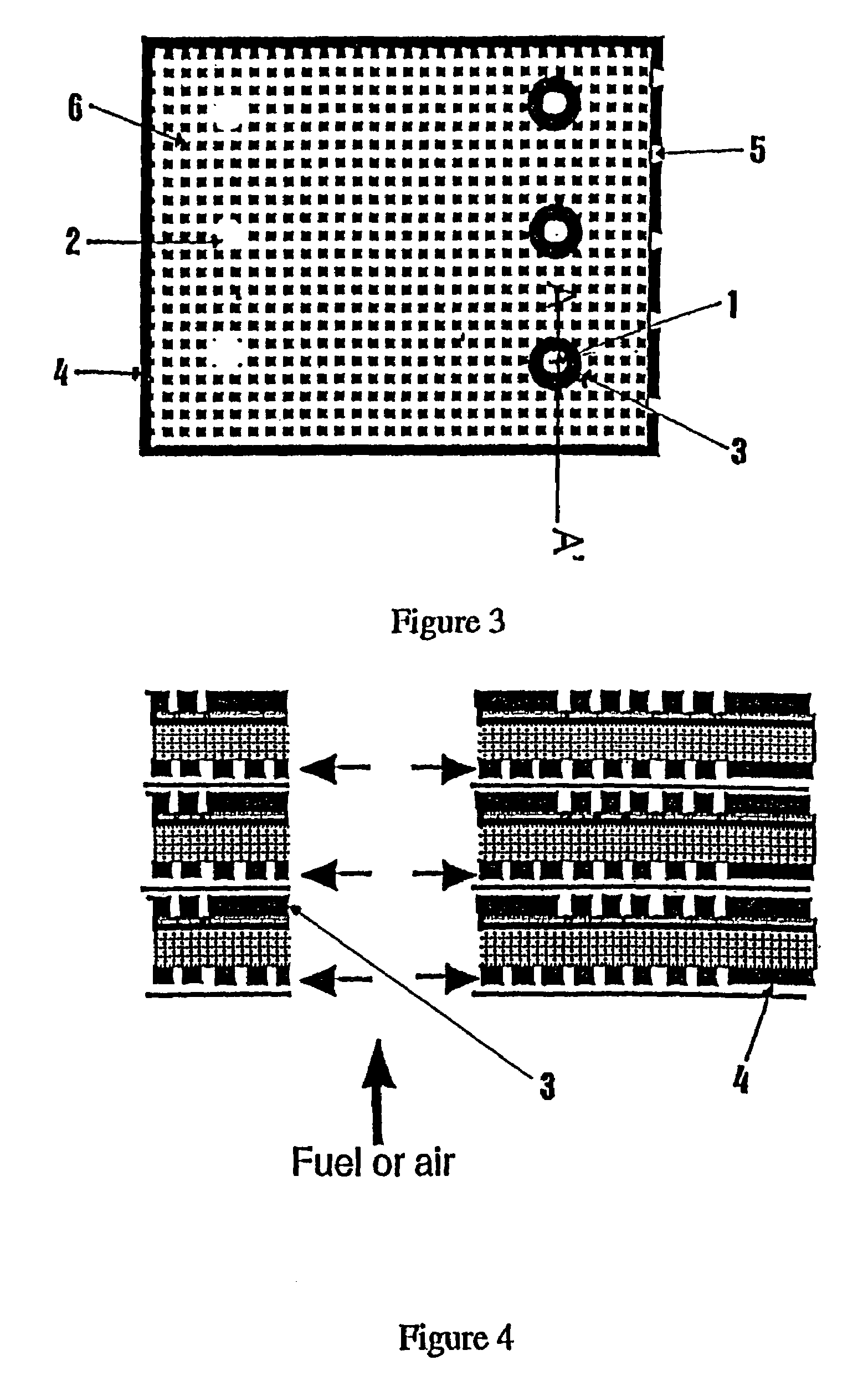

ActiveUS7632586B2Improve toleranceLower ohmic resistanceFuel cells groupingFuel cell auxillariesFuel cellsForming gas

Disclosed is a solid oxide fuel cell (SOFC) positive electrolyte negative (PEN) comprising electrodes on the rear side thereof used for establishing contact between a flat interconnecting plate and a raised structure which is configured in such a way that it forms gas circulation channels with said plate. The PEN and interconnecting plates can have holes so as to create internal gas inlet and outlet tubes. The electrolyte / electrode interface can also be configured as a raised structure increasing the ratio of the extended area to the projected area.

Owner:HTCERAMIX

Torsion spring for electro-mechanical switches and a cantilever-type RF micro-electromechanical switch incorporating the torsion spring

InactiveUS6842097B2Increased durabilityGood electrical contactContact surface shape/structureElectrostatic/electro-adhesion relaysConformal connectionEngineering

A torsion spring for an electro-mechanical switch is presented. The torsion spring comprises a set of tines including at least one tine extending from the free end of the armature of a switch. A terminus portion is rotatably suspended between the tines, and includes a conducting transmission line, at least a portion of which is exposed for electrical contact. The conducting transmission line has a length selected such that the exposed portion of the transmission line forms a circuit between the input and output of the micro-electro-mechanical switch when the micro-electro-mechanical switch is urged into a closed position, with the terminus portion rotating via the tines to form a conformal connection between the exposed portion of the conducting transmission line and the input and output of the switch, thus optimizing the electrical flow therebetween. The switch is also applied to MEMS devices.

