Microwave synthesis method for carbon coated iron phosphate of ion battery composite anode material

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of difficulty in synthesizing LiFePO4 powder, large electric energy, and consumption, and achieve short synthesis time, reduce energy consumption, The effect of preventing the growth of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

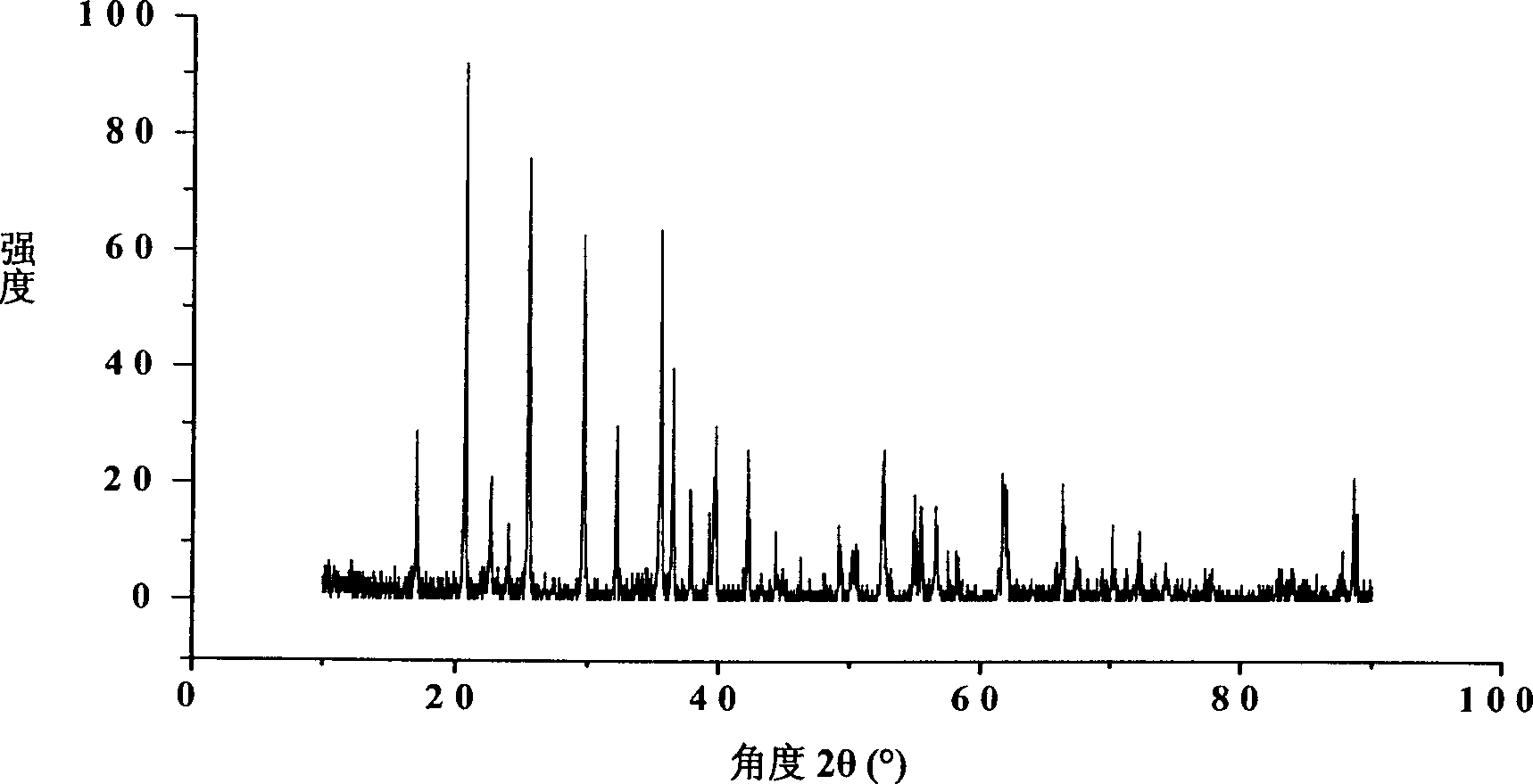

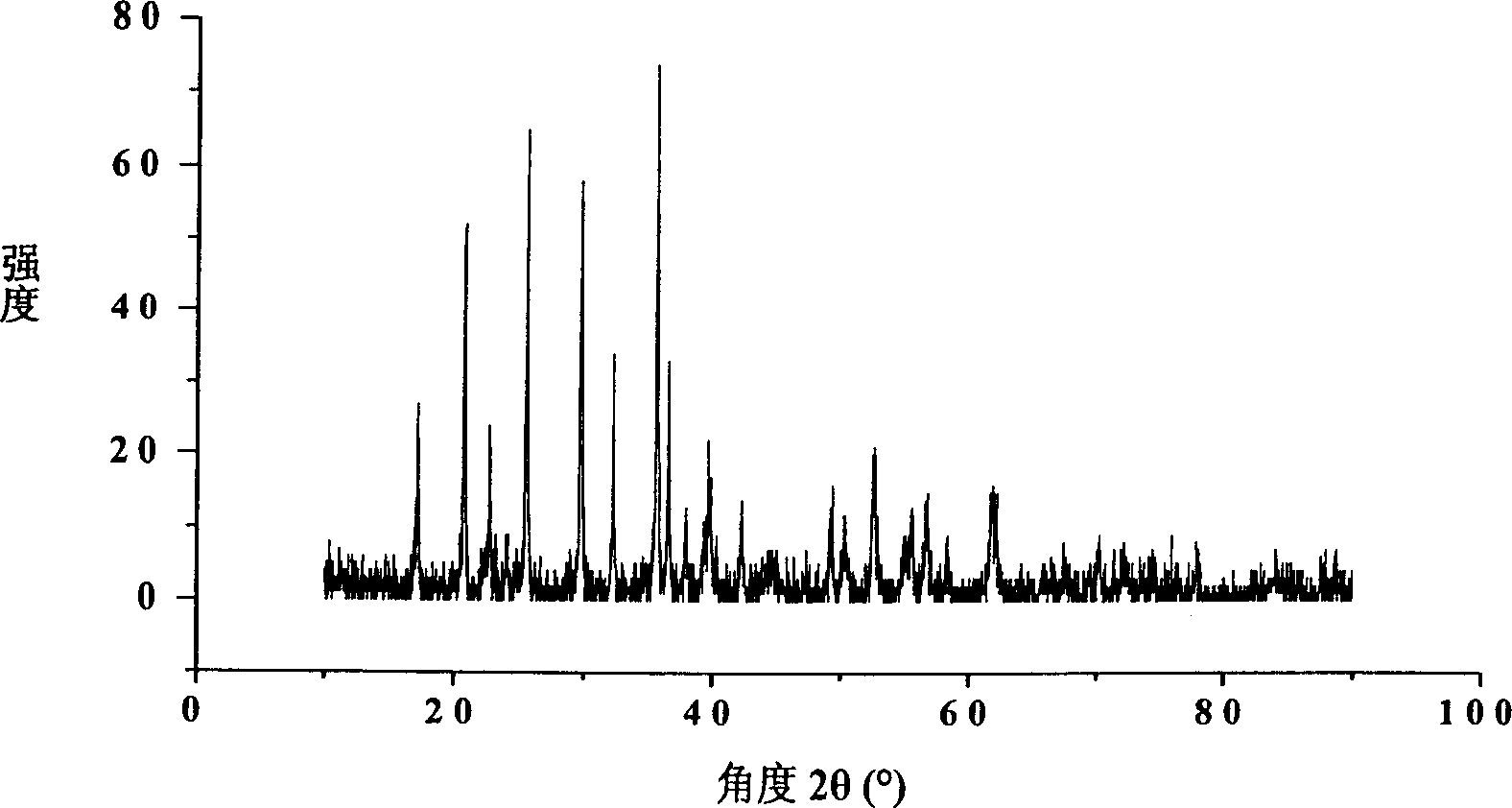

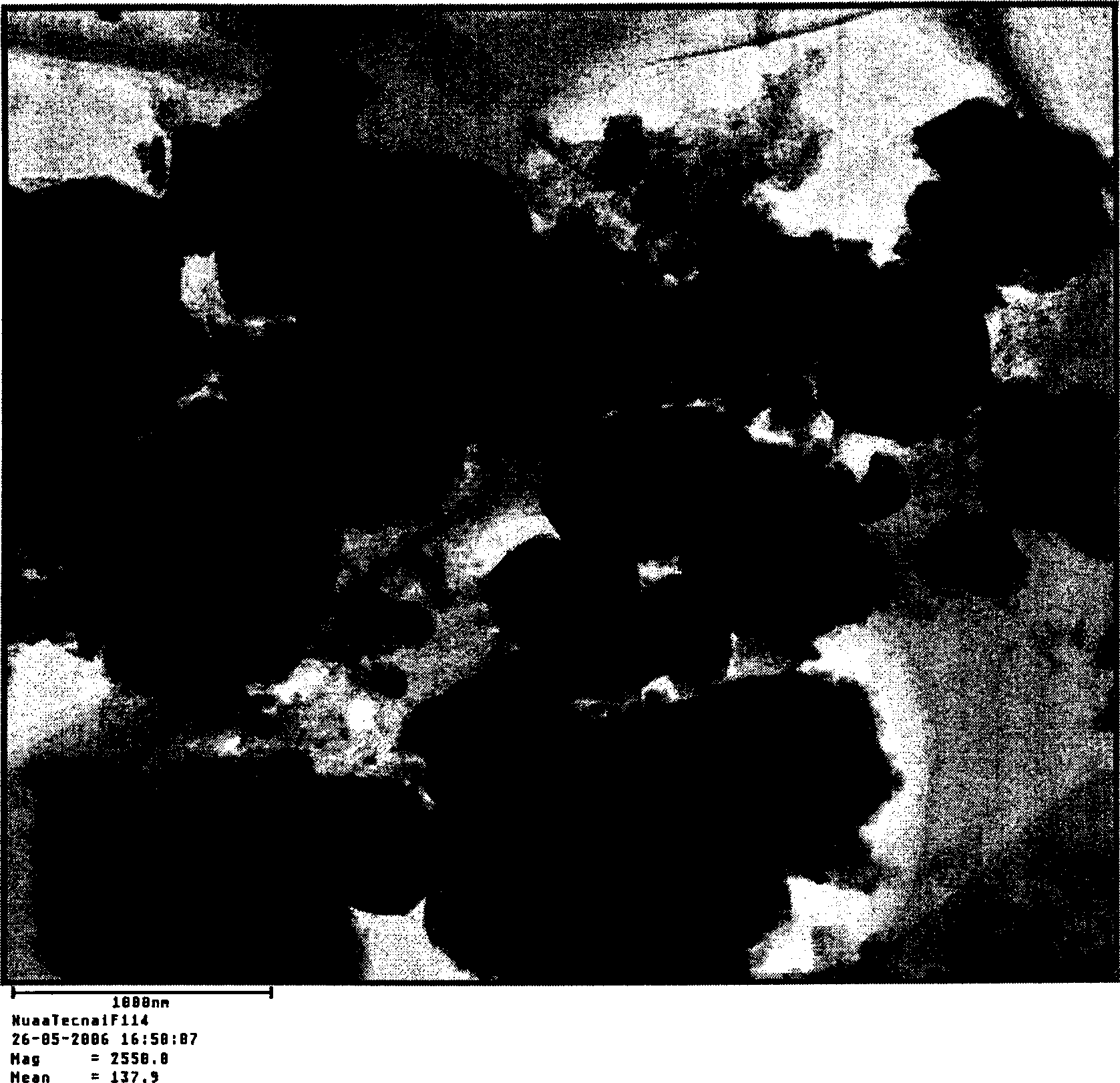

[0021] Example 1: Analytical pure Li 2 CO 3 and ferrous oxalate, (NH 4 ) 2 HPO 4 and citric acid in the stoichiometric ratio (Li:Fe:PO 4: C=1:1:1:1) ratio, put it into a ball mill, use acetone as a dispersant for ball milling for 3 hours, dry the mixed material, press it into a tablet, put it into an alumina crucible filled with activated carbon, and then The crucible was placed in a domestic microwave oven, an aluminum silicate board was placed under the crucible for heat insulation, the power was adjusted to medium and high grade, and