Treatment method of volcanic-ash-paste-reinforced recycled concrete aggregate

A technology of recycled concrete and treatment methods, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as complex operation, achieve simple preparation process, improve utilization rate, and improve resource utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) C30 concrete beams are crushed and screened to obtain recycled concrete fine aggregate (G) with a particle size range of 0.16-2.5mm, and the recycled aggregate is placed in an oven at 60°C to dry to constant weight , to obtain recycled aggregate after drying;

[0025] (2) Use fly ash with a particle size of <45 μm (micron), add water to prepare a pozzolan slurry, the water-solid mass ratio is 10:1, and use ultrasonic dispersion for 8 minutes to form a homogeneous slurry solution;

[0026] (3) Place the recycled aggregate after drying in step (1) into the homogeneous slurry solution prepared in step (2) for soaking, and use a vibrator to vibrate and stir for 30 minutes;

[0027] (4) Put the mixed material treated in step (3) into a square hole sieve with a particle size of 75 μm (microns) to sieve and wash, sieve out the recycled aggregate, and filter off the excess slurry solution;

[0028] (5) Put the regenerated aggregate sieved in step (4) into a tray, put it in...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is that in step (2), the pozzolanic material is silica fume with a particle size of <8 μm (micrometer).

Embodiment 3

[0034] The difference between this example and Example 1 is that in step (2), the pozzolanic material is nano-silicon with a particle size <0.8 μm (micrometer), and the water-solid mass ratio is 20:1.

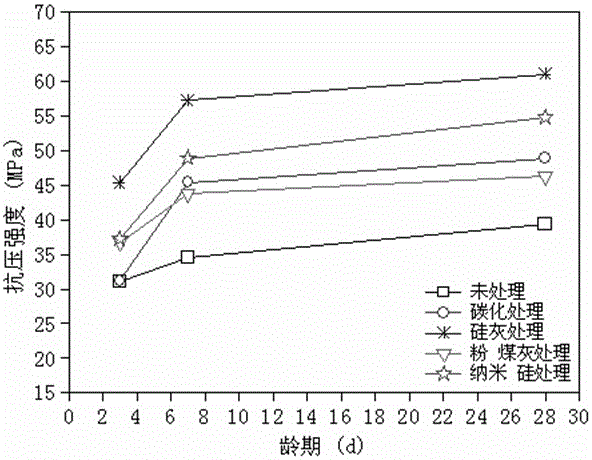

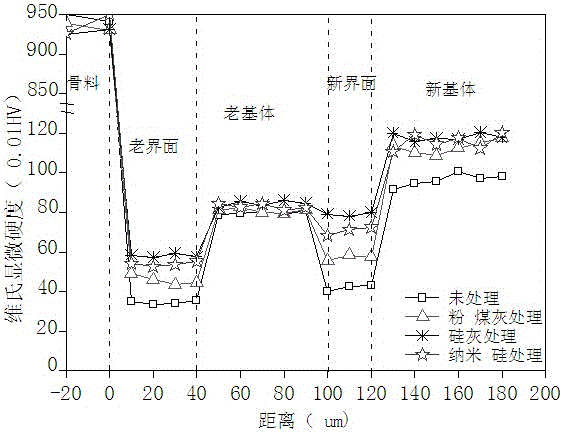

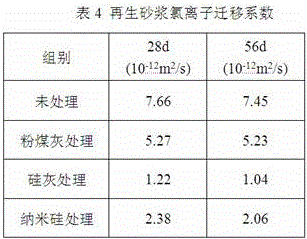

[0035] The recycled concrete aggregate performance detection in the above-mentioned embodiment is as follows:

[0036] (1) Quality change of recycled aggregate before and after treatment

[0037] The weight gain of recycled aggregate before and after treatment, and the proportion of pozzolanic materials in the dried recycled aggregate were calculated, as shown in Table 1.

[0038]

[0039] (2) Performance changes of recycled aggregate before and after treatment

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com