Patents

Literature

58results about How to "Increase the reactive surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

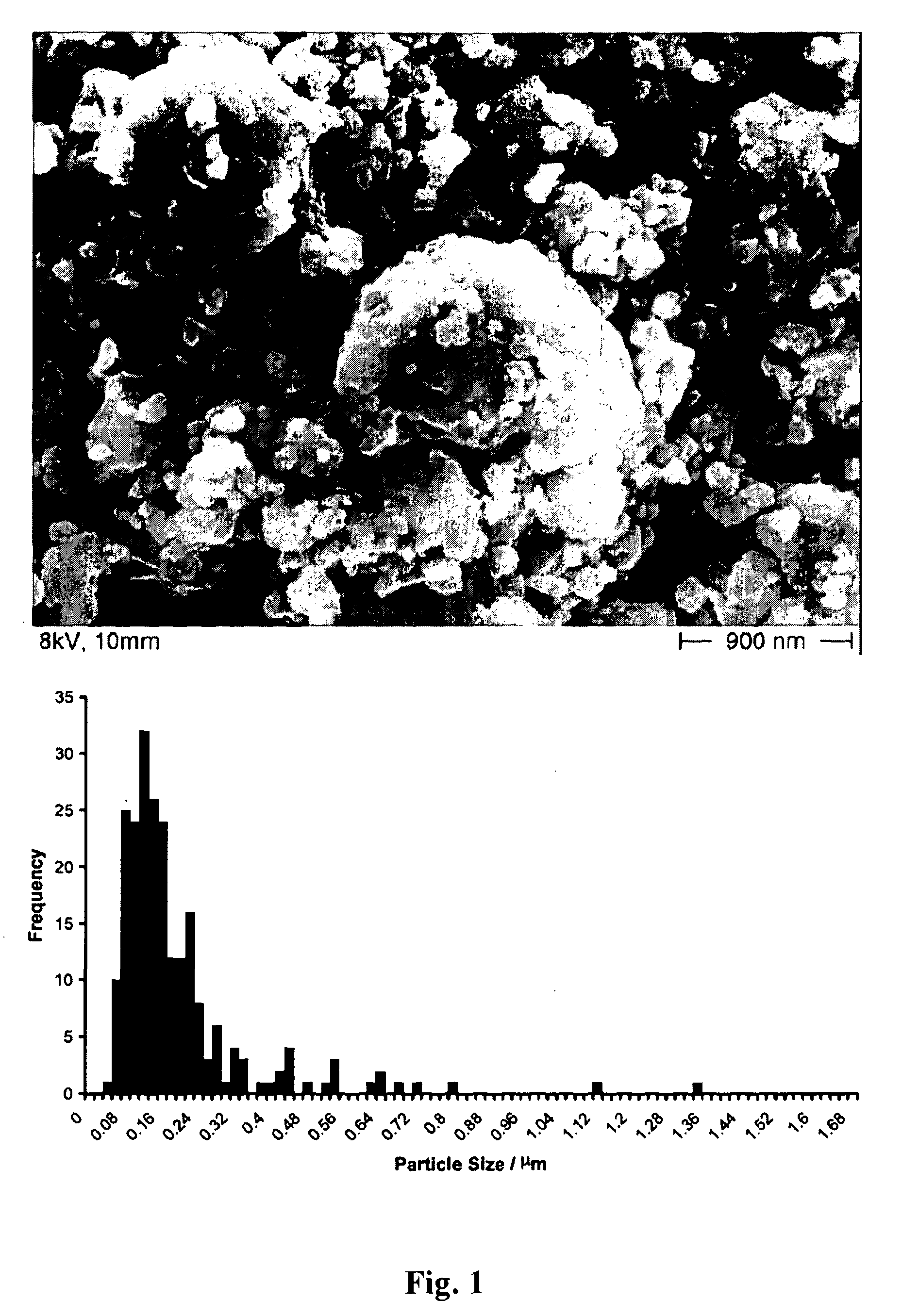

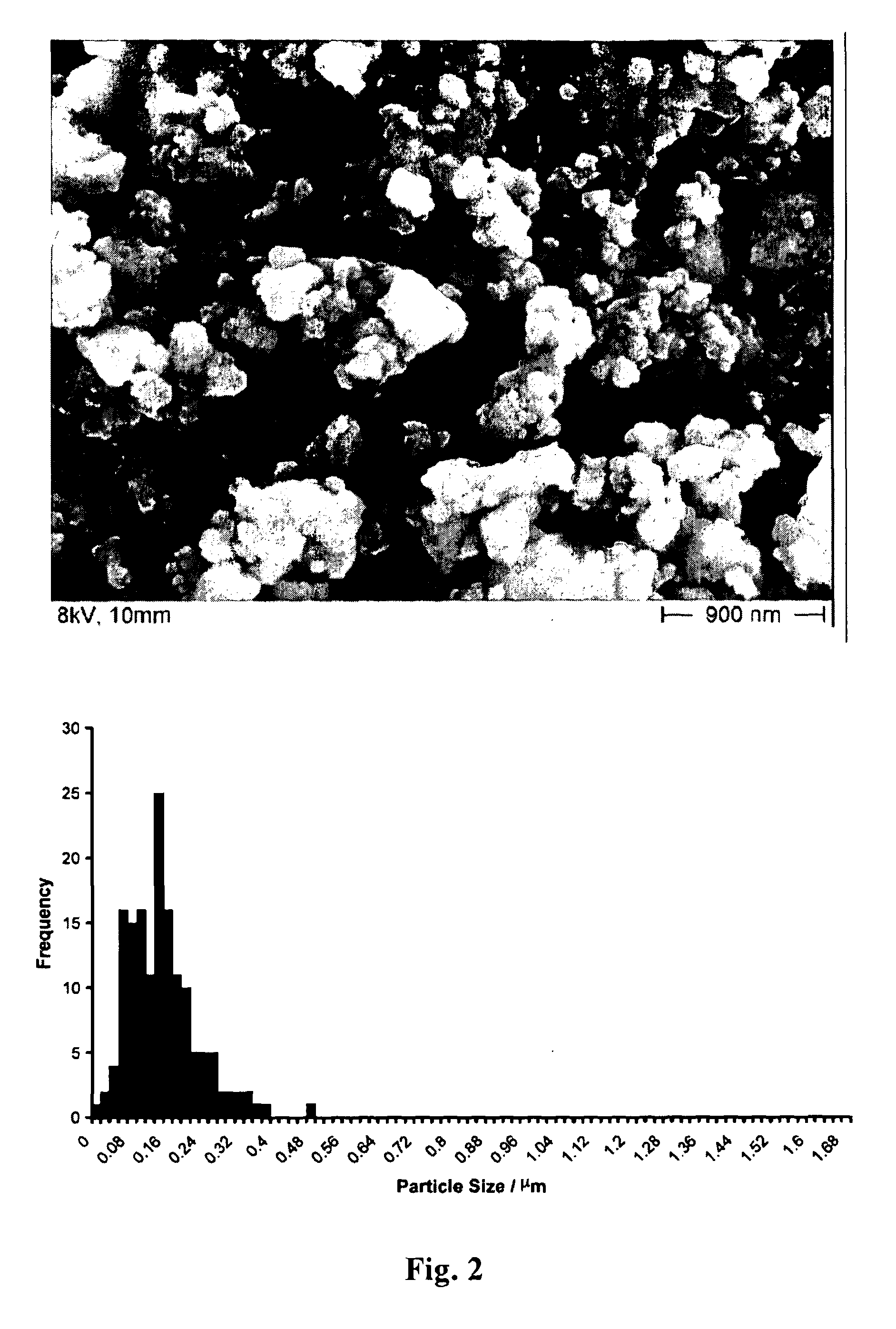

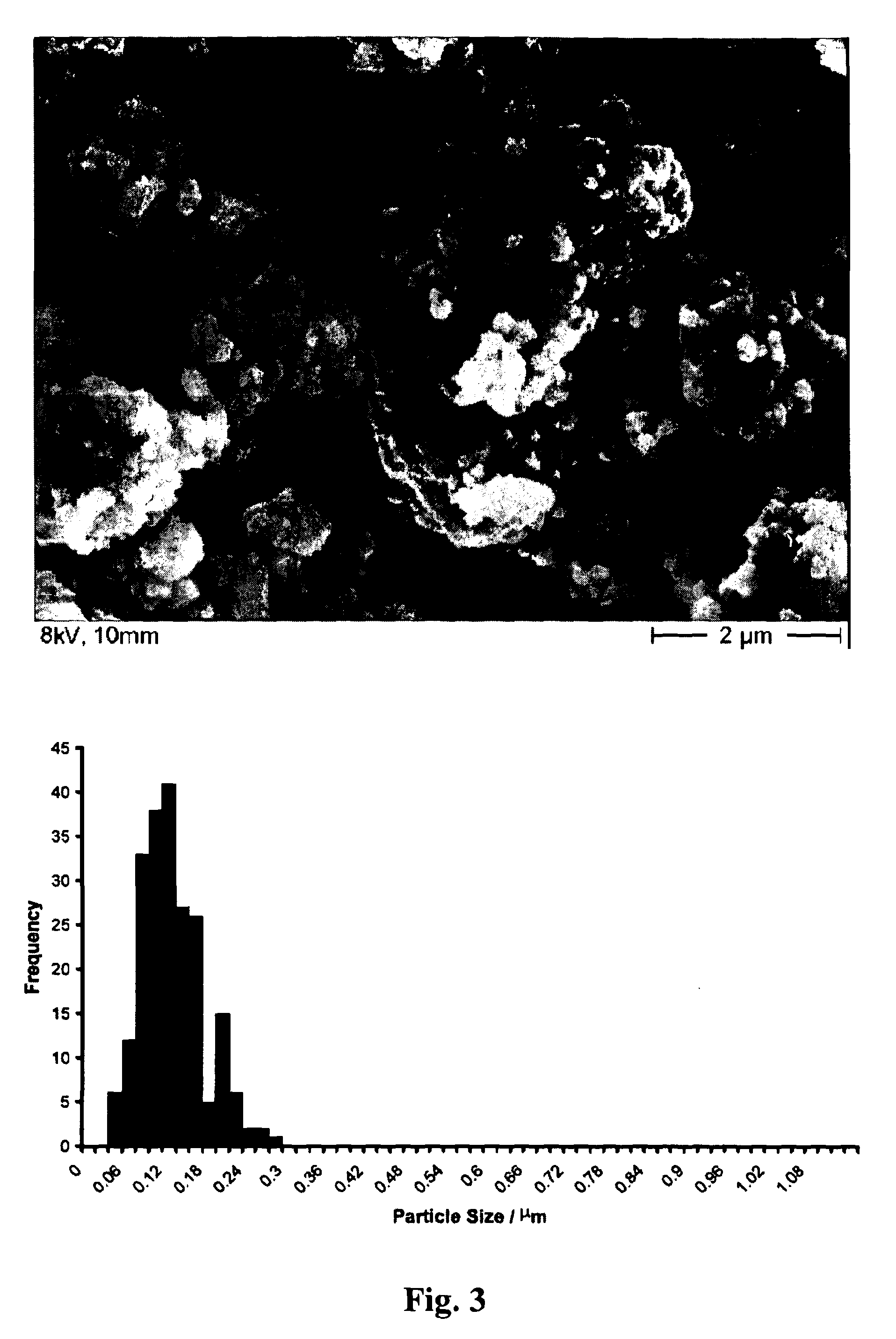

Preparation Of Silicon For Fast Generation Of Hydrogen Through Reaction With Water

InactiveUS20120275981A1Preventing and reducingLow melting pointMaterial nanotechnologyPigmenting treatmentMechanical forceCoating

The invention provides a process for producing nonpassivated silicon, which process comprises providing a sample of silicon and, under inert conditions, reducing the mean particle size in the sample by applying a mechanical force to the sample. The invention also provides nonpassivated silicon which is obtainable by such a process, and compositions which comprise the nonpassivated silicon. Further provided is a process for producing hydrogen, which process comprises contacting water with nonpassivated silicon, thereby producing hydrogen by hydrolysis of said silicon. The invention also provides a pellet for generating hydrogen, the pellet comprising nonpassivated silicon encapsulated within an organic coating.

Owner:ISIS INNOVATION LTD

Method for oxidizing asphaltum

InactiveCN1415699AGood dispersionSmall diameterWorking-up pitch/asphalt/bitumen by chemical meansEngineeringTower

A process for oxidizing asphalt includes such steps as dispersing air in the microbubbles mode in asphalt, loading in asphalt oxidizing tower, and oxidizing. Its advantages are high utilization rate of air, high speed, and simple structure of said oxidizing tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

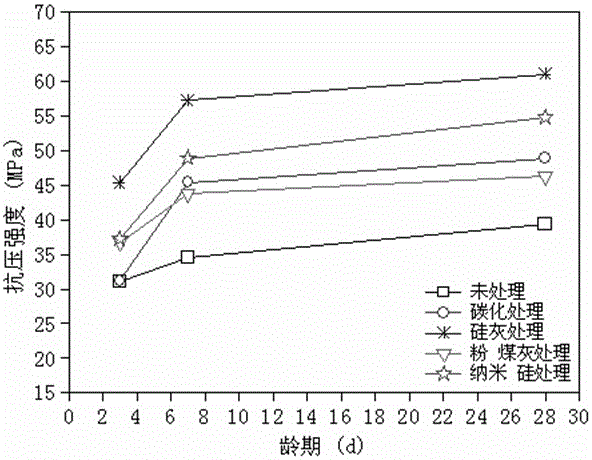

Treatment method of volcanic-ash-paste-reinforced recycled concrete aggregate

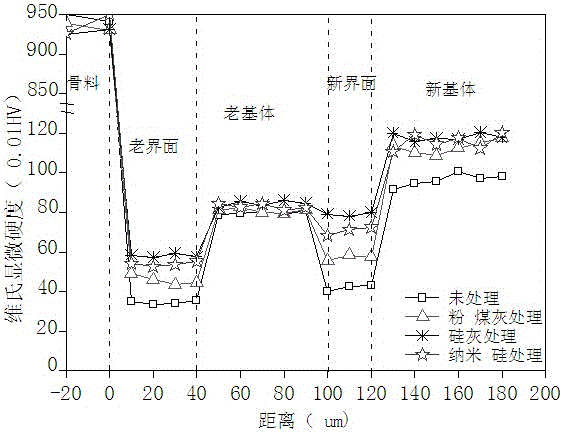

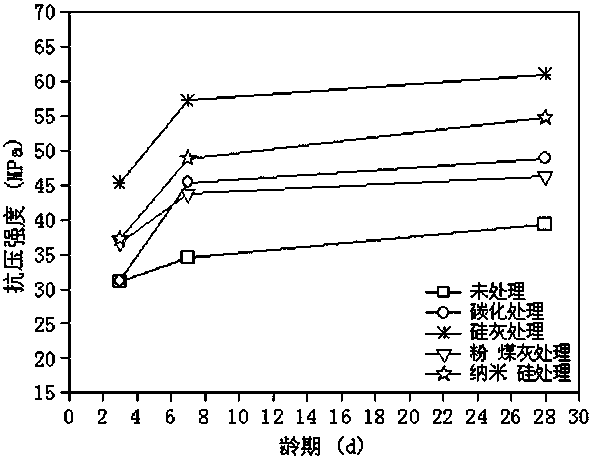

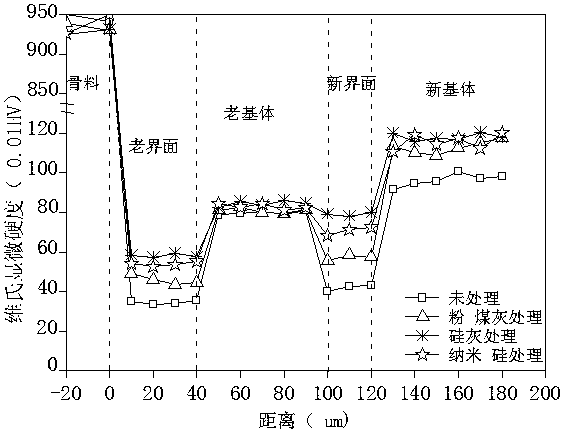

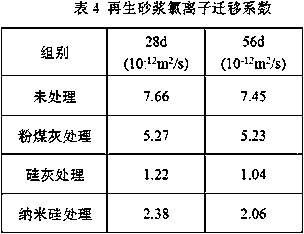

ActiveCN106007438AIncrease the reactive surface area of volcanic ashImprove interface performanceSolid waste managementVolcanic ashIon permeability

The invention relates to a treatment method of volcanic-ash-paste-reinforced recycled concrete aggregate. The method comprises the following steps: (1) carrying out crushing treatment and screening on recycled concrete, and drying to obtain recycled aggregate; (2) adding water into a volcanic ash material with the particle size of less than 60 micrometers to prepare a volcanic ash paste, and carrying out ultrasonic dispersion to form a homogeneous paste solution; (3) immersing the dried recycled aggregate in the step (1) in the homogeneous paste solution prepared in the step (2), and stirring; (4) screening the mixture treated in the step (3) to remove the recycled aggregate, and filtering to remove the excessive paste solution; (5) drying the screened recycled aggregate, and carrying out kneading dispersion on the agglomerate aggregate; and (6) screening the recycled aggregate treated in the step (5) to obtain the volcanic-ash-paste-reinforced recycled concrete aggregate. Compared with the mortar prepared from the untreated recycled concrete aggregate, the 3-day compression strength and 28-day compression strength of the mortar prepared from the volcanic-ash-paste-reinforced recycled concrete aggregate are enhanced by 17% or above, the chlorine ion permeability coefficient is lowered by 30% or above, and the new / old interface microhardness of the mortar is enhanced by 30% or above.

Owner:HUNAN UNIV

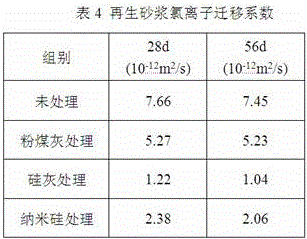

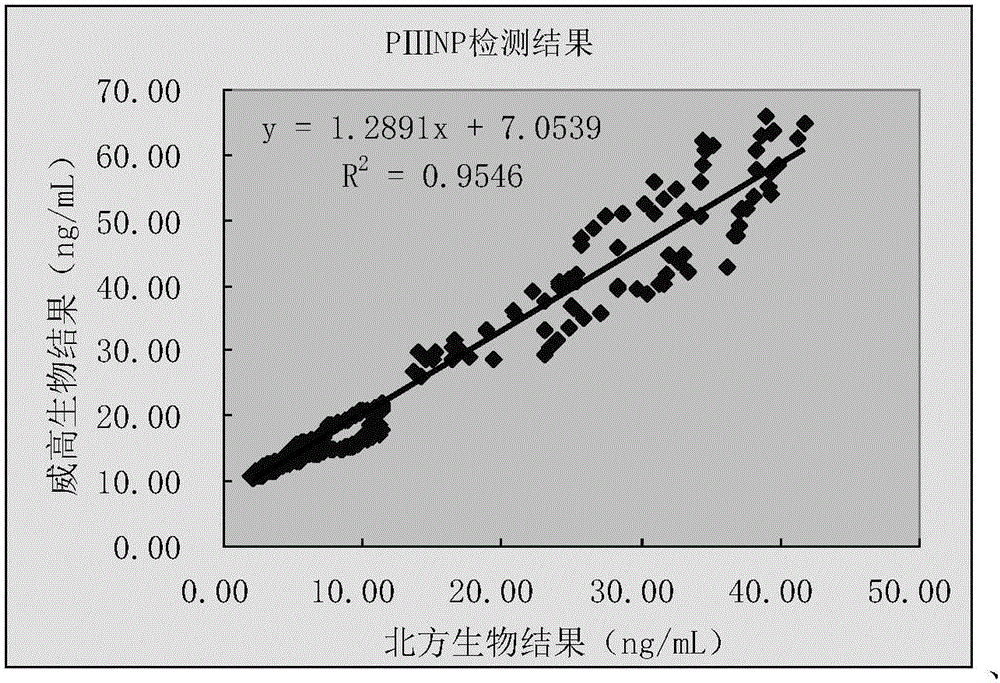

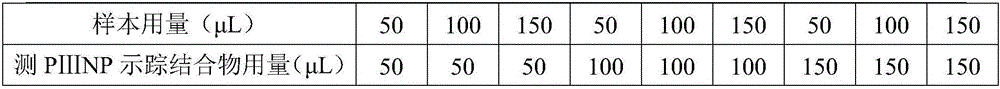

III type procollagen N-terminal peptide quantitative measurement kit and preparation method thereof

InactiveCN106053826AHigh precisionEasy to detectChemiluminescene/bioluminescenceBiological testingQuality controlHepatic fibrosis

The invention provides a magnetic particle chemiluminescence method III type procollagen N-terminal peptide quantitative measurement kit and a preparation method thereof. The kit is composed of PIIINP magnetic particles, tracing conjugate for measuring PIIINP, and a quality control substance. The invention also provides a preparation method of the quantitative measurement kit. The preparation method adopts a micro particle chemiluminescence immunoassay technology, an automatic chemiluminescence method is used to carry out detection, the operation time is reduced, the artificial operation error is reduced, the detection precision and accuracy are improved, and the kit is suitable for assisted diagnosis of early stage hepatic fibrosis in clinic.