Owner:HRL LAB

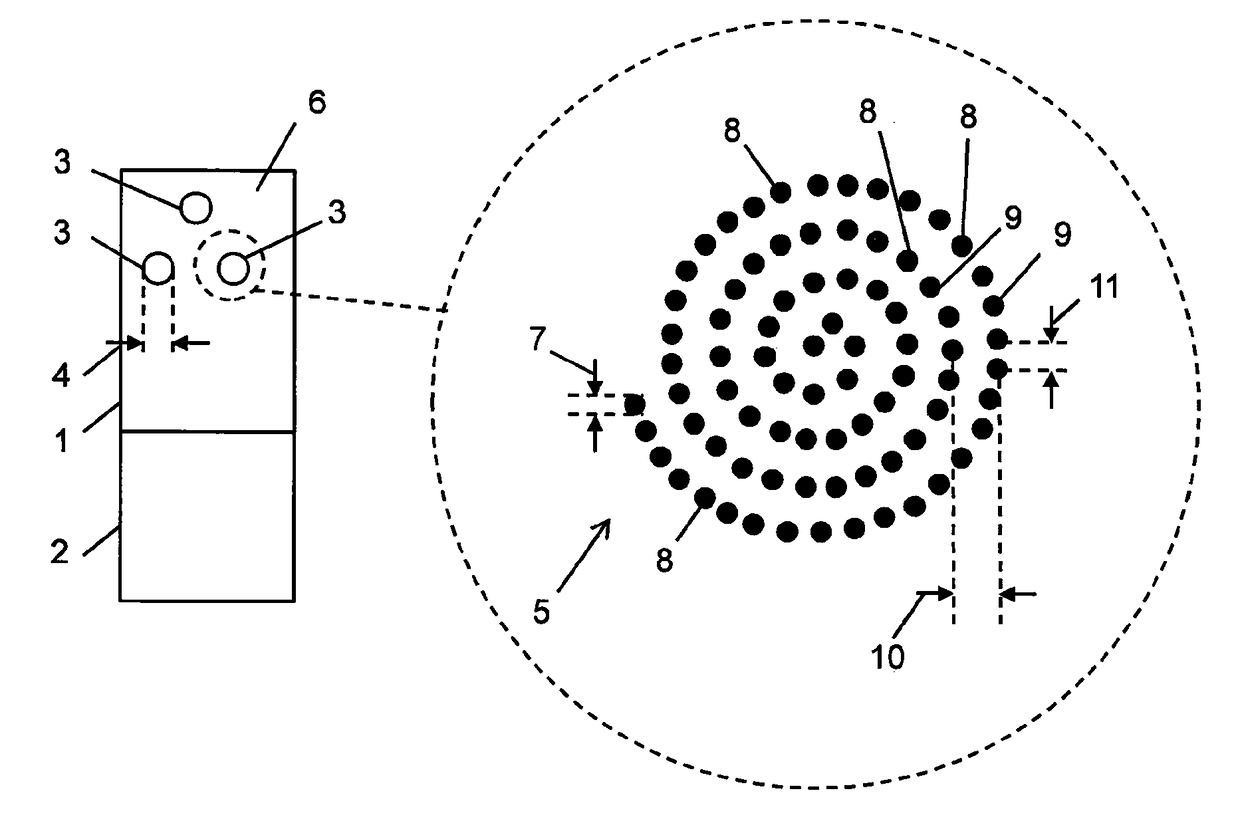

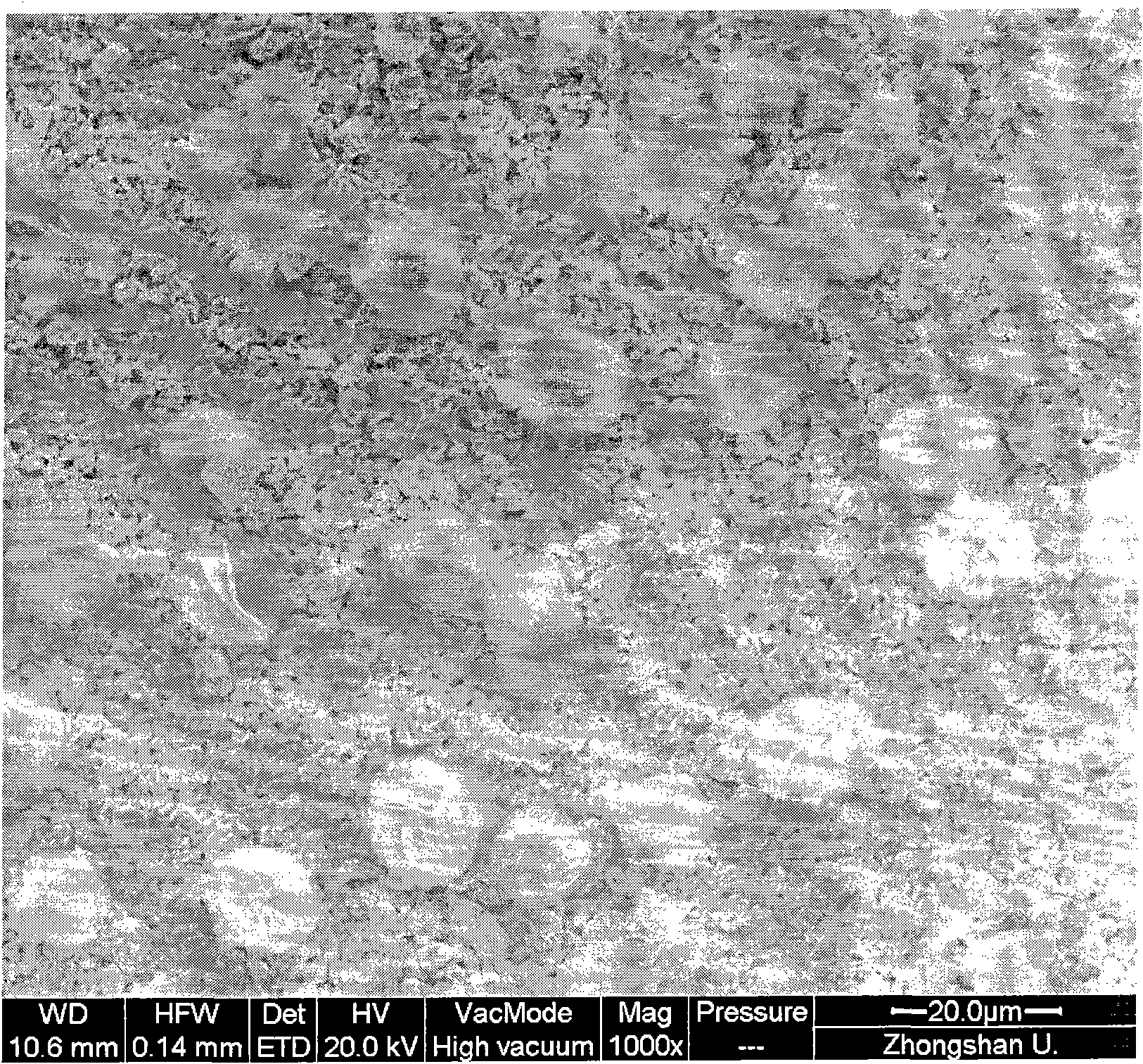

A Weld

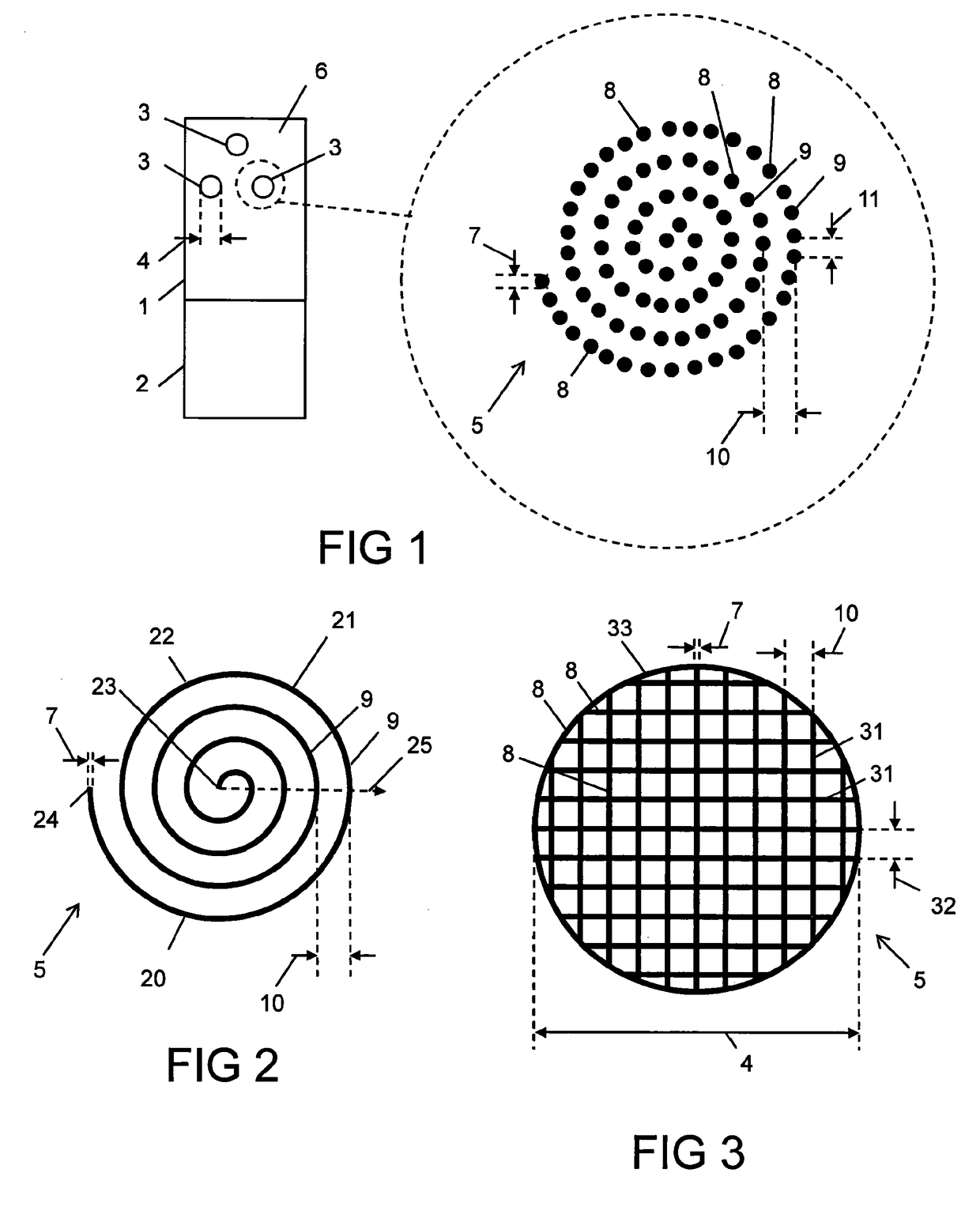

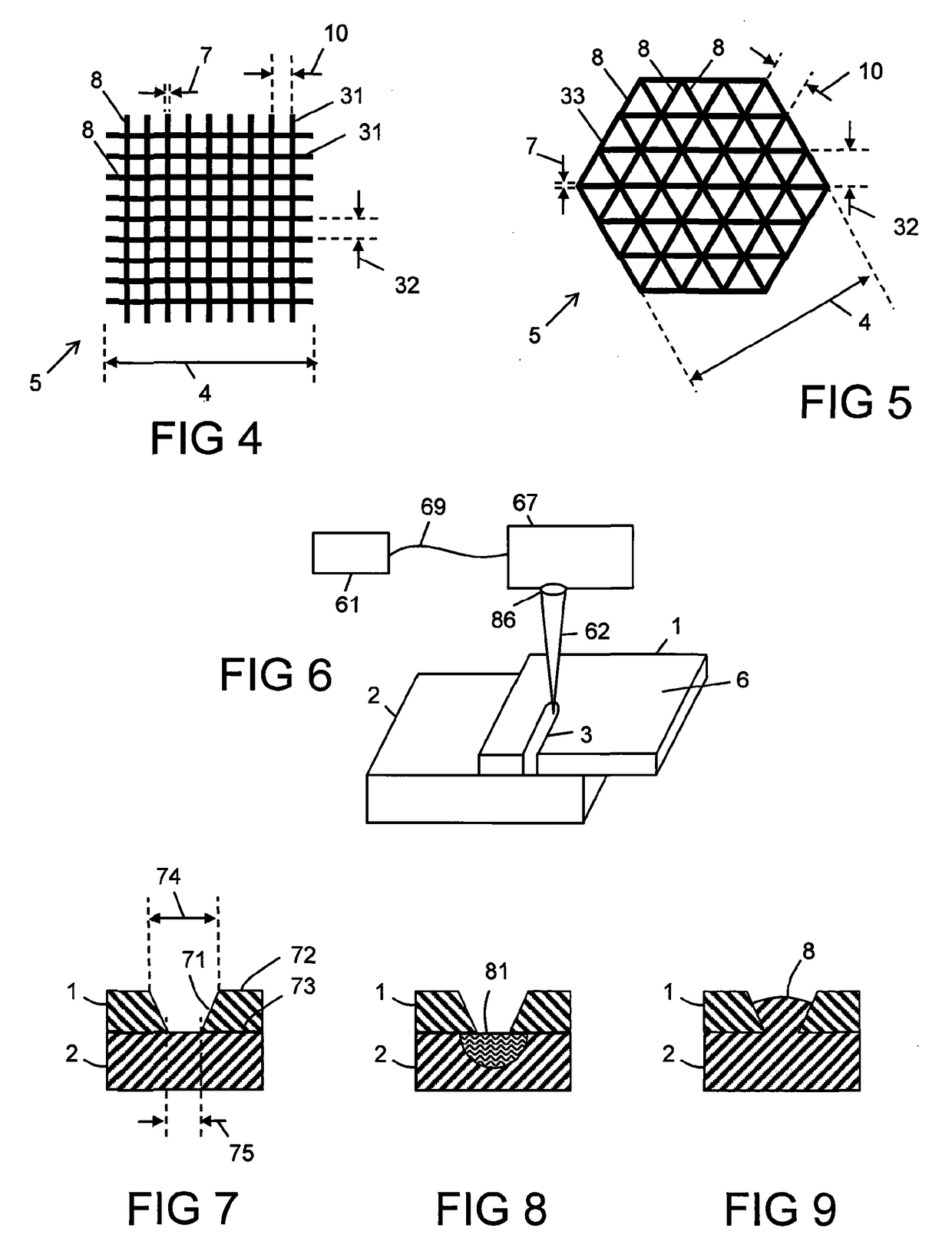

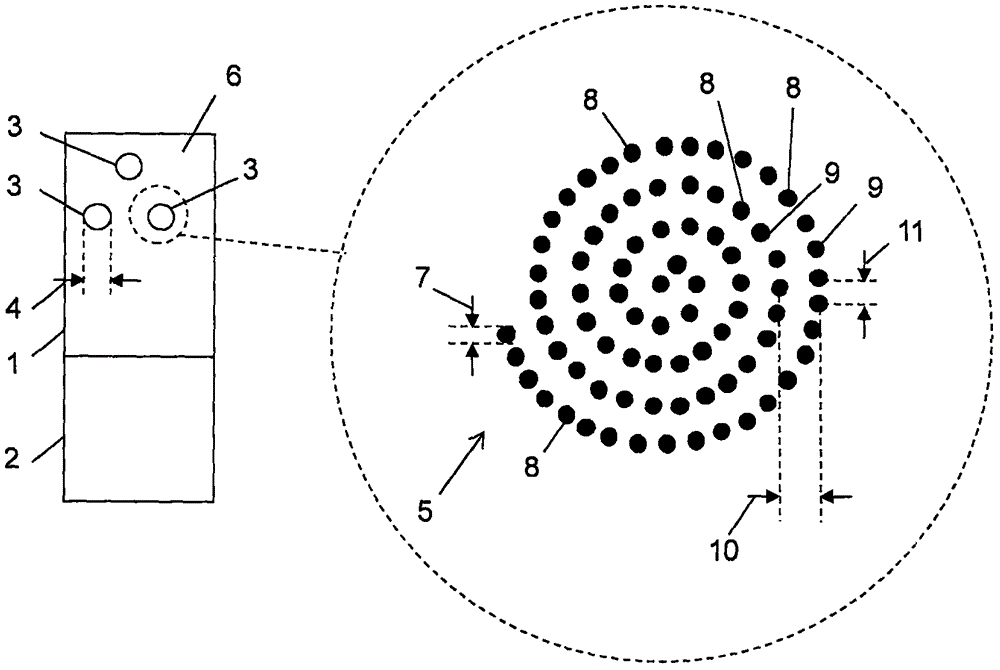

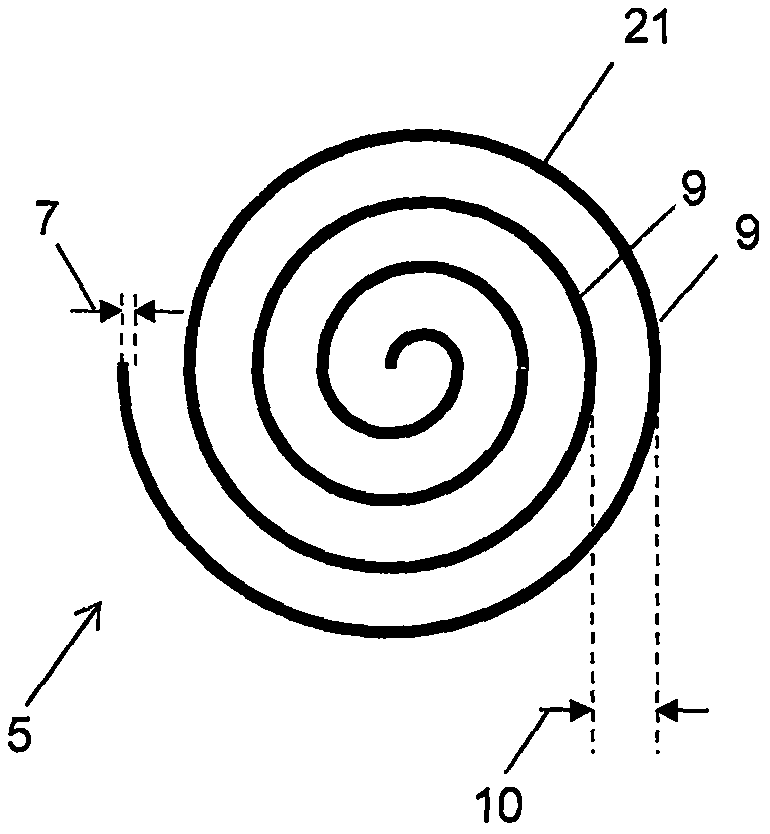

PendingUS20180045232A1Improve surface smoothnessHigh densitySheet joiningLaser beam welding apparatusMetallic materialsMetal

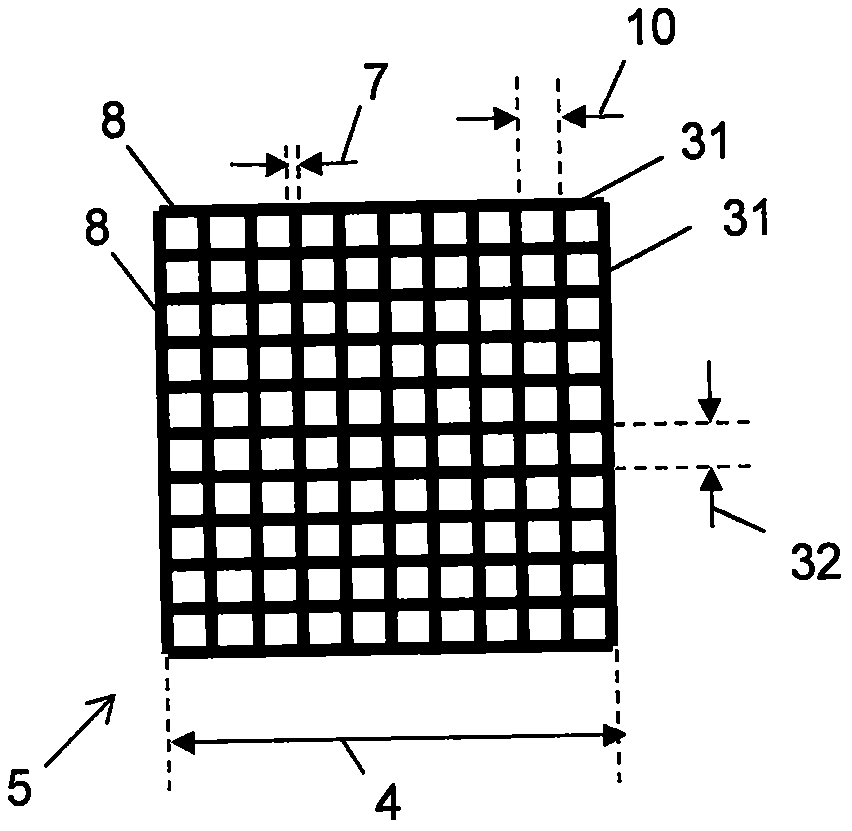

A weld (3) between a first material (1) and a second material (2), the first material (1) being a first metallic material, and the second material (2) being a second metallic material, the weld (3) has a width (4) between 0.5 mm and 7 mm, the weld (3) comprises at least one microweld (8), the microweld (8) forms a welding pattern (5) defined parallel to a surface (6) of the first material (1), and the microweld (8) has a characteristic feature size (7) of between 20 μm and 400 um.