the microwave irradiation time was 10 minutes. The phase analysis results (XRD) of the obtained samples are shown in Figure 1(a). It can be seen from the XRD pattern that the synthesized product is olivine-type LiFePO 4 , no impurity phase. The specific surface area test results of the obtained samples are shown in Table 1, and Table 1 also lists the specific surface area results of the samples synthesized without the organic carbon sourc...

Embodiment 2

[0023] Example 2: Analytical pure Li 2 CO 3 or lithium acetate and ferrous oxalate or ferrous acetate, (NH 4 ) 2 HPO 4 and glucose in stoichiometric ratio (Li:Fe:PO 4 : C=1:1:1:1) ratio, put it into a ball mill, use acetone as a dispersant for ball milling for 3 hours, dry the mixed material, press it into a tablet, put it into an alumina crucible filled with activated carbon, and then The crucible was placed in a domestic microwave oven, an aluminum silicate board was placed under the crucible for heat insulation, the power was adjusted to medium and high grade, and the microwave irradiation time was 10 minutes. The phase analysis result (XRD) of the obtained sample is shown in Figure 1(b). It can be seen from the XRD pattern that the synthesized product is olivine-type LiFePO 4 , no impurity phase. The specific surface area test results of the obtained samples are shown in Table 1. Using ferrous lactate had the same result.

Embodiment 3

[0024] Example 3: Analytical pure LiOH and ferrous oxalate, (NH 4 ) 2 HPO 4 and citric acid in the stoichiometric ratio (Li:Fe:PO 4 : C=1:1:1:1) ratio, put it into a ball mill, use acetone as a dispersant for ball milling for 5 hours, dry the mixed material, press it into a tablet, put it into an alumina crucible filled with activated carbon, and then The crucible was placed in a household microwave oven, an aluminum silicate board was placed under the crucible for heat insulation, the power was adjusted to medium and high grade, and the microwave irradiation time was 8 minutes. The phase of the obtained sample is olivine-type LiFePO 4 , no impurity phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com