Owner:威海威高生物科技有限公司

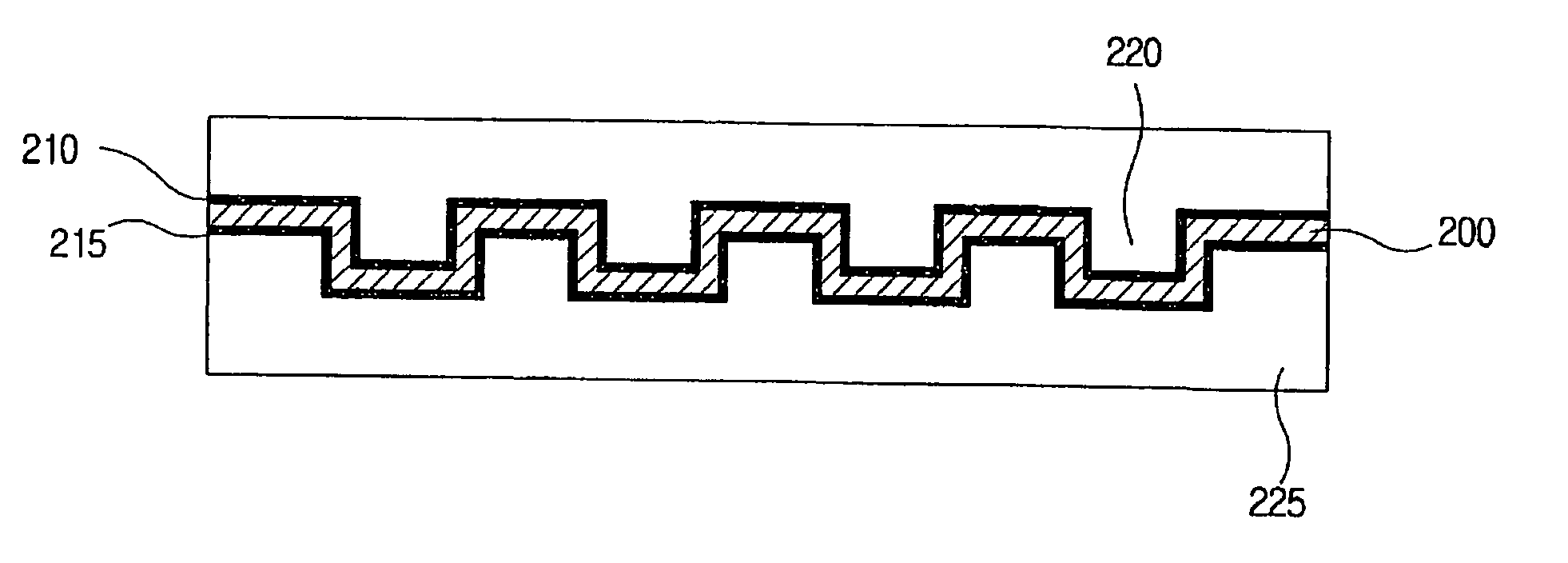

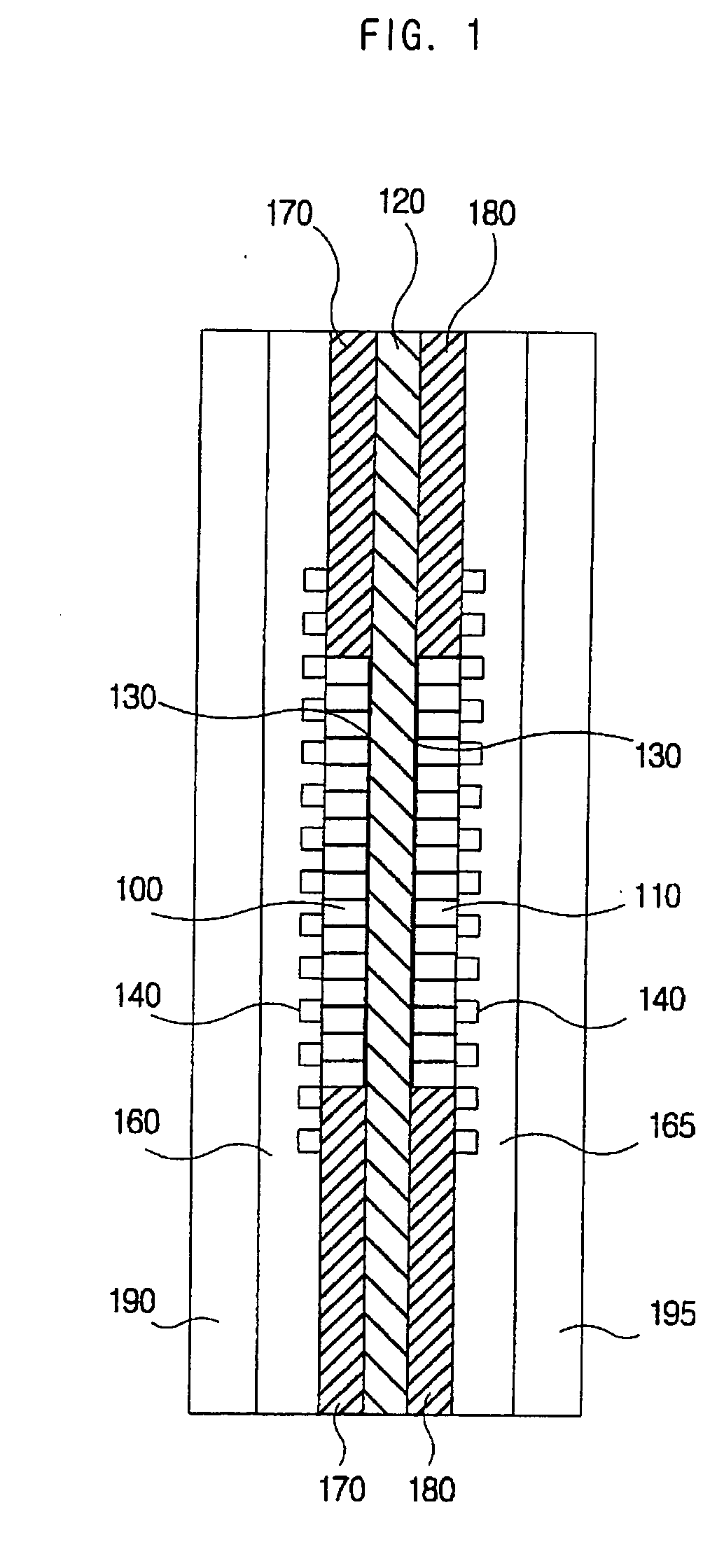

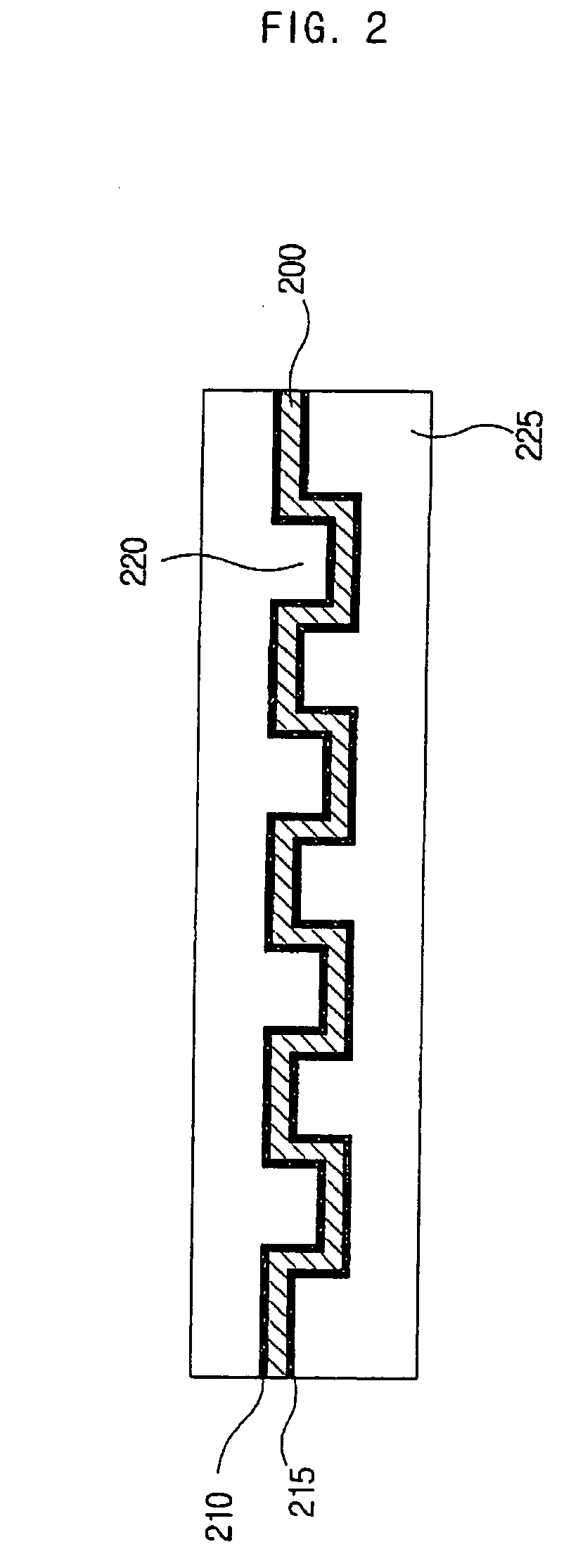

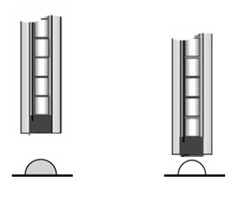

Method for producing membrane electrode assembly

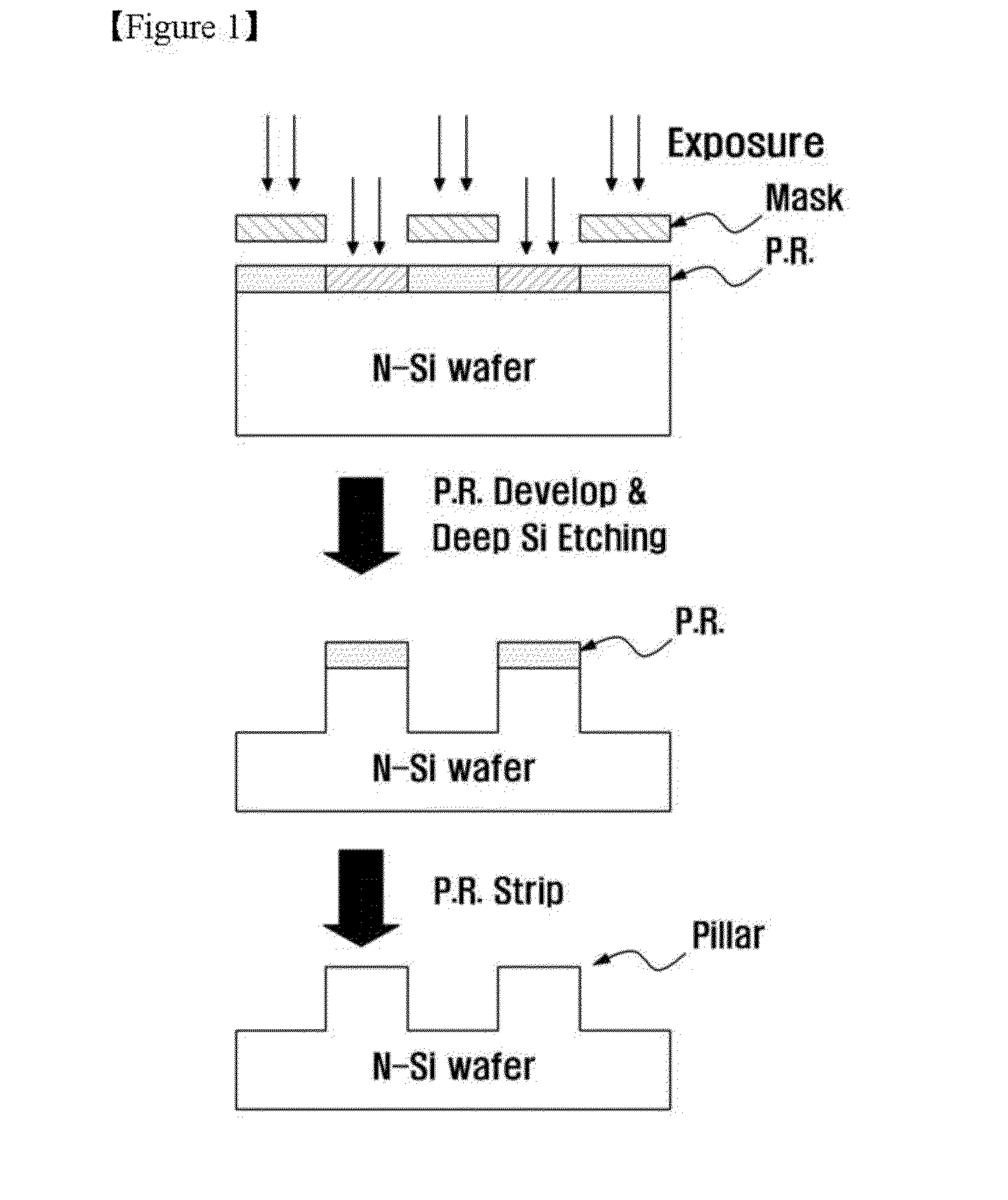

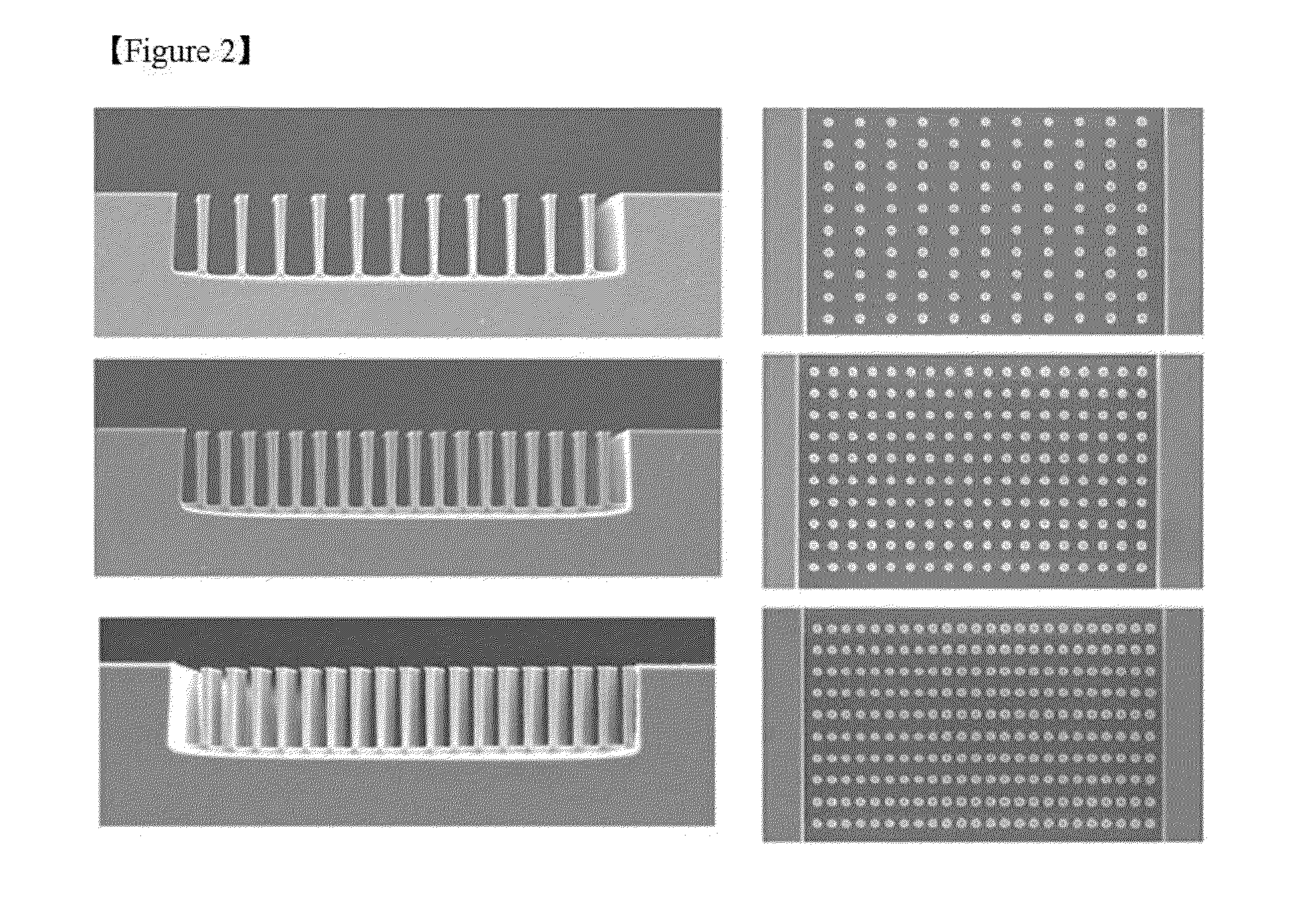

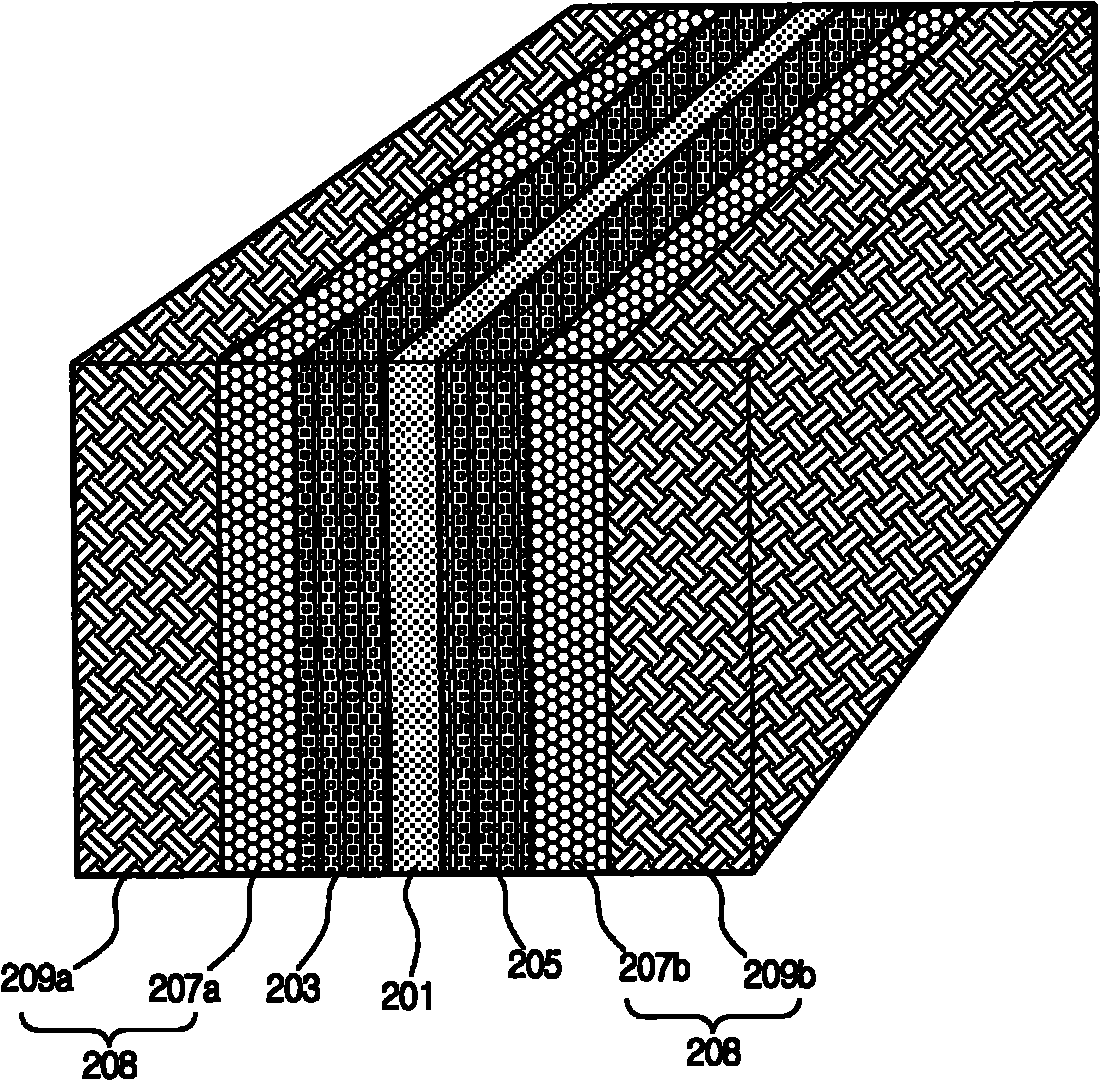

InactiveUS20050238800A1Increase the reactive surface areaGood reproducibilityPrimary cellsElectrode carriers/collectorsStructural reliabilityVolumetric Mass Density