Owner:SPI LASERS UK

A weld

ActiveCN105855706AAvoid generatingImprove efficiencySheet joiningWorkpiece edge portionsMetallic materialsLaser beam welding

Provided is a weld (3) between a first material (1) and a second material (2), the first material (1) being a first metallic material, and the second material (2) being a second metallic material, the weld (3) has a width (4) between 0.5mm and 7mm, the weld (3) comprises at least one microweld (8), the microweld (8) forms a welding pattern (5) defined parallel to a surface (6) of the first material (1), and the microweld (8) has a characteristic feature size (7) of between 20mum and 400mum.

Owner:SPI LASERS UK

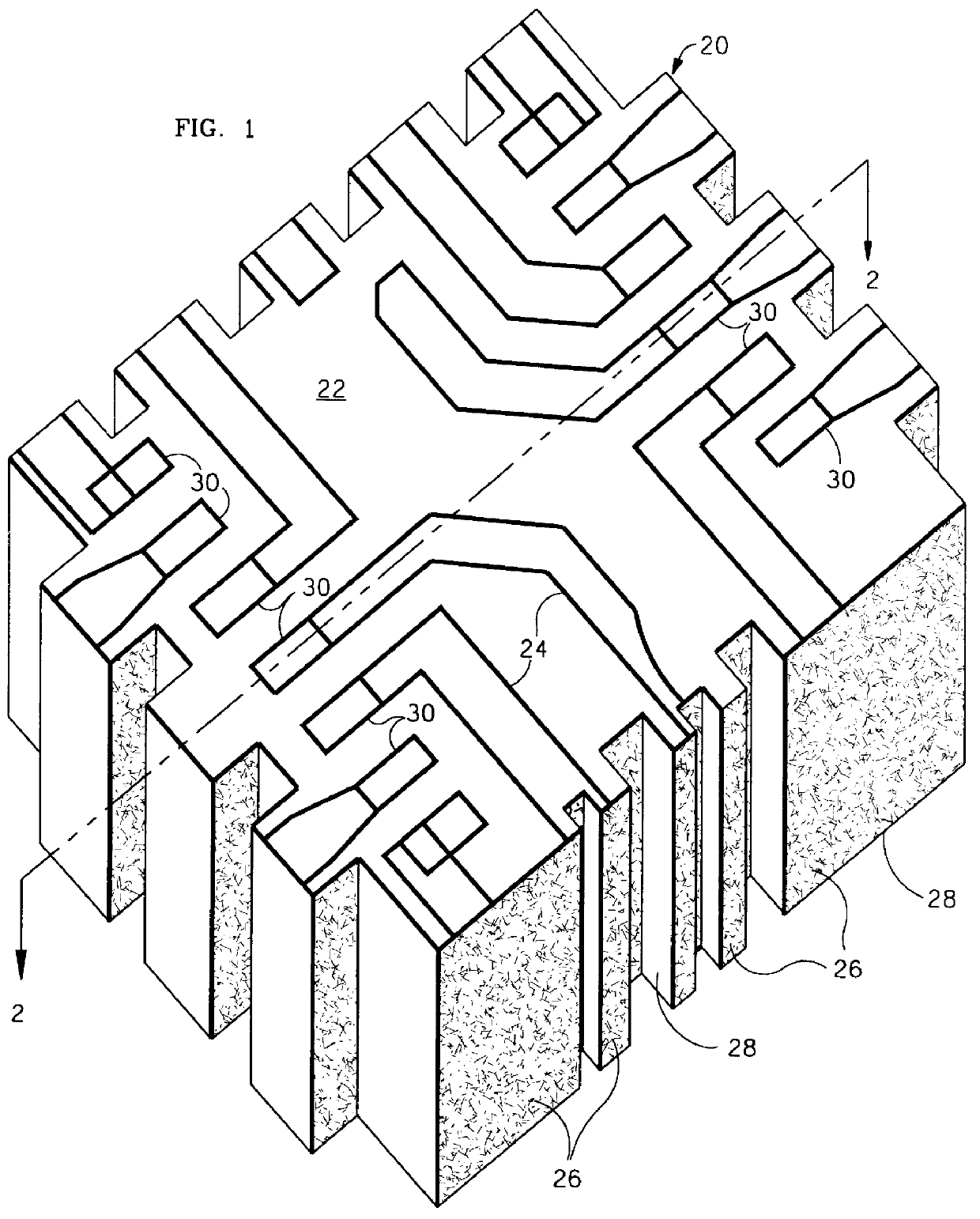

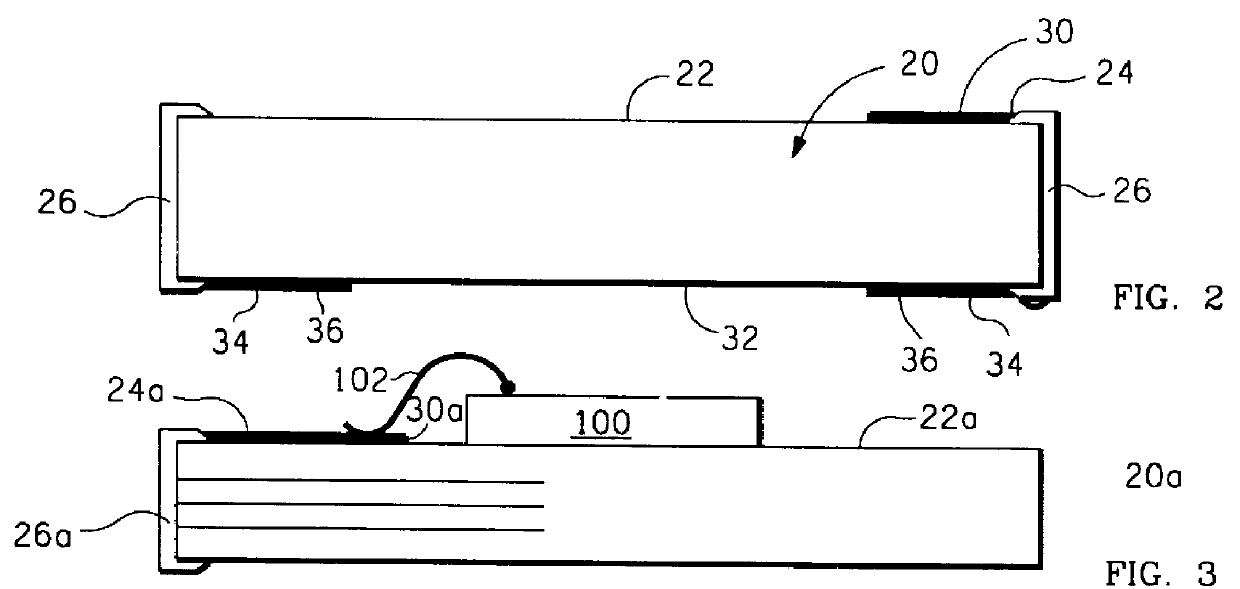

Monolithic integrated multiple electronic components internally interconnected and externally connected by conductive side castellations to the monolith that are of varying width particularly monolithic multiple capacitors

InactiveUS6011684AFirmly connectedSave spaceMultiple fixed capacitorsSemiconductor/solid-state device detailsAudio power amplifierCeramic capacitor

Variable width electrically conductive (i) traces and (ii) pads in the forms of castellations and connecting traces upon the surfaces of volume microminiature electronic components permit variable area electrical interconnection in three dimensions, particularly of monolithic, buried-substrate, multiple ceramic capacitors to integrated circuit receivers and amplifiers to make microminiature hearing aids insertable within the ear canal. A preferred embodiment monolithic multiple capacitor with side, top and bottom surfaces has a number of electrically conductive parallel layers disposed within its body with a conductive trace extending from each layer to be exposed upon a side surface. Metallized bus strips of at least two widths extend along the side surface; relatively thinner bus strips selectively interconnecting the exposed traces to form a plurality of capacitors while the relatively thicker bus strips selectively extend at least some traces to one or more edge(s) of the top and / or bottom surfaces of the body where they may be externally connected, normally to piggy-backed components, by reflow soldering. The different-width metallized bus strips are preferably made by rectangular saw-cut slots in the body at differently spaced intervals, the rectangular saw-cuts forming castellations having a greater depth than width to reduce parasitic capacitance.

Owner:DEVOE ALAN D +1

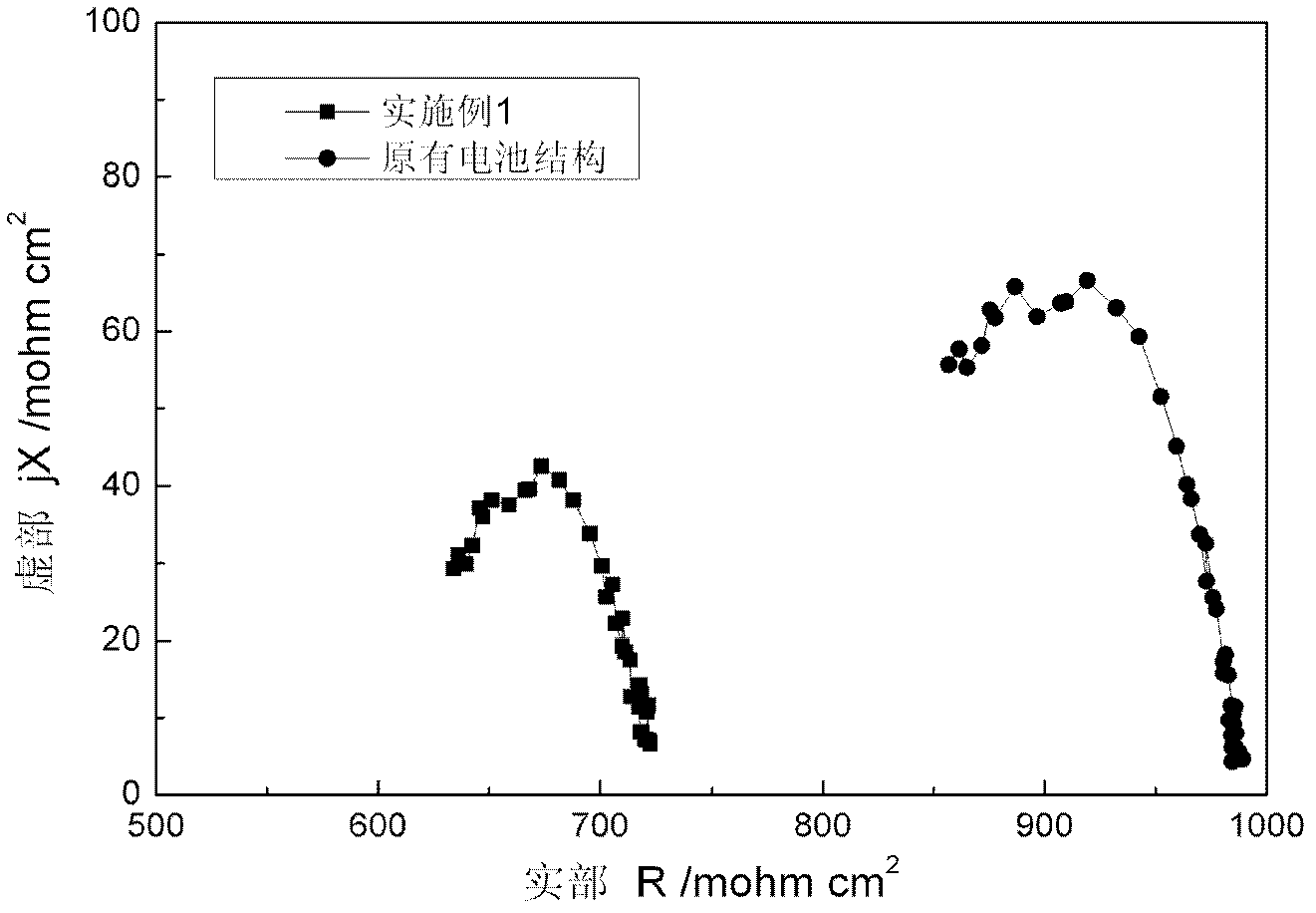

Flow energy storage battery structure

InactiveCN102867978AEasy to buildReduce contact resistanceRegenerative fuel cellsFuel cell detailsPorosityElectrical battery

The invention relates to a flow energy storage battery structure, characterized in that an infill panel is arranged between a bipolar plate and a porous electrode in an electrode frame, the infill panel is made from carbon materials with good electrical conductivity and low porosity or metal materials which are stable in acidic mediums, reduces the body resistances of the electrodes and electrolyte and contact resistance between the electrode bipolar plates to finally reduce the ohmic resistance of the flow energy storage battery. According to the invention, the energy efficiency and voltage efficiency of the flow energy storage battery are raised, so that the working current density is raised, and the weight, volume and cost of the battery with same output power are greatly reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

