Method for continuously producing electric vehicle storage battery pole plate

A battery and electric vehicle technology, applied in the direction of lead-acid battery electrodes, battery electrodes, electrode manufacturing, etc., can solve the problem of low specific capacity of the battery, and achieve the effects of less environmental emissions, weight reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for continuously producing electric vehicle battery pole plates of the present invention comprises the following steps:

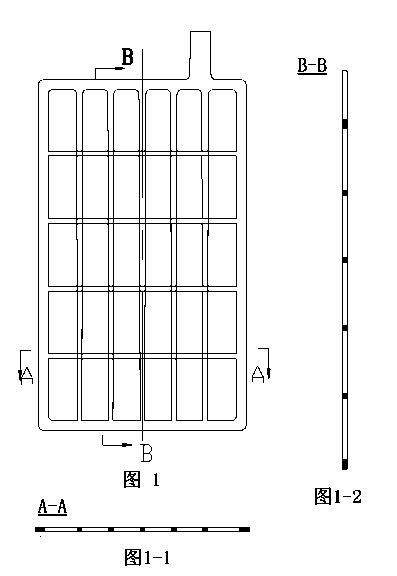

[0027] (1) The lead strip made of lead-calcium alloy is punched to obtain the substrate, and the substrate is a planar plate with grid-like ribs; the lead-calcium alloy can be low-calcium and high-tin-lead alloy. see figure 1 , Picture 1-1 and Figure 1-2 .

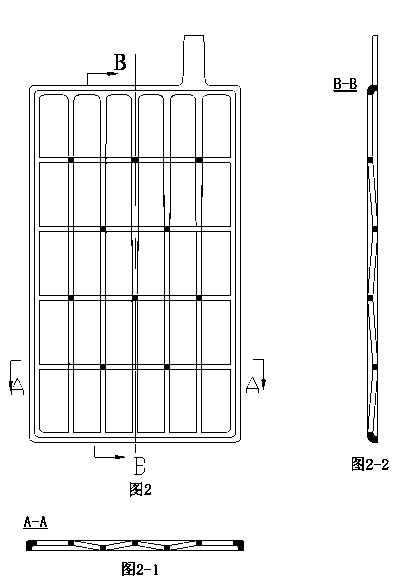

[0028] (2) The substrate is then shaped and roughened by a deformation mold; see figure 2 , diagram 2-1 and Figure 2-2 .

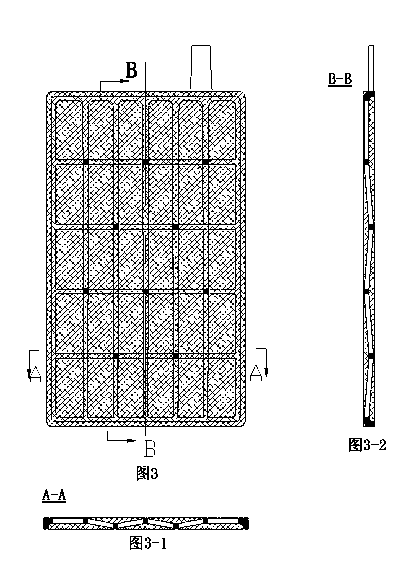

[0029] (3) The active material is then coated on both sides of the substrate shaped and roughened in (2), respectively, to form a grid. see image 3 , Figure 3-1 and Figure 3-2 .

[0030] Among them, the thickness of the substrate in (1) above is shaped and roughened by the deformation mold so that the thickness of the substrate in (2) is doubled while the weight remains unchanged. Dedicated deformation dies (for example by extrusion). And the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com