The present invention relates to a Membrane Electrode Assembly (MEA) which significantly enhances power density as well as structural reliability and method for producing the same. More specifically, it relates to the Membrane Electrode Assembly which has a plurality of protuberances and method for producing the same. The present invention involves making supporting bodies to have a plurality of protuberances on one side of the supporting bodies, forming a catalyst layer on one side of the supporting bodies having the protuberances, interposing a polymer-electrolyte-membrane between the supporting bodies, aligning the supporting bodies for the protuberances to engage each other; and hot-pressing the aligned supporting bodies. The present invention can increase the area of a three-phase boundary in which oxidation-reduction reaction of hydrogen and oxygen occurs and decrease resistance to ion conduction; consequently fuel cells have the characteristic of a large output of power density.

Owner:FUELCELLPOWER

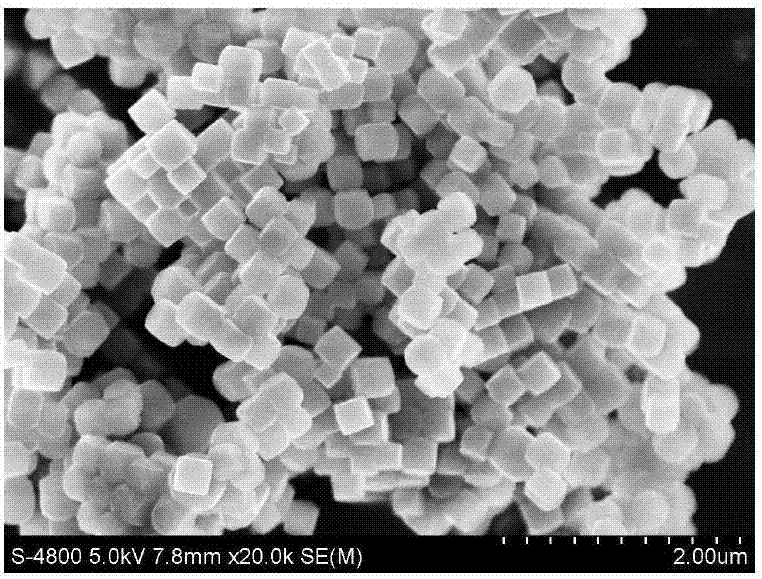

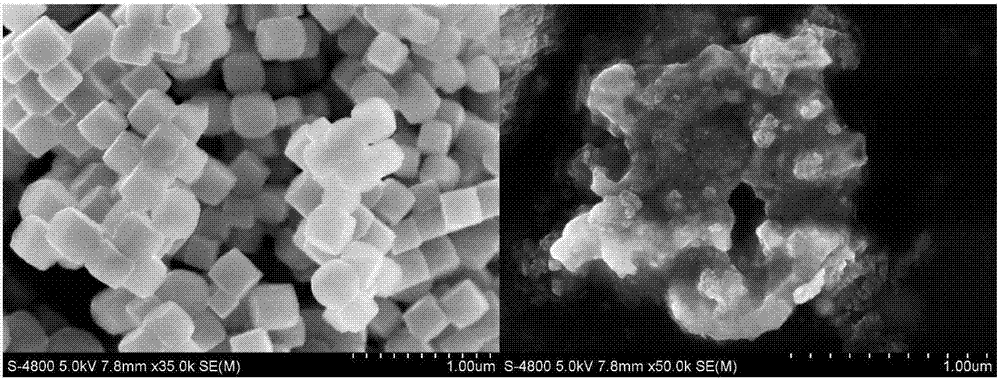

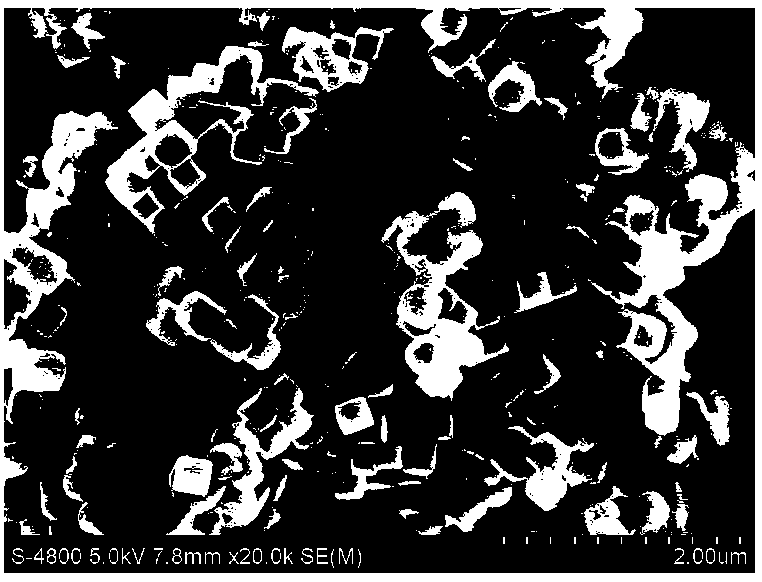

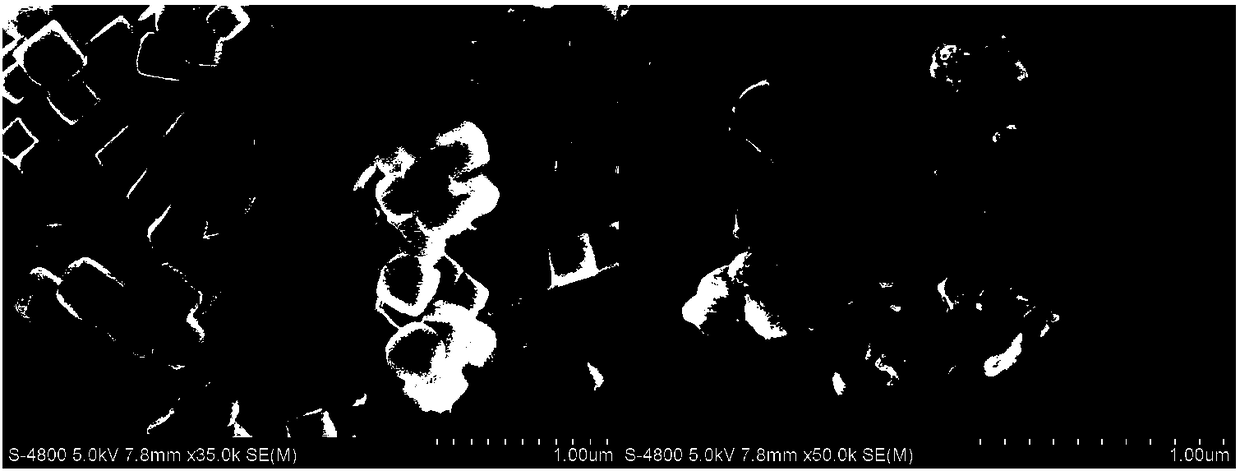

High-performance super-capacitor electrode material Co-Fe type prussian blue nano cube as well as preparation method and application thereof

InactiveCN107253731AMild sourceRich sourcesMaterial nanotechnologyIron cyanidesCapacitancePotassium ferricyanide

The invention relates to a high-performance super-capacitor electrode material Co-Fe type prussian blue nano cube as well as a preparation method and application thereof, and belongs to the technical field of electrode material preparation. According to the preparation method, inorganic cobalt salt and potassium ferricyanide are adopted as reaction raw materials, trisodium citrate is adopted as a complexing stabilizer, a liquid-phase precipitation reaction method is implemented, reaction conditions such as the use amount and the stand aging time of potassium ferricyanide are controlled, a Co-Fe type prussian blue nano cube material with good dispersibility and large specific area is prepared, and the size of the material is about 300nm. By adopting the Co-Fe type prussian blue nano cube material provided by the invention, the capacity of an electrochemical electric container is increased, properties such as the rapid charge and discharge property and the service life of the electric container are improved, the capacitance of the electric container is as high as 447F / g in constant current charge and discharge of 5A / g in a 1mol / L sodium sulfate solution, and the good rate capability is achieved.

Owner:DALIAN NATIONALITIES UNIVERSITY

Formulation and solidifying process for anode lead plaster of long and narrow type valve controlled sealed lead acid accumulator

InactiveCN1482696AHigh initial capacityInhibit sheddingLead-acid accumulator electrodesFiberHermetic seal

A elongated valve control hermetic sealing lead-acid storage battery lead grease formulation and solidification process, wherein the percentages by weight of each ingredient in the lead grease formula are, lead powder 65-80%, red lead 8úÑí½ 20úÑ, short fibers 0.07úÑí½ 0.15úÑ, sulfuric acid 5úÑí½ 10úÑ, water 5úÑí½ 10úÑ, the high temperature and high moisture process is used for solidification, with a temperature of 70-85 degree C., and a moistness over 95%, the curing time is 20h - 30 h, the invention can guarantee both the initial capacity and the cycle life of the battery.

Owner:江苏隆源双登电源有限公司

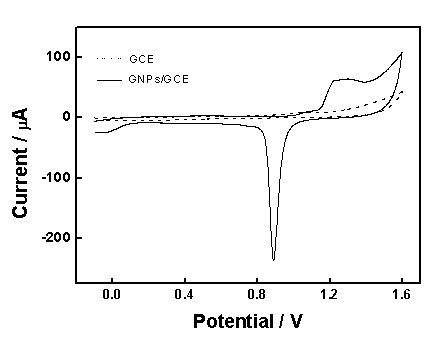

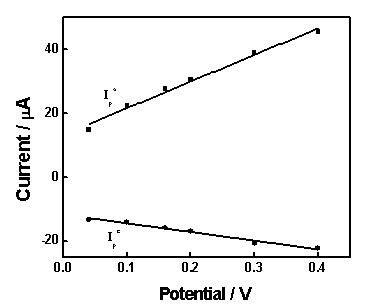

Electro-deposition gold nanoparticles, preparation method and application thereof

InactiveCN101966594AIncrease speedIncrease the reactive surface areaMaterial electrochemical variablesElectrochemistryNanoparticle

The invention relates to electro-deposition gold nanoparticles, a preparation method and application thereof to the field of electrochemical sensors, which is used for increasing the reaction surface area of an electrode and quickening the rate of electronic transfer, and the method of in-situ electrochemical deposition of the gold nanoparticles can be used for rapidly and simply constructing a nano platform of the electrochemical sensors.

Owner:SHANGHAI QIBAO HIGH SCHOOL

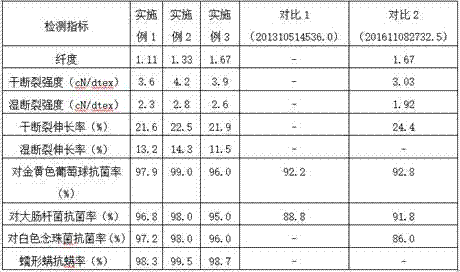

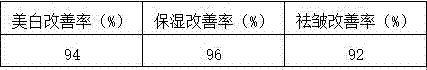

Honeysuckle flower cellulose fiber, and preparation method and application thereof

InactiveCN107164826AImprove washabilityFunctionalCosmetic preparationsToilet preparationsPrurigoPine bark extract

The invention provides a honeysuckle flower cellulose fiber. The honeysuckle flower cellulose fiber is prepared from flax pulp; the honeysuckle flower cellulose fiber contains 5% or more of honeysuckle flower extract, 1-3% of pine bark extract and 2-6% of proteins; the dry fracture strength of the honeysuckle flower cellulose fiber is 3.6-4.2 cN / dtex; the wet fracture strength is 2.3-2.8 cN / dtex; and the dry elongation at break is 21.6-22.5%. The honeysuckle flower cellulose fiber prepared in the invention adopts the flax pulp as a raw material, and the flax contains unsaturated fatty acids, so the honeysuckle flower cellulose fiber has good repairing and protecting effects on skins, has no irritation, has the efficacy of moisturizing dryness, detoxifying, relieving pains and eliminating swelling, and can be used for preventing and treating prurigo and allergy of skins; and a fabric made of the honeysuckle flower cellulose fiber has good compatibility with skins.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

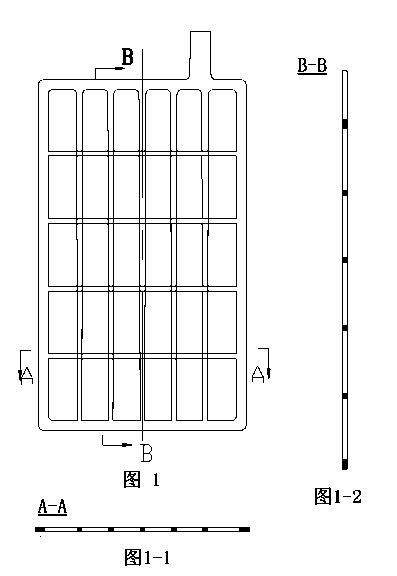

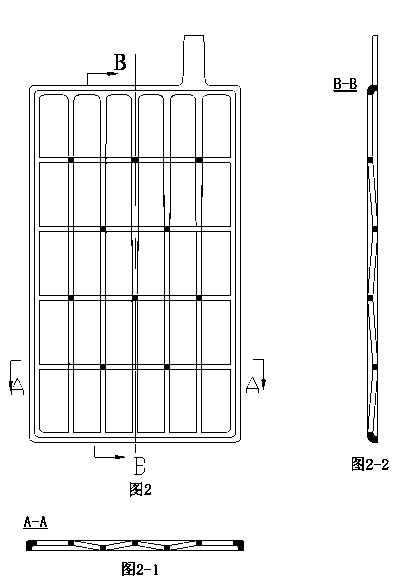

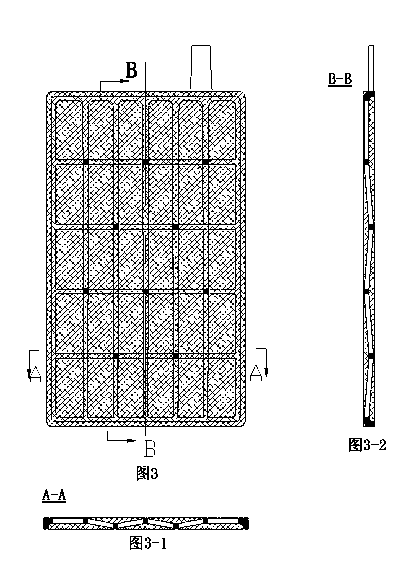

Lead-acid battery grid, polar plate and manufacturing method of grid

ActiveCN101740781AReduce the amount of lead usedImprove charge acceptanceElectrode carriers/collectorsLead-acid accumulator electrodesPunchingEngineering

The invention provides a lead-acid battery grid, comprising a grid main body, bulges which are arranged in arrays are formed on one side of the grid main body, and side-open type through holes are formed between the bulges and the grid main body. The invention also provides a lead-acid battery polar plate which comprises a grid and lead plaster coated on the surface of the grid. The invention also provides a method for preparing the above polar plate grid, comprising the steps of manufacturing a lead belt, rolling belt on the lead belt, punching and deep drawing. The invention can greatly save the use amount of lead, improve the charging receptivity, discharging platform, specific energy and specific power of the polar plate; the method provided in the invention is simple, and the manufactured polar plate grid has high quality, thus being capable of realizing continuous and high-yield production of the polar plate grid, reducing bit material remelting consumption of lead, and loweringproduction energy consumption and material oxidation.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