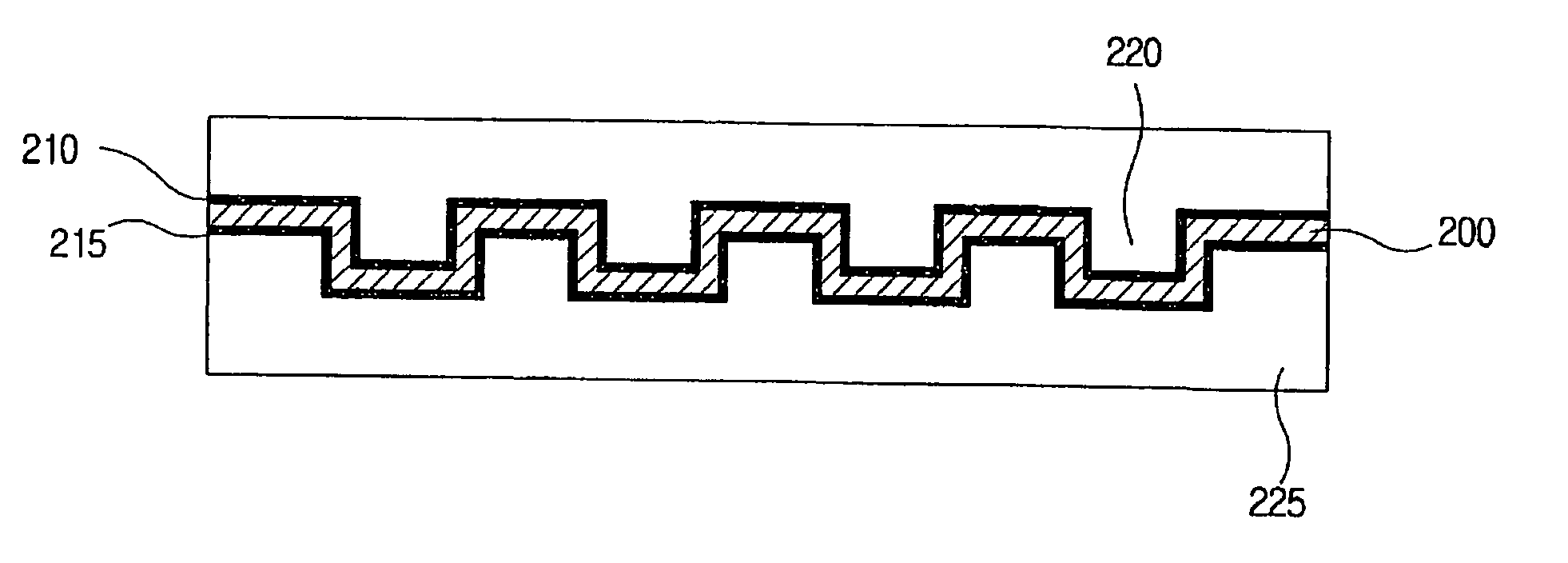

Method for producing membrane electrode assembly

InactiveUS20050238800A1Increase the reactive surface areaGood reproducibilityPrimary cellsElectrode carriers/collectorsStructural reliabilityVolumetric Mass Density

The present invention relates to a Membrane Electrode Assembly (MEA) which significantly enhances power density as well as structural reliability and method for producing the same. More specifically, it relates to the Membrane Electrode Assembly which has a plurality of protuberances and method for producing the same. The present invention involves making supporting bodies to have a plurality of protuberances on one side of the supporting bodies, forming a catalyst layer on one side of the supporting bodies having the protuberances, interposing a polymer-electrolyte-membrane between the supporting bodies, aligning the supporting bodies for the protuberances to engage each other; and hot-pressing the aligned supporting bodies. The present invention can increase the area of a three-phase boundary in which oxidation-reduction reaction of hydrogen and oxygen occurs and decrease resistance to ion conduction; consequently fuel cells have the characteristic of a large output of power density.

Owner:FUELCELLPOWER

Method for producing crack-free polycrystalline silicon rods

ActiveUS20110229717A1Lower ohmic resistanceAvoid crackingPolycrystalline material growthLayered productsGas phaseMetallurgy

The invention relates to a method for producing polycrystalline silicon rods by deposition from the gas phase on a thin rod, wherein one or a plurality of disks consisting of a material having a lower electrical resistivity than the polycrystalline silicon under deposition conditions are introduced above the electrodes and / or below the bridge of the rod pair.

Owner:WACKER CHEM GMBH

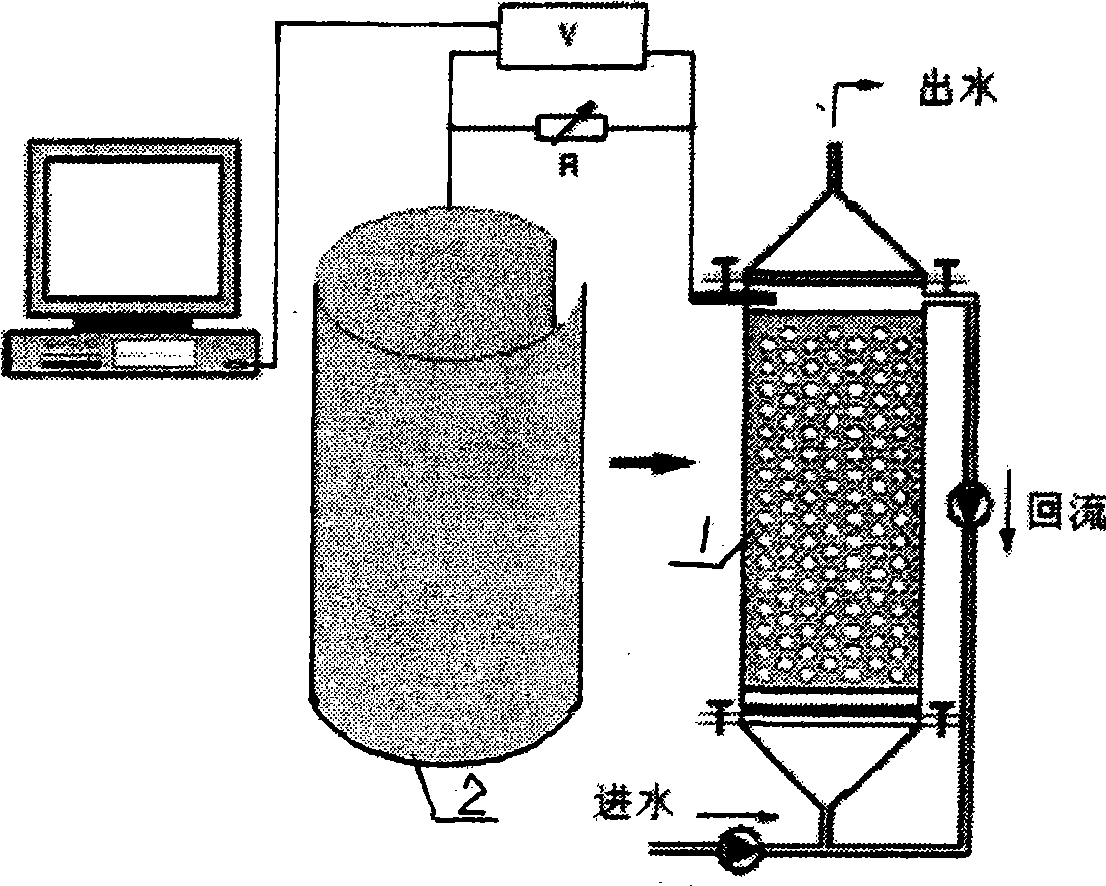

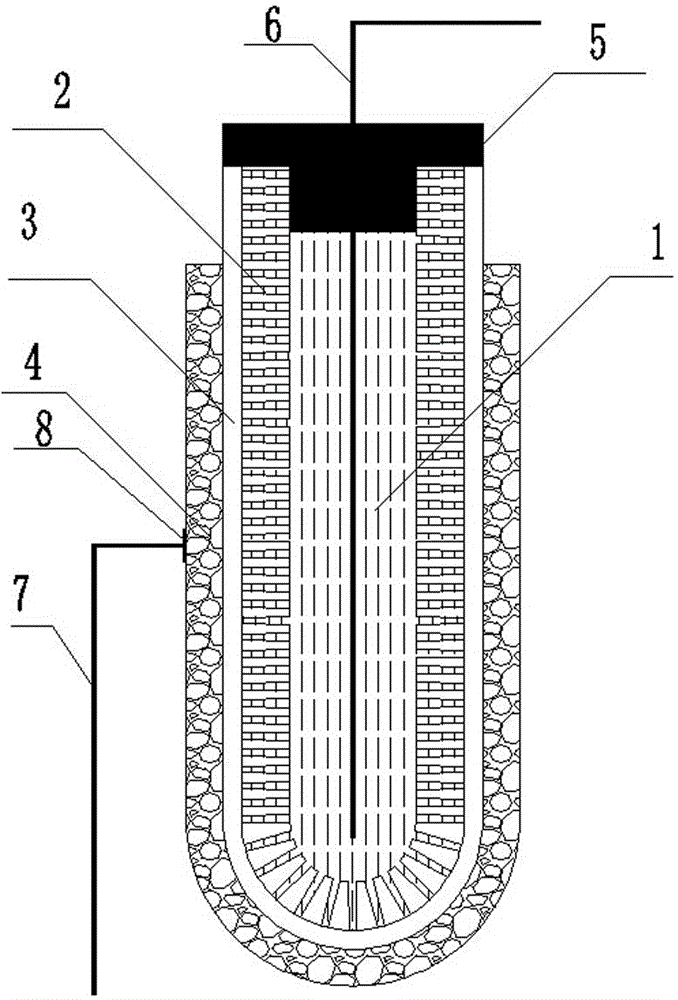

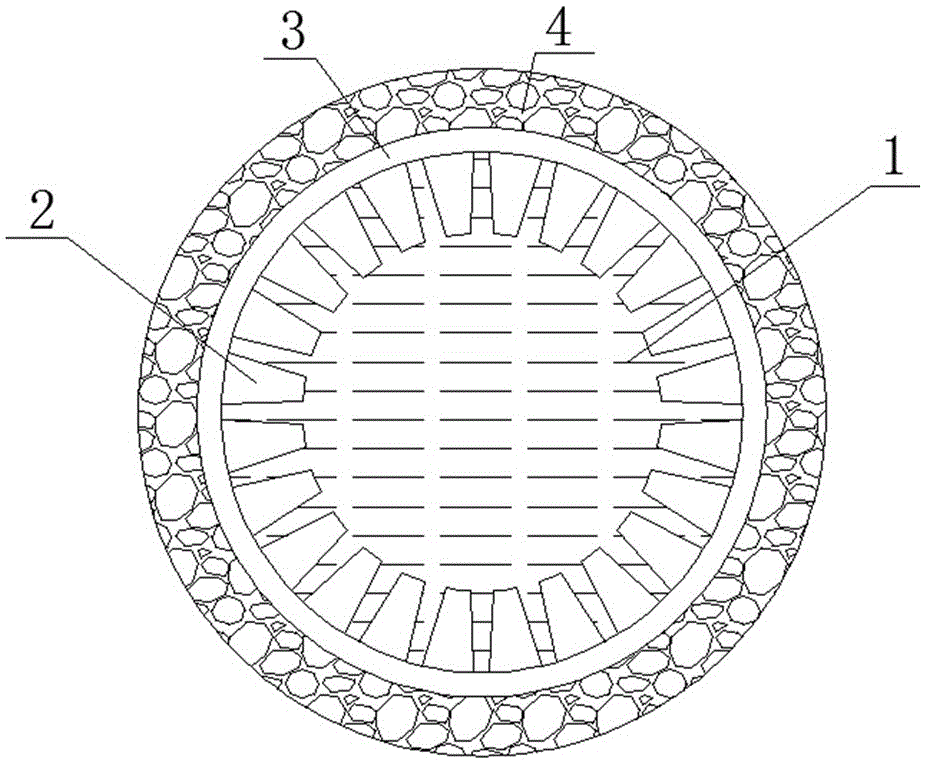

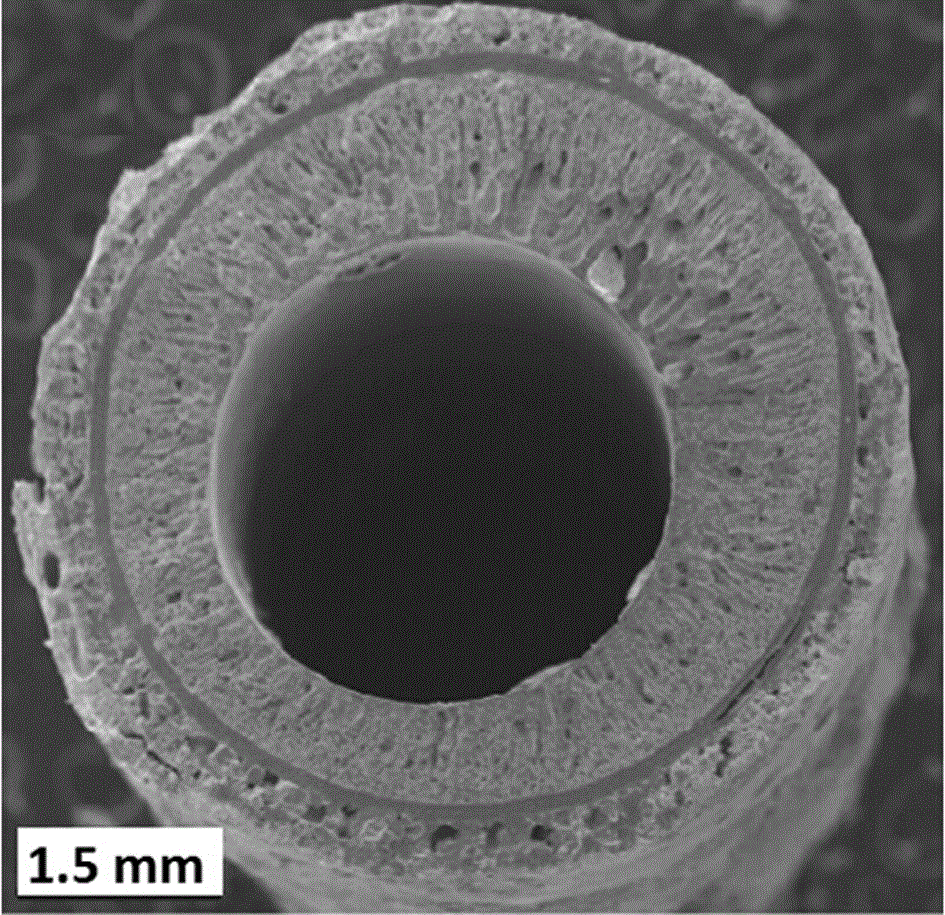

Pipe type lifting-flow air cathode microbiological fuel cell

InactiveCN101431161ALower ohmic resistanceReduced activityBiochemical fuel cellsWhole bodyCopper wire