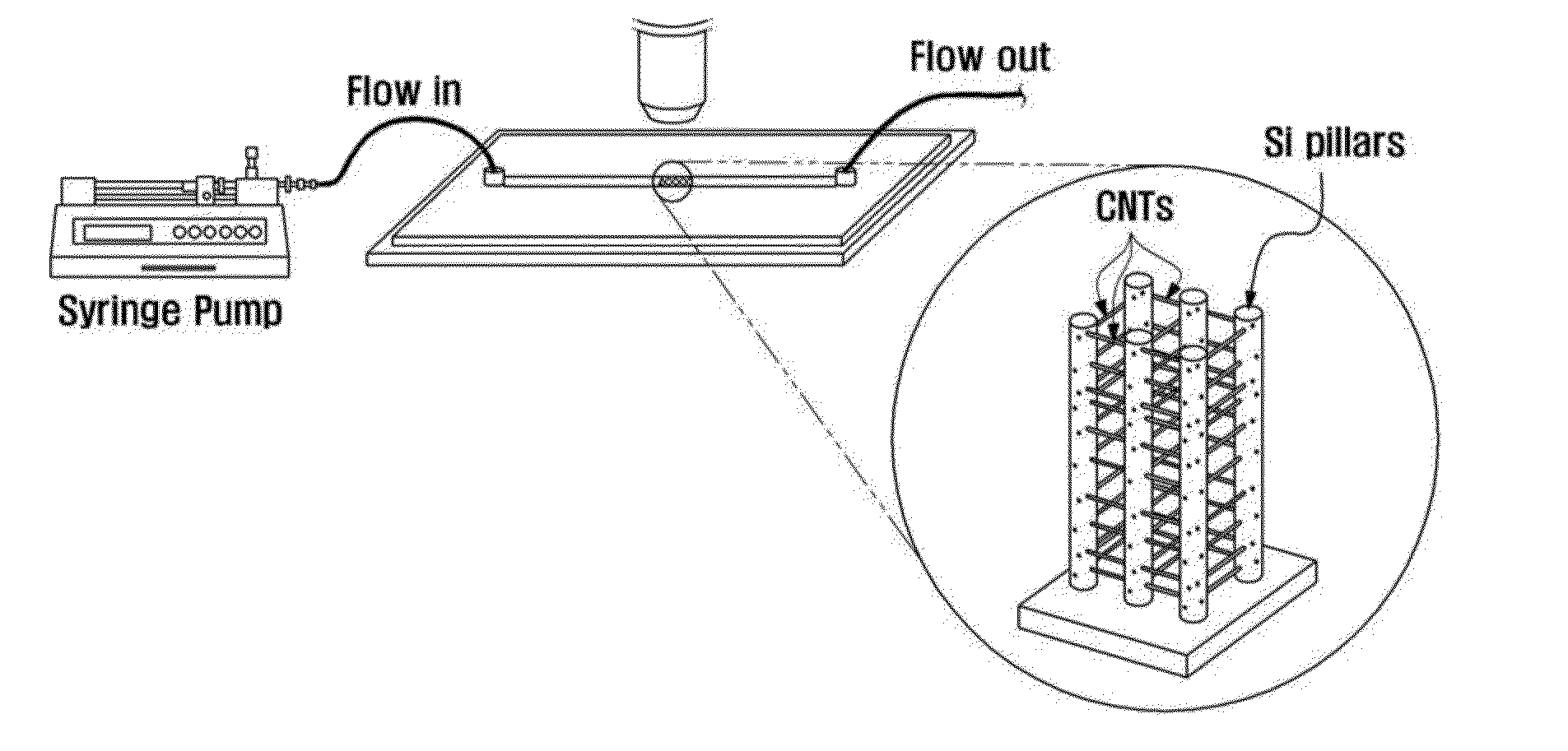

Microfluidic filter using three-dimensional carbon nanotube networks and preparation method thereof

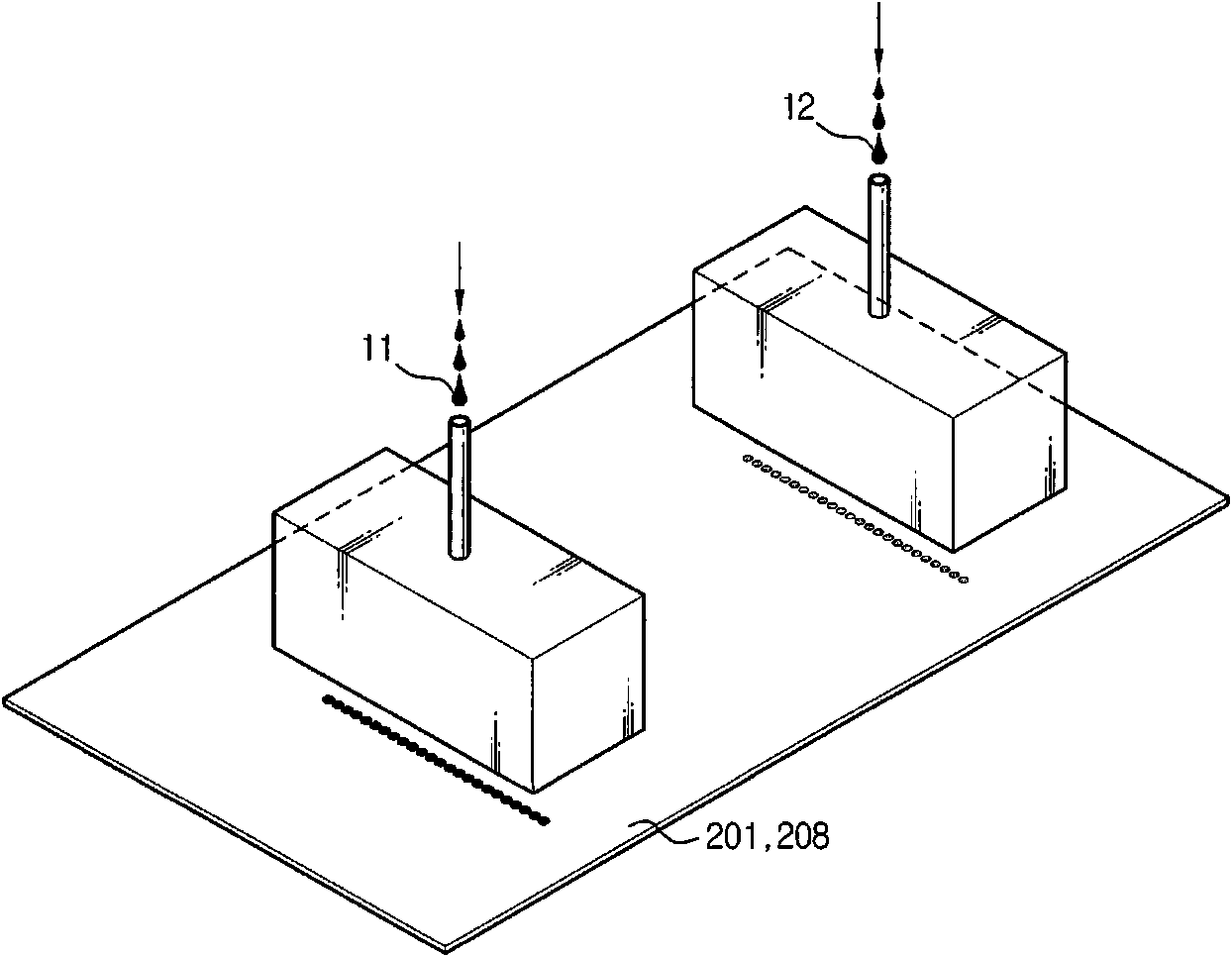

InactiveUS20140001110A1Increase the reactive surface areaHigh strengthSemi-permeable membranesLiquid surface applicatorsNetwork structureCarbon nanotube

The present invention provides a microfluidic filter system using three-dimensional carbon nanotube networks. The density of the carbon nanotubes can be adjusted such that particles having a specific size can be filtered. In addition, the network structures can be maintained even in a fluid. The present invention also provides a method for preparing the microfluidic filter system.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Attapulgite clay/polyanion/polystyrene composite particle and preparation method thereof

InactiveCN105504337ASolve static problemsIncrease the reactive surface areaOther chemical processesWater/sewage treatment by ion-exchangeMicrospherePolystyrene spheres

The invention discloses an attapulgite clay / polyanion / polystyrene composite particle and a preparation method thereof. Polystyrene microspheres are used as a carrier, the polyanion modified by the attapulgite clay covers the surface of the polystyrene microsphere to obtain a core-shell structure of the polyanion-polystyrene microsphere, and then the composite particle integrating the conductivity and the heavy metal ion adsorbability is prepared. The prepared composite particle is high in heavy metal ion adsorbability, the application effect of the polystyrene microspheres in the field of water purification can be enhanced, and the water purification effect is remarkable; and meanwhile, the surface of the composite particle has conductivity, so that the problems of fire potential danger caused by the static electricity during the transportation and pre-processing process of the ordinary polystyrene microspheres can be solved, and the attapulgite clay / polyanion / polystyrene composite particle is safer when used as a building insulated material and a packing material.

Owner:WUHAN UNIV OF TECH

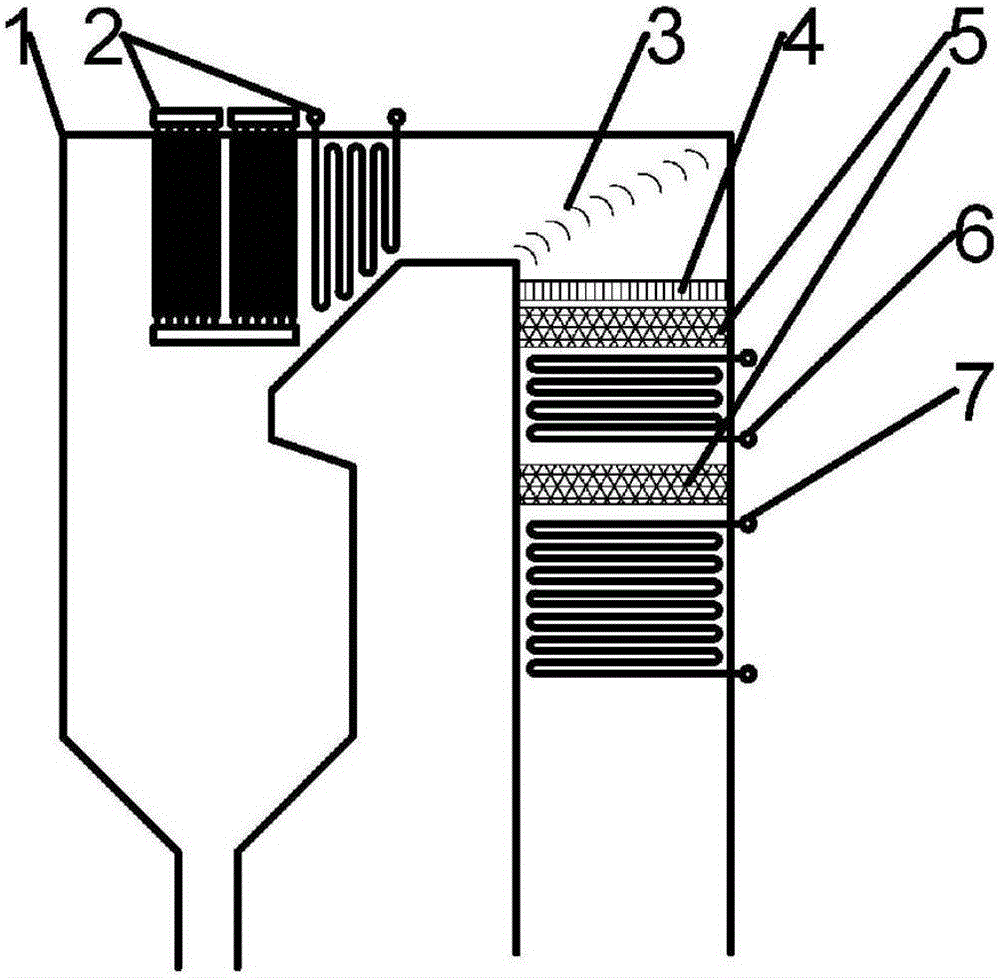

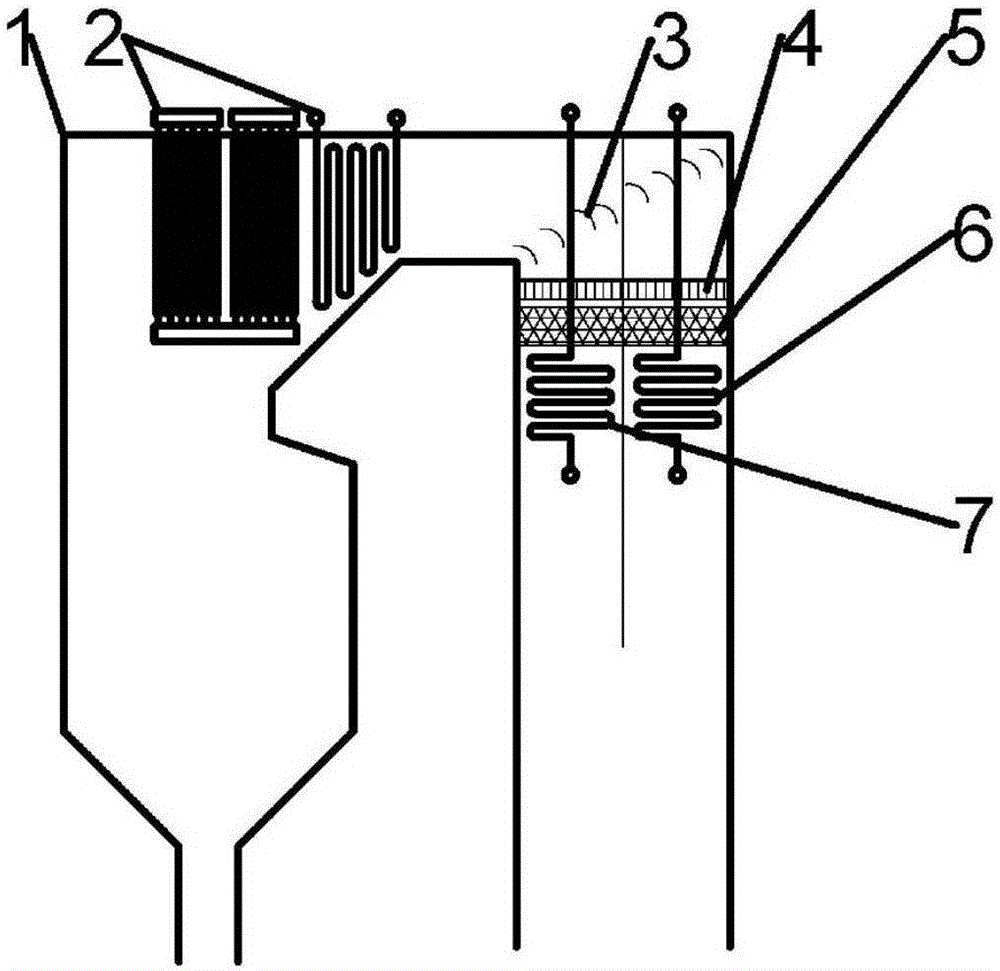

Catalytic removal device for NOx and CO in tail flue of pi-shaped pulverized coal boiler

ActiveCN106322416AEmission reductionReduce the cost of denitrificationEmission preventionSuperheaterNitrogen oxide

The invention discloses a catalytic removal device for NOx and CO in a tail flue of a pi-shaped pulverized coal boiler. The catalytic removal device comprises a shield-type heated surface, a flow guide plate, a flow straightening grid, an active catalytic material, a low-temperature reheater and a low-temperature superheater which are sequentially arranged in the tail flue of the pi-shaped pulverized coal boiler along the flow direction of smoke, wherein the active catalytic material is arranged by virtue of a space in the tail flue of the pi-shaped pulverized coal boiler, NOx is reduced by virtue of CO generated by low-oxygen combustion, and excessive CO is oxidized into CO2, thus the heat efficiency of the boiler is increased while the emission of NOx is effectively reduced. According to the catalytic removal device disclosed by the invention, a heavy-metal oxide catalyst which easily causing secondary pollution is not used, thus normal running of the boiler is not influenced, a running cost is not increased, and a reformation investment is low; the emission of nitrogen oxides at the outlet of the tail flue is effectively reduced in combination with a low-oxygen combustion technology, and meanwhile, the easily-caused problem of efficiency reduction of the boiler due to the low-oxygen combustion is solved; and the catalytic removal device can be used for both environment-friendly reformation for an existing pi-shaped pulverized coal boiler, and design for a newly-constructed pi-shaped pulverized coal boiler.

Owner:HUANENG CLEAN ENERGY RES INST

Application of high-performance supercapacitor electrode material Co-Fe-type Prussian blue nanocube

InactiveCN108083293AMild sourceRich sourcesMaterial nanotechnologyIron cyanidesCapacitancePotassium ferricyanide

The invention relates to application of a high-performance supercapacitor electrode material Co-Fe-type Prussian blue nanocube, and belongs to the technical field of electrode material preparation. With inorganic cobalt salt and potassium ferricyanide as reaction raw materials and trisodium citrate as a complex stabilizer, by adopting a liquid-phase co-precipitation reaction method and controllingreaction conditions such as the dosage of potassium ferricyanide and the standing and aging time, the Co-Fe-type Prussian blue nanocube material with high dispersibility and a large specific surfacearea is prepared, and the size of the material is about 300 nm. By means of the prepared Co-Fe-type Prussian blue nanocube material, the capacity of electrochemical capacitors is increased, the rapidcharge and discharge performance and other performance of the capacitors are improved, the service life of the capacitors is prolonged, the capacitance value is up to 447 F / g when constant-current charge and discharge with the current of 5 A / g are achieved in a 1 mol / L sodium sulfate solution, and the material has good rate performance.

Owner:DALIAN NATIONALITIES UNIVERSITY

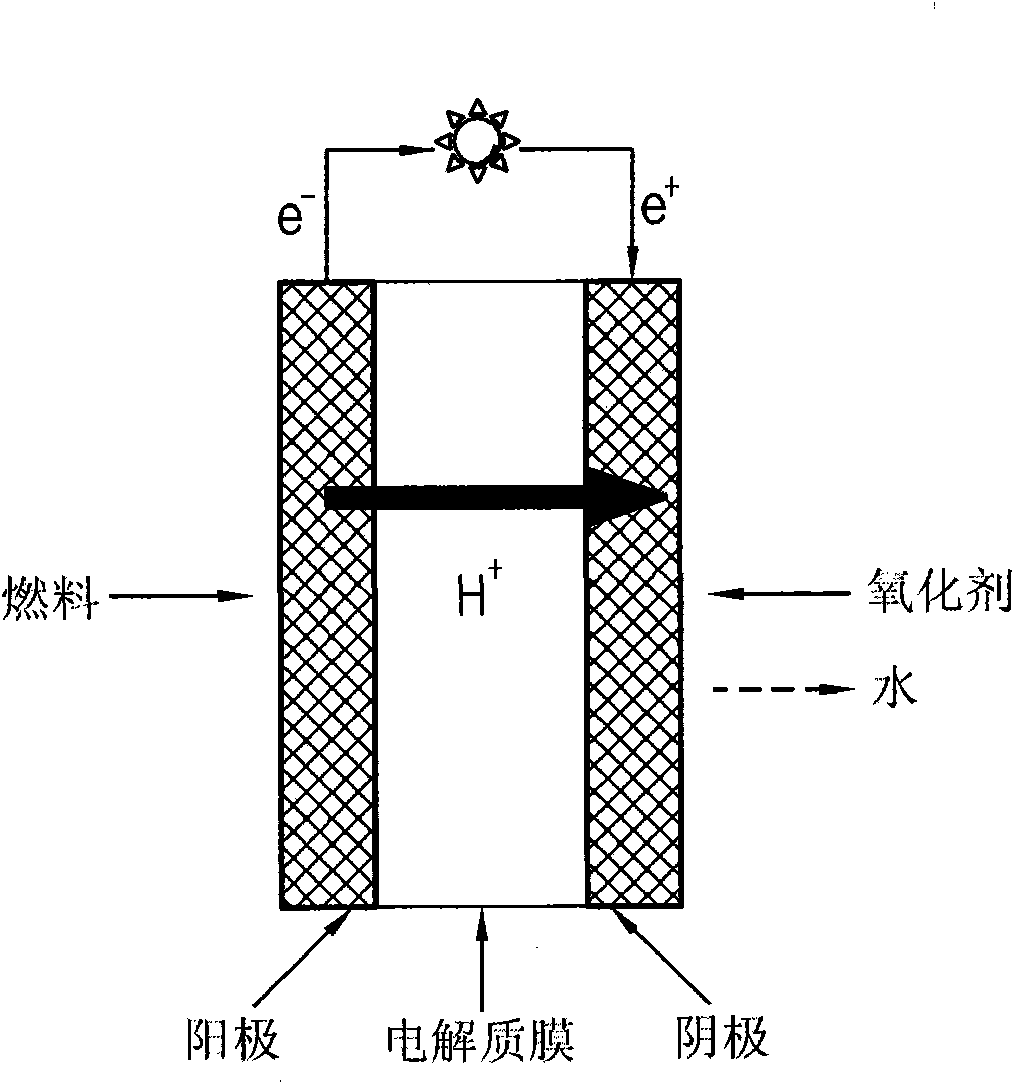

Electrode for fuel cell and method of preparing the same and membrane electrode assembly and fuel cell comprising the same

ActiveCN101861669AImprove ionic conductivityIncrease the reactive surface areaCell electrodesFuel cell detailsIonomerFuel cells

The present invention relates to an electrode for a fuel cell including a catalyst layer that includes a catalyst portion containing a plurality of first catalyst particles dispersed in an ionomer binder resin; and an ionomer portion containing a plurality of second catalyst particles dispersed in an ionomer binder resin, and having a lower concentration of catalyst particles than the catalyst portion, wherein the ionomer portion has a shape of a wall or plural pillars in the catalyst portion. The electrode for a fuel cell according to the present invention has a separate ionomer portion in the catalyst layer, and thus has excellent ion conductivity in an electrode layer and the remarkably improved reaction surface area to enhance the performance of the fuel cell.

Owner:LG CHEM LTD

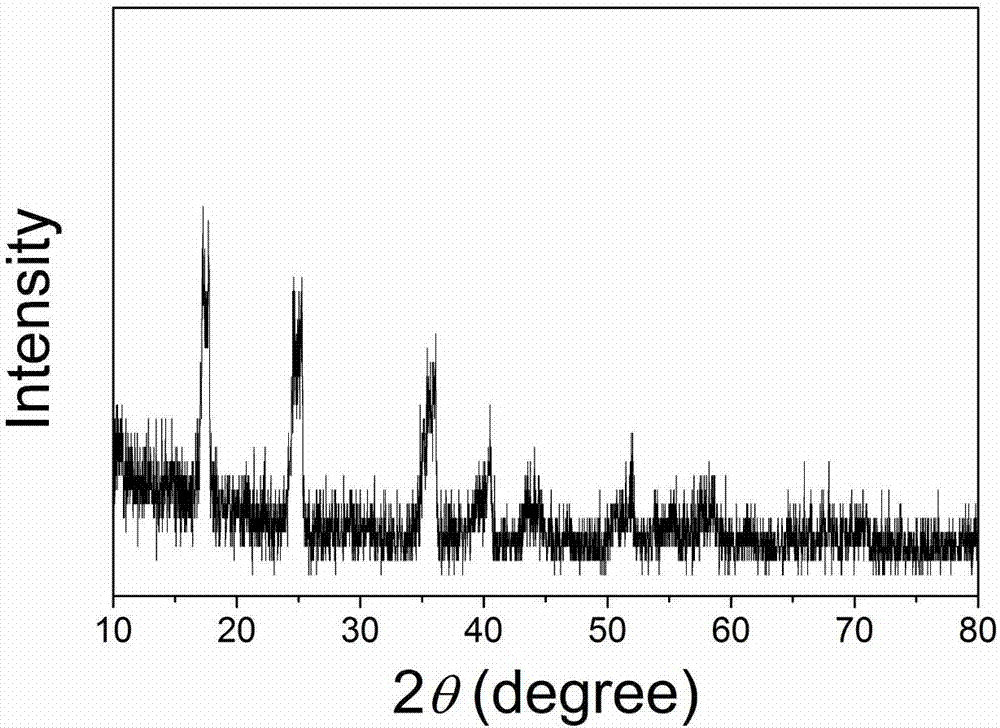

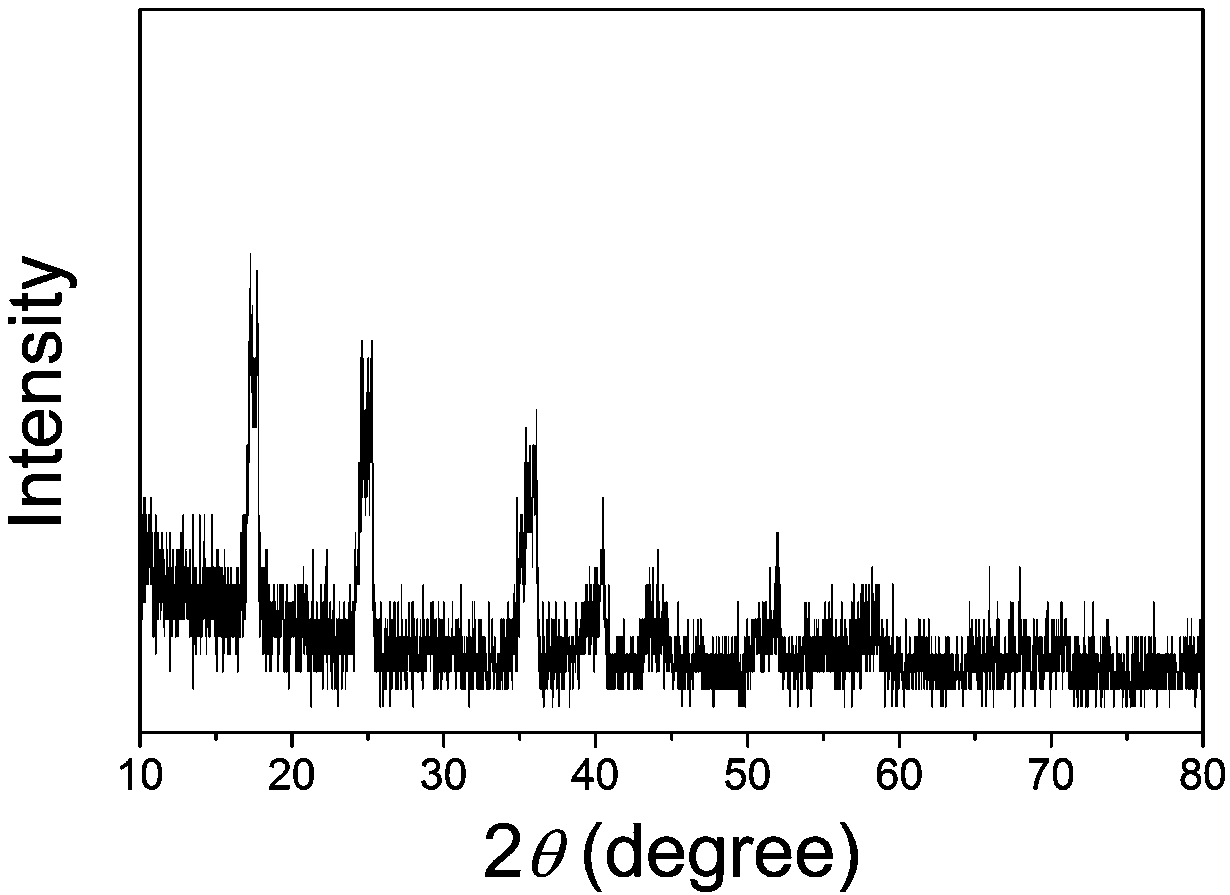

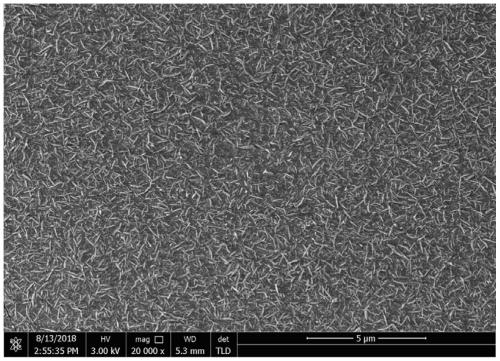

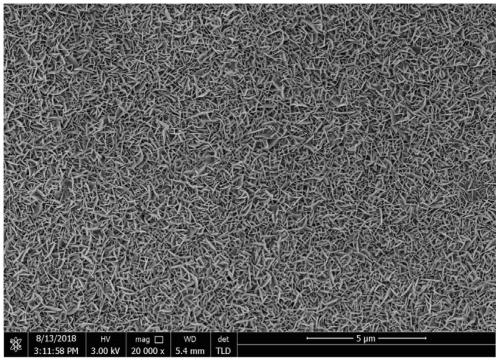

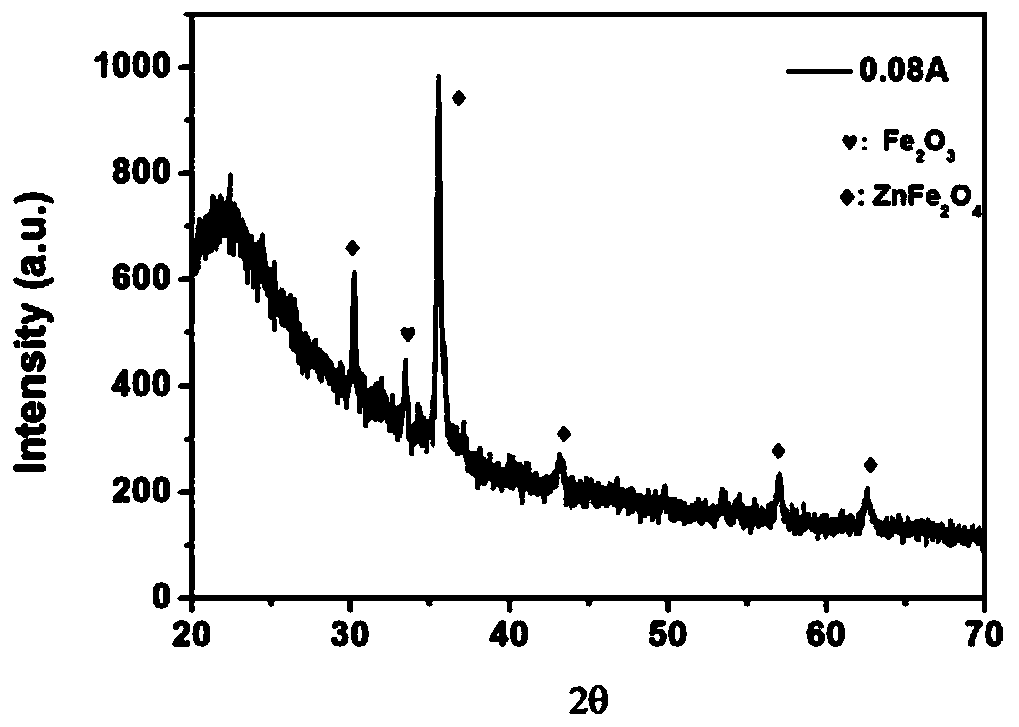

Method for preparing ZnFe2O4/Fe2O3 three-dimensional heterojunction nano-material by magnetron sputtering

ActiveCN109837516ASimple and fast operationMake fastVacuum evaporation coatingSputtering coatingHeterojunctionSputtering

The invention relates to a method for preparing a ZnFe2O4 / Fe2O3 three-dimensional heterojunction nano-material by magnetron sputtering. In a closed environment, Fe and ZnO are taken as target materials, and vacuumized in the closed environment; and when the air pressure in the closed environment is reduced to 2*10<-4>MPa, argon is introduced into the closed environment to serve as sputtering gas;the air pressure of the closed environment is controlled to be 0.15Pa to 0.2Pa, a Fe target material is sputtered through a direct-current sputtering source, the ZnO target material is sputtered by aradio frequency sputtering source, magnetron sputtering is carried out on the Fe target material and the ZnO target material at the same time, and after sputtering is completed, the product is taken out in a muffle furnace for high-temperature annealing treatment to obtain ZnFe2O4 / Fe2O3 three-dimensional heterojunction nano material. The material prepared by the preparation method has a heterogeneous three-dimensional composite nano structure, so that the reaction surface area and the photoelectric catalytic performance of a composite material are effectively improved, and the method can be widely applied to the field of photocatalytic oxidation reduction.

Owner:SOUTHWEST JIAOTONG UNIV

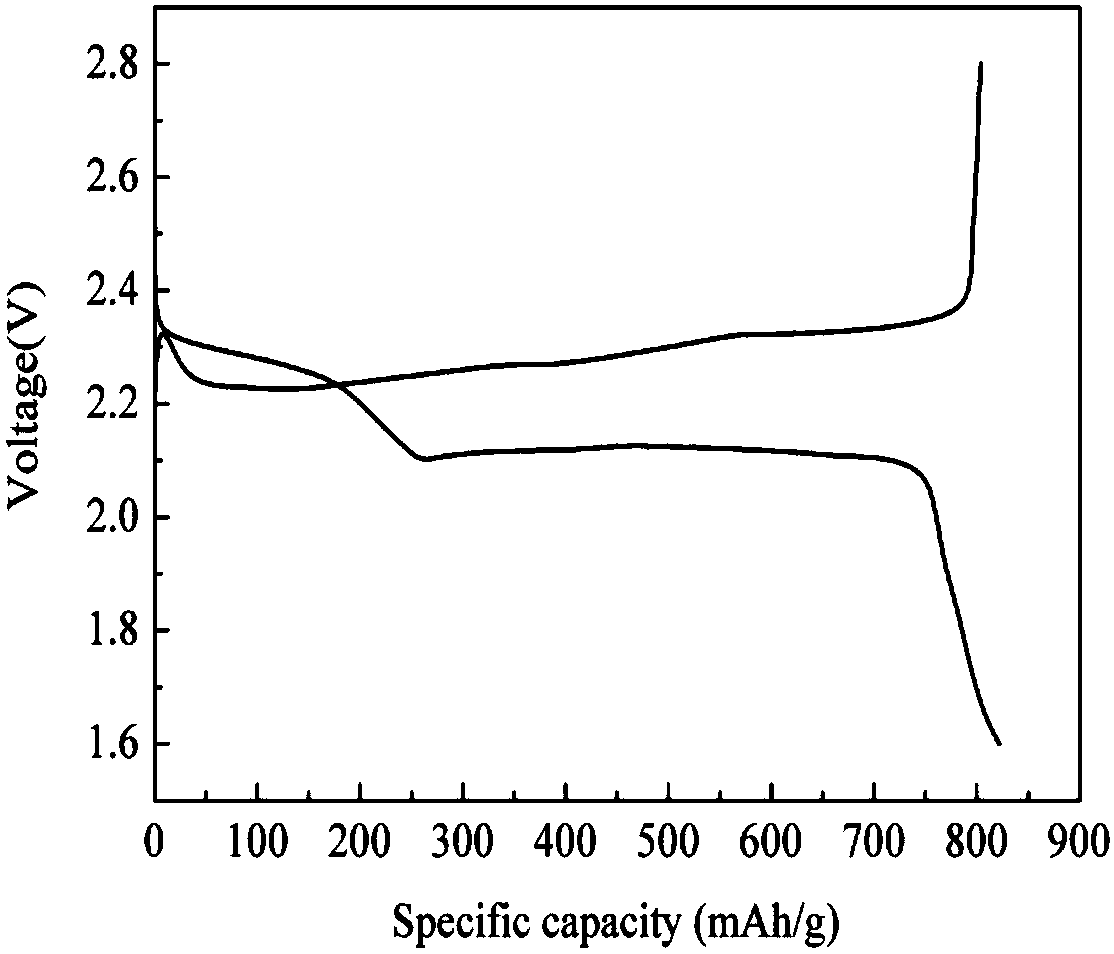

Method for preparing sulfur battery positive pole by using protein

ActiveCN107634183ALarge capacityIncrease flexibilityElectrode manufacturing processesLi-accumulatorsSulfurAdhesive

The invention discloses a method for preparing a sulfur battery positive pole by using protein. The method specifically comprises the following steps: step one, weighing egg white, starch and alkalinealum water respectively, and mixing the weighed materials to form a pasty mixture; step two, drying the pasty mixture obtained through the step one to obtain a cake; step three, putting the cake obtained through the step two into a sintering furnace in which nitrogen is introduced for calcinations treatment to obtain powder; step four, after mixing the powder obtained through the step three withsublimed sulfur, carrying out grinding treatment to obtain mixed powder, and heating the mixed powder to obtain sulfur-carried C-N powder; and step five, mixing the sulfur-carried C-N powder obtainedthrough the step four with a conducting agent and an adhesive to form a mixed material, and carrying out tabletting treatment on the mixed material to obtain the sulfur battery positive pole. A nettedcarbon-nitrogen structure is contained in the positive pole prepared according to the method disclosed by the invention, the capacity of a battery can be increased, the charging and discharging of the battery are easy, and the service life of the battery can be prolonged.