The invention provides a tubular up-flow air cathode microbial fuel cell. The tubular up-flow air cathode microbial fuel cell is composed of a cylindrical organic glass tube, a feed inlet is arranged at the bottom part of the cell, a water outlet is arranged at the top part, holes for facilitating the transfer of protons and ions between a cathode and an anode are evenly drilled on the tube wall, an anode region which is filled with granular activated carbon that is taken as the cell anode is arranged in the tube, the volume of solution in the anode region is 55mL, a carbon rod which leads out electrons is inserted in the anode, the cathode is constituted by tightly coating carbon fabric at the outside of the anode region, a layer of C / Pt powder is coated at the inner surface of the cathode, wherein, the anode is connected with the cathode by a copper wire. The tubular up-flow air cathode microbial fuel cell not only has the advantages of the microbial fuel cell configuration, but also combines the up-flow activated carbon anode and the film-free air cathode into a whole body, thereby leading the distance between the two electrodes to be as small as possible; meanwhile, the anode adopts the ordinary granular carbon and omits film material.

Owner:HARBIN INST OF TECH

Zinc negative electrode material of zinc air cell and preparation method for zinc negative electrode material

InactiveCN106532058AAvoid destructionLower internal resistanceFuel and secondary cellsCell electrodesInternal resistanceZinc–air battery

The invention discloses a zinc negative electrode material of a zinc air cell and a preparation method for the zinc negative electrode material. The negative electrode material comprises metal zinc powder, zinc oxide powder, a binder, and a dual-functional additive with a one-dimensional tubular structure and formed by dual-layer metal oxide; the preparation method comprises the steps of adding the metal zinc powder, the zinc oxide powder, a conductive agent and the dual-functional additive into a binder-containing solution, performing ultrasonic dispersion processing, and heating and evaporating a solvent while stirring to obtain the zinc negative electrode material. The zinc negative electrode material is added with the dual-functional additive which can lower electrode internal resistance as well as supply a diffusion channel for an electrolyte, so that the discharging capacity and the rate capability of the cell can be improved; and meanwhile, a titanium dioxide inner layer has super-hydrophilic property and insulativity, so that the water delivery property of the electrolyte diffusion channel is forcefully enlarged, channel blocking is prevented, and the cycling life and the capacity stability of the cell are effectively prolonged and improved.

Owner:CENT SOUTH UNIV

Production of electrode for fuel cell or electrolyzed membrane

InactiveCN101075672ALower ohmic resistanceReduced polarization lossCell electrodesFinal product manufacturePolymer electrolytesElectrolysis

This is a membrance electrode process method for fuel cell or eletrolysis. The membrance electrode includes a structure of three-layer or five-layer. The three-layer structure is composed by cathode catalytic layer-polymer electrolyte membrance-anode catalytic layer. The process method is as: loading cathode and anode catalytic ink to the two sides of the polymer electrolyte membrance and dry in AC field. The five-layer structure is composed by cathode diffusing layer-cathode catalytic layer-polymer electrolyte membrance-anode catalytic layer-anode diffusing layer. The process method is as: loading cathode and anode catalytic ink to cathode and anode diffusing layer separately and dry in AC field; heat compressing the cathode and anode to the polymer electrolyte membrance.

Owner:TIANJIN UNIV

All-solid-state lithium-air battery and preparation method and application thereof

ActiveCN105742761AAll solid state implementationImprove securityFuel and primary cellsPtru catalystElectrical battery

The invention discloses an all-solid-state lithium-air battery and a preparation method and application thereof. The all-solid-state lithium-air battery provided by the invention comprises a lithium metal anode, a porous ceramic support body, a compact electrolyte thin film, a porous cathode thin film, a sealing material, a current collector and a lead, wherein the porous support body is made of garnet type lithium-ion solid electrolyte material; in an air electrode catalyst and permeation holes of the lithium metal anode, a three-phase boundary for battery reaction is expanded, and the battery polarization resistance is reduced; the thickness of the battery electrolyte thin film is smaller than 30 micrometers, a lithium ion transmission path is shortened, and the battery ohmic resistance is reduced; and the battery is a tubular structure with a closed end, the lithium metal anode is poured into a tube, and the battery is easy to seal and is easy to work in different conditions. The all-solid-state lithium-air battery prepared according to the invention has the advantages of high charging-discharging capacity, high rate performance, high cycle stability, wide working temperature range and the like, and is applicable to the field of various mobile electronic devices and power batteries.

Owner:SUZHOU UNIV

Micro-nano structure bismuth pole for trace heavy metal detection and preparation method thereof

InactiveCN101603938AImprove featuresImprove mass transfer effectMaterial electrochemical variablesMicro nanoEffective surface area

The invention discloses a micro-nano structure bismuth pole for trace heavy metal detection, which is a bismuth array of which the surface is allotted with a micro-nano dimension structure. The micro-nano structure bismuth array comprises a bismuth nano line or a bismuth nano piece, covers the surface of a pole by 20 percent to 70 percent, and effectively improves the effective surface area of the pole. The pole has simple preparation method and high detection sensitivity when being used for trace heavy metal detection and realizes the several-fold increase of the detection sensitivity of the pole.

Owner:SUN YAT SEN UNIV

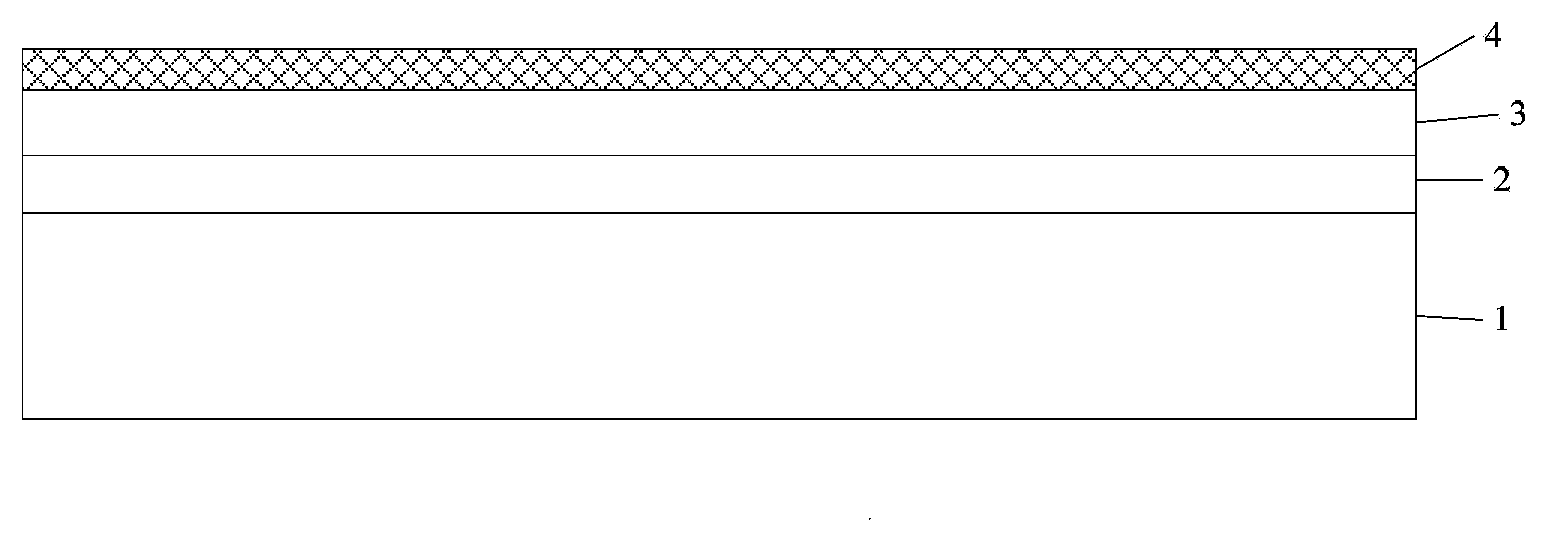

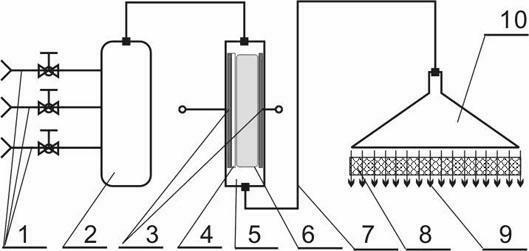

Solid oxide fuel cell composite electrolyte film and preparation thereof

ActiveCN103887549AReduce thicknessLower ohmic resistanceSolid electrolyte fuel cellsFuel cell detailsFuel cellsChemical reaction

The invention discloses a solid oxide fuel cell composite electrolyte film containing a zirconia based electrolyte film and a ceria based electrolyte film, wherein the zirconia based electrolyte film is deposited on an anode substrate, and can effectively isolate the electronic conductivity, the ceria based electrolyte film is deposited on the zirconia based electrolyte film, can effectively isolate chemical reaction of a cathode and the zirconia based electrolyte film and element diffusion, and can improve the contact properties of a cathode / electrolyte interface; the composite electrolyte films are prepared by a magnetron sputtering method, reaction of zirconia and ceria based electrolytes can be avoided, and by use of the composite electrolyte film, diffusion of gases at both sides of the electrolytes can be effectively isolated, the ohmic resistance is reduced, and the cell performance is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