Owner:XIAN UNIV OF TECH

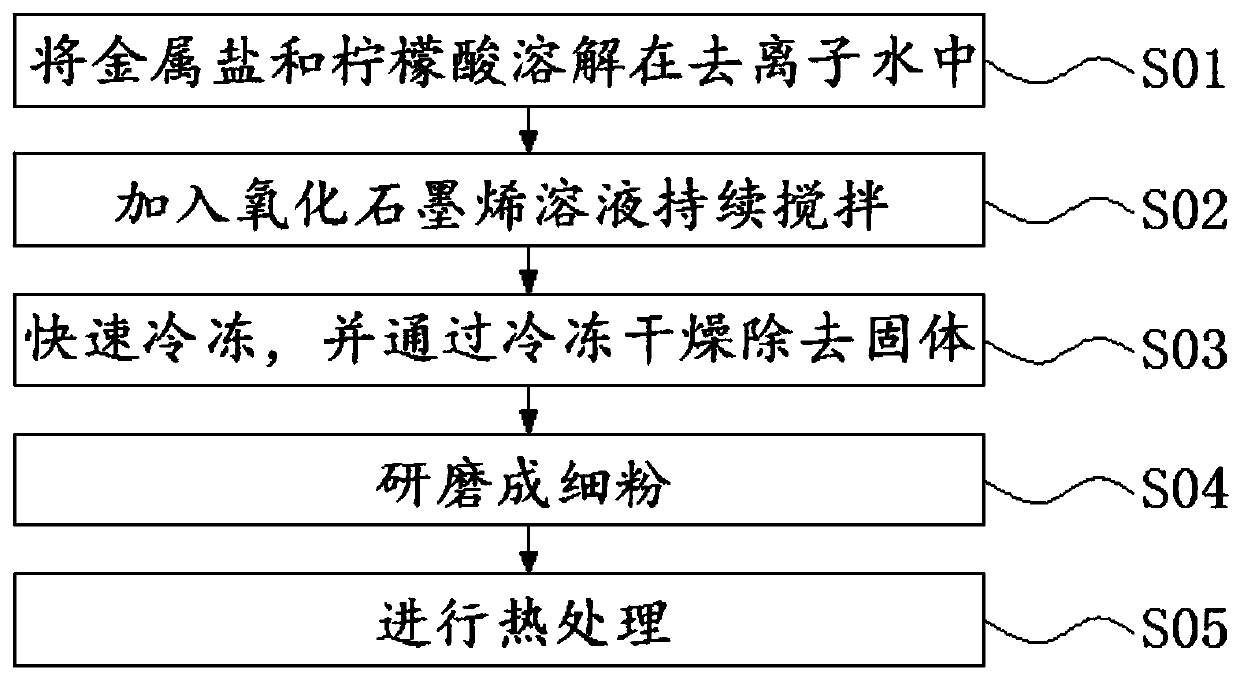

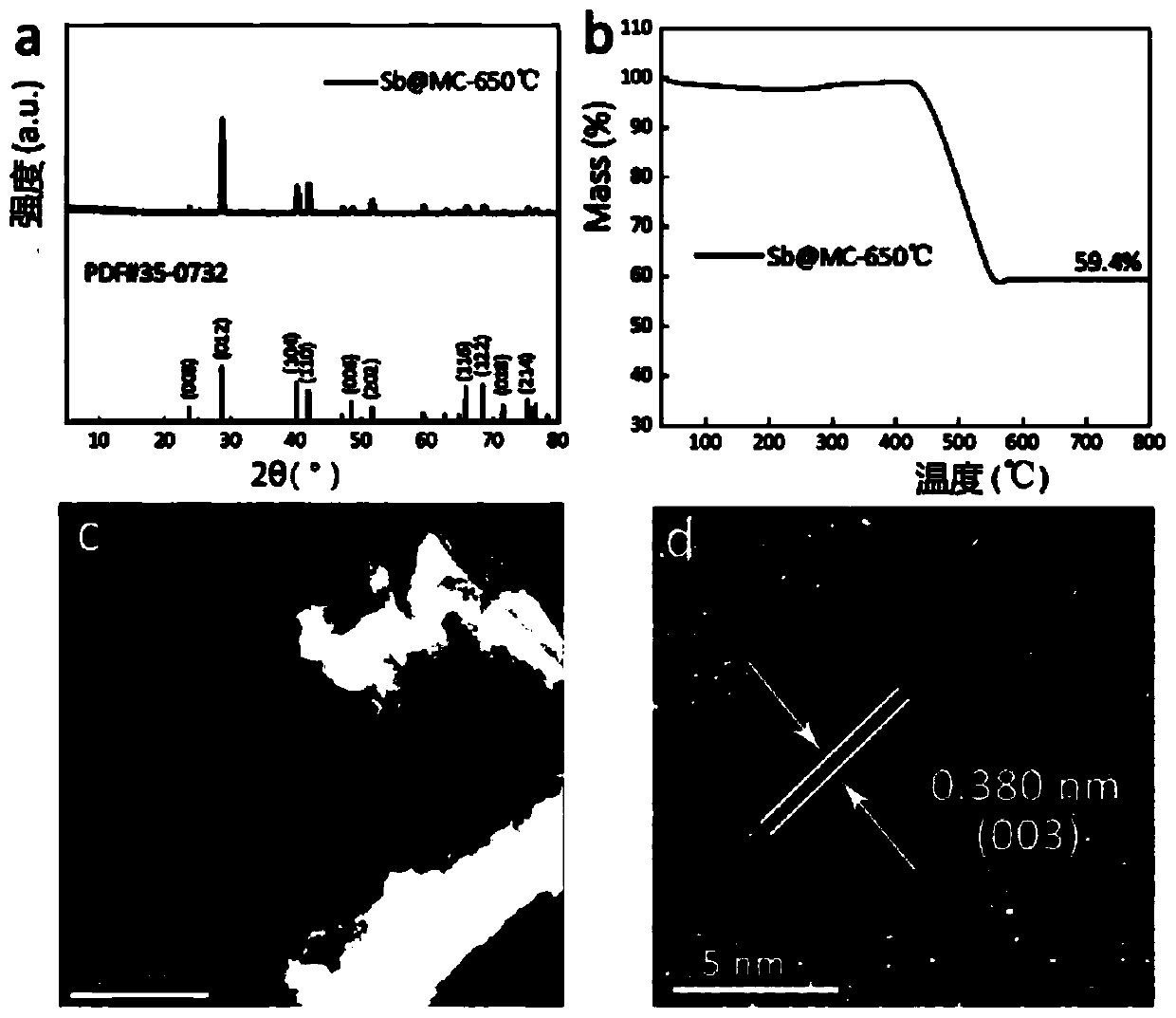

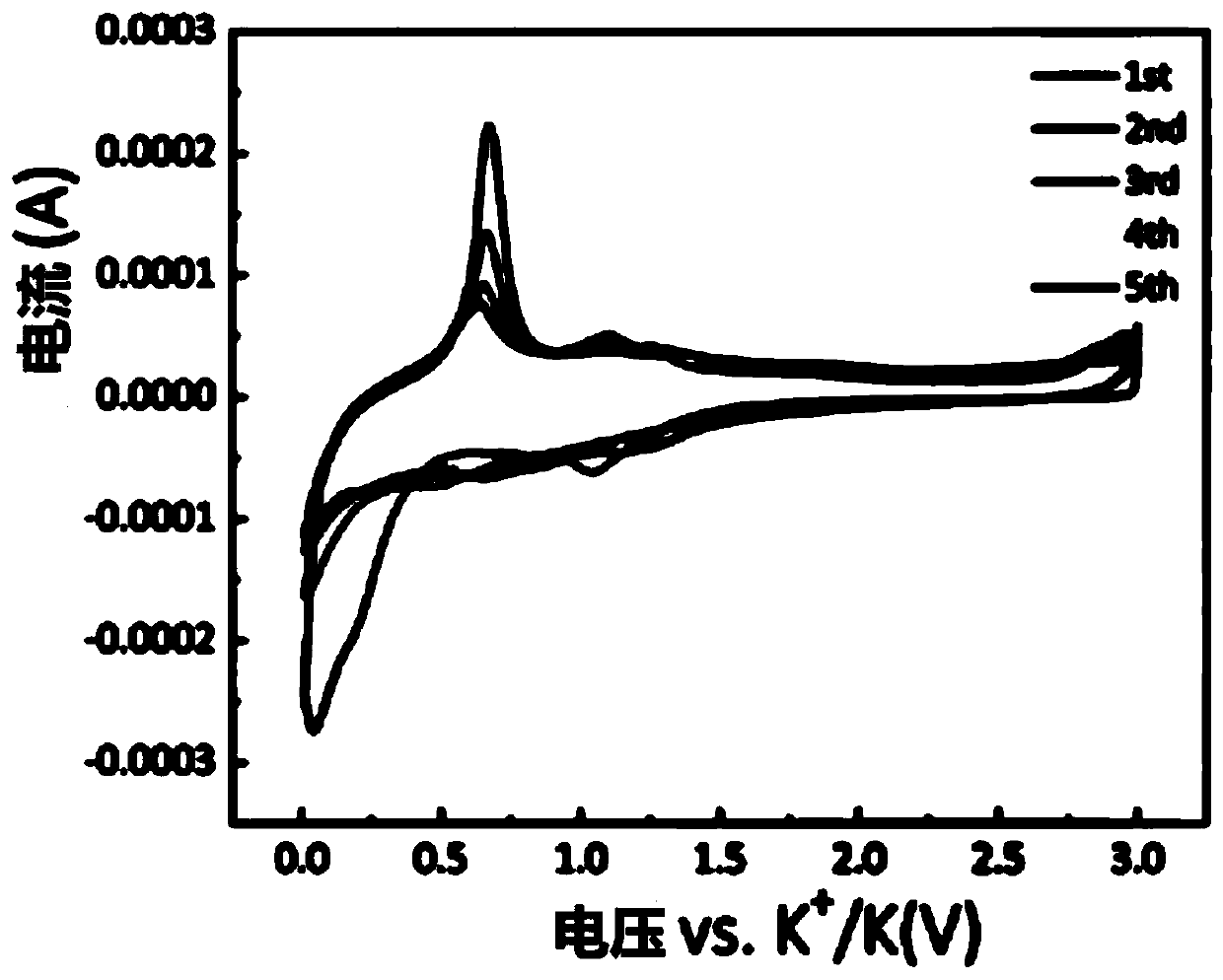

Preparation method of Sb-based ductile carbon composite negative electrode material

InactiveCN110277545AImprove cycle stabilityInhibit aggregationMaterial nanotechnologyCell electrodesCarbon compositesSynthesis methods

The invention discloses a preparation method of a Sb-based ductile carbon composite negative electrode material. The method comprises the steps of dissolving metal salt and citric acid in deionized water to obtain a uniform transparent solution; adding a graphene oxide solution into the transparent solution, and continuously stirring to obtain a uniform mixed solution; rapidly freezing the mixed solution, removing solid by means of freezing and drying to obtain a spongy sample, grinding the spongy sample into fine powder to obtain mixed powder; and carrying out heat treatment on the composite powder. The material is obtained according to a one-step synthesis method, the preparation method is simple, and the material has the advantages of high capacity, long cycle life, excellent rate performance and good stability. Lithium ion batteries based on the Sb-based ductile carbon composite negative electrode material are enabled to have ultra-long cycle stability and excellent rate performance.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

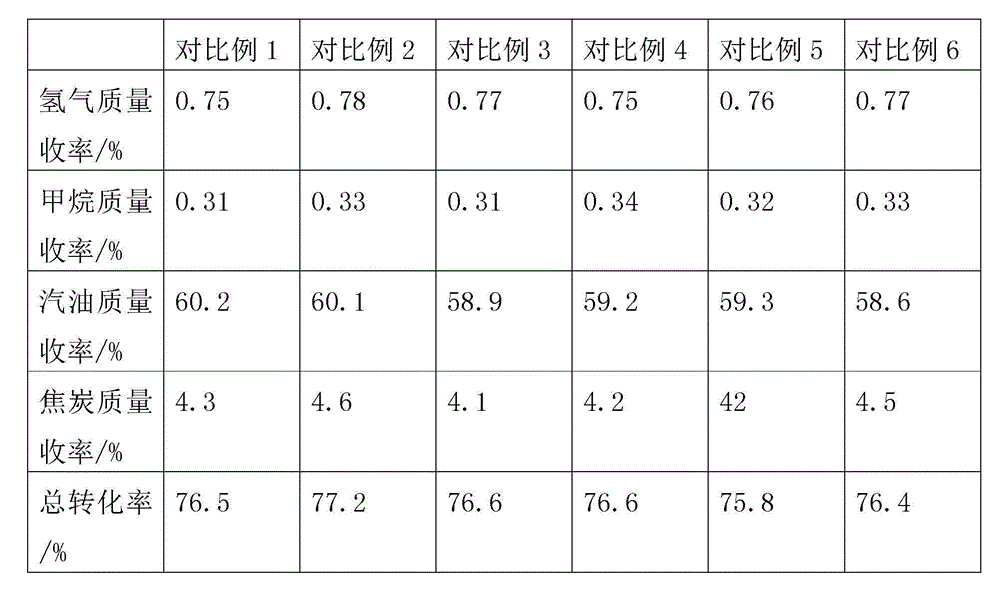

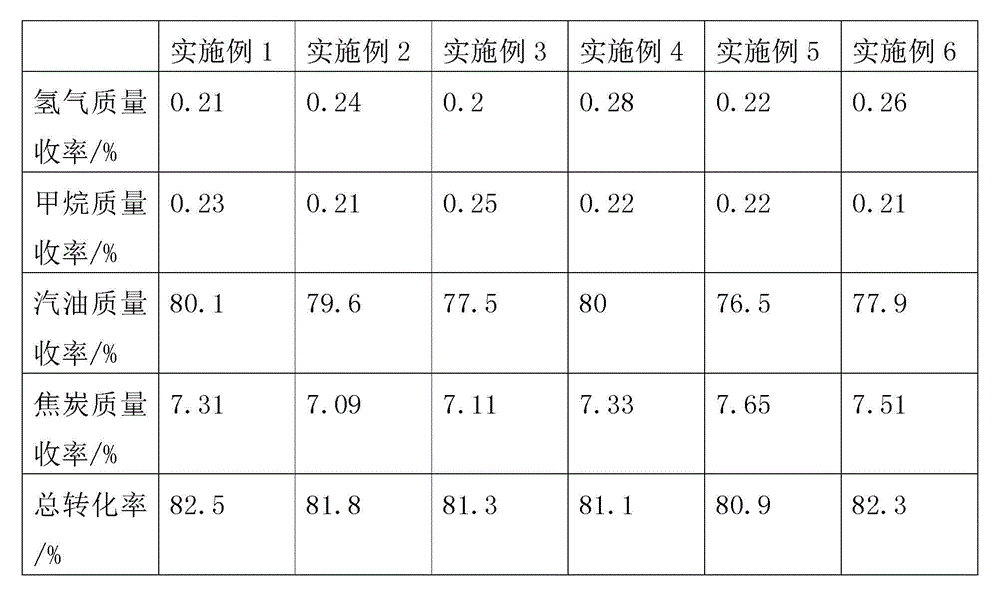

Catalytic-cracking metal passivator

InactiveCN102974403AAdequate responseIncrease the reactive surface areaCatalytic crackingCatalyst protectionAntimony trioxidePollution

The invention discloses a catalytic-cracking metal passivator which is composed of the following components in parts by weight: 7-9 parts of organic acid, 22-27 parts of triethylamine, 140-160 parts of hydrogen peroxide, 135-160 parts of antimony trioxide, 30-40 parts of ammonium bicarbonate and 160-180 parts of water. According to a formula disclosed by the invention, the ammonium bicarbonate is used and is decomposed along with continuous temperature rise to generate gas, so that a reaction surface area is enlarged to make the antimony trioxide react fully and completely. The catalytic-cracking metal passivator disclosed by the invention is high in antimony content, and the pentavalent antimony passivator is low in viscosity, low in solidifying point, high in thermal decomposition temperature and good in stability, has an obvious effect on pollutant metallic nickel on a passivation catalyst in a catalytic cracking process, and has the antimony hanging rate far more than that of organic antimony and trivalent antimony passivators; and in addition, raw materials used according to the invention are low in toxicity and are free from harm to a human body, secondary pollution to the environment and adverse influences to products and subsequent processing of the products.

Owner:江苏汉光实业股份有限公司

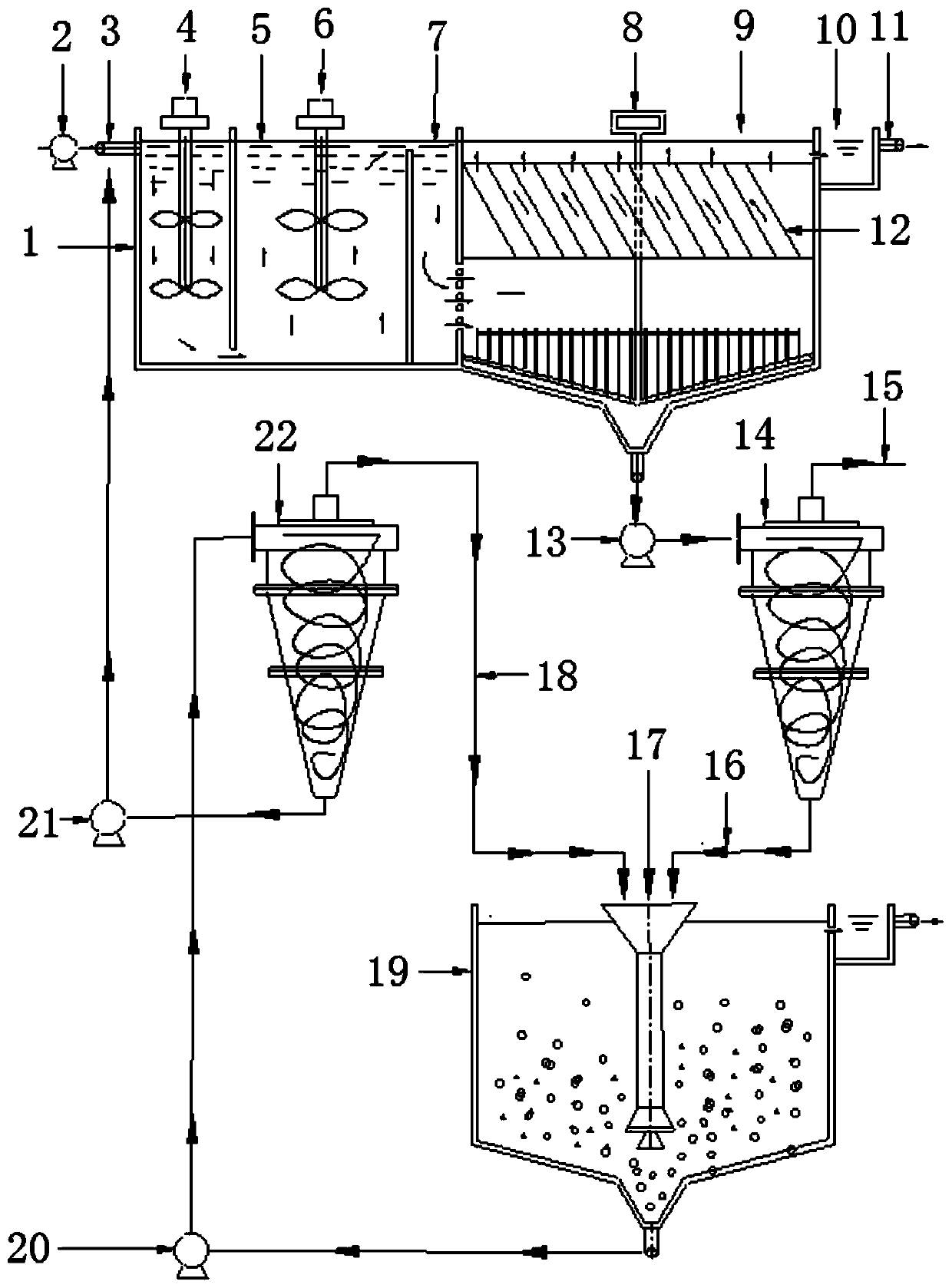

Efficient precipitation device and process with ammonia nitrogen removal capacity

PendingCN110342684AAchieve separationAchieve reuseWater/sewage treatment by centrifugal separationWater contaminantsChemistryTreatment effect

The invention relates to an efficient precipitation device and process with ammonia nitrogen removal capacity. The whole set of precipitation device comprises a coagulation tank, a flocculation tank,an inclined plate sedimentation tank and a slime separator sequentially connected in a sewage treatment direction; a feeding hole for a coagulant and an ammonia nitrogen adsorption material is also arranged at a feeding pipe of the coagulation tank; a bottom outlet of the slime separator is further connected with a regeneration tank; the bottom of the regeneration tank is also connected with a grit-water separator; and an upper outlet of the grit-water separator returns to be connected with the regeneration tank, and a lower outlet of the grit-water separator returns to be connected to the feeding pipe of the coagulation tank. Compared with the prior art, the efficient precipitation device is good in treatment effect, easy to regulate, capable of reducing the floor area while realizing theremoval of suspended matters and ammonia nitrogen, wide in applicability and remarkable in economic benefit.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for oxidizing asphaltum

InactiveCN1183222CGood dispersionSmall diameterWorking-up pitch/asphalt/bitumen by chemical meansEngineeringStatic mixer

A process for oxidizing asphalt includes such steps as dispersing air in the microbubbles mode in asphalt, loading in asphalt oxidizing tower, and oxidizing. Its advantages are high utilization rate of air, high speed, and simple structure of said oxidizing tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for continuously producing electric vehicle storage battery pole plate

InactiveCN103855362AImprove charge reception efficiencyReduce polarizationElectrode rolling/calenderingElectrode carriers/collectorsContinuous/uninterruptedAlloy

The invention discloses a method for continuously producing an electric vehicle storage battery pole plate. The method comprises the following steps: punching a lead belt made by using a lead-calcium alloy to obtain a substrate, and shaping and napping the substrate by a deformation die; and coating the surfaces at two sides of the substrate with an active substance to make a grid. The grid has a large amount of vertical ribs and a small amount of transverse ribs, is in favor of heavy current discharge and the increase of the charging reception efficiency of the pole plate, so the polarization of the pole plate is reduced. The method has the advantages of streamline continuous production, saving of a large amount of people and energy consumption, production efficiency improvement and production cost reduction.