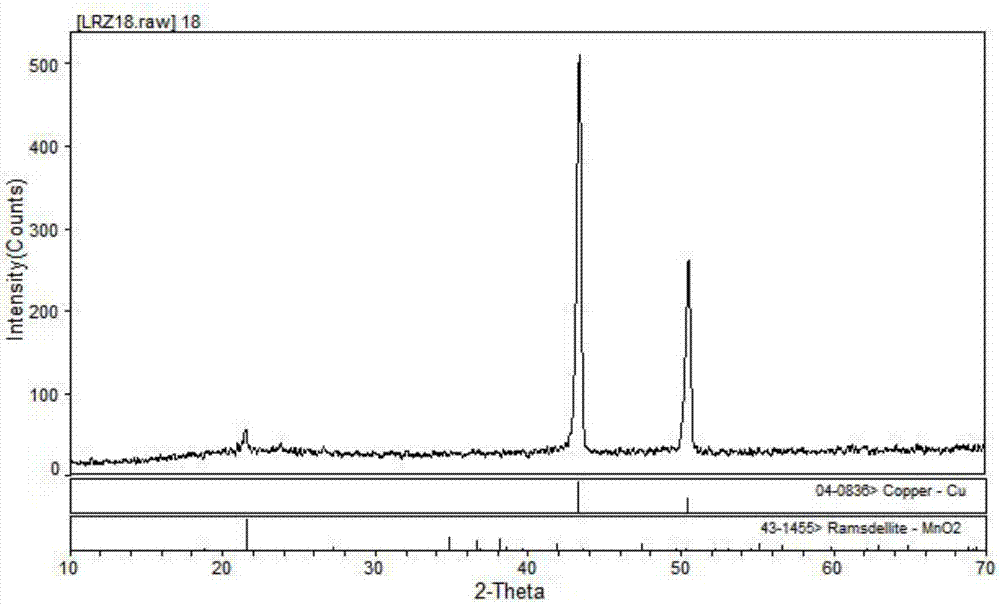

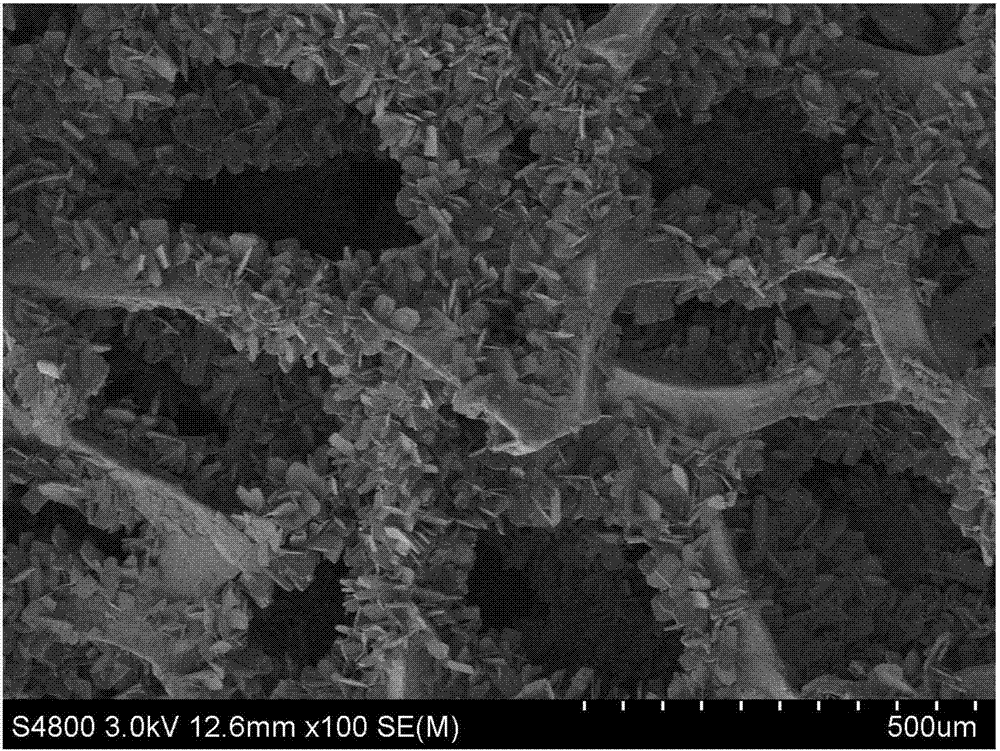

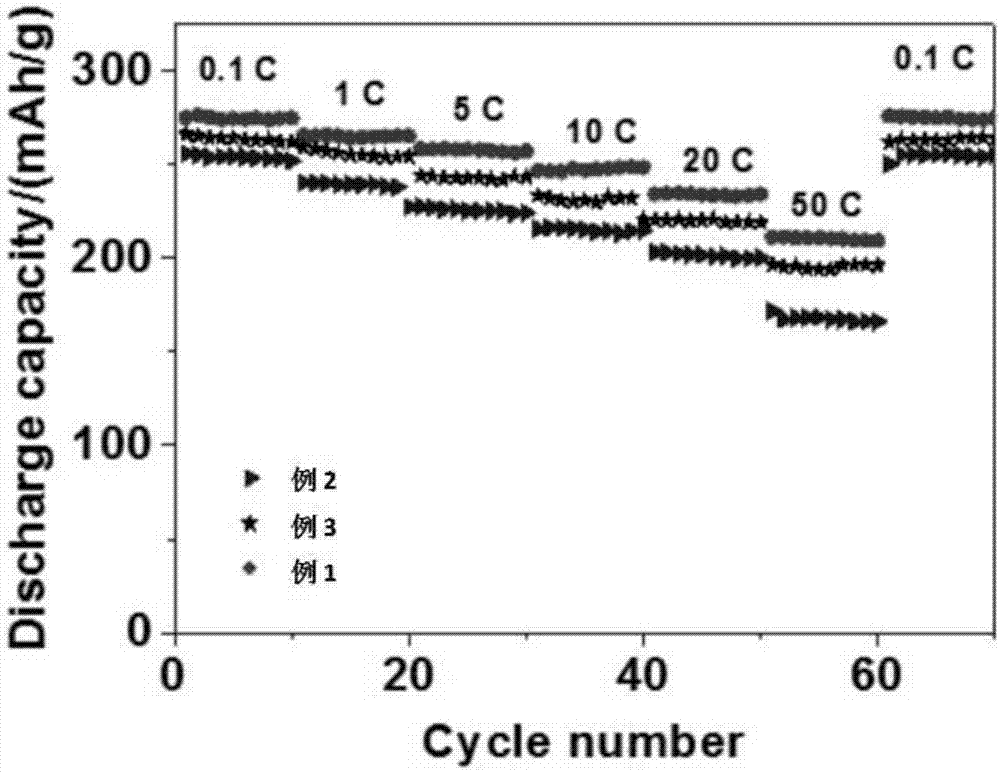

Manganese dioxide/copper foam sodium ion battery self-supporting negative pole preparation method

ActiveCN107093703ACapacity does not affectExcellent rate performanceElectrode carriers/collectorsSecondary cellsAlcoholSulfate

The invention discloses a manganese dioxide / copper foam sodium ion battery self-supporting negative pole preparation method. The method comprises the steps that flake copper foam is treated with absolute ethyl alcohol, washed to be clean and dried, and an electrode substrate is obtained; a manganese sulfate solution of a certain concentration is prepared; the obtained solution and a copper foam sheet are put into a hydrothermal reaction kettle, heating and heat preservation are conducted for a certain time through hydrothermal induction heating equipment, and then the manganese dioxide / copper foam sodium ion battery self-supporting negative pole with a three-dimensional porous communicating frame-shaped structure is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

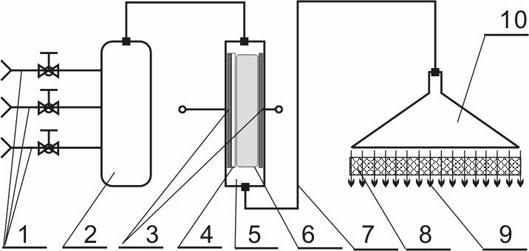

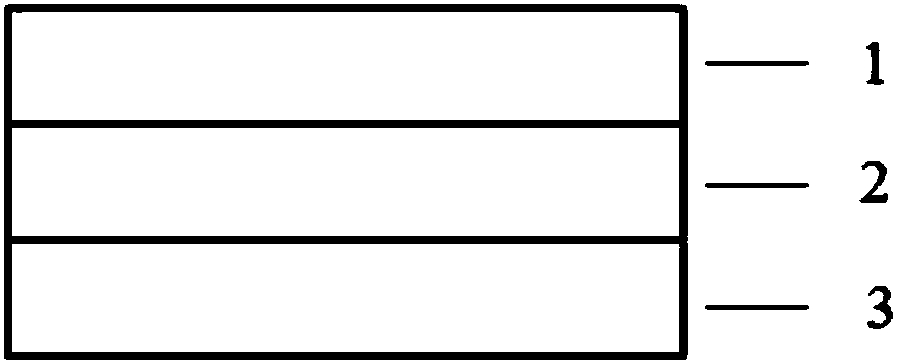

Method for modifying carbon porous material

ActiveCN102522569ANo pollution hazardEnsure consistencyCell electrodesActivated carbonElectrical battery

The invention provides a method for modifying a carbon porous material, characterized in that by applying a high pressure pulse voltage on two opposite plate electrodes and inserting an electrolyte plate which has a high dielectric constant and a compact structure and has an area that is slightly larger than the size of the plate electrodes between the two opposite plate electrodes, a uniform discharge plasma reaction zone is formed between the plate electrodes; mixed gasses containing oxygen are uniformly mixed at normal temperatures and pressures, the mixed gasses are subject to ionization activation by the plasma reaction zone to generate a plurality of oxygen-containing plasma gasses, after gas distribution is carried out, the gasses vertically flow through a pre-cleaned carbon porous material in the thickness direction to react to obtain the activated carbon porous material. The method has the advantages of environmental protection, low cost, mild treatment conditions, easy control of function group quantity, and outstanding improvement of the activity of the electrode material, and the method can realize gradient treatment, can reduce the area resistance of the contacting surface of the porous material and the bipolar plate, so as to increase the battery efficiency. The method uses devices, thus the method is easy for industrialized operation.

Owner:DONGFANG TURBINE CO LTD

Maintenance-free starting lead-acid storage battery with long service life and high specific energy, and production method thereof

PendingCN111599991AImprove conductivityExtend your lifeFinal product manufactureLead-acid accumulator electrodesElectrical batteryInternal resistance

The invention relates to a long-service-life high-specific-energy maintenance-free starting lead-acid storage battery and a production method thereof. According to the battery, lead plasters coated atthe upper portion and the lower portion of a grid of at least one of a positive electrode plate and a negative electrode plate are different, and the conductivity or the utilization rate of the leadplaster at the lower portion of the grid is superior to that of the lead plaster at the upper portion of the grid. According to the invention, the upper portion and the lower portion of an electrode plate adopt different formulas and are respectively coated and filled, wherein the acid content of the lead plaster at the lower portion is different so as to reduce that the apparent density of the lead plaster or the conductive substance content of the lead plaster at the lower portion is different so as to improve the utilization rate, so that the problem of low utilization rate of the active substance at the lower portion is effectively improved, and the capacity of the battery is improved; the internal resistance of the lower portion is reduced, and the utilization rate is improved, so that the problem of high proportion of upper discharge capacity is slowed down, wherein the upper discharge capacity of the electrode plate is reduced and the discharge rate is reduced under the condition of the same discharge capacity, so that the softening and falling of the active substance are reduced, and the service life of the battery is prolonged; and under the condition of the same paste coating amount, the capacity, the low-temperature discharge performance and the cycle durability of the prepared battery are improved.

Owner:CAMEL GRP HUAZHONG BATTERY

A battery current collector and method for preparing same

InactiveCN1670992AControl mechanical propertiesControl conductivityElectrode carriers/collectorsElastomerVanadium redox battery

This invention refers to the electrode material of cell, especially refers to electrode collector of all vanadium oxidation reduction fluid flow cell and preparation thereof, which contains using hydrogenated styrene-butadiene-styrene block polymer and acrylic rubber-plastics cross blended elastomer as base material, doped with carbon conductive medium, moulding to obtain said invention, the volume resistivity of collector is less than 0.1 ohm-cm, hardness (Shore hardness) is 87-110, tensile strength is 3.5-5.0 MPa, elongation at break is 15-30 %. Said invention greatly raises conductivity and reduces ohmic resistance, the voltage efficiency reaches to 95 % under 25 degrees centigrade 30 mA / cm2.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Semiconductor thin-film electrolyte fuel cell and manufacturing method thereof

ActiveCN107768690ALower operating temperatureSimple ingredientsFinal product manufactureCell electrodesSemiconductor materialsElectrolyte

The invention provides a semiconductor thin-film electrolyte fuel cell and a manufacturing method thereof. The semiconductor thin-film electrolyte fuel cell structurally comprises a cathode layer, anelectrolyte layer and an anode layer, wherein the material of the cathode layer is an ABO3-type perovskite oxide material or a layered lithium-containing oxide material or a composite material of theABO3-type perovskite oxide material or the layered lithium-containing oxide material and 0-50wt.% of doped cerium oxide; the material of the electrolyte layer is a binary oxide semiconductor material;and the material of the anode layer is a layered lithium-containing oxide material or a nickel and cobalt oxide material or a composite material of the layered lithium-containing oxide material or the nickel and cobalt oxide material and the 0-50wt.% of doped cerium oxide. The manufacturing method comprises the following manufacturing steps of pressing an anode ceramic plate and then preparing athin-film electrolyte layer at one side of the anode ceramic plate; and pressing a cathode ceramic plate, then pressing the cathode ceramic plate and the anode ceramic plate together through lamination of the electrolyte layer and carrying out high-temperature sintering to obtain a product. An electrolyte thin film is relatively small, adjustable and controllable in thickness; the electrolyte material is simple in composition, low in preparation temperature and low in cost; and the battery has the characteristic of low operating temperature.

Owner:HUBEI UNIV

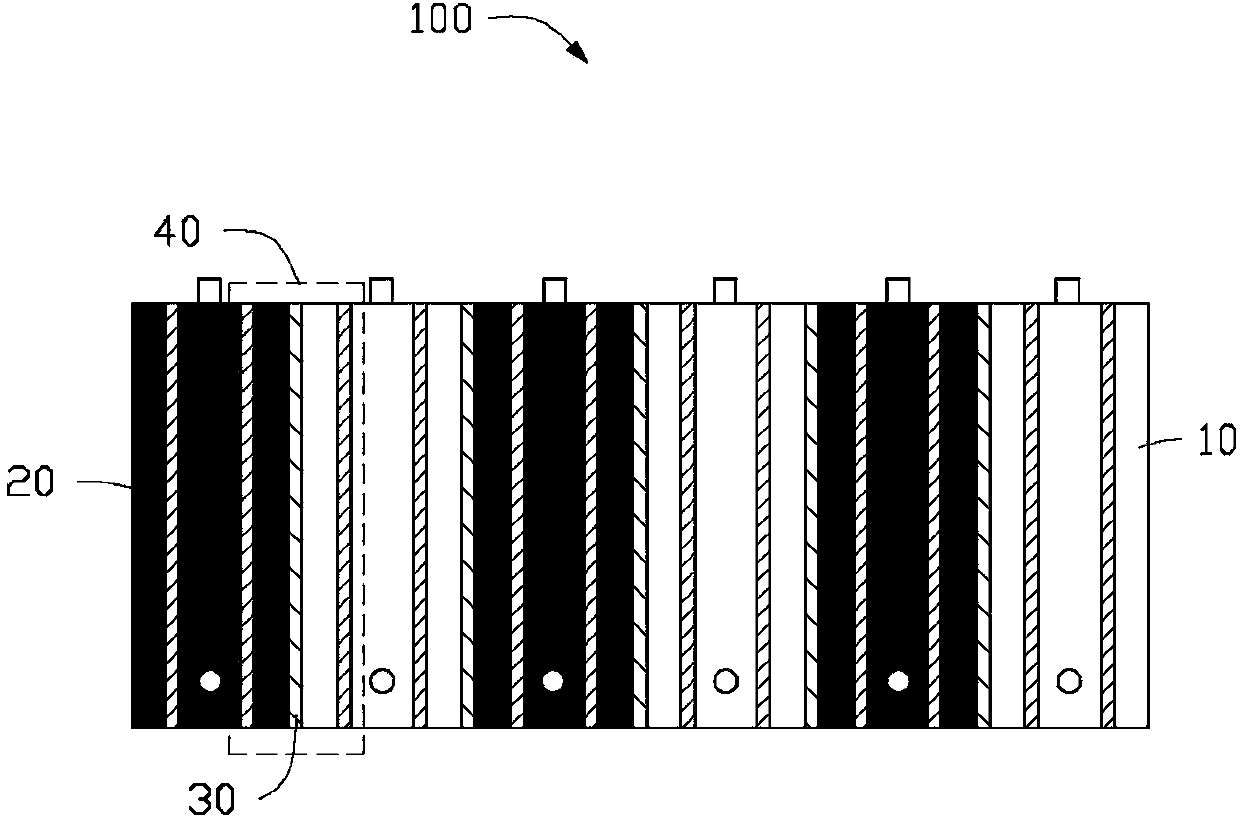

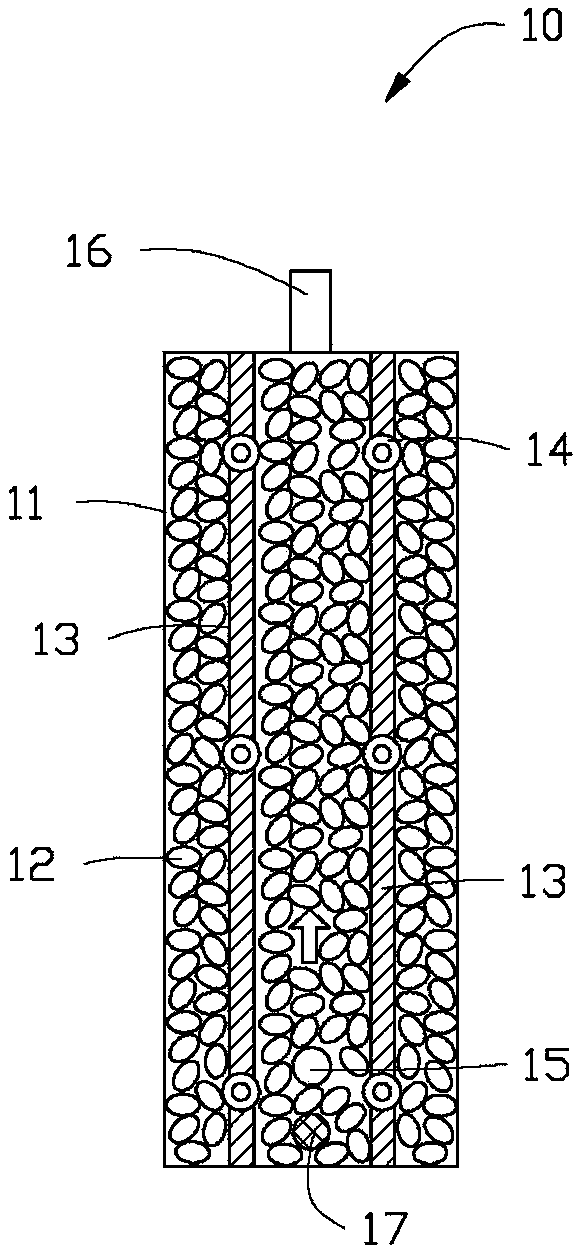

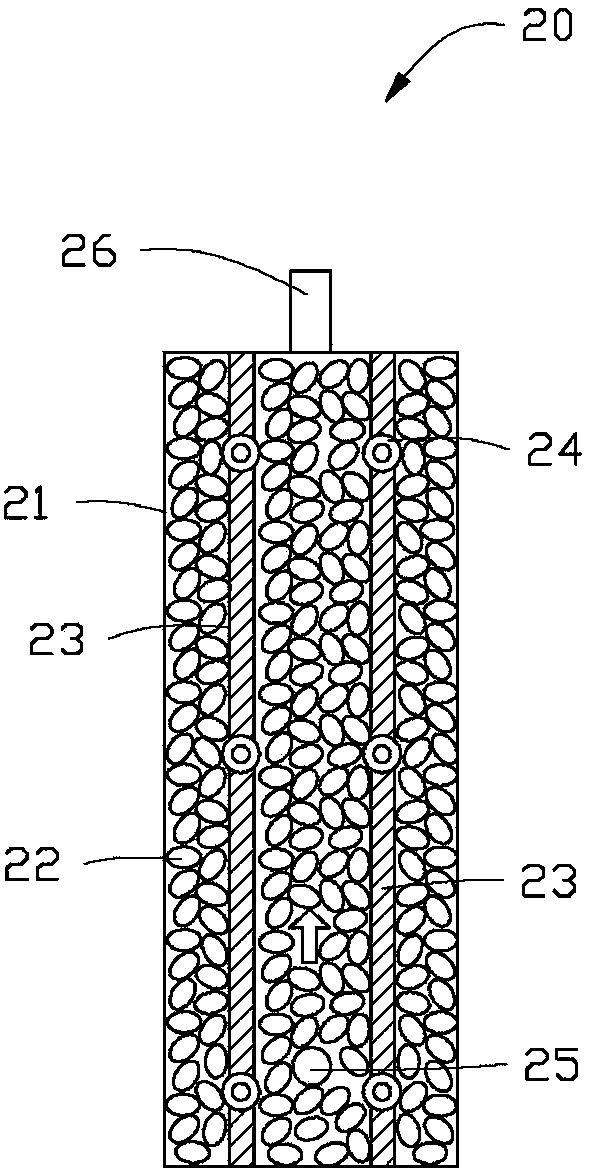

Biological cathode type microbial fuel cell

ActiveCN104167561AImprove power generation performanceImprove output power densityReactant parameters controlCell electrodesMicrobial fuel cellFuel cells

The invention provides a biological cathode type microbial fuel cell which comprises a plurality of cathode cavities, a plurality of anode cavities and a plurality of ion exchange membranes, wherein the plurality of cathode cavities and the plurality of anode cavities are arranged at intervals, and each cathode cavity is separated from the adjacent anode cavity through one ion exchange membrane. Each cathode cavity comprises a first cavity, a cathode active material, two first current collecting metal nets, a plurality of first electronic export ends, a first water inlet, a first water outlet and an aeration device, wherein the two first current collecting metal nets are arranged in the first cavity in parallel and at an interval; the plurality of first electronic export ends are arranged on the first current collecting metal nets at intervals and connected with an external circuit. Each anode cavity is basically the same with each cathode cavity in structure, and the difference is that each anode cavity is filled with an anode active material and no aeration device is arranged.