Owner:TIANNENG GRP HENAN ENERGY TECH

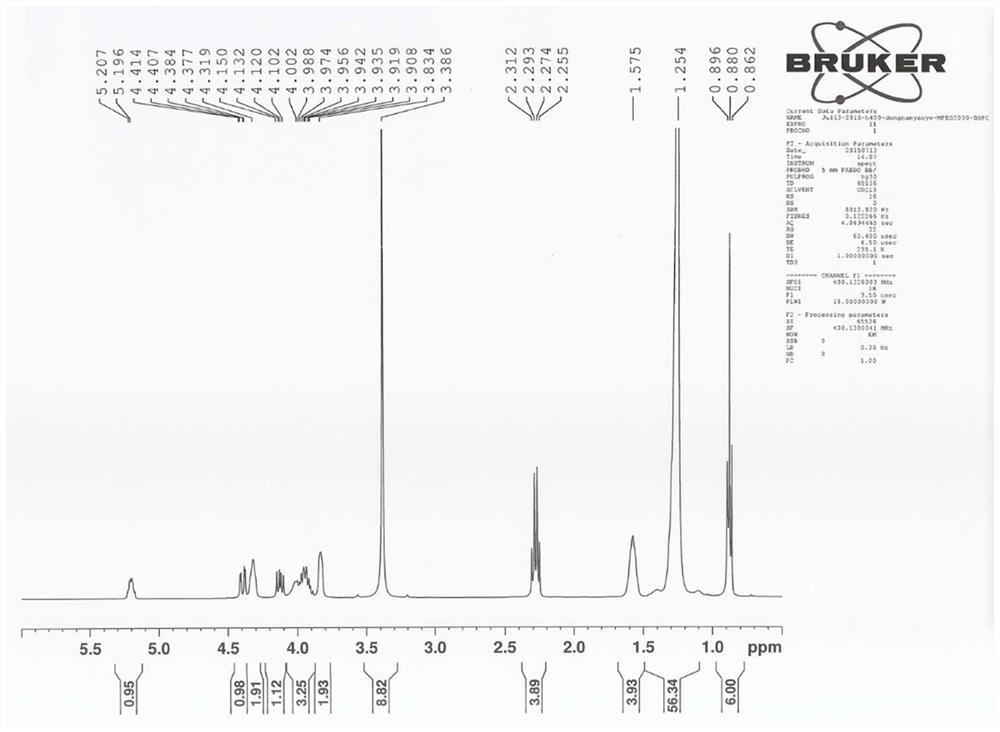

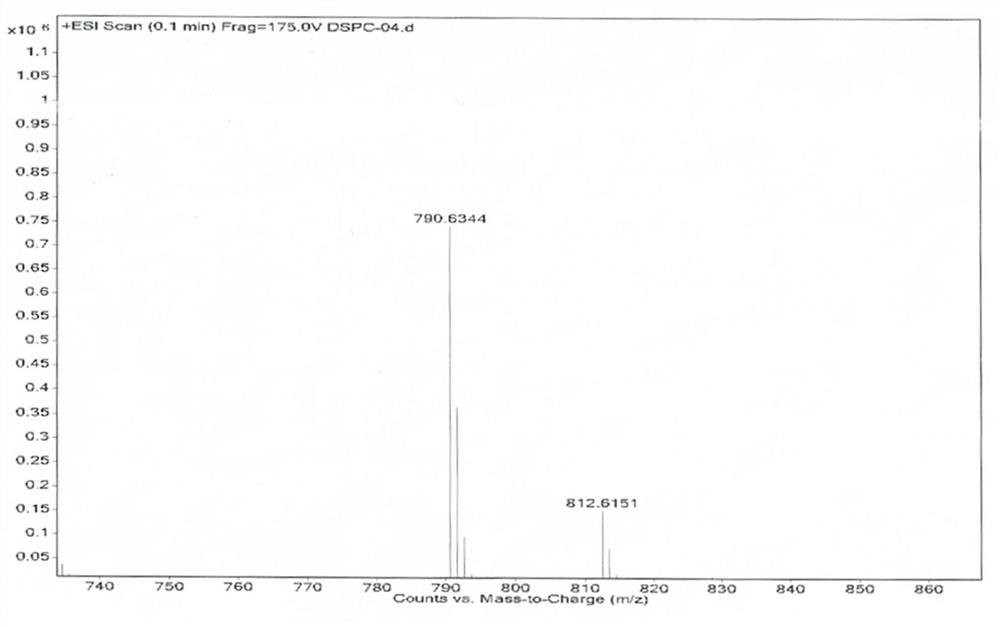

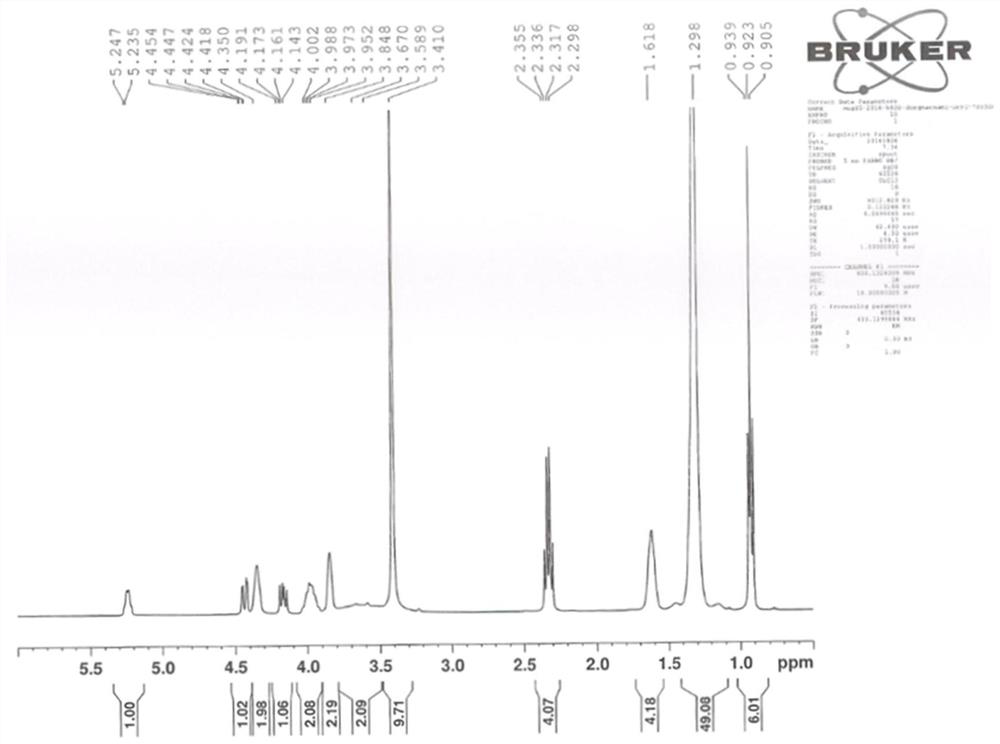

Method for synthesizing phosphatidylcholine by using solid-phase carrier

PendingCN114014889AIncrease the reactive surface areaEasy generationGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsPharmaceutical AidsPhosphatidyl Cholines

The invention provides a method for artificially synthesizing phosphatidylcholine by using a solid-phase carrier, which comprises the following steps of: melting choline glycerophosphate, uniformly adsorbing the melted choline glycerophosphate with activated carbon, carrying out acylation reaction with fatty acid acyl chloride, and filtering and recrystallizing the obtained product to obtain high-purity phosphatidylcholine. The phosphatidylcholine prepared by the method disclosed by the invention can be used as a pharmaceutical adjuvant for various medicines such as injections, tablets and capsules.

Owner:江苏东南纳米材料有限公司

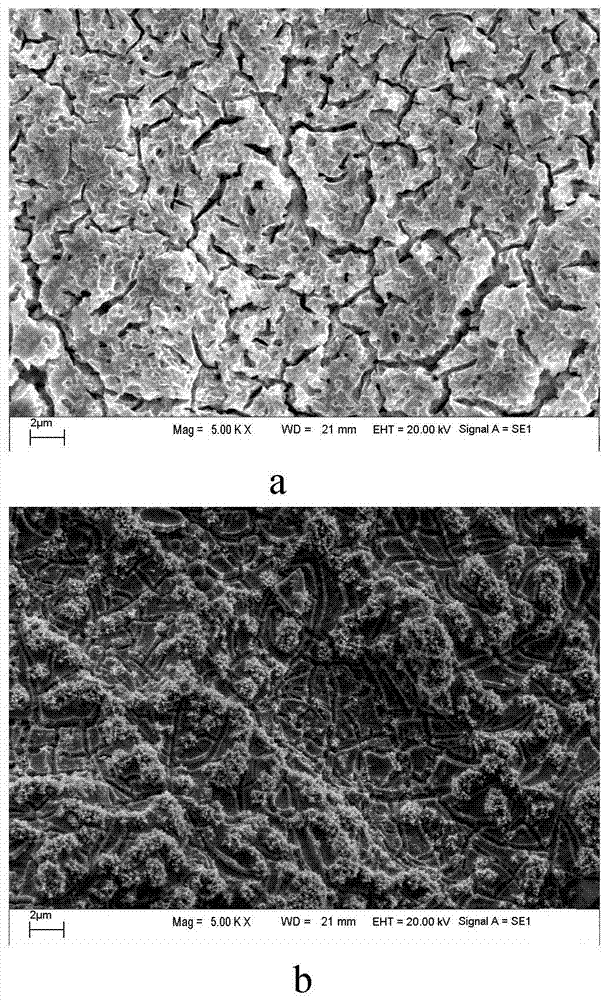

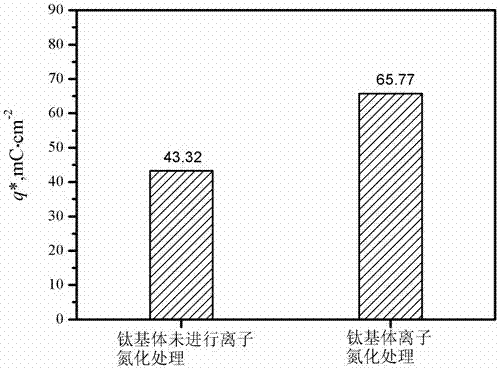

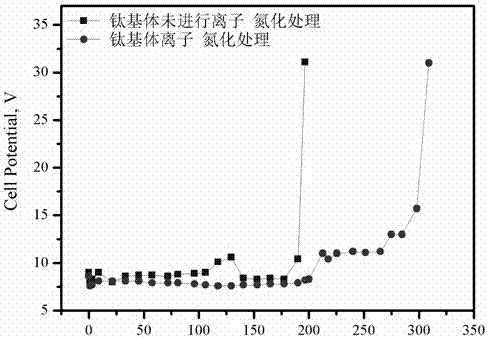

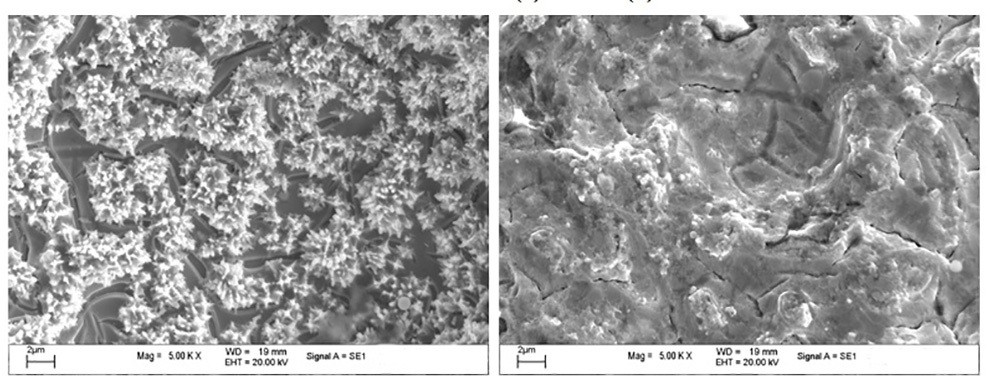

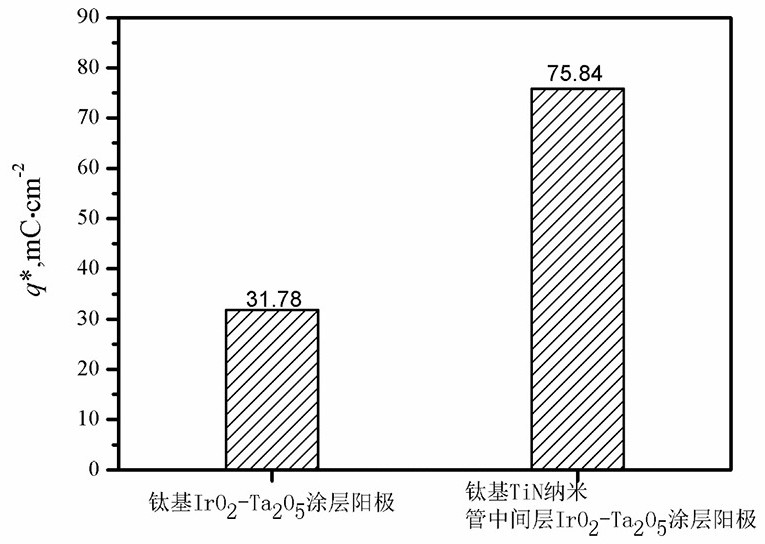

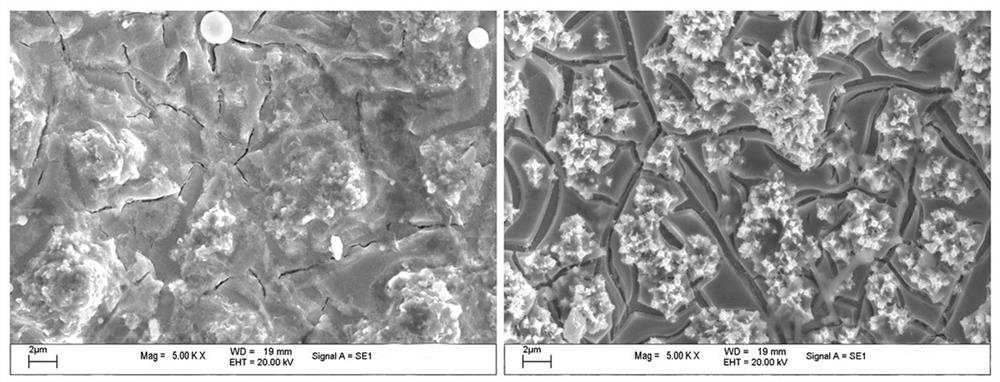

A titanium-based tin x /iro 2 -ta 2 o 5 coated anode

InactiveCN104846398BImprove conductivityImprove thermal conductivitySolid state diffusion coatingLiquid/solution decomposition chemical coatingElectrochemical responseHeat conducting

The invention belongs to the technical field of preparation of an insoluble anode in electrochemical industry, and particularly relates to a titanium-based TiNx / IrO2-Ta2O5 coating anode. The titanium-based TiNx / IrO2-Ta2O5 coating anode comprises a titanium base, a TiNx middle layer and an IrO2-Ta2O5 coating, wherein the titanium base is positioned on the inside of the anode, the TiNx middle layer is positioned in the middle of the anode, and the IrO2-Ta2O5 coating is positioned on the outside of the anode; the TiNx middle layer is prepared by carrying out ion nitriding treatment on the titanium base; and the IrO2-Ta2O5 coating is prepared through a thermal decomposition. The titanium-based TiNx / IrO2-Ta2O5 coating anode provided by the invention can achieve the thickness of the TiNx middle layer at 50-200 micrometers and has the advantages of excellent electricity-conducting property and heat-conducting property and corrosion resistance; compared with an anode which is not subjected to nitrizing treatment, the titanium-based TiNx / IrO2-Ta2O5 coating anode provided by the invention achieves more fine surface crack of the IrO2-Ta2O5 coating and no penetrable crack, has larger reaction surface area, can provide more electrochemical reaction places and can be used for effectively enhancing the stability of the anode and prolonging the service life of the anode.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

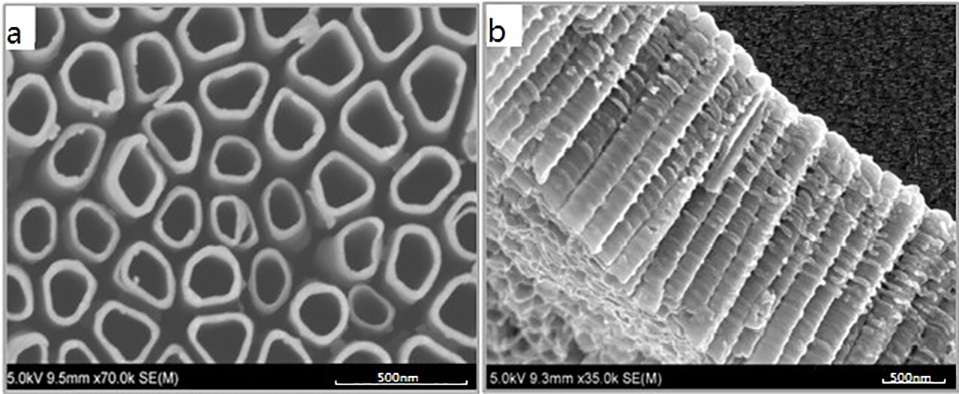

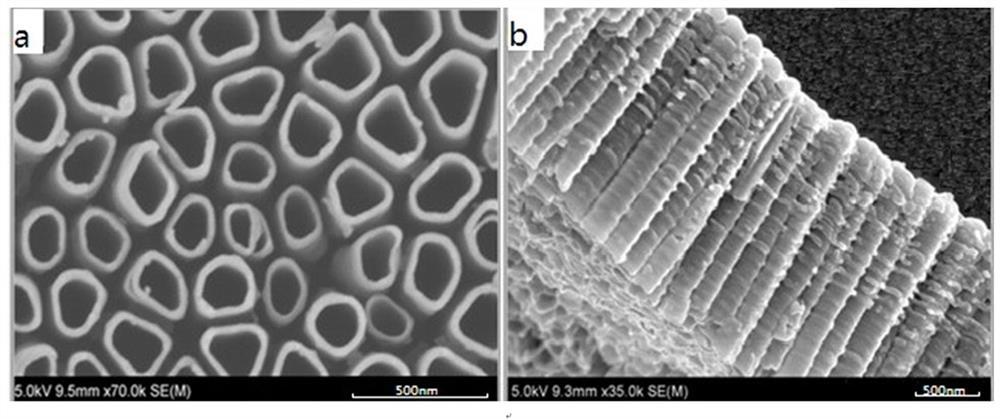

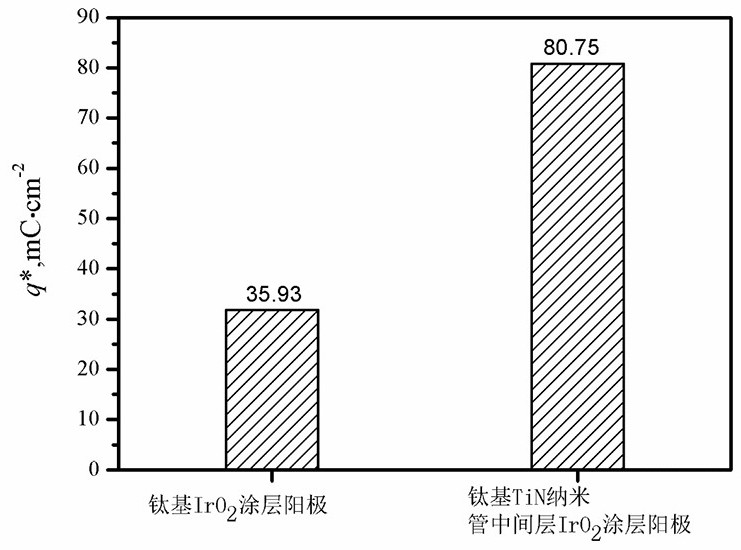

IrO2-Ta2O5 anode with TiN nanotube middle layer

ActiveCN111926345ALarge specific surface areaImprove conductivitySurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingPhysical chemistryTitanium

The invention belongs to the technical field of electrochemical anode manufacture, and relates to preparation of a titanium-based insoluble anode, in particular to an IrO2-Ta2O5 anode with a TiN nanotube middle layer. According to the anode material, Ti serves as a matrix, an IrO2-Ta2O5 nano-coating is prepared on the surface, and meanwhile a TiN nanotube middle layer is prepared between the IrO2-Ta2O5 nano coating and the Ti matrix. The anode product provided by the invention has the characteristics of large specific surface area, excellent electrical conductivity, thermal conductivity, corrosion resistance and the like, and the TiN nanotube middle layer is firmly combined with the IrO2-Ta2O5 coating and the titanium substrate. The IrO2-Ta2O5 coating has obvious crystal grains, the size of the crystal grains is 40-100 nm, and the electrocatalytic activity and the service life of the IrO2-Ta2O5 coating are obviously superior to those of a common titanium-based IrO2-Ta2O5 coating anode.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