Owner:TSINGHUA UNIV

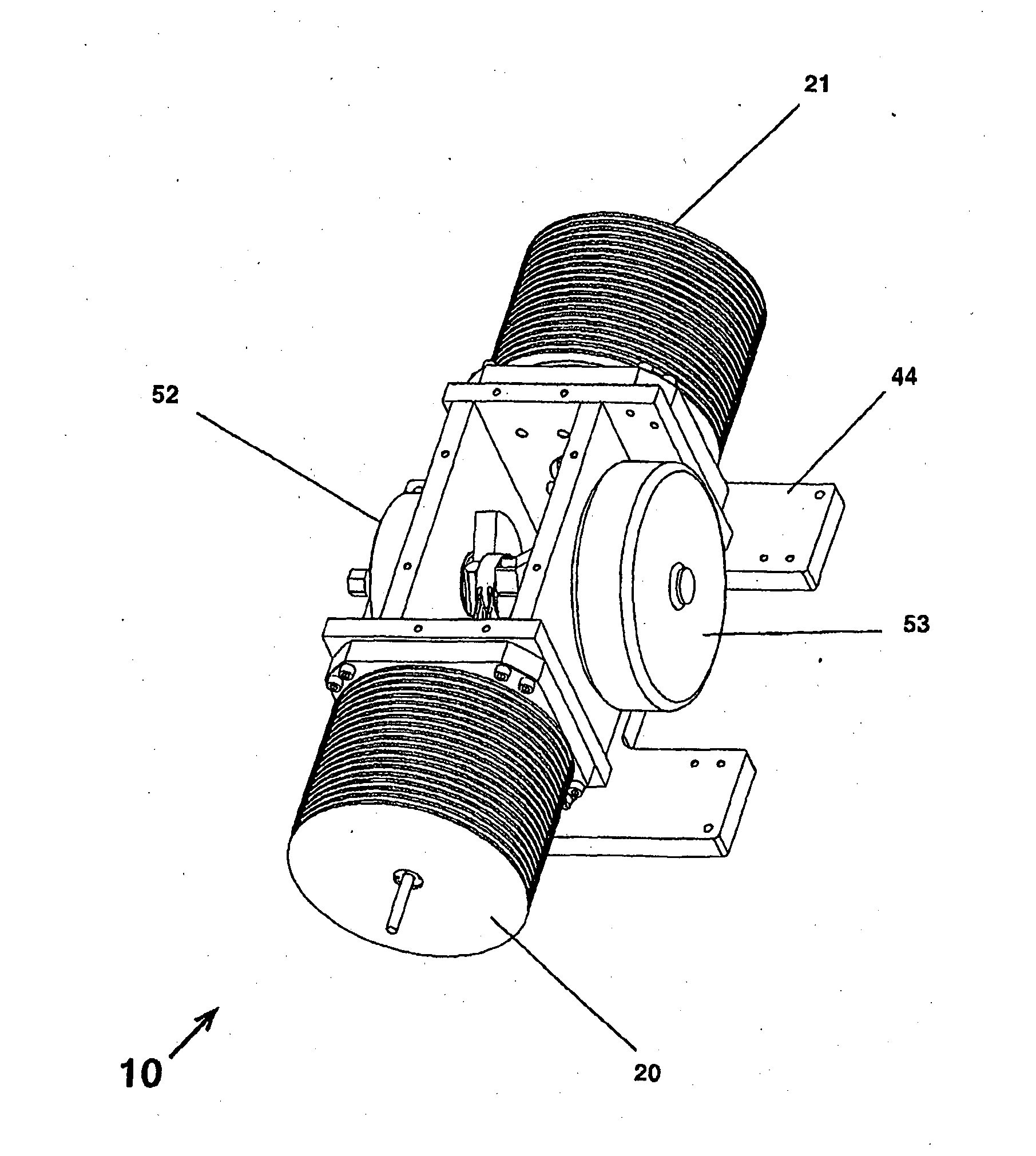

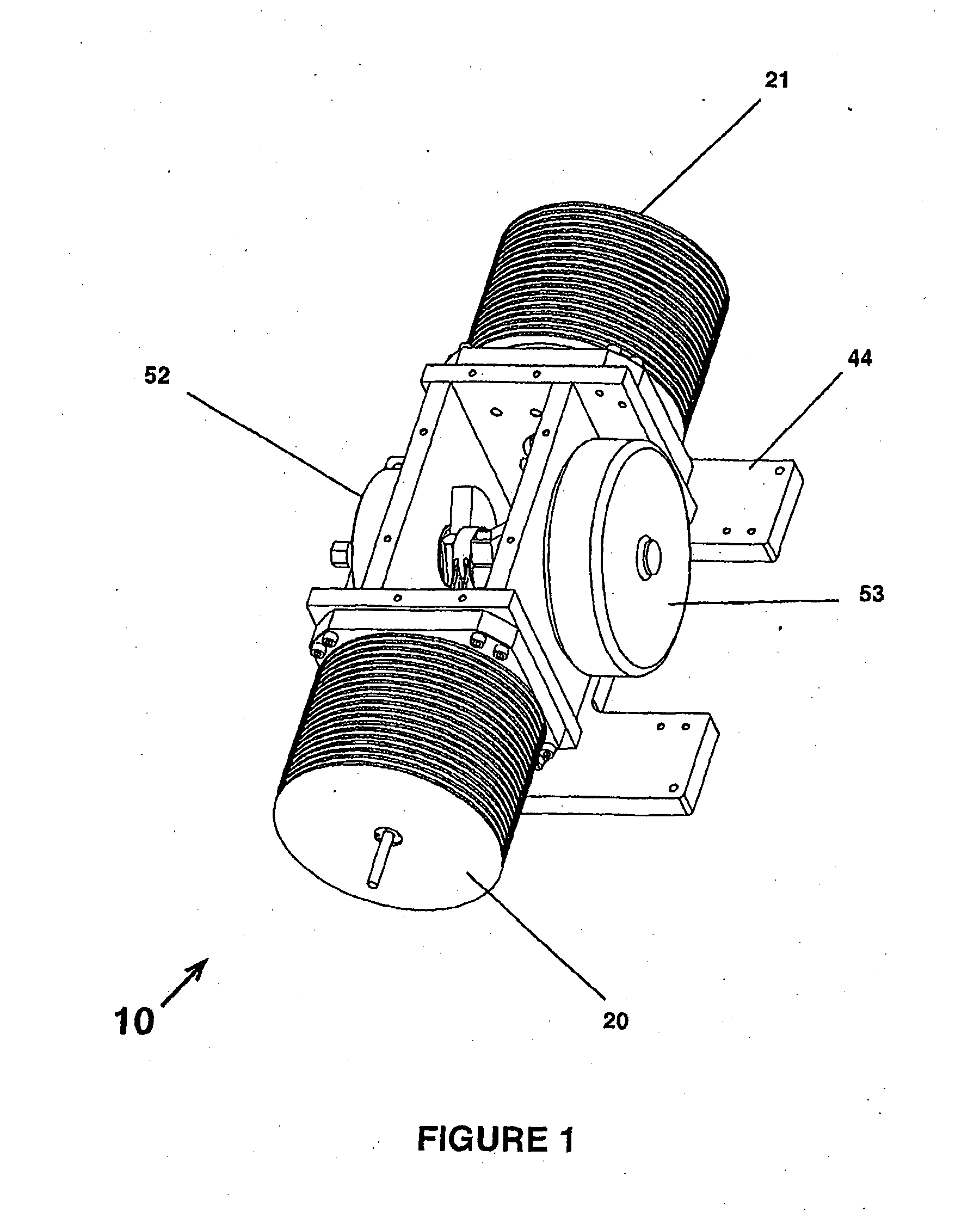

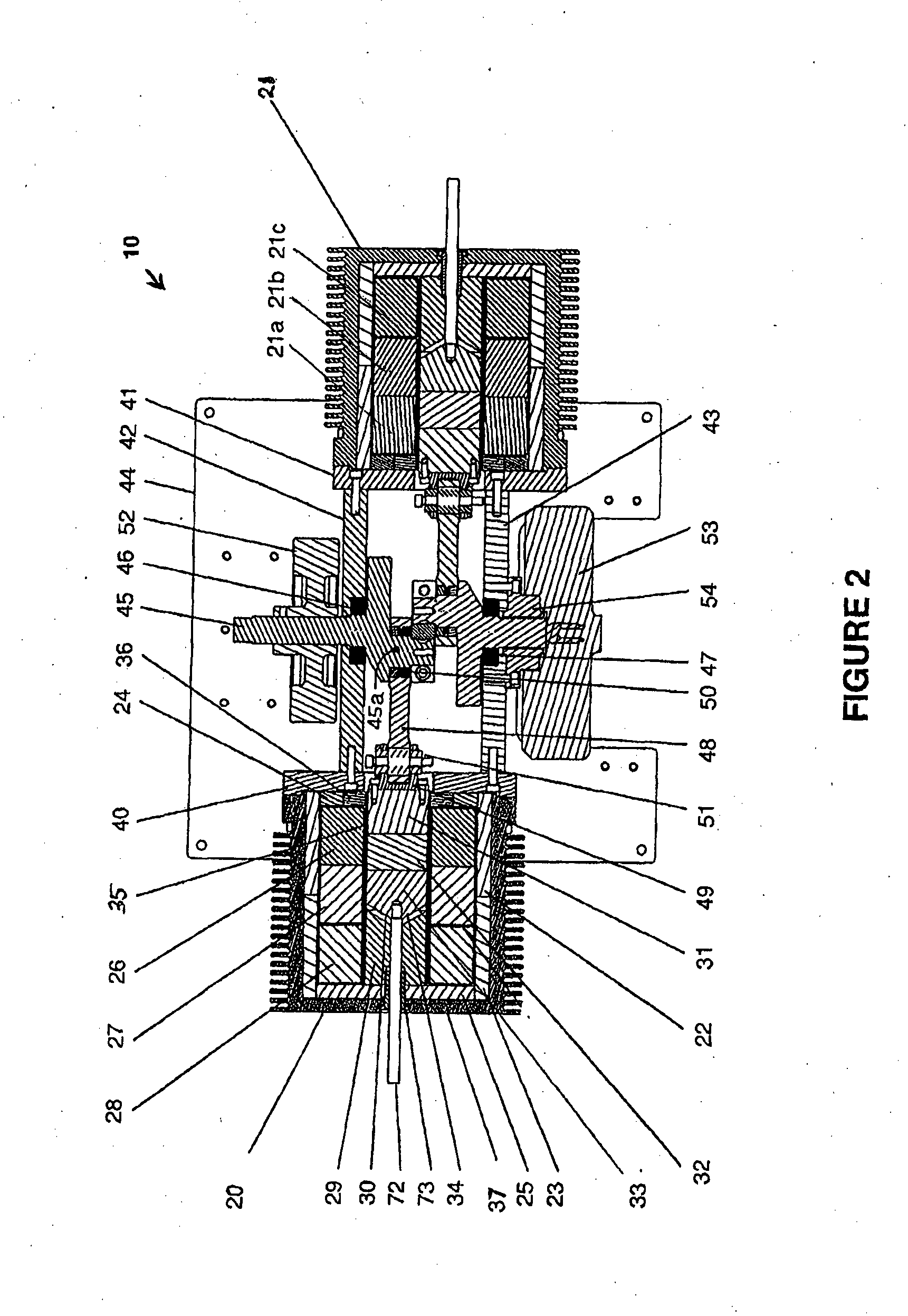

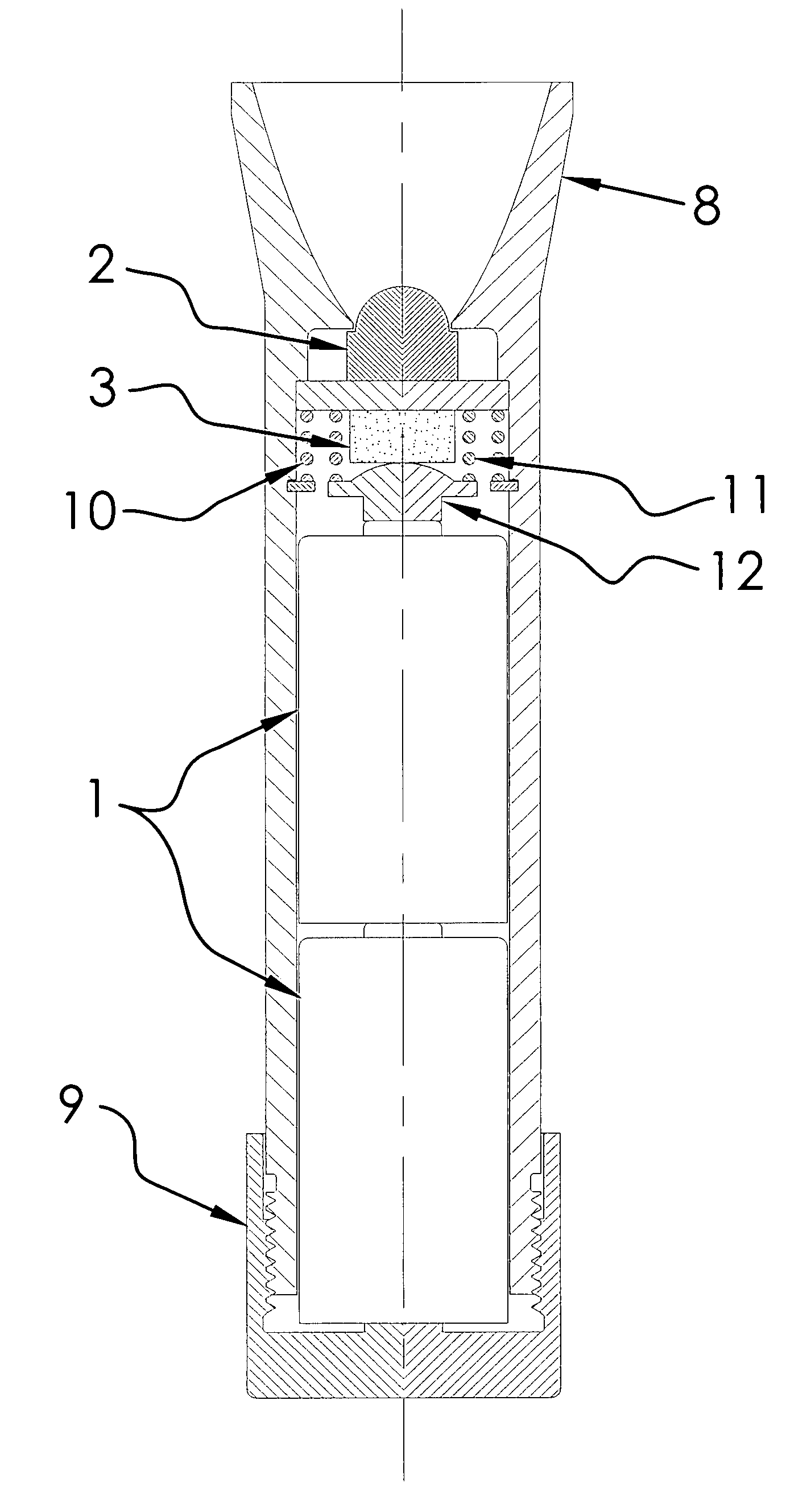

Method and Apparatus for Converting Between Electrical and Mechanical Energy

InactiveUS20140292114A1Lower ohmic resistanceImprove conversion efficiencyGearingMachines/enginesDriver circuitReciprocating motion

The present application relates to conversion between electrical and mechanical energy. In preferred forms, a solenoid assembly is provided that may include a housing containing a core member and a coil assembly including at least one coil, a plunger assembly adapted for reciprocal movement within said housing between a first position and a second position, and a driver circuit for energizing the coil assembly to cause the plunger assembly to move at least between the first and second positions.

Owner:E M I P

Devices and methods for providing adjustable light intensity

InactiveUS20080100413A1Electrical resistance decreaseReduce resistanceElectric circuit arrangementsWith electric batteriesElectrically conductiveElectrical force

The present invention generally relates to light sources that have variable and adjustable luminous intensities. According to certain preferred embodiments of the invention, devices are provided that generally comprise (1) a conductive elastomeric material that is located between a first and second conductive surface; (2) a power source operably connected to the first conductive surface; and (3) a light source operably connected to the second conductive surface. In such embodiments, the conductive elastomeric material comprises an electrical resistance that decreases when the material is compressed or contacts a greater surface area of the first or second conductive surface. By modulating the compression state of the elastomeric material (and, therefore, the ohmic resistance thereof), the amount of electrical power transmitted from the power source to the light source is controlled, which in turn affects the luminous intensity of the light emitted therefrom.

Owner:BAECHTIGER WALTER +1

Torsion spring for electro-mechanical switches and a cantilever-type RF micro-electromechanical switch incorporating the torsion spring

InactiveUS6847277B2Increased durabilityHandle more powerCircuit-breaking switches for excess currentsContact surface shape/structureConformal connectionEngineering

A torsion spring for an electro-mechanical switch is presented. The torsion spring comprises a set of tines including at least one tine extending from the free end of the armature of a switch. A terminus portion is rotatably suspended between the tines, and includes a conducting transmission line, at least a portion of which is exposed for electrical contact. The conducting transmission line has a length selected such that the exposed portion of the transmission line forms a circuit between the input and output of the micro-electro-mechanical switch when the micro-electro-mechanical switch is urged into a closed position, with the terminus portion rotating via the tines to form a conformal connection between the exposed portion of the conducting transmission line and the input and output of the switch, thus optimizing the electrical flow therebetween. The switch is also applied to MEMS devices.

Owner:HRL LAB

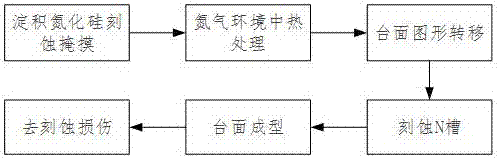

Method for improving extended wavelength gallium indium arsenide detector etching damage

InactiveCN107994094ARepair damageQuality improvementFinal product manufactureSemiconductor devicesIndium arsenideMaterial quality

The invention discloses a method for improving extended wavelength gallium indium arsenide detector etching damage which is provided with a whole set of chip preparation etching processes. The methodincludes the steps: (1) depositing a mask etched by silicon nitride; (2) performing heat treatment in the nitrogen environment; (3) transferring table top images; (4) etching an N groove; (5) forminga table top; (6) removing etching damage. The method has the advantages that the mask etched by the silicon nitride is deposited, the heat treatment is performed in the nitrogen environment, materialdamage can be repaired, complex center density is reduced, material quality is improved, dark current of devices is reduced, hole carrier density can be increased, P-electrode ohmic contact stabilityis facilitated, resistance is reduced, a table top forming process includes gas is etched by the aid of chlorine methane, hydrogen decomposed by the methane in the plasma etching process can passivatedangling bonds formed by etching, and non-radiative recombination center density in materials is reduced. According to an etching damage removing process, damage layers of etching surfaces can be removed, the non-radiative recombination center density is reduced, subsequent passivation effects are enhanced, and the method is applicable to preparation of a high-performance short wave infrared gallium indium arsenide detector.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com