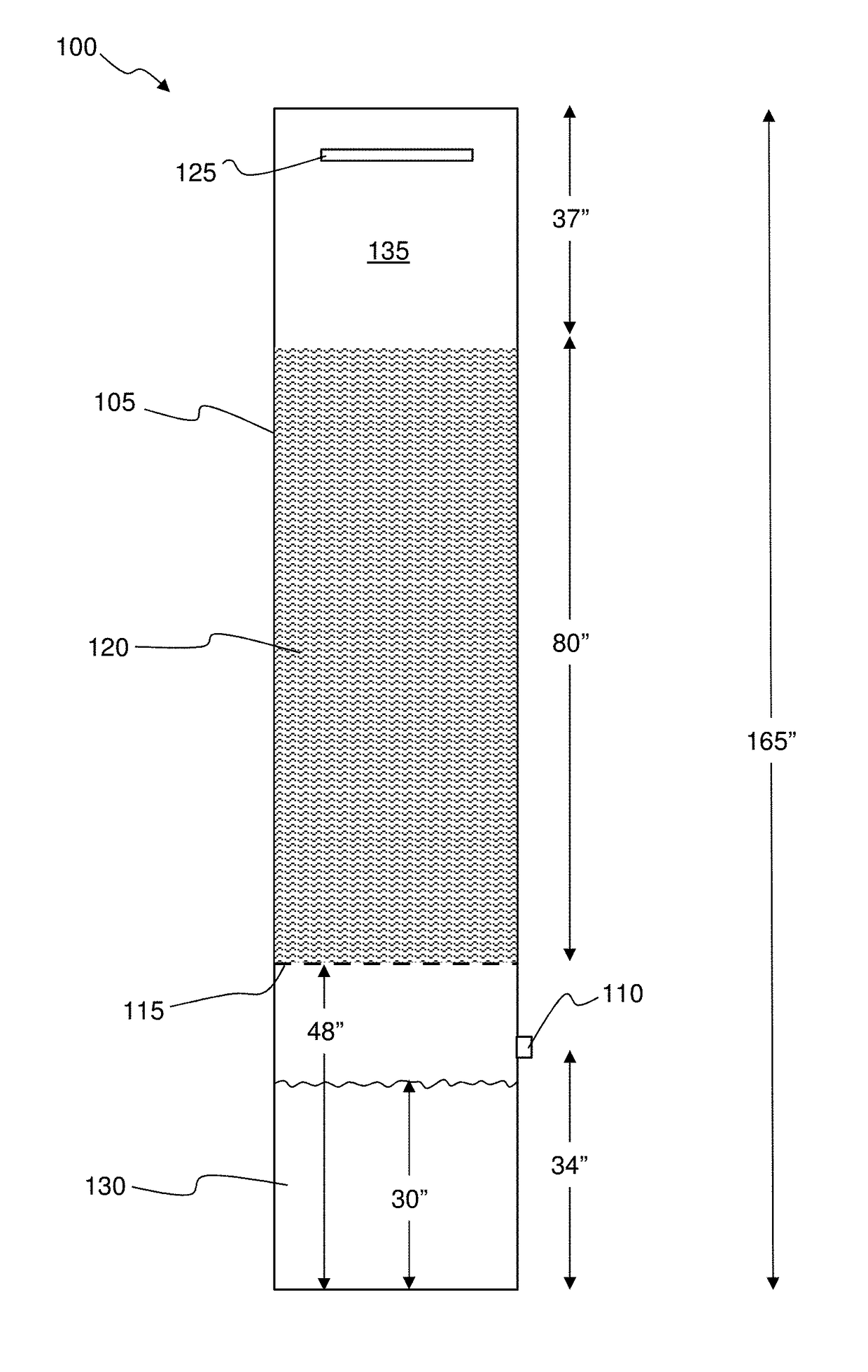

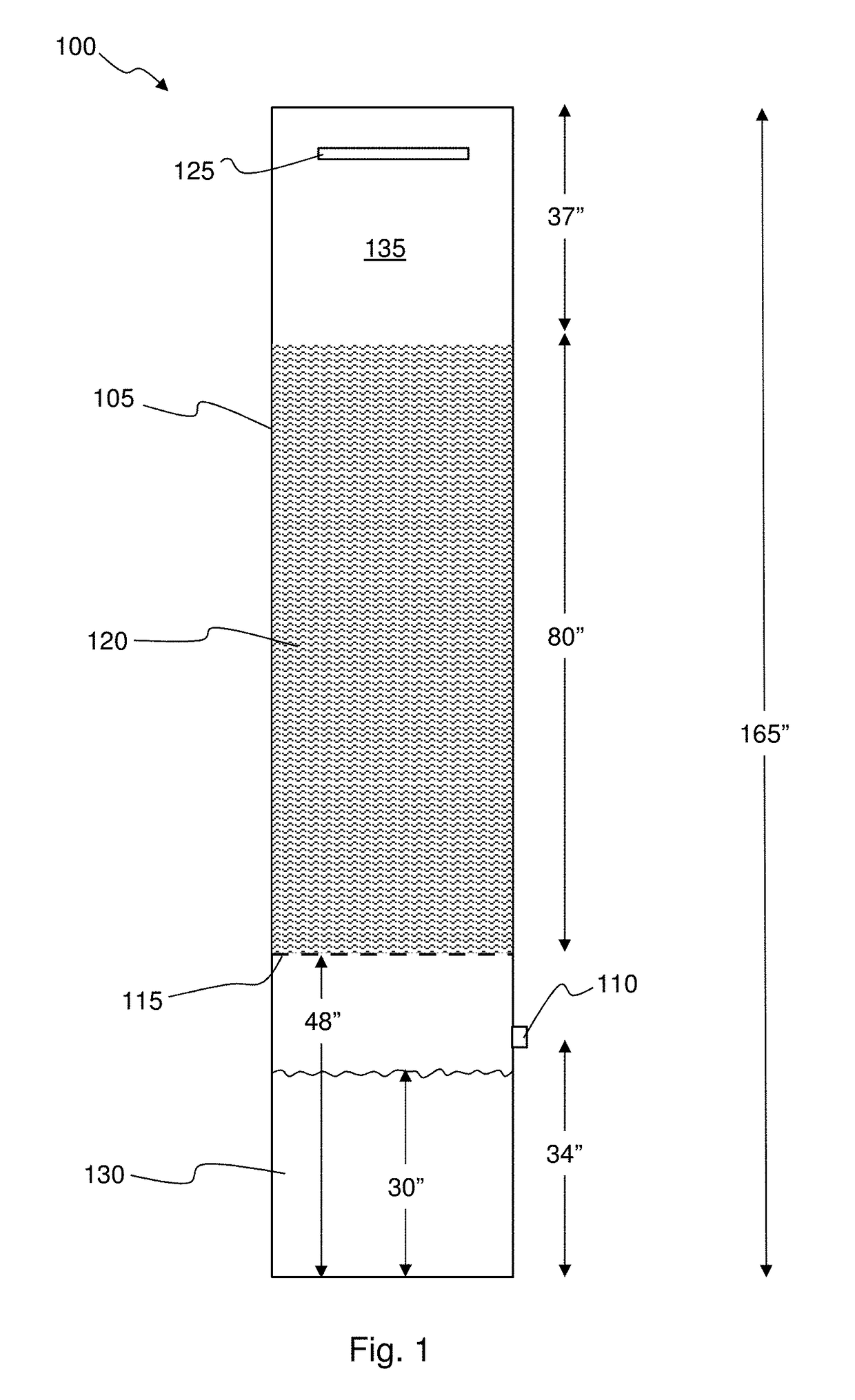

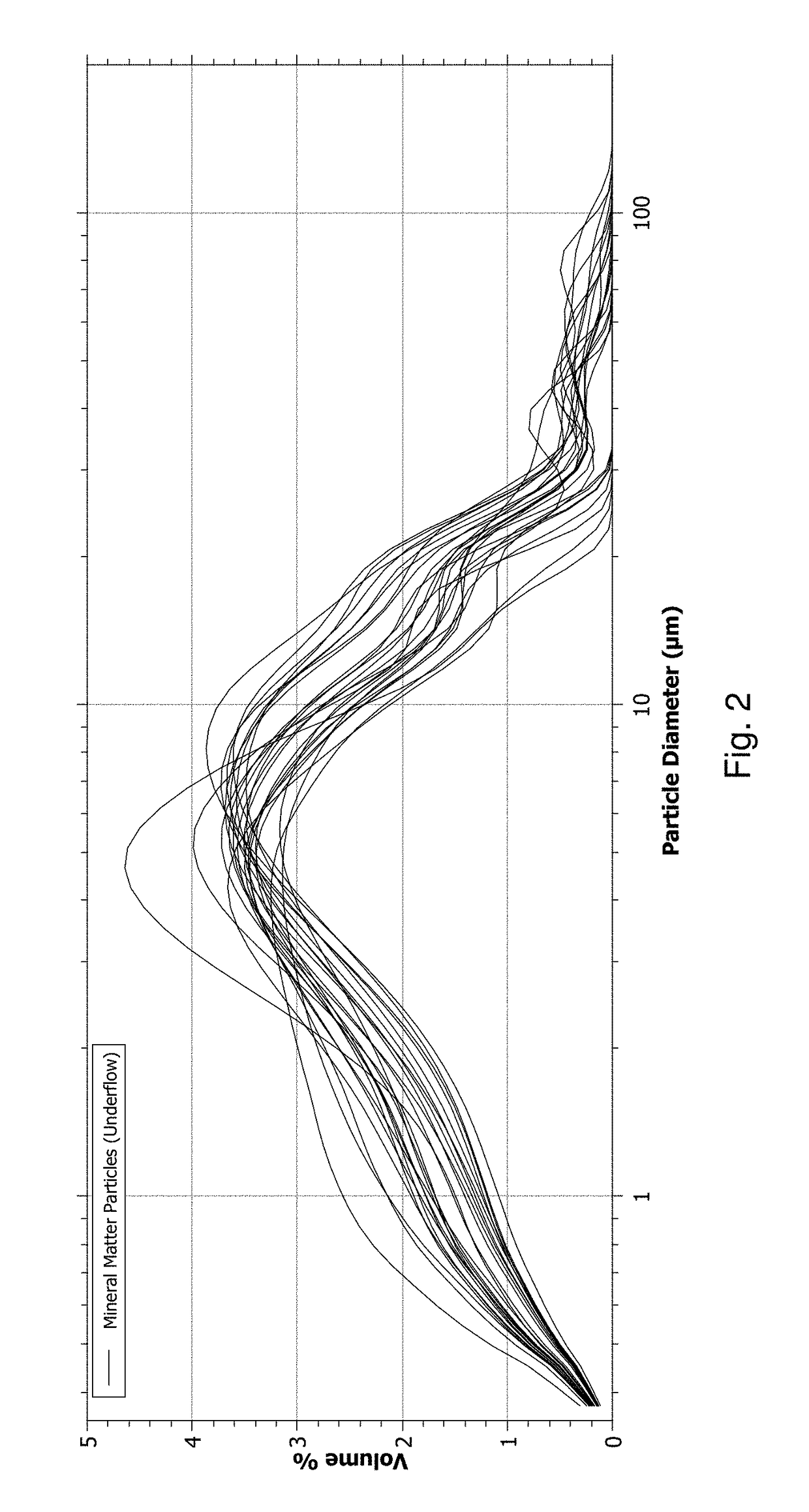

Combustion gas removal from flue gas using coal derived mineral matter

ActiveUS20170197177A1Increase the reactive surface areaImprove reaction speedGas treatmentDispersed particle separationMineral matterNitrate

Coal-derived mineral matter is used to capture or remove combustion gas emissions from flue gas or exhaust gas. The coal-derived mineral matter may be obtained by separating it from coal particles, such as by use of a flotation separation process. Coal-derived mineral matter may also be present in fine coal refuse. In the method of removing combustion gas emissions from flue gas, an aqueous suspension of coal-derived mineral matter particles is contacted with the combustion gas emissions for sufficient time to cause the combustion gas emissions to react with the aqueous suspension and form an enhanced aqueous suspension. The combustion gas emissions may comprise NOx, SOx, CO, or mixtures thereof. An aqueous suspension of coal-derived mineral matter particles containing enhanced amounts of soluble and insoluble sulfate, sulfite, nitrate, nitrite, or carbonate reaction compounds formed by reaction of the aqueous suspension of the coal-derived mineral matter particles with combustion gas emissions.

Owner:EARTH TECH USA

A method for treating recycled concrete aggregate strengthened by volcanic ash

ActiveCN106007438BIncrease the reactive surface areaHigh strengthSolid waste managementReinforced concreteMicrometer

The invention relates to a treatment method of volcanic-ash-paste-reinforced recycled concrete aggregate. The method comprises the following steps: (1) carrying out crushing treatment and screening on recycled concrete, and drying to obtain recycled aggregate; (2) adding water into a volcanic ash material with the particle size of less than 60 micrometers to prepare a volcanic ash paste, and carrying out ultrasonic dispersion to form a homogeneous paste solution; (3) immersing the dried recycled aggregate in the step (1) in the homogeneous paste solution prepared in the step (2), and stirring; (4) screening the mixture treated in the step (3) to remove the recycled aggregate, and filtering to remove the excessive paste solution; (5) drying the screened recycled aggregate, and carrying out kneading dispersion on the agglomerate aggregate; and (6) screening the recycled aggregate treated in the step (5) to obtain the volcanic-ash-paste-reinforced recycled concrete aggregate. Compared with the mortar prepared from the untreated recycled concrete aggregate, the 3-day compression strength and 28-day compression strength of the mortar prepared from the volcanic-ash-paste-reinforced recycled concrete aggregate are enhanced by 17% or above, the chlorine ion permeability coefficient is lowered by 30% or above, and the new / old interface microhardness of the mortar is enhanced by 30% or above.

Owner:HUNAN UNIV

Application and preparation method of a biomass adsorbent modified by straw

ActiveCN109847705BImprove accessibilityIncreased diffusion rateOther chemical processesDispersed particle separationFlue gasSorbent

The invention relates to an application and a preparation method of a biomass adsorbent modified by straws. The straw modified biomass adsorbent is applied to removal of chlorinated aromatic hydrocarbons in a gas phase. The application process comprises the following steps: adding a certain mass of modified biomass adsorbent into a gas containing chlorinated aromatic hydrocarbon; under the conditions that the adsorption temperature is 50 DEG C and the total gas flow is 60 ml / min, performing adsorption for 5-90 min. The acetylated straw material is used for adsorbing chlorinated aromatic hydrocarbon in a gas phase, a new method is provided for removing chlorinated aromatic hydrocarbon in flue gas, and the application range of the biomass modified material is widened. The invention providesa new idea for effective resource utilization of the agricultural waste straw.

Owner:NANKAI UNIV +1

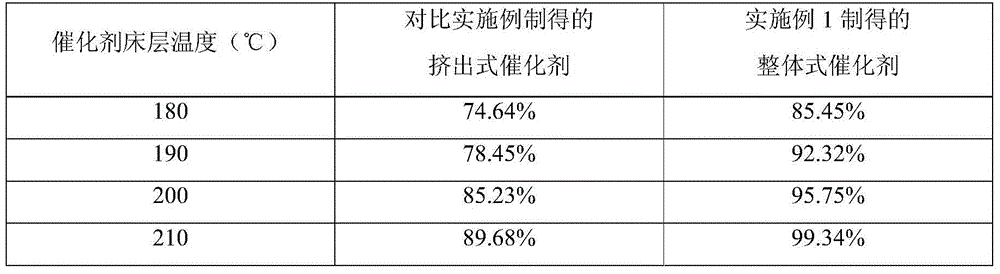

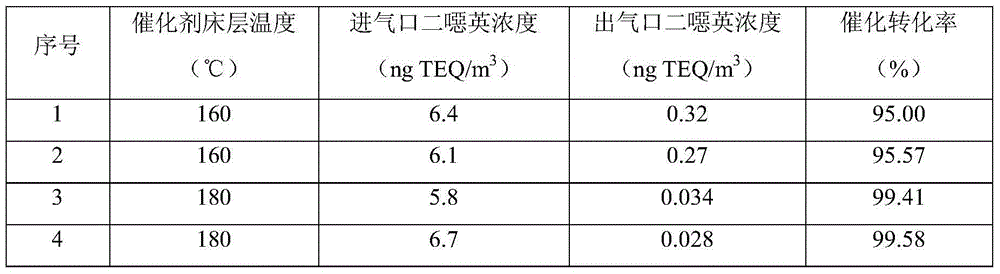

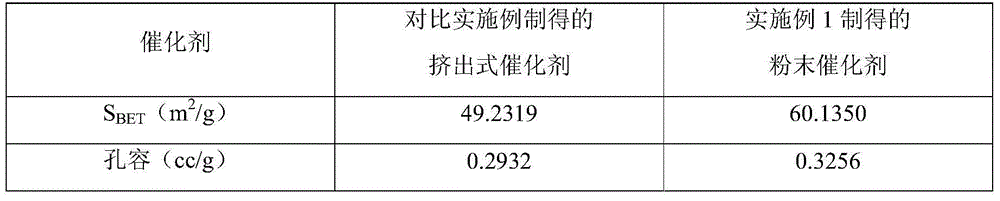

Integral dioxin removal catalyst and preparation method thereof

ActiveCN103657638BLow input costHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsVoid ratioDecomposition

The invention discloses an integral dioxin removing catalyst, which is prepared by coating a catalyst coating constituted by V2O5, WO3 and TiO2 onto honeycomb ceramic of 30-600 meshes serving as a carrier. The catalyst is a vanadium-tungsten-titanium system catalyst, and has a better anti-poisoning effect on HCl and SO2 in waste incineration tail gas; the honeycomb ceramic of 30-600 meshes is taken as the carrier, and has higher adaptability to flue gas dust due to a regular pore canal, so that industrialization and engineering minimization are realized easily, larger reaction surface area is provided, high reaction efficiency can be kept at high space velocity of flue gas, and the investment cost of the catalyst is reduced; catalyst active ingredients are loaded onto the carrier by using a coating process, so that operation is convenient, and the production efficiency is high; in the preparation process of the catalyst, an inorganic pore forming agent is added, so that void ratio is increased, the contact area between a reactant and the catalytic active ingredients is increased, and the catalyst activity is increased; the inorganic bonding agent is added, so that the bonding performance between the coating and the carrier is enhanced, and the coating firmness is improved; in the presence of the catalyst, the decomposition conversion rate of dioxin is over 95 percent at the temperature of 160-180 DEG C.

Owner:CHONGQING YUANDA CATALYST MFG

IrO2 nano-coating anode with TiN nanotube intermediate layer

ActiveCN112030188ALarge specific surface areaImprove conductivityMaterial nanotechnologySurface reaction electrolytic coatingElectrochemical responseTitanium

The invention belongs to the technical field of electrochemical anode manufacturing, relates to preparation of a titanium-based insoluble anode, and particularly relates to an IrO2 nano-coating anodewith a TiN nanotube intermediate layer. The anode material takes Ti as a matrix, an IrO2 nano coating is prepared on the surface, and meanwhile, a TiN nanotube intermediate layer is prepared between the IrO2 nano coating and the Ti matrix. The anode product provided by the invention has the characteristics of large specific surface area, excellent electrical conductivity, thermal conductivity, corrosion resistance and the like, and the TiN nanotube intermediate layer is firmly combined with the IrO2 coating and the titanium matrix. The IrO2 coating of the prepared anode has obvious IrO2 grains, the grain size is 10-100nm, the reaction surface area is larger, and more electrochemical reaction places can be provided. The determination result of the electrocatalytic activity and the service life shows that the IrO2 nano-coating anode is superior to a common titanium-based IrO2 coating anode.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com